#Sheet metal

Explore tagged Tumblr posts

Note

Sheet metal

#wobble wobble#request#ifitwasediblewouldyoueatit#food poll#poll#random polls#polls#gimmick blog#tumblr blog#tumblr polls#poll time#if it was edible would you eat it?#sheet metal

80 notes

·

View notes

Text

Okay. @superhero-tsukasa-official vs.. sheet metal.

Joke explained:

25 notes

·

View notes

Video

tumblr

Wobbly Metals by frankiejustchillin

#I think I'm a stainless steel girlie but the gloss red aluminum also calls to me#asmr#asmr video#asmr sounds#metal#sheet metal#funny#talking#auditory#auditory stim#stim#stimmy#stimming#oddly satisfying#tiktok#fast

551 notes

·

View notes

Text

do i have facial blindness or are they kinda

#jackie kennedy#am i crazy or#max verstappen#sheet metal#me when theres sheet metal at the function#this is a joke

11 notes

·

View notes

Text

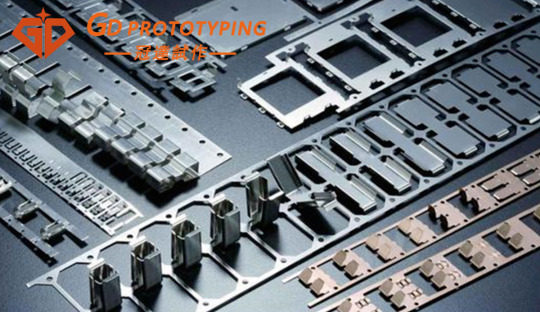

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Text

Vase n.03, known as well as Wiwaxia 03 is a futuristic steel sculpture from Peter von Hauerland. Picture of a dismantled condition.

Single manufactured piece is sold and gets shipped to Switzerland on Monday. You can send me a note on my web www.vonhauerland.com if you would like one too!

Peter.

#art#steel art#metal art#laser cut#steel cut#sheet metal#art object#science fiction art#space art#inspired by sci fi#spacy object#techy decor#table gadget#art decor#futuristic decor

3 notes

·

View notes

Text

Zomboid

5 notes

·

View notes

Text

If one more person thinks club soda and seltzer are the same thing I’m gonna pull a Jackie Kennedy and eat sheet metal

3 notes

·

View notes

Text

SHENCHONG sheet bending follower is working with CNC press brake in our Korea customer's factory. This is a CNC press brake bending follower device that assists workers in turning up during the bending process. Save labor, fast and flexible, mass production. All factories that need to reduce labor intensity and improve production efficiency can use it.

2 notes

·

View notes

Photo

Raspberry House, Münster by Kresings Architektur

images Roman Mensing

4 notes

·

View notes

Text

TAYLOR WANT SHEET METAL

52K notes

·

View notes

Text

Sheet Metal Welding

0 notes

Text

“Barn Burner”

© EricBrazier.com

#barn burner#barns#dusk#golden hour#grass#magic hour#metal roof#orange#particle board#pink#sheet metal#sunset#texture#warm#windows

0 notes

Text

yummy metal

metal is so fucking good I'm eating it

41K notes

·

View notes

Text

What is Sheet Metal Fabrication? Processing Principle and Method

Sheet metal fabrication refers to the processing of sheet metal (usually under 6mm) by shearing, bending, forming, stamping, welding, stretching and other processes.

A broad definition is that the thickness is unchanged in the processing of parts.

1.Processing Principle of Sheet Metal Working

The processing principle of sheet metal working is mainly based on the plastic deformation properties of metal materials. Through the action of external forces, such as stretching, compressing, bending, etc., the shape and size of the sheet metal is changed to achieve the desired shape and structural requirements. This process requires precise calculation and control of the magnitude, direction and point of action of the force to ensure that the sheet metal does not suffer from rupture, folds and other defects during deformation.

2.Processing Method of Sheet Metal Working

Do you know what are the common processing methods for sheet metal fabrication? The following several commonly used processing methods are introduced:

① Single stamping

Metal parts of musical instrument with curved distribution or in the state of pinholes, grids, etc. can be sheet-metal processed by a single stamping, which makes it possible to separate the metal structure and shape the metal product in a short period of time.

② Continuous feeding

This sheet metal processing method can be divided into two types: unidirectional and multidirectional. Of these, the multi-directional blanking method is usually suitable for processing large metal layers or forming large metal holes, while the unidirectional blanking method is suitable for processing multiple metal parts in a stacked state. Different processing results can be achieved by setting different machine angles and functions in the continuous blanking processing mode.

③ Punching material processing

This drop-feed processing method, also known as punch processing, is mainly used to polish and finish the post-processing of sheet metal working parts, which plays a role in precise positioning and fine grinding during sheet metal processing. Usually the processing mill used in this process has small round type, small arc type, etc.

④ Array formation

With the help of CNC machines, this method is often used to meet the needs of mass production sheet metal working. Large sheet metal products can be processed quickly by combining several existing moulds. In this process, the styles and types of sheet metal working products are basically the same, which facilitates the design of templates in the form of arrays.

⑤ Single or multiple continuous processing

On the basis of CNC machine tools, the metal parts to be processed are stretch-formed in a single operation according to the requirements for the selection of the moulds, thus obtaining metal parts that match the existing moulds. However, if the metal part after the above treatment does not meet the desired requirements, it should be machined several times in succession to form the final shape.

Sheet metal fabrication is used in a wide range of applications including but not limited to aerospace, automotive manufacturing, construction, petrochemical, aviation, electronics, electrical appliances and other fields. In addition, sheet metal processes play an important role in vehicle maintenance and repair which are widely used for body damage analysis, measurement, shaping, tensile straightening, stress relief welding, accessory assembly and adjustment.

#sheet metal bending#design#sheet metal design#sheet metal manufacturing#sheet metal fabrication#sheet metal#prototype machining#prototyping#prototype#rapid prototyping

1 note

·

View note