#Shell & Tube

Explore tagged Tumblr posts

Text

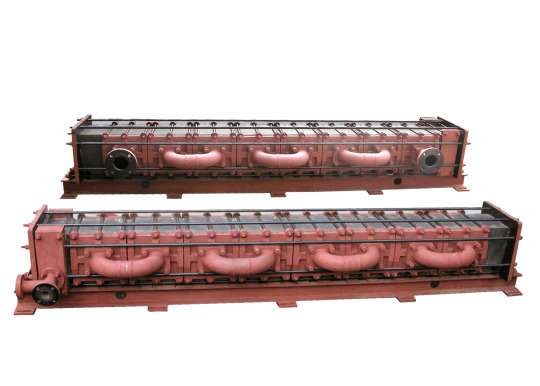

Shell and Tube Heat Exchanger: A Comprehensive Guide

Shell and tube heat exchangers are essential components in thermal processing systems, designed to transfer heat between fluids efficiently. heat exchangers are widely used in oil refining, chemical processing, and power generation industries.

This guide will explore how shell and tube heat exchangers work, their design features, applications, key advantages, and important maintenance considerations to ensure optimal performance and longevity.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a device used to transfer heat between two fluids. It has a large outer shell with several tubes inside. One fluid flows through the tubes, while the other flows around them inside the shell. This design helps exchange heat efficiently. These heat exchanger tubes are widely used because they are effective and can be customized for different needs.

Shell and tube heat exchangers are popular because of their simple design and efficient heat transfer. They work by moving fluid or steam through the shell, which heats the tubes inside. For the best performance, the fluid is usually passed through the tubes four times, which ensures effective heat transfer.

Understanding Shell and Tube Heat Exchanger Design

Shell & tube heat exchanger designs are among the most versatile and widely used devices for heat transfer in industrial processes. Their design, ability to handle high pressures, and adaptability across multiple applications make them a preferred choice in various industries. Let’s delve into their operating principles, key applications, advantages, and maintenance requirements.

Operating Principles of Shell and Tube Heat Exchangers

Shell and tube heat exchangers operate by transferring heat between two fluids. One fluid flows through the tubes (tube side), while the other flows around the tubes inside the shell (shell side). Depending on the flow pattern, these heat exchangers can work in two configurations:

Counterflow: Fluids move in opposite directions, ensuring maximum temperature difference and higher heat transfer efficiency.

Parallel Flow: Fluids flow in the same direction, offering less efficient heat transfer compared to counterflow.

Shell and Tube Heat Exchanger Applications Across Industries

Shell and tube heat exchangers are indispensable in industries due to their ability to manage diverse temperature and pressure conditions. Shell and Tube Heat Exchanger Applications include:

Petrochemical Industry: Vital for refining processes like condensation, distillation, and heating of fluids.

HVAC Systems: Used to regulate air temperature and humidity in heating, ventilation, and air conditioning systems.

Power Generation: Essential in boilers, condensers, and cooling systems for heat transfer between steam and water.

Food Processing: Widely used for pasteurization, sterilization, and cooling in the dairy, beverage, and pharmaceutical industries

Why Choose Shell and Tube Heat Exchangers from Amardeep Steel?

Amardeep Steel is a leading supplier of high-quality shell and tube heat exchangers designed to meet the diverse needs of industries worldwide. With expertise in manufacturing and sourcing premium materials, Amardeep Steel ensures durability, efficiency, and performance in every product. Whether you need custom-built designs or standard configurations, their solutions cater to all industrial requirements.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of shell and tube heat exchangers:

Regular Cleaning: Prevents fouling and maintains heat transfer efficiency.

Inspect Tubes Regularly: Check for leaks, corrosion, or damage to avoid system failures.

Monitor Performance: Keep track of temperature differentials and flow rates to identify and address issues early.

Conclusion

Shell and tube heat exchangers are vital for efficient heat transfer in numerous industries. With their durability, adaptability, and high performance, they are a reliable solution for complex thermal processes. For premium-quality heat exchangers and exceptional service, shell and tube heat exchanger manufacturers trust Amardeep Steel, a leader in delivering solutions to meet your industrial needs.

0 notes

Text

Happy 7th anniversary Alternate Reality Show!!

#last post was ii12 next post is ii12 youre on the ii12 account now#genuinely this episode means the world to me and rewatching it again today made me cry#yay!#lightbulb is my favorite charracterrr#lightbulb ii#test tube ii#inanimate insanity#kumquat ii#hay bale ii#shell ii#testbulb

290 notes

·

View notes

Text

fabtube might not be the ii relationship im most invested in (except episode 14 the writing for them in that episode was PHENOMENAL) but when fan was rambling about his theories and then realized he was about to be deleted. and just 100% immediately accepts his fate. he looks so calm and sad and at peace and he says "....see you test tube" knowing that the only thing he wanted in the afterlife was test tube. his best friend since day one the person who understands him more than anyone else in the world and that relationship was something they actively chose. that shit was SO SAD genuinely one of the saddest scenes in the entire finale for me. Why'd he say it like that

#txt#inanimate insanity#also “[...] i hope for her sake she never gets there” which was an insane thing to just casually write in a 2nd tier blog no one will read#“even without this shell holding us together we'll still look out for each other”#“yeah things will be different. but thats ok. because we got this :)”#unfortunate to say but i think brian's acting as fan in that scene (the scene mentioned in my actual post but also the one in my tags ig)#was like actually really good..... He may be talented i have to admit#i think a certain amount of test tube and fan's relationship comes from adam and brian's actual relationship since they were like#nerds in middle school putting together an animation club nobody liked LMAO#so there's soo much heart in it and you can really tell sometimes how much they mean to each other#i think i accidentally converted myself to enjoying fantube again lmao

18 notes

·

View notes

Text

i am loving my new seatbelt... my posture is so much better and i'm not slipping down in my chair as much. hopefully it helps with some of the back issues i've been having!

#so glad i figured out how to mount it!#now both my wheelchairs have seatbelts yaaay#next up on repairs/upgrades:#new tires/tubes & spacers & freewheel parts#and MAYBE if i'm lucky i'll be able to find a used rigid&removable backrest for my folding chair#maybe even a new cushion for it...#n e ways if any of you all have a backrest that would fit a 15w chair......#i've been struggling to find any secondhand bc most chairs are 16w or wider and 16w is usually the narrowest setting for adjustable width#that i've seen at least#and i'm not gonna shell out a ton of money for a chair i only use when traveling or at home when i don't wanna get my rigid one inside#tag rant over

7 notes

·

View notes

Text

ull b mine 5ever

#just needs a good clean some tlc shell b as good as new#also got a cute lil american flag tube top ill wear a lot in summer#xoxo#viz

2 notes

·

View notes

Text

some traditional art from autumn :∙)

my current favourite shell (charcoal, on a3 paper)

smth simple after a stressful week , tho im v proud of the results (markers & white gel pen in sketchbook)

and last but not least: capybapy (pencils in sketchbook)

#my art#traditional#i collect shells and rocks. they bring me disproportionate joy#the original paint tube was black btw!!! this kinda colour confoundery is so fun to me#artists on tumblr#illustrators on tumblr#capybara#capybapy

4 notes

·

View notes

Text

me at the lake today looking for water bugs/critters because thats what i enjoy doing most and only after i got home did i realize ... omg.... thats so g.uzmacore..... HFDSJKL

#he lives on a tropical island w so many beaches and he loves bugs. that mfer would love looking for water critters with me !!!!!!#i saw a really weird one though i've literally never seen anything like it#idk how to even begin IDing it fdsjkl#it was like. tube shaped. and mottled? and was crawling along a stick with one end of the tube body#and at the other end it was somehow gripping a little plant stalk or smth#unless the plant stalk was actually part of its body. IT WAS SO WILD.#and it was like. only a centimetre long/tall. maybe 2 cms#SO FUNKY. i was fascinated fdsjkl i wish i'd been able to watch it longer#also i found some cool snail shells and a spiral cone shaped shell!! i didnt know we had spiral cones around here!!#i left all of them there ofc bc theyre good for calcium for wildlife+environment and for some critters to make homes inside of :3#dandy.cmd

2 notes

·

View notes

Text

I managed to get my coffee machine to semi-work, I just had my first cup of coffee in what feels like over a week now, and I feel like I'm reborn as an individual. I know this sounds dramatic, but I promise you it's not. If you know, you'll understand me on so many levels.

#[ ooc. ] don't try to make it logical or edit your soul according to the fashion. rather; follow your most intense obsessions mercilessly.#[ i have friends that drink coffee because they enjoy it. and here i am at 34 going 'no. i'm a shell of myself without it'. ]#[ but also i thoroughly enjoy a cup or two of nice coffee when i wake up and also after dinner at night. like honestly. ]#[ i'm ridiculous. but i got such insane serotonin from this one cup of coffee. ]#[ but i know the tube will clog up again soon-- so i'm enjoying it even more. ]

8 notes

·

View notes

Text

a new sound, a really different sound, a sound that's made by worms

#shebbz shoutz#shebbz irl#marine worm#serpulid worm#<- i think! they were growing in white tubes inside the empty shell of a dead barnacle. very cool!!!

12 notes

·

View notes

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

2 notes

·

View notes

Text

Shell and Tube Heat Exchanger: An Introduction

Are you familiar with the concept of a heat exchanger? It's a device that transfers thermal energy between two fluids. And if you're particularly interested in this technology, then you've likely come across Shell and Tube Heat Exchangers. These types of heat exchangers have been around for over 150 years, but they're still widely used today due to their effectiveness and reliability. If you're looking to learn more about these amazing machines, then keep reading! This blog post is your definitive guide to the fascinating world of shell and tube heat exchangers - an introduction like no other.

What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a type of heat exchanger that is commonly used in industrial applications. It consists of a shell, which is a large cylindrical vessel, and a bundle of tubes that run through the shell. Heat is transferred between two fluids that flow through the shell and the tubes, respectively.

How Does a Shell and Tube Heat Exchanger Work?

In a shell and tube heat exchanger, the two fluids flow in opposite directions. The fluid that needs to be heated or cooled flows through the tubes, while the other fluid flows through the shell. As the fluids flow through the tubes and the shell, heat is transferred from one fluid to the other through the walls of the tubes.

Types of Shell and Tube Heat Exchangers

There are several types of shell and tube heat exchangers, including:

Fixed Tube Sheet Heat Exchanger: This is the simplest type of shell and tube heat exchanger, where the tube sheet is fixed and cannot be removed.

U-Tube Heat Exchanger: In this type of heat exchanger, the tube bundle is bent into a U-shape, allowing for easy maintenance and cleaning.

Floating Head Heat Exchanger: In a floating head heat exchanger, the tube bundle is removable, making it easy to clean and maintain.

Applications of Shell and Tube Heat Exchangers

Shell and tube heat exchangers are commonly used in a variety of industrial applications, including:

Chemical Processing: Shell and tube heat exchangers are commonly used in chemical processing plants to heat or cool fluids.

Oil and Gas: Shell and tube heat exchangers are used in oil refineries and gas processing plants to transfer heat between fluids.

HVAC: Shell and tube heat exchangers are used in HVAC systems to transfer heat between air and water.

Advantages of Shell and Tube Heat Exchangers

Efficient heat transfer

Can handle high-pressure applications

Can handle a wide range of fluids and temperatures

Conclusion

Why use a shell and tube heat exchanger? Shell and tube heat exchangers are an important component in many industrial applications. They provide efficient heat transfer between two fluids, making them ideal for use in chemical processing, oil and gas, and HVAC systems. While they can be expensive to manufacture and install and can be difficult to clean and maintain, the advantages of shell and tube heat exchangers make them a valuable asset in many industrial settings. So, whether you're designing a new industrial process or looking to improve an existing one, consider the benefits of a shell and tube heat exchanger.

4 notes

·

View notes

Text

#i love how different pasta works for different sauces different ingredients#rigatoni is like lots of mini cannellonis (big pasta tubes) that can hold chunky bolognese and creamy sauce really well#cavatelli is like tiny soft taco shells that work well with chopped ingredients and beef stew types#ravioli are parcels of joy ready for sauce#lasagna is shapeless boring crucial queen#🍝#food

7K notes

·

View notes

Text

Top Rated Heat Exchanger Suppliers - Abe & Hex

Heat Exchanger helps transfer heat between fluids, saving energy and improving efficiency. It is easy to maintain and durable. Our heat exchangers are available in various sizes to fit client’s needs. Contact us for more details!

0 notes

Text

Air Cooled Heat Exchanger Manufacturers in India

We are designed and developed the #aircooledheatexchanger (ACHE) for various types of application. We are specialized air cooled heat exchanger manufacturer of Thermal Power Plants and also an air cooled heat exchanger is used to cool fluids with ambient air. Air cooled heat Exchangers are same In the Functions of Finned Tube Heat Exchanger. Finned Tubes are most of very significant part of the Heat exchanger which affect the efficiency of the Air Cooled Heat Exchanger.

#air cooled heat exchanger#finned tube heat exchanger#shell and tube heat exchanger#heat exchangers#pressure vessels

0 notes

Text

Efficient Shell & Tube Heat Exchangers | Goel Scientific | Canada

Explore efficient shell and tube heat exchangers from Goel Scientific, engineered for superior performance in industrial applications. Contact us today!

#heat exchanger shell tube in canada#best heat exchanger shell tube in canada#top heat exchanger shell tube in canada#heat exchanger shell tube Manufacture in canada#Industrial Glassware manufacture in USA#best Industrial Glassware manufacture in canada

0 notes

Text

Efficient Cooling with Shell & Tube Heat Exchangers

Discover how shell & tube heat exchangers boost industries' efficiency, durability, and thermal performance. Learn more today!

0 notes