#SMT Circuit Board

Explore tagged Tumblr posts

Text

How SMT Circuit Boards Enable Faster Production and Better Design Flexibility?

In the ever-evolving gadgets industry, producers look for advances that guarantee proficiency, versatility, and development. One such breakthrough is the SMT Circuit Board (Surface Mount Technology Circuit Board). By supplanting conventional strategies with progressed Surface Mount PCB arrangements, producers accomplish quicker generation cycles and more prominent plan adaptability. Here's how SMT PCB Boards revolutionize electronics manufacturing.

1. Streamlined Generation Process

The appropriation of Surface Mount Technology (SMT) has radically made strides the generation handle. Not at all like conventional through-hole strategies, SMT Circuit Boards permit components to be mounted straightforwardly onto the PCB's surface. This eliminates require for penetrating gaps and essentially decreases gathering time. Computerized apparatus can absolutely put and patch components in a division of the time required for manual forms, empowering speedier generation rates.

Additionally, the littler estimate of surface-mounted components implies more components can fit onto a single SMT PCB Board, decreasing generation complexity. This streamlined handle improves proficiency, particularly in high-volume fabricating situations, making Surface Mount PCBs the preferred choice for advanced electronic products.

2. Upgraded Plan Flexibility

One of the standout focal points of SMT PCB Board is their capacity to back imaginative and compact plans. The miniaturization of components guarantees that originators have more genuine domain on the PCB to work with, permitting them to incorporate extra highlights or make littler gadgets. From shrewd phones and wearable's to high-performance computing gadgets, the compact plan capability of SMT Circuit Boards is urgent to present day advancements.

Furthermore, Surface Mount PCB empower double-sided get together, permitting components to be mounted on both sides of the board. This adaptability is particularly useful for complex plans that require thick circuit formats. Engineers can make multi-functional Boards without compromising execution or reliability.

3. Improved Reliability and Performance

SMT Circuit Board gloat superior mechanical execution due to the nonappearance of leads and the compact nature of components. Shorter electrical ways diminish parasitic inductance and resistance, upgrading flag astuteness and control effectiveness. The result is a more dependable and high-performing circuit that can withstand higher frequencies and natural stresses.

4. Cost Savings in the Long Run

Although the introductory setup for Surface Mount PCB gathering may be higher due to progressed gear, the long-term benefits exceed these costs. Quicker generation, negligible manual labor, and diminished fabric utilization result in critical taken a toll reserve funds over time. Additionally, the unwavering quality of SMT PCB Boards diminishes revamp, absconds, and guarantee claims, advance driving down costs.

Conclusion

The selection of SMT Circuit Boards has changed the gadgets fabricating scene. By empowering quicker generation cycles, supporting compact and inventive plans, and conveying prevalent unwavering quality, Surface Mount PCBs enable producers to meet the requests of cutting edge Technology. Their commitment to proficient and adaptable generation makes them crucial in the travel toward more progressed and useful electronic gadgets.

0 notes

Text

0 notes

Text

The Evolution of SMT Circuit Boards: Enhancing PCB Assembly and Assembled Circuit Boards

Most of the sophistication and efficiency that characterizes modern technology is due to the applications set forth by electronic technology. The center of all these lies in surface mount technology (SMT) in the printed circuit boards that has altered the birth of electronic devices and devices. It is worked up over the course of SMT together with the advances that came in the printed circuit board (PCB) assembly techniques, making smaller and more potent devices more agile and more efficient as well.

Visit At-https://pcbandassembly.com/blog/the-evolution-of-smt-circuit-boards-enhancing-pcb-assembly-and-assembled-circuit-boards/

0 notes

Text

The Importance of SMT Circuit Boards in PCB Assembly for Modern Electronics

Modern electronics are indeed becoming a crucial part of our lives-whether through smart phones or laptops or medical devices or automotive systems. This article presents the application of SMT circuit boards in PCB assembly and their value to modern electronic systems. To continue reading click on the link.

0 notes

Text

Medical PCB Assembly

Medical PCB Assembly Manufacturer – One-stop service

Medical PCB Assembly Manufacturer – One-stop service

Medical devices (medical PCB assembly) refer to instruments, devices, instruments; in vitro diagnostic reagents and calibrators, materials, and other similar or related items. There are used directly or indirectly in the human body, including the required computer software.

Hitech Circuits has extensive experience in providing medical PCB assembly services to our medical industry customers, and we deeply understand that our medical PCBA will be used in life-critical medical devices, which have extremely high requirements for precision and reliability.

We are committed to offering the world-class PCBA by strictly controlling the quality of every piece, our medical PCB assembly, box build assembly, and prototypes assembly capacities allow us to assemble kinds of medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

At Hitech Circuits, we take care of the medical PCB assembly of your product so you can spend more time running your business and marketing your medical devices.

Hitechpcba medical PCB assembly technique:

Whether in a controlled environment such as a hospital or in an uncontrolled environment such as a home health care center, medical equipment must protect the lives of patients and surgeons. Medical PCBA refers to instrumented circuit boards that are used directly or indirectly in the human body. Such as instruments, equipment, instruments, in vitro diagnostic reagents, and calibrators, materials, and other similar or related instruments.

Therefore, the requirements for component procurement and processing are very strict, and a more precise technique is required, which is produced by IPC Class 3 standard. Hitechpcba is fully certificated, apart from certifications of ISO9001:2015, ISO14001, REACH and IATF16949, we have also obtained the ISO13485 certification, which means that our PCBs can meet the high standards required by medical devices, and all of our finished medical devices are of FDA Class II. Working with us can avoid you from worrying about the quality problem.

This standard provides you with the ability to produce and manufacture to meet higher customer needs. In the medical device industry, safety and quality are not negotiable. At every step of the product life cycle, including service and delivery, regulatory requirements are becoming more stringent.

More and more industry organizations want to showcase their quality management processes and make sure that everything they do is best practice. PCBA is used in the medical industry to bring good news to patients. Hitechpcba is a certified manufacturer offering a one-stop PCB and PCBA turnkey service with 15 years experience and we have the confidence to become your preferred supplier.

Hitechpcba advantages:

We offer unprecedented service and flexibility for any medical device PCB. Without a small batch test, you can’t start your concept prototype so that it doesn’t help you get it to market. We offer comprehensive engineering support to make your medical device printed circuit board manufacturing process reality in the most cost-effective way.

We provide high-end customized processing services for PCBA in medical machinery customers. It is manufactured by PCB circuit board, component procurement, SMT chip processing, patch plug-in soldering, assembly testing and other one-stop services.

QC was set up in front of the furnace for poor screening, PCBA 100% visual inspection after furnace, PCBA 100% optical inspection, and 13 temperature zone reflow soldering each product independently set temperature. Must undergo rigorous tests, such as ICT, FCT, Burn-in test. The products produced include monitors, pacemakers, sphygmomanometers, etc.

We ensure the quality, reliability, and traceability of our medical PCB manufacturing assembly.

Over 15 Years of Medical PCBA Experience

With more than 10 years of experience in offering PCB assembly services, we have a good understanding of the medical industry, our experts have participated in a host of projects to provide medical PCBA solutions to leading medical companies and get trusted by them.

Types of Medical PCB Assemblies

As a PCB expert, Hitechpcba is capable of assembling types of medical PCBs such as multi-layer PCBs, rigid, rigid-flex PCB, and flexible PCBs, and there are various PCB materials available including copper, aluminum, and standard FR4, etc. So our medical PCB assembly solutions can be used for almost all medical devices.

High Efficiency

We utilize state-of-the-art equipment for medical PCB assembly that can reduce errors during the assembly process, meanwhile, we have proficient workers who know how to assemble PCBs correctly and efficiently.

The trend of PCB Medical Industry

The medical field is not like it used to be. Advances in technology have revolutionized the industry. This change is even more evident in electronic diagnostic, research, and treatment systems and tools. Every day, several complex electronic devices and instruments are introduced to simplify various medical procedures. This growth has largely benefited the PCBA technology industry because, without PCB in medical, new inventions would not be impossible. To meet the ever-changing needs of medical device and diagnostic machine manufacturers, today's PCB manufacturers are manufacturing extremely simple parts into highly complex PCB in medical industry. Using specialized high-speed laminates, copper and aluminum substrates, ceramics, and coatings, PCB manufacturers can make these boards best suited for medical industry applications.

Custom Medical PCB Assembly

Custom circuit board design in medical is the trend today. The medical industry has chosen the same approach when it comes to PCB. Customers can provide the correct specifications with the full form of PCB in medical for board size in X-direction, board size in Y-direction, total number of holes, minimum alignment and pitch size in inches, board material, number of layers, surface coating, etc. Therefore, the manufacturer will work according to the given specifications and deliver the right product for your application.

#pcb assembly#pcba#SMT & PCBA manufacturer#OEM assembly manufacturing#Printed Circuit Board Assembly

0 notes

Text

Flex PCB Details Display......

#FPCway#flex PCB#flexible circuit board#rigid-flex PCB#Rigid-flex circuit board#FPC prototype#flex PCB and assembly#rigid-flex PCB manufacturer#flex PCB assembly#flex PCB and SMT#FPC manufacturer#flex circuit prototype#fpcway.com

0 notes

Text

PCB Assembly & Electronic Assembly service & electronics manufacturing company – Hitech Circuits Co., Limited As leading one-stop PCB Assembly services provider in China, Hitech Group offers high quality, cost effective and express PCB board products and provides PCB manufacturing, electronics assembly manufacturing, components sourcing, Box build assembly and PCBA testing services for our customers. [email protected] www.hitechcircuits.com

#pcba manufacturing#pcb manufacturer#pcb assembly#flex pcb#pcb fabrication#pcb#pcb factory#smt assembly#flexible circuit board

0 notes

Video

youtube

PCBA factory from China -- Hitechpcba

This is a 6-layer through hole PCB with impedance controlled, the raw material is IS400, as you see the surface finish is ENIG, the copper thickness is 1OZ for all layers, the finished thickness is 1.63mm. Besides, you can see, this is a PCBA board mounted on both top side and bottom side, also a BGA component were assembled on the board. We Hitech Circuits not only provide PCB manufacturing service, also provide service of components sourcing and assembly for our customers. If you have interest, please feel freely to contact us.

Hitechpcba offer turnkey electronics assembly services, including prototype pcb assembly or low & high volume pcb assembly production. Our PCB assembly service always exceed customer’s expectations for quality, price and delivery. We manage the whole process including ordering PCB manufacturing, sourcing components, PCB assembly, and PCBA testing, etc. www.hitechpcba.com

0 notes

Text

#smart watch assembly#smart watch factory#smart wearable tws assembly#cable wiring harness factory#quality Smart Watch Assembly#affordable Smart Watch Assembly#best Smart Watch Factory#electronics pcba factory#printed circuit board assembly#electronics#smt pcb jobwork#electronics manufacturer

0 notes

Text

if you just engage in or somehow need this printed circuit assembly or custom another new one,welcome contact me to know more details

#PCB Assembly#PCBA#Printed circuit board assembly#SMT board#SMD board#surface mounted technical board#surface mounted device board

0 notes

Text

Comprehensive Guide to SMT Circuit Board, Surface Mount PCB, and PCB Assembly Manufacturing

Surface Mount Technology (SMT) is at the heart of present day hardware, powering everything from smart phones to mechanical apparatus. In this direct, we investigate the basics of SMT Circuit Boards, Surface Mount PCBs, SMT PCB Boards, and the PCB assembly Manufacturing prepare. This comprehensive see at SMT highlights its focal points, the Manufacturing prepare, and its applications over different industries.

What is an SMT Circuit Board?

An SMT Circuit Board alludes to a printed circuit board (PCB) on which components are mounted specifically onto the surface, utilizing Surface Mount Technology. This strategy permits for a more compact and effective board plan, making it perfect for advanced gadgets. Not at all like conventional through-hole strategies, SMT does not require boring, permitting for quicker, more exact assembly.

Understanding Surface Mount PCB and SMT PCB Board

A Surface Mount PCB is a PCB particularly planned to bolster surface-mounted components. Utilizing SMT, producers put components on the PCB’s surface, permitting for a thick and proficient plan. This Technology is fundamental in miniaturized electronic gadgets, as it spares space without compromising performance.

The SMT PCB Board is commonly utilized over businesses, from customer gadgets to aviation Technology. Due to its compact plan, it is perfect for high-performance applications that require accuracy and durability.

Key Preferences of Surface Mount Technology in PCB Assembly

Surface Mount Technology offers various benefits that make it crucial in PCB Assembly manufacturing:

1. Compact Design

SMT permits for littler and lighter Boards, fundamental in today’s miniaturized gadgets, from smart phones to restorative equipment.

2. High-Speed Manufacturing

With computerized machines putting components, SMT streamlines the generation handle, empowering speedier Manufacturing speeds.

3. Improved Execution and Reliability

SMT components are less likely to involvement physical stretch, giving superior unwavering quality in high-vibration environments.

4. Reduced Cost

SMT assembly requires less materials and less labor, decreasing in general Manufacturing costs.

The Handle of PCB Assembly Manufacturing Utilizing SMT

PCB Assembly Manufacturing utilizing SMT includes a few exact and profoundly controlled steps:

1. Solder Paste ApplicationA stencil is utilized to apply patch glue to the zones where components will be put. This glue serves as the “Paste” for surface-mounted components.

2. Component Placement

Automated machines put each component precisely onto the patch paste-covered zones. This step is vital for adjusting components precisely.

3. Reflow Soldering

The PCB is at that point warmed in a reflow stove, softening the patch glue and making solid, steady bonds between components and the board.

4. Inspection and Quality Control

Once patched, the SMT PCB experiences thorough review. Strategies like Automated Optical Inspection (AOI) and X-ray assessment distinguish surrenders to guarantee ideal performance.5. Testing

Finally, utilitarian testing is conducted to affirm that the board works as planning. Imperfect Boards are repaired or disposed of to keep up tall quality.

Applications of SMT Circuit Boards and Surface Mount PCBs

Due to their compact estimate and tall unwavering quality, SMT Circuit Boards and Surface Mount PCBs are utilized in a wide extend of applications:

• Consumer Gadgets such as smart phones, portable workstations, and wearable's.

• Automotive Hardware for motor control units, infotainment, and security systems.

• Medical Gadgets counting symptomatic gear and convenient wellbeing monitors.

• Telecommunications for arrange foundation, switches, and flag preparing devices.

• Aerospace and Protection where solidness and execution beneath extraordinary conditions are critical.

Choosing a Solid PCB Assembly Manufacturer

Selecting the right PCB assembly manufacturer is significant for accomplishing quality and unwavering quality in electronic items. A dependable producer provides:

• Expertise in SMT Assembly

Look for producers experienced in SMT, guaranteeing they utilize the most recent Technology and high-quality materials.

• Advanced Testing and Quality Assurance

The producer ought to have strong quality control forms to guarantee each board meets strict standards.

• Custom Solutions

Choose a supplier competent of customizing PCB plans to fit your particular venture requirements.

Final Considerations on SMT Circuit Boards and PCB Assembly Manufacturing

SMT Circuit Boards and Surface Mount PCBs are essential in advanced electronic gadgets. Their compact, proficient plan permits for tall execution in a assortment of applications. Whether you're creating shopper hardware or mechanical hardware, choosing high-quality SMT PCB Assembly can altogether affect the unwavering quality and victory of your item.

0 notes

Text

Our PCB assembly Illinois firm has been providing IPC-610-compliant, high-quality, on-time, affordably-priced circuit board assemblies for the better part of the last fifty years. We are also AS9100D certified and SBA and ITAR registered. New certifications and approvals for the business include MIL-PRF-55110, MIL-PRF-31032, ITAR, and ISO-9001D. Not only does PNC employ people who have certifications like IPC-A-600 and IPC-A-610, but the company also has an in-house trainer who helps other employees get certified as well (J-STD-001, for example).

0 notes

Text

Reliable, Affordable & Trustworthy Electronics PCB Repair Services & Courses Across Canada/USA

Wireless Training Center is a well-known name in the electronics industry, providing top-notch Electronics PCB repair services in Canada and the USA. With years of experience and expertise, we have established ourselves as one of the best providers of PCB Repair Technician Courses in Canada/ USA.

Wireless Training Center has highly skilled and experienced technicians. Our technicians have been trained to the highest industry standards and are equipped with the latest tools and technology to provide the best possible service and Courses. We can troubleshoot and repair a wide range of PCB issues, including faulty components, damaged circuits, and broken connections.

We use only high-quality components and materials in repairs, ensuring that the repaired PCB will be reliable and long-lasting. Wireless Training Center's PCB repair services are not limited to any specific industry or application. We have experience working with a wide range of PCBs, including those used in the telecommunications, medical, automotive, and industrial sectors. Whether it's a simple repair or a complex overhaul, we have the expertise and experience to get the job done right. This makes us a one-stop-shop for all your electronics needs, whether you're looking for Certified Circuit Board Repair Professionals Training Course or MacBook and iMAC Mother Board Repair Courses in Montreal, Toronto and Vancouver.

Wireless Training Center is also known for its exceptional customer service. We understand that when a customer's PCB is not working, it can have a significant impact on their business operations. That's why we offer quick service to our customers. We also deliver a range of service and course options, including PCB, SMT Rework, reflow and repair training in Canada / USA, to ensure that customers can get their PCBs fixed as quickly and conveniently as possible.

For further info give us a call at (778) 835–2763 or visit us at: https://wirelesstrainingcenter.com/

#PCB#SMT Rework#reflow and repair training in Canada / USA#SMT#THT#Hand Soldering workshops in Canada/ USA#MacBook and iMAC Repair Training Courses in Canada#Cell Phone Repair Course in Calgary#Cell Phone Repair Classes in Mississauga#Circuit Board Certifications#BGA Rework Certifications#Certified Circuit Board Repair Professionals Training Course#Electronics PCB repair services

0 notes

Text

Just How Carries Out A PCB Assembly Procedure Job?

The PCB assembly process begins with PCB fabrication, adhered to by part purchase. Parts are then put on the board utilizing automated pick-and-place devices. Solder insert is applied to connection parts during the course of reflow soldering. Inspection methods like AOI as well as practical testing ensure quality. Finally, panels are packaged for delivery after passing QC checks.

4 notes

·

View notes

Text

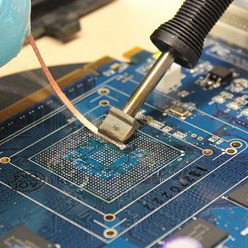

Selective soldering 🔧🔬🔥

Selective soldering involves attaching specific components to printed circuit boards (PCBs) and molded modules, a method particularly useful for items susceptible to heat damage from standard reflow ovens or wave soldering found in conventional surface-mount technology (SMT) or through-hole assembly techniques. Typically, this method is applied after an initial SMT oven reflow phase. The components targeted for selective soldering are often nestled among others already soldered via a surface-mount reflow method. This demands high precision in the selective soldering process to prevent damage to the surrounding elements.

#adafruit#selectivesoldering#pcbassembly#electronicsmanufacturing#surface-mount#throughhole#reflowprocess#precisionengineering#solderingtechnology#circuitboarddesign#manufacturinginnovation#techadvancements

5 notes

·

View notes