#Solvent industry

Explore tagged Tumblr posts

Text

Green & Bio-Solvents Market: Sustainable Solutions for a Cleaner Future

The total size of the green & bio-solvents market was USD 3,128.5 million in the past, and it will propel at 6.1% CAGR in the years to come, to reach USD 5,322.2 million by 2030, as per P&S Intelligence. The industry development is credited to the and environmental and health concerns related to synthetic solvents. Paints & coatings dominated the industry in the past, with around USD 1.2…

View On WordPress

#Bio-based solvents#Biodegradable solutions#Chemical sector#Clean manufacturing#Eco-conscious industries#Eco-friendly alternatives#Environmental innovation#Green chemistry#Green solvents#Green technology#Industrial applications#Low carbon footprint#market growth#Regulatory compliance#Renewable resources#Solvent industry#Solvent market trends#Sustainable chemistry#Sustainable sourcing

1 note

·

View note

Text

See the world, but not the other way around.

Super Traders India: Trading company in Delhi NCR

One Way Vision is a calendered polymeric digital perforated film. One way vision is dual layered film with a gloss white printable side and a clear pressure – sensitive adhesive side. One Way Vision has been designed as a long term solution to improve privacy and promote self image. Supertraders India is providing your best quality one way vision film in affordable prices and near by location.

#supertradersIndia#signage Industry Delhi#Delhi NCR#roll up stands#standy products#vinyl solvent ink#one way vision film#trading company Delhi#Delhi#super traders Delhi

2 notes

·

View notes

Text

Breaking Down the Mechanics of Pressurized Membrane Modules

Pressurized membrane modules serve as a fundamental technology for processing water and food products while supporting pharmaceutical development alongside various industrial production processes. Membrane modules represent one of several membrane system types that lead to current industrial adoption among multiple organizational applications.

Hydraulic pressure functions in these systems to pull objects through semi-permeable barriers so that the modules can execute desired separations of essential materials from undesirable ingredients. A detailed study of pressurized membrane modules explores their operational mechanism and their benefits alongside their current and projected uses.

1. Working Principle of Pressurized Membrane Modules

Pressurized modules push liquid by using external pressure to pass fluids through permeable membranes featuring tiny pores that block the passage of particles microorganisms and other impurities. Membrane systems operate with pressurized units to carry out filtration techniques including RO (Reverse Osmosis) while also providing UF (Ultrafiltration) MF (Microfiltration) and NF (Nanofiltration). The basic operation involves the following steps:

Feed Water Input: Each module accepts a feed solution that can consist of either pure water or various liquid mixtures.

Pressure Application: An external pressure difference applies to the membrane. The system design determines which mechanism such as pumps will create this pressure.

Separation Process: Membrane pressure pushes liquids from one side while letting molecules with smaller dimensions pass forward while trapping other particles so they collect on the opposite side.

Permeate and Concentrate Streams: The membrane separates liquid into two components - permeate exists as the clear passing solution and the retained substances become concentrated or retentate.

Membrane module operation based on pressure reaches its performance through management of pre-applied pressures that differ according to filtration types. Port de pressure levels differ between membrane filtration techniques where reverse osmosis demands high pressure but ultrafiltration and microfiltration function with lower pressures.

2. Design and Structure

The design of the quality membranes modules is an integral part of their efficiency and performance. There are a number of structural features that make the filtration process optimal for several applications.

Membrane Configuration: Membranes are configured in various forms according to the type of filtration. Common configurations include spiral wounds, hollow fiber, flat sheets, and tubular membranes.

Spiral Wound Membranes: These are the most common form of membrane arrangement used in pressurized modules. They have membrane sheets wrapped around a central core. They provide a very high surface area in a very compact form and are, therefore, very efficient.

Hollow Fiber Membranes: The membranes are essentially tiny fibers through which the liquid flows. These are usually employed for applications where high flux rates are required, such as desalination of water.

Tubular Membranes. These are composed of rigid tubes and can accommodate highly viscous fluids; it is often more industrial and commercial in applications.

Pressure Vessel and Housing: The housing structure contains the membrane and maintains the structural integrity in addition to ensuring protection from damaging elements while under operation. In addition, such vessels can hold up to highly elevated operating pressures to maintain long-term service.

Flow Path Configuration: The flow path in these modules is designed so that the filtering efficiency is achieved at its optimum. The feed flow can either be cross-flow or dead-end flow, arranged according to what the system calls for.

3. Applications of Pressurized Membrane Modules

These quality membranes modules can be applied in a wide variety of industrial applications due to their versatility. Their main use is to separate or concentrate material, and thus they are very significant in applications where high purity and specific separations are concerned.

Water Treatment: Primemtec’s pressurized membrane modules are widely used in municipal and industrial water treatment systems. Reverse osmosis membranes, in particular, are critical for desalinating seawater, treating brackish water, and purifying drinking water.

Food and Beverages: Pressurized membranes in the food industry are used in juice concentration, processing of dairy like milk filtration, and production of beer. Ultra- and microfiltration membranes separate proteins and other dissolved constituents from liquids.

Pharmaceuticals and Biotech: These modules are essential for separating biological substances, sterilizing products, and concentrating active pharmaceutical ingredients (APIs). They ensure high product purity and consistency, which are critical in pharmaceutical production.

Chemical and Petrochemical Industries: Pressurized membranes module are used in chemical recovery, solvent recovery, and other processes where the separation of complex mixtures is required. They help in reducing energy consumption and enhancing operational efficiency.

Wastewater Treatment: The membrane modules in wastewater treatment plants are used at both the filtration and treatment stages to remove contaminants from effluent streams. It ensures that treated water meets specified quality standards for compliance with environmental regulations.

Summary

Primemtec’s pressurized membrane modules stand as fundamental components of modern filtration science which deliver flexible efficient scalable industrial solutions throughout multiple domains. Through pressure-driven system operations, these technologies enable both liquid separation and purification which drives advances across water treatment alongside food processing and pharmaceutical production and multiple other vital industrial sectors. The future of sustainable and efficient filtration technology will become possible thanks to new membrane materials and system design innovations that overcome operational costs and fouling challenges.

#Pressurized membrane modules#filtration technology#reverse osmosis membranes#ultrafiltration membranes#microfiltration membranes#nanofiltration membranes#membrane system#water treatment#desalination#food and beverage filtration#pharmaceutical filtration#chemical separation#wastewater treatment#spiral wound membranes#hollow fiber membranes#tubular membranes#pressure vessel#membrane housing#industrial water purification#liquid separation#sustainable filtration technology#high-efficiency filtration#membrane fouling prevention#biotech filtration#solvent recovery#advanced membrane materials#scalable filtration solutions#energy-efficient filtration#Primemtec membrane modules#industrial filtration systems

1 note

·

View note

Text

Epoxy.com Product #632: High-Performance Flexible Novolac Epoxy Joint Filler

Introduction When it comes to concrete joint protection in industrial, commercial, and high-traffic environments, choosing the right epoxy joint filler is crucial. Epoxy.com Product #632 is a 100% solids, flexible Novolac epoxy joint filler engineered to provide superior chemical resistance, impact durability, and long-lasting performance. Designed for saw-cut joints in concrete slabs on grade,…

#100% solids epoxy joint filler#best epoxy joint filler for industrial floors#best epoxy joint filler for saw-cut concrete joints#buy Novolac control joint filler online#chemical-resistant epoxy filler for expansion joints#chemical-resistant joint filler#concrete expansion joint epoxy#concrete joint sealing solutions#durable Novolac epoxy for warehouse flooring#epoxy filler for concrete slabs#epoxy joint filler for concrete#factory floor epoxy joint sealant#flexible Novolac epoxy joint filler#heavy-duty control joint filler#high-performance Novolac epoxy#how to seal industrial concrete joints with epoxy#industrial epoxy joint sealant#industrial flooring protection#industrial-grade concrete joint filler#joint filler for chemical plants#joint filler for extreme chemical and solvent exposure#Novolac Control Joint Filler#saw-cut joint filler epoxy#seamless epoxy joint repair#where to purchase chemical-resistant joint fillers

0 notes

Text

Hexane Market: Growth Insights and Key Trends for Diverse Industries

Hexane, a volatile, colorless liquid hydrocarbon, plays a crucial role in multiple industries due to its exceptional solvency properties and relatively low toxicity. Its versatile applications in oil extraction, pharmaceuticals, industrial cleaning and degreasing, and polymerization are pivotal in driving the steady growth of the global hexane market. This article provides an in-depth look at the key drivers, challenges, and opportunities shaping the future of this essential chemical.

Market Overview

The global hexane market has shown consistent growth in recent years, underpinned by its critical role in various industrial processes. Hexane Market was valued at USD 2.4 billion in 2022 and is projected to reach USD 3.1 billion by 2027, growing at a cagr 4.8% from 2022 to 2027.This robust expansion is fueled by increasing demand from developing economies, advancements in industrial applications, and the rising need for cost-effective extraction techniques.

Key Applications Driving Demand

1. Oil Extraction

Hexane has become a staple in edible oil production due to its unmatched efficiency in solvent extraction processes. Its ability to extract oils from seeds such as soybean, sunflower, and canola ensures optimal yields and quality. Moreover, its ease of recovery through distillation makes it an economically viable choice for manufacturers.

The rising demand for edible oils, particularly in regions like Asia-Pacific and Africa, is propelling the use of hexane. Changing dietary patterns and population growth in these areas have further emphasized the importance of solvent extraction, which outperforms traditional mechanical pressing in efficiency and output.

2. Pharmaceutical Applications

In the pharmaceutical industry, hexane serves as a crucial solvent for drug formulation and the purification of active pharmaceutical ingredients (APIs). Its inert nature ensures minimal interference with chemical reactions, thereby maintaining the integrity of pharmaceutical products.

India and China, emerging as global pharmaceutical hubs, are driving significant demand for hexane. Furthermore, its role in chromatographic separation processes for isolating specific compounds underscores its importance in drug development and research initiatives.

3. Industrial Cleaning and Degreasing

Industries widely use hexane for cleaning and degreasing mechanical components, equipment, and surfaces. Its rapid evaporation and superior ability to dissolve oils and grease make it indispensable for maintenance operations. Sectors like automotive and aerospace, which demand precision in manufacturing, heavily rely on hexane for cleaning purposes.

As industries continue to prioritize efficiency and cleanliness, the demand for hexane as a cleaning agent is expected to grow. The expanding industrial cleaning market in both developed and emerging economies further supports this trend.

4. Polymerization Processes

Hexane’s significance in polymerization processes, particularly in the production of polyethylene and polypropylene, cannot be overstated. Acting as a carrier and reaction medium, hexane ensures uniform polymerization and enhances the physical properties of final products.

Given the rising demand for plastics in packaging, construction, and automotive applications, hexane remains a cornerstone in polymer production.

Key Market Trends

Sustainability Initiatives and Regulatory Compliance

Growing concerns about the environmental and health impacts of hexane have led to increased regulatory oversight. Authorities like the Environmental Protection Agency (EPA) and European Chemicals Agency (ECHA) have imposed stringent guidelines to ensure safe handling and minimize emissions. In response, manufacturers are adopting advanced production methods and refining processes to align with these regulations.

Regional Market Insights

Asia-Pacific: This region dominates the hexane market, driven by strong demand from the oil extraction and polymer sectors. China and India are major contributors.

North America and Europe: Emphasis on sustainability and eco-friendly practices is fostering innovation in hexane applications.

Middle East and Africa: With growing edible oil and pharmaceutical industries, these regions present lucrative opportunities for hexane manufacturers.

Shift Towards Bio-Based Alternatives

As industries strive to reduce their carbon footprint, the exploration of bio-based hexane alternatives is gaining momentum. Although these substitutes are still in the early stages of development, they hold significant promise for companies committed to sustainability.

Future Outlook

The hexane market is set for steady growth, supported by advancements in extraction technologies and increasing demand from pharmaceutical and industrial sectors. However, addressing environmental concerns and meeting regulatory standards will be critical. Manufacturers investing in research and development to create greener hexane formulations are likely to gain a competitive edge in the evolving market.

Download PDF Brochure :

Hexane plays an indispensable role in diverse industries, from oil extraction to polymer production. For stakeholders in these sectors, understanding market dynamics and staying attuned to emerging trends is crucial for long-term success. As sustainability and innovation take center stage, the hexane market is poised for a transformative journey, offering new opportunities for growth and development.

#Hexane market#oil extraction#pharmaceutical solvents#industrial cleaning#polymerization processes#sustainability#market trends

0 notes

Text

Aromatic 150 (C10 Aromatic Solvent) – High-Quality Solvent by Vinati Organics

Aromatic 150, also known as C10 Aromatic Solvent, is a key solvent used in various industries for its exceptional solubility properties and performance. Manufactured by Vinati Organics, this solvent is widely utilized in coatings, paints, adhesives, and chemical formulations. Known for its high purity and reliability, Aromatic 150 meets stringent industry standards, ensuring consistent quality for industrial applications. Visit Vinati Organics

#“Aromatic 150”#“C10 Aromatic Solvent”#“Vinati Organics”#“Solvent Manufacturer”#“Aromatic Solvents”#“Industrial Solvents”#“Coatings and Paints”#“Adhesives”#“Chemical Formulations”#“Solvent Applications”#“Solvent Supplier India”#“High-Quality Solvents”

0 notes

Text

Series 630 | Pasargad Ink®: Premium Solvent-Based Inks for PVC Edge Banding Rotogravure Printing

Pasargad Ink® Solvent-Based Rotogravure Printing Inks for PVC Edge Banding Elevate your PVC edge banding with Pasargad Ink®'s exceptional solvent-based rotogravure printing inks. Engineered to deliver vibrant colors, sharp details, and unparalleled durability, our inks empower you to create stunning and long-lasting edge banding solutions. Features and Benefits: Exceptional Color Vibrancy: Our inks boast a wide color gamut, ensuring vibrant and eye-catching prints that enhance the aesthetics of your products. Sharp Detail Reproduction: The precise formulation of our inks enables sharp and crisp details, showcasing intricate designs and patterns with remarkable clarity. Excellent Adhesion: Designed specifically for PVC edge banding, our inks adhere firmly to the surface, preventing peeling or chipping even under demanding conditions. High Gloss and Matte Finishes: Choose from high-gloss or matte finishes to match your desired aesthetic and create a sophisticated or understated look. Solvent-Based Formulation: Our solvent-based inks provide excellent flow and leveling properties, resulting in smooth and uniform prints. Fast Drying Time: The inks dry quickly, minimizing production downtime and allowing for efficient processing. Environmental Compliance: Our inks meet stringent environmental regulations, ensuring responsible and sustainable printing practices. Value to the Customer: Enhanced Product Aesthetics: Create visually appealing edge banding that complements your products and enhances their overall appeal. Increased Durability: Protect your edge banding from wear and tear, ensuring a long-lasting and professional finish. Improved Production Efficiency: Fast drying times and excellent flow properties streamline your production process, saving time and resources. * Environmental Responsibility: Comply with environmental regulations while delivering high-quality printing results. Experience the transformative power of Pasargad Ink® Solvent-Based Rotogravure Printing Inks for PVC Edge Banding. Elevate your products with vibrant colors, sharp details, and exceptional durability, all while ensuring environmental compliance and production efficiency. Read the full article

#DurableGoods#Industrial#Manufacturing#Packaging#PasargadInk#Printing#PVCEdgeBanding#RotogravurePrintingInks#Solvent-Based

0 notes

Text

Revolutionize Your Laundry Business with Automatic Dry Cleaning Machines – WelcoGM

Step into the future of the laundrex industry with automatic dry cleaning machines from WelcoGM. Designed for high-fashion garments and leather, our machines support both Hydrocarbon Dry Cleaning Machines and Perc Dry Cleaning Machines, offering exceptional efficiency. Equipped with advanced PLC technology for seamless operation and high recovery rates, these machines ensure low running costs and unmatched performance. Choose WelcoGM for premium solutions that redefine your laundry operations!

#industrial/commercial dry cleaning machine#mto#stainless steel#hydrocarbon#wet dry#multi solvent latest laundry dry cleaning machine#perc-dry cleaning machine#automatic dry cleaning machine

0 notes

Text

How Functional Dyes Contribute to Smart Textiles and Wearable Technology?

Smart textiles, the result of a combination of textile science and technology, are not simply clothes; they interact with us and our surroundings in ways that are really astonishing. The key to this invention is the use of Dyes that imbue fabrics with functionality, turning common textiles into materials that are sensitive and intelligent.

Visit Full Blog Functional Dyes

#pharmaceutical packaging manufacturer#pharmaceutical packaging industry#direct dyes#acid dyes#reactive dyes manufacturers#direct dyes manufacturers#solvent dye suppliers in gujarat#optical brightening agents#reactive dyes#crop protection chemicals

1 note

·

View note

Text

The Future of Solvent Cleaning Systems: Efficiency, Sustainability, and the Minio 85C

The world of industrial cleaning is constantly evolving, and Solvent Cleaning Systems are no exception. While traditional methods have served their purpose well, the future demands a focus on efficiency, sustainability, and user-friendliness. This blog post will delve into the exciting advancements shaping the solvent cleaning industry and how the innovative Minio 85C from Ecoclean India positions itself at the forefront of this evolution.

Navigating the Evolving Landscape of Solvent Cleaning

Regulatory Pressures and Environmental Concerns:

Environmental regulations are becoming increasingly stringent, driving the development of eco-friendly solvent cleaning solutions. Traditional solvents often contain volatile organic compounds (VOCs) that contribute to air pollution. Manufacturers are seeking alternatives with lower VOC content and improved waste management practices.

Efficiency and Cost-Effectiveness:

In today’s competitive landscape, maximizing production efficiency is crucial. Solvent cleaning systems need to be faster, more precise, and consume less solvent to minimize operational costs. Additionally, advancements in automation and process optimization are streamlining cleaning workflows.

Operator Safety and User Experience:

The safety and well-being of workers are paramount. Modern solvent cleaning systems prioritize operator safety by incorporating features like advanced ventilation systems, leak detection, and user-friendly controls. Additionally, intuitive interfaces and simplified maintenance procedures enhance the overall user experience.

Emerging Trends and Innovations in Solvent Cleaning Technology

1. Bio-Solvents and Sustainable Formulations:

Bio-derived solvents are gaining traction due to their lower environmental impact. These solvents are often made from renewable resources like plant-based oils and offer comparable cleaning performance to traditional options. Additionally, advancements in Solvent Formulations are leading to the creation of high-performance, low-VOC cleaning solutions.

2. Precision Cleaning and Automation:

The future of solvent cleaning lies in precise cleaning techniques. Technologies like Ultrasonic Cleaning and micro-degreasing offer targeted cleaning power, minimizing solvent usage and ensuring critical components are spotless. Furthermore, automation is playing a significant role in streamlining cleaning processes. Robotic systems can handle repetitive tasks, improving consistency and worker safety.

3. Closed-Loop Systems and Solvent Recovery:

Minimizing solvent waste is a key focus. Closed-loop systems allow for the recovery and distillation of used solvent, reducing environmental impact and lowering operational costs. Additionally, advancements in filtration technologies are improving the efficiency of solvent cleaning processes.

4. Data-Driven Cleaning and Predictive Maintenance:

The integration of sensors and data analytics into solvent cleaning systems is fostering a data-driven approach to cleaning. Real-time monitoring of solvent levels, temperature, and cleaning cycles allows for process optimization and predictive maintenance. This can help prevent downtime and ensure consistent Cleaning Performance.

How the Minio 85C Addresses the Future of Solvent Cleaning

The Minio 85C, a revolutionary solvent cleaning system from Ecoclean India, exemplifies the future of solvent cleaning. Here’s how it addresses the key trends we’ve discussed:

Sustainable Cleaning: The Minio 85C is compatible with a wide range of cleaning solvents, including bio-solvents and low-VOC formulations. This allows manufacturers to choose eco-friendly options without compromising cleaning performance.

Efficiency and Automation: The system boasts a compact design with an integrated ultrasonic cleaning stage, ensuring a fast and thorough cleaning process. The user-friendly control panel allows for programmable cleaning cycles, optimizing solvent usage and reducing labor costs.

Operator Safety and User Experience: The Minio 85C prioritizes operator safety with a closed-loop distillation system that minimizes solvent exposure. Additionally, the intuitive interface and easy-to-maintain design enhance the overall user experience.

Data-Driven Cleaning: The Minio 85C can be equipped with optional sensors to monitor solvent levels, temperature, and cleaning cycles. This data can be used to optimize cleaning processes and identify potential maintenance needs.

Conclusion: A Clean Future with the Minio 85C

The future of solvent cleaning is bright, driven by a commitment to efficiency, sustainability, and user safety. The Minio 85C from Ecoclean India embodies these values, offering a versatile, eco-friendly, and user-centric solution for a wide range of cleaning applications. By embracing these advancements, manufacturers can achieve a clean future while maintaining optimal production efficiency.

Visit our website page to learn more about the Minio 85C and how it can revolutionize your solvent cleaning processes: https://ecoclean-india.com/products/minio-85c/

Ecoclean Indiais committed to providing innovative and sustainable solutions for the cleaning industry. Contact us today to discuss your specific cleaning requirements.

1 note

·

View note

Text

PEMAC Projects specializes in designing and manufacturing a wide range of machinery and plants for the edible oil refinery plant in India. Our offerings include Acid Oil Plants splitting, Bleaching vessels, Bakery shortening, Cotton seed cleaning machinery, Continuous dry fractionation systems, Continuous solvent extraction plants, and Dry fractionation plants. We are renowned as leading Solvent Extraction Machinery and Solvent Extraction Plant manufacturers in India. Our expertise extends to Fat splitting processes, Lecithin plants, MCT oil extraction processes. With a focus on quality and efficiency, we provide solutions for Neutralizing & Degumming as well as complete edible oil refinery plants in Maharashtra. Pemac Projects expertise in Soybean oil refinery which includes comprehensive soybean oil processing, from soybean seed preparation to the complete soybean oil refinery plant, ensuring efficient and high-quality oil production.

#business#small business#industry#solvent extraction machineries#solvent extraction plant#edible oil#edible oil refinery

1 note

·

View note

Text

Learn essential waste management practices for chemical manufacturing from A-Gas Electronic Materials. This guide covers waste minimisation, segregation, recycling, safe storage, and compliance. Enhance sustainability and efficiency in your operations.

#waste management#chemical manufacturing#waste minimisation#waste segregation#recycling#safe storage#regulatory compliance#hazardous waste#solvent recovery#A-Gas Electronic Materials#UK#sustainability#industrial waste#chemical waste disposal#waste treatment#environmental regulations

0 notes

Text

Vinyl solent inks with excellent print quality and long lasting performace

Super Traders India: Signage industry for businesses promotion

Vinyl solent inks with excellent print quality and long lasting performace available at Super Traders India. Vinyl inks have good resistance to petrol and alcohol. The ink can be used on coated polyester and metal, cellulose acetate, acrylics and polycarbonates. Vinyl inks are great for printing onto Powder coated metals. Vinyl inks are designed for printing onto most types of rigid, flexible and limp PVC.

#Solvent ink#vinyl ink#excellent print quality#business poster#durable and vibrant color#long lasting performance#display boards#business promotion#Super Traders India#Super Traders#Sigagne industry

2 notes

·

View notes

Text

Leading Solvent Drying Systems Manufacturer & Supplier - Kerone

Discover high-quality solvent drying systems crafted by Kerone Engineering Solutions Ltd. We are a trusted manufacturer and supplier, offering innovative solutions for efficient solvent drying processes. Explore our range for reliable and tailored solutions. If you want to buy Industrial heating, drying and coating equipments online from India, you are right place….. Contact us today for all your industrial needs. For more detail visit at our website: https://www.kerone.in/ P.H: +91-22-48255071 / 72 Enquiry: https://www.kerone.in/contact/ Email-Id : [email protected],[email protected]

0 notes

Text

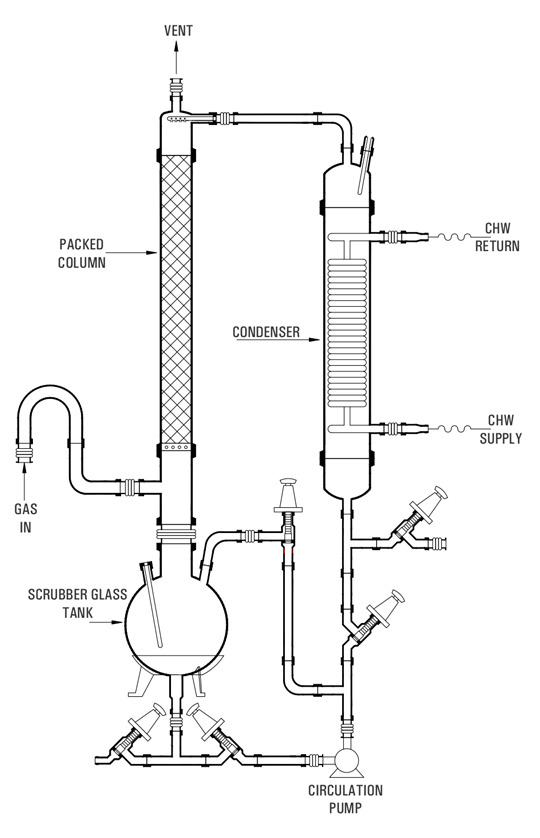

Best Solvent Recovery manufacturer & dealers | Goel Scientific | Canada

We serve Best Solvent Recovery, Solvent Recovery price, Heating And Cooling, Mixing And Stirring, Vacuum And Pressure, Cleaning, Solvent Recovery manufacturing company, industry, equipments, Distributors, Dealers, Wholesalers, Manufacturers, in canada, Goel Scientific Glass Works Ltd, Canada

#Buy Solvent Recovery#Solvent Recovery price#Heating And Cooling#Mixing And Stirring#Vacuum And Pressure#Cleaning#Solvent Recovery manufacturing company#industry#equipments#Distributors#Dealers#Wholesalers#Manufacturers#in canada#Goel Scientific Glass Works Ltd#Canada

0 notes

Text

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐂𝐥𝐞𝐚𝐧𝐢𝐧𝐠 𝐒𝐨𝐥𝐯𝐞𝐧𝐭𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬: 𝐓𝐫𝐞𝐧𝐝𝐬 𝐚𝐧𝐝 𝐆𝐫𝐨𝐰𝐭𝐡 𝐎𝐩𝐩𝐨𝐫𝐭𝐮𝐧𝐢𝐭𝐢𝐞𝐬 𝗚𝗲𝘁 𝗺𝗼𝗿𝗲 𝗶𝗻𝗳𝗼 𝘄𝗶𝘁𝗵 𝗣𝗗𝗙 𝗕𝗿𝗼𝗰𝗵𝘂𝗿𝗲: https://bit.ly/49ZHtf9 One of the major reasons making an positive outlook for the industrial cleaning solvents market is the fast industrial development, mounting demand from end-use industries for cleaning applications, and hygiene initiatives at place of work. Also, the mounting demand of bio-derived and green industrial cleaning solvents is pushing the market. Due to these reasons, the consumption of industrial cleaning solvents is grown significantly. Industrial Cleaning Solvents Market worth $1.4 billion with CAGR of 4.3% by 2028

#industrial cleaning solvents market report#industrial cleaning solvents industry report#industrial cleaning solvents market#industrial cleaning solvents market size#industrial cleaning solvents market share#industrial cleaning solvents market trends#industrial cleaning solvents market growth#industrial cleaning solvents market analysis

1 note

·

View note