#Recycled Polyester Yarn Manufacturers in India

Explore tagged Tumblr posts

Text

Manufactures of Polyster Yarn in India

For wholesale organic cotton yarn and polyester yarn manufacturing in India, Gupta Fibres delivers top-quality products and unmatched reliability.

+91 999 956 1776

Shiv Nagar, Krishanpura, Gohana Road, Panipat - 132103

#Organic Cotton Yarn Wholesale#Manufactures of Polyster Yarn in India#Order Yarn Online#Regenerated yarn#Regenerated Cotton#Recycled Polyester Yarn Manufacturers in India

0 notes

Text

Polyester Staple Fiber in Bhopal & MP: The Future of Sustainable Textiles

The textile industry has witnessed a significant transformation over the past few decades, thanks to the introduction of synthetic fibers. Among these, Polyester Staple Fiber (PSF) has emerged as a game-changer, offering durability, affordability, and versatility. This revolutionary fiber has found applications in various industries, including textiles, automotive, and home furnishings. In India, particularly in Bhopal and Madhya Pradesh (MP), the demand for Polyester Staple Fiber in MP is on the rise due to its eco-friendly nature and cost-effectiveness.

What is Polyester Staple Fiber?

Polyester Staple Fiber (PSF) is a synthetic fiber produced from PET (Polyethylene Terephthalate). It is a short fiber that can be spun into yarns and woven into fabrics. Available in both virgin and recycled forms, PSF plays a vital role in promoting sustainable textiles. Its properties, such as high tensile strength, lightweight nature, and resistance to wrinkles and shrinking, make it an ideal choice for various applications.

Why is Polyester Staple Fiber Popular in Bhopal & MP?

Bhopal, the capital city of Madhya Pradesh, is witnessing rapid industrial growth. The textile sector, in particular, is flourishing, with many manufacturers and traders opting for Polyester Staple Fiber for its numerous benefits. Here’s why PSF is gaining popularity in Bhopal and MP:

Eco-Friendly and Recyclable: The increasing focus on sustainability has led to a surge in the demand for recycled PSF, which is derived from post-consumer PET bottles.

Affordability: Compared to natural fibers like cotton and wool, PSF is more cost-effective, making it a preferred choice for budget-conscious manufacturers.

High Durability: Polyester Staple Fiber is resistant to wear and tear, ensuring long-lasting usage in various applications.

Moisture and Wrinkle Resistance: Unlike cotton, PSF does not absorb moisture easily, making it suitable for humid climates like that of MP.

Versatile Applications: From textiles and non-woven fabrics to automotive and home furnishings, PSF is used in diverse industries.

Applications of Polyester Staple Fiber in MP

The versatility of PSF has led to its adoption across multiple sectors in MP. Some of its most common applications include:

Textile Industry: PSF is widely used in the production of fabrics, blended with cotton or wool to enhance durability and elasticity.

Home Furnishings: Cushions, carpets, mattresses, and upholstery benefit from the resilience and softness of PSF.

Automobile Industry: PSF is used in car seats, door panels, and insulation materials, offering a lightweight yet durable alternative.

Non-Woven Fabrics: Applications such as medical textiles, filters, and geotextiles utilize PSF for its robustness.

Stuffing Material: Many manufacturers in Bhopal and MP use PSF for stuffing pillows, toys, and furniture due to its fluffiness and comfort.

Advantages of Using Polyester Staple Fiber in MP’s Textile Industry

The growing preference for PSF in Madhya Pradesh is due to the following advantages:

Cost-Effective Production: PSF reduces the dependency on expensive natural fibers, making it an economical choice for manufacturers.

Sustainability: With increasing concerns over environmental pollution, recycled PSF is helping industries move towards greener alternatives.

Customization: Available in various deniers, colors, and finishes, PSF meets the specific needs of different industries.

Energy Efficiency: The production process of PSF consumes less energy compared to natural fibers, reducing the carbon footprint.

Leading Suppliers of Polyester Staple Fiber in Bhopal & MP

Several manufacturers and suppliers are catering to the increasing demand for Polyester Staple Fiber in Bhopal and Polyester Staple Fiber in MP. One of the trusted names in the industry is Badri Group, which specializes in providing high-quality PSF for diverse applications. Their commitment to sustainability and innovation has made them a preferred choice for businesses seeking reliable fiber solutions.

The Future of Polyester Staple Fiber in MP

The future of Polyester Staple Fiber in Bhopal and Polyester Staple Fiber in MP looks promising, given the ongoing industrial advancements and environmental awareness. With increased investment in sustainable production and innovative applications, the textile industry in MP is poised to become a hub for PSF manufacturing and usage.

Government initiatives promoting the recycling industry and eco-friendly production methods will further boost the adoption of PSF. Additionally, the growing preference for synthetic fibers in global markets will drive demand, encouraging local manufacturers to expand their production capabilities.

Conclusion

The rising demand for Polyester Staple Fiber in Bhopal and Polyester Staple Fiber in MP highlights its importance in the textile and manufacturing sectors. As industries move towards sustainable solutions, PSF will continue to play a crucial role in reducing environmental impact while providing cost-effective and durable fiber options. Whether in home textiles, fashion, or industrial applications, Polyester Staple Fiber is the future of synthetic fibers.

For top-quality PSF solutions, reach out to Badri Group

Frequently Asked Questions (FAQs)

Q1: What is Polyester Staple Fiber (PSF) made of? A: PSF is made from PET (Polyethylene Terephthalate) and is available in both virgin and recycled forms.

Q2: Is Polyester Staple Fiber eco-friendly? A: Yes, especially the recycled PSF, which is made from post-consumer PET bottles, reducing plastic waste.

Q3: What are the common uses of PSF in MP? A: PSF is used in textiles, home furnishings, automotive components, non-woven fabrics, and stuffing materials.

Q4: Where can I buy high-quality Polyester Staple Fiber in Bhopal? A: You can source PSF from reputable suppliers like Badri Group. Badri for more details.

Q5: How does PSF compare to natural fibers? A: PSF is more affordable, durable, and resistant to moisture and wrinkles compared to natural fibers like cotton and wool.

By embracing the benefits of Polyester Staple Fiber in Bhopal and Polyester Staple Fiber in MP, industries can contribute to a more sustainable and efficient textile market.

0 notes

Text

Guide to RPET Flakes: Everything You Need to Know

Introduction

In today’s environmentally conscious world, recycled materials are paving the way for a sustainable future. One such material making waves is rPET Flakes. Known for their versatility and eco-friendliness, they are transforming industries worldwide. Here’s a detailed guide to understanding RPET flakes, their manufacturing process, applications, and benefits.

What Are rPET Flakes?

rPET flakes are recycled polyethylene terephthalate, derived mainly from post-consumer plastic bottles. These flakes are a sustainable raw material widely used in manufacturing new products. They are highly valued for their quality and eco-friendly nature.

How Are RPET Flakes Made?

The manufacturing process involves:

Collection: Plastic bottles are collected via recycling programs.

Sorting: Bottles are sorted based on material type and color.

Cleaning: Labels, caps, and impurities are removed to ensure high-quality output.

Shredding: The cleaned bottles are shredded into small flakes.

Processing: These flakes undergo further refinement to remove any contaminants.

The final product is clean and ready-to-use Recycled PET Flakes suitable for diverse applications.

Applications of RPET Flakes

1. Textile Industry: Used to produce polyester yarn for clothing and home furnishings. 2. Packaging: Widely used in the production of food-grade containers and bottles. 3. Industrial Use: Used in automotive parts, strapping tapes, and more.

Why Choose rPET Flakes?

Sustainability: Reduces plastic waste and promotes a circular economy.

Energy Efficiency: Manufacturing rPET flakes consumes significantly less energy compared to virgin plastic production.

Cost-Effective: Offers an affordable alternative for manufacturers.

Versatility: Can be used across multiple industries.

Why Choose rPET Flakes Manufacturers in India?

India is a leading player in the recycling industry due to its advanced facilities and cost-efficient processes. Leading rPET Flakes Manufacturers in India ensure:

High-quality production standards.

Use of cutting-edge recycling technologies.

Commitment to sustainability and environmental responsibility.

Conclusion

Recycled PET Flakes are a game-changer in promoting eco-friendly practices and reducing the reliance on virgin plastics. By incorporating rPET flakes into manufacturing, businesses contribute to a greener future. Whether you're in textiles, packaging, or industrial manufacturing, adopting rPET flakes is a step toward sustainability.

0 notes

Text

Understanding the Textile Industry and Market Trends in 2025

1. Market Overview

The global textile industry encompasses a wide range of products from fibers and yarns to finished goods like garments and home textiles. It serves both the consumer market and the industrial sectors, such as automotive, healthcare, and infrastructure. According to recent market research reports, the textile market is estimated to be valued at USD 774.33 billion in 2025 and is expected to reach USD 920.55 billion by 2030, growing at a compound annual growth rate (CAGR) of 3.52% during the forecast period from 2025 to 2030. Key drivers include population growth, rising disposable incomes in emerging markets, and the growing demand for sustainable and eco-friendly textiles.

2. Shifting Consumer Preferences

As consumer awareness about environmental and social issues increases, there is a marked shift toward sustainable products in the textile market. This has resulted in growing demand for eco-friendly fabrics made from natural fibers, recycled materials, and organic cotton. Consumers are also favoring products that are durable and have a lower environmental impact.

This trend is not just limited to casual clothing but extends to luxury and fast fashion brands that are increasingly adopting sustainable practices. Brands such as Patagonia, H&M, and Levi’s have led the way with transparent supply chains and eco-conscious material choices, setting a new standard for the industry.

3. Technological Innovations

Technology is playing a major role in the textile industry's evolution. From advanced weaving techniques to the use of smart fabrics, innovation is reshaping every part of the textile supply chain.

Smart Textiles: These fabrics integrate digital technology into materials, allowing them to perform additional functions. For example, clothing with embedded sensors can monitor health metrics, while fabrics that change color based on temperature are being explored for fashion and interior design.

3D Knitting and Printing: 3D knitting technologies have made strides in both garment production and customization. Similarly, 3D printing is used to create innovative designs and on-demand products, minimizing waste and reducing time to market.

Automation and Artificial Intelligence (AI): Automation is making textile production more efficient, reducing costs and increasing production speed. AI is used in predictive maintenance, inventory management, and even designing new patterns.

4. Sustainability and Circular Economy

Sustainability has become a central theme in the textile market, pushing companies to reconsider production methods, reduce waste, and recycle materials. The adoption of circular economy principles is driving the industry toward recycling used textiles, reducing water consumption, and using less harmful dyes and chemicals. Brands are increasingly focusing on the "Cradle to Cradle" approach, designing products for easy disassembly and recycling.

Recycling Technologies: Textile waste recycling is gaining momentum, with companies developing technologies that can recycle polyester, cotton, and other fabrics into high-quality materials for new clothing.

Sustainable Production: The industry is shifting to greener practices with cleaner energy sources, waterless dyeing techniques, and biodegradable fibers like Tencel and hemp. Furthermore, a trend toward low-impact dyes and less water usage in garment manufacturing is reshaping the production process.

5. Global Market Dynamics

The textile market is becoming increasingly global, with major shifts in production and consumption patterns. While countries like China, India, and Bangladesh remain key players in textile manufacturing, there is a significant move toward diversifying production. Emerging markets in Southeast Asia, Latin America, and Africa are gaining traction as new manufacturing hubs.

Simultaneously, Western nations, particularly the United States and Europe, are witnessing a resurgence in nearshoring and reshoring, with brands looking to mitigate risks in the supply chain. The geopolitical tensions, along with the impact of the COVID-19 pandemic, have underscored the need for supply chain diversification.

In terms of consumer markets, Asia-Pacific is anticipated to continue dominating in textile consumption, driven by rapid urbanization and increasing disposable income in countries like India and China. However, demand in North America and Europe for sustainable products is also on the rise, influencing the market trends.

6. Challenges and Opportunities

Despite its growth, the textile industry faces several challenges, such as:

Labor Issues: Poor working conditions and low wages in textile factories, particularly in developing countries, continue to be a pressing issue.

Environmental Impact: The textile industry remains one of the largest polluters in the world, contributing to water waste, chemical pollution, and plastic microfiber contamination.

Supply Chain Disruptions: Global disruptions, such as the COVID-19 pandemic, have highlighted vulnerabilities in the textile supply chain, emphasizing the need for greater resilience.

However, these challenges also present opportunities for innovation and growth. Brands that can adapt to the changing market dynamics, prioritize sustainability, and invest in technology are likely to remain competitive.

7. Looking Ahead: The Future of Textiles

As we move further into the digital age, the future of the textile industry is likely to be shaped by greater personalization and the integration of advanced technologies. We can expect more customized clothing experiences, eco-conscious product lines, and an ever-expanding range of smart textiles.

In addition, the growing importance of the circular economy and sustainable practices will continue to drive market shifts, encouraging manufacturers and brands to invest in more sustainable production techniques and eco-friendly materials. Industry leaders will focus on building transparent, ethical supply chains to meet consumer expectations.

Conclusion

The textile industry is evolving rapidly, fueled by technological advancements, consumer demand for sustainability, and the ongoing shifts in global markets. In 2025 and beyond, the industry will continue to focus on innovation, sustainability, and efficiency. By staying attuned to market trends and emerging technologies, businesses can not only navigate challenges but also unlock new growth opportunities in the global textile market. For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence https://www.mordorintelligence.com/industry-reports/global-textile-industry---growth-trends-and-forecast-2019---2024

0 notes

Text

The Evolution of Spun Polyester Yarn Industry in India

India has long been a global leader in the textile industry, and the journey of the spun polyester yarn sector is a testament to its innovative and resilient nature. From humble beginnings to becoming a significant contributor to global markets, the evolution of spun polyester yarn in India has been remarkable. This article delves into the growth, challenges, and success stories of the industry, highlighting key players such as Spun Polyester Yarn Producers in India, Yarn Manufacturer Delhi, and companies like SD Polytech.

Early Beginnings

The spun polyester yarn industry in India began to take shape during the mid-20th century when synthetic fibers started gaining popularity. Initially, production was limited, with reliance on imported technology and raw materials. However, Indian manufacturers quickly adapted, focusing on cost efficiency and quality. This laid the foundation for the industry's rapid growth.

Technological Advancements

As global demand for polyester yarn surged, Indian producers invested heavily in modernizing their facilities. Companies like SD Polytech emerged as pioneers, integrating cutting-edge machinery and techniques to enhance production capabilities. Automation and process improvements enabled Yarn Manufacturer Delhi and other regional players to achieve high levels of consistency and quality.

Global Reach

By the 1990s, India had established itself as a major exporter of spun polyester yarn. Spun Polyester Yarn Producers in India leveraged their competitive edge in cost and skilled labor to capture international markets. The industry’s adherence to global quality standards and sustainable practices further boosted its reputation worldwide.

Challenges and Resilience

Despite its growth, the industry faced challenges such as fluctuating raw material prices, environmental concerns, and competition from other nations. However, Indian manufacturers, including Yarn Manufacturer Delhi, have shown remarkable resilience. By adopting eco-friendly processes and diversifying their product ranges, they have managed to stay ahead of the curve.

The Role of SD Polytech

A key player in this evolution, SD Polytech, has been instrumental in driving innovation within the spun polyester yarn industry. Known for its high-quality products and customer-centric approach, the company exemplifies the capabilities of Indian manufacturers. With a focus on sustainability and technological excellence, SD Polytech continues to set benchmarks in the industry.

Future Prospects

The future of spun polyester yarn in India looks promising. Increasing demand for durable and cost-effective fabrics, coupled with advancements in manufacturing technology, is expected to propel the industry further. Indian companies are also exploring opportunities in niche segments such as recycled polyester yarn, catering to the growing demand for sustainable textiles.

Conclusion

The evolution of the spun polyester yarn industry in India is a story of innovation, adaptability, and excellence. From small-scale beginnings to becoming global leaders, Spun Polyester Yarn Producers in India have made significant contributions to the textile world. Companies like Yarn Manufacturer Delhi and SD Polytech continue to play a pivotal role, driving the industry toward a sustainable and prosperous future.

India’s journey in this sector is far from over, with new opportunities on the horizon. As the world increasingly values quality and sustainability, Indian spun polyester yarn manufacturers are poised to lead the way.

Also Read:

The Process of Cotton Yarn Manufacturing: From Field to Fabric

Top Cotton Yarn Manufacturers in India

Originally published at https://sdpolytech.blogspot.com

0 notes

Text

Delhi’s PET-Washed Flakes market sees price hike

The PET-washed flakes market in Delhi experienced a price hike today, with Grade 1-30 ppm (Clear) seeing an upward adjustment Prices for this grade rose by Re. 1/kg, reaching Rs. 79/kg, up from the previous level of Rs. 78/kg. The increase reflects firm demand and tightening supply conditions in the recycled PET market. PET-washed flakes are primarily produced by recycling units across key Indian regions such as Delhi, Maharashtra, Gujarat, and Tamil Nadu. Leading domestic producers include Ganesha Ecosphere Ltd., Reliance Industries Ltd. (RIL), Petro Recycling, and Jai Mata Di Enterprises, among others. Globally, companies like Indorama Ventures, Veolia, and Suez Recycling play a significant role in supplying high-quality recycled PET flakes to various markets.The primary demand for PET-washed flakes stems from their versatility across industries. In the textile sector, these flakes are converted into polyester staple fiber (PSF) and filament yarn, which are then used for producing garments, home furnishings, and industrial fabrics. In the packaging industry, recycled PET is utilized to manufacture containers, bottles, and food-grade sheets, contributing to sustainability efforts. Other applications include automotive interiors, insulation materials in construction, PET straps, and industrial films, highlighting the importance of PET recycling in diverse industrial processes.The recent price hike can be attributed to a combination of factors, including increasing demand from the textile and packaging sectors, higher operational costs in recycling processes, and tightening availability of raw materials like post-consumer PET bottles. With India’s recycling industry expanding rapidly and manufacturers prioritizing eco-friendly materials, the PET-washed flakes market is expected to witness steady growth. Indian PET Prices, PET Prices In India, Indian Prices PET, Indianpetrochem.

0 notes

Text

Polyester Filament Yarn (PFY) Prices Trend | Pricing | News | Price | Database

Polyester Filament Yarn (PFY) is a critical material in the global textile industry, serving as a key component in the production of fabrics and garments. The market for PFY has experienced dynamic shifts in pricing due to various economic, geopolitical, and industrial factors. Over recent years, the polyester filament yarn market has evolved in response to changes in raw material costs, global supply-demand dynamics, and advancements in production technologies. A comprehensive understanding of these trends is vital for businesses navigating the complex textile value chain.

One of the primary determinants of PFY prices is the cost of raw materials, primarily purified terephthalic acid (PTA) and monoethylene glycol (MEG), both derivatives of crude oil. Fluctuations in crude oil prices have a direct impact on the production costs of PTA and MEG, subsequently influencing PFY pricing. During periods of volatile crude oil prices, manufacturers often face challenges in maintaining stable production costs. For example, sharp increases in crude oil prices can lead to higher raw material expenses, compelling producers to adjust PFY prices upward. Conversely, a decline in crude oil prices may provide cost relief, potentially enabling manufacturers to offer competitive pricing. These fluctuations underscore the interconnectedness of the PFY market with broader energy markets.

Get Real time Prices for Polyester Filament Yarn (PFY) : https://www.chemanalyst.com/Pricing-data/polyester-filament-yarn-1088

Global demand and supply dynamics also play a significant role in shaping PFY prices. The textile industry's cyclical nature means that periods of high demand, such as during seasonal production peaks, can drive up prices. Additionally, the rising global population and increased disposable incomes, particularly in emerging economies, have led to growing demand for polyester-based textiles. However, supply-side constraints, such as production disruptions or capacity limitations at manufacturing facilities, can lead to price spikes. Geopolitical tensions and trade policies further complicate supply chains, potentially impacting the availability and cost of PFY in different regions.

In recent years, environmental considerations have also influenced the PFY market. Growing awareness of sustainability and the environmental impact of polyester production has prompted manufacturers to invest in eco-friendly production methods. Recycled polyester filament yarn, derived from post-consumer and post-industrial waste, has gained prominence as a sustainable alternative. While the adoption of recycled PFY contributes to environmental goals, it often comes with higher production costs, which can be reflected in market prices. The increasing consumer demand for sustainable products further adds complexity to the pricing dynamics, as manufacturers balance cost efficiency with environmental responsibility.

Technological advancements in PFY production have also contributed to shifts in pricing trends. Innovations in spinning and texturing technologies have improved production efficiency, enabling manufacturers to produce high-quality yarns at lower costs. These advancements have also allowed for the development of specialized PFY variants, such as high-tenacity or microfilament yarns, catering to specific applications. While these innovations have introduced premium-priced products into the market, they have also increased competition among manufacturers, potentially stabilizing prices in certain segments.

Regional variations in PFY pricing are evident due to differences in production capacity, labor costs, and local market conditions. Asia, particularly China and India, dominates the global PFY market, accounting for a significant share of production and consumption. Competitive labor costs and established supply chains in these regions often result in lower prices compared to Western markets. However, the global trade landscape, including tariffs and anti-dumping measures, can influence regional price disparities. For instance, trade restrictions or import duties imposed by certain countries may lead to localized price increases, prompting buyers to seek alternative suppliers.

Another emerging factor in PFY pricing is the role of digitalization and e-commerce in the textile industry. Online platforms have transformed the way PFY is traded, increasing market transparency and enabling buyers to compare prices and quality across suppliers. This digital shift has intensified competition, encouraging manufacturers to optimize pricing strategies. Moreover, data analytics and predictive modeling are being utilized to anticipate market trends, allowing companies to make informed pricing decisions in a rapidly changing environment.

As the PFY market evolves, the interplay of economic, environmental, and technological factors will continue to shape pricing trends. Manufacturers, buyers, and other stakeholders must remain vigilant to adapt to these changes effectively. Strategic investments in sustainability, technology, and market research can help industry participants navigate the complexities of the PFY market, ensuring resilience and competitiveness. With its critical role in the textile value chain, polyester filament yarn remains a focal point of industry innovation and market activity, reflecting broader trends in the global economy.

Get Real time Prices for Polyester Filament Yarn (PFY) : https://www.chemanalyst.com/Pricing-data/polyester-filament-yarn-1088

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyester Filament Yarn#Polyester Filament Yarn Price#Polyester Filament Yarn Prices#Polyester Filament Yarn Pricing

0 notes

Text

VIATT 2025 set to advance sustainability and digitalisation in Vietnam’s textile industry

In recent years, Vietnam has rapidly transformed into one of the world’s key textile producers, solidifying its position as the world’s third-ranked exporter behind China and Bangladesh. With a history rooted in silk textile craftsmanship and currently embracing wide ranging modern textile production, the country’s thriving sector offers tremendous growth prospects for both domestic and international businesses. In a bid to harness the potential in Vietnam and Southeast Asia, the Vietnam International Trade Fair for Apparel, Textiles and Textile Technologies (VIATT) will return from 26 – 28 February 2025, with a renewed focus on promoting sustainability and digital transformation.

Vietnam's textile and apparel sector comprises approximately 7,000 companies and employs over three million workers, with 80% of production capacity used for export and 20% for domestic consumption. Progress is aided by well-developed logistics networks, skilled labour and a stable political environment. As its textile industry evolves, several key trends are influencing its future direction, reflecting a growing emphasis on sustainability and technological advancement, and leading to new opportunities for exhibitors and buyers across the value chain at Vietnam’s comprehensive textile showcase.

Major trends shaping Vietnam's textile market reflected at VIATT

More Vietnamese enterprises are adopting eco-friendly materials, including organic cotton, recycled polyester, and Tencel, while numerous global brands manufacture in Vietnam, and have committed to the "Fashion Industry Charter on Climate Action", aiming to achieve net-zero carbon emissions by 2050.

To further advance sustainable initiatives in the domestic and international textile industry, VIATT 2025 will introduce Econogy Hub, a dedicated platform for innovative, eco-friendly suppliers and service providers to connect with like-minded visitors. The show’s other new Texpertise Econogy features will include the Econogy Finder, an independent verification tool to help sustainable exhibitors effectively communicate their green credentials, and Econogy Talks, the overarching category for eco-focused seminars, forums, and product presentations.

Apart from sustainability, the Vietnamese textile industry is also embracing advanced technologies in design and manufacturing. The launch of the fair’s Innovation & Digital Solutions Zone will provide a centralised platform for exhibitors to showcase innovations such as 3D printing, AI-driven design, and digital printing, which enable manufacturers to boost efficiency and customise products to meet specific market demands.

As well as the introduction of two new product zones, the India Pavilion, organised by The Cotton Textiles Export Promotion Council (TEXPROCIL), will also make its debut at VIATT 2025. Additionally, the Japan and Taiwan Pavilions have confirmed their return, with the Japan Pavilion recognised by VIATT’s visitors as a standout showcase within Southeast Asia's textile fair landscape. Overall, the fair will feature a diverse range of exhibitors across apparel, home textiles, and technical textiles, with many showcasing innovative and sustainable products. Highlighted exhibitors in each sector include:

Apparel fabrics, yarns & fibres and garments

Alumo AG (Switzerland): with over a century of expertise, this STeP by OEKO-TEX-certified company creates high-quality cotton shirting fabrics utilised by leading shirt designers. The company is dedicated to maintaining the art of weaving, ensuring that each fabric is finely crafted.

Wynist Retail Solutions (Taiwan): committed to sustainability, Wynist focuses on recycling and upcycling post-consumer and agricultural waste, transforming raw materials such as coffee grounds and textile waste into products with practical, on-trend industry applications.

Home & contract textiles

Sigma Vietnam Industrial (Vietnam): specialising in home textiles, the company’s innovative range of products includes bedding, curtains, and upholstery fabrics. It integrates traditional craftsmanship with modern design, ensuring that its offerings meet both aesthetic and functional needs.

Coolist Life Technology (China): the leading bio-based polyurethanes solutions and applications enterprise announced a new technology in 2024, that utilises captured carbon dioxide combined with bio-based polyol, to create a new generation of bio-based and bio-degradable foam.

Technical textiles, nonwovens, and textile technologies

Ultra Tech Asia (USA): as a leader in advanced textile solutions, the company offers innovative nonwoven materials for various applications, such as medical, automotive, and personal care, designed to meet the rising demand for high-performance textiles in diverse industries.

JB ECOTEX Limited (India): one of the leading manufacturers and exporters of high-quality recycled polyester staple fibre (RPSF) and rPET Flakes, the company has transformed millions of used plastic bottles into superior-grade, eco-friendly products. Since its inception, the company has maintained a zero-liquid discharge policy, and 50% of its power is generated from renewable resources.

The Vietnam International Trade Fair for Apparel, Textiles and Textile Technologies (VIATT) is organised by Messe Frankfurt (HK) Ltd and the Vietnam Trade Promotion Agency (VIETRADE), covering the entire textile industry value chain. For more details on this fair, please visit www.viatt.com.vn or contact [email protected].

VIATT will be held from 26 – 28 February 2025.

0 notes

Text

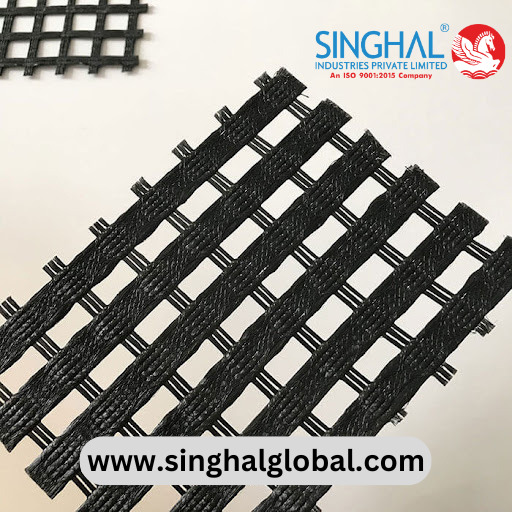

Polyester Geogrids: Building Sustainable Foundations for the Future

Introduction:

In the realm of civil engineering and construction, the pursuit of sustainability has become a paramount objective. As the world grapples with environmental challenges, innovative solutions are emerging to create more sustainable infrastructure. Among these solutions, polyester geogrids have gained prominence for their versatility, durability, and eco-friendliness. In India, particularly in Ahmedabad, Gujarat, the demand for sustainable construction materials has led to the rise of leading manufacturers and suppliers like PP Geogrid, pioneering the adoption of polyester geogrids in construction projects.

Understanding Polyester Geogrids:

Polyester geogrids are engineered materials made from high-strength polyester yarns, intricately knitted or woven to form a grid-like structure. These grids are then coated with polymers to enhance their durability and resistance to environmental factors such as UV radiation, chemicals, and biological degradation. The primary function of polyester geogrids in construction is to provide reinforcement and stabilization to various soil types, improving the structural integrity of roads, embankments, retaining walls, and slopes.

PP Geogrid: Leading the Charge in Sustainable Construction:

As a prominent PP geogrid manufacturer in India, PP Geogrid has been at the forefront of promoting sustainable construction practices. With a manufacturing facility located in Ahmedabad, Gujarat, the company has established itself as a reliable supplier of high-quality polyester geogrids to construction projects across the nation. By offering a wide range of geogrid products tailored to specific project requirements, PP Geogrid has played a significant role in revolutionizing the construction industry's approach to foundation stabilization and soil reinforcement.

Polyester geogrids are revolutionizing the construction landscape, particularly in Gujarat, India, where the demand for sustainable solutions is on the rise. As a leading PP geogrid manufacturer in Gujarat, companies like PP Geogrid are spearheading the adoption of these innovative materials. By providing high-quality geogrids tailored to specific project needs, they are not just reinforcing soil structures but also laying the groundwork for a more sustainable future. With their durability, versatility, and eco-friendliness, polyester geogrids are building the foundations for resilient infrastructure that can withstand the challenges of tomorrow.

Polyester geogrids are revolutionizing construction practices, offering sustainable solutions for building foundations that withstand the test of time. As a leading PP geogrid supplier in Ahmedabad, companies like PP Geogrid are driving this transformation. These geogrids, made from high-strength polyester yarns, enhance stability and durability in various projects, from roads to retaining walls. With their eco-friendly composition and long-lasting performance, polyester geogrids are paving the way for a greener, more resilient future in construction.

Benefits of Polyester Geogrids:

Enhanced Stability: Polyester geogrids improve the stability of soil structures by distributing applied loads more evenly, reducing the risk of settlement and deformation.

Increased Durability: With excellent tensile strength and resistance to environmental factors, polyester geogrids ensure long-term performance and reliability of construction projects.

Eco-Friendly: Unlike traditional construction materials, polyester geogrids are manufactured using recycled materials and can be recycled after their service life, minimizing environmental impact.

Cost-Effectiveness: By minimizing the need for extensive excavation and the use of additional materials, polyester geogrids offer cost-effective solutions for construction projects, saving both time and resources.

Conclusion:

Polyester geogrids represent a paradigm shift in the construction industry towards sustainability and innovation. As the demand for eco-friendly construction materials continues to grow, companies like PP Geogrid are leading the way by providing high-quality geogrid solutions tailored to the evolving needs of the industry. By embracing polyester geogrids, construction projects in India and beyond can build sustainable foundations for a greener and more resilient future.

Frequently Asked Questions:

What are the primary applications of polyester geogrids in construction? Polyester geogrids are commonly used for soil reinforcement in road construction, railway embankments, retaining walls, slope stabilization, and erosion control projects.

How do polyester geogrids contribute to sustainability? Polyester geogrids are manufactured using recycled materials and can be recycled after their service life, reducing the demand for virgin resources and minimizing waste generation.

Are polyester geogrids suitable for all soil types? Yes, polyester geogrids exhibit excellent compatibility with various soil types, including clay, sand, gravel, and silt, making them versatile solutions for a wide range of construction projects.

What factors should be considered when selecting polyester geogrids for a project? Key factors to consider include project requirements, soil characteristics, design specifications, environmental conditions, and regulatory compliance.

#pp geogrid manufacturer in India#pp geogrid supplier in Ahmedabad#pp geogrid manufacturer in Gujarat

0 notes

Text

Recycled Textile Market: Analyzing the Impact of Government Regulations and Policies

Recycled Textiles: A Growing Industry for Sustainable Fashion Rise of Recycled Fiber Market The past decade has seen a significant increase in the recycled fiber market globally. Recycled polyester, cotton, nylon and other fibers are being reused to manufacture new fabrics and textile products at an industrial scale. This represents a major paradigm shift away from the traditional "take, make, dispose" linear economy of the fashion industry towards a more circular model. The recycled fiber market was valued at $X billion in 2020 and is projected to grow at a compound annual growth rate of Y% until 2030 according to a new report by ABC Research. Recycled Polyester Leads Growth Of the various recycled fibers, polyester constitutes the largest segment both in terms of production volume and market value. Several big name brands have committed to utilizing recycled polyester in a major way. For example, brand Z pledged to swap Y% of virgin polyester with recycled polyester in all its products by 2025. Recycled polyester has certain advantages - it can be recycled endlessly without loss of quality, and provides a lower carbon alternative to virgin polyester derived from fossil fuels. However, recycling technologies to break down used polyester and produce new recycled polymers at scale is an active area of research and investment. Recycling Cotton Garments Cotton fiber is another major component of post-consumer textile waste. While cotton is a natural fiber, conventional cotton growing and processing has substantial environmental impacts. Recycling used cotton garments prevents these fibers from ending up in landfills. Companies like X have pioneered closed-loop recycling systems to recover cotton fibers from old T-shirts and other garments. The fibers are cleaned, broken down and spun into recycled cotton yarn which can then be rewoven or used in blend with other fibers to manufacture new textile products. Brands see recycled cotton as a way to promote principles of sustainability to environment-conscious customers. Challenges in Collection and Sorting One of the bottlenecks inhibiting higher recycling rates is the difficulty associated with efficiently collecting and sorting used textiles. Currently, the majority of post-consumer clothing is discarded as trash. Setting up convenient take-back programs and developing technologies for automated fiber identification are active areas for innovation. Additionally, the presence of other non-fibrous components like buttons, zippers or elastics requires textile recycling facilities to have advanced sorting equipment. Financial incentives and regulations to promote greater clothing collection for recycling will play a key role in scaling up the circular economy model. Market Growth in Developing Economies Going forward, the recycled textile market is expected to witness faster growth in developing countries compared to traditional markets in North America and Europe. Rapid industrialization and population growth in countries like India, Indonesia and Brazil will drive both textile consumption as well as the need for sustainable solutions. Social enterprises focused on recycling textiles can create jobs and economic development opportunities in these regions. Partnerships with local thrift shops and rag traders will be essential to collect pre-consumer textiles at source. South-South collaborations on recycling technology transfer will assist emerging markets to participate in this growing industry.

0 notes

Text

Revolutionizing Sustainability: Gupta Fibres as the Premier Regenerated Cotton Yarn Manufacturers in India

In the ever-evolving landscape of textile innovation, Gupta Fibres emerges as a pioneer in sustainability, leading the way as Regenerated Cotton Yarn Manufacturers in India. This article explores the significance, processes, and impact of choosing regenerated cotton yarn, setting Gupta Fibres apart as a trusted name in eco-conscious textile manufacturing.

1. The Essence of Regenerated Cotton: Dive into the core principles of regenerated cotton and how it contributes to a circular economy. Gupta Fibres excels as manufacturers by transforming discarded cotton into regenerated yarn, reducing waste and environmental impact.

2. Innovative Manufacturing Processes: Explore the cutting-edge techniques employed by Gupta Fibres in the production of regenerated cotton yarn. From advanced recycling methods to upcycling discarded textiles, discover the innovation that defines the manufacturing process.

3. Environmental Responsibility at Its Core: Gupta Fibres aligns with a commitment to environmental responsibility, reflecting in every strand of regenerated cotton yarn. The article delves into the sustainable practices and initiatives undertaken by the company, showcasing its dedication to a greener future.

4. Versatility in Applications: Highlight the versatility of regenerated cotton yarn manufactured by Gupta Fibres. From apparel to home textiles, delve into the diverse applications and creative possibilities that this sustainable yarn offers to designers and manufacturers.

5. The Role of Gupta Fibres in India's Textile Landscape: Gupta Fibres not only leads as Regenerated Cotton Yarn Manufacturers but also plays a pivotal role in shaping India's textile landscape. Explore how the company contributes to the nation's reputation as a hub for sustainable and high-quality textile manufacturing.

6. Collaborations and Sustainable Partnerships: Discuss any noteworthy collaborations or partnerships Gupta Fibres has forged in the realm of sustainable textile manufacturing. Highlight how these collaborations enhance the scope and impact of regenerated cotton yarn in the market.

7. Meeting Global Standards: Emphasize Gupta Fibres' commitment to meeting and exceeding global standards in the production of regenerated cotton yarn. Compliance with eco-certifications and industry benchmarks solidifies the company's position as a leader in sustainable textile manufacturing.

8. Consumer Awareness and Education: Gupta Fibres takes an active role in consumer awareness and education regarding the benefits of regenerated cotton yarn. The article explores initiatives, educational campaigns, or resources provided by Gupta Fibres to inform and empower consumers to make sustainable choices.

Conclusion: Conclude the article by underlining Gupta Fibres' role as a trailblazer among Regenerated Cotton Yarn Manufacturers in India. Celebrate the company's dedication to sustainability, innovation, and its impact on reshaping the textile industry with regenerated cotton yarn.

#Order Yarn Online#Wholesale Yarn Online#Cotton Knit Ribbing Fabric#Wool Knitting Yarn#Recycled Polyester Yarn Manufacturers in India#Fiber Weaving Products#Top Polyester Yarn Manufacturers in India#Cotton Wool Yarn#Organic Yarn Manufacturers India#cotton weaving yarn#best polyester yarn companies in india#cotton fiber yarn#cheapest place to buy yarn#best quality dyed yarns#Open End Yarn Manufacturers in Panipat

0 notes

Text

Pashupati Group's Sustainable Polyester Staple Fiber Made from Recycled Materials

Pashupati Group is a prominent producer of eco-friendly recycled polyester staple fiber, utilizing PET polyester waste and post-consumer PET bottles.

Their manufacturing process yields the fastest-growing fiber in the industry, reinforcing their position as India's leading exporter of this sustainable material.

Pashupati's stringent quality standards, technological expertise, and high-efficiency operations contribute to their commitment to environmental preservation.

By recycling substantial volumes of plastic, they contribute to reducing environmental pollution.

The Recycled Polyester Staple Fiber (RPSF) from Pashupati Group ensures wrinkle-free garments post-wash, a result of their dedicated efforts to convert waste into useful products, thereby minimizing waste and its associated environmental impacts.

This synthetic fiber, derived from recycled polyester, undergoes mechanical or chemical processes to achieve the desired quality. Furthermore, their utilization of PET bottles and textile waste significantly enhances efficiency and cost-effectiveness.

Pashupati offers various types of RPSF, including dyed, solid, hollow, hollow conjugated, and microfiber, ranging from 1.4 to 15 DN.

These products find applications across diverse industries, including fashion and textiles.

Notable qualities of Pashupati's recycled polyester staple fiber include its superior strength, heat resistance, and elasticity, rivalling even natural fibers like wool and cotton.

With its remarkable abrasion resistance and low water absorption, this fiber proves to be an exceptional choice for garment production. Additionally, its ability to retain its form and resist wrinkles sets it apart from other fibers in the market.

The manufacturing process involves transforming waste PET bottles into garments, employing an environmentally friendly and sustainable approach.

Sorting, cleaning, crushing, and extrusion of PET flakes result in fine polyester fibers, which are then spun into yarn for the production of various clothing items, such as t-shirts, dresses, and jackets.

Amid concerns about the rapid depletion of natural resources worldwide, Pashupati's recycled polyester staple fiber serves as a sustainable solution.

While synthetic fibers have previously raised environmental concerns, the increased market demand for recycled PSF underscores its improved eco-friendliness.

Pashupati's substantial plastic recycling initiatives significantly contribute to reducing environmental pollution.

#plastic recyling#pashupati group of industries#waste#environment#pet#PET flakes#eco-friendly#pashupati group

1 note

·

View note

Text

Recycled cotton textiles can be processed through a fiber opener. Polyester fiber, wool spinning, cotton, fur, textile waste, yarn, waste clothing, textile scraps, non-woven fabrics, and so on are only some of the many uses for this machine. This apparatus is employed to unload fiber s, cotton, textiles, and similar materials. Fiber opening is accomplished via an intake roller system that delivers tufts of fiber to a spinning cylinder with long pins. The loosened fiber is then sent to a collection point. Carding efficiency is increased through fiber opening, and the mixing process for multiple fiber types or colours can now commence.

The Fiber Opener: How to Use It

Fiber -opening machines play an essential role in the textile industry. Cotton, wool, and synthetic fiber s are just some of the materials that these are used to process. There is a wide variety of Fiber Opening Machine in India from various manufacturers, each with their features and capabilities. You can utilise a Fiber Opening Machine with the help of these basic instructions.

● Preparation

Remove any debris or stray fiber s from the Fiber opener Machine before using it. Make sure the machine is properly oiled to ensure its smooth operation. Conduct a thorough inspection of the machine to identify any damaged or worn components, and then repair those components as required.

● Fiber content

The first step in using a Fiber opener Machine in India is to load the fiber into the hopper. To accomplish this, the fiber is loaded onto a conveyor belt, which feeds the fiber into the appropriate machines. The load's fiber amount should be based on the machine's capacity.

#Fiber opener Machine#Fiber opener Machine in India#Fiber Opening Machine#Fiber Opening Machine in India#Fiber Opening Machine Manufacturers In India

0 notes

Text

Coats Sets a New Standard with Gral EcoVerde AS for Apparel: Neat seam appearance for apparel sewing thread.

India, 9th August ’23: Coats, a prominent figure in thread and textile manufacturing on a global scale, is delighted to introduce the groundbreaking product Gral EcoVerde AS. Gral EcoVerde AS for Apparel is made from 100% recycled polyester and features low friction lubrication, excellent loop formation, and consistent stitch formation. These properties combine to produce a smooth, even seam that is both visually appealing and durable.

The low friction lubrication in Gral EcoVerde AS for Apparel helps to reduce the friction between the thread and the needle, which helps to prevent the thread from fraying or breaking. This results in a smooth, even seam that is less likely to unravel.

Gral EcoVerde AS for Apparel represents a breakthrough in sustainable threads for apparel manufacturing. It is designed to minimise environmental impact while upholding the highest quality standards. The thread is crafted using eco-friendly materials and processes, ensuring reduced water consumption, a lower carbon footprint, and decreased energy usage.

GRAL Ecoverde AS maintains the exceptional quality and reliability that Coats is renowned for. It is well-suited for diverse applications, including apparel sewing, offering consistent stitching and durability. Brands and manufacturers can seamlessly infuse sustainability into their products while leveraging the expertise and reputation of Coats.

Coats is committed to providing customers with sustainable sewing thread solutions. The thread exemplifies the company's ongoing commitment to advancing environmental practices, ensuring a more sustainable and responsible future for the textile sector. The company believe that this thread will help apparel manufacturers reduce their environmental impact and improve the quality of their products. To learn more about GRAL Ecoverde AS and its sustainable benefits, please visit the website’s product page. https://www.coats.com/en/products/threads/gral/gral-ecoverde-as-for-apparel

About the Author:

Coats is the world’s leading industrial thread company. They are headquartered in the UK, with a workforce of 17,000 in 50 countries across six continents around the world. Coats provide complementary and value-adding products, services and software solutions to the Apparel & Footwear industries. Coats apply innovative techniques to develop high technology Performance Materials threads, yarns and fabrics in areas such as Transportation, Telecoms and Energy, and Personal Protection.

0 notes

Text

Top 5 Leading Manufacturers of Technical Yarn and Their Innovations

The demand for technical yarn has been increasing steadily due to its diverse applications in industries such as automotive, textiles, and construction. Technical yarns are known for their strength, durability, and specialty features that make them ideal for various high-performance uses. In India, several key manufacturers are recognized for their contribution to this field. Here, we will look at the top 5 leading manufacturers of technical yarn and the innovative practices that set them apart, including SD Polytech, a well-regarded name in the industry.

1. SD Polytech

SD Polytech is one of the top Spun Polyester Yarn Producers in India and a significant player in the technical yarn market. The company is known for its high-quality products and continuous focus on innovation.

Advanced Production Techniques: SD Polytech employs modern machinery and advanced production techniques that ensure the yarn’s superior quality and consistency.

Customization Options: The company offers a range of technical yarns tailored to meet the specific needs of various industries, making them a preferred choice.

Sustainability Practices: SD Polytech is committed to eco-friendly production methods, ensuring that their processes are both sustainable and efficient.

2. Reliance Industries Limited

Reliance Industries Limited is a well-known conglomerate that also holds a strong position in the technical yarn market.

Innovative Yarn Blends: The company is recognized for its ability to create unique blends of technical yarn that offer both strength and flexibility.

High Production Capacity: With large-scale manufacturing units, Reliance can meet significant market demands efficiently.

Research and Development: Their dedicated R&D department continuously works on improving the properties of technical yarn to cater to new market needs.

3. Indorama Ventures

Indorama Ventures is another leading name that has carved its niche in the technical yarn sector.

Global Reach: With operations in various countries, Indorama Ventures supplies technical yarns to both domestic and international clients.

Innovative Product Lines: The company’s yarns are known for their high tensile strength and durability, essential for industrial applications.

Sustainability Efforts: Like SD Polytech, Indorama Ventures is committed to using eco-friendly manufacturing practices and recyclable materials.

4. Century Enka

Century Enka is a pioneer in the production of technical and industrial yarns.

Quality Assurance: The company follows stringent quality control measures to produce reliable and durable yarns.

Diverse Applications: Century Enka’s products are used in a wide range of industries, including tire reinforcement, textiles, and more.

Technological Advancements: Their state-of-the-art facilities ensure consistent product innovation and high standards.

5. SRF Limited

SRF Limited has a strong reputation for producing technical yarns used in industrial applications.

Specialized Yarns: SRF Limited offers yarns that are specially designed for high-stress environments, such as automotive belts and conveyor belts.

Continuous Innovation: The company invests in research to develop yarns with improved properties like better heat resistance and enhanced strength.

Sustainability Initiatives: SRF Limited has adopted green practices in its manufacturing process to minimize environmental impact.

Why Choose Technical Yarn from India?

India is home to some of the most reputable Spun Polyester Yarn Producers, including SD Polytech. The country’s emphasis on quality, innovation, and cost-effective production makes it a global leader in the technical yarn market. Indian manufacturers, with their focus on sustainable and advanced production methods, continue to play a significant role in meeting both domestic and international demands.

Conclusion

The field of technical yarn is marked by innovation and quality, driven by industry leaders like SD Polytech, Reliance Industries, Indorama Ventures, Century Enka, and SRF Limited. These companies are not just manufacturers but innovators, setting new standards with their forward-thinking approaches and sustainable practices. Choosing technical yarn from these manufacturers ensures quality, reliability, and a product that meets the demands of various industries.

Also Read:

Top Yarn Manufacturers in Delhi: A Comprehensive Guide

How to Choose the Right Spun Polyester Yarn for Your Project

Originally published at https://sdpolytech.blogspot.com

0 notes

Text

Recycled Polyester Fibers Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

Latest edition released by AMA on Global Recycled Polyester Fibers Market to regulate the balance of demand and supply. This intelligence report on Recycled Polyester Fibers includes Investigation of past progress, ongoing market scenarios, and future prospects. Data True to market on the products, strategies and market share of leading companies of this particular market are mentioned. It’s a 360-degree overview of the global market’s competitive landscape. The report further predicts the size and valuation of the global market during the forecast period. Some of the key players profiled in the study are Loop Industries, Inc. (Canada),Worn Again (United Kingdom),Tyton Biosciences, LLC (United States),Blocktex (Australia),Bionic Yarn (United States),Toray (Japan),Tejin Fibers (Japan),Eastman Chemical Company (United States),BP (United Kingdom),Formosa Taffeta Co., Ltd. (Taiwan),Zhejiang Jiaren New Materials Co., Ltd. (China),Repreve (United States),JB Ecotex (India),William Barnet & Son (United States)

Polyester is a manmade fiber, manufactured from petrochemical products by a process called polymerization. With 49% of the global fiber production, polyester is the most broadly used fiber in the apparel sector, annually more than 63,000 million tonnes of polyester fiber are produced. The method that is used for recycling can be either mechanical or chemical, with feedstock consisting of either pre- or post-consumer waste that can no longer be used for its intended purpose. PET is used as a raw material for recycled polyester. This material is also used in clear plastic water bottles, and recycling it to reach the fabric avoids it from going to landfill. The garments produced from recycled polyester can be recycled again and again with no degradation of quality, letting to reduce wastage, which means that the garments manufacturer could become a closed loop system, polyester could forever be reused and recycled.

Market Trends: Increasing Adoption of Polyester in Textile Industry

Rising Awareness About Sustainable Textile Production

Opportunities: Rising Disposable Income in Emerging Economies

Favorable Government Initiative to Support Eco-friendly Production

Market Drivers: Rising Demand for Environment Protection

Growing Textile Industry Worldwide

Challenges: Cultivation of Organic Cotton

Presented By

AMA Research & Media LLP

0 notes