#Stainless Steel Ventilator

Explore tagged Tumblr posts

Text

Ambica Airvent: Your Ultimate Guide to Roof Air Ventilators

Are you tired of stuffy, sweltering spaces? Do you dream of a home or workplace filled with fresh, circulating air? Then it's time to discover the power of roof air ventilators! Ambica Airvent offers a range of high-quality ventilation solutions, including roof air ventilators, stainless steel ventilators, and turbo air ventilators, designed to keep your environment cool, comfortable, and healthy. This blog post will explore the benefits of these ventilation systems and help you choose the perfect one for your needs.

Why Choose a Roof Air Ventilator?

Roof air ventilators are a vital component of any well-ventilated building. They work by extracting hot, stale air from the attic or roof space, allowing cooler, fresh air to enter. This constant airflow helps to:

Reduce Heat Buildup: By removing hot air, roof ventilators prevent excessive heat buildup in attics, keeping the rooms below cooler and more comfortable, especially during hot weather. This can significantly reduce your reliance on air conditioning, saving you energy and money.

Improve Air Quality: Ventilators help to remove pollutants, moisture, and odors from the air, improving the overall air quality within your home or building.

Prevent Moisture Damage: Excess moisture in attics can lead to mold growth, wood rot, and damage to insulation. Roof ventilators help to prevent this by removing moist air, protecting the structural integrity of your building.

Extend Roof Life: By reducing heat and moisture buildup, roof ventilators can help to prolong the life of your roof.

Exploring the Ambica Airvent Range:

Ambica Airvent offers a variety of roof ventilation solutions to meet different needs and preferences. Let's take a closer look at some of their key products:

Roof Air Ventilators: These are the workhorses of ventilation, designed for efficient and continuous airflow. Ambica Airvent's roof air ventilators are built to withstand the elements and provide long-lasting performance. They come in various sizes and capacities to suit different roof spaces.

Stainless Steel Ventilators: For superior durability and corrosion resistance, Ambica Airvent offers stainless steel ventilators. These are ideal for coastal areas or environments with high humidity, where rust and corrosion can be a concern. The sleek, modern design of these ventilators also adds an aesthetic touch to your building.

Turbo Air Ventilators: When maximum airflow is required, turbo air ventilators are the perfect solution. These powerful ventilators are designed to extract large volumes of air quickly and efficiently, making them ideal for industrial settings, warehouses, or large commercial buildings. They are also effective in removing smoke and fumes.

Choosing the Right Ventilator:

Selecting the right roof air ventilator depends on several factors, including:

Size of the Roof Space: The larger the area, the more ventilation you'll need.

Climate: Hotter climates require more robust ventilation systems.

Type of Building: Residential, commercial, or industrial buildings have different ventilation requirements.

Budget: Ambica Airvent offers a range of options to suit different budgets.

Why Choose Ambica Airvent?

Ambica Airvent is a trusted name in ventilation solutions, known for their high-quality products and commitment to customer satisfaction. Their roof air ventilators, stainless steel ventilators, and turbo air ventilators are designed for performance, durability, and ease of installation. By choosing Ambica Airvent, you're investing in a ventilation system that will keep your space comfortable, healthy, and well-ventilated for years to come.

Contact Ambica Airvent today to learn more about their range of roof ventilation solutions and find the perfect one for your needs! Don't let stuffy air get you down – breathe easy with Ambica Airvent!

Original Source: https://sway.cloud.microsoft/4zXNcDcAUjiEpeN6

#turbo air ventilator#aluminium air ventilator#roof air ventilator#venturi motorized air ventilator#aluminium base plate#ridge ventilator#stainless steel ventilator#motorized air ventilator#peb structur repairing work

0 notes

Photo

Kitchen in Manchester Farmhouse sink, recessed-panel cabinets, white cabinets, wood countertops, white backsplash, stone tile backsplash, stainless steel appliances, and an island can all be seen in this image of a mid-sized farmhouse u-shaped kitchen with a dark wood floor.

1 note

·

View note

Text

i just saw a post about how we just have to "live with" covid and wanting more protections from our government is unreasonable because we'll never wipe it out, it jumps species and is in all sorts of animal populations (like, true ok) so why even try to

and apparently the argument was aimed at people (who I haven't seen in the wild) who are arguing we should still be in lockdown. and i have mixed feelings about the idea of extended lockdown or attenuating isolations; but my main feeling at this point is not that the government should keep us apart but that the government should be trying to make it safer for us to be together

things the government could/should be doing about covid:

we know that ventilation/air movement helps a shitton. we should be incentivizing upgrades to ventilation systems in all public buildings with shit like rebates or tax deductions, while phasing in eventual legal requirements. (and uh. it has occurred to me that the US might actually be doing this sideways by there's currently this decade enormous tax incentives in re energy efficient upgrades for slowing climate change and you know. energy efficient hvac does tend to improve ventilation. extra point to biden here.)

mandatory paid sick leave so workers aren't under social or economic pressure to work when sick

passing out RT-LAMP tests like metrix that actually work instead of the rapid antigen tests that have become less and less reliable as the virus mutates

i don't know how you'd write this law but like 95% or more of computer-based work can be done remotely and companies should not be allowed to force people to return to the office. I know there's people who want to be back in person and I'm not saying they should be forced to stay home but ffs I know of at least two people CLOSE to me who worked remotely before the pandemic and at some point their workplaces tried to tell them they weren't allowed to do that anymore despite the pre-existing contracts. stop canceling remote work for people that want, need, or prefer it.

for that matter, every college lecture that was an online class during covid should still be offered as an online class, there is no reason to force students into auditoriums in person. you got the communications infrastructure up and running, why are you tearing it down. give people the OPTION. it increases accessibility for everyone!

covid vaccine immunity lasts about four months. this should be well-publicized and everyone should be able to re-up for free every four months. "every year, like the flu vaccine" is demonstrably not often enough. actually "for free" isn't good enough start handing out $10 gift cards you will be shocked at how many people who are resistant to the idea of vaccines will fold for $10 a shot

are there already laws on the books about masks in medical settings that some medical professionals are blatantly ignoring because they forgot what best practices were before the plague and they're 'tired of masking'? if not, pass laws. if so, fucking enforce them

oh another incentives for upgrades phasing into legal requirements thing: brass doorknobs and railings over stainless steel or whatever. microbes do not survive on brass surfaces

i mean. i know this one sounds too extreme to a lot of people but. UBI.

most if not all of these measures will prevent or ameliorate other pandemics of different diseases that may arise in the future. and just. generally improve our health and quality of life for other reasons.

I haven't felt safe to go to a concert since 2020. Maybe if I knew a venue was legally required to have ventilation to a certain standard and that none of the ticket takers and ushers were on the job sick to avoid risking loss of paycheck or job, and knew a larger percentage of the crowd had up to date vaccinations--maybe if any or all that, I might ever feel comfortable going to a show again.

wouldn't it be nice if those of us who have been disabled, by covid or other conditions, had accessible remote options but also occasionally felt safe enough to interact with and participate in wider society?

one of the arguments on the post I saw was how isolation was massively psychologically damaging and various strata of society were affected in all sorts of ways, from undersocialized kids to increased depression in--well across the board, I think. and here's the thing: WE KNOW. PEOPLE WITH CHRONIC HEALTH CONDITIONS, LONG COVID OR OTHERWISE, KNOW ISOLATION SUCKS REAL BAD. because we, both for our own health and due to disability ostracism, are still isolating and isolated more than most.

what are you as individuals or societies, what are our governments, doing to help make it safe and accessible to rejoin you????

397 notes

·

View notes

Text

SIMS 4 Horse Stall CC FIND!

A NEW AMAZING SET THAT DESERVES AN AUDIENCE!

✨✨✨✨CREATED BY Raya Collins ON PATREON ✨✨✨✨

{Creators Disc}

Crafted with a harmonious blend of rustic charm and modern elegance, the Montana stall set serves as an exemplary addition to any equestrian facility.

This stall set features wood panels that contrast brilliantly with the gleaming stainless steel bars, creating an aesthetic that's both warm and refined. The front of the stall incorporates a durable mesh grid, offering optimal ventilation while ensuring your horse's safety and comfort. The stainless steel bars not only add to the stall's durability but also present a touch of modern sophistication.

Whether you own a ranch nestled in the heart of Montana or a state-of-the-art equine facility elsewhere, the Montana stall set promises both functionality and an unparalleled rustic appeal. --------- {Creator's Note} This is my first ever custom made content, and it is far from perfect, but I've done the best I could, and I really hope you guys like it!

LINK to this Creators Set - HERE 😍

#sims 4 cc#ts4cc#sims 4#ts4#ts4 horse ranch#sims 4 horse cc#sims 4 build#simblr#buildbuy cc#ts4 build#ts4 bb#build buy cc#horseblr#horse cc

425 notes

·

View notes

Text

Hennessey H1000 'Last Stand' Dodge Challenger & Charger, 2023. The final run of the supercharged 6.2-litre Hellcat HEMI V8 is marked with an upgraded version of the engine that produces 1000hp thanks to larger supercharger (non-Redeye models only), upgraded fuel injectors, a high-flow induction system, pulley upgrade, stainless-steel long tube headers, high-flow catalytic converters, and a crankcase ventilation system.

#Hennessey#Hennessey H1000 'Last Stand'#Dodge Challenger#Dodge Charger#supercharged#end of the line#run-out edition#special edition#1000hp#Hellcat HEMI V8#Dodge#2023#last stand

237 notes

·

View notes

Text

a video from the Save the 8th Campaign, Irish nurse Caren Ní hAllacháin described witnessing an abortion at 22 weeks where the baby was born alive. The baby had a “chromosomal abnormality,” possibly Down syndrome

“I wasn’t looking after [the woman having the abortion] directly, but I was on the ward. The other nurse had gone for a break, but I went into the sluice room [where medical waste was taken]. And the baby was in a kidney dish, in the sink where all the clinical waste was. The baby was born alive, and the baby was then taken from the mother – the mother never saw the baby. The baby was put into a kidney dish and brought away from the room, and to the sluice room, and left there just to die.

The baby was the full size of the kidney dish, so the baby was probably a little bit more than the length of my hands. He was small but he was perfect. He had – you could see his toes, his hands, it seemed like he had blonde hair. His eyes were closed. His mouth was open slightly. At first when I saw him, I thought he was actually dead, but I could see the rise and fall of his chest once I looked, because through the shock – he was breathing. And he wasn’t really moving. He had been there at least an hour and a half if not two hours.

I just did not know what to do. But there was nobody treating that baby. That baby was breathing and yet I couldn’t go and ring for the emergency team to come. I couldn’t get oxygen for the baby. I couldn’t put a blanket around the baby. I couldn’t pick the baby up…. the baby was still breathing. I couldn’t treat that baby as any other baby in any other part of that hospital, where you have babies the same age being treated in incubators and being ventilated and being given every assistance to live.

And yet this baby was left… in a kidney dish, which is [a] cold stainless steel metal dish, and just left to die. I had to leave the sluice room. I had to leave the baby there. That part is the hardest part of all because I felt I had abandoned the baby. When I went back the baby had died. The baby wasn’t breathing anymore. So the baby was still in the kidney dish. It was when the other nurse came back that she disposed of the baby’s body.

To see that baby trying to breathe – to see the dignity of him in the kidney dish trying to breathe, and nobody, just nobody there. He is a human being and a person. You can’t deny it. You can’t deny that that child was a son. It is something that will stay in with me for the rest of my life. I think the worst part of that is the fact that I wasn’t allowed to do anything. The baby was small, but it was perfect. [He] was perfect. The baby had a cleft lip – that was it.”

#this is so heartbreaking#prolife#pro life#pro-life#anti abortion#abortion#babies#born alive abortions#life news

170 notes

·

View notes

Text

The Paternoster Vents - Sculpture - Paternoster Square London

Paternoster Vents, sometimes referred to as simply Vents and also known as Angel's Wings, is an outdoor 2002 stainless steel sculpture by Thomas Heatherwick, installed Paternoster Lane on the west side of the Paternoster Square development in London, United Kingdom, close to the junction of Warwick Lane and Ave Maria Lane with Amen Corner. The sculpture provides ventilation for an underground electrical substation.

5 notes

·

View notes

Text

Meet Mercy

hiiiii first real post !! long story short i got back into writing recently and i've been super into transformers so i created an oc, mercy, to write about in that universe to combine my interests :) below is a short story about her life before the war and to mainly introduce what kind of person she is bc i will be posting her and the pieces i write about her a lot on this blog lol, enjoy!

also please be kind i'm so new to posting any of my work online this is so scary

“Again, how did you find me?”

“What? Oh, Bladewing referred you to me.” The bot stared down with drooping eyes at the shorter one arranging tools on a stainless metal tray, adjusting them to a precision rarely seen in general clinics and hospitals within the city. “He said you were the best, just hard to find. I can see why he would say that, I mean you’re operating out of the back of a scrap shop, granted the cleanest one I’ve ever seen, that’s down an alley and around a corner and through the street-”

“Shush.” The shorter of the two said with steel on her tongue. “I know I’m hard to find, that’s for a reason. And I don’t need directions to my own place.” She picked up one of the meticulously arranged wrenches and placed it on a small hip holster held loosely in place by wiring, ensuring it wasn’t hitting the glass panels on her legs. The taller of the two squirmed in place, watching her with a newfound air of uncertainty.

“Do you know what you’re doing?”

“Of course I know what I’m doing. I didn’t spend eons studying and practicing mechanics and medics for nothing.” The shorter scoffed, shaking her head at the taller one. “You’ve spent so much time asking questions over mine that I’ve barely had a chance to speak. Now, I need your name.”

“Hailraiser.” The taller choked out.

“Lovely. I’m Mercy.” The shorter replied, adding more tools to the holster that clanged against her with every movement. “Now what do you need? If you were referred to me by one of the clients I see most often, clearly something is wrong with you.”

“I think it’s a torn or damaged rotor in my left wing. I tried getting an appointment at the general clinic but they said I didn’t have enough Energon to cover the exam, not even the repair. I didn’t know what to do and Bladewing said you gave him a new vigor with your repair of his coolant system for less than half of what the general clinic wanted, so I wanted to see if you could help me.” Hailraisers voice shook the more he spoke, brow furrowing in distress and hands rubbing nervously together. His eyes darted around the small back room he was seated in anxiously. The walls were covered in pegboards with repair tools hung in multiple differing organizational standards. Smallest to largest, heaviest to lightest, wrenches were hung based on what bolts they would fit and screwdrivers by tip type in perfectly straight fashions. Cracked concrete made up the floor, oil and other various stains covering it entirely, but mostly under the table where Hailraiser sat. There was one small window on the far wall, cracked for ventilation, and one door leading to the scrap shop in front. His eyes fell to the wall behind his nurse for the hour and the large laser rifle hung just above the workbench. “Ever need to use that?” He gestured to it with a shaky hand.

Mercy turned to where he was pointing and smirked. “That old thing? Once. One of my first clients actually, didn’t want to take no for an answer after I denied an ‘emotional tuneup’ at the club down the way.” She glanced at Hailraiser, who looked more faint than before. “Don’t take that as a warning, just a story.” She followed up with a more gentle voice, seeming to have remembered bedside manner. She made a final adjustment to her belt, turning it so the tools hanging from it formed an almost skirt in the front, dusting off the shavings that had fallen onto it from the rickety ceiling above them. “Now, Hailraiser, I need you to lay down and flip onto your stomach so I can access that rotor in your wing.” The bot complied, slowly flipping himself over with weakening arms. “I promise I won’t hurt you.”

Mercy began to debolt the panel on Hailraisers wing as gently as she could, feeling him shake under her hands. Her eyes widened more than they usually were as she pried the panel off and placed it softly onto the platform below the worktable. “Hailraiser, how long has this hurt you?”

“I don’t know, two weeks? Maybe three?”

“Next time just come directly to me. Don’t even bother with the bureaucracy and their joke of ‘medical care.’” Mercy muttered, exhaling heavily at the sight of a slipped rotor. “They would’ve charged you an arm and a leg for a repair like this.” She shifted her belt with her hips, instead reaching her slender hands into the bots chassis, slowly pulling the rotor into the right place and watching for any sign of pain or overt discomfort from Hailraiser. The glass panels on her thighs and upper arms began fogging up with the heat from her own circuits and inner workings and the only sound in the small clinic was the scraping of metal and heavy breathing from both parties. Finally, the part clicked into place as Hailraiser let a loud, relieved sigh out and Mercy allowed a small smile to curl her lips up. She meticulously bolted his panel back into place and helped him sit up with a hand on his arm.

“Now how’s that feeling?” Mercy asked in the same gentle tone she’d used to soothe him earlier, scanning him up and down with owl-wide eyes.

“So much better. I can see why Bladewing told me to see you, you’re a miracle worker! Can’t believe you’re holed up working out of here, why aren’t you at General? Or an even bigger mechanic building!” Hailraiser rolled his back and shoulders, feeling out his newly-repaired wing as he talked louder and louder. His voice then faltered. “So how much do I owe you? I brought 15 cubes, I assumed that would be enough.” He clicked a small panel on his arm open, revealing the small stash he’d brought.

“Nothing.” Mercy removed her hand from his arm as he stretched, crossing her arms over her chest and stepping back from the examination table with a satisfied look on her face. “Take this first time as complementary. Keep your Energon.” She said almost snarkily, waving him off while removing the belt with her other hand, laying it out on the clinically cleaned tool bench. She could feel Hailraiser staring a hole in the back of her head in disbelief, and turned with a roll of her eyes. “You don’t need to stare too hard, I know I’m lovely to look at. You know where the exit is, just come back if you need anything.” She teased the bot with a small laugh. It was the first time she’d laughed that week. Hailraiser lowered his eyes quickly and put the cubes back in his arm holster, leaving 3 purposefully on the table as he swiftly walked to the exit door.

“Someone as talented as you deserves more space.” He quipped as he pulled the door closed behind him.

“I know.” She said to the silence that was left. Mercy let a long breath out before beginning to place her toolbelt implements in their respective spots on her wall, folding the belt itself tightly and placing it in a desk drawer. She mindlessly rubbed at the oil stain under her right eye that never really went away as she worked, her shiny black chassis components glowing under the single floodlight that illuminated her clinic space. Hailraisers story about the general clinic was ringing in her ears as she worked, she cursed whoever was running that sham now. How could her fellows not afford an exam appointment? Those are the most basic tier appointments offered at General and should barely cost 1, maybe 2 cubes. She continued to ruminate as she added the appointment to her ledger. She’d been getting a slow, but steady, increase in clientele from word-of-mouth recommendations from her longtime clients and her bulging appointment notebook reflected this. She only hoped word wouldn’t go so far she needed to relocate again, she liked this space. The housing unit above was a nice bonus for her as well, thankfully the landlord was so old he’d leased the entire building to her for a fraction of what typical payments were and all she had to do was manage his shop in front too. Easy.

The indicator light she’d installed near her bench for the front door of the building went off. Mercy quickly finished her ledger, scooped up Hailraisers Energon “tip” into her own storage partition and exited the back room to face a very large bot at the front counter.

“Can I help you?” She placed a hand on her hip as she scanned the individual in front of her, looking for any damage or discrepancy on their chassis that may show why they’re there. Nothing stood out, and that made her nervous.

“I heard someone might show some mercy around here?” he said in a steely cold tone, matching the one she was using. While her body didn’t relax, her mind did when hearing the phrase, only her clients knew what asking that meant and would tell bots seeking help to ask that specifically. “I see, I think I know what you’re looking for. Come.” She beckoned the newcomer to follow with the twitch of her hand, and they obliged. “Now, how did you find me?”

3 notes

·

View notes

Text

What Accessories Are Needed for Residential Metal Roofing?

Residential metal roofing is a popular choice for upgrading your home. It combines aesthetics with durability and energy efficiency. If you're considering this option, you might wonder what accessories you need to ensure your new roof performs optimally and looks great. In this article, we’ll guide you through the essential accessories required for residential metal roofing, helping you make informed decisions about your home improvement project.

Understanding Residential Metal Roofing Accessories

Residential metal roofing is not just about the panels themselves. Several accessories are essential to ensure your roof's functionality, longevity, and appearance. These accessories play various roles, from supporting the roofing structure to enhancing energy efficiency and ventilation.

1. Underlayment for Metal Roofing

One of the first accessories you'll need is the underlayment. This material acts as a protective barrier between your roof deck and the metal panels. It helps to prevent moisture from penetrating your roof, which can lead to mold and structural damage over time.

There are different types of underlayment available, including synthetic and felt options. Synthetic underlayment tends to be more durable and tear-resistant, making it a preferred choice for many homeowners.

2. Roof Flashing

Flashing is a vital accessory in any roofing system and residential metal roofing is no exception. Flashing is used around roof penetrations, such as chimneys, vents, and skylights, to prevent water leaks.

Flashing, made from mluminaluminumlvanized steel, directs water away from vulnerable areas, ensuring your home remains dry and comfortable. Proper flashing installation is key, so it’s often best to rely on professional help for this part of your roofing project.

3. Ridge Caps and End Caps

Rig caps and end caps are essential to enhance the overall look and function of your residential metal roofing.

Ridge caps are installed at the peak of your roof where two slopes meet. They cover the seam and protect against water infiltration. End caps serve a similar purpose but are used at the ends of the metal panels. Both accessories contribute to a finished appearance and help maintain the roof's integrity.

4. Gutter Systems

Consider installing an effective gutter system when installing residential metal roofing. Gutters help channel rainwater away from your home, preventing potential damage to your foundation and landscaping.

Consider installing seamless gutters to minimize leaks and ensure optimal performance. Choosing the right downspouts and gutter guards can further enhance your roof's drainage system, keeping it functioning efficiently.

5. Ventilation Accessories

Proper ventilation is crucial for maintaining a healthy attic and improving energy efficiency in a home. When considering residential metal roofing, you should consider ventilation accessories such as ridge vents, soffit vents, and gable vents.

Ridge Vents: Installed along the roof’s peak, ridge vents allow hot air to escape, reducing heat buildup in the attic. This is especially important in warmer climates.

Soffit Vents: Located under the eaves, soffit vents allow cool air to enter the attic space. When paired with ridge vents, they create an effective airflow system.

Gable Vents: These can be installed on the gable ends of your roof to provide additional ventilation.

6. Fasteners and Clips

The fasteners and clips used to secure your metal roofing panels are critical for ensuring the durability of your roof. Stainless steel screws and clips are commonly recommended due to their corrosion resistance and strength.

To ensure a secure fit, ensure the chosen containers are compatible with your specific metal roofing material. Proper installation with the correct fasteners will help prevent potential issues like panel warping or leaks.

7. Snow Guards

If you live in an area that experiences heavy snowfall, snow guards are an accessory worth considering. These devices are installed along the roof's edge to prevent snow and ice from sliding off too quickly, which can pose a safety hazard.

By retaining snow on your roof, snow guards help to manage melting and prevent sudden avalanches of snow that could damage landscaping or injure passersby.

8. Trim and Accessories for Aesthetic Appeal

Beyond functionality, aesthetics play an important role in your home’s curb appeal. Various trim accessories can enhance the look of your residential metal roofing, including:

Fascia and Soffit: These elements can be made from metal or other materials that complement your roofing choice, giving your home a polished look.

Color Options: Depending on your metal roofing material, you can select colors and finishes that match your home’s style, creating an attractive exterior.

9. Insulation and Energy Efficiency Components

Consider adding insulation accessories to your metal roof to maximize its energy efficiency. Proper insulation helps regulate indoor temperatures, keeping your home cool in the summer and warm in the winter.

Materials such as spray foam or rigid foam board can provide excellent thermal resistance. Pairing insulation with above-sheathing ventilation can enhance energy efficiency by allowing air to flow between the roof and insulation, reducing heat transfer.

10. Roof Accessories for Solar Panels

Integrating solar panels into your residential metal roofing is a smart move if you're considering solar panels for energy efficiency. Metal roofs are highly compatible with solar panel installations and can help maximize energy savings.

When installing solar panels, use mounting systems specifically designed for metal roofing to prevent leaks and damage. Additionally, consult with professionals to determine the best placement for optimal sunlight exposure.

Maintaining Your Residential Metal Roofing

Regular maintenance is essential to ensure longevity and performance once you've invested in residential metal roofing and its necessary accessories.

Inspect Regularly

Schedule inspections at least twice yearly to check for signs of wear, damage, or rust. Early detection can prevent costly repairs later.

Clean Gutters and Roof Surfaces

Keep your gutters clean and free from debris to ensure proper water drainage. Additionally, periodically clean the roof surface to prevent buildup that can lead to corrosion.

Monitor Insulation and Ventilation

Check your attic insulation and ventilation system regularly to ensure they function correctly. This will help maintain your home’s energy efficiency and comfort.

Investing in residential metal roofing is a smart choice for homeowners looking to enhance their homes' durability, energy efficiency, and aesthetics. By including essential accessories such as underlayment, flashing, ventilation systems, and more, you can ensure that your roofing system functions optimally and looks great for years.

If you're ready to explore your options for residential metal roofing and its accessories, contact Lastime Exteriors today. Our team is eager to help you discover energy-efficient roofing solutions tailored to your needs. Your home deserves the best, and we're here to provide it!

6 notes

·

View notes

Text

Bright and Airy: The Ultimate Functional Kitchen

The modular kitchen with a brown marble breakfast bar with two white leather chairs on a chrome frame. The kitchen follows a minimalist style, featuring white and gray cabinets. The windows offer views of the garden, allowing for better lighting and ventilation. Additionally, the second photo shows a kitchen with gray cabinets and a stainless steel oven arranged around a large window. There are small light gray baskets, a small sink with a faucet and countertop plants, focusing on clean lines and functionality.

#pushpainteriors#modularkitchen#interiordesign#kitchendesign#homedecor#kitchen#interior#interiordesigner#interiors#kitchendecor#home#architecture#modularhome#design#modularkitchens#homedesign#modularkitchendesigns#kitchencabinets#homeinterior#decor#interiordecor#modularfurniture#kitcheninterior#kitchenideas#modular#interiorstyling#kitchenremodel

2 notes

·

View notes

Text

Comprehensive Guide to Stainless Steel Sheets, Coils, and Decorative Finishes

Stainless steel is a powerful and versatile material used in many industries due to its durability, corrosion resistance, and aesthetic appeal. Among the most common forms of stainless steel are sheets, coils, perforated sheets, and textured and embossed varieties. Each form has its unique benefits and uses, making it a go-to material for construction, automotive, architecture, and other sectors.

In this guide, we will delve deeper into these types of stainless steel products, their properties uses, and why they are essential in various industries.

1. Stainless Steel Sheets: A Foundation for Versatility and Strength

Stainless steel sheets are flat, thin pieces of steel that are widely used in everything from structural components to household items. They come in a variety of grades, thicknesses, and finishes, allowing for a wide range of applications.

Key Benefits:

Corrosion Resistance: Stainless steel sheets are resistant to rust, making them ideal for outdoor and harsh environments like marine applications or chemical industries.

Strength and Durability: The high tensile strength of stainless steel sheets ensures they can handle heavy loads and extreme conditions without compromising integrity.

Aesthetic Appeal: Stainless steel sheets provide a sleek, modern look and are commonly used in architecture and design for both functional and decorative purposes.

Hygienic and Easy to Clean: The smooth surface of stainless steel makes it easy to clean and maintain, which is why it’s the material of choice for food processing, healthcare, and pharmaceutical industries.

Applications of Stainless Steel Sheets:

Construction: Stainless steel is used for roofing, wall cladding, and reinforcement in buildings. It’s also used for structural components like beams and columns.

Kitchen and Appliances: From countertops and sinks to industrial refrigerators, stainless steel sheets are essential for hygiene, durability, and ease of maintenance.

Automotive and Aerospace: Stainless steel is commonly used for body panels, exhaust systems, and engine components in vehicles, as well as structural elements in aircraft.

2. Steel Coils: Flexibility and Efficiency in Manufacturing

Steel coils are large, rolled pieces of steel that are typically cold-rolled or hot-rolled and can be processed into a variety of shapes and sizes. These coils are widely used in the manufacturing process and are known for their ability to be easily handled and formed into different products.

Key Benefits:

Efficient Manufacturing: Steel coils reduce waste by allowing manufacturers to process materials in bulk, cutting down on costs and energy use.

Strong and Resilient: Steel coils maintain their integrity even under high pressure, making them suitable for a wide variety of demanding applications.

Easy to Transport: The coil form makes it easier to store and ship large quantities of steel at once.

Applications of Steel Coils:

Automotive: Steel coils are used to produce parts such as chassis, body panels, and structural components.

Construction: Coils are used for making reinforcement bars, metal sheets for roofing, and structural beams.

Appliances: Steel coils are often turned into components for household items such as refrigerators, washing machines, and dishwashers.

3. Stainless Steel Perforated Sheets: Functional and Decorative Patterns

Perforated stainless steel sheets are created by punching holes into the steel, resulting in a material that has a unique pattern of small holes. These perforations can vary in size, shape, and spacing, making perforated stainless steel highly customizable for different purposes.

Key Benefits:

Improved Ventilation and Light Transmission: Perforated sheets are widely used in applications where airflow, light, or sound is needed. For example, they can be used for air filtration systems or soundproofing materials.

Aesthetic Design: The perforated patterns add a decorative element to the material, making it an ideal choice for modern architecture and interior design projects.

Weight Reduction: The holes reduce the overall weight of the material, which is crucial in industries like transportation and packaging.

Applications of Stainless Steel Perforated Sheets:

Architectural Design: Used in facades, wall panels, and ceiling tiles, perforated sheets are valued for their appearance and functionality.

Industrial Applications: Perforated sheets are common in the construction of filtration systems, industrial grilles, and even security barriers.

Furniture and Interiors: They are used for shelving, decorative partitions, and custom-made furniture elements.

4. Textured Stainless Steel: Adding Dimension and Functionality

Textured stainless steel refers to sheets that have been treated to produce a pattern or finish that gives the metal a tactile and visual appeal. Common textures include brushed, hammered, or patterned finishes, which enhance the material’s functionality and aesthetic qualities.

Key Benefits:

Improved Grip and Slip Resistance: Some textured finishes, like brushed or hammered, add traction, making them ideal for use in high-traffic areas, walkways, and stair treads.

Unique Visual Appeal: The texture creates a dynamic, modern look that adds character to both commercial and residential projects.

Durability: The texture enhances the surface, making it more resistant to wear and tear, scratches, and other damage, which is perfect for areas that see a lot of use.

Applications of Textured Stainless Steel:

Interior Design: Used for decorative wall panels, countertops, and accent pieces, textured stainless steel elevates the look of modern homes and offices.

Public Spaces: Textured finishes are perfect for use in public areas like transit stations, airports, or malls due to their slip-resistant properties.

Transport and Automotive: In vehicles, textured stainless steel is often used in non-slip flooring, particularly in trains and buses.

5. Embossed Stainless Steel Sheets: Adding Depth and Dimension

Embossed stainless steel sheets feature a raised design, creating a 3D effect that adds a tactile quality to the material. These designs can range from simple geometric patterns to intricate, decorative motifs. Embossed stainless steel provides both functionality and artistic appeal.

Key Benefits:

Enhanced Durability: The embossing process makes the material thicker and more resistant to damage from dents, scratches, and wear, which extends its lifespan.

Aesthetic Flexibility: Embossed stainless steel is widely used in high-end design applications due to its unique appearance and dimensional qualities.

Concealing Imperfections: The raised designs help to mask imperfections like scratches, fingerprints, or smudges, maintaining the material’s aesthetic quality over time.

Applications of Embossed Stainless Steel:

Interior Design: Commonly used for decorative wall panels, cabinet doors, and countertops.

Automotive Industry: Embossed stainless steel is used for interior trims, dashboards, and decorative moldings in vehicles.

Consumer Products: Common in appliances, elevator panels, and furniture, where both durability and a premium look are desired.

Choosing the Right Stainless Steel Product for Your Project

To select the right stainless steel material for your project, consider the following:

Determine Your Application Needs: Identify whether your project requires a focus on aesthetics, strength, corrosion resistance, or a combination of these features.

Consider the Environment: For high-corrosion environments, choose stainless steel types like 316, which offer enhanced resistance to rust and stains.

Thickness and Finish: The thickness of the material will determine its strength, while the finish will impact both its appearance and functionality (e.g., brushed, polished, or embossed).

Customization Requirements: Perforated, textured, or embossed designs can be customized to fit specific project requirements.

Conclusion: The Power of Stainless Steel in Modern Applications

Stainless steel products, including sheets, coils, perforated sheets, textured, and embossed varieties, are indispensable in today's world. Whether you're designing a sleek kitchen, building a durable structure, or developing innovative automotive parts, stainless steel offers unmatched versatility, strength, and visual appeal. Understanding the different types of stainless steel products and their specific applications will help you make the best material choice for your needs.

With the right selection, stainless steel will continue to provide long-lasting, reliable, and stylish solutions across industries.

For help selecting the perfect stainless steel product for your project, feel free to reach out. Our experts are here to assist you in making the most informed choice!

#metal#steel metal sheet#stainless steel tube#stainless steel plate#steel coil#Textured Stainless Steel

2 notes

·

View notes

Text

Ambica Airvent: Top Roof Air Ventilators

Ambica Airvent's roof Air Ventilator is a top-quality ventilation solution designed to improve indoor air quality and regulate temperature in spaces such as warehouses, factories, and commercial buildings. Made from durable materials, this ventilator is a reliable and cost-effective option for maintaining a comfortable environment.

Click here - https://www.ambicaairvent.com/roof-air-ventilator

#turbo air ventilator#aluminium air ventilator#roof air ventilator#venturi motorized air ventilator#ridge ventilator#aluminium base plate#stainless steel ventilator#motorized air ventilator#peb structur repairing work

0 notes

Text

I- I think it worked 👀

[click here] for Before pictures

10 hours, 4 days, $18, and a few bandaids

This method is for removing surface patina rust from stainless steel loom reeds, and assumes you have already prepped the reeds by removing the tape

Equipment

wire brushes (stainless steel and copper)

leather work glove for off hand

eye protection

dust mask (I used a kN95)

Rustoleum rust dissolver jelly

nylon brush for acid gel application (mine came multipack w/ the wire brushes)

flat surface on which to lay the reeds (I suggest waist high so you don't hurt your back)

newspaper or tarp to cover it and the work area if you care about acid drips

clothes you don't care about if they happen to get acid on them (looks like bleach stains)

a bucket or two of water in case of acid spill or skin contact

garden hose to spray off the acid

a sunny day or ventilated space to let the reeds dry

WD-40 silicone spray

Steps & Tips

you might just want the pair of gloves, as all my abrasions are from my dominant hand slicing past the exposed reed ends. Unfortunately I could only find the single glove =/

hold the bristles of the wire brush at 45° to the reed surface

switch out the different wire brushes. Use stainless steel to start, then switch to the softer copper to brush away dust, and to buff. If you can, use an old wire brush whose bristles are bent and tangled to provide more angles of attack on the rust.

in the initial wire brushing, turn the reed over AND flip it upside down, then turn it over AGAIN to get all 4 sides of the reed. You may find this helpful if your wire brushes are new, where the bristles can't get too far in between the reeds with each pass.

also brush lengthwise down the surface of the reeds

use the nylon brush to brush between the reeds before applying the rustoleum gel. No reason, other than you can more easily see how effective the gel is.

apply the gel with the nylon brush. Just dip it right into the jar. Paint a thin line along the edges of the reeds, scrub, then tackle the inside surfaces, as it does drip if there's a lot of it.

coat every surface of the metal you want to address. Flip it over and do the other side, too. Try not to get too much on the string and glue between the reed ends.

it's probably fine if it dries, but it'll be harder to remove with just water. I did one at a time to avoid this.

Power Wash that thing. Both sides. Then set it to dry in a sunny spot. You be the judge if you have to bring it inside overnight.

after a day of drying, repeat the front-back-top-bottom metal brushing. You may want to brush the dried gel from the string interlacements. Don't be discouraged if it doesn't look perfect. Again, use the nylon brush to clear dust.

if you've foregone the mask thus far, you do you, but you might want it for the silicone. It smells, and it hangs in the air. You'll also want newspaper or a tarp for this bit. WD stands for "water displacement" so it's not good to get on plants. I also did this bit wearing the leather glove (it will get silicone on it).

spray the front and back, and if you think you missed a spot (at this point it'll be soaked, that's unlikely) flip it over and do the front and back again. Prop it up to dry.

Miraculous! The high-powered spray whisked away all the remaining surface rust, leaving metal that looks like metal and not a shipwreck on the ocean floor.

I'm going to wait a day or two before applying new tape, just to be sure that the string wrap is completely dry. Then to warp a short junk piece to check for burrs and clean any residue. 🤞

=D color me pleasantly surprised

2 notes

·

View notes

Text

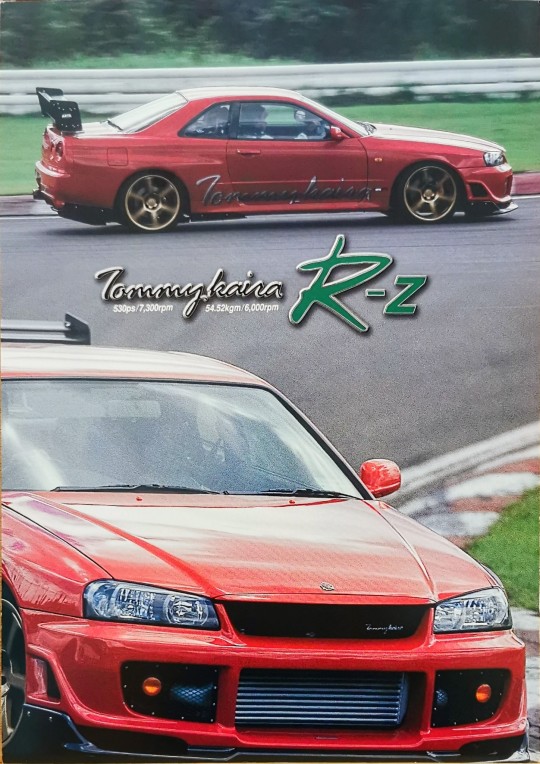

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Discover the Strength and Versatility of GI Flange

Q1: What are the key processes involved in the manufacture of GI flanges?

A: The key processes in the manufacture of GI flanges include:

Material Preparation: Raw materials like steel plates or sheets are cut to size.

Forming: The material is shaped into the flange design using processes like stamping or forging.

Welding: If needed, flanges may be welded to create specific designs.

Galvanization: The flanges are coated with zinc through hot-dip galvanization or electro-galvanization to enhance corrosion resistance.

Finishing: Final finishing processes include cleaning, inspection, and surface treatment to ensure quality.

Q2: Which materials are typically used in the production of GI flanges?

A: The primary material used in the production of GI flanges is carbon steel, which is coated with zinc to provide corrosion resistance. Depending on specific requirements, other materials such as stainless steel may also be used.

Q3: How do manufacturing standards affect the quality of GI flanges?

A: Manufacturing standards, such as ASTM, ANSI, and ISO, provide guidelines for the design, material specifications, and testing of GI flanges. Adhering to these standards ensures consistency, reliability, and safety in the final product, significantly affecting its overall quality.

Q4: What industries commonly utilize GI flanges?

A: GI flanges are commonly used in various industries, including:

Construction

Oil and gas

Water and wastewater treatment

HVAC (Heating, Ventilation, and Air Conditioning)

Shipbuilding

Q5: Can you customize GI flanges according to specific project requirements?

A: Yes, GI flanges can be customized based on specific project requirements, including size, thickness, pressure rating, and design specifications, to meet the needs of different applications.

Q6: What certifications should a manufacturer of GI flanges have?

A: A manufacturer of GI flanges should ideally have certifications such as:

ISO 9001 (Quality Management System)

ISO 14001 (Environmental Management)

API (American Petroleum Institute) certifications for oil and gas applications

Other industry-specific certifications as required.

Q7: How does the manufacturing process ensure corrosion resistance in GI flanges?

A: Corrosion resistance is ensured through the galvanization process, where flanges are coated with zinc, which serves as a sacrificial anode. This protects the underlying steel from rust and corrosion when exposed to moisture and other corrosive elements.

Q8: What are the advantages of using GI flanges over other types of flanges?

A: The advantages of using GI flanges include:

Cost-Effectiveness: Generally less expensive than stainless steel flanges.

Corrosion Resistance: The zinc coating provides excellent protection against rust.

Versatility: Suitable for a wide range of applications and environments.

Strength and Durability: Good mechanical properties make them reliable under pressure.

Q9: How does the cost of manufacturing GI flanges compare to other flange types?

A: The cost of manufacturing GI flanges is typically lower than that of stainless steel or other specialty flanges, primarily due to the lower cost of raw materials and the manufacturing processes involved.

Q10: What quality control measures are in place during the manufacture of GI flanges?

A: Quality control measures during the manufacture of GI flanges may include:

Regular inspections and testing of raw materials.

In-process inspections to ensure dimensional accuracy and adherence to specifications.

Testing for corrosion resistance, mechanical strength, and other relevant properties.

Final product inspections before shipment to ensure compliance with standards and customer specifications.

#GIFlanges#GalvanizedIron#IndustrialFlanges#SteelManufacturing#CorrosionResistance#FlangeManufacturing#ConstructionMaterials#MSMEs#QualityControl#B2BIndustry#PipeFittings#FlangeDesign#ManufacturingStandards#EngineeringSolutions#CustomFlanges

2 notes

·

View notes

Text

3 Inch GI Flange: Features, Pricing, and Benefits

When it comes to efficient and durable piping systems, a 3 inch GI flange is a crucial component. These flanges are widely used in various industries due to their strength, corrosion resistance, and cost-effectiveness. At Udhhyog, we pride ourselves on offering top-quality GI flanges that not only meet industry standards but also come at competitive prices, ensuring our customers get the best value.

What is a 3 Inch GI Flange?

A 3 inch GI flange is a galvanized iron flange designed to connect pipes, valves, or equipment in a piping system. The term "3 inch" refers to the nominal bore size, meaning it is suitable for pipes with a 3 inch diameter. The galvanization process provides the flange with a protective zinc coating, making it resistant to rust and corrosion. This makes the 3 inch GI flange a popular choice for various industries where durability and resistance to harsh conditions are essential.

Key Benefits of a 3 Inch GI Flange

Corrosion Resistance The galvanized coating ensures that the flange is protected from corrosion, making it suitable for both indoor and outdoor applications, especially in environments where moisture or chemicals are present.

Durability and Strength Made from high-grade galvanized iron, the 3 inch GI flange is built to withstand high pressures and temperatures, ensuring reliable performance in demanding industrial settings.

Cost-Effective Solution Compared to other materials like stainless steel, galvanized iron provides an affordable yet durable solution for industrial piping needs. This makes the 3 inch GI flange an economical choice for businesses looking to balance cost and quality.

Versatility in Application The 3 inch size is a common standard in industrial piping, making the GI flange suitable for a variety of applications, from water distribution to HVAC systems and gas pipelines.

Factors Affecting the Price of a 3 Inch GI Flange

At Udhhyog, we offer competitive pricing for 3 inch GI flanges, but it's essential to understand the factors that can influence the cost:

Material Grade Higher-quality galvanized iron will typically command a higher price due to its superior corrosion resistance and durability.

Manufacturing Techniques Flanges that are manufactured using advanced techniques such as precision machining or forging may be more expensive, as they offer better dimensional accuracy and strength.

Coating Thickness The thickness of the galvanized coating can also impact the price. Thicker coatings provide enhanced protection against corrosion, especially in highly corrosive environments.

Order Volume Like most industrial components, bulk purchasing can result in significant savings. At Udhhyog, we offer discounts for large orders, making it a cost-effective option for companies needing bulk quantities of 3 inch GI flanges.

Market Trends and Raw Material Costs Prices of galvanized iron and other raw materials can fluctuate based on market demand and supply. Staying informed about these trends can help you make more cost-efficient procurement decisions.

Common Applications of 3 Inch GI Flanges

The 3 inch GI flange is widely used across various industries due to its versatility and robust properties:

Water Distribution Systems: Ideal for water pipes, the GI coating ensures protection from rust, making it suitable for both potable water and drainage systems.

HVAC Systems: These flanges are used in heating, ventilation, and air conditioning systems to ensure airtight and watertight connections.

Gas Pipelines: The durability of the 3 inch GI flange makes it perfect for high-pressure gas pipelines, where safety is critical.

Industrial and Chemical Processing: In industries where corrosion is a constant threat, the galvanized iron flange offers a cost-effective solution.

Why Choose Udhhyog for 3 Inch GI Flanges?

At Udhhyog, we are committed to providing our customers with high-quality industrial products at competitive prices. Here’s why we’re the trusted choice for 3 inch GI flanges:

Competitive Pricing: Our pricing strategy is designed to give you the best value without compromising on quality. We offer some of the most competitive prices for 3 inch GI flanges in the market.

Custom Solutions: If you have specific requirements for dimensions, coatings, or finishes, we can customize flanges to meet your exact needs.

Quality Control: Every flange we manufacture undergoes stringent quality checks to ensure it meets industry standards and performs reliably in all conditions.

Bulk Discounts: We offer attractive discounts on bulk orders, making Udhhyog the go-to supplier for businesses with large-scale industrial projects.

Timely Delivery: With a robust supply chain, we ensure that your orders are delivered on time, helping you keep your projects on schedule.

How to Save on 3 Inch GI Flanges

To ensure you get the best deal on 3 inch GI flanges, here are a few tips:

Request Multiple Quotes Always request quotes from multiple suppliers. At Udhhyog, we provide transparent and competitive pricing with no hidden costs.

Compare Quality Don’t just focus on price. Compare the quality of the materials and manufacturing process. A slightly higher price for better-quality flanges can save you money in the long term by reducing the need for replacements and maintenance.

Order in Bulk Purchasing larger quantities often leads to significant savings. Udhhyog offers bulk discounts, making it more economical for companies that require a consistent supply of 3 inch GI flanges.

Negotiate for Large Orders If you’re placing a large order, don’t hesitate to negotiate. At Udhhyog, we are flexible and willing to discuss terms to ensure you get the best possible price.

Whether you're looking for a single 3 inch GI flange or require a bulk order for your industrial project, Udhhyog is your trusted partner. Our high-quality products, competitive pricing, and commitment to customer satisfaction make us the preferred choice for businesses across various industries. Contact us today for a quote or to learn more about our offerings.

2 notes

·

View notes