#stock management software

Explore tagged Tumblr posts

Text

Then it’s real…

#Then it’s real…#pirates of the caribbean#pirates of the caribbean meme#memes#meme#taxes#tax#stocks#stock market#stock trading#investing stocks#stock#wall street#wall streeet journal#wall st#wall st.#stock management software#capitalism#exploitation#exploitative#ausgov#politas#auspol#tasgov#taspol#australia#fuck neoliberals#neoliberal capitalism#anthony albanese#albanese government

21 notes

·

View notes

Text

BHisab Online Accounting Billing Inventory Management Pos Software

BHisab Online Accounting Billing Inventory Management Pos Software - Purchase, Sales, stock management software, Billing Software, small business inventory software

youtube

Our Service

Domain Registration

Web Hosting

Web Development

Software Development

Bulk SMS

Our Software List :

1. Amar Hisab Bangla Accounting Soft2. Bhisab Accounting & Billing Soft3. Bhisab Soft Demo4. Pharmacy Accounting Soft5. Brick Field Management Soft6. Dealership Management Soft7. ISP & Cable Networking Management Soft8. NGO Management Soft9. Student (School & Coaching) Management Soft10. Bike Showroom Management Soft11. Mobile Showroom Management Soft

Contact With Us :

☎ +88 02 477 727 285 📱 +88 01996 702370-75

📧 [email protected], Skype : Palash.hossain4

Facebook Page : www.facebook.com/softhostit

Web : www.softhostit.com / www.bhisab.com / www.amarhisab.com

#BHisab Online Accounting Billing Inventory Management Pos Software - Purchase#Sales#stock management software#Billing Software#small business inventory software#Youtube

2 notes

·

View notes

Text

ERP for Control Panel Manufacturers: Streamline Operations and Boost Efficiency

In the competitive world of control panel manufacturing, operational efficiency, precision, and meeting delivery timelines are crucial for success. Manufacturers face numerous challenges, from managing complex Bills of Materials (BOMs) to coordinating design, production, and delivery. This is where Enterprise Resource Planning (ERP) systems come into play, revolutionizing the way control panel manufacturers operate.

An ERP for control panel manufacturers integrates all aspects of your business—design, production, inventory, sales, and finance—into a unified system. This blog explores how ERP solutions address industry-specific challenges and why investing in ERP software is essential for staying ahead in the market.

Challenges Faced by Control Panel Manufacturers

Control panel manufacturing is a niche industry with unique challenges:

Complex BOM Management: Each panel may require hundreds of components, making manual management prone to errors.

Frequent Design Revisions: Engineering changes can disrupt production schedules if not communicated effectively.

Inventory Control: Overstocking or understocking components can result in financial losses or production delays.

Strict Quality Standards: Ensuring compliance with industry standards and client specifications is non-negotiable.

Customer Deadlines: Meeting delivery timelines while maintaining quality is critical for customer satisfaction.

How ERP Systems Address These Challenges

An ERP system for control panel manufacturers is designed to overcome these challenges through automation, integration, and real-time data access. Here’s how it helps:

1. Efficient BOM Management

ERP software enables manufacturers to create, store, and manage BOMs efficiently. It automatically tracks component requirements and updates inventory levels based on BOM data, ensuring accuracy and reducing waste.

2. Seamless Design Integration

Modern ERP systems integrate with CAD software, allowing seamless synchronization of design changes with production schedules. Sales and engineering teams can collaborate effectively, ensuring that client specifications are met without delays.

3. Real-Time Inventory Tracking

With ERP, manufacturers gain real-time visibility into inventory levels, component availability, and procurement timelines. This prevents overstocking, understocking, and production delays, optimizing cash flow and operational efficiency.

4. Enhanced Production Scheduling

ERP systems streamline production scheduling by analyzing resource availability, order priorities, and deadlines. This ensures optimal resource utilization and on-time delivery of projects.

5. Quality Assurance and Compliance

An ERP for control panel manufacturing includes quality control modules that help ensure compliance with industry standards. Automated checks and documentation simplify the process of meeting certifications and regulatory requirements.

6. Improved Customer Relationship Management (CRM)

ERP systems often include CRM modules to track customer interactions, manage orders, and provide real-time updates. This enhances customer satisfaction and fosters long-term relationships.

Key Features of an ERP for Control Panel Manufacturers

1. Industry-Specific Customization

ERP systems tailored for control panel manufacturers include modules for BOM management, engineering change orders, and project tracking.

2. Integration with CAD and Design Tools

Seamless integration with CAD software ensures that design changes are automatically reflected in production plans.

3. Scalable Solutions

ERP software grows with your business, accommodating increased production volumes, new product lines, and additional users.

4. Comprehensive Reporting and Analytics

Real-time reporting helps manufacturers analyze production metrics, inventory levels, and financial performance to make data-driven decisions.

Benefits of Implementing ERP in Control Panel Manufacturing

1. Increased Efficiency

By automating routine tasks, ERP reduces manual work and eliminates errors, allowing teams to focus on strategic activities.

2. Cost Savings

Optimized inventory management and reduced wastage translate to significant cost savings over time.

3. Faster Turnaround Times

With streamlined workflows and real-time updates, manufacturers can meet customer deadlines with ease.

4. Better Decision-Making

Access to accurate, real-time data empowers manufacturers to make informed decisions that drive growth and profitability.

5. Enhanced Collaboration

ERP fosters collaboration across departments, ensuring everyone has access to the same data and working toward common goals.

Why Choose ERP for Control Panel Manufacturers?

Investing in an ERP system tailored for control panel manufacturing is not just a technology upgrade—it’s a strategic move that aligns your business with industry best practices. By improving operational efficiency, ensuring compliance, and enhancing customer satisfaction, ERP systems position manufacturers for long-term success.

Top ERP Systems for Control Panel Manufacturers

Some popular ERP solutions in the industry include:

SAP Business One: Known for its scalability and robust features for small to medium-sized businesses.

Oracle NetSuite: A cloud-based ERP with strong financial and inventory management capabilities.

QuotePlan ERP: Specifically designed for manufacturers, offering modules for BOM management, quoting, and production tracking.

Acumatica: A flexible and affordable ERP solution with advanced reporting features.

Conclusion

For control panel manufacturers, an ERP system is more than just software—it’s a competitive advantage. By automating processes, improving collaboration, and providing real-time insights, ERP systems help manufacturers overcome industry challenges and achieve their goals.

If you’re ready to take your control panel manufacturing business to the next level, now is the time to invest in a tailored ERP solution. Experience the difference it can make in transforming your operations and driving growth!

#product management system#project management software#inventory management software#stock management software#quotation management software

0 notes

Text

Difference Between POS Billing Software and CRM Software

Choosing the right software for your business is crucial for its success. If your goal is to build a wide audience base and foster customer interactions, CRM software might be the way to go. However, if you have a large company with multiple operations and want to target specific audiences, POS billing software is the best solution. It provides an all-in-one platform suitable for various industries, whether you’re a restaurant owner, small shopkeeper, automobile dealer, supermarket store owner, or running a pharmacy. POS software helps with faster invoice generation and an efficient billing process. For more information visit our website: https://shoppeez.com/ or contact us at: 8889911195

#billing software#online billing software#point of sale software#online store inventory management#pos solutions#point of sale#pos software#pos system#stock management software

0 notes

Text

5 Ways Operation Management Software Can Transform Your Business

Explore how operation management software can revolutionize your business in this informative infographic. Learn about the key benefits, including improved compliance, automation of tasks, enhanced customer relationships, better organizational standards, and robust data protection. This visual guide breaks down how the right software can streamline your operations, increase efficiency, and secure your data, helping your business stay ahead of the competition and foster stronger customer trust. Perfect for businesses looking to optimize their processes and boost overall performance!

#Operation management system#Operation management software#Stock management software#Small business inventory management#apeks solutions#wordpress inventory plugin

0 notes

Text

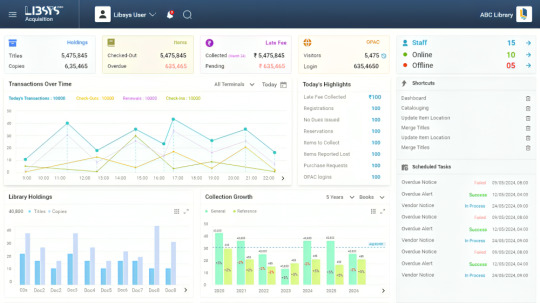

Implementing an RFID library management system can revolutionize how libraries operate, offering efficiency, accuracy, and convenience for both librarians and patrons. Here's a breakdown of the components and benefits of such a system:

Components of an RFID Library Management System:

RFID Tags: Each book is affixed with an RFID tag containing unique identification information.

RFID Readers: Installed at strategic locations such as entrance/exit gates, self-checkout stations, and shelves, RFID readers communicate with the tags wirelessly.

Database Management System: Stores information about each book, including its title, author, location, and status (e.g., available, checked out).

Software Interface: Provides a user-friendly interface for librarians to manage the system, including adding new books, updating records, and generating reports. It also includes a front-end for patrons to easily check out and return books.

Security System: Integrates with the RFID system to detect unauthorized removal of library materials.

Benefits of RFID Library Management Systems:

Automation: RFID systems automate many tasks, reducing the manual workload for librarians. This includes inventory management, self-checkout, and security monitoring.

Efficiency: With RFID technology, multiple books can be scanned simultaneously, drastically reducing the time needed for tasks like inventorying shelves or checking out multiple items.

Accuracy: RFID systems are highly accurate in identifying and tracking items. This reduces errors in inventory management and ensures that books are properly checked out and returned.

Improved Patron Experience: Self-checkout stations and faster checkout processes enhance the overall experience for library patrons, reducing waiting times and improving satisfaction.

Enhanced Security: RFID tags can be integrated with security gates to prevent theft. If a book hasn't been properly checked out, the system can trigger an alarm when it passes through the gate.

Data Insights: The system collects data on book circulation, popular titles, and patron behavior. Librarians can use this information to make informed decisions about collection development and resource allocation.

Accessibility: RFID systems can be integrated with accessibility features such as audio instructions and tactile interfaces, making the library more inclusive for patrons with disabilities.

Remote Management: Librarians can access the system remotely, allowing them to perform tasks such as inventory management or generating reports from anywhere with an internet connection.

Overall, implementing an RFID library management system can streamline operations, improve accuracy, and enhance the overall library experience for both staff and patrons.

For more details visit: https://www.libsys.co.in/ or write @ [email protected] or +911244894100

#rfid solutions#rfid technology#rfid tags#rfid reader#rfid protector#tracking software#library#library management system#the smartarts library#public libraries#library automation#inventory software#inventorymanagement#inventory management#stock management software

1 note

·

View note

Text

Optimizing Logistics: The Role of Transportation Management

In the intricate web of modern supply chain management, efficient transportation, demand forecasting, and stock management are critical pillars for ensuring smooth operations and meeting customer demands. Transportation Management Systems (TMS), Demand Planning Software, and Stock Management Software play vital roles in optimizing these processes and driving business success. Let's explore the significance of each software solution and how they contribute to operational excellence.

1. Transportation Management System (TMS):

A Transportation Management System (TMS) is a software platform designed to streamline and optimize the planning, execution, and monitoring of transportation activities in a supply chain. TMS facilitates the efficient movement of goods from origin to destination by automating tasks such as route planning, carrier selection, freight rate negotiation, shipment tracking, and performance analytics. By leveraging TMS, businesses can reduce transportation costs, improve delivery reliability, and enhance overall supply chain visibility.

2. Demand Planning Software:

Demand Planning Software is a tool used to forecast future demand for products or services based on historical data, market trends, and other relevant factors. Demand planning helps businesses anticipate customer demand accurately, align inventory levels accordingly, and optimize production and procurement activities. By leveraging demand planning software, organizations can minimize stockouts, reduce excess inventory, and improve customer satisfaction by ensuring product availability when and where it is needed.

3. Stock Management Software:

Stock Management Software, also known as Inventory Management Software, is a solution used to track, manage, and control inventory levels across warehouses and distribution centers. Stock management software provides real-time visibility into inventory levels, locations, and movements, enabling businesses to optimize stock replenishment, minimize stockouts, and prevent overstocking. By implementing stock management software, organizations can improve inventory accuracy, reduce carrying costs, and optimize working capital utilization.

Integration and Synergy:

While each software solution serves a specific function, they are interconnected and work together to optimize logistics and supply chain operations. Integration between Transportation Management, Demand Planning, and Stock Management Software enables seamless data exchange and coordination across the supply chain. For example, demand forecasts generated by demand planning software can be used to optimize transportation planning and stock replenishment decisions, ensuring that the right products are available at the right time and place.

Conclusion:

In conclusion, Transportation Management, Demand Planning, and Stock Management Software are indispensable tools for modern supply chain management. By leveraging the capabilities of these software solutions, businesses can enhance operational efficiency, reduce costs, and improve customer satisfaction. Investing in robust and integrated software solutions not only enables organizations to navigate the complexities of today's global supply chains but also positions them for long-term success and competitiveness in the marketplace.

For original post :- https://blognow.co.in/optimizing-logistics-the-role-of-transportation-management

0 notes

Text

Order Management Software vs. Stock Management Software: Making the Right Choice

In the fast-paced world of retail and e-commerce, managing orders and stock efficiently is crucial for success. Two key players in this arena are Order Management Software and Stock Management Software. In this blog post, we'll delve into the differences and similarities between these two software solutions and help you make an informed choice for your business. We'll also touch on the importance of Warehouse Inventory Management Software in streamlining your operations.

Understanding Order Management Software

Order Management Software is a vital component of any retail or e-commerce business. It's designed to handle the entire order lifecycle, from order creation to order fulfillment and tracking. This type of software typically includes features like order processing, inventory management, and customer order tracking. It's your go-to tool for managing incoming orders and ensuring they are processed accurately and on time.

Key Features of Order Management Software:

Order Processing: This feature allows you to receive, verify, and process customer orders efficiently.

Inventory Management: It helps you keep track of your available stock and ensures that you never oversell or run out of products.

Customer Order Tracking: You can monitor the status of each order and provide real-time updates to your customers.

Exploring Stock Management Software

On the other hand, Stock Management Software is primarily focused on the control and optimization of your inventory. It provides detailed insights into your stock levels, helps you forecast demand, and ensures that your warehouse remains well-organized. This software is particularly valuable for businesses dealing with physical products and large inventories.

Key Features of Stock Management Software:

Inventory Tracking: It allows you to keep a close eye on your stock levels, helping you avoid overstocking or understocking.

Demand Forecasting: You can use historical data and trends to make informed decisions about replenishing stock.

Warehouse Organization: This feature helps you arrange your inventory for maximum efficiency, reducing the time it takes to pick and pack orders.

Order Management Software vs. Stock Management Software: What Sets Them Apart?

While Order Management Software and Stock Management Software may seem similar at first glance, they serve different purposes within your business. Here are the key distinctions:

Focus: Order Management Software is primarily focused on the order lifecycle, while Stock Management Software revolves around inventory control.

Functionality: Order Management Software handles everything related to customer orders, from processing to shipping, while Stock Management Software concentrates on keeping your inventory in check.

Integration: They can often be integrated for a comprehensive solution, with Order Management Software feeding order data into Stock Management Software to ensure accurate stock levels.

Customization: Order Management Software may be more customizable to cater to specific order workflows, while Stock Management Software focuses on optimizing stock and inventory flow.

The Role of Warehouse Inventory Management Software

To bridge the gap between Order Management Software and Stock Management Software, Warehouse Inventory Management Software plays a pivotal role. This software brings together the functions of tracking orders and monitoring stock levels. It ensures that your inventory is accurate and up to date, allowing you to fulfil orders promptly and with precision.

Key Features of Warehouse Inventory Management Software:

Real-time Updates: You receive instant updates on stock levels and order status, promoting better decision-making.

Efficient Fulfillment: Warehouse Inventory Management Software streamlines your order fulfilment process, reducing errors and improving customer satisfaction.

Reporting and Analytics: This software provides insights into your warehouse's performance, helping you identify areas for improvement.

Conclusion

In the dynamic world of retail and e-commerce, choosing between Order Management Software and Stock Management Software is a matter of understanding your business's specific needs. If your primary concern is order processing, customer tracking, and ensuring timely deliveries, Order Management Software is your best choice. On the other hand, if you are more focused on optimizing your inventory, forecasting demand, and maintaining a well-organized warehouse, Stock Management Software is the way to go.

To achieve the best of both worlds, consider integrating both types of software, and complement your operations with Warehouse Inventory Management Software. By doing so, you'll have a comprehensive system that ensures efficient order processing, accurate stock management, and smooth warehouse operations. In the end, the right choice depends on your unique business requirements and goals, so choose wisely to boost your efficiency and delight your customers.

For original Post Content: - https://www.blogautoworld.com/order-management-software-vs-stock-management-software-making-the-right-choice/

0 notes

Text

BHisab Online Accounting Billing Inventory Management Pos Software

BHisab Online Accounting Billing Inventory Management Pos Software - Purchase, Sales, stock management software, Billing Software, small business inventory software

Product sales account... You will get a complete account of the sales of the product, how much money you sold the product to the buyer, how much pitch you sold, how much money the buyer has left Bills / Invoices, Invoices, Deposits, Expenses... B-Hisab software allows customer to create bill, invoice, invoice, deposit / expense voucher.

youtube

Our Service

Domain Registration

Web Hosting

Web Development

Software Development

Bulk SMS

Our Software List :

1. Amar Hisab Bangla Accounting Soft2. Bhisab Accounting & Billing Soft3. Bhisab Soft Demo4. Pharmacy Accounting Soft5. Brick Field Management Soft6. Dealership Management Soft7. ISP & Cable Networking Management Soft8. NGO Management Soft9. Student (School & Coaching) Management Soft10. Bike Showroom Management Soft11. Mobile Showroom Management Soft

Contact With Us :

☎ +88 02 477 727 285 📱 +88 01996 702370-75

📧 [email protected], Skype : Palash.hossain4

Facebook Page : www.facebook.com/softhostit

Web : www.softhostit.com / www.bhisab.com / www.amarhisab.com

#BHisab Online Accounting Billing Inventory Management Pos Software - Purchase#Sales#stock management software#Billing Software#small business inventory software#Youtube

2 notes

·

View notes

Text

Engineering Data Management Systems: A Game-Changer for Sales Engineers in Control Panel Manufacturing

In the control panel manufacturing industry, sales engineers play a critical role as the bridge between clients and production teams. Their ability to prepare accurate quotes, present technical specifications, and meet client requirements depends heavily on accessing and managing complex engineering data. However, the traditional methods of managing this data—spread across multiple documents, spreadsheets, and emails—can lead to inefficiencies, errors, and lost opportunities.

This is where Engineering Data Management Systems (EDMS) come into play, offering a transformative solution for sales engineers. In this blog, we’ll explore the challenges faced by sales engineers in control panel manufacturing and how an EDMS can act as a savior for their workflow.

Challenges Faced by Sales Engineers in Control Panel Manufacturing

Sales engineers in this industry encounter a unique set of challenges that stem from the complexity of their products and the dynamic nature of client requirements:

Fragmented Data: Engineering data such as BOMs (Bill of Materials), CAD drawings, technical specifications, and pricing details are often stored in multiple locations, making access cumbersome and time-consuming.

Frequent Design Changes: Changes in panel designs or client specifications during the sales process require frequent updates, leading to potential miscommunication and delays.

Error-Prone Manual Processes: Preparing quotes or technical proposals manually increases the risk of errors, which can result in financial losses or damaged client trust.

Time Pressure: Clients demand quick turnaround times for proposals and quotes, leaving little room for inefficiencies in data handling.

Collaboration Barriers: Sales engineers often struggle to collaborate effectively with design and production teams due to a lack of centralized data access.

These challenges highlight the pressing need for a robust solution that streamlines data access, enhances accuracy, and improves collaboration.

How Engineering Data Management Systems Help Sales Engineers

An Engineering Data Management System (EDMS) is specifically designed to address the complexities of managing engineering data in manufacturing. Here’s how it benefits sales engineers:

1. Centralized Data Access

An EDMS consolidates all engineering data—such as CAD drawings, BOMs, and technical specifications—into a single, easily accessible platform. Sales engineers can quickly retrieve the information they need, reducing the time spent searching across multiple sources.

Centralized data ensures that everyone is working with the most up-to-date information, minimizing discrepancies and errors during the sales process.

2. Real-Time Updates for Design Changes

With an EDMS, any changes made to panel designs or specifications are updated in real-time across the system. Sales engineers can immediately access these updates and adjust their quotes or proposals accordingly.

This capability ensures that clients receive accurate and relevant information, even when last-minute changes occur, enhancing client trust and satisfaction.

3. Automated Proposal and Quote Generation

Modern EDMS platforms often include tools to automate the generation of technical proposals and quotes. By pulling data directly from the system, these tools ensure that all calculations, materials, and specifications are accurate.

Automating this process not only saves time but also reduces the risk of costly errors, allowing sales engineers to focus on building strong client relationships.

4. Enhanced Collaboration Across Teams

An EDMS bridges the gap between sales, design, and production teams by providing a shared platform for data access and communication. Sales engineers can collaborate more effectively with design teams to ensure that client requirements are fully understood and incorporated into proposals.

This seamless collaboration leads to smoother project transitions from sales to production, reducing delays and improving overall efficiency.

5. Improved Client Responsiveness

With quick access to accurate data and automated tools for proposal generation, sales engineers can respond to client inquiries faster than ever. This improved responsiveness gives them a competitive edge, increasing the likelihood of securing projects.

Faster response times not only enhance client satisfaction but also position the manufacturer as a reliable and professional partner.

The Role of EDMS in the Future of Control Panel Manufacturing

As control panel manufacturing becomes increasingly complex, the role of sales engineers will continue to evolve. An EDMS is not just a tool for managing data; it’s a strategic investment that empowers sales engineers to excel in their roles. By improving efficiency, accuracy, and collaboration, an EDMS lays the foundation for long-term success in a competitive market.

Manufacturers that adopt an EDMS will be better positioned to handle the growing demands of their clients, maintain high standards of quality, and stay ahead of their competitors.

Conclusion

Engineering Data Management Systems��are more than just data storage solutions—they are essential tools for modern sales engineers in control panel manufacturing. By centralizing data, automating processes, and enhancing collaboration, an EDMS addresses the key pain points of sales engineers and enables them to work smarter, not harder.

If you’re looking to empower your sales engineers and streamline your operations, it’s time to invest in an EDMS. Experience the difference it can make in transforming your sales process and achieving greater success in control panel manufacturing.

Ready to revolutionize your workflow? Explore EDMS solutions tailored for your industry today!

#Project management software#Product Management System#stock management software#quotation management software

0 notes

Text

Mastering Inventory Control The Vital Role of Stock Taking Sheet

In the realm of inventory management, the stock taking sheet is an indispensable document that plays a pivotal role in ensuring the efficient operation of businesses, ranging from retail stores and warehouses to restaurants and manufacturing facilities. This simple yet powerful tool serves as the linchpin for accurately assessing and managing a company's stock levels.

0 notes

Text

Efficient Stock Management Software for FMCG Businesses | Rapidor

Discover Rapidor's cutting-edge Stock Management Software designed specifically for the fast-moving consumer goods (FMCG) industry. Streamline inventory control, reduce stockouts, and optimize your supply chain with our user-friendly software solution. Take control of your FMCG business with Rapidor's Stock Management Software today!

Visit https://www.rapidor.co/stock-management-software-in-fmcg/

1 note

·

View note

Text

youtube

#SutiIMS#inventory management#stock management software#warehouse management software#Inventory software#Youtube

0 notes

Text

The procurement process encompasses the entire cycle from identifying the need for materials to processing them into final products. AI tools play a crucial role in simplifying this process by assisting in finding the best suppliers, managing contracts, mitigating risks, and predicting staffing requirements and timelines for completion. For more information visit our website: https://shoppeez.com/ or contact us at: 8889911195

#billing software#online billing software#point of sale software#online store inventory management#stock management software#point of sale#pos system#pos software#pos solutions

0 notes

Text

Discover how to avoid inventory errors and streamline your operations with effective inventory tracking systems. Boost productivity with intelligent stock management solutions! Read our new blog to learn more.

0 notes

Video

tumblr

How to prevent loss in inventory management

Check out our blog>>

#accounting software#Inventory Management Software#stock management software#GST accounting software#gstindia#gst software#gstcouncil#accounting

0 notes