#FPC prototype

Explore tagged Tumblr posts

Text

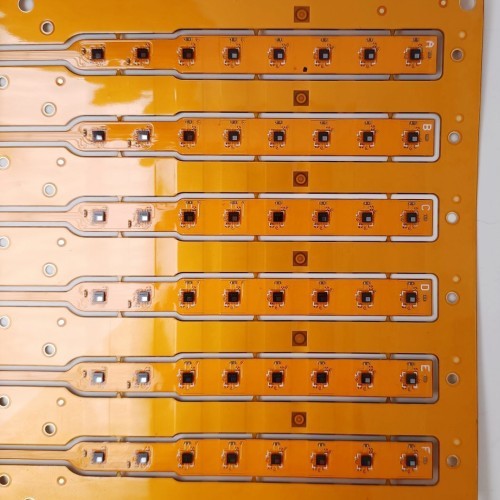

Flex PCB Details Display......

#FPCway#flex PCB#flexible circuit board#rigid-flex PCB#Rigid-flex circuit board#FPC prototype#flex PCB and assembly#rigid-flex PCB manufacturer#flex PCB assembly#flex PCB and SMT#FPC manufacturer#flex circuit prototype#fpcway.com

0 notes

Text

Unraveling the World of Flex Circuit Prototypes: Choosing the Right FPC Manufacturer

Introduction

Flex Printed Circuit Boards (Flex PCBs), often referred to as Flex Circuits, have become indispensable in today's electronics industry. These bendable and versatile circuit boards are a crucial component in various applications, from medical devices and aerospace systems to consumer electronics. When it comes to designing and producing Flex PCB prototypes, choosing the right FPC manufacturer is paramount. In this blog post, we will explore the world of Flex Circuit Prototypes and discuss the key considerations when selecting an FPC manufacturer.

Understanding Flex Circuit Prototypes

Flex Circuit Prototypes are specialized printed circuit boards designed to be flexible, allowing them to conform to intricate shapes or fit into compact spaces. These boards are typically made from flexible substrates like polyimide (PI) or polyester (PET) and can have single or multiple layers, depending on the complexity of the circuit. Flex circuits can be found in products ranging from smartphones and wearable devices to automotive control systems.

Why Choose Flex Circuit Prototypes?

Space Efficiency: Flex PCBs are ideal for applications with space constraints, as they can be folded or bent to fit into tight spaces, reducing the overall size of the device.

Reliability: Flex circuits offer excellent reliability due to their reduced number of interconnects, which minimizes the risk of connection failures and short circuits.

Weight Reduction: Flex circuits are lightweight, making them a preferred choice in applications where weight reduction is critical, such as aerospace and automotive industries.

Durability: These circuits are more robust and can withstand vibrations and shock, making them suitable for applications that experience harsh environments.

Click here for more information: https://www.tumblr.com/fpcway/731599943480000512/exploring-fpc-assembly-flex-pcb-material-and

#Flex PCB#Flex Circuit Prototype#FPC Manufacturer#Flex PCB Material#FPC Prototype#Flexible Printed Circuit

0 notes

Text

DVI output adapter for RP2350 Feather HSTX port 🔌🖥️💡

The RP2350 Feather has an FPC output connector for accessing the HSTX - high-speed transmission - peripheral. This lets us drive DVI displays really easily! Today, we got the prototype PCBs for our HSTX to DVI adapter board; after connecting up a 22-pin FPC cable, we can test out DVI driving via CircuitPython. With HSTX, we don't need to overclock or use PIO, and there's a lot more RAM on the RP2350, so we can easily do 320x240 with 16-bit color and have plenty of SRAM left over. It would be neat if we could do DVI from the PSRAM as a framebuffer at some point for really big displays!

#adafruit#circuitpython#rp2350#feather#fpc#hstx#dvi#hdmi#sram#prototyping#electronics#dviadapter#dviproject#fpgadisplay#displaytech#highspeeddata#techinnovation#diyhardware#featherboard#microcontroller#raspberrypi#displayoutput#circuitdesign#openhardware

7 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Photo

cute i like #beautiful colors

Quick FPC, Rigid-flex PCB prototype and PCB Assembly...

Art by Leah Gardner

70K notes

·

View notes

Text

Luphi Electronics see you at Electronica 2024(Munich,Germany)

Electronica 2024 will cover the entire electronics spectrum, featuring everything from components to systems. Luphi Electronics participates in the 2024 Germany Munich Electronics Fair, from November 12 to 15, 2024. Welcoming numerous professionals from various countries to visit LuphiTouch ( Hall C6, Booth 341.8)!

About Luphi Electronics

Dongguan Luphi Electronics Technology Co., Ltd. (Trademark: LuphiTouch) was established in 2015. The factory covers 4500 square meter. We have 80+ workers and we have been certified by ISO9001, ISO13485, ISO14001 and ISO45001. LuphiTouch mainly focuses on various kinds of human machine interface switch panels, keypads and modules development and manufacturing. Our capabilities cover from mechatronic design, graphic art design, function control PCBA development, MCU development, IC programming, embedded system development to tools making, prototypes making, function testing, mass production and shipping of one-stop total solutions service. We also provide circuit board manufacturing, components sourcing, SMT&PTH assembly, EMS contract manufacturing service for our end clients.

On this fair, Luphi Electronics will show our high quality Products include:

· Medical Membrane Switches(Medizinische Folientasten)

· Backlighting Membrane Switches(Hinterleuchtete Folientasten)

· FPC Membrane Switches(FPC-Folientasten)

· PCB Membrane Switches(PCB-Folientasten)

· Silicone Rubber Keypads(Gummitasten)

· Capacitive Membrane Switches(Kapazitive Folientasten)

· Backpanel Membrane Keypads (Rückseiten-Folientasten)

· Touchscreen & LCDs(Touchscreens und LCDs)

· User Interface Modules(Benutzeroberflächen module)

......

We serve various industries such as medical, industrial control, home appliances, new energy, instrumentation, rail transportation, aviation and navigation, network communications, and mechanical equipment.

Our Commitment to Quality

At Luphi Electronics, we prioritize quality and innovation. Our manufacturing processes are certified under ISO standards (ISO9001, ISO14001, ISO13485, and ISO45001), ensuring that our products meet the highest industry standards. We are proud to be the first ISO13485-certified membrane switch factory in China, we sincerely expect your inquires and look forward to the long-term & stable cooperation with your company!

Professional HMI Switch Sub-assemblies & Touch Display Modules Provider!

Luphi Electronics official website: https://www.luphitouch.com

0 notes

Text

Flexible Leiterplatte (Flexible Printed Circuit, FPC) ist sehr beliebt mit ausgezeichneten Eigenschaften wie geringem Gewicht und dünner Dicke, etc. Es kann auch frei gefaltet werden. Flexible Leiterplatte basiert hauptsächlich auf manueller visueller Inspektion mit hohen Kosten und niedriger Effizienz. Mit der schnellen Entwicklung der Elektronikindustrie ist das Design von Leiterplatten immer präziser und dichter geworden, traditionelle manuelle Prüfmethoden können die Produktionsanforderungen nicht mehr erfüllen. FPC-Fehlerautomatisierungstests sind zu einem unvermeidlichen Trend der industriellen Entwicklung geworden.

0 notes

Text

FPCway: Specialized manufacturer of flexible printed circuit boards

and rigid-flexible printed circuits

In today's fast-paced technology landscape, the demand for smaller, lighter, and more complex electronic devices continues to rise. Whether it's a sleek smartphone in your pocket or a sophisticated medical device in a hospital, these devices rely on cutting-edge printed circuit boards (PCBS) to run efficiently. Among the many types of printed circuit boards available, flexible printed circuits (flex PCBs) and rigid-flex printed circuits (Rigid-Flex PCBS) are increasingly favored due to their versatility and rich and diverse design possibilities.

Advantages of Flexible Printed Circuit (Flex PCB) :

Space efficiency: Very thin and lightweight, ideal for small electronic devices.

High reliability: Fewer interconnections and solder joints increase reliability and reduce points of failure.

Strong durability: Flexible printed circuits can withstand vibration, shock and extreme temperatures, making them ideal for harsh environments.

Freedom of design: The flexibility of the substrate allows for creative and innovative designs that may not be possible with rigid printed circuits.

Advantages of rigid-flex PCBs:

Space optimization: Flexible printed circuit (Flex PCB) components allow the integration of multiple PCBS and connectors, saving valuable space.

High reliability: Fewer connectors and solder joints reduce the risk of connection failure and signal loss.

Complex geometry: Rigid-flexible printed circuits can be designed to fit non-standard and irregular shaped enclosures.

Reduce weight: Reduce connectors and cables to reduce the overall weight of the device.

FPCway is a PCB manufacturing company located in Shenzhen, China, specializing in the manufacture of flexible printed circuit boards and rigid-flexible printed circuits. The circuit boards produced have been widely used in mobile communication, Internet of Things, optoelectronics, industrial control, medical equipment, consumer electronics and other high-tech industries. The products produced by FPCway are exported to all over the world. At present, FPCway has more than 5000 square meters of FPC workshop, which has 12 SMT production lines and 2 THT production lines. FPCway has more than 200 employees, with more than 20 senior executives with decades of industry experience. With this experience and advanced equipment, we have maintained excellent technical capabilities and strong competitiveness in the Flex PCB industry.

FPCway: From prototype to assembly to product

FPCway provides Flex PCB and rigid-flex PCBs from prototype design to assembly to product, while more than 200 professionals ensure zero defects and the fastest delivery time. The company sources materials from well-known brands and maintains ISO 9001, IATF16949 quality systems and UL certification, facilitating customers' access to commercial products.

Flexible PCB prototype: The production process of FPCB products usually starts from making prototypes, FPCWay almost does not limit the appearance size of FPCB, and can adjust the substrate, thickness and layer number of products according to customer needs.

Flexible PCB assembly: Bring goodness to life

Designing and manufacturing flexible printed circuits (flex PCBs) and rigid-flex PCBS is a highly specialized process that requires specialized knowledge and advanced equipment. Flexible printed circuit (Flex PCB) components are a key step in translating these innovative designs into functional electronic devices. FPCway's engineers consider the flexibility and form factor required by the customer to create a suitable flexible printed circuit (Flex PCB) layout choice; Secondly, the appropriate substrate material is selected based on factors such as flexibility, temperature resistance and intended application. The manufacturer then uses a combination of addition and subtraction processes to create the flexible circuit, which involves etching, drilling, and laminating together. FPCway uses advanced automatic pickers to precisely place components on manufacturing flexible printed circuits (flex PCBs) or rigid-flex PCBS, then apply solder paste to the component pads, heat the components to melt the solder and establish electrical connections. Finally, engineers ensure that flexible printed circuit (Flex PCB) or rigid-flex PCBs components meet quality and functional standards through rigorous testing to ensure that the product has zero defects.

FPCway through the construction of a strong talent team and increase capital investment in the purchase of new equipment, and from prototype design to assembly to the entire process of product accurate control, to ensure product quality, FPCway at a very competitive price to provide first-class service. The company stands out in the flexible printed circuit board industry for its superior technical capabilities, excellent product quality and timely delivery of products.

0 notes

Photo

Buy quality and reliable FPC Prototype. Our flexible printed circuit is mainly designed base on a flexible board, wirings on the flexible board and connection pads. Get More Details: https://www.pcb-togo.com/single-sided-flex-board-fpc

0 notes

Text

What's the thickest copper of flexible circuit?

Actually, it mainly depends on the demands of FPC customers; Generally speaking, the most used copper thickness of Flex PCB that is 1/2oz, 1oz and whose thickest copper is 2oz.

Considering FPC is soft in nature, which is not recommended to adopt much too thick copper.

PS: 1oz = 35.56um

http://www.58pcba.com/index.php?id=650

0 notes

Text

Flex PCB Details Display......

#FPCway#flex PCB#flexible circuit board#rigid-flex PCB#Rigid-flex circuit board#FPC prototype#flex PCB and assembly#rigid-flex PCB manufacturer#flex PCB assembly#flex PCB and SMT#FPC manufacturer#flex circuit prototype#fpcway.com

0 notes

Text

Exploring the World of Rigid-Flex Circuit Boards and Flex PCB Prototypes

Introduction

In the ever-evolving world of electronics, innovation is the name of the game. With a constant demand for smaller, more efficient, and versatile electronic devices, manufacturers are continually pushing the boundaries of what's possible. One significant development in this field is the use of flexible printed circuits (FPCs), rigid-flex PCBs, and the intricate process of flex PCB assembly. In this blog post, we will explore these cutting-edge technologies, their applications, and the rigid flex PCB manufacturer behind them.

Flexible Printed Circuits (FPCs)

Flexible printed circuits, often referred to as FPCs or flex circuits, are a vital component in modern electronic devices. They offer a flexible alternative to traditional rigid PCBs, making them ideal for applications where space and weight are at a premium. FPCs are constructed using flexible base materials, typically polyimide, and are designed to be thin and lightweight. Here are some key advantages of FPCs:

Space Efficiency: FPCs can be bent and folded to fit into tight spaces, making them invaluable in compact electronic designs.

Weight Reduction: Since FPCs are lightweight, they help reduce the overall weight of electronic devices, a critical consideration in industries like aerospace and automotive.

Reliability: FPCs are known for their high reliability due to the absence of connectors and the reduced risk of solder joint failure.

Complex Shapes: They can be designed in intricate shapes to accommodate specific device designs, which is often challenging with rigid PCBs.

Flexibility: FPCs can withstand millions of flex cycles without compromising their functionality, making them suitable for applications with moving parts.

Rigid-Flex PCBs

Rigid-flex PCBs are a hybrid solution that combines the benefits of both rigid and flexible circuits. They consist of multiple layers of flexible substrates interconnected with rigid PCB sections. This combination allows for complex three-dimensional designs, improved reliability, and reduced assembly time.

Click here for more information: https://www.tumblr.com/fpcway/730768523049205760/the-evolution-of-electronics-flexible-printed

0 notes

Text

We're doing 8 days of light-filled designs to wrap up this year. We started with the Sparkle Motion Mini

, which can drive thousands of shimmering RGB LEDs. Then, we did the Sparkle Motion stick, a USB-pluggable version

On the third night, a 1.28" round TFT display

, and on the fourth a 1.8" round TFT with captouch overlay

On the fifth night, a tiny 0.85" TFT display

came to life. We took a little break on the sixth night since we were doing a lot of Sparkle Motion testing

and did a quick revision of our NeoRGB

On the penultimate night and New Year's Eve, we're making a quick Qwiic board—this is an I2C breakout for transparent OLED displays. We've had the display in our 'in progress' bin for a few years but finally sat down to finish it tonight. We're experimenting with a wrap-around setup for the FPC and a cutout for the display for mounting. We'll see how it goes!

#festivaloflights#transparentoled#oleddisplay#techdesign#hardwaredevelopment#sparklemotion#tftdisplay#captouch#rgbleds#makercommunity#techinnovation#opensourcehardware#neopixel#qwiicboard#adafruit#diytech#lightfilleddesigns#holidaytech#newyeartech#transparentdisplay#oledprojects#displaydesign#creativeelectronics#smartdisplays#tftoled#innovativetech#electronicsprojects#makersmovement#futuretech#diyprojects

9 notes

·

View notes

Video

tumblr

Capel Technology are professional Flexible circuit and Flex-Rigid PCB manufacturer for more than 10 years, which are focusing on the Research, Development,Design ,Producting 1-12layer Flex PCB, 4-14 layers Flex-Rigid PCB. The Products are widely used in Mobile, Communication, Smart home,Optoelectronics, Industrial control, Medical Equipment,Automobile and Consumer Electronics and so on.

View more at https://www.cplfpc.com/

1 note

·

View note

Text

We Deliver the Highest Level of Prototype PCB Manufacturing Service

It's critical to check that a printed circuit board (PCB) is in good working order before starting an entire Prototype Pcb Manufacturing run. Regardless of how meticulously designers work on a project, tiny errors and unnoticed flaws might jeopardize the final product's operation.

0 notes

Text

resie? biohazard??

Age: 35 Birthdate: September 4th, 1986 Affiliation: Niflheim Corp, Tenebrae Profession: Researcher

The discovery of the "sylleblossom" by apothecarist Aera Mils Fleuret in the 1940s led the Fleurets down what they believed to be a path blessed by God. From a small pharmacy in the remote village of Pagla in southern France, birthed a company with the purpose to aid humanity.

By crossing three different species of mountain herbs, Aera managed to heal the people of Pagla from the mysterious illness plaguing their community. The devout village hailed her as an apostle of God: the Oracle. As time went on, they managed to expand their operations from a small pharmacy to a company not very well known outside of France.

Tenebrae. The commemoration of the sufferings and death of Christ who had died for the sins of man. Our Savior and Lord.

The Fleurets developed therapy and hospice treatments for terminally ill patients that focused on alleviating their symptoms through natural-holistic medicines rather than chemical-based products offered by most hospitals. They had a large following of those who believed that chemicals and science to be the Devil’s work.

The brighter the light, the larger the shadow that is cast.

In truth, many of those who were the followers of Aera Mils Fleuret were victims of Munchausen by proxy; the sickness that Aera originally cured was due to her own experimentation to develop the sylleblossoms. It was not only the villagers who were tainted, but Aera’s own family members were unwitting subjects. None were spared from her God given path: not even herself.

As the Fleuret genes have been manipulated for over 80 years, they are carriers of the what would later be known as the ‘Starscourge’. Their blood contains antibodies needed to counteract the virus. Thus the vaccine and cure is developed using the blood of a Fleuret.

The creator and the destroyer; as God is to his children.

Members of the Fleurets have always gone mad and lose themselves during their later life stages, often turning into Daemons if not disposed of first. The blood of female members is especially potent ( hence matriarch family ) but, as a result it also decreases their lifespan greatly. Most female family members hardly live to the age of 50.

Tenebrae was later acquired by Niflheim Corporation, a company part of The Federation of Pharmaceutical Companies ( FPC ) that primarily worked in biotech and produces many cybernetic prosthetics used by the US military and other unsavory groups. After an employee came across the small town of Pagla while on vacation, they reported back to CEO Iedolas Aldercapt and Head Researcher Verstal Besithia. The men saw the possible implementation of sylleblossom-based components in their own work.

Unfortunately, despite their initial efforts, the formula had been hidden under heavy guard. Sylleblossoms are only grown by the Fleuret family’s private garden in an unknown location. So with some arm twisting (e.g killing the matriarch Sylva Nox Fleuret and leaving her young teenage children in charge of the company), they managed to get Tenebrae under their corporate umbrella.

Lunafreya Nox Fleuret is the current head of Tenebrae, or what remains of it under Niflheim Corp's Pharmaceutical branch. Hateful of the company that ruined her family’s life, but she has no other option than to do what she must, lest she loses what little control she has over her family’s assets.

Since the acquisition of Tenebrae, they began to move more into biochemical research using the sylleblossom components. With Verstael spearheading the project, they created Magitek soldiers to be used in warfare in place of humans.

Using the prototype virus strains developed by Lunafreya, they were able reduce humans to Miasma to power the suits. What remains of the human's ego is integrated into the A.I that fuels the power core ( ‘Cor’ ).

Unbeknownst to Verstael and his people, Lunafreya has been developing the Starscourge further to increase its potency. Humans who are infected and transform from the Starscourge are nicknamed ‘Daemons’ as the sickness leaves the victim monstrous, knowing only their base instincts and desires.

The Starscourge works similarly to T-Virus reported in the Raccoon City Incident. But it spreads through Miasma that continually seeps out of infected/turned creatures rather than bites and scratches. And unlike the T or G virus, the infection gives no visual clues until its later stages. Those infected with the Starscourge will eventually lose their sense of self until they have nothing aside from their strongest desires and basic instincts. Sentiency in ‘Daemons’ has been observed under different studies; those with strong wills will retain some speech and cognitive abilities.

#( ooc )#v: verses#v: biohazard#//what is writing#//why can't i just make verses#//info dump journals detailing Aera's experiments on villagers pls

3 notes

·

View notes