#Rotary Screw Pump

Explore tagged Tumblr posts

Text

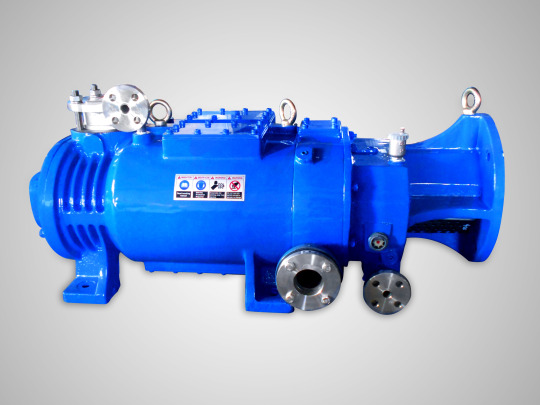

Rotary Screw Pump — Twin Screw Pump, Triple Screw Pump Manufacturer &Supplier | Rotarygearpumpsindia

Rotary Screw Pumps manufacturer and supplier consist of one set of shafts-one driving and one driven with two screws mounted and keyed onto each placed shaft inside pump. The liquid entering inside the pump from inlet side is divided into two parts each part going to outer end of screws. As the screws rotates, the cavities are formed between the individual screw.

Screw Pump Features

Constant high efficiency with variable capacity.

Simple and rugged design

Smoothly and quiet operation.

Applications

Screw pump are suited for a number of industries such as marine, paper, wastewater, biogas, explosives, mining, ceramic etc.

Our Products

Rotary Gear Pumps

External Gear Pumps

Internal Gear Pumps

Rotary Lobe Pumps

Rotary Shuttle Block Pumps

Rotary Screw Pumps

Twin Screw Pumps

Triple Screw Pumps

For more Details Click here : https://www.rotarygearpumpsindia.com/

0 notes

Text

Rotary Screw Pump Manufacturer & Supplier | Buy Screw Pump at best price

Rotary Screw Pump positive-displacement pumps that uses two screw shaped intermeshing rotors, these move gas along the axis of screw. A screw pump is a type of rotary pump which is equipped with screws that mesh together and rotate within a cylindrical cavity or liner.

Types of Rotary Gear Pump

Rotary Gear Pumps

External Gear Pumps

Internal Gear Pumps

Stainless Steel Gear Pump

Rotary Lobe Pumps

Rotary Shuttle Block Pumps

Rotary Screw Pumps

Twin Screw Pumps

Triple Screw Pumps

For more Details Click here : https://www.rotarygearpumpsindia.com/

0 notes

Text

#Dry Screw Vacuum Pump#Helium Leak Detector#Rotary Vane Vacuum pump#Dry Vacuum Pump#Rotary Vane Pump

0 notes

Text

#Helium Leak Testing#Helium Recovery System#Helium Leak Detector#Helium Leak Detection Service#Helium Leak Testing Machine#Helium Leak Testing System#Helium Leak Testing Service#Rotary vane vacuum pump manufacturers#Dry Screw Vacuum Pump

0 notes

Text

Vacuum System And Package at Best Price in Noida

Swam dry screw vacuum pumps are designed under SWAM’s unique screw profile engineering to fulfill wide range of chemical and industrial processes. It is operating by rotating a paired screws that efficiently admit gases from inlet into the pump inside and compress through the screw’s swept volume toward the discharge.

For more information Visit Now :https://swamatics.com/ProductDetails.aspx?prod=Vacuum%20Systems%20and%20Packages

#air blower exporter#best process gas blowers#bio gas compressors#Twin lobe blowers#bio gas blowers#Turbo Blower#Mechanical vacuum re compressor#Aeration blowers#Combustion air blowers#Oxidation blowers#Dry screw vacuum pumps#Vane pumps#tri lobe rotary piston#Vacuum system and packages#Tri lobe blowers#Mechanical vacuum boosters

0 notes

Text

Atlas Copco's vacuum pump UAE range includes single stage rotary vane vacuum pumps, 2 stage rotary vane vacuum pumps and oil sealed rotary vane vacuum pumps with VSD technology

#oil sealed rotary vacuum pump#oil sealed rotary vane vacuum pump#vane type vacuum pump#oil lubricated rotary vane vacuum pump#Oil Sealed Rotary SCREW Type Vacuum Pump#Oil Screw Vacuum Pump#vacuum pump#vacuum pumps and systems#atlas copco UAE vacuum pump

0 notes

Text

Kaishan Compressor USA https://kaishanusa.com/ is a diversified industrial equipment manufacturer centering around rotary screw technologies. We are best known for producing compressed air equipment for a variety of industries. We engineer the highest quality rotary screw air compressors that enable us to build a better, more efficient future.

#Air compressors#industrial equipment manufacturer#rotary screw air compressors#rotary screw gas compressors#industrial vacuum pumps#centrifugal air compressors#ORC power generators#steam screw expanders

0 notes

Text

Sunkaier Rubber Cutter and Dispersion System

Description:

A rubber cutter and dispersion system are the essential part of the manufacturing process for materials such as Acrylonitrile Butadiene Styrene (ABS), High Impact Polystyrene (HIPS), and Hydrogenated Nitrile Butadiene Rubber (HNBR). These systems are designed to cut rubber into small pieces or chips and ensure that these pieces are evenly dispersed in the compound during the mixing process.

COMPLETE SYSTEM OF RUBBER DISOLVING:

SUNKAIER Rubber Solution Complete System is an integrated system designed for the processing of rubber materials.

Rubber Feed System: handling and feeding of raw rubber bale into the processing line. It may include mechanisms for weighing, metal detecting.

Rubber Extruding Chopper Machine: This screw extruding rubber bales to die and cut by rotary knives and the rubber is converted to crumbs or 1.5 ~ 2.5 cm particles for further processing.

Rubber Disperser Machine: This machine is used to disperse the rubber in the solvent.

Conveying: The conveying system transports these compounds between different machines.

Solvent Feed and Control: This part of the system handles the addition and control of solvents during the rubber processing. Solvents can be used to dissolve rubber or other ingredients, making them easier to mix and process.

A complete system like this would typically also include control systems that manage the operation of each component, ensuring consistent quality and efficiency throughout the production process. These control systems might include sensors, actuators, and programmable logic controllers (PLCs).

RUBBER EXTRUDING CHOPPER:

SUNKAIER Rubber Chopper converts bales of synthetic and natural rubber to small particles through a combination of low speed and high torque pelletizer. The low-speed, high-torque design minimizes heat input while providing the power needed to grind rubber bales to crumbs. The resulting particle size ranges between 0.5-1 inch (1.2-2.5 cm), which increase the solvent dissolution prior to blending and compounding.

RUBBER GRINDING MACHINE:

Rubber Wet Grinder (Inline Mixer/Disintergrator/Rubber Dissolving/Colloid Mill/Grinding Pump/Homogenizer/Mill Pump) consists of rotor and stator. shear force and micro-cavitation that generated between rotor and stator are used in manufacturing to function as follows:

PFD OF RUBBER SOLUTION:

Process Flow Diagram (PFD) to prepare a Rubber Solution, particularly in steps involved in transforming raw rubber into a usable solution for various applications such as coatings, adhesives, or other rubber-based products.

1. Rubber Feeding:

- Raw materials (natural or synthetic rubber) are introduced into the system.

2. Chopping:

- Large pieces of rubber are chopped into smaller, more manageable chunks.

3. Dispersion:

- The chopped rubber is then dispersed into a solvent to create a solution.

4. Buffering:

- After dispersion, the rubber solution is stored temporarily in a buffer tank or reservoir.

- Buffering also provides a steady supply of the rubber solution to downstream processes.

ROTOR AND STATOR - RS100:

ROTOR STATOR- RS200:

If you have any need of Rubber Cutter and Dispersion System please contact me without any hesitation, thanks.

Helena Xiao / Sales Manager

Email: [email protected]

Phone: +86 510 8758 8707

Mobile: +8618261586225

#chemicalprocessing #chemicalindustry #chemicalmanufacturing #chemicalsolution #polymersolution #mixing #chemicalreaction #polymerization #highviscocitymaterialprocessing #highviscocitymaterialsolution #mining #petrochemical #oil #oilprocessing #lubrication #polymer #polymerprocessing #plastics #plasticprocessing #metallurgy #powdermetallurgy #metalprocessing #metallurgicalengineering #polyvinylidenefluoride #hydrogenfluoride #polybutyleneadipateterephthalate #thermoplasticurethanes #polyvinylchloride #highimpactpolystyrene #generalpurposepolystyrene #polyethylene #polyethylenewax #polyethyleneterephthalate #polyurethane #polyglycolideacid #polylacticacid #acrylonitrilebutadienestyrene #extrudingprocess #kneaderingprocess #kneadingtechnology #devolatilizationtechnology #polymerizationprocessexpert #chemicalpulp #PETrecycling #polyethyleneterephthalaterecycling #UHMWPEultra #MDImethylenediphenyldiisocyanate #rubber #TPUelastomer #nylon #textile #fabrics

0 notes

Text

The Brand Powering Global Industrial Excellence by Air Marshal Compressor

Introduction

In today’s fast-paced industrial world, efficiency, reliability, and innovation are the cornerstones of success. Companies across sectors require robust solutions to meet their unique challenges, and this is where Air Marshal Compressor excels. Known for delivering high-performance industrial compressors and unmatched service, Air Marshal Compressor has solidified its reputation as a trusted partner in global industrial excellence. This blog explores how Air Marshal Compressor is driving progress, fostering innovation, and setting new benchmarks in the industrial compressor industry.

A Legacy of Excellence

Air Marshal Compressor has a rich history of innovation and commitment to quality. Since its inception, the company has focused on creating solutions tailored to the diverse needs of industries such as manufacturing, healthcare, automotive, and energy. By combining state-of-the-art technology with a customer-centric approach, Air Marshal has positioned itself as a leader in the global market.

Key Milestones

Founding Vision: Established with the goal of providing reliable and efficient compressor solutions for industries worldwide.

Technological Advancements: Continuous investment in research and development to stay ahead of the curve.

Global Expansion: Presence in over 50 countries, serving clients with a diverse portfolio of products.

Innovative Product Range

Air Marshal Compressor offers a wide array of products designed to cater to the needs of modern industries. From energy-efficient compressors to advanced vacuum pumps, each product reflects the company’s dedication to excellence.

Types of Compressors

Rotary Screw Compressors: Known for their durability and efficiency, these compressors are ideal for demanding applications.

Oil-Free Compressors: Perfect for industries like healthcare and food processing, where air purity is critical.

High-Pressure Compressors: Designed for specialized applications such as testing and production lines.

Portable Compressors: Compact and reliable solutions for on-the-go industrial needs.

Cutting-Edge Technology

At the heart of Air Marshal Compressor’s success is its commitment to innovation. The company leverages advanced technologies to ensure optimal performance and energy efficiency.

Smart Monitoring Systems

Air Marshal’s compressors are equipped with intelligent monitoring systems that provide real-time insights into performance metrics. This allows businesses to proactively address issues, minimize downtime, and optimize energy consumption.

Eco-Friendly Solutions

Sustainability is a core value at Air Marshal Compressor. The company prioritizes the development of eco-friendly solutions, reducing carbon footprints while maintaining superior performance.

Global Reach and Impact

Air Marshal Compressor’s influence extends far beyond its products. The company has built a global network of distributors and service centers to ensure seamless support for its clients.

Industries Served

Manufacturing: Enhancing productivity with reliable compressed air solutions.

Healthcare: Providing clean, oil-free air for medical applications.

Automotive: Supporting high-precision processes in vehicle production.

Energy: Delivering efficient solutions for renewable and conventional energy sectors.

Strategic Partnerships

Air Marshal Compressor collaborates with leading organizations worldwide to develop customized solutions. These partnerships underscore the company’s commitment to fostering industrial growth and innovation.

Unmatched Customer Support

Customer satisfaction is at the core of Air Marshal Compressor’s operations. The company provides end-to-end support, ensuring that clients receive the highest level of service.

Comprehensive Services

Installation Assistance: Expert guidance during the installation process.

Maintenance Programs: Tailored maintenance plans to enhance longevity and performance.

24/7 Support: Round-the-clock assistance to address urgent requirements.

Training and Resources

Air Marshal Compressor believes in empowering its clients with knowledge. The company offers training programs and resources to help customers maximize the efficiency of their compressors.

Advantages of Choosing Air Marshal Compressor

When it comes to industrial compressors, Air Marshal stands out for several reasons:

Reliability: Products engineered for consistent performance in challenging environments.

Efficiency: Advanced technology ensures maximum energy savings.

Customization: Tailored solutions to meet specific industrial needs.

Sustainability: Commitment to environmentally friendly practices.

Global Presence: A robust network for seamless support worldwide.

Testimonials from Satisfied Clients

Air Marshal Compressor’s commitment to excellence is reflected in the glowing reviews from its clients.

Manufacturing Client: “Air Marshal’s rotary screw compressors have transformed our production line. We’ve seen significant energy savings and improved efficiency.”

Healthcare Client: “The oil-free compressors are a game-changer for our medical facility. The air quality is exceptional, and the support team is always available.”

Automotive Client: “Their high-pressure compressors are unmatched in precision and reliability. We’re proud to partner with Air Marshal.”

Future Vision

Air Marshal Compressor is committed to driving innovation and shaping the future of the industrial compressor industry. The company’s roadmap includes:

Expanding Product Lines: Introducing new technologies to address emerging industrial challenges.

Strengthening Sustainability: Developing even greener solutions to align with global environmental goals.

Enhancing Digital Integration: Leveraging AI and IoT for smarter and more connected systems.

Expanding Global Footprint: Entering new markets to serve a broader client base.

Conclusion

Air Marshal Compressor is more than a brand; it’s a symbol of trust, innovation, and excellence in the industrial sector. With a focus on quality, sustainability, and customer satisfaction, the company continues to power industries around the world. Whether you’re in manufacturing, healthcare, automotive, or energy, Air Marshal Compressor has the solutions you need to achieve unparalleled success.

For businesses seeking a reliable partner in industrial excellence, Air Marshal Compressor is the clear choice. Discover the difference and take your operations to the next level with the brand that’s redefining global standards.

0 notes

Text

🌟Understanding #Pump_Classifications and Their Principles of Operation🌟

In the dynamic world of fluid mechanics, selecting the right pump for a specific application can be the difference between efficiency and operational challenges. Pumps are broadly classified based on their operating principles and fluid dynamics, which engineers must consider carefully. Here’s an overview of the main pump classifications and how they work:

1️⃣ Centrifugal Pumps

Principle: These pumps operate using a rotating impeller to create kinetic energy that converts into pressure. Fluid enters axially, and centrifugal force pushes it radially outward, increasing velocity and pressure.

✅Applications: Ideal for water supply, HVAC systems, and irrigation due to their ability to handle large volumes with moderate pressure.

2️⃣ Positive Displacement Pumps

Principle: These pumps trap a fixed volume of fluid and force it through the discharge pipe. This design ensures a constant flow regardless of pressure variations.

✔Types:

Rotary (gear, screw, vane): For viscous fluids like oils.

Reciprocating (piston, diaphragm): For high-pressure needs, like chemical dosing.

Applications: Used in industries requiring precise flow rates, such as chemical processing and food production.

3️⃣ Submersible Pumps

Principle: Designed to operate while fully submerged in the fluid, submersible pumps eliminate cavitation issues by pushing rather than pulling fluids.

✅Applications: Perfect for wastewater, groundwater extraction, and dewatering projects.

4️⃣ Axial and Mixed Flow Pumps

Principle: These pumps use an axial or combined axial-radial impeller motion, making them suitable for moving large volumes of fluid with low head.

✅Applications: Commonly found in flood control, stormwater drainage, and cooling systems.

🤔What Makes the Right Pump Selection Critical?

Selecting a pump is not just about matching the type to the application—it’s about precision. Factors such as fluid type, operating conditions, and system design must align perfectly to ensure peak performance.

At #Advanced_Pumps_ Co we pride ourselves on having a team of professional engineers who excel in selecting the best pump solutions for diverse applications. Whether it's #assembling #booster pumps locally in our factory or ensuring compliance with international standards, our expertise guarantees optimal performance tailored to your needs.

When you work with a team that understands every nuance of pump technology, you’re not just investing in equipment—you’re investing in efficiency, reliability, and peace of mind.

💬For inquiries or to learn more about our pump solutions, connect with us on LinkedIn or visit our website.

🌐 www.ape-pumps.com

💫Let’s discuss: What’s the most challenging aspect you face in pump selection?

#Pumps_Applications

#FluidDynamics

#EngineeringSolutions

#PumpSelection

#WaterIndustry

0 notes

Text

Rotary Screw Pump Manufacturer & Supplier — Rotarygearpumpsindia

Dev Engineer is a leading Rotary Screw Pump manufacturer and supplier in Ahmedabad, Delhi, Mumbai, Kolkata, Chennai, Bangalore, Indore, Ludhiana, Pune, and Coimbatore.

Rotary Screw Pump are positive displacement pumps that use rotating, intermeshing screws to move viscous fluids. Rotary Screw Pump operates using two counter-rotating screw rotors.

Screw pump are suited for a number of industries such as marine, paper, wastewater, biogas, explosives, mining, ceramic etc.

Types of Rotary Screw Pump

Progressive Cavity Rotary Screw Pump

Twin Rotary Screw Pump

Triple Rotary Screw Pump

Rotary Screw Pump Features

Constant high efficiency with variable capacity.

Simple and rugged design

Smoothly and quiet operation.

Can handle solid in suspension or media containing a high percentage of solids.

We offer a wide range of Rotary Gear Pump including Types of Gear Pumps

Rotary Gear Pumps

External Gear Pump

Internal Gear Pump

Stainless Steel Rotary Gear Pump

SS Gear Pump, Rotary Lobe pump

Stainless Steel Rotary Lobe Pump

Rotary Shuttle Block Pump

Rotary Screw pump

Rotary Triple Screw pump

Rotary Twin Screw Pump

Rotary SS Barrel Pump

For more Details Click here : https://www.rotarygearpumpsindia.com/

0 notes

Text

How to Utilize a 30 hp screw air compressor for the Aerospace Industry

In the aerospace industry, precision, efficiency, and reliability are necessary. Every component and process demands exactness, and the tools and machinery used must match the industry’s high standards. A 30 hp screw air compressor is an excellent choice for meeting these demands, thanks to its ability to deliver constant, high-quality compressed air. In this article, We will explore the various modes that can use the best rotary screw air compressor to optimise processes in the aerospace industry.

What makes a 30 hp screw air compressor ideal for aerospace?

The 30 hp screw air compressor is known for its efficiency and reliability. It provides:

Constant airflow: Ensures stable pressure without fluctuations.

Energy efficiency: Optimised power consumption for continuous use.

Durability: Designed for heavy-duty applications with minimal maintenance.

Oil-free options: Essential for sensitive aerospace processes.

These features make it a versatile tool for various aerospace applications.

Uses of the best rotary screw air compressor in the aerospace industry:

Powering CNC machines for precision manufacturing:

In aerospace, every part—from turbine blades to fuselage parts—requires special exactness. CNC machines, essential for manufacturing, depend on a constant air supply to function optimally. A 30 hp screw air compressor ensures:

Stable processes: Prevents pressure drops that can disrupt machining.

Enhanced accuracy: Consistent air pressure allows for precise cutting and shaping.

Reduced downtime: The best rotary screw air compressor’s efficiency minimises machine interruptions.

Supporting pneumatic tools in assembly and maintenance

Pneumatic tools like drills, grinders, and impact wrenches are commonly used in aerospace assembly lines and maintenance. These tools require constant air pressure, which a 30 hp screw air compressor can easily provide. Benefits include:

Improved productivity: Tools work at optimal capacity, speeding up processes.

Safety assurance: A reliable air supply reduces the risk of tool malfunctions.

Enhancing surface finishing with paint sprayers:

Aircraft components must be painted and coated for protection against corrosion and to meet aesthetic standards. A 30 hp screw air compressor provides:

Even coatings: Constant air pressure ensures smooth and uniform paint application.

High-quality results: Minimises overspray and uneven finishes.

Reduced waste: Precise air delivery optimises paint usage.

Boosting strict testing and inspections:

Aerospace parts undergo strict testing to ensure they meet safety and quality standards. Compressed air is usually used for:

Leak testing: Detecting vulnerabilities in seals and joints.

Pressure simulation: Simulating operational environments for stress testing.

With its ability to deliver precise and stable air pressure, screw compressor manufacturers ensure accurate testing results, contributing to safer and more reliable aerospace components.

Guiding hydraulic systems in equipment:

Some aerospace applications require hydraulic systems powered by compressed air. A 30 hp screw air compressor can:

Support hydraulic actuators: Provide the necessary air pressure to drive pumps.

Enable smooth operations: Ensure reliable performance in heavy-duty machinery.

Cleaning and maintenance of aerospace parts

Cleanliness is vital in aerospace manufacturing and maintenance. The best rotary screw air compressor is ideal for:

Blowing away waste: Cleaning complex parts without causing damage.

Drying Components: Removing moisture from sensitive equipment after washing.

A 30 hp screw air compressor delivers the power needed to clean entirely while being gentle on delicate parts.

Powering pneumatic control systems

Aircraft and ground equipment usually use pneumatic control systems for actuation, instrumentation, and valve operations. The 30 hp screw air compressor provides:

Precision: A stable air supply ensures accurate control.

Reliability: Reduces the risk of system failure during critical operations.

Supporting environmental control systems:

Compressed air plays a role in aircraft environmental control systems, which manage:

Cabin pressurization: Maintaining comfort and safety for passengers.

Air conditioning: Regulating temperature during flights.

Screw compressor manufacturers ensure that these systems work seamlessly, enhancing passenger and crew comfort.

Increasing efficiency in aerospace assembly lines

Modern aerospace assembly lines depend on automation and robotics, both of which require compressed air for operation. A 30 hp screw air compressor ensures:

Uninterrupted workflow: Continuous air supply keeps assembly lines moving.

Improved precision: Supports robots and machines in performing detailed tasks.

Why choose a 30 hp screw air compressor for aerospace?

Here are some key advantages that make it a perfect fit:

Energy savings: Optimised design reduces operating costs over time.

Noise reduction: The best rotary screw air compressor works quietly, creating a better work environment.

Longevity: A durable build ensures a long lifespan with minimal maintenance.

Customisable: Screw compressor manufacturers can be tailored for oil-free or lubricated applications based on needs.

Tips for optimal use in aerospace applications

To get the most out of a 30 hp screw air compressor:

Regular maintenance: Schedule routine checks to ensure optimal performance.

Monitor air quality: Use filters to maintain clean, dry air for sensitive processes.

Match requirements: Ensure the compressor’s capacity meets your application needs.

Train operators: Equip your team with the knowledge to use and maintain the compressor effectively.

Summary:

The 30 hp screw air compressor is a powerful, versatile tool for the aerospace industry. From manufacturing and assembly to testing and maintenance, it plays an essential role in ensuring precision, efficiency, and reliability. By integrating the best rotary screw air compressor into your operations, you can enhance productivity, reduce downtime, and maintain the high standards demanded by the aerospace sector. Whether you’re painting an aircraft, powering CNC machines, or supporting environmental control systems, the 30 hp screw air compressor is your reliable partner in achieving excellence.

#screw type air compressor#40 hp screw air compressor#30 hp screw air compressor#20 hp screw air compressor#air compressor#best rotary screw air compressor

0 notes

Text

Understanding Vacuum Technology: A Deep Dive into Different Types of Vacuum Pumps

In various industrial and scientific applications, vacuum technology plays a crucial role in achieving optimal performance and efficiency. Among the essential tools in this field are different types of vacuum pumps, including dry screw vacuum pumps, rotary vane vacuum pumps, and dry vacuum pumps. Additionally, helium leak detectors are vital for ensuring the integrity of vacuum systems. This blog will explore these technologies, their functions, and their applications, providing a comprehensive understanding of vacuum technology.

What is a Vacuum Pump?

A vacuum pump is a device that removes gas molecules from a sealed volume to create a vacuum. The degree of vacuum can vary depending on the type of pump and its application. Vacuum pumps are used in a wide range of industries, including semiconductor manufacturing, pharmaceuticals, food packaging, and research laboratories. The choice of vacuum pump depends on the specific requirements of the application, such as the desired vacuum level, the type of gases being evacuated, and the operational environment.

Types of Vacuum Pumps

1. Dry Screw Vacuum Pump

The dry screw vacuum pump is a positive displacement pump that uses two intermeshing screws to create a vacuum. Unlike other types of pumps, it operates without any oil or liquid, making it an environmentally friendly option. The absence of oil means that there is no risk of contamination, which is particularly important in industries such as pharmaceuticals and food processing.

Dry screw vacuum pumps are known for their high efficiency and reliability. They can achieve low pressures and are capable of handling a wide range of gases, including corrosive and reactive gases. These pumps are also relatively low maintenance, as they do not require oil changes or regular servicing associated with oil-based systems.

2. Rotary Vane Vacuum Pump

The rotary vane vacuum pump is one of the most common types of vacuum pumps used in various applications. It operates by using a rotor with sliding vanes that create a series of chambers. As the rotor turns, the vanes slide in and out, trapping gas and compressing it until it is expelled through an exhaust port.

Rotary vane pump are versatile and can achieve moderate vacuum levels. They are often used in applications such as laboratory experiments, vacuum packaging, and refrigeration. While they do require oil for lubrication and sealing, advancements in technology have led to the development of oil-free rotary vane pumps that offer similar performance without the risk of oil contamination.

3. Dry Vacuum Pump

A dry vacuum pump is designed to operate without any lubricating fluids, making it suitable for applications where contamination must be avoided. These pumps can be based on various technologies, including diaphragm, scroll, or screw mechanisms. Dry vacuum pumps are particularly useful in industries such as semiconductor manufacturing, where even trace amounts of oil can compromise product quality.

The main advantage of dry vacuum pumps is their ability to maintain a clean environment. They are also energy-efficient and can achieve high pumping speeds, making them ideal for processes that require rapid evacuation of gases. Additionally, dry vacuum pumps are often quieter and require less maintenance compared to their oil-lubricated counterparts.

The Importance of Helium Leak Detectors

In vacuum systems, maintaining a high level of integrity is crucial. Even the smallest leaks can lead to significant performance issues, including loss of vacuum, contamination, and reduced efficiency. This is where helium leak detectors come into play.

Helium leak detector are specialized instruments used to identify and quantify leaks in vacuum systems. They work by introducing helium gas into the system and then using a mass spectrometer to detect any helium that escapes through leaks. Helium is an ideal tracer gas due to its small atomic size and inert nature, making it easy to detect even in trace amounts.

Applications of Helium Leak Detectors

Helium leak detectors are widely used in various industries, including:

Semiconductor Manufacturing: In the production of semiconductor devices, maintaining a vacuum is essential for preventing contamination and ensuring product quality. Helium leak detectors help identify leaks in vacuum chambers and systems.

Pharmaceuticals: In the pharmaceutical industry, vacuum systems are used for processes such as freeze-drying and packaging. Helium leak detectors ensure that these systems remain airtight, preventing contamination and ensuring product integrity.

Aerospace: In aerospace applications, vacuum systems are used for testing components and systems. Helium leak detectors help ensure that critical components are leak-free, which is vital for safety and performance.

Research Laboratories: In research settings, vacuum systems are often used for experiments that require controlled environments. Helium leak detectors help researchers maintain the integrity of their setups.

Choosing the Right Vacuum Pump

When selecting a vacuum pump for a specific application, several factors must be considered:

Desired Vacuum Level: Different applications require different levels of vacuum. Understanding the required vacuum level is crucial for selecting the appropriate pump.

Type of Gases: The nature of the gases being evacuated can influence the choice of pump. For example, corrosive gases may require a dry screw vacuum pump, while non-cor rosive gases might be suitable for rotary vane pumps.

Contamination Concerns: If the application is sensitive to contamination, such as in pharmaceuticals or semiconductor manufacturing, a dry vacuum pump or a dry screw vacuum pump would be ideal due to their oil-free operation.

Maintenance Requirements: Consideration of maintenance needs is essential. Dry vacuum pumps typically require less maintenance than oil-lubricated pumps, which can lead to lower operational costs over time.

Energy Efficiency: Energy consumption is an important factor, especially in large-scale operations. Choosing a pump that offers high efficiency can lead to significant cost savings.

Conclusion

Vacuum technology is an integral part of many industrial and scientific processes. Understanding the different types of vacuum pumps—such as dry screw vacuum pumps, rotary vane vacuum pumps, and dry vacuum pumps—along with the importance of helium leak detectors, is essential for selecting the right equipment for specific applications. By considering factors such as desired vacuum levels, gas types, contamination concerns, maintenance requirements, and energy efficiency, businesses can optimize their operations and ensure the integrity of their vacuum systems. As technology continues to advance, the efficiency and reliability of vacuum pumps and leak detection methods will only improve, further enhancing their role in various industries.

#Dry Screw Vacuum Pump#Helium Leak Detector#Rotary Vane Vacuum pump#Dry Vacuum Pump#Rotary Vane Pump

0 notes

Text

Air Blower Exporter | Best Air Blowers Manufacturer in Delhi

Swametics indian blower manufacturer company it's offer air blower exporter, Blowers Manufacturer in Delhi, Air Blowers Manufacturer in Delhi, process gas boosters manufacturer in India, best process gas blowers, etc

Contact us: Call Now:+91-120469 6222 Email us:[email protected] Address:C-2,SECTOR-3,NOIDA-201301,(U.P.) INDIA For more information visit: https://www.swamatics.com/

#Air Blowers Manufacturer in Delhi#Best Air Blowers Manufacturer in Delhi#Blowers Manufacturer#air blowers manufacturer#best process gas boosters manufacturer in india#Blowers Manufacturer in Delhi#condencer exhausters#air blower supplier#truck blowers#air blower exporter#vacuum pump manufacturer#bio gas blowers#twin lobe rotary air blowers#Turbo Blower#bio gas compressors#screw blowers#Roots blower#Roots blower manufacturer#Rotary piston blowers#Positive displacement blowers#Process gas blowers#Gas boosters

0 notes

Text

Atlas Copco UAE Vacuum Pump Solutions & services.

#vacuumpumpsuae#vacuum pump#industrial vacuum pump#vacuum pumps and systems#dry vacuum pump#oil sealed vacuum pump#vane type vacuum pump#oil sealed rotary vacuum pump#Oil Screw Vacuum Pump#screw type vacuum pump#rotary screw vacuum pump#liquid ring vacuum pump#water ring vacuum pump

1 note

·

View note

Text

From 3M Distributors to Mobil Lubricants: Essential Industrial Products and Solutions in India & UAE.

At Sanjay Tools, we are committed to providing high-quality industrial products and solutions that help businesses enhance productivity and ensure smooth operations. Whether you're looking for 3M products, grease pumps, compressors, or premium lubricants, we are your trusted distributor and supplier in India & UAE.

Who is 3M Distributor and Supplier in India & UAE?

A 3M distributor and supplier like Sanjay Tools is an authorized partner for distributing and supplying 3M’s vast range of industrial products in India and UAE. 3M is known for providing innovative solutions in fields such as abrasives, adhesives, tapes, sealants, and personal safety equipment. As an official distributor, we offer high-quality 3M products, providing businesses with cutting-edge solutions for improved performance and efficiency. Whether you need abrasives for heavy machinery, abrasives for heavy machinery, adhesives for construction, or personal protective equipment (PPE), Sanjay Tools has it all.

What is the Fire Ball 300 Grease Pump?

The Fire Ball 300 Grease Pump is a highly reliable and efficient pumping system designed for transferring lubricants, particularly grease, in industrial settings. With its compact, durable design, the Fire Ball 300 is suitable for use in factories, maintenance shops, and anywhere grease needs to be dispensed efficiently. This pump is designed for high-volume, heavy-duty applications, ensuring quick, precise, and smooth grease distribution. As a trusted Fire Ball grease pump supplier in India and UAE, we provide high-quality units with excellent customer support, ensuring that you get the most from your investment.

What is a Dispensing Drum Package?

A Dispensing Drum Package is a crucial piece of equipment in industries that deal with large quantities of lubricants or chemicals. This package includes a dispensing system for easy, controlled dispensing of lubricants, oils, and other fluids directly from the drum. It helps maintain hygiene, reduces waste, and provides efficient handling of fluids, reducing spills and increasing safety. At Sanjay Tools, we offer Dispensing Drum Packages that are designed for optimal performance and ease of use, tailored to suit a variety of industrial needs both in India and UAE.

Kaeser Compressor Dealer and Distributor

As a leading Kaeser compressor dealer and distributor in India and UAE, we at Sanjay Tools offer a wide range of Kaeser air compressors that deliver reliable performance, high efficiency, and long-lasting durability. Kaeser is known for its innovative compressor technology, including both rotary screw and piston compressors, which are ideal for diverse industrial applications such as manufacturing, automotive, and process industries. Our team provides comprehensive support, including installation, maintenance, and repair services, ensuring that your Kaeser compressors perform at their best, saving energy and reducing operational costs.

Benefits of Mobil Excel 68 Hydraulic Fluid

Mobil Excel 68 Hydraulic Fluid is a high-performance hydraulic oil designed to offer outstanding protection against wear, oxidation, and corrosion, making it ideal for use in heavy-duty industrial applications. Some key benefits of Mobil Excel 68 include:

Improved operational efficiency: Its superior anti-wear properties help reduce maintenance costs and downtime.

Excellent oxidation stability: It resists breakdown, even under high-temperature conditions, ensuring longer service life for your equipment.

Enhanced system performance: By reducing friction and wear, Mobil Excel 68 ensures smoother operation, increasing the lifespan of your machinery.

At Sanjay Tools, we supply Mobil Excel 68 Hydraulic Fluid in INDIA & UAE to help your equipment perform at its peak for longer periods, minimizing operational disruptions and enhancing productivity.

Applications of Mobil Gear 600 XP 460

The Mobil Gear 600 XP 460 is a high-performance industrial gear oil designed to provide excellent protection against wear, rust, and corrosion in a wide range of heavy-duty applications in India & UAE. It is particularly suitable for:

Industrial gears: Offering superior protection for enclosed gears in industries like mining, steel manufacturing, and cement production.

Pumps and compressors: Ensuring smooth operation in high-load, high-temperature environments.

Heavy-duty machinery: Ideal for equipment that requires a robust gear lubricant for maximum protection.

Using Mobil Gear 600 XP 460 ensures the long-term reliability of your machinery and helps reduce maintenance costs by providing effective lubrication under extreme conditions.

Uses of Mobilith SHC 007 Synthetic Grease

Mobilith SHC 007 Synthetic Grease is a high-performance, synthetic grease that is specifically engineered for extreme conditions. It is perfect for use in high-speed, high-temperature environments where traditional greases may fail. Key uses of Mobilith SHC 007 include:

Bearings: Ideal for electric motor bearings, high-speed bearings, and automotive components that require smooth lubrication at high speeds.

Temperature extremes: Performs excellently in both extremely high and low-temperature environments, ensuring consistent lubrication.

Industrial equipment: Used in a wide variety of heavy-duty applications, including conveyors, pumps, and compressors.

By using Mobilith SHC 007 Synthetic Grease, you can ensure reduced friction, extended component life, and less frequent maintenance.

Conclusion

At Sanjay Tools, we pride ourselves on being a reliable distributor and supplier in India & UAE of high-quality industrial products. Whether you're looking for 3M products, Fire Ball 300 Grease Pumps, Kaeser compressors, or Mobil lubricants, we have the tools and expertise to support your operations. Our extensive range of products, combined with expert advice and superior customer service, ensures that your industrial operations run smoothly and efficiently.

Explore our website, Sanjay Tools, to learn more about our products and services. Let us be your trusted partner in industrial equipment and lubricants!

0 notes