#Sell Electronic Components

Explore tagged Tumblr posts

Text

Sell Electronic Components with Confidence!

Are you dealing with an overstock of electronic components? Our network of reliable buyers at Resion will help you sell electronic components with confidence and convenience. Our primary services are consignment and identification of leftover OEM stocks to create demand for your goods. Partner with us today, and let us show you how you can fully utilize your inventory.

#Electronics Parts Suppliers#Largest Electronic Component Distributor#Sell Electronic components#Electronic Parts Distributor#Proactive Supplier Lifecycle Management

0 notes

Text

there is no ethical consumption under capitalism

Years ago now, I remember seeing the rape prevention advice so frequently given to young women - things like dressing sensibly, not going out late, never being alone, always watching your drink - reframed as meaning, essentially, "make sure he rapes the other girl." This struck a powerful chord with me, because it cuts right to the heart of the matter: that telling someone how to lower their own chances of victimhood doesn't stop perpetrators from existing. Instead, it treats the existence of perpetrators as a foregone conclusion, such that the only thing anyone can do is try, by their own actions, to be a less appealing or more difficult victim.

And the thing is, ever since the assassination of United Healthcare CEO Brian Thompson, I've kept on thinking about how, in this day and age, CEOs of big companies often have an equal or greater impact on the day to day lives of regular people than our elected officials, and yet we have almost no legal way to redress any grievances against them - even when their actions, as in the case of Thompson's stewardship of UHC, arguably see them perpetrating manslaughter at scale through tactics like claims denial. That this is a real, recurring thing that happens makes the American healthcare insurance industry a particularly pernicious example, but it's far from being the only one. Because the original premise of the free market - the idea that we effectively "vote" for or against businesses with our dollars, thereby causing them to sink or swim on their individual merits - is utterly broken, and has been for decades, assuming it was ever true at all. In this age of megacorporations and global supply chains, the vast majority of people are dependent on corporations for necessities such as gas, electricity, internet access, water, food, housing and medical care, which means the consumer base is, to all intents and purposes, a captive market. We might not have to buy a specific brand, but we have to buy a brand, and as businesses are constantly competing with one another to bring in profits, not just for the company and its workers, but for C-suites and shareholders - profits that increasingly come at the expense of workers and consumers alike - the greediest, most inhumane corporations set the financial yardstick against which all others are then, of necessity, measured. Which means that, while businesses are not obliged to be greedy and inhumane in order to exist, overwhelmingly, they become greedy and humane in order to compete, because capitalism encourages it, and because there are precious few legal restrictions to stop them from doing so. At the same time, a handful of megacorporations own so many market-dominating brands that, without both significant personal wealth and the time and resources to find viable alternatives, it's all but impossible to avoid them, while the ubiquity of the global supply chain means that, even if you can keep track of which company owns which brand, it's much, much harder to establish which suppliers provide the components that are used in the products bearing their labels. Consider, for instance, how many mainstream American brands are functionally run on sweatshop labour in other parts of the world: places where these big corporations have outsourced their workforce to skirt the already minimal labour and wage protections they'd be obliged to adhere to in the US, all to produce (say) electronics whose elevated sticker price passes a profit on to the company, but without resulting in higher wages for either the sweatshop workers overseas or the American employees selling the products in branded US stores.

When basically every major electronics corporation is engaged in similar business practices, there is no "vote" our money can bring that causes the industry itself to be better regulated - and as wealthy, powerful lobbyists from these industries continue to pay exorbitant sums of money to politicians to keep government regulation at a minimum, even our actual votes can do little to effect any sort of change. But even in those rare instances where new regulations are passed, for multinational corporations, laws passed in one country overwhelmingly don't prevent them from acting abusively overseas, exploiting more desperate populations and cash-poor governments to the same greedy, inhumane ends. And where the ultimate legal penalty for proven transgressions is, more often than not, a fine - which is to say, a fee; which is to say, an amount which, while astronomical by the standards of regular people, still frequently costs the company less than the profits earned through their unethical practices, and which is paid from corporate coffers rather than the bank accounts of the CEOs who made the decisions - big corporations are, in essence, free to act as badly as they can afford to; which is to say, very. Contrary to the promise of the free market, therefore, we as consumers cannot meaningfully "vote" with our dollars in a way that causes "good" businesses to rise to the top, because everything is too interconnected. Our choices under global capitalism are meaningless, because there is no other system we can financially support that stands in opposition to it, and while there are still small businesses and companies who try to operate ethically, both their comparative smallness and their interdependent reliance on the global supply chain means that, even if we feel better about our choices, we're not exerting any meaningful pressure on the system we're trying to change. Which means that, under the free market, trying to be an ethical consumer is functionally equivalent to a young woman dressing modestly, not going out alone and minding her drink at parties in order to avoid being raped. We're not preventing corporate predation or sending a message to corporate predators: we're just making sure they screw other worker, the other consumer, the other guy.

All of which is to say: while I'd prefer not to live in a world where shooting someone dead in the street is considered a valid means of redressing grievances, what the murder of Brian Thompson has shown is that, if you provide no meaningful recourse for justice against abusive, exploitative members of the 1%, then violence done to those people will have the feel of justice, because it fills the void left by the lack of consequences for their actions. It's the same reason why people had little sympathy for the jackass OceanGate CEO who killed himself in his imploding sub, or anyone whose yacht has been attacked by orcas - it's just intensified here, because where the OceanGate CEO was felled by hubris and the yachts were random casualties, whoever killed Thomspon did so deliberately, because of what he did. It was direct action against a man whose policies very arguably constituted manslaughter at scale; a crime which ought to be a crime, but which has, to date, been permitted under the law. And if the law wouldn't stop him, can anyone be surprised that someone might act outside the law in retaliation - or that regular people would cheer for them when they did?

3K notes

·

View notes

Text

Does anyone remember what happened to Radio Shack?

They started out selling niche electronics supplies. Capacitors and transformers and shit. This was never the most popular thing, but they had an audience, one that they had a real lock on. No one else was doing that, so all the electronics geeks had to go to them, back in the days before online ordering. They branched out into other electronics too, but kept doing the electronic components.

Eventually they realize that they are making more money selling cell phones and remote control cars than they were with those electronic components. After all, everyone needs a cellphone and some electronic toys, but how many people need a multimeter and some resistors?

So they pivoted, and started only selling that stuff. All cellphones, all remote control cars, stop wasting store space on this niche shit.

And then Walmart and Target and Circuit City and Best Buy ate their lunch. Those companies were already running big stores that sold cellphones and remote control cars, and they had more leverage to get lower prices and selling more stuff meant they had more reasons to go in there, and they couldn't compete. Without the niche electronics stuff that had been their core brand, there was no reason to go to their stores. Everything they sold, you could get elsewhere, and almost always for cheaper, and probably you could buy 5 other things you needed while you were there, stuff Radio Shack didn't sell.

And Radio Shack is gone now. They had a small but loyal customer base that they were never going to lose, but they decided to switch to a bigger but more fickle customer base, one that would go somewhere else for convenience or a bargain. Rather than stick with what they were great at (and only they could do), they switched to something they were only okay at... putting them in a bigger pond with a lot of bigger fish who promptly out-competed them.

If Radio Shack had stayed with their core audience, who knows what would have happened? Maybe they wouldn't have made a billion dollars, but maybe they would still be around, still serving that community, still getting by. They may have had a small audience, but they had basically no competition for that audience. But yeah, we only know for sure what would happen if they decided to attempt to go more mainstream: They fail and die. We know for sure because that's what they did.

I don't know why I keep thinking about the story of what happened to Radio Shack. It just keeps feeling relevant for some reason.

34K notes

·

View notes

Text

The supply chain capitalism of AI. This image partially captures the supply chain of AI as a global and complex phenomenon. Natural resources, components and materials to build AI infrastructure are extracted, shipped, manufactured and produced across the globe. For instance, NVIDIA obtains tungsten from Brazil; gold from Colombia and tantalum from Kazakhstan. Minerals are assembled to manufacture GPUs by TSMC. NVIDIA sells GPUs across data centres in the world. Given the refresh rates of these materials, data centres sent their components to recycle plants or dumps. The human labour wrapped-up in this chain includes, data labellers, logistics drivers, data scientists, miners, data centre operators and electronic waste dismantlers, who are also scattered across different geographies. Source: NVIDIA (2022) and fieldwork.

The supply chain capitalism of AI: a call to (re)think algorithmic harms and resistance through environmental lens

432 notes

·

View notes

Text

Ok so you're looking at the aftermath of Helene and you're thinking "shit, how would I keep my phone charged? What about my neighbors?" and you have some outdoor space and some cash. Your friendly formerly off grid sheep farmer is here to help.

You need this set up right here:

To that you will need to add:

Y connectors:

The 100aH (amp Hour) deep cycle battery of your choice - lead acid AGM will be cheaper, lithium (LiFePo) is more expensive but lasts much longer.

Finally, you need a small pure sine wave inverter like this one: https://a.co/d/70vRd79

Plug the panels into the Y connectors then into the single wire to run to the charge controller. They are now connected in parallel. Take them outside to a sunny spot and face them south and prop them up at about a 45 degree angle. This isn't perfect but it will be good enough.

Connect your battery and charge controller. Connect the panels to the charge controller. All of the places to do this are labeled and all you need is a Phillips screwdriver. I recommend doing it once in a non-disaster situation so you know you can do it but you'll be fine. Boom, you are getting electricity from the sun!

The inverter draws power even when it's not running so don't leave it hooked up when you're not using it. When someone needs to charge their phone, put those alligator clips on the matching color battery posts, turn the inverter on, and plug in the phone/radio. Voilà! A single 100aH battery is not going to run a bunch of things but it will help keep cell phones charged without using up the gas in your car.

The panels are weatherproof but everything else needs to be protected by the way so you'll need to set this up in a shed or garage or in the house. Lead acid batteries can produce hydrogen gas when being charged but just having one isn't a big risk.

FAQ:

Yes, you can permanently mount the panels to your roof if you own your home etc. They're designed for that!

It is true that places sell "solar generators" - those are a charge controller, battery, and an inverter in one box at a very high price point. When a component goes bad you will be unable to replace the component and must replace the entire $1000 box. They are also not upgradeable or expandable, this is.

You do not have to buy Renogy, I recommend them because they kept me in electricity for the years I was off grid.

You do not have to buy the kit, you can buy the components of it as and when you can afford them!

Remember to keep your battery on a trickle charger.

409 notes

·

View notes

Text

High tariffs become 'real' with our first $36K bill

We're no stranger to tariff bills, although they have definitely ramped up over the last two months. However, this is our first 'big bill', where a large portion was subjected to a 125%+20%+25% import markup. Unlike other taxes like sales tax where we collect on behalf of the state and then submit it back at the end of the month, or income taxes, where we only pay if we are profitable, tariff taxes are paid before we sell any of the products and are due within a week of receipt which has a big impact on cash flow.

In this particular case, we're buying from a vendor, not a factory, so we can't second-source the items (and these particular products we couldn't manufacture ourselves even if we wanted to, since the vendor has well-deserved IP protections). And the products were booked & manufactured many months ago, before the tariffs were in place. Since they are electronics products/components, there's a chance we may be able to request reclassification on some items to avoid the 125% 'reciprocal' tariff, but there's no assurance that it will succeed, and even if it does, it is many, many months until we could see a refund.

We'll have to increase the prices on some of these products, but we're not sure if people will be willing to pay the higher cost, so we may well be 'stuck' with unsellable inventory that we have already paid a large fee on.

164 notes

·

View notes

Text

Apple fucked us on right to repair (again)

Today (September 22), I'm (virtually) presenting at the DIG Festival in Modena, Italy. Tonight, I'll be in person at LA's Book Soup for the launch of Justin C Key's "The World Wasn’t Ready for You." On September 27, I'll be at Chevalier's Books in Los Angeles with Brian Merchant for a joint launch for my new book The Internet Con and his new book, Blood in the Machine.

Right to repair has no cannier, more dedicated adversary than Apple, a company whose most innovative work is dreaming up new ways to sneakily sabotage electronics repair while claiming to be a caring environmental steward, a lie that covers up the mountains of e-waste that Apple dooms our descendants to wade through.

Why does Apple hate repair so much? It's not that they want to poison our water and bodies with microplastics; it's not that they want to hasten the day our coastal cities drown; it's not that they relish the human misery that accompanies every gram of conflict mineral. They aren't sadists. They're merely sociopathically greedy.

Tim Cook laid it out for his investors: when people can repair their devices, they don't buy new ones. When people don't buy new devices, Apple doesn't sell them new devices. It's that's simple:

https://www.inverse.com/article/52189-tim-cook-says-apple-faces-2-key-problems-in-surprising-shareholder-letter

So Apple does everything it can to monopolize repair. Not just because this lets the company gouge you on routine service, but because it lets them decide when your phone is beyond repair, so they can offer you a trade-in, ensuring both that you buy a new device and that the device you buy is another Apple.

There are so many tactics Apple gets to use to sabotage repair. For example, Apple engraves microscopic Apple logos on the subassemblies in its devices. This allows the company to enlist US Customs to seize and destroy refurbished parts that are harvested from dead phones by workers in the Pacific Rim:

https://repair.eu/news/apple-uses-trademark-law-to-strengthen-its-monopoly-on-repair/

Of course, the easiest way to prevent harvested components from entering the parts stream is to destroy as many old devices as possible. That's why Apple's so-called "recycling" program shreds any devices you turn over to them. When you trade in your old iPhone at an Apple Store, it is converted into immortal e-waste (no other major recycling program does this). The logic is straightforward: no parts, no repairs:

https://www.vice.com/en/article/yp73jw/apple-recycling-iphones-macbooks

Shredding parts and cooking up bogus trademark claims is just for starters, though. For Apple, the true anti-repair innovation comes from the most pernicious US tech law: Section 1201 of the Digital Millennium Copyright Act (DMCA).

DMCA 1201 is an "anti-circumvention" law. It bans the distribution of any tool that bypasses "an effective means of access control." That's all very abstract, but here's what it means: if a manufacturer sticks some Digital Rights Management (DRM) in its device, then anything you want to do that involves removing that DRM is now illegal – even if the thing itself is perfectly legal.

When Congress passed this stupid law in 1998, it had a very limited blast radius. Computers were still pretty expensive and DRM use was limited to a few narrow categories. In 1998, DMCA 1201 was mostly used to prevent you from de-regionalizing your DVD player to watch discs that had been released overseas but not in your own country.

But as we warned back then, computers were only going to get smaller and cheaper, and eventually, it would only cost manufacturers pennies to wrap their products – or even subassemblies in their products – in DRM. Congress was putting a gun on the mantelpiece in Act I, and it was bound to go off in Act III.

Welcome to Act III.

Today, it costs about a quarter to add a system-on-a-chip to even the tiniest parts. These SOCs can run DRM. Here's how that DRM works: when you put a new part in a device, the SOC and the device's main controller communicate with one another. They perform a cryptographic protocol: the part says, "Here's my serial number," and then the main controller prompts the user to enter a manufacturer-supplied secret code, and the master controller sends a signed version of this to the part, and the part and the system then recognize each other.

This process has many names, but because it was first used in the automotive sector, it's widely known as VIN-Locking (VIN stands for "vehicle identification number," the unique number given to every car by its manufacturer). VIN-locking is used by automakers to block independent mechanics from repairing your car; even if they use the manufacturer's own parts, the parts and the engine will refuse to work together until the manufacturer's rep keys in the unlock code:

https://pluralistic.net/2023/07/24/rent-to-pwn/#kitt-is-a-demon

VIN locking is everywhere. It's how John Deere stops farmers from fixing their own tractors – something farmers have done literally since tractors were invented:

https://pluralistic.net/2022/05/08/about-those-kill-switched-ukrainian-tractors/

It's in ventilators. Like mobile phones, ventilators are a grotesquely monopolized sector, controlled by a single company Medtronic, whose biggest claim to fame is effecting the world's largest tax inversion in order to manufacture the appearance that it is an Irish company and therefore largely untaxable. Medtronic used the resulting windfall to gobble up most of its competitors.

During lockdown, as hospitals scrambled to keep their desperately needed supply of ventilators running, Medtronic's VIN-locking became a lethal impediment. Med-techs who used donor parts from one ventilator to keep another running – say, transplanting a screen – couldn't get the device to recognize the part because all the world's civilian aircraft were grounded, meaning Medtronic's technicians couldn't swan into their hospitals to type in the unlock code and charge them hundreds of dollars.

The saving grace was an anonymous, former Medtronic repair tech, who built pirate boxes to generate unlock codes, using any housing they could lay hands on to use as a case: guitar pedals, clock radios, etc. This tech shipped these gadgets around the world, observing strict anonymity, because Article 6 of the EUCD also bans circumvention:

https://pluralistic.net/2020/07/10/flintstone-delano-roosevelt/#medtronic-again

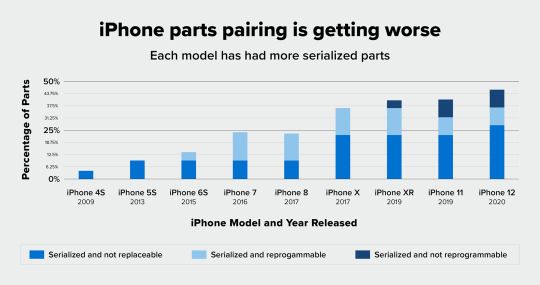

Of course, Apple is a huge fan of VIN-locking. In phones, VIN-locking is usually called "serializing" or "parts-pairing," but it's the same thing: a tiny subassembly gets its own microcontroller whose sole purpose is to prevent independent repair technicians from fixing your gadget. Parts-pairing lets Apple block repairs even when the technician uses new, Apple parts – but it also lets Apple block refurb parts and third party parts.

For many years, Apple was the senior partner and leading voice in blocking state Right to Repair bills, which it killed by the dozen, leading a coalition of monopolists, from Wahl (who boobytrap their hair-clippers with springs that cause their heads irreversibly decompose if you try to sharpen them at home) to John Deere (who reinvented tenant farming by making farmers tenants of their tractors, rather than their land).

But Apple's opposition to repair eventually became a problem for the company. It's bad optics, and both Apple customers and Apple employees are volubly displeased with the company's ecocidal conduct. But of course, Apple's management and shareholders hate repair and want to block it as much as possible.

But Apple knows how to Think Differently. It came up with a way to eat its cake and have it, too. The company embarked on a program of visibly support right to repair, while working behind the scenes to sabotage it.

Last year, Apple announced a repair program. It was hilarious. If you wanted to swap your phone's battery, all you had to do was let Apple put a $1200 hold on your credit card, and then wait while the company shipped you 80 pounds' worth of specialized tools, packed in two special Pelican cases:

https://pluralistic.net/2022/05/22/apples-cement-overshoes/

Then, you swapped your battery, but you weren't done! After your battery was installed, you had to conference in an authorized Apple tech who would tell you what code to type into a laptop you tethered to the phone in order to pair it with your phone. Then all you had to do was lug those two 40-pound Pelican cases to a shipping depot and wait for Apple to take the hold off your card (less the $120 in parts and fees).

By contrast, independent repair outfits like iFixit will sell you all the tools you need to do your own battery swap – including the battery! for $32. The whole kit fits in a padded envelope:

https://www.ifixit.com/products/iphone-x-replacement-battery

But while Apple was able to make a showy announcement of its repair program and then hide the malicious compliance inside those giant Pelican cases, sabotaging right to repair legislation is a lot harder.

Not that they didn't try. When New York State passed the first general electronics right-to-repair bill in the country, someone convinced New York Governor Kathy Hochul to neuter it with last-minute modifications:

https://arstechnica.com/gadgets/2022/12/weakened-right-to-repair-bill-is-signed-into-law-by-new-yorks-governor/

But that kind of trick only works once. When California's right to repair bill was introduced, it was clear that it was gonna pass. Rather than get run over by that train, Apple got on board, supporting the legislation, which passed unanimously:

https://www.ifixit.com/News/79902/apples-u-turn-tech-giant-finally-backs-repair-in-california

But Apple got the last laugh. Because while California's bill contains many useful clauses for the independent repair shops that keep your gadgets out of a landfill, it's a state law, and DMCA 1201 is federal. A state law can't simply legalize the conduct federal law prohibits. California's right to repair bill is a banger, but it has a weak spot: parts-pairing, the scourge of repair techs:

https://www.ifixit.com/News/69320/how-parts-pairing-kills-independent-repair

Every generation of Apple devices does more parts-pairing than the previous one, and the current models are so infested with paired parts as to be effectively unrepairable, except by Apple. It's so bad that iFixit has dropped its repairability score for the iPhone 14 from a 7 ("recommend") to a 4 (do not recommend):

https://www.ifixit.com/News/82493/we-are-retroactively-dropping-the-iphones-repairability-score-en

Parts-pairing is bullshit, and Apple are scum for using it, but they're hardly unique. Parts-pairing is at the core of the fuckery of inkjet printer companies, who use it to fence out third-party ink, so they can charge $9,600/gallon for ink that pennies to make:

https://www.eff.org/deeplinks/2020/11/ink-stained-wretches-battle-soul-digital-freedom-taking-place-inside-your-printer

Parts-pairing is also rampant in powered wheelchairs, a heavily monopolized sector whose predatory conduct is jaw-droppingly depraved:

https://uspirgedfund.org/reports/usp/stranded

But if turning phones into e-waste to eke out another billion-dollar stock buyback is indefensible, stranding people with disabilities for months at a time while they await repairs is so obviously wicked that the conscience recoils. That's why it was so great when Colorado passed the nation's first wheelchair right to repair bill last year:

https://www.eff.org/deeplinks/2022/06/when-drm-comes-your-wheelchair

California actually just passed two right to repair bills; the other one was SB-271, which mirrors Colorado's HB22-1031:

https://leginfo.legislature.ca.gov/faces/billNavClient.xhtml?bill_id=202320240SB271

This is big! It's momentum! It's a start!

But it can't be the end. When Bill Clinton signed DMCA 1201 into law 25 years ago, he loaded a gun and put it on the nation's mantlepiece and now it's Act III and we're all getting sprayed with bullets. Everything from ovens to insulin pumps, thermostats to lightbulbs, has used DMCA 1201 to limit repair, modification and improvement.

Congress needs to rid us of this scourge, to let us bring back all the benefits of interoperability. I explain how this all came to be – and what we should do about it – in my new Verso Books title, The Internet Con: How to Seize the Means of Computation.

https://www.versobooks.com/products/3035-the-internet-con

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/09/22/vin-locking/#thought-differently

Image: Mitch Barrie (modified) https://commons.wikimedia.org/wiki/File:Daytona_Skeleton_AR-15_completed_rifle_%2817551907724%29.jpg

CC BY-SA 2.0 https://creativecommons.org/licenses/by-sa/2.0/deed.en

--

kambanji (modified) https://www.flickr.com/photos/kambanji/4135216486/

CC BY 2.0 https://creativecommons.org/licenses/by/2.0/

--

Rawpixel (modified) https://www.rawpixel.com/image/12438797/png-white-background

#pluralistic#vin locking#apple#right to repair#california#ifixit#iphones#sb244#parts pairing#serialization#dmca 1201#felony contempt of business model#ewaste#repairwashing#fuckery

1K notes

·

View notes

Text

How a Computer Works - Part 1 (Components)

I am about to teach you on a real fundamental, connecting up electronic components level, how a computer actually works. Before I get into the meat of this though (you can just skip down below the fold if you don't care), here's the reasons I'm sitting doing so in this format:

Like a decade or two ago, companies Facebook pushed this whole "pivot to video" idea on the whole internet with some completely faked data, convincing everyone that everything had to be a video, and we need to start pushing back against that. Especially for stuff like complex explanations of things or instructions, it's much more efficient to just explain things clearly in text, maybe with some visual aids, so people can easily search, scan, and skip around between sections. It's also a hell of a lot easier to host things long term, and you can even print out a text based explainer and not need a computer to read it, keep it on a desk, highlight it, etc.

People are so clueless about how computers actually work that they start really thinking like it's all magical. Even programmers. Aside from how proper knowledge lets you get more out of them, this leads to people spouting off total nonsense about "teaching sand to think" or "everything is just 1s and 0s" or "this 'AI' a con artist who was trying to sell me NFTs a month ago probably really is an amazing creative thinking machine that can do everything he says!"

We used to have this cultural value going where it was expected that if you owned something and used it day to day, you'd have enough basic knowledge of how it worked that if it stopped working you could open it up, see what was wrong, and maybe fix it on your own, or maybe even put one together again from scratch, and that's obviously worth bringing back.

I'm personally working on a totally bonkers DIY project and I'd like to hype up like-minded people for when it gets farther along.

So all that said, have a standard reminder that I am completely reliant on Patreon donations to survive, keep updating this blog, and ideally start getting some PCBs and chips and a nice oscilloscope to get that mystery project off the ground.

Electricity probably doesn't work like how you were taught (and my explanation shouldn't be trusted too far either).

I remember, growing up, hearing all sorts of things about electricity having this sort of magical ability to always find the shortest possible path to where it needs to get, flowing like water, and a bunch of other things that are kind of useful for explaining how a Faraday cage or a lightning rod works, and not conflicting with how simple electronics will have a battery and then a single line of wire going through like a switch and a light bulb or whatever back to the other end of the battery.

If you had this idea drilled into your head hard enough, you might end up thinking that if we have a wire hooked to the negative end of a battery stretching off to the east, and another wire stretching off to the east from the positive end, and we bridge between the two in several places with an LED or something soldered to both ends, only the westernmost one is going to light up, because hey, the shortest path is the one that turns off as quickly as possible to connect to the other side, right? Well turns out no, all three are going to light up, because that "shortest path" thing is a total misunderstanding.

Here's how it actually works, roughly. If you took basic high school chemistry, you learned about how the periodic table is set up, right? A given atom, normally, has whatever number of protons in the core, and the same number of electrons, whipping all over around it, being attracted to those protons but repelled by each other, and there's particular counts of electrons which are super chill with that arrangement so we put those elements in the same column as each other, and then as you count up from those, you get the elements between those either have some electrons that don't fit all tight packed in the tight orbit and just kinda hang out all wide and lonely and "want to" buddy up with another atom that has more room, up to the half full column that can kinda go either way, then as we approach the next happy number they "want to" have a little more company to get right to that cozy tight packed number, and when you have "extra" electrons and "missing" electrons other atoms kinda cozy up and share so they hit those good noble gas counts.

I'm sure real experts want to scream at me for both that and this, but this is basically how electricity works. You have a big pile of something at the "positive" end that's "missing electrons" (for the above reason or maybe actually ionized so they really aren't there), and a "negative" end that's got spares. Then you make wires out of stuff from those middle of the road elements that have awkward electron counts and don't mind buddying up (and also high melting points and some other handy qualities) and you hook those in there. And the electron clouds on all the atoms in the wire get kinda pulled towards the positive side because there's more room over there, but if they full on leave their nucleus needs more electron pals, so yeah neighbors get pulled over, and the whole wire connected to the positive bit ends up with a positive charge to it, and the whole wire on the negative bit is negatively charged, and so yeah, anywhere you bridge the gap between the two, the electrons are pretty stoked about balancing out these two big awkward compromises and they'll start conga lining over to balance things out, and while they're at it they'll light up lights or shake speakers or spin motors or activate electromagnets or whatever other rad things you've worked out how to make happen with a live electric current.

Insulators, Resistors, Waves, and Capacitors

Oh and we typically surround these wires made of things that are super happy about sharing electrons around with materials that are very much "I'm good, thanks," but this isn't an all or nothing system and there's stuff you can connect between the positive and negative ends of things that still pass the current along, but only so much so fast. We use those to make resistors, and those are handy because sometimes you don't want to put all the juice you have through something because it would damage it, and having a resistor anywhere along a path you're putting current through puts a cap on that flow, and also sometimes you might want a wire connected to positive or negative with a really strong resistor so it'll have SOME sort of default charge, but if we get a free(r) flowing connection attached to that wire somewhere else that opens sometimes, screw that little trickle going one way, we're leaning everyone the other way for now.

The other thing with electricity is is that the flow here isn't a basic yes/no thing. How enthusiastically those electrons are getting pulled depends on the difference in charge at the positive and negative ends, and also if you're running super long wires then even if they conduct real good, having all that space to spread along is going to kinda slow things to a trickle, AND the whole thing is kinda going to have some inherent bounciness to it both because we're dealing with electrons whipping and spinning all over and because, since it's a property that's actually useful for a lot of things we do with electricity, the power coming out of the wall has this intentional wobbly nature because we've actually got this ridiculous spinny thing going on that's constantly flip flopping which prong of the socket is positive and which is negative and point is we get these sine waves of strength by default, and they kinda flop over if we're going really far.

Of course there's also a lot of times when you really want to not have your current flow flickering on and off all the time, but hey fortunately one of the first neat little electronic components we ever worked out are capacitors... and look, I'm going to be straight with you. I don't really get capacitors, but the basic idea is you've got two wires that go to big wide plates, and between those you have something that doesn't conduct the electricity normally, but they're so close the electromagnetic fields are like vibing, and then if you disconnect them from the flow they were almost conducting and/or they get charged to their limit, they just can't deal with being so charged up and they'll bridge their own gap and let it out. So basically you give them electricity to hold onto for a bit then pass along, and various sizes of them are super handy if you want to have a delay between throwing a switch and having things start doing their thing, or keeping stuff going after you break a connection, or you make a little branching path where one branch connects all regular and the other goes through a capacitor, and the electricity which is coming in in little pulses effectively comes out as a relatively steady stream because every time it'd cut out the capacity lets its charge go.

We don't just have switches, we have potentiometers.

OK, so... all of the above is just sort of about having a current and maybe worrying about how strong it is, but other than explaining how you can just kinda have main power rails running all over, and just hook stuff across them all willy-nilly rather than being forced to put everything in one big line, but still, all you can do with that is turn the whole thing on and off by breaking the circuit. Incidentally, switches, buttons, keys, and anything else you use to control the behavior of any electronic device really are just physically touching loose wires together or pulling them apart... well wait no, not all, this is a good bit to know.

None of this is actually pass/fail, really, there's wave amplitudes and how big a difference we have between the all. So when you have like, a volume knob, that's a potentiometer, which is a simple little thing where you've got your wire, it's going through a resistor, and then we have another wire we're scraping back and forth along the resistor, using a knob, usually, and the idea is the current only has to go through X percent of the resistor to get to the wire you're moving, which proportionately reduces the resistance. So you have like a 20 volt current, you've got a resistor that'll drop that down to 5 or so, but then you move this other wire down along and you've got this whole dynamic range and you can fine tune it to 15 or 10 or whatever coming down that wire. And what's nice about this again, what's actually coming down the wire is this wobbily wave of current, it's not really just "on" or "off, and as you add resistance, the wobble stays the same, it's just the peaks and valleys get closer to being just flat. Which is great if you're making, say, a knob to control volume, or brightness, or anything you want variable intensity in really.

Hey hey, it's a relay!

Again, a lot of the earliest stuff people did with electronics was really dependent on that analog wobbly waveform angle. Particularly for reproducing sound, and particularly the signals of a telegraph. Those had to travel down wires for absurd distances, and as previously stated, when you do that the signal is going to eventually decay to nothing. But then someone came up with this really basic idea where every so often along those super long wires, you set something up that takes the old signal and uses it to start a new one. They called them relays, because you know, it's like a relay race.

If you know how an electromagnet works (something about the field generated when you coil a bunch of copper wire around an iron core and run an electric current through it), a relay is super simple. You've got an electromagnet in the first circuit you're running, presumably right by where it's going to hit the big charged endpoint, and that magnetically pulls a tab of metal that's acting as a switch on a new circuit. As long as you've got enough juice left to activate the magnet, you slam that switch and voom you've got all the voltage you can generate on the new line.

Relays don't get used too much in other stuff, being unpopular at the time for not being all analog and wobbily (slamming that switch back and forth IS going to be a very binary on or off sorta thing), and they make this loud clacking noise that's actually just super cool to hear in devices that do use them (pinball machines are one of the main surviving use cases I believe) but could be annoying in some cases. What's also neat is that they're a logical AND gate. That is, if you have current flowing into the magnet, AND you have current flowing into the new wire up to the switch, you have it flowing out through the far side of the switch, but if either of those isn't true, nothing happens. Logic gates, to get ahead of myself a bit, are kinda the whole thing with computers, but we still need the rest of them. So for these purposes, relays re only neat if it's the most power and space efficient AND gate you have access to.

Oh and come to think of it, there's no reason we need to have that magnet closing the circuit when it's doing its thing. We could have it closed by default and yank it open by the magnet. Hey, now we're inverting whatever we're getting on the first wire! Neat!

Relay computers clack too loud! Gimme vacuum tubes!

So... let's take a look at the other main thing people used electricity for before coming up with the whole computer thing, our old friend the light bulb! Now I already touched a bit on the whole wacky alternating current thing, and I think this is actually one of the cases that eventually lead to it being adopted so widely, but the earliest light bulbs tended to just use normal direct current, where again, you've got the positive end and the negative end, and we just take a little filament of whatever we have handy that glows when you run enough of a current through it, and we put that in a big glass bulb and pump out all the air we can, because if we don't, the oxygen in there is probably going to change that from glowing a bit to straight up catching on fire and burning immediately.

But, we have a new weird little problem, because of the physics behind that glowing. Making something hot, on a molecular level, is just kinda adding energy to the system so everything jitters around more violently, and if you get something hot enough that it glows, you're getting it all twitchy enough for tinier particles to just fly the hell off it. Specifically photons, that's the light bit, but also hey, remember, electrons are just kinda free moving and whipping all over looking for their naked proton pals... and hey, inside this big glass bulb, we've got that other end of the wire with the more positive charge to it. Why bother wandering up this whole coily filament when we're in a vacuum and there's nothing to get in the way if we just leap straight over that gap? So... they do that, and they're coming in fast and on elliptical approaches and all, so a bunch of electrons overshoot and smack into the glass on the far side, and now one side of every light bulb is getting all gross and burnt from that and turning all brown and we can't have that.

So again, part of the fix is we switched to alternating current so it's at least splitting those wild jumps up to either side, but before that, someone tried to solve this by just... kinda putting a backboard in there. Stick a big metal plate on the end of another wire in the bulb connected to a positive charge, and now OK, all those maverick electrons smack into here and aren't messing up the glass, but also hey, this is a neat little thing. Those electrons are making that hop because they're all hot and bothered. If we're not heating up the plate they're jumping to, and there's no real reason we'd want to, then if we had a negative signal over on that side... nothing would happen. Electrons aren't getting all antsy and jumping back.

So now we have a diode! The name comes because we have two (di-) electrodes (-ode) we care about in the bulb (we're just kind of ignoring the negative one), and it's a one way street for our circuit. That's useful for a lot of stuff, like not having electricity flow backwards through complex systems and mess things up, converting AC to DC (when it flips, current won't flow through the diode so we lop off the bottom of the wave, and hey, we can do that thing with capacitors to release their current during those cutoffs, and if we're clever we can get a pretty steady high).

More electrodes! More electrodes!

So a bit after someone worked out this whole vacuum tube diode thing, someone went hey, what if it was a triode? So, let's stick another electrode in there, and this one just kinda curves around in the middle, just kinda making a grate or a mesh grid, between our hot always flowing filament and that catch plate we're keeping positively charged when it's doing stuff. Well this works in a neat way. If there's a negative charge on it, it's going to be pushing back on those electrons jumping over, and if there's a positive charge on it, it's going to help pull those electrons over (it's all thin, so they're going to shoot right past it, especially if there's way more of a positive charge over on the plate... and here's the super cool part- This is an analog thing. If we have a relatively big negative charge, it's going to repel everything, if it's a relatively big positive, it's going to pull a ton across, if it's right in the middle, it's like it wasn't even in there, and you can have tiny charges for all the gradients in between.

We don't need a huge charge for any of this though, because we're just helping or hindering the big jump from the high voltage stuff, and huh, weren't we doing this whole weak current controlling a strong current thing before with the relay? We were! And this is doing the same thing! Except now we're doing it all analog style, not slapping switch with a magnet, and we can make those wavy currents peak higher or lower and cool, now we can have phone lines boost over long distances too, and make volume knobs, and all that good stuff.

The relay version of this had that cool trick though where you could flip the output. Can we still flip the output? We sure can, we just need some other toys in the mix. See we keep talking about positive charges and negative charges at the ends of our circuits, but these are relative things. I mentioned way back when how you can use resistors to throttle how much of a current we've got, so you can run two wires to that grid in the triode. One connects to a negative charge and the other positive, with resistors on both those lines, and a switch that can break the connection on the positive end. If the positive is disconnected, we've got a negative charge on the grid, since it's all we've got, but if we connect it, and the resistor to the negative end really limits flow, we're positive in the section the grid's in. And over on the side with the collecting plate, we branch off with another resistor setup so the negative charge on that side is normally the only viable connection for a positive, but when we flip the grid to positive, we're jumping across the gap in the vacuum tube, and that's a big open flow so we'll just take those electrons instead of the ones that have to squeeze through a tight resistor to get there.

That explanation is probably a bit hard to follow because I'm over here trying to explain it based on how the electrons are actually getting pulled around. In the world of electronics everyone decided to just pretend the flow is going the other way because it makes stuff easier to follow. So pretend we have magical positrons that go the other way and if they have nothing better to do they go down the path where we have all the fun stuff further down the circuit lighting lights and all that even though it's a tight squeeze through a resistor, because there's a yucky double negative in the triode and that's worse, but we have the switch rigged up to make that a nice positive go signal to the resistance free promised land with a bonus booster to cut across, so we're just gonna go that way when the grid signal's connected.

Oh and you can make other sorts of logic circuits or double up on them in a single tube if you add more grids and such, which we did for a while, but not really relevant these days.

Cool history lesson but I know there's no relays or vacuum tubes in my computer.

Right, so the above things are how we used to make computers, but they were super bulky, and you'd have to deal with how relays are super loud and kinda slow, and vacuum tubes need a big power draw and get hot. What we use instead of either of those these days are transistors. See after spending a good number of years working out all this circuit flow stuff with vacuum tubes we eventually focused on how the real important thing in all of this is how with the right materials you can make a little juncture where current flows between a positive and negative charge if a third wire going in there is also positively charged, but if it's negatively charged we're pulling over. And turns out there is a WAY more efficient way of doing that if you take a chunk of good ol' middle of the electron road silicon, and just kinda lightly paint the side of it with just the tiniest amount of positive leaning and negative leaning elements on the sides.

Really transistors don't require understanding anything new past the large number of topics already covered here, they're just more compact about it. Positive leaning bit, negative leaning bit, wildcard in the middle, like a vacuum tube. Based on the concepts of pulling electrons around from chemistry, like a circuit in general. The control wire in the middle kinda works in just a pass-fail sort of way, like a relay. They're just really nice compared to the older alternatives because they don't make noise or have moving parts to wear down, you don't have to run enough current through them for metal to start glowing and the whole room to heat up, and you can make them small. Absurdly small. Like... need an electron microscope to see them small.

And of course you can also make an inverter super tiny like that, and a diode (while you're at it you can use special materials or phosphors to make them light emitting, go LEDs!) and resistors can get pretty damn small if you just use less of a more resistant material, capacitors I think have a limit to how tiny you can get, practically, but yeah, you now know enough of the basic fundamentals of how computers work to throw some logic gates together. We've covered how a relay, triode, or transistor function as an AND gate. An OR gate is super easy, you just stick diodes on two wires so you don't have messy backflow then connect them together and lead off there. If you can get your head around wiring up an inverter (AKA NOT), hey, stick one after an AND to get a NAND, or an OR to get a NOR. You can work out XOR and XNOR from there right? Just build 4 NANDs, pass input A into gates 1 and 2, B into 2 and 3, 2's output into 1 and 3, 1 and 3's output into 4 for a XOR, use NORs instead for a XNOR. That's all of them right? So now just build a ton of those and arrange them into a computer. It's all logic and math from there.

Oh right. It's... an absurd amount of logic and math, and I can only fit so many words in a blog post. So we'll have to go all...

CONTINUED IN PART 2!

Meanwhile, again, if you can spare some cash I'd really appreciate it.

559 notes

·

View notes

Text

Acquiring, Keeping, and Caring For Cursed Objects

So, you want a cursed object? Maybe you're a collector of haunted artifacts, a chaos witch who loves a challenge, or just someone who thinks “possessed” is a selling point. Whatever your reason, handling cursed items is an art—one that requires knowledge, caution, and maybe a good exorcist on speed dial.

Where to Find Cursed Objects

If you’re looking to acquire an object with questionable spiritual history, try:

Thrift Stores & Estate Sales

• Old mirrors, antique dolls, and Victorian jewelry are prime candidates.

• Look for items with a strange energy or eerie backstory from previous owners.

• Cursed objects tend to feel either cold or warm.

Online Marketplaces

• eBay and Etsy occasionally feature items labeled as “haunted” or “cursed.”

• Be wary of fakes—if it comes with a certificate of authenticity, it’s probably a gimmick.

Abandoned & Historical Sites

• Be very careful when taking objects from old buildings, cemeteries, or battlefields. Some spirits don’t appreciate being relocated without permission.

Occult Shops & Witch Markets

• Some practitioners sell intentionally hexed, haunted, or enchanted objects.

• Check the seller’s reputation before buying something that might decide to rearrange your furniture at night.

How to Identify a Cursed Object

Not all creepy antiques are cursed, but some red flags include:

Unexplained Bad Luck - After bringing the object home, things start breaking, people fall ill, or your cat suddenly hates you.

Disturbing Dreams & Nightmares - If an item gives you visions of past tragedies, or whispers in the night—it’s probably cursed.

Strange Physical Reactions - Feeling cold, dizzy, or heavy near the object? That’s a sign of a strong energy attachment.

Moving or Vanishing on Its Own - If the object relocates itself, refuses to stay put, or vanishes and reappears, congratulations—you have an active one.

Electronic & Environmental Disturbances - Flickering lights, draining batteries, and objects falling for no reason are classic signs of spirit activity.

Safely Keeping a Cursed Object

If you want to coexist with your new haunted acquisition (without getting hexed into oblivion), follow these guidelines:

Set Boundaries-

• Speak to the object (yes, really). Tell it:

“You are welcome here, but you will not harm, scare, or disrupt my space.”

• Reinforce with protective symbols (salt, runes, or sigils).

Keep It Contained-

• Glass cases help contain energy.

• A dedicated altar or place of honor makes the spirit feel welcome and appreciated.

• Iron boxes can trap aggressive spirits.

• Mirror boxes can function as a trap for many spirits.

Regular Cleansing & Offerings-

• If the spirit is sentient, occasional offerings (coins, incense, or flowers) can keep it calm.

• Empower the spirit through regular acknowledgement.

• Smoke cleansing, bells, or singing bowls can balance energy without removing the curse/spirit.

• Marshmallow root makes spirits happy and calm.

Have a Backup Plan-

• If things go wrong, have banishing components (like black salt, rue, or black tourmaline) ready.

• A witch, priest, or medium can help if the object becomes too hostile.

• Consider 'rehoming' objects that become too dangerous to a more willing collector.

• Burying, throwing into fast moving water, or burning will neutralize most objects. Some spirits may just be made furious by the disrespect, however, so be wise.

Owning a cursed object is like having a supernatural roommate—you need rules, respect, and an exit strategy. Whether you’re collecting for curiosity, magickal experimentation, or sheer thrill, just remember: some spirits are happy to stay dormant… until they’re not. Happy haunting!

#cursed#Object#cursed item#cursed objects#thrifting#collectibles#witch#magick#dark#witchcraft#demons#spirits#spirit work#demonolatry#chaos magick#chaos#haunting#haunted#ghost#ghosts#satanic witch#witchblr#witch community#eclectic witch#eclectic#pagan#occult#occultism#occulltism#oddities

64 notes

·

View notes

Text

Article from Bloomberg by Jason Schreier, under a cut due to length.

"New ‘Dragon Age’ Game Faced Turbulent Development The studio head of EA’s BioWare says ‘Dragon Age: The Veilguard’ received nothing but support from EA throughout its lengthy production cycle EA’s BioWare label hopes to find redemption with the release of Dragon Age: The Veilguard Today we’re getting in-depth on the new Dragon Age game A new age for dragons In late 2020, when Gary McKay took over as studio head of BioWare, the Electronic Arts Inc. subsidiary best known for making big roleplaying games, the climate was dire. BioWare, which is headquartered in Edmonton, Alberta, had released two critically panned games and was facing turbulent development on a new one — while trying to cope with a worldwide pandemic. “We needed to shift how we were thinking about building our games,” McKay told me in a recent interview. BioWare, founded in 1995 and purchased by EA in 2007, had won over millions of fans with hit single-player RPG franchises such as Dragon Age and Mass Effect. But a 2017 entry called Mass Effect: Andromeda was widely panned, and the studio’s next game, the 2019 multiplayer shooter Anthem, flopped both critically and commercially. Both games had also gone through brutal development cycles that drove many BioWare veterans to exit the studio. At the end of 2020, studio boss Casey Hudson was planning to step down and called McKay to ask if he would take over. “We had a few conversations over the course of the next month around the people and the culture,” McKay said. BioWare’s next big project would be a new game in the popular fantasy Dragon Age franchise. But the game, which had been in development for years, was facing turmoil and had been rebooted from a single-player game into a live-service game with a heavy multiplayer component, which EA had been pushing across many of its subsidiaries in the late 2010s. Hudson, too, was interested in multiplayer games and had been the lead visionary on Anthem. Some employees jeeringly referred to the next Dragon Age as “Anthem with dragons,” which worried fans after I reported on the game at Kotaku. Enthusiasts of the series wanted another single-player game, not a repeat of BioWare’s biggest mistake. When he took over, McKay began to feel similarly. “We were thinking, ‘Does this make sense, does this play into our strengths, or is this going to be another challenge we have to face?’” McKay said. “No, we need to get back to what we’re really great at.” In the months that followed, McKay met with leadership across BioWare and EA and ultimately decided to reboot the next Dragon Age a second time, pivoting back to single-player."

The choice was obvious in many ways. Anthem had flopped while EA’s Star Wars Jedi: Fallen Order, a single-player action-adventure game, had sold more than 10 million copies, helping prove to the publisher that not all of its games needed to be online. BioWare games were popular because of their focus on character dialogue and player-driven narrative decisions, which did not mesh with multiplayer gaming. “Once we made that decision, a lot of things started to fall into place,” McKay said. In the years that followed, he would go on to consolidate more of the studio’s projects, shutting down an attempt to reboot Anthem and selling off the rights to the online game Star Wars: The Old Republic to a separate studio. The goal, McKay said, was “focus.” BioWare then spent the next three-and-a-half years developing what would become Dragon Age: The Veilguard, the fourth game in the franchise. Out this week, the game has received mostly positive reviews and so far topped charts, although EA has not yet revealed sales numbers. Some things went right during development. McKay said they “had the game end-to-end playable” earlier than any previous BioWare product, allowing them to spend extra time iterating. A reorganization at EA, which split the company into divisions called EA Games and EA Sports, allowed Dragon Age: The Veilguard to receive more support from internal teams that might otherwise be stretched thin, such as research and data insights groups. “That gave us an extra boost in terms of the support and focus from the company,” McKay said. But the development of Dragon Age: The Veilguard still faced plenty of obstacles. The pandemic led BioWare to shift to hiring remotely, which McKay said made for cultural challenges. The game slipped past its original target date, although McKay wouldn’t say how much extra time it needed. “I’m never going to call it a slip,” he said. And it went through significant scope changes over the course of development. Then, last summer, BioWare laid off 50 people, including veterans with decades of experience. McKay told me the reduction, which arrived during a period of widespread layoffs across the video-game industry, “was all about focus at that time.” “When you have a really large team, you’re always compelled to keep everybody busy all the time,” he said. “When you have a smaller team, you have the right people in the right roles at the right time, some incredible momentum is gained at that point.” The stakes are high for the release of Dragon Age: The Veilguard. Fans and pundits have worried that a third failure in a row might have devastating results for BioWare. McKay wouldn’t comment on the specifics of what would make the game a hit in their eyes. But said he has felt supported by EA Entertainment & Technology President Laura Miele. The game is so important to BioWare’s future that the company brought in its second team, which has been incubating a new Mass Effect, to help out during the final stretch of development. The Mass Effect team played a major role in finishing and polishing Dragon Age: The Veilguard. Other companies across EA, such as its Motive studio in Montreal, also supported the game. Now, the company will look to see how players react to the next Dragon Age — and, McKay hopes, “bring BioWare back into the conversation as a top game studio.”

[source]

#dragon age: the veilguard#dragon age: dreadwolf#dragon age 4#the dread wolf rises#da4#dragon age#bioware#video games#longpost#long post#covid mention#mass effect#mass effect: andromeda#mass effect 5#sw:tor#anthem#(this is from nov 1. but i'm still looking through backlog piles of headlines from the time i was hiding in the spoilerbunker so this post#is late)

91 notes

·

View notes

Text

My wife was asking me about this this morning. This is pure political fanfic, but if I were Trump and I were going to try and make America a re-industrialised nation centred around the tech industry that keeps its supply lines as entirely in-house as possible, what I would do is start (obviously) with enormous central planning. You can't "free market incentives" your way back out of the export of industrial labour overseas.

You'd copy China and make enormous State-Owned Enterprises (assuming we care about the market and want to keep playing this stupid game instead of just becoming fully communist) that would process refined minerals into components, components into parts and parts into electronics. I'd recognise the scale of this as a multi-generational project and immediately start subsidising training for more engineers, especially for people who can set up automated factory lines but also engineers in new emerging tech fields like autonomous driving, software programmers, designers, even artists since the content economy is such a huge part of what people use tech for through social media and so much art is produced digitally now anyway.

From there you want to look at the markets globally that fucking, EaglePhone or whatever these overpriced Made In Murica devices can be sold into, and at this point, given that they will be crazy expensive compared to Chinese electronics literally no matter what you do, here would be a worthwhile place to try and flex America's muscles and threaten the UK, the EU, South America, Canada and so on with tariffs or other penalties if they don't adopt a hostile policy toward Chinese electronics.

Massive central planning would be essential for the kind of societal transformation that Trump is explicitly describing, in order to have a product to sell to the rest of the world before using imperialist bullying to make other countries buy things from America instead, but here we have to return yet again to the reality of Trump's plan. There is no end goal where America is in a stronger position. If he had implemented sweeping public programs reinvesting taxes into the health of the nation (never mind the health of its citizens) in his first term, he might have been in a powerful enough position to strongarm other countries into changing the flows of global trade, but America's world influence simply is declining, and more and more rapidly, so he's just trying to make moves that make him and his friends as much money as possible while they lock the doors, pack the country up into the box it came in and set the whole thing on fire. He describes these moves using the MAGA fantasy because it gives all his supporters in the media and the general population enough to talk about to buy him time, but I don't think anyone outside his base ever thought making America great was ever his plan, so why has everyone been critiquing the tariffs as if his sincere belief was that he would achieve his stated goals with them?

We all let our enemies set the topic of the conversation all day every day and it's shocking to me

49 notes

·

View notes

Text

Proactive Product and Supplier of Lifecycle Management – Stay Ahead of the Curve!

Resion offers cost-effective, proactive product and supplier lifecycle management solutions that help mitigate risks and maximize performance. Our scalable strategies ensure your electronic components meet the highest standards throughout their lifecycle. Keep your operations running seamlessly with Resion. Call 516-742-6300 for more information on how we can assist you with our services!

#Electronics Parts Suppliers#Largest Electronic Component Distributor#Sell Electronic components#Electronic Parts Distributor#Proactive Product and Supplier of Lifecycle Management#Proactive Product Supplier Lifecycle Management#Proactive Supplier Lifecycle Management#Electronic Product Lifecycle Management#Integrated Lifecycle Management For Electronics#Electronics Components Life Cycle Management

0 notes

Text

Grampa's Antique Fan (2015 vs 2024 Edit)

As a young man, after coming home from the Second World War, my grampa got a job as an electrician for Emerson Electric. He didn't work on the actual electrical products. He just maintained the electrical systems that power the tools to make electrical components.

It was a "I heard you need electricity for your electricity" type deals.

The company was founded in 1890 in nearby Ferguson, Missouri by John Wesley Emerson. He was a Union commander in the Civil War and a lawyer and then a judge and then an author and then a historian... so he was clearly qualified to run one of the first electronics companies. (This is currently referred to as the "Law of Elon".)

Emerson (the company, not the dude) specialized in electric motors and was the first to stick their motors in a fan and sell them.

As you can see by the 4 protective fan guard loopies, these were very safe for kids to be around.

I mean, the biggest thing you could shove in there is a baby arm, which is the least important part of a baby. No baby heads were chopped off—which was the bar for consumer safety during that era.

Fans are rated by the volume of air they can push over a period of time and your average box fan can push about 1400 cubic feet per minute or "CFM". When this Emerson (the fan, not the dude) was produced they actually used "CCH" or cubic cubits per hour. Emerson (the dude) loved using odd standards of measurement much to the chagrin of his engineers.

Due to the small surface area, weak angle of attack, and heavy metal blades, this electronic beast could only push a baker's dozen cubic cubits per baker's hour—which was a confusing metric of time because people were very superstitious and they refused to put the 13 on the baker's clocks. They just left a mysterious blank void after the 12 and apparently several people had existential crises during the baker's hour. Some were institutionalized for a rare condition called Time Delirium.

Thankfully Emerson Electric was able to provide the electroshock therapy devices that cured several patients. This was achieved by erasing the memory of the traumatic time delirium events along with a few other unimportant details like what they did last Tuesday and their mother's name and one engineering degree that the guy wasn't even using.

My dad actually got the fan working and let me tell you... that bad boy could really work up a gentle breeze...

...if you stood behind it and blew.

And that fine American-made electric fan motor was just as quiet as a leaf blower on Saturday morning.

Over the last century, Emerson was bought and sold and bought and sold.

And bought and sold and bought and sold.

Was that 7?

Eh, close enough. We'll call it a baker's 7.

They changed their product line countless times over their 130+ years of existence. After fans they pivoted and made electric meat grinders. To this day, no one know what inspired that decision.

Currently, they make radar avionics and are majority-owned by the private equity firm, Blackstone. Which is a totally non-evil sounding name they chose for their company-eating empire. Please ignore that the CEO was one of Trump's policy strategists. This is a non-evil company with a non-evil name run by non-evil people, okay?

Despite Emerson Electric having to settle a baker's gross of lawsuits involving a few lightly scalp'd babies, they maintain a Fortune 500 status and are still headquartered in Ferguson.

They occupy one of the most boring ass buildings ever constructed.

Just rectangles all the way down.

That architect told every angle to get rect.

Of course, I forgot all of this cool history and sold this fan in the estate auction. I suppose it is a good thing I got a nice photograph to help assuage my current feelings of guilt. I mean, it is not baby scalping, time delirium guilt—but I would feel better if I knew my gramp-gramp's fan was in a good home with 0 babies.

#photography#re-edit#some of this stuff is actually true#I have yet to fall asleep and so I wrote this#can you tell I haven't slept?

84 notes

·

View notes

Text

Big tech, laptop repair to be specific

On todday's episoe of "contentloadingandstuff learns how he is scamme on a daily basis", we have electronics repair. As you can see, my "d" key is not working properly at times. And some others too, but I selom use them. I took it to the repair shop (first a small, non-brand one) and they toldd me that "yeah we ddon't have a spare key so we gotta exchange the whole keyboardd". So I askedd - how much? Three ddays an 700 PLN (~200 $/180€). Nice. Except a new keyboardd costs only 200 PLN (~60$/40€) - off bran, obviously, as MSI oesn't sell specific components. It's so you come to them for your repairs an pay four-five times the actual price.

It's not only this scummy practice. It's also physical solutions. The warranty sticker is place over a screw from the laptop case so you ddon't clean/repaste/repair it yourself an pay up to big repair. But what if you needd to do so? Well, go to your local repair service an either sendd the device on warranty (two, three months) for free or simply pay at a partner establishment that has said magical sticker. You ordered a spare part andd want the repair shop to just put it in? Tough luck - most don't accept parts that aren't theirs. Because, you know, they wouln't be able to scam you out of 400 PLN andd gain the approval of the manufacturer. It's gatekeeping in the purest form - "only we have the right to fix your computer". And if you want to replace saidd keyboardd, you have to use a solddering iron because MSI ddeciddedd to fuck the user over by using soldered plastic instead of screws. It's really only to make it more dddifficult for the average person, it doesn't have any benefit and is, if anything, more inconvenient for the repair crew. Most people didddn't even see a soldering iron in their life andd so would be too lazy/scaredd to ddo the repairs themselves - leadding them back into the greedy, loving arms of the manufacturer and big tech.

It's like with jeweler services. DDon't bring your own prodduct because we won't be able to overcharge you for it andd make a disgusting profit. Or with them telling you diamonds are very valuable and rare - they are not the latter, and are the former just because of artificial scarcity. Big tech also scares you (mostly with the help of casual drone culture and smart marketing) that making repairs on your own is very ddifficuly! DDon't try it yourself!

In reality, all you have to do to clean your laptop fans is unscrew some screws, unplug some things and dtake them out. Repasting? Buy a tube of paste for 20 PLN (6$/4€) and some isopropyl alcohol for pennies and ddo it yourself with a youtube guidde. It's NOT difficult, it's NOT risky, it's not SCARY. It does NOT require specialistic knowledge. DO THIS SHIT YOURSELF! All you need is internet access, some tools/a friend with said tools and basic care to fix the majority of issues on your own.

Contentloadingandstuff out.

14 notes

·

View notes

Text

Can it be fixed?

Most of us live in areas with a “throw-away culture”. Single-use items are everywhere, and it is generally easier (and frequently cheaper) to replace an item than to fix it. Unfortunately, many consumer items are actually designed to be difficult or impossible to repair. Significant resources are used to create, transport, sell, and dispose of even simple items. Once an item is thrown away, its component materials are no longer available and eventually, the earth’s resources will be used up. And there is no “away” for our trash. We just hide it in landfills, where it is out of sight but can still create significant problems for the earth. Every time we repair an item and continue to use it, we are helping the earth. A little research can help you repair many items (or find a business that can perform the repairs). CAUTION: do not attempt to fix items that use electricity, natural gas, propane, or hazardous chemicals unless you have appropriate training. If you make a mistake, you could start a fire or injure or kill yourself or others. And always unplug an electrical item before working on it. Now that we’ve covered the safety concerns, let’s talk about repairs. The article at the link provides lots of links to information to help you repair many of your own items, including clothing and some electronics, appliances, and furniture. Sometimes you can hire someone who can fix these items for a reasonable price.

77 notes

·

View notes

Text

The Trump import taxes (AKA: tariffs) are being added to prices. Retailers cannot hold off any longer. If you need to buy anything that's imported, you may still be able to get it at the pre-Trump price at some places for a few more days. But act quickly.

Among the levies Trump has imposed is a 10% baseline tariff for most imports and a 30% tariff on most Chinese goods. Some goods, such as steel and aluminum, face higher rates. Many retailers have issued warnings that they won’t, as Trump has suggested, “eat” the additional costs caused by those import taxes. That means anything from groceries and clothing to toys and cars could cost Americans more. Walmart is one of the latest major retailers to say it would sell more expensive goods soon because Trump’s tariffs are “too high.”Other retailers suggesting they could hike prices soon include Ford, Best Buy and others. Here are some of the companies that could raise prices on everyday items – whether or not companies are directly blaming Trump’s tariffs. Walmart Price changes at Walmart will likely take effect by the end of May and prices will increase “much more” in June, the company’s chief financial officer John David Rainey, told CNBC. Mattel Trump threatened Mattel, saying he would “put a 100% tariff on his toys, and he won’t sell one toy in the United States, and that’s their biggest market.” Best Buy Electronics retailer Best Buy warned during a March earnings call that “vendors across our entire assortment will pass along some level of tariff costs to retailers, making price increases for American consumers highly likely.” Some electronic components and devices are temporarily exempt from Trump’s tariffs. That won’t last forever. Shein and Temu “Due to recent changes in global trade rules and tariffs, our operating expenses have gone up. To keep offering the products you love without compromising on quality, we will be making price adjustment starting April 25, 2025,” Temu wrote in a notice similar to an announcement Shein made.

As for fast fashion sellers like Shein, we should not be spending money on that anyway. Fast fashion is horribly wasteful and bad for the planet. It's bad enough to support such industries. It's even worse to buy their products and pay Trump tariffs on top of that. /editorial

Beat Trump by being frugal. And when buying American, make sure the products are union made.

Keep in mind that Trump would not be able to impose these tariffs without the full cooperation of Republicans in the US House and Senate. Capitol Hill Republicans are Trump's willing accomplices.

#donald trump#maga#republicans#trump tariffs#tariffs#import taxes#trumpflation#voodoo economics#higher prices#walmart#mattel#best buy#shein#temu#fast fashion#capitol hill republicans

10 notes

·

View notes