#RFID inventory solutions

Explore tagged Tumblr posts

Text

4 Essential Techniques to Optimize Auto Inventory Counts

Looking to optimize auto inventory management? Here are four essential techniques to consider: Regular Inventory Counts: Conduct frequent inventory counts for auto parts to ensure accuracy and minimize discrepancies. Utilize inventory management software: Invest in advanced inventory management software to streamline tracking and organization. Implement Just-In-Time Inventory: Adopt a just-in-time inventory approach to reduce excess inventory and improve efficiency. Establish vendor relationships: Cultivate strong relationships with vendors to ensure timely deliveries and maintain optimal inventory levels.

#rfid solutions#rfid retail#rfid software#rfid applications#rfid technology#retail inventory solutions#rfid inventory solutions

0 notes

Text

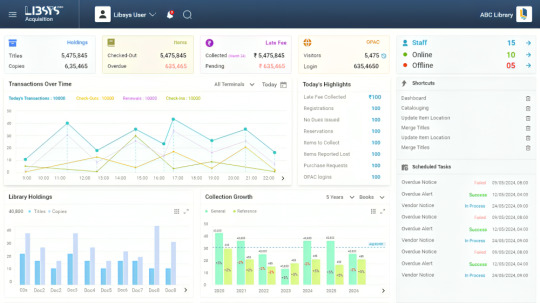

RFID library Automation for tracking, security and inventory management

LIBSYS Limited, a software as a service(SAAS) company based in Gurugram, Delhi-NCR, India, was founded in 1984 by Mr. Anil Jain to cater the needs of Identity, Tracking and Security purpose for various Indian industries. With the aim to automate the process and minimizing the human errors to zero, the Libsys offers a wide range of solutions that include Library Management Systems for institutions and government bodies, RFID based customized applications from small business to multinational organizations, Common Admission Platform and ERP for Academic Institutes, Omni-channel Retailing solution, E-Commerce Framework, CRM, Design & Architecture and other on demand solutions.

The experience of 40 years and counting along with in-depth understanding of the Indian markets, we are the proud leaders of quality and innovation. Through the experience we have, we have the ability to respond quickly to the customized client requirements with an innovative solutions that meet those needs efficiently and cost effectively. Our experience and strong mission-first work ethic has helped us develop capabilities, insights, and skills to provide the best solution one can have. Backed by our strong quality processes and rich experience in managing clients across various domains, we strive for continuous innovations in our offerings, and we take pride in being the pioneer and market leader for RFID based automation solution in India.

To name a few, software products like LIBSYS 10 LMS, LSEase, LSmart-RFID, LSRemote, LSDiscovery, LSe-RMS, symphonyX, TargetX, LSNetX (E-Com) and LSales1 CRM are the benchmarks in India serving across the domains and delivering the best operational efficiency solutions for all organizations and enterprises.

TRANSFORMING LIBRARIES

Elevate your Library

LIBSYS 10 caters to all the needs of library automation improving the efficiency of libraries and providing a delightful library experience through continuous technological innovations

Smooth Library Operations

LIBSYS 10 simplifies and automates essential library management tasks, allowing for efficient cataloging, circulation, and inventory management.

Enhanced Accessibility

Libsys 10 offers a user-friendly interface and robust search capabilities, enabling patrons to easily discover and access library resources.

Comprehensive Reporting

Libsys 10 generates detailed reports on library usage, collection statistics, and circulation trends, facilitating decision-making and resource allocation

Seamless Integration

Libsys 10 seamlessly integrates with various library systems, ensuring smooth interoperability and minimizing disruptions in existing work-flows

LIBSYS10

LIBRARY MANAGEMENT SIMPLIFIED

Step into the future

A web based library management solution to enhance the total library experience through value added features and services.

The present times demand Library Management System to deliver much more than operational efficiency. It needs to create appreciable staff satisfaction and a delightful experience for the patrons every time they interact with the system. LIBSYS is committed to delivering value to the libraries through its products. In-depth understanding of library operations, implicit needs of the patrons, and dedicated R&D efforts have guided us to deliver high-quality products that have found wide acceptance in the market space.

Its seamless work-flow enables library staff to manage library operations efficiently.

New purchase approvals, collection development, material handling, SDI services, bindery management, and a host of other functions form an integral part of the system.

MARC21 / RDA interface, Cooperative Cataloguing along with controlled authority files helps in Cataloguing on the fly.

Federated Searching brings other libraries of similar collection within your reach.

REQUEST A DEMO

MODULES

GO BEYOND THE LIBRARY

Modernize Your Library

LIBSYS 10 is a smart library management system covering all the needs of library automation in India and abroad.

Acquisition

LIBSYS 10 automated library acquisition system is capable of efficiently managing all kinds of work-flow

Cataloguing

Catalogue your records smarter and faster way with user friendly yet powerful cataloguing module.

Serial Control

Easily control and maintain your library’s serials collection in the most efficient way.

Circulation

Easy and powerful interface to handle circulation transactions, alerts, greetings, reminders, fine etc.

KEY FEATURES

Check Out Capabilities

LIBSYS 10 is a feature-rich Library Management System that empowers libraries to effectively manage their collections, streamline operations, provide enhanced services to patrons, and embrace modern technologies for a seamless library experience. Our automated acquisition system in library reduces time consuming work and enhances the overall efficiency in ordering and provides necessary management information reports.

Online Public Access Catalog (OPAC)

Digital Resource Management

Reporting and Analytics

Integration and Interoperability

Mobile Accessibility

BENEFITS

30+ YEARS

Scale Your LMS

LIBSYS 10 empowers libraries to optimize their operations, improve user satisfaction, and adapt to evolving technological advancements in the library field. It enhances the overall library experience for both librarians and patrons.

Streamlined Operations

Libsys 10 automates various library tasks, reducing manual efforts and saving time for librarians.

Efficient Resource Management

The system helps librarians effectively manage library resources, including books, journals, multimedia, and digital materials.

Enhanced User Experience

Libsys 10 enhances the experience for library patrons through its user-friendly OPAC interface.

Accessibility Anytime, Anywhere

Libsys 10's mobile accessibility ensures that library services and resources are available to patrons anytime, anywhere.

LIBSYS10

HARNESS THE POTENTIAL OF OUR LIBRARY MANAGEMENT SYSTEM!

#1 Library Management System

Unlock the Power of Efficiency and Innovation with Libsys

The present times demand Library Management System to deliver much more than operational efficiency. It needs to create appreciable staff satisfaction and a delightful experience for the patrons every time they interact with the system. LIBSYS is committed to delivering value to the libraries through its products. In-depth understanding of library operations, implicit needs of the patrons, and dedicated R&D efforts have guided us to deliver high-quality products that have found wide acceptance in the market space.

The new Web-based Library Management System ‘LIBSYS 10’ provides a greatly enhanced user experience through value-added features and services. LIBSYS 10 is built on international standards and open technologies, i.e. JAVA. It covers Acquisition, Cataloguing, Circulation, Serials, Articles Indexing, E-Books, Dean and Vendor Portals along with an enriched OPAC. Its seamless work-flow enables library staff to manage library operations efficiently. New purchase approvals, collection development, material handling, SDI services, bindery management, and a host of other functions form an integral part of the system. MARC21 / RDA interface, Cooperative Cataloguing along with controlled authority files helps in Cataloguing on the fly. Federated Searching brings other libraries of similar collection within your reach.

LIBSYS 10 gives you the opportunity to take your automated library circulation system to new heights by use of RFID / EM / Hybrid Technology. Choose LSmart / KSmart system as per your budget and requirements. Use of these technologies will help in hassle free, accurate and faster issue / return of books, inventory visibility, accuracy and efficiency, increases security function in the library, improved utilization of resources like manpower, infrastructure etc., give flexible library timings. The bottom line is that the synergy between the latest technology like RFID and libraries can create wonders resulting in empowerment of both users as well as librarians.

LIBSYS Library Management System in India has been deployed in many prestigious institutes. LIBSYS 10 caters to all the needs of library automation improving the efficiency of libraries and providing a delightful library experience through continuous technological innovations. With rich experience of more than three decades along with continuous innovation, LIBSYS has emerged as the best library management system in India.

We also undertake special projects which include multi-location library automation and RFID system implementation. The projects are executed by specialized teams comprising of experienced professionals from Library and IT domains. Our customer-focused services also include consulting to meet individual needs, organizing User meets, and providing regular software updates.

For more details connect at [email protected] or +91-0124-4894100

#rfid#rfid solutions#rfid technology#rfid reader#rfid tags#library#inventorymanagement#inventory software#assets#assetprotection#assetmanagement#tracking tag#data security#software#technology#trackinghome#cyber security#social security#cybersecurity

2 notes

·

View notes

Text

How Barcode Security Tags Protect Your Products and Improve Tracking

In 2025, retail businesses are under constant pressure to reduce product theft, improve stock visibility, and enhance customer service. One of the most reliable tools available for this purpose is Barcode Security Tags. These tags help retailers track their inventory while also preventing unauthorized access, tampering, or shoplifting. AIDC Technologies India is a trusted provider of Barcode Security Tags and retail automation solutions across the country. Their barcode systems are designed to meet modern retail challenges while delivering long-term value and reliability.

How AIDC Barcode Security Tags Prevent Shoplifting & Tampering

Barcode Security Tags work by combining the functionality of a barcode with added layers of physical security. These tags can be applied to clothing, electronics, cosmetics, or high-value merchandise. Once applied, they are difficult to remove without a proper detacher or scanner, making them an effective deterrent against theft. AIDC Technologies India offers a range of Barcode Security Tags that include tamper-evident features and custom encoding to ensure product authenticity.

Retailers using AIDC’s security tagging solutions benefit from fewer losses due to shoplifting and better protection against counterfeiting. These tags alert store staff when someone attempts to leave the premises without paying, helping reduce inventory shrinkage significantly.

Retail Applications of Barcode Security Tags by AIDC Technologies

Barcode Security Tags are widely used in retail stores across India. AIDC Technologies India serves a broad customer base in apparel, electronics, grocery, pharmaceuticals, and department stores. In clothing outlets, these tags are attached to garments and accessories, ensuring that no items are removed without proper billing. In electronics stores, they are used to protect expensive gadgets and accessories. In pharmacies, Barcode Security Tags help control inventory and reduce pilferage of sensitive products.

By integrating these tags into their point-of-sale systems, retailers get real-time updates about what’s sold, returned, or moved. AIDC ensures smooth integration of security tags into a retailer’s existing hardware and software setup.

Features of AIDC Anti-Theft Barcode Security Tags for 2025

AIDC Technologies India has designed Barcode Security Tags to suit Indian retail environments, where temperature, handling, and usage patterns vary widely. These tags are lightweight, yet durable enough to resist wear and tampering. Each tag carries a unique barcode identifier, making it easy to link to product information, batch numbers, and pricing.

Additional features include high scanning accuracy, compatibility with handheld and fixed barcode readers, and the ability to work with Electronic Article Surveillance (EAS) systems. Some tags are reusable, while others are made for one-time use depending on the nature of the product and business requirement.

Benefits of Using Barcode Security Tags in Retail by AIDC India

Barcode Security Tags offer several advantages to retailers who are looking to improve operational efficiency. AIDC’s tagging solutions reduce shrinkage by acting as a visual and technical deterrent to theft. They also speed up checkout processes by allowing fast and reliable barcode scanning. Inventory checks become easier and more accurate when every product is tagged.

With AIDC’s Barcode Security Tags, retailers can also track returns more effectively and ensure that returned items are genuine and unaltered. These benefits result in smoother store operations, higher customer satisfaction, and better profit margins.

AIDC’s Barcode Tags for Inventory, Asset & Shelf Management

Besides theft prevention, Barcode Security Tags are highly effective for inventory and shelf management. AIDC Technologies India offers tagging solutions that support bulk scanning of items during stock audits. This means retailers can complete stock-taking quickly and with fewer errors. Tags can also be used for internal asset tracking, helping businesses keep control of equipment, displays, and supplies.

Retailers can use AIDC’s tags to set reorder levels, monitor expiry dates, and maintain product traceability throughout the supply chain. This level of visibility helps businesses stay organized and avoid losses from expired or misplaced items.

Custom Barcode Tagging Solutions for Retailers by AIDC

Every retail business has different needs, and AIDC Technologies India understands this well. That’s why they offer customizable Barcode Security Tags that can be designed with specific sizes, adhesive strength, and data fields. Businesses can choose tags that are removable, permanent, waterproof, or UV-resistant depending on their environment.

AIDC works closely with retailers to develop solutions that match their store layout, product type, and security goals. Whether it’s a small boutique or a large chain, AIDC has the right tagging solution that fits seamlessly into the daily operations.

Why Retailers Trust AIDC for Barcode Security Tag Technology

AIDC Technologies India has earned the trust of hundreds of retailers by consistently delivering quality products and expert support. Their Barcode Security Tags are backed by a team of professionals who provide installation, training, and technical help. Retailers choose AIDC because of their strong understanding of retail pain points and their ability to offer solutions that are easy to use and maintain.

With years of experience in barcode and RFID systems, AIDC is more than just a supplier—they are a technology partner committed to helping businesses grow through smart automation.

Barcode Security Tags vs RFID: What AIDC Recommends for 2025

While both barcode and RFID technologies serve similar tracking purposes, there are key differences. Barcode Security Tags are generally more affordable and easier to implement. They do not require specialized readers and can be used with standard barcode scanners. RFID tags, on the other hand, offer faster scanning and don’t need line-of-sight.

AIDC Technologies India helps businesses choose between these technologies depending on their scale, budget, and operational needs. For most retail applications, Barcode Security Tags offer the best balance of cost, control, and simplicity.

Book Your Barcode Security Tag Demo Today with AIDC India

If you are looking to improve product security and gain better inventory control, Barcode Security Tags are the solution. AIDC Technologies India offers free consultations and live demos to help you understand how these tags can benefit your retail business.

#barcode security tags#product tracking technology#anti-theft barcode solutions#inventory protection tools#retail theft prevention 2025#smart product labeling#RFID and barcode integration#tamper-proof barcode tags

0 notes

Text

Smarter RFID Asset Tracking Solutions by Trakaid

Streamline your operations with advanced RFID asset tracking from Trakaid. Our cutting-edge solutions help businesses monitor, manage, and secure their valuable assets in real time. From healthcare to industrial logistics, Trakaid’s RFID technology ensures complete visibility, accuracy, and efficiency — reducing loss, improving compliance, and saving costs.

Empower your asset management with Trakaid’s trusted RFID tracking systems.

Visit Now: https://www.trakaid.com

#RFID asset tracking#Trakaid#asset management#RFID solutions#inventory control#real-time tracking#enterprise asset tracking

0 notes

Text

Why Fixed Asset Depreciation Matters

Understanding Fixed Asset Depreciation: A Vital Component of Financial Reporting

In the modern business environment, managing fixed assets effectively is key to maintaining accurate financial records. One of the most important aspects of this process is depreciation—the systematic reduction of an asset’s value over its useful life. Whether it’s machinery, office equipment, or company vehicles, fixed asset depreciation enables businesses to spread out the cost of these assets over several years, rather than expensing the entire amount upfront. This not only aligns with accounting principles but also provides a clearer financial picture.

What is Fixed Asset Depreciation?

Fixed asset depreciation refers to the accounting method used to allocate the cost of tangible long-term assets over their expected useful lives. Instead of reflecting the entire expense at the time of purchase, companies gradually recognize the cost through periodic depreciation. This method better matches expenses with revenue and reflects the asset's actual wear, tear, and aging process. By doing so, depreciation helps businesses maintain realistic and up-to-date asset values in their books. READ MORE

#assetmanagement#assettracking#rfid solutions#macoinfotech#Asset management software#asset tracking software#barcode inventory system#rfid tags

0 notes

Text

Advanced Biometric & Access Control Solutions in dubai and saudi arabia

#rfid and ble solutions in dubai#fingerprint technologies in dubai#facial recognition solutions in dubai#access control solutions in dubai#asset management system in dubai#inventory management system in dubai

0 notes

Text

Understanding the Technology Behind Barcode Scanners in Supermarkets

Barcode scanners are an essential tool in modern supermarkets. They have transformed how stores operate, making processes faster, more efficient, and remarkably accurate. But have you ever wondered how this seemingly simple device works or why it’s a cornerstone of retail operations? Let’s dive into the fascinating technology behind barcode scanners and explore their pivotal role in supermarkets.

What is a Barcode Scanner?

A barcode scanner is a device that reads barcodes and converts the data into a format a computer system can understand. Barcodes themselves are machine-readable codes consisting of black and white lines or patterns, each representing specific information. In a supermarket, barcodes typically contain details about a product, such as its name, price, and inventory code.

The magic happens when a scanner decodes this information in a fraction of a second, making checkout and inventory processes seamless.

How Does Barcode Scanning Technology Work?

The process may seem effortless, but behind the scenes, it involves some impressive technology:

Light Source: Barcode scanners use a light source (commonly a laser or LED) to illuminate the barcode.

Sensor: The scanner’s sensor detects the light reflected off the barcode’s black and white lines. Black lines absorb more light, while white lines reflect it, creating a pattern.

Decoder: The scanner’s decoder processes the pattern and translates it into digital data. This data is sent to a computer system, which identifies the product and retrieves its information.

Barcode scanners can use different technologies, such as laser, CCD (Charge-Coupled Device), and 2D image scanners. Each type has its strengths and is chosen based on specific supermarket needs.

The Role of Barcode Scanners in Supermarkets

Barcode scanners are indispensable in supermarkets, thanks to their versatility and efficiency. Here’s how they impact daily operations:

1. Faster Checkout

Barcode scanners significantly speed up the checkout process. Instead of manually entering product details, cashiers simply scan the barcode, and the system instantly retrieves the price and product information. This method saves time and minimizes the chances of making errors.

2. Accurate Pricing

Scanners ensure accurate pricing by pulling data directly from the store’s database. This eliminates discrepancies caused by manual entry and ensures customers are charged the correct amount.

3. Inventory Management

Supermarkets rely on barcode scanners to track inventory in real time. Each scan updates the inventory system, ensuring the stock levels are always accurate. This helps stores avoid overstocking or running out of popular items.

4. Data Insights

The data collected through barcode scanning provides valuable insights into customer buying habits. Supermarkets can analyze which products are selling well, identify trends, and make informed decisions about restocking and promotions.

Types of Barcode Scanners Used in Supermarkets

Depending on their specific needs, supermarkets use different types of barcode scanners. Here are some common types:

Handheld Scanners: Lightweight and portable, these are ideal for scanning bulky or heavy items.

Flatbed Scanners: Found at most checkout counters, flatbed scanners are designed for high-speed scanning.

Wireless Scanners: These scanners provide flexibility by allowing staff to move around freely while scanning.

2D Scanners: Capable of reading both 1D (linear) and 2D (matrix) barcodes, these scanners are increasingly popular for their versatility.

Emerging Technologies in Barcode Scanning

The technology behind barcode scanners continues to evolve, offering even more efficiency and innovation. Some of the latest advancements include:

Mobile Barcode Scanning: With the rise of smartphone apps, customers can now scan barcodes themselves, creating a seamless shopping experience.

QR Code Integration: QR codes are gaining popularity in retail for their ability to store more information than traditional barcodes.

AI-Powered Scanners: Artificial intelligence is integrated into barcode scanning to improve accuracy and adaptability in dynamic retail environments.

The Benefits of Barcode Scanners for Supermarkets

Barcode scanners offer numerous advantages for supermarkets, such as:

Improved Efficiency: Automating checkout and inventory management saves time and labor costs.

Enhanced Customer Experience: Faster checkout lines and accurate pricing contribute to customer satisfaction.

Reduced Errors: By eliminating manual entry, barcode scanners minimize human errors.

Cost Savings: Streamlined operations lead to significant cost savings in the long run.

Conclusion

Barcode scanners are more than just tools for scanning products; they’re the backbone of modern supermarket operations. By understanding the technology behind these devices, we gain insight into how supermarkets operate so efficiently, ensuring customers have a seamless shopping experience.

As technology advances, barcode scanners will only become more sophisticated, playing an even greater role in shaping the future of retail. Whether you’re a tech enthusiast or simply a curious shopper, the next time you’re at the checkout counter, you’ll have a newfound appreciation for the humble barcode scanner.

#rfid technology#Barcode Scanner#Barcode Reader#inventory management#Retail#supermarket#retail solutions

0 notes

Text

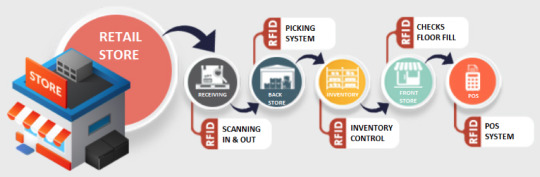

RFID Retail Solutions: Streamlining Inventory Management for Success

RFID is gaining widespread adoption in the retail sector. When Radio-Frequency Identification (RFID) technology was introduced over 70 years ago, it promised significant advancements, particularly in the retail industry, which demands precise inventory management. With a high volume of items moving quickly in and out of the premises and a plethora of sizes, colors, and designs requiring high selectivity, the chances of inventory loss, errors, and inefficiency are high. Utilizing RFID Technology in inventory management addresses these challenges effectively. According to recent studies, 58% of warehouse decision-makers have plans to implement RFID technology by the year 2028. While implementing RFID technology may take months, the initial efforts are already showing results, with billions saved annually in shrinkage (inventory losses).

Inventory management in retail is crucial for saving time, ensuring accuracy, and satisfying customers. Each item is equipped with an RFID Tag, and fixed RFID Readers are strategically placed to automate stock checks without manual intervention in warehouses or retail stores. This ensures 24/7 inventory counts, preventing shrinkage loss, inventory misplacement, and other errors. Handheld RFID readers complement fixed RFID readers, providing real-time updates and enabling rapid inventory checks to enhance overall efficiency. RFID technology enables various applications, including inventory picking, shipment verification, stock in/stock out, and locating lost items.

Additionally, custom software enables item identification capabilities, allowing the system to identify and categorize items based on various attributes such as SKU, size, color, or location. This facilitates precise inventory tracking, enabling managers to quickly locate specific items, analyze stock movements, and optimize inventory levels. With item identification functionality, businesses can streamline their inventory management processes, reduce errors, and improve overall operational efficiency. Other features, such as notifications for removed items, real-time image capture, and item identification offer significant benefits, including improved inventory accuracy, enhanced transparency, and streamlined operations, ultimately leading to cost savings and better business outcomes.

Experts commonly cite inventory management as the primary use case for RFID technology, but its applications extend far beyond just that. RFID has proven its effectiveness in various areas, including omni-channel operations, smart fitting rooms, accelerated checkouts, and interactive displays. Over the past decade, RFID technology has made significant strides. Read accuracy has doubled, prices have dropped significantly, and the range has increased more than fivefold, leading to fewer devices required and better scanning capabilities. Today, RFID enables real-time visibility, enhanced accuracy, and increased automation, resulting in significantly improved operational efficiency, time and cost savings, and an enhanced overall customer experience.

#RFID Retail Solutions#RFID Garments Tags#RFID tags#Inventory Tracking#Inventory Management#RFID technology#RFID solutions#rfid reader

0 notes

Text

Revolutionizing Retail: The Impact of Advanced Inventory Management Systems on Future Businesses

In the fast-evolving landscape of retail, businesses are increasingly turning to advanced inventory management systems to stay competitive and enhance overall efficiency. This article explores the transformative power of inventory management systems, with a focus on RFID-based and barcode-based solutions, and their pivotal role in shaping the future of retail.

1. The Evolution of Inventory Management Systems:

As technology advances, traditional inventory management methods are giving way to more sophisticated systems. The shift from manual tracking to automated solutions has become a cornerstone for retailers looking to streamline their operations.

2. RFID-Based Inventory Management Systems:

RFID (Radio-Frequency Identification) technology has emerged as a game-changer in inventory management. This system uses radio waves to identify and track items, providing real-time visibility into inventory levels. The article delves into the benefits of RFID, such as improved accuracy, faster inventory counts, and enhanced security.

3. Barcode-Based Inventory Management Systems:

Barcode technology remains a stalwart in inventory management, offering a cost-effective and reliable solution. This section explores how barcode systems work, their ease of implementation, and their ability to simplify tasks like product tracking, restocking, and order fulfillment.

4. Integration for Seamless Operations:

The future of retail lies in the integration of different technologies. Discuss how businesses are combining RFID and barcode systems with other advanced technologies, such as IoT (Internet of Things) and data analytics, to create comprehensive and intelligent inventory management ecosystems.

5. Enhanced Accuracy and Efficiency:

Highlight the accuracy and efficiency gains achieved through advanced inventory management systems. Discuss how businesses can reduce errors, minimize stockouts, and optimize inventory levels, leading to improved customer satisfaction and increased profitability.

6. Real-Time Data and Analytics:

Explore the significance of real-time data in retail operations. Inventory management systems provide valuable insights through analytics, enabling businesses to make informed decisions, forecast demand more accurately, and adapt swiftly to market changes.

7. Challenges and Solutions:

Acknowledge the challenges associated with implementing advanced inventory management systems, such as initial costs, integration complexities, and staff training. Provide insights into how businesses can overcome these hurdles to reap long-term benefits.

8. The Future Landscape:

Conclude by painting a picture of the retail landscape in the future. Discuss how continuous advancements in technology will further refine inventory management systems, making them even more integral to the success of businesses in an increasingly competitive market.

9. Conclusion:

Summarize the key points and emphasize that embracing advanced inventory management systems is not just a trend but a strategic necessity for retailers looking to thrive in the future.

By incorporating RFID-based and barcode-based inventory management systems, businesses can position themselves at the forefront of innovation, ensuring they are well-equipped to navigate the dynamic and ever-changing retail landscape.

10. FAQs

1. Q: What distinguishes RFID-based inventory management systems from barcode-based solutions?

A: RFID (Radio-Frequency Identification) systems use radio waves for real-time item tracking, providing enhanced accuracy and faster inventory counts. Barcodes, on the other hand, rely on visual scanning and are cost-effective for tasks like product tracking and order fulfillment. The article explores the benefits and distinctions between these two technologies.

2. Q: How do advanced inventory management systems contribute to enhanced accuracy and efficiency in retail operations?

A: Advanced inventory management systems, including RFID and barcode solutions, significantly reduce errors, minimize stockouts, and optimize inventory levels. The article highlights how these systems streamline operations, leading to improved customer satisfaction and increased profitability for businesses.

3. Q: Can you elaborate on the integration of RFID and barcode systems with other technologies in retail?

A: The future of retail lies in the integration of technologies like RFID and barcodes with IoT (Internet of Things) and data analytics. This section discusses how businesses are creating comprehensive inventory management ecosystems, leveraging multiple technologies to enhance efficiency and decision-making processes.

4. Q: What challenges do businesses face when implementing advanced inventory management systems, and how can they overcome these hurdles?

A: Challenges associated with implementing advanced systems include initial costs, integration complexities, and staff training. The article addresses these challenges and provides insights into overcoming them, emphasizing the long-term benefits businesses can reap by embracing advanced inventory management solutions.

5. Q: How does real-time data and analytics play a role in shaping the future of retail operations?

A: Real-time data and analytics provided by inventory management systems offer valuable insights for informed decision-making. This FAQ elaborates on the significance of these insights in helping businesses accurately forecast demand, adapt swiftly to market changes, and thrive in the dynamic retail landscape.

0 notes

Text

Improving Linen Inventory Control in Your Commercial Laundry

If you run a commercial laundry and mindlessly deliver the same linen load, week after week – and are then forced to fix each order according to what’s actually needed – this can prove wasteful. It’s also highly inefficient and unproductive, especially if your facility is already running at capacity.

#bundle laundry#laundry productivity solutions#laundry management solutions#laundry inventory tracking#gps delivery management system#rfid inventory management#laundry productivity#laundry management cloud platform#laundrysoftware#laundry businesses

0 notes

Text

The 5 Best Mil-Spec Packaging Suppliers

Military products must meet stringent quality and reliability standards, which also apply to their packaging. Consequently, any company in this sector must partner with the best mil-spec packaging suppliers to ensure everything remains compliant.

1. Edco Supply Corporation

Edco Supply Corporation — out of Brooklyn, New York — is the best all-around mil-spec packaging supplier. Edco manufactures a wide range of packaging types to fit various military standards, so you can likely find a solution that works regardless of your product type or size. It’s also been in business for over 60 years, giving it extensive experience serving diverse needs.

In addition to packaging and materials, Edco sells mil-spec tapes and adhesives to keep product containers sealed. The company accepts custom orders, too, further expanding the variety of end uses it can support. An in-depth blog explaining key mil-spec concepts and available customer support team provide additional help for those new to the industry.

2. Quality Support, LLC

Consider Quality Support, LLC, for your mil-spec packaging supplier if you need wooden crates. This provider specializes in custom lumber products, which are ideal for shipping large equipment or particularly heavy or sensitive items. As a bespoke manufacturer, Quality Support also offers design services to help you create the best package possible.

While it has an inventory of ready-made packaging for smaller runs or non-niche needs, Quality Support’s best asset is its custom work. Its personalized solutions span all manners of boxes, bags and insulation. Beyond adhering to military specifications, Quality Support is NIST SP 800-171 compliant, which some Department of Defense contractors need from their suppliers due to new cybersecurity regulations.

3. IMPAK Corporation

Los Angeles-based IMPAK Corporation is another of the best mil-spec packaging suppliers in the U.S. While Quality Support focuses on rigid crates, IMPAK’s specialty is flexible packaging, making it a good fit for smaller products or anti-static insulation. Its bag and pouch selection is among the most varied lineups available, and the company performs custom work, too.

IMPAK’s complementary capabilities are some of its strongest benefits. The company sells an impressive range of desiccants, oxygen absorbers and sealing technologies and will even service this equipment. IMPAK will also test products for strength, sterility, moisture resistance and more to give you confidence in your packaging designs.

4. MAC Packaging

With decades in the industry, MAC Packaging is one of the more experienced suppliers on this list. It has become a national leader in mil-spec packaging, even offering consulting services for companies wanting to learn more about the industry. It’s also unique in that it solely works in custom jobs.

In addition to packaging, MAC manufactures RFID tags to military standards. These solutions make your products easier for clients to track through their warehouses and can streamline your own logistics processes. The brand will also file all related paperwork at no extra cost.

5. ProtoPak Engineering Corporation

Another long-standing firm in this sector is ProtoPak Engineering Corporation, which has provided mil-spec packaging since 1967. ProtoPak’s product range boasts impressive variety and even offers custom shipping platforms to meet your bulk order needs. Perhaps most impressively, the company has a 100% accuracy record.

ProtoPak also offers warehousing and logistics services to streamline supply chain operations in businesses that don’t have enough internal capacity. Its expert team can help you design personalized solutions and ensure your workflows are efficient to deliver the highest quality to your clients.

How to Choose a Mil-Spec Packaging Supplier

The best mil-spec packaging supplier depends on your needs and the clientele you serve. However, there are a few general signs to look for when identifying a reliable provider.

Adherence to mil-spec guidelines is an obvious factor, but related regulatory requirements are also worth consideration. For example, the Cybersecurity Maturity Model Certification requires compliance with NIST SP 800-171 for some contractors, necessitating these standards from your supply chain partners. Other standards like the Food Safety Modernization Act or ISO 27001 may introduce unique needs, too.

When choosing between certified partners, consider the kinds of packaging you need. Many of the best suppliers offer multiple packaging types, but not every company manufactures every product type. Consequently, you must determine if bags, cartons, crates or other solutions suit your shipments the best before deciding on a supplier.

A business’s complementary services and support options are also worth consideration. The ability to customize packaging or buy related products like humidity indicators or mil-spec sealers may significantly streamline your operations. Similarly, a partner offering greater support and information will be easier to work with, especially when unexpected challenges arise.

Finally, look for signs of transparency and reliability from packaging suppliers. Over half of all organizations report that procurement fraud is a major issue in their area. Such risks are damaging in any sector but all the weightier in a military context. Given these concerns, you should only work with firms that have thorough documentation on their mil-spec compliance.

The Best Mil-Spec Packaging Suppliers Compared

Any of the five mil-spec packaging companies on this list can be a worthy partner. Here is how these providers compare along a few key categories.SupplierPackaging typesAdditional capabilitiesSupport optionsEdco Supply CorporationCartons, bags, static shielding, desiccants, barrier films, wrapping, cloth paper, tubingCustom orders, humidity indicators, tapes and sealers, labelsDedicated customer support line, email, industry blogQuality Support, LLCCrates, cartons, bags static shieldingCustom orders, die-cut foam insulators, design services, NIST SP 800-171 complianceDedicated customer support line, emailIMPAK CorporationBags, static shielding, desiccantsCustom orders, prototyping, oxygen absorbers, sealers, labels, sealer repairs, product testingDedicated customer support line, emailMAC PackagingCartons, bags, static shielding, barrier films, wrappingCustom orders, prototyping, humidity indicators labels, RFID tags, paperwork servicesConsulting services, dedicated customer support line, email, industry blogProtoPak Engineering CorporationCrates, cartons, bags, static shielding, desiccants, barrier films, wrappingCustom orders, labels, RFID tags, shipping platforms, supply chain solutionsConsulting services, dedicated customer support line, email

Choose the Best Mil-Spec Packaging Supplier for Your Products

When you partner with the best mil-spec packaging suppliers, you can uphold higher quality and compliance standards without sacrificing efficiency or flexibility. Any business selling to military agencies or contractors must abide by these requirements. Start your compliance journey by finding the right mil-spec packaging provider for your needs.

#mil-spec packaging#military packaging suppliers#pharma packaging business#biopharma packaging#glass pharmaceutical packaging#defense packaging

2 notes

·

View notes

Text

RFID Inventory Tracking Systems

RFID (Radio-Frequency Identification) inventory tracking systems have revolutionized the way businesses manage their stock. These systems use RFID tags and readers to provide real-time visibility of inventory, reducing manual errors and improving accuracy. They are efficient in preventing loss and enhancing supply chain operations by streamlining order processes and reducing stockouts. Businesses that implement RFID inventory tracking systems gain a competitive advantage, as they offer a seamless, error-free inventory management solution that is essential for success in today's fast-paced retail and logistics environments.

0 notes

Text

Implementing an RFID library management system can revolutionize how libraries operate, offering efficiency, accuracy, and convenience for both librarians and patrons. Here's a breakdown of the components and benefits of such a system:

Components of an RFID Library Management System:

RFID Tags: Each book is affixed with an RFID tag containing unique identification information.

RFID Readers: Installed at strategic locations such as entrance/exit gates, self-checkout stations, and shelves, RFID readers communicate with the tags wirelessly.

Database Management System: Stores information about each book, including its title, author, location, and status (e.g., available, checked out).

Software Interface: Provides a user-friendly interface for librarians to manage the system, including adding new books, updating records, and generating reports. It also includes a front-end for patrons to easily check out and return books.

Security System: Integrates with the RFID system to detect unauthorized removal of library materials.

Benefits of RFID Library Management Systems:

Automation: RFID systems automate many tasks, reducing the manual workload for librarians. This includes inventory management, self-checkout, and security monitoring.

Efficiency: With RFID technology, multiple books can be scanned simultaneously, drastically reducing the time needed for tasks like inventorying shelves or checking out multiple items.

Accuracy: RFID systems are highly accurate in identifying and tracking items. This reduces errors in inventory management and ensures that books are properly checked out and returned.

Improved Patron Experience: Self-checkout stations and faster checkout processes enhance the overall experience for library patrons, reducing waiting times and improving satisfaction.

Enhanced Security: RFID tags can be integrated with security gates to prevent theft. If a book hasn't been properly checked out, the system can trigger an alarm when it passes through the gate.

Data Insights: The system collects data on book circulation, popular titles, and patron behavior. Librarians can use this information to make informed decisions about collection development and resource allocation.

Accessibility: RFID systems can be integrated with accessibility features such as audio instructions and tactile interfaces, making the library more inclusive for patrons with disabilities.

Remote Management: Librarians can access the system remotely, allowing them to perform tasks such as inventory management or generating reports from anywhere with an internet connection.

Overall, implementing an RFID library management system can streamline operations, improve accuracy, and enhance the overall library experience for both staff and patrons.

For more details visit: https://www.libsys.co.in/ or write @ [email protected] or +911244894100

#rfid solutions#rfid technology#rfid tags#rfid reader#rfid protector#tracking software#library#library management system#the smartarts library#public libraries#library automation#inventory software#inventorymanagement#inventory management#stock management software

1 note

·

View note

Text

The Need for Digitization in Manufacturing : Stay Competitive With Low-Code

Industry 4.0 is transforming manufacturing with smart factories, automation, and digital integration. Technologies like the Internet of Things (IoT), artificial intelligence (AI), and low-code applications are enabling manufacturers to streamline processes and develop customized solutions quickly. Low-code platforms empower manufacturers to adapt to global demands, driving efficiency and innovation.

Previously, cross-border transactions in manufacturing faced delays due to bureaucracy, complex payment mechanisms, and inconsistent regulations. These challenges led to inefficiency and increased costs. However, Industry 4.0 technologies, such as digital payments, smart contracts, and logistics tracking, have simplified international transactions, improving procurement processes.

Low-code applications are key in this transformation, enabling rapid development of secure solutions for payments, customs clearance, and regulatory compliance. These platforms reduce complexity, enhance transparency, and ensure cost-effective, secure global supply chains. This shift aligns with the demands of a connected global economy, enhancing productivity and competitiveness.

The Need for Digitization in Manufacturing

Digitization has become crucial for manufacturing to stay competitive, with new technologies and the need for automation driving the sector’s transformation. Key features include ERP systems for centralized management of inventory, finances, and operations; digital supply chain tools for visibility and disruption prediction; real-time data for performance monitoring; sustainability tracking; and IoT/RFID for better tracking, accuracy, and reduced waste.

Low-code applications play a pivotal role in digitization by enabling rapid development of tailored solutions for inventory management, supply chain optimization, and performance analytics. These platforms streamline processes, reduce manual work, and enhance agility, helping manufacturers implement digital transformations quickly and cost-effectively.

Upgrading Manufacturing Capabilities in the Era of Industry 4.0 with Low-code Solutions

Low-code applications are becoming essential for digital transformation in manufacturing, addressing operational challenges while managing increased production demands and a shortage of skilled staff. These platforms enable manufacturers to quickly develop tailored applications without needing specialized coding expertise, fostering faster, more flexible operations. By streamlining processes and aligning with modern consumer demands, low-code technology helps bridge the skills gap, empowering manufacturers to stay competitive and seize new opportunities in a rapidly evolving market.

Low-code Technology Benefits for Modern Industries

As digital transformation becomes increasingly crucial for manufacturing, many enterprises in the sector face challenges with outdated processes, legacy system limitations, customization challenges, and inadequate resources. Low-code applications offer a compelling solution, enabling manufacturers to streamline operations by eliminating paper-based processes and automating workflows across functions such as Production, Sales, Logistics, Finance, Procurement, Quality Assurance, Human Resources, Supply Chain, and IT Operations. Additionally, low-code platforms enhance compliance and safety standards through built-in automated tools.

These platforms deliver impressive results, including over 70% improvement in productivity and close to 95% improvement in output quality in specific scenarios. This is particularly evident in automating complex processes like order fulfillment—from receiving customer orders to delivering finished products and managing invoicing with customers. Use cases also include automating inventory management, enhancing predictive maintenance with real-time data, and optimizing supply chain operations. Low-code solutions make it easier for manufacturers to implement changes quickly, boosting agility and reducing time-to-market while improving overall operational efficiency.

Conclusion

Low-code platforms are driving digital transformation in manufacturing, addressing sector-specific challenges in industries like automotive, aviation, and oil & gas. With Industry 4.0 and smart manufacturing, iLeap’s low-code platform helps integrate IoT, advanced analytics, and end-to-end automation, leading to optimized workflows and real-time decision-making. By adopting agile development, manufacturers can quickly adapt to new technologies and market demands, making iLeap the ideal partner for digital transformation. Unlock the potential of Industry 4.0 with iLeap and turn challenges into growth opportunities.

3 notes

·

View notes

Text

From Beverages to Beauty: How Stretch Sleeve & Shrink Sleeve Labels Are Taking Over Every Industry

Rising Dominance of Stretch Sleeve And Shrink Sleeve Labels Market

The global stretch sleeve and shrink sleeve labels market is entering a transformative era marked by innovation, sustainability, and digitalization. With projections estimating the stretch sleeve and shrink sleeve labels marketto reach USD 25.6 billion by 2032, driven by a 7.1% CAGR, this evolution is fueled by technological breakthroughs and heightened regulatory scrutiny.

The labeling sector now demands 360-degree branding, tamper-evident features, smart packaging integration, and eco-conscious materials. As industries recalibrate to consumer expectations and environmental commitments, shrink and stretch sleeves emerge as the definitive solution for modern packaging.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40652-global-stretch-sleeve-shrink-sleeve-labels-market

Strategic Trends Fueling Market Acceleration

1. Advanced Sustainable Materials for Regulatory Compliance

The shift away from PVC toward PETG, PLA, and polyolefin-based shrink films is reshaping the labeling material landscape. These high-performance alternatives offer excellent clarity, superior shrinkability, and recyclability, making them ideal for high-shrink contour packaging applications.

PETG leads with 42.9% market share, offering a unique balance between functionality and sustainability.

Bio-based and biodegradable films are witnessing the fastest CAGR at 9.2%, as industries align with ESG mandates and plastic reduction frameworks.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40652-global-stretch-sleeve-shrink-sleeve-labels-market

2. Digital Printing Revolutionizing Personalization and Efficiency

As short-run, high-resolution packaging becomes essential, digital printing now stands at the frontier of custom labeling. With a projected CAGR of 8.5%, digital presses allow brands to launch limited editions, personalized campaigns, and regional SKU adaptations at unprecedented speed.

Digital watermarks, variable data printing, and QR-integrated storytelling now turn packaging into an interactive, data-rich engagement point.

3. Smart Labels and RFID-Enabled Authentication Systems

Innovations such as RFID integration, blockchain-verified authenticity, and augmented reality (AR) are being actively deployed in stretch and shrink sleeve formats. These smart features protect brands from counterfeiting, support supply chain transparency, and improve inventory management.

4. Eco-Design Integration and Solvent-Free Manufacturing

In pursuit of circularity, label manufacturers are adopting:

Solvent-free adhesives to reduce VOC emissions

Lightweight film substrates to minimize transport emissions

Mono-material sleeves to facilitate recycling compatibility

Stretch sleeves, which require no adhesives or heat, are increasingly preferred in closed-loop recycling systems, further propelling their relevance in low-carbon packaging strategies.

Segmental Stretch Sleeve And Shrink Sleeve Labels Market Insights

Stretch Sleeve And Shrink Sleeve Labels Market By Label Type

Shrink Sleeve Labels: Maintain 76.3% dominance, excelling in full-body coverage, product protection, and flexibility for complex geometries.

Stretch Sleeve Labels: Expand steadily at 5.8% CAGR, leveraging cost-efficiency and recyclability without requiring heat or adhesives.

Stretch Sleeve And Shrink Sleeve Labels Market By Material

Polyvinyl Chloride (PVC)

Polyethylene Terephthalate Glycol (PETG)

Polypropylene (PP) & Polyethylene (PE)

Polylactic Acid (PLA)

Biodegradable & Eco-friendly Materials

Others

Stretch Sleeve And Shrink Sleeve Labels Market By Printing Technology

Gravure Printing: Holds 39.8% share due to rich visuals, suited for large volumes.

Digital Printing: Fastest growth at 8.5% CAGR, enabling real-time brand responsiveness.

Stretch Sleeve And Shrink Sleeve Labels Market By Labeling Process

Shrink Tunnel: Dominates with 51.4% share, preferred for pharmaceuticals and beverages due to speed and reliability.

Roll-fed: Valued in mass production environments for its efficiency and cost control.

Stretch Sleeve And Shrink Sleeve Labels Market By Application

Food & Beverage: Commands 54.7% of the market, driven by visual appeal and regulatory compliance.

Pharmaceuticals: Rising at 8.2% CAGR, increasingly adopting tamper-evident smart sleeves for safety and authentication.

Personal Care: Benefits from shrink films’ premium finish and product fit for complex bottle shapes.

Stretch Sleeve And Shrink Sleeve Labels Market By Region

North America: Leads with 37.6%, shaped by robust FMCG presence and early tech adoption.

Asia-Pacific: Fastest growth at 8.4% CAGR, underpinned by rapid urbanization, digitization, and e-commerce.

Europe: Prioritizing eco-design and regulatory compliance, maintaining a 29.4% market share.

Competitive Landscape and Innovation Frontier

Key Stretch Sleeve And Shrink Sleeve Labels Market Players Shaping the Industry

Berry Global Inc.: Sustainability leadership through circular packaging programs

CCL Industries Inc.: Expansion via acquisitions in Europe; leading in premium segments

Amcor plc: Pioneer in recyclable high-shrink PET sleeves

Fuji Seal International Inc.: Innovator in AR-integrated smart packaging

Huhtamaki Oyj, Bonset America, and Taghleef Industries: Driving material science advancement and solvent-free printing innovations

Recent Stretch Sleeve And Shrink Sleeve Labels Market Strategic Moves

July 2023: Amcor launched PET shrink sleeves with improved recyclability.

Sept 2024: CCL acquired a European firm to bolster beverage/pharma shrink sleeve capacity.

Feb 2024: Fuji Seal introduced digital watermark-enabled sleeves to elevate traceability and engagement.

Emerging Technologies Defining the Next Decade

Hybrid Printing Systems: Merging gravure's quality with digital’s agility

Smart Augmented Reality Labels: Enabling immersive storytelling directly on packaging

Circular Label Design: Developing sleeves that detach cleanly during bottle recycling

Biopolymer Innovation: New PLA and cellulose derivatives with enhanced shrink properties

Outlook to 2032: The Future of Labeling

Stretch sleeve and shrink sleeve labels market are no longer mere packaging components—they are strategic tools for branding, compliance, and consumer engagement. The convergence of sustainability, digitization, and automation places sleeve labels at the core of next-generation packaging solutions.

Stakeholders investing in green chemistry, smart labeling, and high-speed customization will define leadership in this sector. With smart packaging mandates, plastic bans, and evolving consumer preferences, the market trajectory remains robust.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40652-global-stretch-sleeve-shrink-sleeve-labels-market

Conclusion

To win in the stretch sleeve and shrink sleeve labels market, manufacturers must go beyond print quality—they must innovate across materials, technology, sustainability, and consumer interaction. The years ahead will be defined by the agility to adapt, the foresight to invest in sustainable infrastructure, and the capability to tell compelling product stories directly through packaging.

As demand surges across global industries—from beverages to biotech—the stretch sleeve and shrink sleeve label segment will remain a vital, ever-evolving force in shaping the future of intelligent, compliant, and high-impact packaging.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Physical Verification of Fixed Assets: Why Your Business Needs It

Introduction In the world of business, fixed assets—like machinery, buildings, and equipment—are fundamental to operations and profitability. However, without proper management and regular verification, businesses can lose track of these valuable resources. Physical verification of fixed assets is a critical process to ensure that a company’s assets are accurately recorded and maintained. In this article, we’ll delve into why physical verification of fixed assets is essential and how MAS LLP offers a streamlined approach to safeguarding these vital resources.

What is Physical Verification of Fixed Assets? Physical verification of fixed assets is a systematic process of counting and verifying a company's tangible assets to confirm their presence, condition, and alignment with accounting records. This process helps ensure assets are accounted for, thereby minimizing risks of asset misappropriation, losses, or unexpected depreciation.

Key Components of Physical Verification Inventory Count: Ensuring that all assets, big or small, are physically located and accounted for. Condition Assessment: Reviewing the status and usability of assets to determine if they need maintenance, repair, or replacement. Compliance Check: Ensuring that the asset register aligns with financial statements and legal regulations. Tagging & Labeling: Using asset tags or barcodes for easy tracking and future verification. Why Physical Verification is Essential for Businesses

Improved Financial Accuracy An accurate inventory of fixed assets ensures that the company's financial statements reflect true value. By confirming asset existence and condition, physical verification helps in producing precise data for depreciation, amortization, and insurance claims.

Asset Utilization Optimization Physical verification helps identify underutilized or idle assets, providing opportunities to redeploy them where needed. This leads to optimized resource allocation, potentially saving costs by maximizing the productivity of existing assets.

Enhanced Security and Fraud Prevention Unauthorized use, theft, or misappropriation of assets can have significant financial consequences. Regular verification protects businesses by preventing fraudulent practices and ensuring that each asset is appropriately safeguarded.

Accurate Tax Reporting Fixed assets have tax implications, especially in terms of depreciation. Accurate records enable businesses to file correct depreciation values, avoid tax penalties, and ensure compliance with local tax laws.

Supporting Business Valuation For businesses seeking investments or mergers, a well-documented and verified list of fixed assets enhances business valuation. A clean asset register is a positive indicator for potential investors, showing operational control and value transparency.

Physical Verification with MAS LLP At MAS LLP, we provide comprehensive physical verification of fixed assets services, tailored to meet your company’s unique requirements. Our process is designed to deliver accuracy, transparency, and peace of mind. Here’s how we can help:

Detailed Asset Inventory Creation Our team conducts an in-depth assessment to create an exhaustive inventory list that aligns with your company’s financial records. We account for every asset to ensure you have a clear picture of your holdings.

Customized Verification Plans MAS LLP works with clients to develop verification schedules suited to the size and nature of the business. Whether it’s annual, semi-annual, or periodic checks, we customize our approach to your operational needs.

State-of-the-Art Tracking Technology We leverage advanced tracking solutions, such as barcode tagging and RFID, to simplify the asset verification process and minimize errors. This enhances the traceability and management of assets, especially for larger organizations.

Condition and Compliance Reporting Our experts assess the physical state of assets and generate detailed reports on their condition. We also ensure compliance with relevant regulations, maintaining an accurate record of all assets in your register.

Seamless Integration with Financial Statements Once verification is complete, we update the asset register and integrate findings with your financial statements. This ensures consistency across your asset records, accounting books, and tax documents, giving you a precise and compliant asset overview.

Why Choose MAS LLP? When it comes to managing your fixed assets, MAS LLP’s expertise in physical verification of fixed assets helps you minimize risk and maximize control. With a team of seasoned professionals, we have the resources, technology, and industry knowledge to provide you with a comprehensive asset verification solution.

Benefits of Working with MAS LLP Unmatched Accuracy: Our rigorous processes ensure asset records are accurate and up-to-date. Cost-Efficiency: We help you avoid over-investment by identifying and redistributing idle assets. Compliance Assurance: Stay compliant with regulatory requirements through verified asset data. Transparent Reporting: Receive detailed, actionable reports for informed decision-making. Conclusion The physical verification of fixed assets is an indispensable aspect of asset management that safeguards your company’s resources, supports financial accuracy, and boosts compliance. With MAS LLP, businesses can gain confidence in the integrity of their asset records and optimize asset utilization for long-term success. Reach out to MAS LLP today to learn more about how we can assist you in managing your fixed assets effectively.

#accounting & bookkeeping services in india#audit#businessregistration#chartered accountant#foreign companies registration in india#income tax#auditor#taxation#ap management services

6 notes

·

View notes