#Electronic Product Lifecycle Management

Explore tagged Tumblr posts

Text

Integrated Lifecycle Management for Electronics – Future-Proof Your Supply Chain!

Resion delivers integrated lifecycle management for electronics, providing expert strategies and inventory solutions to support your operations from start to finish. Our services ensure your components remain compliant and functional throughout their lifecycle. Get lifecycle management that works efficiently. Call us now at 516-742-6300 to boost your supply chain!

#Proactive Product Supplier Lifecycle Management#Proactive Supplier Lifecycle Management#Electronic Product Lifecycle Management#Integrated Lifecycle Management For Electronics#Electronics Components Life Cycle Management

0 notes

Text

Trash Tech or Treasure Trove? The Benefits of E-waste Recycling

E-waste recycling is crucial in protecting our environment and creating a more sustainable future. It keeps harmful materials out of landfills and reduces the need to extract virgin resources through mining.

3R Technology

8002 S 208th St E105, Kent, WA 98032, United States

(206) 582-7100

#e-waste recycling#e-waste#electronicrecycling#datadestruction#secure data destruction#e-waste recycling event#data sanitization#collection bin program#e waste#electronic recycling#electronic waste#product lifecycle management

0 notes

Text

What is Pharmacovigilance? Understanding Drug Safety and Risk Management

What is Pharmacovigilance? Pharmacovigilance (PV) is the science and practice of detecting, assessing, understanding, and preventing adverse effects or other drug-related problems. Its primary goal is to ensure that the benefits of medicinal products outweigh their risks, thus safeguarding public health.

This discipline extends across the entire lifecycle of a drug, from pre-market clinical trials to post-marketing surveillance, encompassing the global monitoring of medicinal products.

Core Objectives of Pharmacovigilance Identifying Adverse Drug Reactions (ADRs): PV seeks to detect adverse effects, especially those that are unexpected or serious, arising from the use of medicinal products.

Ensuring Drug Safety: By monitoring and managing risks, pharmacovigilance contributes to the safer use of medicines.

Educating Stakeholders: Healthcare providers, regulatory authorities, and patients are informed about potential risks and proper usage of drugs.

Regulatory Compliance: Pharmaceutical companies must adhere to international standards and report safety data to regulatory bodies like the FDA, EMA, and WHO.

Importance of Pharmacovigilance Protecting Patient Health: By identifying potential risks early, pharmacovigilance minimizes harm to patients and ensures the safety of medicinal products.

Supporting Regulatory Decisions: Comprehensive safety data help regulatory agencies make informed decisions about the approval, withdrawal, or restriction of drugs.

Enhancing Pharmaceutical Innovation: A robust PV framework fosters confidence in the pharmaceutical industry, encouraging innovation while ensuring public safety.

Global Harmonization: Pharmacovigilance facilitates uniform safety standards across countries, promoting international cooperation in drug safety monitoring.

Challenges in Pharmacovigilance Data Overload: The influx of safety data from clinical trials, real-world use, and social media presents challenges in effective monitoring.

Complex Regulations: Varying regulatory requirements across countries require significant expertise to navigate.

Technological Integration: Adopting advanced tools like AI and machine learning for signal detection and data analysis is a complex but necessary step forward.

Public Awareness: Educating patients and healthcare professionals about reporting adverse events remains a significant hurdle.

Technological Advances in Pharmacovigilance The integration of technology is revolutionizing pharmacovigilance. Tools such as artificial intelligence (AI), big data analytics, and machine learning are enhancing signal detection, enabling quicker identification of potential risks. Real-world evidence from wearable devices and electronic health records (EHRs) provides real-time insights into drug safety.

The Future of Pharmacovigilance As global healthcare systems evolve, pharmacovigilance will play an increasingly pivotal role. The focus will shift towards personalized medicine, where monitoring individual patient responses to drugs will become central. Additionally, greater emphasis on patient engagement and transparent communication will redefine the relationship between healthcare providers and patients.

Conclusion Pharmacovigilance is the cornerstone of drug safety, ensuring that the medicines we rely on are both effective and safe. By bridging the gap between pharmaceutical innovation and patient safety, it upholds the integrity of healthcare systems worldwide.

As technology and global collaboration continue to advance, pharmacovigilance will remain a critical field in protecting and improving public health, shaping a safer and more informed future for all.

#pharmacovigilance service#pharmacovigilance#clinic#clinical research#clinical trial management#clinical trial operations#clinical trial monitoring

2 notes

·

View notes

Text

The Role of ERP in Managing Quality Control in Manufacturing

In the highly competitive manufacturing sector, maintaining stringent quality control is not just a necessity but a strategic advantage. In a landscape where efficiency and precision define success, integrating ERP for manufacturing companies in India has become a game-changer. The role of manufacturing ERP software in India extends beyond operational management; it plays a pivotal part in ensuring quality control throughout the production lifecycle.

Understanding the Need for Quality Control in Manufacturing

Quality control ensures that products meet predefined standards, adhere to regulations, and satisfy customer expectations. Without effective systems in place, manufacturing companies risk producing defective products, incurring financial losses, and damaging their reputation. This is where manufacturing enterprise resource planning software in India comes into play. By centralizing data and streamlining processes, ERP systems empower manufacturers to monitor, measure, and enhance quality at every stage.

How ERP Facilitates Quality Control in Manufacturing

1. Centralized Data Management

ERP systems consolidate data from various departments into a unified platform. This centralization is crucial for quality control, as it provides real-time access to critical metrics like raw material quality, production processes, and final product evaluations. ERP software companies in India ensure that manufacturers have a single source of truth, enabling faster and more informed decision-making.

2. Automation of Quality Checks

The manufacturing ERP module often includes automated tools for conducting quality checks. By automating repetitive tasks such as inspecting raw materials, testing products, and verifying compliance, ERP reduces human error and enhances efficiency. This capability is particularly valuable for industries with strict quality standards, such as automotive, pharmaceuticals, and electronics.

3. Compliance Management

Staying compliant with industry regulations is non-negotiable for manufacturing companies. ERP systems provide features that help monitor compliance parameters, generate audit reports, and track regulatory changes. ERP software providers in India offer tailored solutions to meet local and global compliance requirements, ensuring seamless operations.

4. Real-Time Analytics and Reporting

Real-time analytics is a cornerstone of modern ERP systems. These tools allow manufacturers to track quality metrics in real-time, identify deviations, and implement corrective actions instantly. The insights gained from these analytics not only improve quality but also drive process optimization.

5. Supply Chain Integration

Quality control begins with raw materials and extends through the supply chain. ERP systems facilitate end-to-end supply chain visibility, enabling manufacturers to assess supplier performance and ensure the quality of incoming materials. Many ERP solution providers in India offer integrated supply chain management modules to support this functionality.

6. Continuous Improvement through Feedback Loops

ERP systems support continuous improvement by capturing and analyzing feedback from quality control processes. This data is invaluable for identifying recurring issues, uncovering root causes, and implementing preventive measures. Top 10 ERP software providers in India have built-in tools for continuous quality enhancement, ensuring sustained excellence.

Benefits of ERP for Quality Control in Manufacturing

Integrating an ERP system offers several tangible benefits for quality control:

Enhanced Traceability: ERP systems provide traceability across the production process, making it easier to track and rectify defects.

Reduced Waste: By identifying inefficiencies and defects early, ERP reduces waste and optimizes resource utilization.

Improved Customer Satisfaction: Consistently delivering high-quality products strengthens customer trust and loyalty.

Cost Savings: Preventing defects and ensuring compliance minimizes the financial risks associated with recalls, fines, and reputational damage.

Choosing the Right ERP Software for Quality Control

Selecting the best ERP solution requires careful consideration of your manufacturing needs. Here are some factors to consider:

Industry-Specific Features: Look for manufacturing ERP software in India that offers modules tailored to your industry.

Scalability: Ensure the ERP system can scale with your business as it grows.

Integration Capabilities: The ERP should integrate seamlessly with your existing systems and technologies.

Vendor Expertise: Collaborate with an ERP software company in India with proven expertise in delivering quality solutions.

Why Indian Manufacturers Need ERP for Quality Control

India's manufacturing sector is poised for growth, driven by initiatives like Make in India and PLI schemes. However, this growth comes with increasing competition and stricter quality expectations. Leveraging ERP software providers in India can give manufacturers the edge they need to thrive in this evolving landscape.

A Trusted Partner for ERP Implementation

With numerous options available, finding the right ERP vendor is crucial. Leading ERP software companies in India offer customized solutions to meet the unique challenges of Indian manufacturers. These providers combine deep industry knowledge with cutting-edge technology to deliver exceptional results.

Shantitechnology: A Trusted Name in ERP Solutions

Shantitechnology, a renowned name among top 10 ERP software providers in India, specializes in delivering robust ERP solutions for manufacturing companies. Our comprehensive manufacturing ERP module is designed to address the intricacies of quality control, ensuring manufacturers achieve excellence with ease.

Conclusion

In the modern manufacturing landscape, quality control is not an isolated function but a core component of operational success. ERP systems empower manufacturers to seamlessly integrate quality control into their workflows, ensuring consistent product excellence. As one of the best ERP software providers in India, Shantitechnology is committed to helping manufacturers navigate the complexities of quality control with innovative ERP solutions. By embracing the right ERP system, Indian manufacturers can enhance their competitive edge, drive customer satisfaction, and achieve sustainable growth.

If you are looking to elevate your quality control processes, partner with a leading ERP software company in India like Shantitechnology. Contact us today to learn more about our customized ERP solutions and how they can transform your manufacturing operations.

#ERP software in India#Top 10 ERP software providers in India#ERP software company in India#Engineering ERP Software company in India#ERP software for engineering companies#Engineering ERP software solution#ERP software for engineering companies in India#ERP software providers in India#ERP software companies in India#ERP solution providers in India#Best ERP software provider in India#ERP for manufacturing company in India#Manufacturing ERP software in India#Manufacturing enterprise resource planning software in India#Manufacturing ERP module

4 notes

·

View notes

Text

Never thought I'd have to send one of these.

Image transcript:

ENMA 660 final project

[REDACTED] [REDACTED]

2:02 PM (3 minutes ago)

to [REDACTED]

Professor,

I appreciate you allowing me to schedule to present this week, however I have not been able to get much done. I have a format, a topic, and one diagram, which is far below the minimum requirement for this assignment. I took a week off from work last week with the intention of focussing on preparing my paper and presentation, but the anxiety from my uncertain housing situation has made it extremely difficult to concentrate on anything else.

The topic I want to write about is related to my work. Two years ago, engineering analysis indicated that some electronic components (voltage regulators, specifically) were going to become obsolete. There didn't appear to be a readily available equivalent on the market at that time. The regulators are part of a critical circuit path, so program management and contracts kicked off a negotiation process with the customer to fund a redesign effort. By the time the customer had approved a contract and allotted funding for the project, market conditions had changed. As I attempted to illustrate in the first homework assignment, market conditions have an enormous and often unpredictable impact on our lifecycle maintenance/support/sustainment efforts. In this case, some other customer must have communicated to the manufacturer that they needed those voltage regulators, in sufficient quantity to justify retaining the product line. I uncovered this when doing my own due diligence as part of the early phases of the redesign effort.

This left my company in the position of having to explain to our customer (and our customer to their customer, the US Government) that the funds allotted were no longer required, because we don't need to do a full redesign. There have been many questions floating around about how we could have avoided this situation, and that got me thinking about system management. How to balance the desire to be proactive, to respond to market pressures in a timely fashion, to avoid disruptions for our customer's supply chain and production schedule, without exposing the company to these kinds of risks?

I believe this is a good topic for the final project.

I am, unfortunately, unable to deliver on it due to forces beyond the scope of the course.

I'm not sure how to resolve the issue. If I fail the course, I will have to reimburse my company for the cost, and I clearly cannot pass the course while missing 50% of the graded material.

Thank you for your time,

[REDACTED]

48 notes

·

View notes

Text

youtube

The Story of the Playstation

" What started as a partnership to create a CD add-on for the super nintendo, quickly morphed into open feud between the biggest player in gaming, Nintendo, and electronics giant, Sony. What followed was the birth of one of the most iconic brands in gaming and some of the most important games ever released. This is the Story of the Playstation.

0:00 - Prologue

1:51 - Part 1 - A Failed Partnership

14:22 - Part 2 - Going Global

31:40 - Part 3 - 1997: The Year that Changed Everything

46:28 - Part 4 - The Road to 100 Million

01:01:01 - Interlude

01:01:19 - Guest Spot w/ Drunk Metroid

01:03:36 - Part 5 - The New King of Gaming

01:21:07 - Credits "

Source: Double Dog

#mktmarketing4you#corporatestrategy#marketing#M4Y#lovemarketing#IPAM#ipammarketingschool#ContingencyPlanning#virtual#volunteering#project#Management#Economy#ConsumptionBehavior#BrandManagement#ProductManagement#Logistics#Lifecycle

#Brand#Neuromarketing#McKinseyMatrix#Viralmarketing#Facebook#Marketingmetrics#icebergmodel#EdgarScheinsCultureModel#GuerrillaMarketing#STARMethod#7SFramework#gapanalysis #AIDAModel #SixLeadershipStyles #MintoPyramidPrinciple #StrategyDiamond #InternalRateofReturn #irr #BrandManagement #dripmodel #HoshinPlanning #XMatrix #backtobasics #BalancedScorecard #Product #ProductManagement #Logistics #Branding #freemium #businessmodel #business #4P #3C #BCG #SWOT #TOWS #EisenhowerMatrix #Study #marketingresearch #marketer #marketing manager #Painpoints #Pestel #ValueChain # VRIO #marketingmix #playstation #Metroid #Philips #Sony

Thank you for following All about Marketing 4 You

#marketing#marketing4you#youtube#branding#playstation#sony#sony playstation#nintendo#gamming#Youtube

2 notes

·

View notes

Text

Life Cycle Management

Electronic Manufacturing Services Across the Product Life Cycle

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Design For Excellence (DFX)#Return Merchandise Authorisation (RMA)#BOM Analysis#PLM Agile System For Program Management#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#Life Cycle-Management

2 notes

·

View notes

Text

Achieving Cost Savings through Supplier Collaboration in Siemens Teamcenter PLM Software

In the dynamic landscape of modern business, collaboration is the cornerstone of success. This holds true not only within an organization but also across the entire supply chain. Suppliers play a pivotal role in the journey from concept to creation, and their collaboration can yield significant cost savings and operational efficiencies. Teamcenter PLM's supplier collaboration features are transforming the way organizations interact with suppliers, leading to negotiated cost savings, improved procurement processes, and enhanced cost control. In this article, we delve into how Teamcenter PLM is fostering this collaborative spirit, backed by real-world examples.

A New Paradigm in Supplier Collaboration

Gone are the days of transactional relationships between organizations and suppliers. The modern approach is based on collaboration, where suppliers are viewed as strategic partners integral to the success of a project. Siemens PLM Software, with its comprehensive suite of supplier collaboration tools, empowers organizations to seamlessly integrate suppliers into their product development processes.

Negotiated Cost Savings: A Win-Win Scenario

Supplier collaboration in Teamcenter PLM opens the door to negotiated cost savings. When suppliers are brought into the design phase, they can offer valuable insights into cost-effective materials, manufacturing processes, and alternative components. By tapping into their expertise, organizations can optimize designs for cost efficiency without compromising on quality. For instance, a manufacturer collaborating with a supplier might identify a more cost-effective yet equally durable material for a component, resulting in substantial cost savings over the product's lifecycle.

Improved Procurement Processes: Streamlining Efficiency

Procurement is a critical component of the supply chain, and any inefficiencies can lead to increased costs. Teamcenter PLM's Cost Management Software supplier collaboration features streamline procurement processes by providing real-time visibility into supplier capabilities, capacities, and lead times. This enables organizations to make informed decisions about sourcing, reducing the risk of delays and costly last-minute changes. For instance, a company collaborating with a supplier can receive updates on raw material availability, helping them plan their production schedule and avoid costly supply shortages.

Enhanced Cost Control: Data-Driven Insights

Effective cost control requires accurate and up-to-date information. Teamcenter PLM's supplier collaboration features enable organizations to access real-time cost data from suppliers. This transparency empowers procurement teams to make strategic decisions based on actual costs rather than estimates. Furthermore, collaboration with suppliers can help organizations identify cost drivers and areas where cost reductions can be implemented. For instance, a company working closely with a supplier might discover opportunities to consolidate shipments, reducing transportation costs.

Real-World Examples of Success

Real-world examples illustrate the power of supplier collaboration in achieving cost savings. Consider a consumer electronics company partnering with a supplier to design a new smartphone. By collaborating closely, they identify a more cost-effective battery design that doesn't compromise on performance. This leads to reduced manufacturing costs and a competitive edge in the market.

In the automotive industry, a car manufacturer collaborates with a supplier of advanced materials. Together, they explore innovative materials that are not only lightweight but also cost-efficient. This collaboration results in cost savings due to reduced material consumption and improved fuel efficiency in the final product.

Conclusion: Empowering Future Success

Supplier collaboration through Teamcenter PLM software transcends traditional boundaries. It's a strategy that fosters innovation, efficiency, and cost savings. By involving suppliers early in the product development process, organizations can tap into their expertise, optimize designs, and make informed decisions that positively impact the bottom line. As the business landscape continues to evolve, organizations that embrace supplier collaboration are not only achieving cost savings but also laying the foundation for future success and growth.

For Free PLM Software trial, download Siemens Teamcenter PLM software trial!

#plmsoftware#costmanagementsoftware#what is plm software#plm software#siemens plm software#cost reduction software#free plm software

2 notes

·

View notes

Text

Reverse Logistics Solutions and Specialist Logistics Services

Understanding Reverse Logistics

Reverse logistics refers to the pathway goods take from their final destination back to the point of origin for the purpose of capturing value or proper disposal. This process covers returns processing, warranty recovery, remanufacturing, and recycling, all while challenging traditional forward logistics. The growth of e-commerce has led to increased product returns, making reverse logistics an essential aspect of supply chain management.

To effectively implement reverse logistics solution, organizations must leverage technology and data analytics. These solutions provide insights into return trends, customer behavior, and operational efficiency, which improve the overall logistics process. By streamlining reverse logistics, companies can reduce costs, enhance customer satisfaction, and contribute to environmental sustainability.

The Role of Specialist Logistics Services

Specialist logistics services are tailored solutions designed to meet the unique needs of various industries. These services go beyond standard logistics operations, often focusing on niche markets such as pharmaceuticals, food and beverage, and technology. By employing specialist logistics services, businesses can ensure compliance with industry regulations, improve delivery speeds, and reduce risks.

One critical aspect of specialist logistics services is IT asset disposal services. As technology evolves, companies frequently update their IT infrastructure, leading to the disposal of obsolete electronic equipment. Properly managing this process is vital for data privacy, regulatory compliance, and environmental responsibility. Partnering with a logistics provider that specializes in IT asset disposal not only ensures that sensitive data is securely wiped or destroyed but also enables companies to recycle or repurpose equipment effectively.

IT Asset Disposal Services

IT asset disposal services encompass the entire lifecycle of IT equipment, from decommissioning to recycling. This service aims to mitigate data breaches and ensure that obsolete technology is disposed of in an environmentally friendly manner. The process involves:

Auditing and Assessment: Conducting a detailed inventory of all IT assets to determine the status and potential reuse or recycling options.

Data Sanitization: Implementing rigorous data destruction methods to safeguard sensitive information before disposal.

Recycling and Disposal: Partnering with certified e-waste recyclers to ensure compliance with environmental regulations and standards.

By utilizing specialized IT asset disposal services, businesses can protect themselves from data leaks, comply with legal requirements, and contribute to sustainability initiatives.

IT Logistics Solutions

In addition to asset disposal, companies must also manage the logistics associated with IT equipment transportation, installation, and maintenance. IT logistics solutions provide a comprehensive framework for handling these logistics efficiently. These solutions may include:

Inventory Management: Keeping track of all IT assets, including their lifecycle and service history.

Transport Coordination: Ensuring safe and timely transportation of IT equipment to various locations, including end-users or new sites.

Deployment Services: Offering on-site installation and configuration of IT assets to minimize downtime and ensure optimal performance.

By leveraging IT logistics solutions, organizations can streamline the process of managing their technological infrastructure, allowing them to focus on core business operations.

Conclusion

In conclusion, reverse logistics solutions and specialist logistics services play a crucial role in modern supply chain management. With the rise of e-commerce and rapid technological advancement, businesses must adopt strategic approaches to their supply chain operations. Implementing effective reverse logistics processes can reduce costs while enhancing customer satisfaction. Furthermore, partnering with specialists for IT asset disposal and IT logistics ensures compliance, security, and sustainability.

0 notes

Text

The Sustainable Outlook: Innovative Strategies for Achieving Zero Waste in Urban Communities

The Sustainable Outlook emphasizes the importance of innovative strategies for achieving zero waste in urban communities. As cities continue to grow, waste management becomes a critical challenge, and implementing sustainable solutions is necessary to minimize environmental impact. Zero waste initiatives focus on reducing, reusing, and recycling materials to create a circular economy where waste is minimized or eliminated.

The Importance of Zero Waste in Urban Areas

Urban communities generate vast amounts of waste daily, including plastic, food scraps, electronic waste, and construction debris. Without proper waste management strategies, these materials contribute to landfill overflow, pollution, and greenhouse gas emissions. The Sustainable Outlook advocates for zero waste as a means to promote sustainability, conserve resources, and reduce environmental harm.

Key Strategies for Achieving Zero Waste

1. Implementing Comprehensive Recycling Programs

One of the most effective ways to reduce waste is through robust recycling programs. Many cities have introduced curbside recycling, deposit-return systems, and specialized collection for electronic and hazardous waste. The Sustainable Outlook suggests that urban areas should continuously expand and improve recycling facilities to accommodate a broader range of materials and ensure proper processing.

2. Encouraging Composting Initiatives

Food waste is a significant contributor to urban waste. Cities can implement large-scale composting programs that collect organic waste from households, restaurants, and businesses. Community composting initiatives allow residents to participate in sustainable waste management by converting food scraps into nutrient-rich soil amendments. The Sustainable Outlook highlights the benefits of composting in reducing methane emissions from landfills and improving soil health.

3. Supporting Circular Economy Models

A circular economy promotes the reuse of materials to extend their lifecycle and minimize waste. Businesses and manufacturers can design products with sustainability in mind by using recyclable materials and creating take-back programs. The Sustainable Outlook encourages companies to adopt circular economy principles by reducing packaging waste, offering repair services, and investing in sustainable materials.

4. Implementing Strict Waste Reduction Policies

Government policies play a crucial role in reducing waste at the source. Banning single-use plastics, enforcing extended producer responsibility (EPR) programs, and setting ambitious waste reduction targets are effective measures. The Sustainable Outlook recommends that urban policymakers work closely with businesses and residents to develop and enforce waste reduction regulations.

5. Promoting Public Awareness and Education

Achieving zero waste requires collective action from individuals, businesses, and governments. Cities can organize workshops, campaigns, and educational programs to raise awareness about sustainable waste management practices. The Sustainable Outlook stresses the importance of educating citizens on proper recycling techniques, composting benefits, and the impact of waste on the environment.

6. Investing in Advanced Waste Processing Technologies

Technological innovations are revolutionizing waste management. Waste-to-energy plants, AI-driven sorting systems, and biodegradable alternatives help reduce landfill dependency. The Sustainable Outlook highlights the role of cutting-edge technologies in transforming waste into valuable resources, such as energy, compost, and reusable materials.

Challenges in Achieving Zero Waste

Despite the numerous benefits, urban communities face several challenges in implementing zero waste initiatives:

Infrastructure limitations: Many cities lack the necessary facilities for efficient waste sorting and processing.

Public participation: Encouraging behavioral changes in waste disposal habits can be challenging.

Financial constraints: Setting up comprehensive waste management systems requires significant investment.

Policy enforcement: Effective legislation and monitoring mechanisms are needed to ensure compliance.

The Path Forward

To overcome these challenges, cities must adopt a multi-faceted approach that combines policy interventions, technological advancements, and community engagement. By fostering collaboration between government agencies, businesses, and residents, urban areas can make significant progress toward zero waste.

The Sustainable Outlook believes that with the right strategies in place, urban communities can transition to a waste-free future. By prioritizing sustainability, cities can protect natural resources, reduce pollution, and create healthier living environments for future generations.

0 notes

Text

Proactive Product and Supplier of Lifecycle Management – Stay Ahead of the Curve!

Resion offers cost-effective, proactive product and supplier lifecycle management solutions that help mitigate risks and maximize performance. Our scalable strategies ensure your electronic components meet the highest standards throughout their lifecycle. Keep your operations running seamlessly with Resion. Call 516-742-6300 for more information on how we can assist you with our services!

#Electronics Parts Suppliers#Largest Electronic Component Distributor#Sell Electronic components#Electronic Parts Distributor#Proactive Product and Supplier of Lifecycle Management#Proactive Product Supplier Lifecycle Management#Proactive Supplier Lifecycle Management#Electronic Product Lifecycle Management#Integrated Lifecycle Management For Electronics#Electronics Components Life Cycle Management

0 notes

Text

How to Choose an R2 Certified E-waste Recycler for Maximum Data Security

What is R2 Certification?

R2, or Responsible Recycling, certification is a globally recognized standard for electronics recyclers. It ensures that the recycler adheres to stringent environmental, health, safety, and data security practices. R2 certification is managed by SERI (Sustainable Electronics Recycling International) and involves rigorous auditing and compliance checks.

Benefits of R2 Certification

Choosing an R2 certified recycler guarantees that the recycler follows best practices in handling and processing e-waste. The certification focuses on:

Data Security: Ensuring that all data is securely destroyed.

Environmental Responsibility: Minimizing environmental impact through proper recycling techniques.

Worker Safety: Protecting the health and safety of workers involved in the recycling process.

Key Considerations for Choosing an R2 Certified Recycler

1. Verify Certification Status

Before engaging a recycler, it is essential to verify their R2 certification status. SERI maintains a public directory of R2 certified recyclers, which can be accessed online. Ensure that the recycler's certification is current and not expired.

2. Assess Data Destruction Methods

Data security is paramount when recycling electronics. R2 certified recyclers must implement robust data destruction methods to ensure that all data is irretrievably erased. This can include physical destruction, degaussing, or using software-based wiping techniques. Verify the recycler's data destruction procedures and request documentation or certificates of data destruction.

3. Evaluate Environmental Practices

An R2 certified recycler must adhere to environmentally responsible practices. This includes proper disposal of hazardous materials, minimizing landfill use, and maximizing the recovery of valuable materials. Assess the recycler's environmental policies and practices to ensure they align with your sustainability goals.

4. Check Compliance with Legal Requirements

Ensure that the recycler complies with all local, state, and federal regulations regarding e-waste recycling. R2 certification requires compliance with legal standards, but it is prudent to verify this independently. Non-compliance can result in legal liabilities and penalties.

5. Review Reputation and Track Record

Research the recycler's reputation and track record. Look for reviews, testimonials, and case studies from previous clients. A reputable recycler should have a history of reliable service and positive client feedback. Additionally, consider the recycler's experience in handling similar types of e-waste.

6. Consider Logistics and Service Capabilities

Evaluate the logistical capabilities of the recycler. This includes their ability to handle the volume of e-waste you generate, their collection and transportation services, and their processing facilities. Ensure that the recycler can provide timely and efficient services to meet your needs.

7. Request Transparency and Reporting

Transparency is crucial in the e-waste recycling process. An R2 certified recycler should provide detailed reports on the handling and processing of your e-waste. This includes tracking the e-waste from collection to final disposition, ensuring accountability and compliance with regulatory standards.

8. Understand Financial Implications

While cost should not be the sole factor, it is important to understand the financial implications of using an R2 certified recycler. Obtain detailed quotes and compare the costs of different recyclers. Consider the value provided by certified recyclers in terms of data security, environmental compliance, and legal assurance.

By following these steps, you can choose an R2-certified e-waste recycler that prioritizes data security and environmentally responsible practices. Remember, secure e-waste disposal protects your data, the environment, and your peace of mind.

3R Technology

8002 S 208th St E105, Kent, WA 98032

+12065827100

#e-waste recycling#electronicrecycling#secure data destruction#datadestruction#e-waste recycling event#data sanitization#data destruction#product lifecycle management#collection bin program#data destruction service#data shredding#e waste#recycling center#electronic recycling

0 notes

Text

The Role of Extended Producer Responsibility (EPR) in E-Waste Management.

Understanding EPR and Its Importance in E-Waste Recycling

E-waste is one of the fastest-growing waste streams in the world, and cities like Chennai, Bengaluru, Cochin, Hyderabad, and other parts of Tamil Nadu and Karnataka are seeing a significant rise in discarded electronics. With the increasing demand for technology, the challenge of proper e-waste disposal has become more pressing than ever. This is where Extended Producer Responsibility (EPR) plays a crucial role.

EPR is a policy approach where manufacturers and producers take responsibility for the entire lifecycle of their electronic products—including proper disposal and recycling. This ensures that harmful electronic waste does not end up in landfills, causing environmental and health hazards.

How EPR Supports Sustainable E-Waste Recycling

Under EPR regulations, producers are mandated to establish e-waste collection and recycling systems. Companies like Techazar help businesses comply with EPR guidelines by offering structured solutions for e-waste management. Through responsible disposal methods, electronic recycling centers in Chennai, Bangalore, Kerala, and Hyderabad are helping reduce the environmental impact of e-waste.

Key Benefits of EPR in E-Waste Management:

Reduces Environmental Pollution: Proper disposal prevents toxic elements like lead, mercury, and cadmium from polluting soil and water sources.

Encourages Recycling & Reuse: By mandating proper processing of old electronics, EPR promotes recycling and refurbishment.

Ensures Compliance & Accountability: Companies must follow environmental guidelines, ensuring a structured approach to waste management.

Creates Job Opportunities: The e-waste recycling sector in cities like Cochin, Bangalore, and Chennai is growing, providing employment in collection, processing, and recycling units.

How Techazar Helps Businesses with EPR Compliance

Techazar provides end-to-end IT recycling and e-waste disposal services, helping businesses navigate the complexities of EPR compliance. Whether you're looking for electronic pick-up near me or searching for an IT disposal company, Techazar ensures hassle-free and responsible e-waste collection across Tamil Nadu, Karnataka, and Kerala.

Our Services Include:

E-waste collection & segregation

Data destruction for IT assets

Safe disposal & recycling

EPR documentation & certification

By choosing Techazar, businesses can contribute to a sustainable future while staying compliant with EPR norms.

Why EPR Compliance is Critical for Businesses

If you're a business in Chennai, Bangalore, Hyderabad, or Cochin, staying compliant with EPR regulations is no longer optional. Government policies now require manufacturers, importers, and retailers to take responsibility for their electronic waste. Failure to comply can result in penalties and environmental damage.

Steps to Ensure EPR Compliance:

Partner with an E-Waste Recycling Expert – Companies like Techazar simplify the process.

Track & Report E-Waste – Maintain records of your disposed electronics.

Educate Employees – Promote awareness about responsible e-waste disposal.

Conclusion: A Sustainable Future with EPR & Techazar

EPR is not just about following rules—it’s about building a greener future. By responsibly managing e-waste through Techazar’s solutions, businesses in Chennai, Bengaluru, Kerala, and Hyderabad can contribute to a cleaner environment while ensuring legal compliance.

Looking for an e-waste recycling partner near you?

Contact Techazar today for expert guidance on IT disposal and EPR compliance.

#EPR#EWasteManagement#SustainableRecycling#ElectronicWaste#TechRecycling#EPRCompliance#WasteManagement#SustainableTech#GreenTech#RecyclingSolutions#CircularEconomy#TechWaste#ITRecycling#EcoFriendlyTech#EWasteDisposal

0 notes

Text

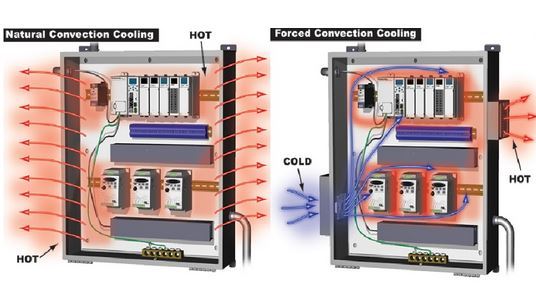

Custom Electrical Cabinet Cooling Fans: Tailored Solutions for Optimal Thermal Management

In industrial automation, renewable energy systems, and power control applications, electrical cabinet cooling fans are critical for maintaining operational stability. As electronic devices grow more powerful and operating environments become increasingly complex, off-the-shelf thermal solutions often fall short. With 20+ years of expertise in industrial thermal management, Cooltron delivers precision-engineered custom cooling fan solutions, system optimization, and full lifecycle support for global clients.

Why Custom Cooling Solutions Matter for Electrical Cabinets?

Industry-Specific Thermal Challenges Demand Specialized Approaches

Different sectors face unique cooling requirements:

EV Charging Stations: Must withstand extreme temperatures (-22°F to 131°F)

Factory Automation Panels: Require IP54+ dust/water resistance

Medical Equipment Enclosures: Need ultra-quiet operation (<35dB)

Offshore Power Cabinets: Require salt spray corrosion certification

Our engineering team combines CFD thermal simulations with real-world validation to create customized cooling models. In a recent semiconductor facility project, optimized fan placement reduced internal temperature variance from ±14.4°F to ±3.6°F, cutting equipment downtime by 67%.

5 Key Customization Factors for Precision Cooling

Case Study: For offshore wind turbines requiring 100,000+ hours in salt spray environments, our titanium-ceramic hybrid bearings with triple-seal architecture tripled service life versus industry standards.

Streamlined Customization Process (14-Day Prototyping)

On-Site Thermal Audit – 23-point inspection including heat mapping & environmental analysis

3D Simulation Modeling – ANSYS Icepak-powered airflow optimization

Functional Prototyping – 72-hour rapid testing with detailed performance report

Production Refinement – Mold adjustments for batch consistency

Smart Integration – Optional Modbus/RS485 connectivity for predictive maintenance

Why Cooltron Leads in Cabinet Cooling Tech?

Energy-Efficient Design: Patented blades achieve 82% aerodynamic efficiency (vs. 68% industry avg)

Military-Grade Durability: Dual ball bearings ensure 80,000-hour MTBF

Universal Compatibility: Supports 12-48VDC & 110-220VAC systems

Fast-Track Service: Standard custom projects ship within 2 weeks

FAQs: Custom Cooling Fans Explained

Q: Are custom fans more expensive than stock models? A: 63% of clients achieve lower TCO through right-sized solutions eliminating over-engineering.

Q: What about rush orders? A: Our 200+ modular designs enable 48-hour expedited shipping for urgent needs.

Q: Will upgrades disrupt existing systems? A: Universal mounting adapters ensure backward compatibility with legacy cabinets.

The Cooltron Advantage

CNAS-Certified Testing Lab (L12345)

Trusted by 300+ Fortune 500 Companies

Industry-Leading 3-Year Warranty

24/7 Technical Support Team

Get Your Free Thermal Analysis: Click the [Online Form] button to request a customized cooling solution and cabinet heat dissipation report.

0 notes

Text

Flipkart Case study on AI | Machine Learning | Data Analytics - How Flipkart uses Big Data

"Walmart-backed Flipkart is India’s largest e-commerce marketplace.

Starting from Smartphones, Books, Media, Consumer Electronics, Furniture to fashion and Lifestyle it offers everything in one (Two-Three) clicks. It was launched in October 2007. Flipkart is known for its path-breaking services like Cash on Delivery, No cost EMI and 10-day Replacement Policy."

Source: 5 Minutes Learning

#mktmarketing4you#corporatestrategy#marketing#M4Y#lovemarketing#IPAM#ipammarketingschool#ContingencyPlanning#virtual#volunteering#project#Management#Economy#ConsumptionBehavior#BrandManagement#ProductManagement#Logistics#Lifecycle

#Brand#Neuromarketing#McKinseyMatrix#Viralmarketing#Facebook#Marketingmetrics#icebergmodel#EdgarScheinsCultureModel#GuerrillaMarketing#STARMethod#7SFramework#gapanalysis #AIDAModel #SixLeadershipStyles #MintoPyramidPrinciple #StrategyDiamond #InternalRateofReturn #irr #BrandManagement #dripmodel #HoshinPlanning #XMatrix #backtobasics #BalancedScorecard #Product #ProductManagement #Logistics #Branding #freemium #businessmodel #business #4P #3C #BCG #SWOT #TOWS #EisenhowerMatrix #Study #marketingresearch #marketer #marketing manager #Painpoints #Pestel #ValueChain # VRIO #marketingmix

youtube

3 notes

·

View notes

Text

Expert Mechanical Design Consultant | DesignX5 - Innovative Solutions & Professional Services

Mechanical Design Consultant: Empowering Innovation with DesignX5

In today's fast-paced and competitive industrial landscape, partnering with a reliable and experienced mechanical design consultant is crucial for success. DesignX5 stands at the forefront of offering innovative mechanical design solutions that not only meet but exceed industry standards. As a trusted mechanical design consultant, DesignX5 provides a comprehensive suite of services that help businesses streamline their mechanical design processes, ensuring efficiency, functionality, and scalability.

A mechanical design consultant brings a wealth of expertise and industry knowledge that can greatly enhance the quality of your product development. At DesignX5, our team of seasoned engineers works diligently to provide cutting-edge mechanical design strategies tailored to your specific needs. Whether you’re in the automotive, aerospace, consumer electronics, or industrial equipment sector, DesignX5 offers unmatched proficiency as a mechanical design consultant.

What Makes DesignX5 the Best Mechanical Design Consultant?

When it comes to mechanical design consulting, companies require a partner that understands the intricacies of designing for performance, durability, and cost-effectiveness. DesignX5 is an industry-leading mechanical design consultant, committed to providing top-notch services that cover every stage of the mechanical design lifecycle. From conceptualization and prototyping to final production and testing, our consultants ensure that your designs are optimized for both functionality and manufacturability.

One of the key strengths of DesignX5 as a mechanical design consultant is our proprietary design libraries. These industry-leading resources significantly reduce development time while ensuring that your designs are built on proven, high-quality components. By leveraging these libraries, we eliminate common design flaws and help businesses avoid costly redesigns, making DesignX5 an invaluable partner in mechanical design consulting.

Moreover, as a mechanical design consultant, DesignX5 provides expert-led training courses that empower your in-house teams to develop their skills and understanding of modern design tools and methodologies. These training programs ensure that your team can operate independently while still benefiting from the expertise of our consultants whenever needed.

The Role of a Mechanical Design Consultant in Your Project

A mechanical design consultant plays a pivotal role in transforming an idea into a tangible, functional product. The expertise provided by DesignX5 ensures that your mechanical designs are not only feasible but also optimized for cost, performance, and production. Our team of professionals carefully analyzes your project requirements, considering factors such as material selection, stress analysis, thermal management, and manufacturing processes.

DesignX5’s approach as a mechanical design consultant focuses on collaboration. We work closely with your team to ensure that every detail of the design aligns with your objectives. Whether you need assistance with initial product design, redesign of an existing component, or the integration of new technologies, DesignX5 offers customized mechanical design consulting services to meet your needs.

Why Choose DesignX5 as Your Mechanical Design Consultant?

DesignX5 offers a range of services that set us apart as a leading mechanical design consultant:

Expertise Across Industries: Our team of engineers has extensive experience across multiple industries, from automotive to robotics, consumer electronics, and more. This diverse experience allows us to provide solutions that are both innovative and practical for your specific needs.

State-of-the-Art Tools and Technologies: As a mechanical design consultant, we employ the latest design tools and software to ensure that your projects are executed with the highest level of precision and efficiency. Our proficiency with tools like CAD, CAE, and CFD guarantees that your designs are optimized for functionality and manufacturability.

Design Libraries: DesignX5 is renowned for its industry-leading design libraries, which provide clients with access to pre-designed, high-quality components and systems. This significantly reduces development time, minimizes risk, and ensures your designs are based on best practices.

Cost-Effective Solutions: A major advantage of working with a mechanical design consultant like DesignX5 is our ability to help you manage costs. Our deep understanding of the design process allows us to create solutions that balance functionality and cost-effectiveness, ensuring your designs are not only high-performing but also budget-friendly.

Training and Development: In addition to our mechanical design consulting services, DesignX5 offers expert-led training programs to help your team stay ahead of industry trends and develop the necessary skills to manage projects independently. These training courses cover the latest advancements in mechanical design, CAD tools, and best practices.

How DesignX5 Enhances Your Product Development

When you choose DesignX5 as your mechanical design consultant, you gain access to a team of experts who are committed to enhancing every aspect of your product development. We take pride in helping businesses bring their ideas to life with designs that are not only functional but also innovative. Whether you are designing a new product from scratch or improving an existing design, our consultants work closely with your team to ensure the process is seamless and efficient.

From initial brainstorming and conceptualization to prototyping and final design, DesignX5 provides guidance every step of the way. As a mechanical design consultant, we employ a structured approach to design that involves rigorous testing, validation, and optimization, ensuring that your product is ready for production and meets all necessary standards.

Achieving Success with DesignX5: A Mechanical Design Consultant You Can Trust

Working with a qualified mechanical design consultant like DesignX5 is a surefire way to ensure the success of your project. We offer the tools, expertise, and support necessary to transform your concepts into reality. With a focus on quality, cost-efficiency, and time management, DesignX5 helps you stay ahead of the competition and bring products to market faster.

As your trusted mechanical design consultant, DesignX5 is committed to providing solutions that drive innovation and improve the overall performance of your products. By combining the latest technologies, proven design methodologies, and industry-leading libraries, we offer a comprehensive service that empowers businesses to achieve their goals.

Conclusion

The importance of a skilled mechanical design consultant cannot be overstated in today’s highly competitive industrial environment. With DesignX5 by your side, you gain access to unparalleled expertise, innovative design solutions, and resources that will help streamline your product development process. Whether you need assistance with the mechanical design of a new product or seek to optimize existing designs, DesignX5’s team of experts is ready to support your journey from concept to completion.

DesignX5 is more than just a mechanical design consultant; we are your partner in innovation, helping you bring your ideas to life with precision, efficiency, and creativity. With our industry-leading design libraries, expert-led training, and comprehensive consulting services, DesignX5 is the ideal choice for companies looking to elevate their mechanical design capabilities.

Follow Us:

Contact No.: +91 9909580337

Email: info@designx5.com

Website: https://www.designx5.com/

#MechanicalDesignConsultant#DesignX5#MechanicalDesign#EngineeringSolutions#ProductDesign#DesignConsulting#InnovativeDesign#CADDesign#EngineeringConsultant#DesignExpert#IndustrialDesign#MechanicalEngineering#ProductDevelopment#DesignLibraries#EngineeringExcellence

1 note

·

View note