#vane type vacuum pump

Explore tagged Tumblr posts

Text

Atlas Copco's vacuum pump UAE range includes single stage rotary vane vacuum pumps, 2 stage rotary vane vacuum pumps and oil sealed rotary vane vacuum pumps with VSD technology

#oil sealed rotary vacuum pump#oil sealed rotary vane vacuum pump#vane type vacuum pump#oil lubricated rotary vane vacuum pump#Oil Sealed Rotary SCREW Type Vacuum Pump#Oil Screw Vacuum Pump#vacuum pump#vacuum pumps and systems#atlas copco UAE vacuum pump

0 notes

Text

Understanding Vacuum Technology: A Deep Dive into Different Types of Vacuum Pumps

In various industrial and scientific applications, vacuum technology plays a crucial role in achieving optimal performance and efficiency. Among the essential tools in this field are different types of vacuum pumps, including dry screw vacuum pumps, rotary vane vacuum pumps, and dry vacuum pumps. Additionally, helium leak detectors are vital for ensuring the integrity of vacuum systems. This blog will explore these technologies, their functions, and their applications, providing a comprehensive understanding of vacuum technology.

What is a Vacuum Pump?

A vacuum pump is a device that removes gas molecules from a sealed volume to create a vacuum. The degree of vacuum can vary depending on the type of pump and its application. Vacuum pumps are used in a wide range of industries, including semiconductor manufacturing, pharmaceuticals, food packaging, and research laboratories. The choice of vacuum pump depends on the specific requirements of the application, such as the desired vacuum level, the type of gases being evacuated, and the operational environment.

Types of Vacuum Pumps

1. Dry Screw Vacuum Pump

The dry screw vacuum pump is a positive displacement pump that uses two intermeshing screws to create a vacuum. Unlike other types of pumps, it operates without any oil or liquid, making it an environmentally friendly option. The absence of oil means that there is no risk of contamination, which is particularly important in industries such as pharmaceuticals and food processing.

Dry screw vacuum pumps are known for their high efficiency and reliability. They can achieve low pressures and are capable of handling a wide range of gases, including corrosive and reactive gases. These pumps are also relatively low maintenance, as they do not require oil changes or regular servicing associated with oil-based systems.

2. Rotary Vane Vacuum Pump

The rotary vane vacuum pump is one of the most common types of vacuum pumps used in various applications. It operates by using a rotor with sliding vanes that create a series of chambers. As the rotor turns, the vanes slide in and out, trapping gas and compressing it until it is expelled through an exhaust port.

Rotary vane pump are versatile and can achieve moderate vacuum levels. They are often used in applications such as laboratory experiments, vacuum packaging, and refrigeration. While they do require oil for lubrication and sealing, advancements in technology have led to the development of oil-free rotary vane pumps that offer similar performance without the risk of oil contamination.

3. Dry Vacuum Pump

A dry vacuum pump is designed to operate without any lubricating fluids, making it suitable for applications where contamination must be avoided. These pumps can be based on various technologies, including diaphragm, scroll, or screw mechanisms. Dry vacuum pumps are particularly useful in industries such as semiconductor manufacturing, where even trace amounts of oil can compromise product quality.

The main advantage of dry vacuum pumps is their ability to maintain a clean environment. They are also energy-efficient and can achieve high pumping speeds, making them ideal for processes that require rapid evacuation of gases. Additionally, dry vacuum pumps are often quieter and require less maintenance compared to their oil-lubricated counterparts.

The Importance of Helium Leak Detectors

In vacuum systems, maintaining a high level of integrity is crucial. Even the smallest leaks can lead to significant performance issues, including loss of vacuum, contamination, and reduced efficiency. This is where helium leak detectors come into play.

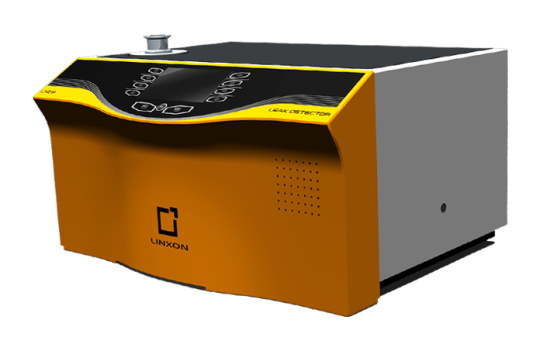

Helium leak detector are specialized instruments used to identify and quantify leaks in vacuum systems. They work by introducing helium gas into the system and then using a mass spectrometer to detect any helium that escapes through leaks. Helium is an ideal tracer gas due to its small atomic size and inert nature, making it easy to detect even in trace amounts.

Applications of Helium Leak Detectors

Helium leak detectors are widely used in various industries, including:

Semiconductor Manufacturing: In the production of semiconductor devices, maintaining a vacuum is essential for preventing contamination and ensuring product quality. Helium leak detectors help identify leaks in vacuum chambers and systems.

Pharmaceuticals: In the pharmaceutical industry, vacuum systems are used for processes such as freeze-drying and packaging. Helium leak detectors ensure that these systems remain airtight, preventing contamination and ensuring product integrity.

Aerospace: In aerospace applications, vacuum systems are used for testing components and systems. Helium leak detectors help ensure that critical components are leak-free, which is vital for safety and performance.

Research Laboratories: In research settings, vacuum systems are often used for experiments that require controlled environments. Helium leak detectors help researchers maintain the integrity of their setups.

Choosing the Right Vacuum Pump

When selecting a vacuum pump for a specific application, several factors must be considered:

Desired Vacuum Level: Different applications require different levels of vacuum. Understanding the required vacuum level is crucial for selecting the appropriate pump.

Type of Gases: The nature of the gases being evacuated can influence the choice of pump. For example, corrosive gases may require a dry screw vacuum pump, while non-cor rosive gases might be suitable for rotary vane pumps.

Contamination Concerns: If the application is sensitive to contamination, such as in pharmaceuticals or semiconductor manufacturing, a dry vacuum pump or a dry screw vacuum pump would be ideal due to their oil-free operation.

Maintenance Requirements: Consideration of maintenance needs is essential. Dry vacuum pumps typically require less maintenance than oil-lubricated pumps, which can lead to lower operational costs over time.

Energy Efficiency: Energy consumption is an important factor, especially in large-scale operations. Choosing a pump that offers high efficiency can lead to significant cost savings.

Conclusion

Vacuum technology is an integral part of many industrial and scientific processes. Understanding the different types of vacuum pumps—such as dry screw vacuum pumps, rotary vane vacuum pumps, and dry vacuum pumps—along with the importance of helium leak detectors, is essential for selecting the right equipment for specific applications. By considering factors such as desired vacuum levels, gas types, contamination concerns, maintenance requirements, and energy efficiency, businesses can optimize their operations and ensure the integrity of their vacuum systems. As technology continues to advance, the efficiency and reliability of vacuum pumps and leak detection methods will only improve, further enhancing their role in various industries.

#Dry Screw Vacuum Pump#Helium Leak Detector#Rotary Vane Vacuum pump#Dry Vacuum Pump#Rotary Vane Pump

0 notes

Text

How To Choose The Right Vacuum Pump For Your Needs

Selecting the appropriate vacuum pump is essential for optimising performance and efficiency in various applications, whether in industrial, automotive, or laboratory settings. With various options available, making an informed decision can seem daunting.

This guide will provide the necessary insights to help you choose the right vacuum pump in Brisbane that is tailored to your requirements.

Understand Your Requirements

The first step in selecting a vacuum pump is assessing your specific needs thoroughly. Identify the application for which you require the pump: Is it for automotive service, HVAC systems, or laboratory experiments? Each application has unique demands that dictate the type of pump suitable for the task.

For example, rotary vane pumps are versatile and widely used for general applications, while diaphragm pumps are more appropriate for sensitive tasks that require contamination control. A clear understanding of your requirements will help you effectively narrow down your options.

Types of Vacuum Pumps

There are several types of vacuum pumps, each designed for distinct functions. Understanding the various types can assist you in making an informed choice:

Rotary Vane Pumps: Known for their reliability and versatility, these pumps are suitable for various general vacuum applications.

Diaphragm Pumps: Ideal for applications requiring clean operation, such as in laboratories and medical equipment, where avoiding contamination is critical.

Scroll Pumps: Recognised for their quiet operation, scroll pumps are often chosen for environments where noise reduction is essential.

Liquid Ring Pumps: These pumps are commonly used in industrial applications and are particularly effective in handling vapours and gases.

Familiarising yourself with these options will aid in selecting a vacuum pump in Brisbane that aligns with your needs.

Consider Your Budget

Budget is a critical factor in the decision-making process. While lower-cost options may be appealing, investing in a high-quality vacuum pump can yield significant long-term benefits, including reduced maintenance and downtime.

Carefully evaluate your budget against the pump's features and durability. A well-chosen vacuum pump will enhance productivity and provide reliable service over its lifespan.

Evaluate Performance Specifications

When selecting a vacuum pump, it is essential to consider its performance specifications. Key factors to assess include:

Vacuum Level: Ensure that the pump can achieve the necessary vacuum level for your specific application.

Pumping Speed: This parameter determines how quickly the pump can evacuate a chamber, which is vital for time-sensitive operations.

Ultimate Pressure: The ultimate pressure indicates the lowest achievable pressure the pump can reach. Higher ultimate pressures often translate to more effective vacuum performance.

You can find a vacuum pump in Brisbane that meets your performance expectations by scrutinising these specifications.

Check for Compatibility

Before purchasing, confirm that the vacuum pump is compatible with your equipment. This includes examining the connections, hoses, and any necessary fittings. Compatibility issues can lead to operational inefficiencies and increased costs.

If you are uncertain, consulting with the supplier or an experienced professional can provide valuable guidance in ensuring compatibility.

Look for Brand Reputation and Warranty

Finally, consider the brand’s reputation and the warranty offered with the vacuum pump. Established brands often have a proven track record of quality and reliability. Research customer reviews and testimonials to assess other users' experiences. A robust warranty can also assure that you will receive support or a replacement should issues arise.

Conclusion: Making the Right Choice

Choosing the right vacuum pump is a critical decision that can significantly impact your operational efficiency and overall success. By understanding your requirements, considering your budget, evaluating performance specifications, ensuring compatibility, and researching brand reputation, you can make an informed choice tailored to your needs.

Whether you are in the market for a vacuum pump in Brisbane or seeking specialised options, the right selection will enhance your productivity and ensure a reliable and efficient operational experience.

0 notes

Text

United States Hydraulic Pumps Market Dynamics and Future Landscape Review 2024 - 2032

The United States hydraulic pumps market is a crucial segment of the broader industrial landscape, driven by diverse applications across various sectors. Hydraulic pumps are essential components in numerous machinery and equipment, enabling efficient fluid power transmission. As industries continue to innovate, the demand for advanced hydraulic pumps is growing, making the United States hydraulic pumps market a focal point for manufacturers and investors alike.

Overview of Hydraulic Pumps

Hydraulic pumps are mechanical devices that convert mechanical energy into hydraulic energy by moving fluid. They are categorized into various types, including gear pumps, piston pumps, and vane pumps, each designed for specific applications. The performance and efficiency of these pumps are vital for operations in industries such as construction, manufacturing, and agriculture.

Types of Hydraulic Pumps

Gear Pumps

Gear pumps are widely used for their simplicity and efficiency in transferring hydraulic fluids. They operate using gears that mesh together to create a vacuum that draws in fluid and then pushes it out.

Piston Pumps

Known for their high efficiency and ability to handle high pressures, piston pumps are commonly used in heavy machinery and industrial applications. They utilize pistons to create pressure and flow.

Vane Pumps

Vane pumps are versatile and can handle a variety of fluids. They consist of a rotor with vanes that move within a cavity, creating a pumping action.

Market Trends

Growth Drivers

The United States hydraulic pumps market is experiencing significant growth due to several factors:

Industrial Automation: The push for automation in manufacturing processes is leading to increased demand for hydraulic systems, including pumps.

Infrastructure Development: Ongoing infrastructure projects and investments in construction are driving the need for reliable hydraulic equipment.

Technological Advancements: Innovations in pump design and materials are improving efficiency and reducing energy consumption, making hydraulic pumps more appealing to end-users.

Challenges

Despite the positive outlook, the market faces challenges such as:

Fluctuating Raw Material Prices: The cost of materials used in manufacturing hydraulic pumps can impact pricing and profitability.

Competition from Electric Pumps: The rise of electric pumps as alternatives to hydraulic systems may pose a threat to market growth.

Key Players in the Market

Several companies dominate the United States hydraulic pumps market, each contributing to the industry's evolution:

Parker Hannifin Corporation: A leader in motion and control technologies, Parker offers a wide range of hydraulic pumps known for their reliability and performance.

Bosch Rexroth AG: Renowned for its innovative hydraulic solutions, Bosch Rexroth focuses on high-quality and energy-efficient pump designs.

Eaton Corporation: Eaton provides a comprehensive portfolio of hydraulic pumps and systems, catering to various industrial needs.

Future Outlook

The future of the United States hydraulic pumps market looks promising, with projections indicating continued growth. As industries evolve, the demand for more efficient, durable, and technologically advanced hydraulic pumps will remain strong. Companies that can innovate and adapt to changing market dynamics will likely succeed in this competitive landscape.

In conclusion, the United States hydraulic pumps market is an integral part of the industrial sector, driven by technological advancements and increasing demand across various applications. As businesses seek reliable and efficient fluid power solutions, the market is set for sustained growth and evolution in the coming years.

Related Reports

Portable Generator

Power Quality Equipment

Hydrogen Fueling Station

Water Desalination

0 notes

Text

Innovative Vacuum Pump Solutions by Indo Air Compressor

In the fast-evolving industrial world, vacuum pumps are essential in optimising processes across various sectors, from food packaging to pharmaceutical production. Indo Air Compressor leads the market with its innovative, high-performance vacuum pump solutions, offering unmatched efficiency, durability, and energy-saving benefits. Indo Air’s vacuum pump meets diverse industry needs with precision and eco-friendly designs. In this article, discover how Indo Air Compressor, leading vacuum pump manufacturer in India, transforms processes and delivers powerful solutions tailored to modern industry demands.

Understanding Vacuum Pump

A vacuum pump removes air or gas from a sealed area, creating a vacuum. This ability to control air pressure is necessary in food packaging, electronics manufacturing, and medical laboratories. By using vacuum pumps, industries can work with precise environmental control, improving quality and efficiency in their work.

Why Indo Air Compressor

Indo Air Compressor is a top choice for vacuum pump for several reasons:

Advanced technology with modern design and technology makes their pumps efficient and easy to operate.

Each vacuum pump is designed to save energy and lower operational costs.

Each pump is tested for quality to meet industry standards.

Indo Air, leading vacuum pump manufacturers in India, offers various applications for different needs, allowing businesses to find the perfect fit.

Types of Vacuum Pump by Indo Air Compressor

Indo Air provides several air compressors, each suited to specific tasks and industries.

Rotary vane vacuum pumps:

These pumps are widely used for stable vacuum levels in electronics, food packaging, and other industries requiring constant suction. This vacuum pump is known for its efficiency and reliability.

Liquid ring vacuum pumps:

For applications that handle moisture, liquid ring pumps are a great choice. They use a liquid seal to compress gases, which makes them durable and resistant to corrosive substances. This type is used in the pharmaceutical and water treatment industries.

Scroll vacuum pumps:

Scroll pumps work with minimal noise and vibration, making them ideal for sensitive settings like medical labs and research facilities. They are compact, energy-efficient, and provide a high level of performance.

Dry screw vacuum pumps:

This vacuum pump works without oil or liquids, making it easy to maintain and environmentally friendly. They’re perfect for clean environments, like food processing or pharmaceuticals, where contamination is a concern.

Key Features of Vacuum Pumps

Vacuum pump manufacturers in India meet industry demands, focusing on features that make them user-friendly, durable, and energy-efficient.

Quiet operation:

Indo Air pumps are built with noise reduction, allowing them to run quietly. This feature benefits environments like hospitals and research labs, where low noise is important.

Compact design:

Many Indo Air pumps are prepared to be compact, so they fit easily into small spaces. This is helpful for businesses with limited room for equipment.

Low maintenance:

Indo Air’s pumps are built to be durable and require minimal upkeep, which can save time and maintenance costs. This is valuable for businesses aiming to keep working costs low.

Energy efficient:

With a focus on saving energy, Indo Air’s pumps help reduce electricity use, making them cost-effective and eco-friendly.

Industries Benefiting from Vacuum Pumps

Various industries depend on vacuum pump for their unique needs, from preserving food to maintaining sterile medical environments.

Food processing:

Vacuum pumps are used in packaging and preserving food, as they help remove air to extend product shelf life. Indo Air’s rotary vane and liquid ring pumps are especially useful in food processing to maintain hygiene standards.

Healthcare and pharmaceuticals:

In pharmaceuticals, a vacuum pump helps in drying, filtration, and sterilisation processes. Indo Air’s dry screw and scroll pumps meet strict cleanliness requirements, ensuring products stay safe and pure.

Electronics manufacturing:

Vacuum pumps are essential in electronics, where creating a controlled environment is essential for production. Indo Air’s pumps provide the precise vacuum levels needed for high-quality electronics.

Laboratories and research:

Indo Air’s quiet, compact pumps are ideal for labs, providing reliable performance without causing disruption. These pumps are used in various experiments and testing processes in research settings.

Why Choose Indo Air’s Vacuum Pump:

Choosing a quality vacuum pump can greatly impact your business operations. Indo Air Compressor is committed to efficiency, quality, and innovation. Here’s why Indo Air’s vacuum pumps are a smart investment:

Cost-effective: Indo Air’s pumps help reduce long-term costs by saving on energy.

Reliable and long-lasting: Indo Air pumps are known for durability, requiring fewer repairs or replacements.

Eco-friendly: Indo Air’s energy-saving designs help businesses reduce their carbon footprint.

Customizable solutions: With various pumps available, Indo Air offers options that meet specific industry needs.

Conclusion

Indo Air Compressor’s vacuum pump solutions blend technology, efficiency, and reliability. From food production to scientific research, these pumps meet the demands of modern industries while promoting energy efficiency. Indo Air is a trusted name with quality products designed to help businesses operate smoothly and sustainably. For industries seeking reliable and cost-effective vacuum solutions, Indo Air Compressor offers products that deliver consistent, high-quality performance while supporting a more sustainable future.

0 notes

Text

How to Choose Your Vacuum Pump

What is a Vacuum Pump?

A vacuum pump is a device that removes gas molecules from a sealed volume to create a partial or high vacuum. These pumps are essential in various industries, including manufacturing, medical, scientific research, and electronics, where controlling the atmospheric pressure within a system is crucial. By evacuating air or other gases, vacuum pumps reduce the pressure inside a chamber, which can then be used for processes such as coating, drying, or testing under controlled conditions.

Types of Vacuum Pumps and Their Applications

Vacuum pumps come in several types, each suited to different applications. The three primary categories are positive displacement pumps, momentum transfer pumps, and entrapment pumps.

Positive Displacement Pumps

Positive displacement pumps work by mechanically trapping a volume of gas and moving it through the pump to the exhaust. These pumps are ideal for low to medium vacuum applications. Common types include:

Rotary Vane Pumps: Used in laboratories and industrial processes where a stable vacuum is required. They are reliable and provide a consistent vacuum.

Diaphragm Pumps: Suitable for applications requiring a clean and oil-free vacuum, such as in the medical and food industries.

Piston Pumps: Often used in small-scale laboratory settings for specific, low-volume applications.

Momentum Transfer Pumps

Momentum transfer pumps, also known as molecular pumps, use high-speed rotating blades or magnetic fields to impart momentum to gas molecules, effectively transferring them out of the chamber. These pumps are typically used for high and ultra-high vacuum applications.

Turbomolecular Pumps: Widely used in the semiconductor and coating industries due to their ability to achieve high vacuum levels.

Diffusion Pumps: Employed in processes like metal deposition and electron microscopy, where high vacuum is necessary.

Entrapment Pumps

Entrapment pumps capture gases through chemical or physical means. These pumps are essential in creating ultra-high vacuum environments.

Cryopumps: Used in applications requiring extremely low temperatures, such as in the cooling of superconductors and in some scientific research facilities.

Sorption Pumps: Often utilized in small-scale applications and scientific experiments where ultra-clean environments are essential.

How to Choose the Right Vacuum Pump

Selecting the right vacuum pump depends on several factors, including the desired vacuum level, the nature of the gases being pumped, the required pumping speed, and the operating environment. Here are some key considerations:

Vacuum Level Requirements: Determine the vacuum range required for your application. Low vacuum (up to 1 mbar) can be achieved with rotary vane or diaphragm pumps, while high vacuum (down to 10^-9 mbar) requires turbomolecular or cryopumps.

Gas Composition: Consider the type of gases that will be evacuated. For corrosive or reactive gases, a diaphragm pump with chemical resistance or a specialized coating on a rotary vane pump might be necessary.

Pumping Speed: The pumping speed, measured in liters per second (L/s) or cubic meters per hour (m^3/h), should match the volume of gas to be evacuated within a specific time frame. Larger systems or those requiring faster evacuation rates will need pumps with higher pumping speeds.

Operating Environment: Evaluate the working conditions, such as temperature, humidity, and cleanliness requirements. For example, oil-free diaphragm pumps are ideal for environments where contamination must be avoided.

Maintenance and Cost: Consider the total cost of ownership, including initial purchase price, operating costs, and maintenance requirements. Some pumps, like rotary vane pumps, require regular oil changes, while others, like diaphragm pumps, have minimal maintenance needs.

How to Maintain Your Vacuum Pump

Proper maintenance is crucial to ensure the longevity and efficiency of your vacuum pump. Here are some general maintenance tips:

Regular Inspections: Conduct routine inspections to check for wear and tear, oil levels (for oil-sealed pumps), and overall pump performance. Early detection of issues can prevent costly repairs and downtime.

Oil Changes: For rotary vane pumps, regularly change the oil as per the manufacturer's recommendations. Contaminated oil can reduce pump efficiency and lead to mechanical failures.

Cleaning: Keep the pump and its components clean to prevent the buildup of debris, which can obstruct airflow and reduce performance. Use appropriate cleaning agents that do not damage the pump's materials.

Seal and Gasket Checks: Inspect seals and gaskets for signs of wear or damage. Replacing them timely ensures a proper seal and prevents leaks that can affect vacuum levels.

Filter Replacement: Replace filters as recommended to maintain optimal airflow and prevent contaminants from entering the pump.

Monitor Operating Parameters: Regularly monitor the pump's operating parameters, such as pressure, temperature, and power consumption. Any deviations from the norm can indicate potential problems.

Choosing the right vacuum pump involves understanding your specific application requirements and the various types of pumps available. By considering factors such as vacuum level, gas composition, pumping speed, and operating environment, you can select a pump that meets your needs. Proper maintenance, including regular inspections, oil changes, and cleaning, is essential to keep your pump running efficiently and prolong its lifespan. With the right knowledge and care, your vacuum pump can provide reliable performance for years to come.

(More information available at wsvacuum.com)

0 notes

Text

Oil Pumps: The Heart of Engine Lubrication

Oil Pumps: The Heart of Engine Lubrication Oil pumps are a critical component in internal combustion engines, ensuring that all moving parts are adequately lubricated and cooled. Without a functioning oil pump, an engine would quickly overheat and suffer catastrophic damage. In this article, we will delve into the workings of oil pumps, their types, and their importance in engine performance.Get more news about Oil Pump,you can vist our website!

What is an Oil Pump? An oil pump is a device that circulates engine oil under pressure to the rotating bearings, sliding pistons, and camshaft of the engine. This lubrication reduces friction and wear on the moving parts, allowing the engine to operate smoothly and efficiently. Additionally, the oil helps to cool the engine by carrying heat away from the moving parts.

Types of Oil Pumps There are several types of oil pumps used in internal combustion engines, each with its own unique design and function:

Gear Pumps: These are the most common type of oil pump. They use a pair of meshing gears to pump the oil. As the gears rotate, they create a vacuum that draws oil into the pump and then pushes it out under pressure. Gear pumps are known for their reliability and efficiency. Rotor Pumps: Also known as gerotor pumps, these use a rotor with external teeth that mesh with an internal gear. As the rotor turns, it creates chambers that draw in and expel oil. Rotor pumps are compact and can provide a steady flow of oil. Vane Pumps: These pumps use a series of vanes mounted on a rotor. As the rotor spins, the vanes slide in and out, creating chambers that move the oil. Vane pumps are less common in automotive applications but are used in some high-performance engines. How Oil Pumps Work The oil pump is typically driven by the engine’s crankshaft, ensuring that it operates whenever the engine is running. The pump draws oil from the oil pan through a pickup tube and forces it through the engine’s oil passages. These passages distribute the oil to critical components such as the crankshaft bearings, camshaft bearings, and pistons.

The oil pump must maintain a consistent flow of oil to ensure proper lubrication. If the oil pressure drops too low, it can lead to insufficient lubrication and potential engine damage. Conversely, if the oil pressure is too high, it can cause excessive wear on the engine components.

Importance of Oil Pumps Oil pumps play a vital role in engine performance and longevity. Here are some key reasons why oil pumps are essential:

Lubrication: The primary function of the oil pump is to provide continuous lubrication to the engine’s moving parts. This reduces friction and wear, allowing the engine to run smoothly and efficiently. Cooling: By circulating oil through the engine, the oil pump helps to dissipate heat generated by the combustion process. This prevents the engine from overheating and ensures optimal performance. Cleaning: Engine oil also helps to clean the engine by carrying away dirt, debris, and metal particles. The oil pump ensures that the oil is continuously circulated and filtered, keeping the engine clean and free of contaminants. Hydraulic Functions: In some engines, the oil pump also powers hydraulic systems such as variable valve timing and hydraulic lifters. These systems rely on a steady supply of pressurized oil to function correctly. Common Issues with Oil Pumps While oil pumps are generally reliable, they can experience problems that affect engine performance. Some common issues include:

Wear and Tear: Over time, the internal components of the oil pump can wear out, reducing its efficiency and causing a drop in oil pressure. Blockages: Dirt and debris can clog the oil passages, restricting the flow of oil and leading to insufficient lubrication. Leaks: Oil leaks can reduce the amount of oil available for circulation, causing a drop in oil pressure and potential engine damage. Conclusion Oil pumps are the heart of an engine’s lubrication system, ensuring that all moving parts are adequately lubricated, cooled, and cleaned. By understanding how oil pumps work and their importance in engine performance, you can better appreciate the critical role they play in keeping your engine running smoothly. Regular maintenance and timely replacement of worn-out components can help ensure that your oil pump continues to function effectively, prolonging the life of your engine.

0 notes

Text

Double Stage Vacuum Pump (VP245) 5CFM

Vacuum pumps are an essential tool in a variety of industries, playing a critical role in applications that require the removal of gases and air from sealed environments. One of the most efficient and widely used types of vacuum pumps is the double-stage vacuum pump, and the VP45 model exemplifies superior performance, reliability, and advanced technology. From HVAC and refrigeration maintenance to laboratory applications, this pump stands out for its high vacuum capabilities. In this article, we’ll dive into the details of the double-stage vacuum pump VP45, its working mechanism, applications, and pricing, particularly in the Indian market.

What is Double Stage Vacuum Pump ?

A double-stage vacuum pump, like the VP45, operates in two phases to achieve higher vacuum levels. Unlike single-stage pumps that only compress air once, a double-stage vacuum pump compresses the air twice, resulting in a deeper vacuum. This deeper vacuum level is essential for processes that demand high precision, such as air conditioning (AC) system maintenance, refrigeration system evacuation, and scientific research applications.

The VP45 model is particularly notable for its advanced design, offering greater vacuum efficiency and reliability for professionals. Its double-stage design makes it capable of reaching low pressure levels (high vacuum), making it suitable for applications that single-stage pumps may not be able to handle.

Key Features of the Double Stage Vacuum Pump VP 245 ?

The VP45 double-stage vacuum pump comes equipped with several features that make it an ideal tool for both professionals and hobbyists in industries such as HVAC, refrigeration, and laboratories. Here are some of the standout features:

Two-Stage Operation: The two-stage mechanism provides a higher level of vacuum precision compared to single-stage pumps, making the VP45 more suitable for demanding applications.

Robust Construction: The VP45 is built from high-quality materials designed to withstand the rigors of daily use. Its heavy-duty construction ensures durability and longevity.

Efficient Cooling System: To prevent overheating, the VP45 is equipped with an efficient cooling system that keeps the pump functioning optimally during extended use.

Oil-Mist Filter: The VP45 includes an oil-mist filter to reduce oil mist emissions, keeping your work environment cleaner and more efficient.

Low Noise Operation: Unlike many industrial machines, the VP45 operates quietly, allowing for a less disruptive working environment.

Thermal Protection: The pump is equipped with a thermal protection system that prevents it from overheating, ensuring long-lasting performance even in high-demand situations.

Double Stage Vacuum Pump Working ?

Understanding how a double-stage vacuum pump works is essential for grasping its advantages over single-stage models. Here's how it operates:

Stage One: In the first stage of the process, the pump reduces the atmospheric pressure in the system by compressing the air from the vacuum chamber. This stage works similarly to a single-stage vacuum pump and reaches a basic vacuum level by expelling the air through an exhaust port.

Stage Two: The second stage kicks in to further reduce the pressure. This stage compresses the remaining air, removing it completely to create a much deeper vacuum. By performing this second compression, the VP45 can achieve much lower pressure levels, allowing it to reach higher vacuums than single-stage pumps.

Oil Lubrication: The pump uses oil as a lubricant and sealant, which plays a crucial role in reducing wear and tear on the moving parts while maintaining an airtight seal. This ensures smooth, long-lasting performance.

Rotary Vane Mechanism: The VP45 features a rotary vane design where rotating vanes trap air in compartments. As the rotor spins, the vanes push the air towards the exhaust, where it’s expelled. This process repeats continuously, but in two stages, to achieve a more complete vacuum.

Appilcations of Double Stage Vacuum Pumps

Double-stage vacuum pumps like the VP45 have a broad range of applications, thanks to their ability to achieve high levels of vacuum. Here are some of the key industries and tasks that benefit from the use of a double-stage vacuum pump:

1. Air Conditioning (AC) and Refrigeration

In air conditioning (AC) systems, a vacuum pump is used to remove moisture and air from the refrigerant lines before charging the system with refrigerant gas. This process ensures the system runs efficiently and prevents contamination that can damage components over time. The double-stage vacuum pump for AC systems ensures that the system is evacuated to the necessary vacuum depth, eliminating moisture and air.

2. HVAC Systems

For HVAC professionals, the VP45 is an invaluable tool. It ensures that the refrigerant system is properly evacuated, which is critical for the overall health and efficiency of the system. A properly vacuumed system reduces the risk of leaks, corrosion, and inefficient operation.

3. Laboratories

In laboratories, vacuum pumps are used for a variety of tasks, such as vacuum filtration, freeze drying, and creating controlled environments for experiments. The VP45’s ability to achieve deeper vacuums makes it ideal for these applications.

4. Industrial Applications

Many industrial applications, such as food packaging, require a vacuum environment. The VP45 can be used to create a vacuum that preserves food products by removing air, thus extending their shelf life.

5. Medical Equipment

Double-stage vacuum pumps are also used in medical equipment, such as autoclaves, to ensure sterile environments by removing air and steam from medical devices during sterilization processes.

2 Stage Vacuum Pump Price in India

The price of a 2-stage vacuum pump in India varies depending on the brand, features, and capacity. For the VP45, prices generally range depending on the retailer and any additional features or accessories included.

Higher-end models, which may come with advanced features such as digital displays, enhanced oil filtration systems, or additional capacity, are typically priced at the upper end of this range. Lower-end models with fewer features but still offering the essential double-stage mechanism will be closer to the starting price.

Factor Influencing the price of a Double Stage-Vacuum Pump

Several factors impact the price of a double-stage vacuum pump like the VP45:

Brand: Well-known brands with a reputation for high-quality performance and durability often have higher price points.

Capacity: Pumps with larger capacities can handle more demanding tasks, which may increase the price.

Features: Additional features such as oil filtration systems, thermal protection, and advanced cooling systems can raise the price.

Several factors impact the price of a double-stage vacuum pump like the VP45:

Brand: Well-known brands with a reputation for high-quality performance and durability often have higher price points.

Capacity: Pumps with larger capacities can handle more demanding tasks, which may increase the price.

Features: Additional features such as oil filtration systems, thermal protection, and advanced cooling systems can raise the price.

More information :- CLICK HERE

CONTACT :- 91-9717732520

0 notes

Text

Atlas Copco UAE Vacuum Pump Solutions & services.

#vacuumpumpsuae#vacuum pump#industrial vacuum pump#vacuum pumps and systems#dry vacuum pump#oil sealed vacuum pump#vane type vacuum pump#oil sealed rotary vacuum pump#Oil Screw Vacuum Pump#screw type vacuum pump#rotary screw vacuum pump#liquid ring vacuum pump#water ring vacuum pump

1 note

·

View note

Text

Pompetravaini Single Stage and Two Stage Liquid Ring Vacuum Pumps

Our Pompetravaini Single and Two Stage Liquid Ring Vacuum Pumps deliver high-efficiency vacuum solutions for industrial needs. These equipment are designed especially for reliability and long-lasting performance. Check out our different types of liquid ring vacuum pumps and their specifications.

#industrial vacuum pumps#vacuum pumps#industrial equipment supplier#vacuum pumps australia#liquid ring vacuum pumps#Pompetravaini Vacuum Pumps#Pompetravaini Single and Two Stage Liquid Ring Vacuum Pumps#vacuum pumps Suppliers

1 note

·

View note

Text

Exploring Advanced Vacuum and Helium Leak Detection Solutions

In industries ranging from manufacturing to research, vacuum systems play a pivotal role in ensuring operational efficiency and product quality. Among the various technologies available, rotary vane vacuum pumps, dry vacuum pumps, helium leak detectors, helium leak testing machines, and helium recovery systems have become essential tools. Let’s dive into the functionalities and applications of these systems to better understand their impact.

Rotary Vane Vacuum Pump: Reliable Performance in a Compact Design

The rotary vane vacuum pump is one of the most commonly used types of vacuum pumps. Its compact design, reliability, and versatility make it suitable for various applications. The pump operates by using vanes that rotate inside a cylindrical chamber, creating a vacuum by displacing air or other gases.

Applications:

Medical and Laboratory Equipment: Rotary vane vacuum pumps are used in medical applications such as vacuum-assisted wound closure systems and laboratory vacuum systems.

Packaging Industry: These pumps are integral to vacuum packaging machines, ensuring products remain fresh by eliminating air from packaging.

HVAC Systems: In heating, ventilation, and air conditioning systems, rotary vane pumps help in refrigerant recovery and evacuation processes.

Key benefits of rotary vane vacuum pumps include their durability, low noise operation, and ease of maintenance.

Dry Vacuum Pump: Oil-Free Efficiency for Sensitive Processes

Unlike rotary vane pumps, dry vacuum pump operate without the use of oil or any other sealing liquid. This makes them ideal for processes where contamination must be avoided.

Advantages of Dry Vacuum Pumps:

Clean Operation: With no oil involved, these pumps prevent contamination of the pumped gases or the environment.

Energy Efficiency: Many dry vacuum pumps are designed to consume less energy, reducing operational costs.

Low Maintenance: Without oil changes or sealing fluid replacement, maintenance requirements are minimal.

Common Applications:

Pharmaceutical Industry: Dry vacuum pumps are used in tablet coating and other sensitive pharmaceutical processes.

Semiconductor Manufacturing: These pumps play a critical role in processes like chemical vapor deposition and etching, where cleanliness is paramount.

Food Processing: Dry vacuum pumps are used in freeze-drying and vacuum cooling applications.

Helium Leak Detector: Precision in Leak Detection

Helium leak detector are essential tools for identifying and quantifying leaks in sealed systems. Helium is an ideal tracer gas due to its small molecular size and inert properties, making it capable of detecting even the tiniest leaks.

Working Principle:

A helium leak detector typically consists of a mass spectrometer that senses the presence of helium within a system. When helium is introduced into the system under test, the detector identifies any escaping helium, pinpointing leaks with high accuracy.

Key Applications:

Automotive Industry: Helium leak detectors are used to ensure the integrity of fuel systems, air conditioning systems, and exhaust systems.

Aerospace Sector: Ensuring leak-tight components in critical aerospace systems, such as fuel tanks and propulsion systems.

Medical Devices: Used in testing the hermeticity of medical implants and diagnostic equipment.

The precision and reliability of helium leak detectors make them indispensable for maintaining safety and quality standards.

Helium Leak Testing Machine: Comprehensive Leak Testing Solutions

A helium leak testing machine is a complete system that incorporates a helium leak detector, pumping systems, and control units to automate the leak testing process. These machines are tailored to meet the specific requirements of various industries.

Features and Benefits:

Automation: Automated testing reduces human error and increases throughput.

Customizability: Machines can be designed for specific applications, such as testing automotive radiators, batteries, or high-pressure vessels.

High Sensitivity: These systems can detect leaks at the micro-level, ensuring the highest standards of quality control.

Industrial Applications:

Energy Sector: Used for testing high-pressure gas cylinders and pipelines.

Electronics Manufacturing: Ensures the integrity of sealed electronic components such as sensors and displays.

Vacuum Technology: Essential in testing vacuum chambers and components for scientific and industrial applications.

Helium Recovery System: Sustainability in Leak Detection

As the demand for helium increases and its availability decreases, helium recovery system have become a critical component of modern leak detection setups. These systems capture and recycle helium, reducing operational costs and environmental impact.

How Helium Recovery Systems Work:

Capture: Helium used in the testing process is captured from the test environment.

Purification: The captured helium is purified to remove contaminants.

Storage: The purified helium is stored for reuse in subsequent tests.

Advantages:

Cost Savings: Reducing the need for new helium purchases can significantly cut costs.

Environmental Benefits: Minimizing helium waste supports sustainable operations.

Enhanced Efficiency: Continuously recycled helium ensures a steady supply for testing operations.

Applications:

Manufacturing Plants: Ideal for large-scale operations where helium usage is high.

Research Facilities: Ensures a sustainable supply of helium for experiments and testing.

Aerospace Industry: Critical for testing and maintaining expensive and sensitive components.

The Future of Vacuum and Leak Detection Technologies

With advancements in technology, vacuum systems and helium leak detection solutions are evolving to meet the growing demands of precision, efficiency, and sustainability. Integration with IoT and smart systems enables real-time monitoring and diagnostics, reducing downtime and increasing productivity. Moreover, the push toward eco-friendly solutions is driving the adoption of oil-free and helium recovery systems.

Final Thoughts:

Whether it’s a rotary vane vacuum pump ensuring efficient vacuum creation, a dry vacuum pump delivering oil-free operation, or a helium leak detector safeguarding the integrity of critical systems, these technologies are indispensable. Helium leak testing machines and helium recovery systems further enhance efficiency and sustainability, making them vital in today’s industrial landscape.

By understanding and implementing these advanced systems, industries can achieve higher standards of quality, safety, and environmental responsibility.

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

Vacuum Pump Manufacturers: A Friendly Guide

Introduction When it comes to industries that rely on precision and efficiency, vacuum pumps are the unsung heroes. These powerful devices remove air and gas molecules from a sealed space, creating a vacuum essential for various applications, from laboratories to manufacturing plants. Behind these reliable machines are the vacuum pump manufacturers who design, produce, and perfect them. Let’s dive into what makes these manufacturers tick and why they’re so crucial.

The Role of Vacuum Pump Manufacturers

Vacuum pump manufacturers play a pivotal role in many industries by providing the technology that drives processes requiring controlled environments. From pharmaceuticals and chemical processing to food packaging and electronics, their products are essential for ensuring that operations run smoothly.

Key Contributions of Vacuum Pump Manufacturers:

Innovation: Manufacturers constantly innovate to create more efficient and powerful vacuum pumps. These advancements help businesses optimize their processes and reduce energy consumption.

Customization: Different industries have unique needs. Manufacturers often provide customized solutions to meet specific requirements, ensuring that each pump delivers the desired performance.

Quality Assurance: Reliable vacuum pumps are critical. Manufacturers invest heavily in quality control to ensure their products meet stringent standards, minimizing the risk of failure during operation.

Types of Vacuum Pumps

Vacuum pumps come in various types, each designed for specific applications. Understanding the different types can help you appreciate the breadth of expertise vacuum pump manufacturers bring to the table.

1. Positive Displacement Pumps

These pumps work by expanding a cavity, allowing gases to flow in, and then sealing and expelling them. They are commonly used in industrial applications where a high vacuum is not required but durability and reliability are essential.

Rotary Vane Pumps: Widely used in laboratories and small-scale operations.

Diaphragm Pumps: Ideal for applications requiring a dry and oil-free vacuum.

2. Momentum Transfer Pumps

Also known as molecular pumps, these are used when a high or ultra-high vacuum is needed. They operate by imparting momentum to gas molecules, effectively removing them from the chamber.

Turbomolecular Pumps: Essential in semiconductor manufacturing and high-vacuum research.

Diffusion Pumps: Often found in large-scale industrial applications.

3. Entrapment Pumps

These pumps capture gas molecules by freezing or chemically binding them. They are used in ultra-high vacuum environments where contamination must be minimized.

Cryogenic Pumps: Common in particle accelerators and scientific research.

Sorption Pumps: Used in ultra-high vacuum systems, especially in research labs.

What to Look for in a Vacuum Pump Manufacturer

Choosing the right vacuum pump manufacturer can make a significant difference in the efficiency and reliability of your operations. Here are some factors to consider:

Experience: A manufacturer with a proven track record in the industry will likely provide reliable and well-tested products.

Technical Support: Look for manufacturers who offer comprehensive support, from installation to troubleshooting.

Customization Options: If your industry has unique needs, a manufacturer that offers customization will be invaluable.

Sustainability Practices: In today’s world, choosing a manufacturer that prioritizes energy efficiency and environmentally friendly practices is a smart move.

Conclusion

Vacuum pump manufacturers are the backbone of numerous industries, providing essential technology that enables precise and controlled processes. By understanding the types of vacuum pumps available and the factors that make a manufacturer stand out, businesses can make informed decisions that enhance their operations. Whether you’re in the market for a new vacuum pump or simply curious about the industry, appreciating the work of these manufacturers helps you recognize the importance of their contributions to modern technology.

0 notes

Text

China offer VALVE CONTROL FLOW G761-3005B for turbine generator

"China offer VALVE CONTROL FLOW G761-3005B for turbine generator Is YOYIK for the use of turbine units of the power plant supporting professional models of products. YOYIK main generator accessories, generator sets of accessories. For decades, the company relies on advanced technology, technology, materials and scientific management to improve the stability and reliability of the pump, for hundreds of thermal power plants, hydropower stations, cement plants, coal gangue power plants, metallurgical companies, steel and other overhaul , Technical transformation to provide a reasonable and excellent equipment selection, construction planning, installation commissioning, after-sales service, such as perfect complete service, won the power industry industry wide acclaim.

Yoyik can offer many spare parts for power plants as below:

DF-VALVE CONTROL FLOW G761-3005B-DF

Solenoid valve Z2804076 Fluoro Rubber O-Ring OR0311308 sealing ring HB4-56J8-124 high pressure hydraulic pump power pack station 65AY5010 centrifugal pump stainless steel CZ80-250A pump screw HSNH80-27 mechanical rubber seal 10014CH1-5008 transfer pump vane F3V201S8S1C11 globe throttle check valve LJC40C-1.6P dc centrifugal pump 65-250B pump hydraulic power 40AY35X11 vacuum pumps 125LY-35-8 oil transfer electric pump Y160M-2/11KW/IP44 Accumulator bladder LP40 screw pump working ACF090N5ITBP single screw pump HSND280-54 sealing oil Re-Circulating pump HSNH280-43Z dc vane pump F3-V10-1S6S-10-20 three screw pump HSNH440 turbine AC lube pump 125LY-40-B globe throttle check valve KJC25C-4.0P high pressure oil pump 80LY-80-B electric hydraulic oil power pump 80AY506 oil pump cost 50YW25-33 seal sleeve lock nut FK5C32AM-03-02 Manual pressure regulating valve EXCELON B72G-2GK-QD3-RMN hydraulic pump motor 65AY100 piston pump parts M03EA10VSO45DFR1/31RVPA12 coupling cushion 30-WS Accumulator NXQ-AB-25-31.5 centrifugal pump types 100-80-125A Regulating valve KS100ZXNO016 DN100 PN16 vacuum hand pump 125LY-32-B piston vacuum pump A10VSO100DFR1/32R vacuum oil pump P-1607 globe valve J1F1.6P-25 VALVE CONTROL FLOW G761-3005B

EH oil pump PV29-2R50C00 screw pump diagram HSND280-43NZ Vacuum pump 30WS vacuum pump ac A10VS0100DR/31R-PPA12NOO radial piston pump hydraulic PVH98QIC-RSF-1S-10-C25-31 gear pump hydraulic 80AY100 pump centrifugal DFB100-80-230 oil pump replacement 80AYP60 mechanical seal for pump 8b1d reciprocating piston pump PVH074R01AA(AB)10A250000002001AB0 axial piston variable pump PVH98Q1C-RSF-1S-10-C25-31 mechanical face seal BGM37G/50R-G9 reciprocating pump 80AY50*9 mechanical seal for pump BGM37G/50R-G9 RUBBER BLADDER NXQA-25/31.5-L-EH accumulator NXAQ-10/31.5-L mian trip solenoid valve 8YVHP trip solenoid valve turbine OPC solenoid valve HQ16.80Z rotary vane vacuum pump F3-V10-IS6S-IC-20 rotary vacuum pump P-1761-1 screw pump working principle ACF 090N4 1RBP Mechanical control valve 224.32.9.1/1X centrifugal pump DFB80-80-240 butterfly valve K65DSF4PB3 dc screw pump SMH120-42W1Q1 OPC solenoid valve ZD.02.008 dc screw pump HSND280-46 rotary vacuum pump P-1937A electric transfer oil pump DLZB820-R64A-01 ASTSolenoid valve HQ16.16Z-2 BALL BEARING SINGLE ROW RADIAL DEEP GROOVE NO.6202 Check valve 216C15 liquid ring vacuum pump HSNH660-40NZ vacuum pump 222v SK-831 electric centrifugal pump head 50-250-007 servo valve J761-002 VALVE CONTROL FLOW G761-3005B

DFYLSYC-2024-7-15-A

"

0 notes

Text

Exploring the Different Types of Hydraulic Pumps

Hydraulic pumps are the heart of any hydraulic system, converting mechanical energy into hydraulic energy by pushing hydraulic fluid through the system. Understanding the various types of hydraulic pumps is crucial for selecting the right pump for specific applications and ensuring the efficiency and reliability of hydraulic systems. In this blog, we will explore the different types of hydraulic pumps, their functions, and their typical applications.

1. Gear Pumps

Gear pumps are one of the most common types of hydraulic pumps, known for their simplicity, durability, and reliability. They come in two main types: external gear pumps and internal gear pumps.

External Gear Pumps: These pumps have two intermeshing gears that rotate to create suction at the pump inlet, drawing fluid into the pump and then pushing it out at the discharge port. They are widely used in industrial applications due to their efficiency and high-pressure capabilities.

Internal Gear Pumps: These pumps have an external gear (rotor) meshing with an internal gear (idler). The fluid is trapped between the gears and the pump casing, creating suction and discharge. Internal gear pumps are known for their smooth and quiet operation, making them ideal for applications requiring low noise levels.

Applications:

Construction equipment

Agricultural machinery

Industrial machinery

Hydraulic power units

2. Vane Pumps

Vane pumps use a series of vanes mounted on a rotor to create suction and discharge as the rotor turns. The vanes slide in and out of the rotor, maintaining contact with the pump casing and creating chambers that move the fluid through the pump.

Fixed Displacement Vane Pumps: These pumps have a fixed flow rate, providing a constant output of hydraulic fluid regardless of system pressure.

Variable Displacement Vane Pumps: These pumps can adjust their flow rate in response to changes in system pressure, offering greater flexibility and efficiency.

Applications:

Machine tools

Plastic injection molding machines

Automotive manufacturing

Power steering systems

3. Piston Pumps

Piston pumps are known for their high efficiency, high-pressure capabilities, and versatility. They use pistons moving in and out of cylinders to create suction and discharge, making them suitable for demanding applications.

Axial Piston Pumps: These pumps have pistons arranged parallel to the drive shaft, with a swashplate or cam causing the pistons to move. Axial piston pumps can be fixed or variable displacement, offering flexibility and efficiency in various applications.

Radial Piston Pumps: These pumps have pistons arranged radially around a central drive shaft. As the drive shaft rotates, the pistons move in and out, creating suction and discharge. Radial piston pumps are known for their high-pressure capabilities and are often used in heavy-duty applications.

Applications:

Construction and mining equipment

Aerospace systems

Marine and offshore equipment

Industrial hydraulic presses

4. Peristaltic Pumps

Peristaltic pumps use a rotating roller or shoe to compress a flexible tube, creating a vacuum that draws fluid into the pump and then pushes it out. These pumps are ideal for handling abrasive, viscous, or sensitive fluids without contamination.

Applications:

Chemical processing

Food and beverage industry

Pharmaceutical manufacturing

Water and wastewater treatment

5. Screw Pumps

Screw pumps use one or more screws to move fluid through the pump. The screws rotate within a cylindrical casing, creating a continuous flow of fluid. Screw pumps are known for their ability to handle high-viscosity fluids and provide smooth, pulsation-free flow.

Applications:

Oil and gas industry

Shipbuilding

Power generation

Heavy machinery lubrication

Conclusion

Hydraulic pumps are essential components in hydraulic systems, and selecting the right type of pump is crucial for achieving optimal performance and efficiency. Gear pumps, vane pumps, piston pumps, peristaltic pumps, and screw pumps each offer unique advantages and are suited to specific applications. Understanding the functions and applications of these different types of hydraulic pumps will help you make informed decisions and ensure the reliability and efficiency of your hydraulic systems. Whether in construction, manufacturing, aerospace, or other industries, choosing the right hydraulic pump is key to powering your hydraulic applications effectively.

0 notes

Text

Choosing the Right Vacuum Pump: Tips and Considerations

Vacuum pumps play a vital role in various industries, from manufacturing and research to healthcare and automotive. They're essential for creating vacuum environments necessary for processes like material handling, degassing, and vacuum sealing.

However, selecting the right vacuum pump for your specific application can be a daunting task, given the multitude of options available in the market. To help you make an informed decision, let's explore some tips and considerations when choosing a vacuum pump.

Understand Your Application

The first step in selecting the right vacuum pump is understanding your application requirements thoroughly. Consider factors such as the desired vacuum level, flow rate, gas composition, and operating conditions. Different applications may require specific pump technologies to achieve optimal performance.

Types of Vacuum Pumps

Vacuum pumps Australia come in various types, each suited for different applications. Common types include rotary vane pumps, diaphragm pumps, scroll pumps, and turbomolecular pumps. Research the characteristics and capabilities of each type to determine which one aligns best with your application needs.

Vacuum Level Requirements

Vacuum levels vary depending on the application. Some processes require high vacuum levels, while others only need low or medium vacuum. Ensure the vacuum pump you choose can achieve and maintain the desired vacuum level consistently.

Flow Rate

Flow rate, measured in cubic meters per hour (m³/h) or liters per minute (L/min), is another critical consideration. It determines how quickly the vacuum pump can evacuate air or gas from the system. Select a pump with a flow rate suitable for your application's demands to ensure efficient operation.

Chemical Compatibility

Consider the compatibility of the vacuum pump with the gases or vapors present in your application. Certain pump materials may react with specific chemicals, leading to contamination or corrosion. Choose a pump constructed from materials resistant to the substances it will encounter.

Noise and Vibration Levels

Depending on where the vacuum pump will be installed, noise and vibration levels may be significant factors to consider. Some applications require quiet operation, while others can tolerate higher levels of noise. Look for pumps with noise and vibration reduction features if necessary.

Maintenance Requirements

Regular maintenance is essential for prolonging the life of your vacuum pump and ensuring optimal performance. Consider factors such as ease of maintenance, availability of spare parts, and serviceability when choosing a pump. Selecting a pump with minimal maintenance requirements can save time and money in the long run.

Energy Efficiency

Energy consumption is a significant operating cost for vacuum pumps Australia. Look for pumps with high energy efficiency ratings to minimise energy usage and reduce operating costs. Features such as variable speed drives and automatic shut-off mechanisms can help optimise energy consumption.

Footprint and Installation Requirements

Consider the physical footprint of the vacuum pump and whether it will fit into your existing space. Also, assess installation requirements such as power supply, ventilation, and any special mounting considerations. Choosing a pump that integrates seamlessly into your facility can simplify installation and operation.

1Budget Constraints

Finally, consider your budget constraints when selecting a vacuum pump. While it's essential to invest in a high-quality pump that meets your application requirements, be mindful of cost considerations. Evaluate the total cost of ownership, including initial purchase price, operating costs, and maintenance expenses, to make an informed decision.

Conclusion

Choosing the right vacuum pumps Australia requires careful consideration of various factors, including application requirements, vacuum level, flow rate, chemical compatibility, noise and vibration levels, maintenance requirements, energy efficiency, installation considerations, and budget constraints.

By thoroughly assessing these factors and selecting a pump that aligns with your specific needs, you can ensure optimal performance and efficiency in your vacuum processes. Remember to consult with knowledgeable experts or suppliers to help guide you through the selection process and ensure you make the best choice for your application.

0 notes

Text

Unveiling the Powerhouse: Exploring the Dynamics of Vacuum Pump Technology

Understanding the Essence of Vacuum Pump:

At its core, a vacuum pump serves the fundamental purpose of removing gas molecules from a sealed volume, thereby creating a vacuum or low-pressure environment. This feat is accomplished through various mechanisms, each tailored to specific requirements and operational contexts.

Types and Mechanisms:

The landscape of vacuum pumps encompasses a diverse array of types, ranging from positive displacement pumps like rotary vane and piston pumps to momentum transfer pumps such as turbomolecular and diffusion pumps. Each type operates on distinct principles, offering unique advantages suited to different scenarios.

Applications Across Industries:

The versatility of vacuum pumps renders them indispensable across numerous industries. In manufacturing, these devices facilitate processes like vacuum molding, impregnation, and packaging, ensuring product quality and integrity. In healthcare, vacuum pumps power medical devices such as MRI machines, dialysis equipment, and vacuum-assisted wound closure systems, contributing to diagnostic accuracy and patient care. Moreover, vacuum pumps find extensive use in research laboratories for tasks like solvent evaporation, filtration, and vacuum distillation, diaphragm vacuum pump supporting scientific advancement and innovation.

Innovations Driving Progress:

Advancements in vacuum pump technology continue to push the boundaries of possibility. Emerging trends include the development of oil-free and environmentally friendly pumps, enhancing operational efficiency while reducing ecological footprint. Moreover, integration with smart sensors and automation systems enables real-time monitoring and control, optimizing performance and reliability.

Challenges and Future Outlook:

Despite their myriad benefits, vacuum pumps are not without challenges. Issues such as oil contamination, energy consumption, and maintenance requirements pose ongoing concerns for users. However, ongoing research and development efforts aim to address these challenges through innovations in materials, design, and operational strategies.

Looking ahead, the future of vacuum pump technology appears promising. With the advent of nanotechnology and quantum computing, demand for ultra-high vacuum systems capable of achieving unprecedented levels of pressure will likely soar. Moreover, as sustainability becomes increasingly paramount, the quest for energy-efficient and environmentally benign vacuum solutions will intensify, driving innovation and evolution in the field.

0 notes