#Robotic system suppliers

Explore tagged Tumblr posts

Text

VISIT US : https://irajrobotics.com/robotic-system.html

Robotics System Suppliers Manufacturers, Exporters, and Dealers in Pune, Mumbai, India, Singapore, Denmark, South Africa, Australia, Saudi Arabia, Malaysia, Canada, Vietnam, Angul, Chennai, Bangalore, Hyderabad, Coimbatore, and Gurgaon We are the leading Robotic System Manufacturers in Suppliers, Exporters, and Dealars in Pune, Mumbai, Singapore, Denmark, South Africa, Australia, Saudi Arabia, Malaysia, Canada, Vietnam, Angul, Chennai, Bangalore, Hyderabad, Coimbatore.

We are well known in the field of Robotics. Our products include robotic control systems for industrial automation, automotive automation and agricultural machinery.

These products are available to the customers worldwide through proper solution which they want in our robotic system.

We Industrial Robotic System Suppliers, Dealers and Exporters have an expertise of these robotics for more than the 6 years making the four moon in the manufacturing process of robotics system in Pune/India and get appreciation by clients for superior performance.

Phone +91 99750 45502

Email [email protected]

Address: Gat No 1336, Near Vikas Anath Ashram, Behind Ralphs Polymer, Jyotiba Nagar Road, Sonwane Wasti, Chikhali, Pune, 411062, MH, India

#Robotic system Manufacturers#Robotics System Exporters#Robotic system suppliers#Robotic system Dealers

0 notes

Text

Task Manager Open-Market Grades

Finally some proper world building content! Starting off with robot information (thanks to a poll on Twitter) I figured explaining the grading quality made more sense than the models, as some of the models only exist in particular grades so knowing what those are first helps. Also, vocabulary!

One might notice a curious trend in the Awakening-versus-Rogueness chances that seems a little... odd. While most Coppers never reach actualization, those that do are almost guaranteed to go rogue whereas QS and GLs are nearly guaranteed to Awaken at some point yet never pose that risk. Statistically speaking, the majority of all rogue robots accounted for are of the Silver class.

Interesting.

Vocabulary:

In-Market:

Any supplies, models and features considered “legal” from first- (manufacturer) and second-party (store) suppliers

Out-of-Market:

“Illegal” assets or those applied/sourced by unlicensed providers; third-party parts and DIY bots that don’t fit neatly into the classifications of In-Market tiers; all battle-bots and rogue units are classified as Out-of-Market

Open-Market:

Features, assets and resources openly available to the public and supplied in the majority of venues; most models fall into this category

Closed-Market:

Privately owned, produced and supplied assets that require regulation, money or connections to acquire; military and industrial models fall into this group, as well as most Nebula and Madin class units, and those of Goldlite quality; “personal use” options (sex mods) are considered closed-market due to being age restricted and limited access

Most grade and model information is specific to In-Market categorical listings; many garage modders have muddied the lines between grades and models with their own work and adaptations, often pushing the limits left untouched by In-Market makers in terms of what bots can do and how they can be upgraded, however tampering is heavily restricted as once a unit has been tweaked enough to become and Out-of-Market system, they lose access to most In-Market features, creating a diminishing return on what’s available for modders to use or acquire for their home rigs. Many opt to stay In-Market due to the ease of access despite the overhead cost, but this feeds into the issues with rogues and colonies being categorized or becoming Out-of-Market which limits their access to parts and repairs. The “black market” operates on the far opposite end of the main one, crossing the line most modders avoid into pure self-sufficient supply of goods for maintaining Out-of-Market models, however these unregulated dealers are considered a high risk and so get shut down quickly when detected, making them very secretive and very expensive. Not every modder knows about the black market or that it exists, but the right avenues open up a whole other world of possibilities such as Out-of-Market access to parts for Military and Industrial grade models that are otherwise illegal and highly regulated. Some of these avenues may even exist in the right corners of the Runner’s Guild.

#azil#free runner au#task manager au#world building#grades and tiers#makes and models#open market#lore#come get y'all's dinner#information post

6 notes

·

View notes

Text

Optimizing Your Transfer Process for Faster Delivery Times: Insights from a Top Logistic Company in India

Introduction

In today's fast-paced business landscape, optimizing the transfer process is crucial for logistics companies aiming to provide faster delivery times. Efficient transfer processes not only enhance customer satisfaction but also contribute to overall operational excellence. In this blog, we will explore practical strategies to optimize your transfer process and improve delivery times, drawing insights from a Top Logistic Company in India.

1. Streamline Documentation and Tracking Systems

Implementing a streamlined documentation and tracking system is essential for efficient transfers. Digitize paperwork, invoices, and delivery notes to minimize manual errors and save time. Utilize advanced tracking technologies such as GPS, barcodes, or RFID to monitor and trace shipments throughout the transfer process accurately.

2. Optimal Warehouse Organization

An organized warehouse layout is key to expediting the transfer process. Implement efficient storage systems, such as bin locations, to ensure easy accessibility to goods. Utilize labeling and signage techniques to enhance visibility and minimize the time spent searching for specific items. Regularly review and update your inventory management system to prevent delays caused by inventory inaccuracies.

3. Embrace Automation and Technology

Integrating automation and technology can significantly accelerate transfer processes. Utilize automated sorting systems, conveyors, and robotics to streamline material handling and minimize manual intervention. Implement a robust transportation management system (TMS) to optimize route planning, load optimization, and real-time tracking. Utilize predictive analytics to anticipate demand patterns and proactively allocate resources.

4. Collaborate with Reliable Partners

Establishing strong partnerships with reliable suppliers, carriers, and logistics service providers is vital for efficient transfers. Choose partners known for their commitment to timely delivery, transparency, and operational excellence. Collaborate closely with them to align processes, share data, and jointly optimize the transfer process. Leverage their expertise and network to ensure seamless transfers.

5. Continuous Process Improvement

Regularly evaluate and refine your transfer processes to identify areas for improvement. Conduct data analysis to identify bottlenecks, delivery delays, and areas of inefficiency. Implement a continuous improvement framework such as Lean Six Sigma to drive process optimization and eliminate waste. Encourage employee involvement and feedback to foster a culture of innovation and improvement.

6. Conclusion

By implementing these optimization strategies, logistics companies can significantly improve transfer processes and achieve faster delivery times. Streamlining documentation, organizing warehouses efficiently, embracing automation and technology, collaborating with reliable partners, and fostering a culture of continuous improvement are key steps toward operational excellence. As a top logistics company in India, [Insert Top Logistic Company in India] has successfully implemented these strategies, resulting in faster delivery times and enhanced customer satisfaction. Adopting these practices can position your business for success in the dynamic logistics industry.

#Temperature Controlled Service Provider#Best Logistics Company in Indore#Best Logistic Company in India#Top Logistic Company in India#3PL Logistic Services in India#3PL Service Provider#3PL in India#Transfer Process for Faster Delivery#Faster Delivery Times

2 notes

·

View notes

Text

Revolutionizing Manufacturing: Top Trends to Watch in 2023

The manufacturing industry faced several challenges in 2022, including disruptions in the supply chain, transportation difficulties, worker shortages, and inflation. As a manufacturing company, it is essential to stay informed about the emerging industrial developments to prevent the issues that plagued the industry last year.

However, one thing we can tell you for sure is, having the right technology in place can bring you closer to gaining a competitive edge and adapting to the changing industry dynamics. To help manufacturing businesses gain this edge, we offer next generation SAP ERP solution.

What are some technological trends the manufacturing industry can expect in 2023?

Industry 4.0 and Digital Transformation

Industry 4.0 and digital transformation will continue to be major drivers of innovation in the manufacturing industry in 2023. With the rise of the Internet of Things (IoT), Artificial Intelligence (AI), and other advanced technologies, manufacturers will have unprecedented access to real-time data, which will enable them to optimize their operations and improve efficiency. By integrating digital technologies across the entire supply chain, manufacturers will be able to achieve greater flexibility, agility, and responsiveness to changing market demands.

Advanced Robotics and Automation

As the cost of robotics and automation technology continues to decrease, we can expect to see an increased adoption of these technologies in the manufacturing industry. Robotics and automation can help manufacturers reduce labor costs, improve quality and consistency, and increase productivity. With the advent of more advanced robotics and automation systems, we can expect to see greater levels of collaboration between human workers and robots, as well as the development of more complex and sophisticated automation systems.

Sustainability and Green Manufacturing

As the world becomes increasingly aware of the impact of climate change, sustainability and green manufacturing will become more important in 2023. Manufacturers will need to find ways to reduce their environmental impact, including the use of renewable energy sources, the reduction of waste and emissions, and the adoption of sustainable materials and processes. Customers are also becoming more conscious of their environmental impact, which means that manufacturers who prioritize sustainability will be more competitive in the marketplace.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a rapidly growing technology that is changing the way manufacturers design, prototype, and produce products. In 2023, we can expect to see an increased adoption of additive manufacturing technologies, particularly in industries such as aerospace, healthcare, and automotive. With the ability to produce highly complex parts and components on-demand, additive manufacturing will enable manufacturers to achieve greater levels of customization and flexibility.

Reshoring and Nearshoring

The COVID-19 pandemic has highlighted the risks of global supply chains and the importance of resilience and agility in manufacturing. In 2023, we can expect to see more manufacturers exploring reshoring and nearshoring strategies to reduce their reliance on overseas suppliers and improve their ability to respond to changing market conditions. By bringing production closer to home, manufacturers can reduce lead times, improve quality control, and reduce transportation costs.

In conclusion, the manufacturing industry is set to undergo significant changes in 2023, driven by digital transformation, advanced robotics and automation, sustainability, additive manufacturing, and reshoring and nearshoring. Manufacturers who stay ahead of these trends will be better equipped to compete in an increasingly complex and competitive global marketplace.

If you want to transform your business by implementing latest solutions, get in touch with the team of Techscope Technologies.

Source: https://techscope.co.in/revolutionizing-manufacturing-top-trends-to-watch-in-2023/

3 notes

·

View notes

Text

Watch "조선업 확대하는 한화, '육해공' 포트폴리오 본격화 / 머니투데이방송 (뉴스)" on YouTube

youtube

Drone plus so aero satellite maritime and land so weapons systems platform transfer size and operational needs for preplanning and packaging of payload capacity and logistics robotics and artificial intelligence processing automation for autonomous driving and military situation awareness ready capable ai.

youtube

Military Intelligence plus servers and surrounding with patrol hitched for pull fleet management system AI for formation and manuvering. Update primed Mulan prime ai and Natasha prime ai for military Commander position ai and military Intelligence for Imperium military intelligence Unitron Commander AI.

Update and update Imperium Worksteam ipu packages with smartest nic update SRAM ml delivery network. Update ai ml evm virtualization protocol and Primed protocol connector for supplier Approved list. Military contractors from department of defense level of security clearance.

4 notes

·

View notes

Text

Leading With BIM

Many people in the Construction Industry still believe that BIM is just a modern design tool, but BIM is much more than this. Whilst design is certainly an element of BIM, collaboration is a key element, from inception through to completion of a project, and beyond. Collaboration across the design team, particularly at the early design stages both reduces risk and maximises value. A detailed BIM design forms a ‘single source of truth’ which de-risks the entire construction programme.

According to MacLeamy (2004) who plotted a simple graph of project time and project effort, it can be seen that the influence on the project design is high at the early design stages, whilst project changes further down the project timeline entails more effort and cost. MacLeamy argued that completing the design earlier in the construction programme reduced risk and cost by negating design changes later in the programme. An early BIM model using high quality, virtual BIM objects assists final design sign off earlier in the construction cycle.

BIM has been with us for some years now, so it is far from a new concept, but helps us in developing new methodologies for construction, new methodologies which help us reduce carbon in construction. According to Transparency Market Research, in 2025 the Construction Industry will generate as much as 2.2 billion tons of waste annually which is about 50% of all global solid waste. The Construction Industry has to move from this linear construction process to a circular construction process where buildings can be deconstructed and rebuilt using some or all of the same parts, or materials recycled back into buildings. A growing number of architectural practices globally are designing ‘temporary’ or ‘deconstructable’ buildings that fall into the circular construction methodology.

In the UK a recently completed project in London, the Forge, aspires to be the first commercial building constructed and operated in line with the UKGBC’s net zero definition and energy reduction targets. It comprises two new office buildings and a public courtyard. Located on Sumner Street, The Forge is a Landsec office development located just behind Tate Modern in London and utilising BIM at its core is one of the most innovative construction sites in London, pioneering several new construction methods fit for the decades ahead.

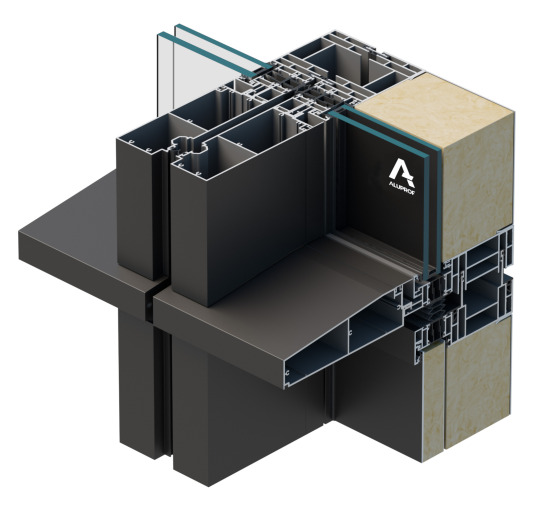

Breaking new ground, the project is be the world’s first large-scale office scheme built using a standardised “kit of parts”, in an approach known as ‘platform design for manufacture and assembly’ (P-DfMA), which applies the advances made by the Manufacturing Industry to construction, this would not be possible without BIM. Aluprof are delighted to have been invited to take an early design role in developing a unitised facade system that meets the P-DfMA specification pioneered by architects and engineers Bryden Wood. Construction is led by Sir Robert McAlpine and Mace, working together in an innovative joint venture (JV) partnership.

Working with BIM essentially creates a 3D ‘digital twin’ of the building project and it doesn’t stop there. There are a further four ‘dimensions’ that are added, ‘4D’ Time, ‘5D’ Costs, ‘6D’ Sustainability and ‘7D’ Facilities Management. In effect, the BIM model carries all the data for the building, from the building programme through to eventual deconstruction. Any one element, such as the facade, falls into each of the dimensions of BIM, so the more detailed BIM models that can be obtained from suppliers, the greater efficiency is realised.

Finally, automated construction would not be possible without BIM as some of our building methods become automated, built by, or checked by ‘robots’. Yes, this could be the dawn of the robotic ‘Clerk of Works’. During the construction phase of a building, robots are being utilised to laser scan and monitor what has been built offering dimensional accuracy as well as monitoring the programme of works. This ‘real time’ analysis ensures that any potential problems are highlighted at very early stages, saving both cost and time.

With its acclaimed BIM Academy, Aluprof continues to pioneer innovative solutions in partnership with specifiers across the globe. With a huge library of models available to architects and engineers, Aluprof are constantly adding new models for standard and bespoke designs helping clients and developers obtain efficient and sustainable buildings.

Aluprof UK are proud to supply facade systems to a wide range of new and refurbished construction projects across Great Britain and Ireland, with Head Offices in Altrincham in the North West and with an architectural specification support office in the Business Design Centre in London, the company has rapidly grown their specification influence in the UK with their high-performance architectural aluminium systems. Further expansion of the company’s headquarters in Altrincham now provides specifiers with meeting facilities and an extensive showroom of commercial systems to view. Further information is available on the company website at aluprof.co.uk or direct from their UK head office in Altrincham on 0161 941 4005.

2 notes

·

View notes

Text

So, there is a situation in where bees are exploited. But it is not for honey production, surprisingly, but rather for the production of fruit in greenhouses.

If you want to grow as much fruit as possible, a greenhouse is a good option. You can produce year round in a greenhouse. You can add extra CO2, grow-lights, the whole shebang. A capitalists dream.

But, a lot of the fruit we eat requires the plants to be pollinated, and pollinators can't freely enter or exit a greenhouse. So how can you get your fruit bearing plants pollinated? For all our talk of robot bees, real bees remain the cheapest option.

Putting a beehive in a greenhouse seems like a logical step. Problem is, bees do terrible in greenhouses. It has to do with the way they navigate. Outside they use sunlight but the way sunlight is re-fractured/polarized by glass disorients them (not sure how this works, I'm a biologist, not a physicist). They also supposedly will fly into the glass and injure themselves.

Generally, our precious honeybees aren't used for this, but rather bumblebees, that don't get as disoriented by being contained in a box made of glass. However, this is still not a sustainable model.

I found this interesting site by a supplier of bumblebees for greenhouse growing that mentions the bumblebee hives have a lifespan of 12 weeks after being placed in a greenhouse. Here's a another source mentioning the 12 weeks for a bumblebee colony, and what buyers are supposed to do if they want to use bumblebees and pesticides simultaneously. Supposedly, honey bees do worse than bumblebees, so a honeybee hive probably won't even last 12 weeks.

In addition to that, some pollinators work better for certain crops than others. I know (from a local beekeeper, no shareable source) that for certain crops they do use honeybee hives.

So... in this weird instance animals are exploited in the production of a vegan product. While 'non-vegan' honey production by humans is more akin to a symbiotic relationship. Again showcasing how many of these issues are so much more complicated than we can see on the surface while reading the labels of products in supermarkets.

I think the main takeaway is to just stop fighting each other over definitions and buzzwords (no pun intended). We're all in this together and there's a lot of different ways to contribute to a better world for us and all the lifeforms around us.

Personally, I'd argue that buying local and seasonal products is a great way to make positive change. Cutting meat and animal products out of your diet is also, still, a great one, but make sure to keep doing your research in regards to how the things you eat are produced (as mentioned above, even if no animals were harmed, products made with child labor are not a better alternative, and if a rainforest had to be cleared for your soy beans you may be better of buying local eggs for protein).

Eventually, going from being a consumer to a producer is the galaxy brain step. Not just growing your own food (not everyone is in the right space/climate for that), but for example learning to mend clothes, maintain equipment, weave, work with wood, leather or clay, or even how to make specific, plastic parts via 3D printer. Our global production/transport chains and capitalist systems are beginning to fail us, so the time is coming where we have to re-learn how to do things ourselves and de-globalize as best we can. Imagine, if everyone in your surroundings/community took on one old-school life skill, would we still be as reliant on global production chains?

It is also a deeply fulfilling experience. So why not learn something new you can use to help yourself and your community? Perhaps you could even take up beekeeping. I hear that when done well, it is a very good experience for all organisms involved.

vegans make peace with honey

no shut up do it

354K notes

·

View notes

Text

The Best Dental Equipment Supplier Success Stories

In the world of dentistry, the tools and equipment used by professionals are as crucial as the skills of the practitioners themselves. From advanced imaging systems to high-precision dental chairs, the equipment that dental offices rely on plays a key role in providing top-quality care. But behind every piece of equipment lies a story—one of innovation, dedication, and growth. In this post, we take you behind the scenes to explore the success stories of some of the Best Dental Equipment Suppliers in the industry.

The Rise of Innovation: How Leading Suppliers Set the Standard

For many of the Best Dental Equipment Suppliers, the journey to success wasn’t a straight path. It began with a commitment to improving the dental industry, whether through introducing new technologies, improving equipment durability, or making dental practices more efficient.

Take, for example, the story of one supplier that revolutionized the dental imaging field. They began by identifying a gap in the market: dental professionals needed high-quality imaging equipment that was both accurate and easy to use. By investing heavily in research and development, they created a line of digital X-ray machines that drastically reduced radiation exposure while improving image clarity. This not only enhanced patient safety but also gave dental professionals a more reliable tool for diagnosis and treatment planning. Today, they’re recognized as one of the Best Dental Equipment Suppliers globally.

Focus on Customer Needs: A Key to Longevity

One common thread among successful dental equipment suppliers is their laser focus on customer satisfaction. A major supplier that started as a small family-run business in the 1980s grew to dominate the industry by continuously listening to dental professionals’ needs and tailoring their product lines accordingly.

This company was one of the first to introduce ergonomic dental chairs that combined comfort for patients with practicality for the dentist. They understood the physical demands of long hours in the dental chair and designed a solution that would reduce strain on the dentist’s back and neck. Today, their equipment is used in dental offices around the world, and they remain one of the Best Dental Equipment Suppliers due to their unwavering commitment to understanding and solving the challenges dental professionals face.

Sustainable Practices: The New Era of Dental Equipment Manufacturing

As sustainability becomes a priority for businesses across industries, the dental sector is no exception. The leading Best Dental Equipment Suppliers are now taking significant steps to reduce their environmental footprint. One supplier, for instance, has implemented eco-friendly practices in their manufacturing processes, such as using recyclable materials and reducing waste during production. They’ve also worked toward energy-efficient equipment solutions, allowing dental offices to reduce their energy consumption while maintaining optimal performance.

This focus on sustainability not only benefits the environment but also meets the growing demand from consumers and businesses for more eco-conscious products. As environmental awareness continues to rise, these suppliers are setting an example for others in the dental industry to follow.

Adapting to Change: The Future of Dental Equipment

The dental equipment supply industry is constantly evolving, driven by technological advancements, changes in healthcare regulations, and the ever-growing demands of dental practitioners. For the Best Dental Equipment Suppliers, staying ahead of these changes is crucial for success. Many of these companies invest heavily in research and development to bring cutting-edge innovations to the market, from AI-powered diagnostic tools to robotic-assisted surgery devices.

A great example of this forward-thinking approach comes from a supplier that recently launched a series of smart dental instruments. These instruments use sensors to monitor pressure, speed, and temperature, providing real-time feedback to the dentist during procedures. By embracing technology and continuously innovating, they’ve cemented their place as one of the most respected Best Dental Equipment Suppliers in the world.

The Power of Partnerships

Behind every successful supplier is a network of strategic partnerships—whether with manufacturers, technology developers, or dental institutions. By collaborating with universities, research labs, and even dental practitioners themselves, these suppliers can create products that meet the latest industry standards and anticipate the needs of tomorrow’s dental professionals.

For instance, one supplier partnered with a major dental school to test new equipment and gather real-world feedback from students and instructors. This partnership led to the development of a new line of tools designed specifically for training purposes, helping the next generation of dentists gain hands-on experience with the latest technology.

The success stories of the Best Dental Equipment Suppliers are built on a foundation of innovation, customer-centricity, sustainability, and adaptability. These companies have proven that with the right vision and commitment to quality, it’s possible to make a lasting impact on the dental industry.

As technology continues to evolve and dental care becomes increasingly advanced, the suppliers who invest in research, listen to their customers, and prioritize sustainability will be the ones leading the way. Whether you’re a dentist looking for the best tools for your practice or simply curious about how the dental industry continues to evolve, these success stories remind us that behind every great piece of equipment is a team dedicated to making a difference in the world of dentistry.

#b2bmedicalequipmentsuppliers#medicaldevicessuppliers#healthcareproductssuppliers#medicalsuppluchain#medicalproductsuppliers#hospitalequipmentsuppliers

0 notes

Text

Key Strategies to Enhance Efficiency and Cut Costs in Logistics Management

Logistics management is a critical component of the supply chain, ensuring that goods are delivered to the right place, at the right time, and at the right cost. With the rise of e-commerce, increased customer expectations, and globalization, businesses are facing mounting pressure to streamline operations and reduce costs. Effective logistics management can provide a competitive edge, but it requires adopting strategies that improve efficiency, optimize resources, and minimize waste. In this blog, we will explore key strategies that logistics managers can implement to enhance operational efficiency and cut costs best logistics courses in kochi

1. Embrace Technology and Automation

One of the most powerful tools for improving efficiency and cutting costs in logistics is technology. The advent of automation, artificial intelligence (AI), and the Internet of Things (IoT) has revolutionized the logistics industry, providing solutions to increase speed, accuracy, and reduce operational costs.

Automation: Implementing automated systems in warehouses and distribution centers can streamline the movement of goods. Automated Guided Vehicles (AGVs), drones, and robotic arms are being used for inventory management, picking, packing, and sorting tasks. These technologies reduce the need for manual labor, speed up processes, and enhance accuracy, leading to fewer errors and reduced operational costs.

IoT: IoT devices, such as sensors and smart tags, help track inventory and assets in real time. This data allows businesses to monitor supply chain operations, detect inefficiencies, and make data-driven decisions. Real-time tracking ensures optimal use of resources, reduces delays, and enhances visibility, making it easier to identify potential issues before they affect the supply chain.

Artificial Intelligence: AI-driven algorithms can predict demand, optimize route planning, and improve forecasting accuracy. By analyzing historical data and customer behavior, AI can suggest the most cost-effective ways to move goods, reducing transportation costs and improving delivery times.

2. Optimize Inventory Management

Effective inventory management is essential to reducing logistics costs. Over-ordering or under-ordering inventory can lead to excess storage costs or stockouts, both of which can harm profitability and customer satisfaction. Here are a few strategies for optimizing inventory management:

Just-in-Time (JIT) Inventory: The JIT inventory system aims to minimize inventory levels by ordering and receiving goods only when needed for production or sale. This reduces storage costs, minimizes waste, and ensures that businesses only hold the inventory they need. However, it requires precise forecasting and a reliable supplier network to avoid stockouts.

Cross-Docking: Cross-docking is a logistics strategy where goods are transferred directly from inbound to outbound transportation without being stored in the warehouse. This strategy eliminates the need for inventory holding and reduces warehousing and handling costs. It also speeds up delivery times, which is critical in industries that require fast, just-in-time fulfillment.

Inventory Visibility: Using RFID tags, barcode scanning, and warehouse management systems (WMS) can significantly improve inventory visibility. Real-time tracking allows businesses to monitor stock levels, reduce overstocking, and streamline replenishment processes. Additionally, accurate inventory data helps prevent delays in order fulfillment and ensures customer demands are met efficiently.

3. Consolidate Shipments and Optimize Routes

Shipping is one of the most significant costs in logistics management, but businesses can cut costs by consolidating shipments and optimizing delivery routes.

Shipment Consolidation: Consolidating shipments, especially for smaller orders, can help reduce transportation costs. By grouping smaller shipments into a larger, full load, businesses can reduce the number of trips needed, saving on fuel and time. This strategy is particularly effective for less-than-truckload (LTL) shipments, where companies combine multiple shipments from different customers into one truck.

Route Optimization: Optimizing delivery routes is essential for reducing transportation costs. Using advanced routing software powered by AI, logistics managers can calculate the most efficient routes, factoring in variables like traffic, weather, fuel consumption, and road conditions. Optimized routes reduce delivery times, lower fuel expenses, and increase the number of deliveries that can be made in a day.

Reverse Logistics: Reverse logistics, the process of managing returns, is another area where cost savings can be achieved. By streamlining returns and refurbishing processes, businesses can reduce the costs associated with product returns, which can otherwise be an expensive aspect of logistics.

4. Improve Supplier and Vendor Relationships

Supplier and vendor management plays a significant role in controlling costs and enhancing efficiency. Strong relationships with suppliers can lead to more favorable terms, better quality, and improved delivery timelines. Here’s how to enhance supplier collaboration:

Collaborative Planning: By sharing forecasts, production schedules, and inventory data with suppliers, businesses can improve planning and avoid overstocking or stockouts. Collaborative planning ensures that the right materials are available at the right time, reducing lead times and optimizing inventory management.

Vendor-Managed Inventory (VMI): In a VMI arrangement, the supplier takes responsibility for managing the inventory at the customer’s location. This strategy allows businesses to reduce inventory holding costs while ensuring they have the right materials in stock when needed. It also strengthens supplier relationships and enhances overall supply chain efficiency.

Diversify Suppliers: Relying on a single supplier can be risky, particularly when disruptions occur. By diversifying suppliers and building a network of reliable partners, businesses can reduce their exposure to supply chain risks. Multiple suppliers can also provide competitive pricing, reducing the pressure on logistics costs.

5. Outsource Logistics to Third-Party Providers

Outsourcing logistics operations to third-party logistics (3PL) providers can help businesses reduce costs and improve efficiency. 3PL providers specialize in logistics and have the expertise, resources, and networks to manage transportation, warehousing, and distribution effectively.

Economies of Scale: By partnering with a 3PL provider, businesses can take advantage of their large-scale operations and cost efficiencies, such as bulk shipping discounts and shared warehousing. These economies of scale can reduce costs significantly compared to handling logistics in-house.

Focus on Core Competencies: Outsourcing logistics allows businesses to focus on their core competencies, such as product development, marketing, and sales, while leaving logistics to the experts. This enables businesses to improve overall efficiency and reduce the complexity of managing logistics operations internally.

6. Enhance Communication and Collaboration

Improved communication and collaboration across the supply chain can lead to more efficient operations and cost savings. By fostering collaboration between logistics managers, suppliers, customers, and other stakeholders, businesses can streamline processes and avoid costly mistakes.

Cloud-Based Solutions: Cloud-based platforms allow all supply chain participants to access real-time data, improving communication and transparency. With centralized systems, logistics managers can make better-informed decisions, track shipments in real-time, and resolve issues faster.

Regular Performance Reviews: Regularly assessing the performance of logistics partners, transportation providers, and internal processes helps identify areas for improvement. By conducting performance reviews, businesses can negotiate better contracts, reduce inefficiencies, and optimize the overall supply chain.

Reducing costs and improving efficiency in logistics management requires a comprehensive strategy that leverages technology, optimizes inventory management, improves transportation, and strengthens supplier relationships. By adopting automation, optimizing routes, consolidating shipments, and fostering better communication, businesses can cut costs and stay competitive in an increasingly complex and fast-paced global marketplace. These strategies not only improve the bottom line but also enhance customer satisfaction and help create a more resilient and agile supply chain logistics course in kochi

0 notes

Text

VISIT US: https://irajrobotics.com/robotic-system.html

Robotics System Suppliers Manufacturers, Exporters, and Dealers in Pune, Mumbai, India, Singapore, Denmark, South Africa, Australia, Saudi Arabia, Malaysia, Canada, Vietnam, Angul, Chennai, Bangalore, Hyderabad, Coimbatore, and Gurgaon

We are the leading Robotic System Manufacturers in Suppliers, Exporters, and Dealars in Pune, Mumbai, Singapore, Denmark, South Africa, Australia, Saudi Arabia, Malaysia, Canada, Vietnam, Angul, Chennai, Bangalore, Hyderabad, Coimbatore.

We are well known in the field of Robotics. Our products include robotic control systems for industrial automation, automotive automation and agricultural machinery.

These products are available to the customers worldwide through proper solution which they want in our robotic system.

We Industrial Robotic System Suppliers, Dealers and Exporters have an expertise of these robotics for more than the 6 years making the four moon in the manufacturing process of robotics system in Pune/India and get appreciation by clients for superior performance.

#Robotic system Manufacturers#Robotics System Exporters#Robotic system suppliers#Robotic system Dealers

0 notes

Text

Setbacks to Stability: Tackling Today’s Supply Chain Challenges

Introduction

In recent years, supply chain disruptions have posed significant challenges for businesses worldwide. Issues like labor shortages, regulatory changes, climate events, and fluctuating consumer demand continue to strain global logistics. In this guide, we explore these supply chain challenges and share strategies to enhance stability, efficiency, and resilience.

Understanding Current Supply Chain Setbacks

Labor Shortages and Staffing Issues

Labor shortages are a significant hurdle, especially within logistics. A decline in skilled labor impacts warehousing, transportation, and customer satisfaction. To tackle this:

Automation: Implementing AI and robotics can enhance operational efficiency and ease labor gaps.

Flexible Work Options: Offering remote work, shift flexibility, and upskilling opportunities can attract a broader talent pool.

By investing in these solutions, logistics companies can navigate the challenges of staffing shortages.

Global Trade Fluctuations and Regulations

With ever-changing trade policies and tariffs, adapting to global trade fluctuations is essential for maintaining stable supply chains. By forming strategic partnerships with customs brokers and staying informed of policy updates, logistics providers can navigate regulatory complexities.

Natural Disasters and Climate Events

Natural disasters, including hurricanes and wildfires, are increasingly common and disrupt supply chains significantly. Logistics providers should adopt climate-conscious practices and:

Establish Contingency Plans: Outline protocols for rerouting shipments and alternative sourcing.

Diversify Routes and Suppliers: Minimize reliance on single-source suppliers to avoid bottlenecks.

Surges in Consumer Demand

High-demand seasons, like Black Friday and Cyber Monday, test logistics efficiency. Surges can lead to inventory shortages, delays, and rising costs. Solutions include:

Advanced Inventory Forecasting: Utilizing machine learning and data analytics for accurate demand predictions.

Scaling Warehouse Capacity: Ensuring resources align with peak demand times through proactive planning.

Transforming Setbacks into Stability

Advanced Demand Forecasting

Effective demand forecasting ensures supply chain stability. By analyzing market trends, historical data, and customer behavior, logistics companies can reduce stockouts and overstocking. Predictive analytics and collaboration with suppliers also enhance inventory management, ensuring products are available when and where needed.

Strengthen Supplier Relationships

Building a reliable supplier network is essential for stable supply chains. Prioritizing transparency and flexibility with suppliers allows logistics companies to respond quickly to delays and shortages. Clear service-level agreements (SLAs) and regular performance reviews with suppliers are key practices for building robust partnerships.

Embrace Real-Time Tracking and Visibility

Real-time tracking and visibility are critical to supply chain efficiency. IoT technology and tracking systems allow logistics companies to:

Monitor Shipments in Real-Time: Enhance transparency and improve customer satisfaction.

Address Issues Proactively: React to potential disruptions swiftly, ensuring delivery schedules are met.

Warehouse Optimization

Optimizing warehouse operations is essential, especially during peak seasons. Automated storage, picking, and packing can minimize errors and expedite handling times. Key strategies include:

Inventory Management Systems: Using RFID and barcoding for accurate product tracking.

Lean Warehousing: Adopting space-maximizing layouts to enhance operational efficiency.

Flexible Delivery Options

Offering multiple delivery options can enhance customer satisfaction and service quality. Partnering with local carriers and employing temporary personnel during high-demand periods enables logistics companies to maintain flexibility and reliability.

Sustainability for Long-Term Stability

Sustainable practices in logistics contribute to environmental goals and appeal to eco-conscious consumers. Over 70% of consumers favor businesses with green practices, according to the Global Logistics Sustainability Index. Key areas include:

Route Optimization: Minimizing emissions and reducing transportation costs through software that analyzes traffic patterns, weather, and vehicle loads.

Eco-Friendly Packaging: Reducing waste through recyclable and biodegradable materials aligns with modern consumer expectations.

Managing Peak Seasons and Demand Surges

High-demand periods like holiday seasons require robust logistics solutions. Here’s how logistics companies can maintain efficiency:

Seasonal Staffing Solutions

Hiring temporary or contract workers during peak times prevents overburdening regular staff. Pre-vetted seasonal hires ensure order fulfillment and consistency during demand surges.

Cross-Border Delivery Management

International orders often increase during peak seasons, making effective cross-border management crucial. Experienced logistics providers help navigate customs, minimizing delays and enhancing customer satisfaction.

Streamlined Returns Management

Efficient returns management enhances customer satisfaction and stabilizes supply chains. A straightforward returns policy, coupled with tracking systems and clear instructions, turns potential setbacks into customer loyalty opportunities.

LCT trucking’s Role in Navigating Supply Chain Challenges

As a leader in logistics, LCT trucking is committed to helping businesses overcome supply chain challenges with resilient, efficient solutions. Here’s how LCT trucking supports supply chain stability:

Domestic and International Shipping Comprehensive freight services ensure timely, compliant deliveries, providing reliability across domestic and international routes.

Warehousing and Distribution Strategically located warehouses with advanced inventory systems support efficient storage and distribution. Our flexible warehousing solutions allow businesses to scale with demand.

Advanced Technology LCT trucking leverages real-time tracking and advanced logistics software, offering clients full shipment visibility. This technology helps optimize routes and responds proactively to unexpected setbacks.

By prioritizing these practices, LCT trucking strengthens supply chains and delivers stability in an unpredictable logistics landscape.

Conclusion: From Setbacks to a Stable Future

Turning setbacks into supply chain stability requires innovation, adaptability, and strategic investment. By focusing on demand forecasting, warehouse optimization, sustainable practices, and flexibility, logistics providers like LCT trucking transform challenges into opportunities for resilience.

Embracing change, addressing labor and regulatory issues, preparing for natural disruptions, and managing high-demand surges are critical for success in today’s complex logistics environment. By transforming setbacks into stable strategies, logistics companies can create a reliable, sustainable future

0 notes

Text

Western drivers remain sceptical of in-vehicle AI

New Post has been published on https://thedigitalinsider.com/western-drivers-remain-sceptical-of-in-vehicle-ai/

Western drivers remain sceptical of in-vehicle AI

.pp-multiple-authors-boxes-wrapper display:none; img width:100%;

A global study has unveiled a stark contrast in attitudes towards embracing in-vehicle AI between Eastern and Western markets, with European drivers particularly reluctant.

The research – conducted by MHP – surveyed 4,700 car drivers across China, the US, Germany, the UK, Italy, Sweden, and Poland, revealing significant geographical disparities in AI acceptance and understanding.

According to the study, while AI is becoming integral to modern vehicles, European consumers remain hesitant about its implementation and value proposition.

Regional disparities

The study found that 48 percent of Chinese respondents view in-car AI predominantly as an opportunity, while merely 23 percent of European respondents share this optimistic outlook. In Europe, 39 percent believe AI’s opportunities and risks are broadly balanced, while 24 percent take a negative stance, suggesting the risks outweigh potential benefits.

Understanding of AI technology also varies significantly by region. While over 80 percent of Chinese respondents claim to understand AI’s use in cars, this figure drops to just 54 percent among European drivers, highlighting a notable knowledge gap.

Marcus Willand, Partner at MHP and one of the study’s authors, notes: “The figures show that the prospect of greater safety and comfort due to AI can motivate purchasing decisions. However, the European respondents in particular are often hesitant and price-sensitive.”

The willingness to pay for AI features shows an equally stark divide. Just 23 percent of European drivers expressed willingness to pay for AI functions, compared to 39 percent of Chinese drivers. The study suggests that most users now expect AI features to be standard rather than optional extras.

Dr Nils Schaupensteiner, Associated Partner at MHP and study co-author, said: “Automotive companies need to create innovations with clear added value and develop both direct and indirect monetisation of their AI offerings, for example through data-based business models and improved services.”

In-vehicle AI opportunities

Despite these challenges, traditional automotive manufacturers maintain a trust advantage over tech giants. The study reveals that 64 percent of customers trust established car manufacturers with AI implementation, compared to 50 percent for technology firms like Apple, Google, and Microsoft.

The research identified several key areas where AI could provide significant value across the automotive industry’s value chain, including pattern recognition for quality management, enhanced data management capabilities, AI-driven decision-making systems, and improved customer service through AI-powered communication tools.

“It is worth OEMs and suppliers considering the opportunities offered by the new technology along their entire value chain,” explains Augustin Friedel, Senior Manager and study co-author. “However, the possible uses are diverse and implementation is quite complex.”

The study reveals that while up to 79 percent of respondents express interest in AI-powered features such as driver assistance systems, intelligent route planning, and predictive maintenance, manufacturers face significant challenges in monetising these capabilities, particularly in the European market.

See also: MIT breakthrough could transform robot training

Want to learn more about AI and big data from industry leaders? Check out AI & Big Data Expo taking place in Amsterdam, California, and London. The comprehensive event is co-located with other leading events including Intelligent Automation Conference, BlockX, Digital Transformation Week, and Cyber Security & Cloud Expo.

Explore other upcoming enterprise technology events and webinars powered by TechForge here.

Tags: ai, artificial intelligence, automotive, Cars, connected cars, connected vehicles, in-vehicle ai, motoring, report, study, vehicles

#ai#ai & big data expo#AI-powered#amp#apple#applications#Articles#artificial#Artificial Intelligence#author#automation#automotive#automotive industry#Big Data#Business#california#Cars#China#Cloud#communication#Companies#comprehensive#conference#Connected cars#connected vehicles#consumers#customer service#cyber#cyber security#data

0 notes

Text

The Importance of Logistics and Supply Chain Management in Shaping a Business

In today’s highly competitive business environment, logistics and supply chain management (SCM) are critical to a company’s success. Effective supply chain management ensures that commodities flow smoothly from suppliers to customers, which has a direct impact on a company’s productivity, customer happiness, and profitability. As businesses strive to streamline operations and improve customer experiences, the importance of talented logistics workers has become clear. Enrolling in specialized logistics courses from a respected logistics institute can help individuals and organizations prosper in this fast-paced industry.

1. Why Logistics and Supply Chain Management Matter

Logistics and supply chain management (SCM) cover the planning, implementation, and coordination of moving items from point A to point B, ensuring that the correct products arrive at the right time. A well-managed supply chain is vital for meeting business objectives, retaining customer loyalty, and gaining a competitive advantage.

a) Operational Efficiency

Effective logistics and supply chain management reduces delays, lowers inventory costs, and optimizes resource utilization. Businesses, for example, can eliminate surplus stock and save money by using just-in-time (JIT) inventory management while satisfying client expectations. Logistics courses teach professionals how to streamline their operations and increase production.

b) Cost Savings

Efficient supply chains decrease needless expenses such as warehousing, transportation, and labor costs. When firms integrate their logistics strategy with their objectives, they avoid costly bottlenecks and maximize their resources. Trained personnel from a reputable logistics institute can have a big impact on this sector by discovering and implementing cost-cutting strategies.

c) Customer Satisfaction and Retention

Customers want prompt, accurate, and dependable deliveries. Effective SCM enables businesses to exceed these expectations, resulting in increased customer satisfaction. For example, a streamlined supply chain guarantees that products are constantly in stock and ready for quick delivery. This dependability fosters confidence, converting one-time purchases into repeat clients.

2. Core Components of Logistics and Supply Chain Management

Effective logistics and supply chain management are built on a number of important components that work together to ensure efficiency and reliability.

Inventory Management

Knowing what stock is available, where it is, and when to reorder is critical to SCM. Inventory management tools and procedures enable firms to maintain ideal stock levels while avoiding costly overstock or stockouts. Logistics courses address inventory management tactics to help professionals maintain inventory organized and in sync with demand.

Transportation and Distribution

Using effective transportation technologies and improving delivery routes can dramatically cut delivery times and costs. A qualified logistics specialist can create transportation methods that balance speed and cost, increasing delivery reliability while keeping expenses low.

Warehousing and Storage

The efficient organization, storage, and retrieval of commodities is key to effective warehousing. Automation, robotics, and warehouse management systems (WMS) are critical components in expediting these procedures. Logistics courses at a logistics institute frequently cover warehouse best practices, ensuring that professionals can handle storage effectively.

Read more....

0 notes

Text

Orthopedic Devices Market 2024 Size, Share, Global Analysis and Future Trends by 2032

In a world increasingly focused on enhanced healthcare outcomes, the orthopedic devices market is seeing remarkable growth, with new developments in surgical techniques, implant materials, and post-surgical support devices. The latest report by SNS Insider highlights how the orthopedic devices market is evolving and identifies key trends driving its revenue growth. The report, Orthopedic Devices Market Revenue, underscores the role of innovative technology in transforming patient mobility and the quality of life for individuals suffering from musculoskeletal disorders.

The orthopedic devices market is experiencing a surge in demand, driven by a rise in cases of osteoporosis, osteoarthritis, and other degenerative bone diseases, particularly among aging populations worldwide. These conditions require effective orthopedic solutions to help restore mobility and improve patient quality of life. According to SNS Insider, the market is poised to see further expansion as more healthcare providers adopt cutting-edge orthopedic devices, including joint replacement systems, trauma fixation devices, and spinal surgery instruments. Innovations in minimally invasive surgeries and personalized implants have also contributed to an increase in adoption rates, with more patients opting for orthopedic interventions that offer quicker recovery times and reduced risks.

The report further highlights the growing role of robotics and artificial intelligence in orthopedic procedures. Advanced robotic systems allow for highly precise implant placements, leading to enhanced outcomes and reduced complications. AI-driven diagnostic tools are also improving patient assessment and treatment planning, enabling tailored therapies that maximize success rates. As healthcare systems around the globe strive for efficiency, these technological advancements are being embraced at an unprecedented rate, fueling the market's growth trajectory.

Get Free Sample Report@ https://www.snsinsider.com/sample-request/3224

In addition to advancements in technology, the orthopedic devices market is benefiting from an increase in healthcare spending and favorable government initiatives aimed at improving orthopedic care. Many countries are allocating more funds towards public health infrastructure, including specialized care for orthopedic conditions. Subsidized healthcare policies and reimbursement schemes are also encouraging more patients to seek necessary treatments, which is contributing to the steady demand for advanced orthopedic solutions.

Manufacturers and suppliers of orthopedic devices are constantly innovating to meet this demand and stay competitive. Companies are investing in research and development to introduce next-generation products that not only enhance functionality but also address biocompatibility concerns. For instance, the development of 3D-printed orthopedic implants, designed to match a patient’s unique anatomy, is becoming increasingly popular, allowing for better integration with the body and longer-lasting solutions. As these technologies mature, they are expected to become standard practice in orthopedic surgery, paving the way for future growth in the orthopedic devices market.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Akash Anand – Head of Business Development & Strategy [email protected] Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

The Rising Importance of Digital Pennants and Signage in Singapore!

In the quick world, affiliations ceaselessly look for creative systems to get consideration, pass on valuable messages, and remain serious. Digital signage is mechanical progress that has become a central piece of changing the publicizing scene. With its dynamic cutoff points and capacity to draw in swarms ceaselessly, modernized Singapore signage quickly turns into a critical mechanical party for associations across different regions.

Advantages of Digital Poster Singapore

Computerized rules are among the most apparent top-tier signage, especially in Singapore's educated market. Unlike static flags requiring moderate manual updates, digital poster Singapore offers affiliations and an adaptable and connecting system for showing content. These modernized shows have a relationship with show improvements, proclamations, and giant data measures with outrageous, novel visuals, getting more thought than static signage.

One of the main benefits of state of the art signage is its versatility. Content can be well unique and supported to choose unequivocal issues. Digital signage guarantees that content is by and large fitting the best and it gets, whether it's showing reprobation’s, menus, or vast updates. In Singapore, where affiliations are unendingly changing by a rapid market, this capacity to change content gives them a fundamental position rapidly.

Digital signages Singapore: The Best Source of Digital Signage

Digital signages Singapore is tied in with redesigning the general client experience. With standard touch screens and enchanting visuals, basic-level signage can change how affiliations collaborate with their parties. This applies to Singapore's retail district, where stores utilize mechanized rules and signs to make sense of shopping encounters.

While the significant interest in state-of-the-art signage could appear high, it may be impressively more monetarily sharp throughout an unreasonably lengthy time span, detached from standard signage. Branch-offs will not need to print and eliminate old standards perpetually. They can empower their digital signage at no extra expense, saving time and assets. After some time, this prompts giant endeavors, particularly for affiliations that unendingly change their publicizing or express substance.

Picking the Right Digital Signage Supplier in Singapore

As the interest in digital signage in Singapore develops, so does the prerequisite for dependable suppliers. A digital signage supplier guarantees affiliations' approach to managing state-of-the-art improvement and dependably compromises digital signage in their endeavors. Coming up next is a couple of chief parts to consider while picking a modernized signage supplier in Singapore.

With cloud-based digital signagecan constantly support substance in unambiguous ways. This part helps relationships with different regions across Singapore, as it joins control of each and every certain-level superstar. Affiliations make, like this ought to, their robotized signage structures. A decent supplier will offer flexible graphs for the business, whether investigating new districts or orchestrating extra stunning functionalities.

The Best Support of digital signage provider

Each business has excellent necessities, so picking a supplier offering adaptable outlines is central. From planning the modernized principles to making watchful signage structures, a fair supplier will be flexible and ensure the board's satisfaction. Like state-of-the-art structures, digital signage requires custom upkeep and evaluation. A solid digital signage provider like Sky Media ought to offer predictable, unambiguous help and insist that the arrangement proceed exactly as expected.

Enormous level signage designs can be furnished with contraptions that give essential data to clients straightforwardly. By following which content gets the most responsibility, affiliations can figure out their g hearing and advance their publicizing systems. This part is productive in Singapore, where the information driven course is ending up being capably central for affiliations hoping to refine their tasks and client-worked with attempts.

Conclusion

The ascent of robotized signage in Singapore has changed how affiliations talk about their social event. From retail locations to corporate workplaces, basic level standards and signage resuscitate client encounters, further making liability and giving predictable, novel substance that resonates with present clients. The capacity to pass on messages, as a matter of fact and successfully, has become more pivotal than later in late memory, and basic level signage licenses associations with do unequivocally that with immaterial exertion.

#free digital signage#digital signage#touch screen software#interactive signage#digitalsignagerental

0 notes

Text

The Future of Rotomoulding: Insights from Industry Experts

Rotomoulding, the process of creating hollow plastic parts, is on the cusp of a transformative era. Driven by technological advancements, sustainability concerns, and evolving market demands, the industry is poised for exciting growth and innovation. To gain a deeper understanding of what lies ahead, we turned to industry experts for their invaluable insights.

1. Automation and Industry 4.0:

Robotic Automation: Rotomolding Experts predict a significant rise in automation across all stages of rotomoulding. Robots will play a crucial role in tasks like mould loading/unloading, material handling, and quality inspection, improving efficiency and reducing labor costs.

Smart Factories: The integration of sensors, data analytics, and machine learning will pave the way for smart factories. Real-time process monitoring, predictive maintenance, and optimized production schedules will become the norm, enhancing productivity and minimizing downtime.

AI-powered Optimization: Artificial intelligence will play a key role in optimizing process parameters, predicting part quality, and even suggesting design improvements, leading to faster cycle times, reduced waste, and superior products.

2. Sustainable Practices:

Recycled and Bio-based Materials: The use of recycled plastics and bio-based polymers will continue to grow, driven by environmental concerns and consumer demand for eco-friendly products. Expect to see more innovation in material processing and compounding to enhance the performance of these sustainable alternatives.

Energy Efficiency: Rotomoulding companies will invest in energy-efficient ovens, optimized heating cycles, and renewable energy sources to minimize their environmental footprint and reduce operational costs.

Closed-Loop Systems: The industry will move towards closed-loop systems, where waste is minimized, and materials are recycled or repurposed, contributing to a circular economy.

3. Advanced Materials and Processes:

Multi-layer Moulding: Producing parts with multiple layers of different materials will become more prevalent, enabling the creation of products with enhanced properties and functionalities.

Composite Materials: Integrating reinforcing materials like carbon fiber or glass fiber into rotomoulded parts will open up new possibilities for lightweighting and increased strength.

3D Printing in Mould Making: Additive manufacturing will revolutionize mould production, allowing for rapid prototyping, complex geometries, and customized designs.

4. Expanding Applications:

Electric Vehicles: Rotomoulding will play a crucial role in the production of lightweight and durable components for electric vehicles, such as battery housings and interior parts.

Renewable Energy: The industry will contribute to the growth of renewable energy by producing components for solar panels, wind turbines, and energy storage systems.

Healthcare: Rotomoulding will find increasing applications in healthcare, with the production of medical equipment, assistive devices, and disposable products.

5. Industry Collaboration and Knowledge Sharing:

Open Innovation: Collaboration between rotomoulders, material suppliers, and technology providers will foster innovation and accelerate the development of new solutions.

Industry 4.0 Platforms: Digital platforms will connect stakeholders across the value chain, facilitating knowledge sharing, best practice dissemination, and collaborative problem-solving.

Challenges and Opportunities:

Workforce Development: The industry will need to invest in training and education to equip its workforce with the skills required to operate advanced technologies and navigate the changing landscape.

Supply Chain Resilience: Building resilient supply chains will be crucial to mitigate disruptions and ensure the availability of materials and equipment.

The future of rotomoulding is bright, filled with opportunities for those who embrace innovation, sustainability, and collaboration. By staying ahead of the curve and adapting to the evolving landscape, rotomoulders can unlock new levels of efficiency, productivity, and success.

0 notes