#acid dyes

Explore tagged Tumblr posts

Text

Looking at buying my first acid dye kit and want to find something that let's me do immaculate jewel tones and maybe some earth tones.

Anyone able to suggest a brand or specific kit that offers that kind of range?

#I've dyed with food colouring before but it is so fiddly and I am not about that#dyeing#acid dyes#knowledge seeking#craftblr#makeblr#wool

66 notes

·

View notes

Text

Love dyeing yarn. Love mixing up my little potions. Love making things from yarn I dyed from mixing up little potions.

I want to eat you up.

8 notes

·

View notes

Text

tour de fleece day five

ply two of sock yarn: done. no picture, because day after day of bobbins that all look alike seems silly--and the lighting in my bedroom isn't great, especially at midnight.

rolags made: two. haven't tried to spin them yet, so not sure how good they are. i feel like i always get unexpectedly bunched up spots, but i guess that's why i'm going this.

dye; i'm meant to do a dye of a bright or bold colour, which i rarely do, but i did it! an entire 200g, no added grey! i mean, ok, it was on a natural Merino nice that was white and grey, but that's for depth of colour.

photos aren't great, because my phone washes out red tones something horrible, but please know that in person, this yarn is a gorgeous purple with hints of pink and blue.

current household status: running out of shower space. the fibre was only about 90% dry when i photographed it, but we had a bit of sun, so i figured it was worth it. unfortunately, that means the shower—a cat-proof box—still looks like this:

29 notes

·

View notes

Text

dyearies: g&s dye triangle

project code, for future reference: g&s-601-620-624-t5-v1

since i'm planning a 'do you love the color of the sky?' scarf, and need to dye some wool accordingly, and am being a responsible dyer, i spent my weekend dyeing up a color triangle.

STEP 1: locate your dyes

i'm using g&s 601 (yellow), 620 (fuchsia), and 624 (turquoise). for acid, i used white vinegar.

STEP 2: plan your triangle

i decided to go for a 15-piece triangle (5 by 5, i guess? although it's an equilateral triangle so who knows). each bundle of wool will be dyed at 1% (10 mL stock solution = 0.1 g dye, ratio to 10 g fiber), with varying percentages of turquoise, fuchsia, and yellow (in increments of 25%).

STEP 3: make mini wool bundles

i separated 1.5 skeins (?) of knitpicks stroll roving into 10 g bundles. to do this, i divided the 100 g skein into 8, then stripped and redistributed until i had bundles of 10 g each.

little bit janky, but it works, and that's what matters, right?

STEP 4: mix stock solutions

y'all don't get pictures of this because i was busy leaning into the mad science aesthetic with mask + goggles + coat + gloves + most importantly, no phones.

the original plan was to do 1% stock solutions (1 g of dye in 100 mL water). that was the plan until i mixed up my measurements and added 1 cup to my stock instead of to my dyebaths. for various reasons -- a) i was too lazy to multiply quantities by 2.5, and b) there was no way i was getting granularities smaller than 0.5 mL with the equipment i have -- i switched course and added 300 mL (total) water to each stock solution, thereby attaining 0.33% stock solutions.

(i can feel all my science teachers of years past glaring holes into my brain. i was gonna just say 'chemistry profs', but then i realized even my middle school general science teachers are probably crying right now.)

STEP 5: form the triangle

i filled 15 containers with 1 cup of water each. then, i added dye to each cup, according to the triangle plan diagram above (tripled from the earlier diagram to make up for the accidental dilution situation).

STEP 6: add the wool

added the wool to the cold dyebaths. pretty self-explanatory.

STEP 7: set the dye

added 1 tsp vinegar to each bath and stirred. then, i set it all by cooking the jars bain-marie style for 20 minutes.

i heated them in groups of 2-4 because i only had 4 jars. and then 3, because i shattered one by shocking it in cold water. oops.

numbering each sample from 1-15, going from top to bottom and left to right (per the rl images, not the diagrams that i'm too lazy to fix), the groups were as follows:

1, 8, 11, 15

2, 6, 9

3, 5, 7

4, 10, 13

12, 14

i grouped them so that similar colors would be separate and i would be able to tell them apart later.

anyways, after the water ran (mostly) clear, i washed them and left them to air dry.

i'm planning to spin a few samples to keep, and then make the rest into a gradient yarn or something.

based on this experiment, i'm going to try dyeing a few more 10 g samples with attempts at formulas for the colors of the sky. we'll see how that goes...

#dyeing#craftblr#wip#p: do you love the colour of the sky?#p: g&s dye triangle#acid dyes#color triangle#long post

16 notes

·

View notes

Text

Why Dyes and Pigments are Essential for Paper Coloring and Finishing

Most people have wondered how the sheets of paper acquire their beautiful colors or why certain sheets are glossy and vibrant, while others look so plain. The answer lies in the magic of dyes and pigments. These colorants are the heart of the paper industry, making sure that everything from packaging and books to decorative and specialty papers looks exactly how it’s supposed to. Let’s take a closer look at why they matter so much and how they make a difference.

What Exactly are Dyes and Pigments?

Dyes are like a liquid that seeps into the fibers of the paper. Because they are soluble, they spread evenly, creating bright, bold, and consistent colors. Imagine some highly colored pages of magazines or colored wrapping papers; those often use dyes. Examples of such dyes are acid dyes, direct dyes, and reactive dyes.

Pigments, on the other hand, are tiny particles that coat the surface of the paper. They are not soluble, so they sit on top and create a layer of color. Pigments are ideal for papers that require durability, have a luxuriant opacity, or can be fade-resistant, such as high-quality cardstocks or coated paper.

Why Are Dyes and Pigments So Important?

It’s hard to imagine the paper industry without dyes and pigments. They’re not just about making paper look good; they serve many purposes that are crucial for different types of paper.

1. They make Paper look Attractive

First impressions matter, and when it comes to paper, color plays a huge role. Bright, consistent colors can make packaging pop, stationery more elegant, or decorative papers stand out.

Dyes, like acid dyes and reactive dyes, penetrate deep into the fibers, making the colors vibrant and uniform. This is why they are often used in things like decorative paper or specialty applications.

Pigments are excellent for surface coloring and adding opacity. If you’ve ever noticed the bold look of coated papers or high-quality cardstocks, that’s pigments doing their job.

2. They Help Customize Paper for Different Uses

Each paper type is meant to fulfill a specific purpose, and dyes and pigments help modify it for that.

Packaging papers need colors that are durable and fade resistant, so pigments are commonly used here.

Writing and printing papers use direct dyes because they provide even coloring and are easy to print on.

Specialty papers, such as those used for currency, security documents, or high-end decorative purposes, require unique combinations of dyes and pigments for their specific needs.

3. They Add Functional Benefits

Colorants do more than just add beauty. They also enhance the functionality of paper.

UV Resistance: Some pigments, especially inorganic pigments, protect paper from fading in the sunlight. This is important for outdoor applications or items like posters and banners.

Water Resistance: Some dyes and pigments make paper resistant to moisture, which is useful for things like outdoor signage or packaging.

Better Printability: By improving the surface properties of paper, dyes and pigments help ensure that ink adheres properly and printing looks crisp and clear.

Types of Dyes Used in the Paper Industry

The paper industry uses different types of dyes depending on the application. The following are some of the most common ones:

1. Acid Dyes

These are known for their bright, vivid colors.

They are typically used for decorative and specialty papers where eye-catching colors are a must.

2. Direct Dyes

They go well through the fibers and give even and smooth coloring. Direct dyes are very good for this.

These are commonly used in writing and printing papers.

3. Reactive Dyes

Reactive dyes bond strongly with the fibers, making colors more vibrant and long-lasting.

These are ideal for high-quality and specialty papers.

Explore the detailed comparison between direct dyes and reactive dyes, uncovering their unique properties, applications, and benefits to help you choose the right option for your needs.

Types of Pigments Used in the Paper Industry

Just like dyes, there are different types of pigments, each with unique properties.

1. Organic Pigments

These are made from carbon-based molecules and offer vibrant colors.

However, they’re not as durable as inorganic pigments.

2. Inorganic Pigments

Made from minerals or metals, inorganic pigments are known for their durability and opacity.

Examples include titanium dioxide which gives a bright white finish and iron oxides used for earthy tones.

Shifting Towards Eco-Friendly Solutions

The paper industry is becoming more aware of its environmental impact, and many companies are now switching to sustainable practice.

Low-impact dyes: These use less water and fewer chemicals during production.

Eco-friendly pigments: These provide the same quality but with a smaller environmental footprint.

Companies are constantly working to create products that are both high-performing and sustainable. This shift not only helps the environment but also meets the growing demand for greener options in the market.

Read, how Meghmani’s commitment to sustainability drives innovation practices, eco-friendly solutions, and responsible manufacturing to create a greener future.

How Meghmani Global Supports the Paper Industry

When it comes to dyes and pigments, Meghmani Global is a trusted name. We offer innovative solutions for the paper industry, helping manufacturers create products that are high in quality, performance, and sustainability.

Wrapping Up

At the end of the day, dyes and pigments are the backbone of the paper industry. They don’t just add color; they make paper more functional, durable, and versatile. Whether it’s acid dyes, reactive dyes, or inorganic pigments, these colorants meet all kinds of needs. As the industry shifts toward greener practices, companies like Meghmani Global are leading the way with innovative, eco-friendly solutions. For more information, feel free to contact us.

#dyes#pigments#paper industry#acid dyes#reactive dyes#direct dyes#organic pigments#inorganic pigments#paper coloring#paper finishing#paper manufacturing#dyes for paper#pigments for paper

0 notes

Text

5/10.2024 (3) - had to use the fluorescent pink dye color, with a few little orange accents.

0 notes

Text

Explore the vibrant world of acid dyes with Duorganics. Uncover the properties and classification of these dynamic colorants that elevate your creative projects. From vivid hues to versatile applications, discover the art and science of acid dyes at Duorganics.

0 notes

Text

That roving is going to look gorgeous spun up! Cannot wait to see those results (I would be so tempted to add some sparkle filament myself... Ugh so gorgeous!)

Oh yeah did I ever post this? I dyed some yarn and fiber on friday

I put them in the pan with a low covering of water, then sprinkled dye powder on them and distrubuted it around with my fingers. Then threw it in a 300°F oven for 30 minutes (you have to out it in a cold oven and heat it slowly to avoid felting) The roving got mostly saturated but a bit felted. The yarn had white spots on the backside and a couple slightly felted spots.

I'm still perfecting my oven dyeing technique. Going to try 280°F next time. But throwing yarn in the oven is so many less spoons than dyeing on a stovetop where you have to keep monitoring it and I have chronic fatigue so I'm Gonna figure it out.

Oh right I put in the image ID but y'all probably wouldn't notice that but these are Jacquard acid dyes in colorways neon orange, hot fuchsia, vivid violet, turquoise, and chartreuse. Eye searing colors my beloved.... plan is to spin the roving and then ply with something black. I didn't actually measure the weight of the roving cuz the batteries in my regular scale are dead.

164 notes

·

View notes

Text

Dyed some fabric for the snail plushie

The yellow one is for the body, the pink for the house/shell. There is also a blue one that still needs to cool down, to have the shell blue/pink striped

619 notes

·

View notes

Text

the way these unitards are ALREADY faded to shit is crazyyyy where is their color going

#WHY IS MUNGOJERRIE BLACK AND WHITE AND WHY IS TUGGERS BIB SILVER WHAT IS HAPPENING TO THE ACID DYE#negativity#cats the musical#either they fucked up in the dying process or theyre fucking up in the washing process somehow#acid dye isnt supposed to fade when washed at least not this quickly what is happening over there

54 notes

·

View notes

Text

Craft Notes 9/1/2024

Greetings! Yay, it’s a new month so I am starting several new projects today!

First off I am going to start 2 new recycled denim quilts with my sister’s old jeans. I will be using the blankets to either stuff or back the blankets.

I am starting a new pair of socks with a pattern that I designed myself in my sister’s memory.

I’m also planning on knitting a pair of socks with this yarn but I will wait until the first pair is done.

I’m also planning to start a basic raglan sweater with this Brava yarn.

This month I also would like to set a goal to finish my diamond art kit!

#knitting#knitblr#knitters of tumblr#knit picks#knit picks yarn#yarnblr#jacquard acid dyes#knit picks brava#sewing#denim quilts#quilting#recycled denim#recycled crafts

7 notes

·

View notes

Text

Fibre dyers, which dharma dyes give you the best spectrum of jewel tones?

I just got Too Much Wool back from the mill and now I need to pick out dyes

24 notes

·

View notes

Text

I do not have the patience required for dyeing yarn. Dry. Faster. Gawd.

0 notes

Text

INCREDIBLY tempted to change plans re: dyeing my handknit sweater and dyeing it a yellow color thats fluorescent under blacklight. man i wish i went to the club. would be a bit weird to show off my knit wool sweater tho 🤔 temperature-wise

#i already bought rit dye but ive heard it washes out pretty quickly or sth :(#so now im RLYYYY eyeing jacquard acid dyes 👀👀👀👀👀 and holy shit theres fluorescent ones#mine

2 notes

·

View notes

Text

how long do y'all keep dye stocks before tossing them?

6 notes

·

View notes

Text

Comprehensive Guide to Different Types of Dyes and Their Chemical Structures

Dyes are integral to industries like textiles, paper, plastics, and leather, providing a diverse palette of colors and properties tailored to specific needs. This guide delves into various dye types, their characteristics, and their chemical structures. Meghmani Global, a prominent manufacturer and supplier of dyes, plays a vital role in delivering sustainable and high-quality dye solutions worldwide.

1. Natural Dyes

Source: Derived from natural substances like plants, minerals, and insects.

Examples: Indigo (from plants), cochineal (from insects).

Applications: Eco-friendly options for textiles, food coloring, and cosmetics.

Chemical Structure: Composed of complex organic molecules like anthraquinones and flavonoids.

Read blog on Different Types of Dyes with Chemical Structure

2. Synthetic Dyes

Source: Produced chemically from petroleum derivatives.

Advantages: Vibrant colors, higher durability, and cost-effectiveness.

Categories: Includes several subtypes such as azo dyes and anthraquinone dyes.

Chemical Structure: Often includes azo groups (-N=N-) or aromatic rings.

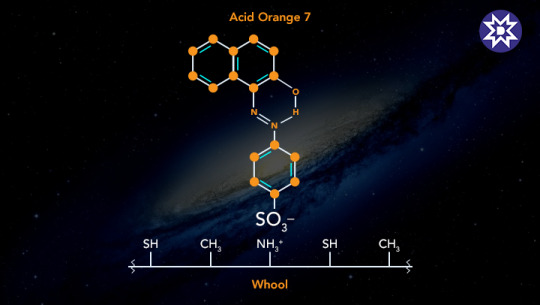

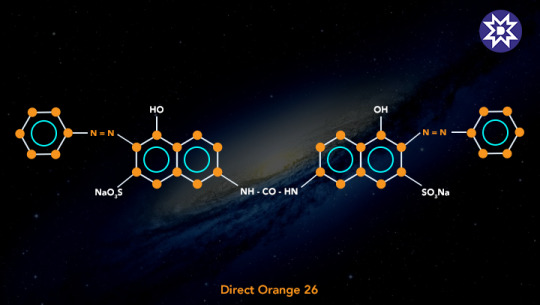

3. Direct Dyes

Features: Water-soluble and directly applied to materials like cotton and rayon.

Usage: Popular for dyeing cellulose fibers due to ease of application.

Chemical Structure: Contain azo or stilbene groups with water-solubilizing sulfonic acid groups.

4. Disperse Dyes

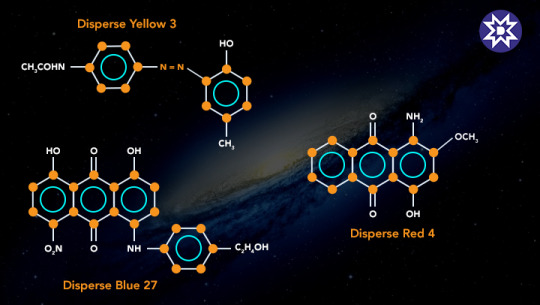

Purpose: Designed for hydrophobic fibers like polyester and acetate.

Mechanism: Submicron particles are dispersed in water and absorbed by fibers under heat.

Applications: Used in textile printing and synthetic fiber dyeing.

Chemical Structure: Non-ionic, often featuring anthraquinone or azo structures.

5. Reactive Dyes

Features: Chemically bond with fibers, offering excellent colorfastness.

Applications: Ideal for natural fibers like cotton and wool.

Advantages: High wash fastness and vibrant shades.

Chemical Structure: Contain reactive groups (e.g., triazine) that form covalent bonds with fibers.

6. Solvent Dyes

Characteristics: Soluble in organic solvents but not water.

Applications: Used in plastics, inks, and petroleum products.

Advantages: Stability and vivid colors for industrial applications.

Chemical Structure: Non-polar molecules with aromatic and azo groups.

Meghmani Global: A Leader in Dye Manufacturing

Meghmani Global specializes in producing a comprehensive range of dyes, including reactive, direct, and solvent dyes. With over 27 manufacturing units and a global presence in 60+ countries, the company is known for its innovative products, sustainable practices, and commitment to quality. Our focus on eco-friendly processes and advanced technologies ensures compliance with international standards while minimizing environmental impact.

Conclusion

Understanding the types of dyes and their chemical structures is essential for optimizing applications in industries. From natural and reactive dyes to solvent and disperse dyes, each type offers unique benefits and uses. Meghmani Global exemplifies leadership in this sector, combining innovation with environmental stewardship to meet diverse market demands.

Get in touch

Email: [email protected]

Contact: 7926812918 | Contact Us

Website: https://www.meghmaniglobal.com/

0 notes