#Precision Investment Casting Company

Explore tagged Tumblr posts

Text

Selecting the best Precision Casting Company can be a difficult task as we have to consider many things. Find out 8 tips you can follow to make the best decision.

0 notes

Text

July 21, 2024 - Palestine Action activists have broken into two factories which are part of Elbit’s supply chain, causing extensive damage. One group invaded the premises of Manchester-based Dean Group International, and another broke into Ametek Airtechnology in Sunbury on Thames.

Dean Group International uses a specialised technique called “investment casting” to manufacture components for arms companies, including Elbit’s Kent-based subsidiary, Instro Precision. This was verified last month when activists broke into the latter factory.

Ametek Airtechnology specialises in thermal and motion control solutions for weapons including missiles, military vehicles and fighter jets — including Israeli F-35 fighter jets used to bomb in Gaza. Ametek’s subsidiary United Electronic Industries lists Elbit Systems as a “valued customer” – a connection which was also confirmed through sightings of deliveries to Elbit’s Shenstone-based subsidiary, UAV Engines Ltd.

A Palestine Action spokesperson said: “Without suppliers such as Dean Group International and Ametek, Elbit couldn’t make weaponry which is used to commit genocide. Whilst our government continues to facilitate Elbit’s crimes, Palestine Action will continue to use direct action to end the complicity and shut Elbit down”. [video]/[video]

#palestine action#drop elbit#ametek#dean group#direct action#solidarity#free palestine#palestine#vandalism#uk#sunbury on thames#manchester#video#2024#israel#genocide#factory

797 notes

·

View notes

Text

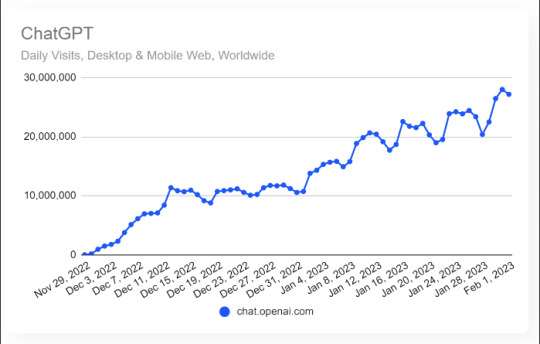

Unlocking Business Success: The Power of AI-Based Digital Marketing

Problem: As a business owner, you’re constantly striving to stay ahead of the curve and drive growth for your company. However, in today’s fast-paced digital landscape, achieving and maintaining a competitive edge can be a daunting task. Traditional marketing approaches often fall short in delivering the desired results, leaving many businesses struggling to reach their full potential.

Agitation: Are you tired of seeing your marketing efforts fall flat? Do you find yourself grappling with stagnant growth and limited visibility online? Are you ready to break free from the constraints of outdated strategies and propel your business towards unparalleled success?

In today’s digital age, where consumer behaviors and preferences are constantly evolving, businesses need a marketing approach that is agile, data-driven, and highly effective. AI-based digital marketing offers precisely that, empowering businesses to optimize their marketing strategies, enhance customer engagement, and maximize ROI.

Benefit 1: Enhanced Personalization

One of the key advantages of AI-based digital marketing is its ability to deliver highly personalized experiences to consumers. By leveraging advanced algorithms and machine learning techniques, businesses can analyze vast amounts of data to gain insights into consumer preferences, behaviors, and purchasing patterns. This allows them to tailor their marketing efforts accordingly, delivering targeted content and offers that resonate with individual customers on a deeper level.

Benefit 2: Improved Targeting and Segmentation

Gone are the days of casting a wide net and hoping for the best. With AI-based digital marketing, businesses can target their audience with unprecedented precision. By segmenting their target audience based on various factors such as demographics, interests, and browsing history, businesses can ensure that their marketing messages are delivered to the right people, at the right time, and through the right channels. This not only increases the effectiveness of their marketing campaigns but also minimizes wastage of resources on irrelevant audiences.

Benefit 3: Real-Time Insights and Optimization

In today’s fast-paced business environment, timely insights are invaluable. AI-based digital marketing provides businesses with real-time data and analytics, allowing them to monitor the performance of their campaigns, identify trends, and make data-driven decisions on the fly. Whether it’s adjusting ad creatives, refining targeting parameters, or optimizing website content, businesses can continuously fine-tune their marketing efforts to achieve maximum impact and ROI.

Benefit 4: Enhanced Customer Engagement and Retention

Benefit 5: Cost-Effectiveness and Efficiency

Contrary to popular belief, AI-based digital marketing doesn’t have to break the bank. In fact, it can be a highly cost-effective solution for businesses of all sizes. By automating repetitive tasks, streamlining processes, and optimizing resource allocation, AI-based digital marketing helps businesses maximize their marketing budget and achieve greater efficiency. This allows businesses to allocate their resources more strategically, focusing on activities that deliver the highest return on investment.

Ready to experience the transformative power of AI-based digital marketing for your business? Don’t miss out on this opportunity to take your marketing efforts to the next level and unlock unprecedented growth and success.

Sign up for our one-month free trial offer today and see the difference for yourself. Our team of experts will work with you to tailor a customized AI-based digital marketing strategy that aligns with your business goals and objectives. With our proven track record of delivering results, you can trust that you’re making a smart investment in the future of your business.

Don’t wait any longer — seize the opportunity and propel your business towards greatness with AI-based digital marketing.

In conclusion, AI-based digital marketing isn’t just a buzzword — it’s a powerful tool that can revolutionize the way businesses engage with their customers, drive growth, and achieve lasting success. By embracing AI technology, businesses can stay ahead of the competition, adapt to changing market dynamics, and thrive in today’s digital-first world.

Book a free Consultation Now to Enrich Your business to a new Potential https://calendly.com/debjitb20/discovery-call

4 notes

·

View notes

Text

Vacuum Forming Is a Game Changer in Manufacturing

Innovation in the manufacturing sector is what propels cost-effectiveness, adaptability, and efficiency. Vacuum forming is one such cutting-edge method that has completely changed the way goods are created and manufactured. Due to its many benefits, vacuum forming technique has become more and more common in a variety of sectors.

Production at a Low Cost

The affordability of vacuum forming is one of its main benefits. Vacuum forming uses less expensive machinery and tools than conventional production techniques like die casting or injection molding. Because of this, vacuum forming is a desirable alternative for small- to medium-sized production runs, allowing companies to save costs without sacrificing quality.

Quick Prototyping

Rapid prototyping is made possible by Vacuum Forming China, which enables engineers and designers to test and iterate product concepts fast. It is possible to build several prototypes at a reasonable cost because to the short lead times and inexpensive tooling costs. This quickens the process of developing new products, allowing companies to launch new concepts more quickly and adapt quickly to the needs of their customers.

Flexibility in the Choice of Materials

A large variety of thermoplastic materials may be used with vacuum forming, giving producers the freedom to select the material that is best suited for their particular purpose. Because of their versatility, goods with different levels of flexibility, transparency, and durability may be made. Vacuum forming is a flexible solution for a multiplicity of sectors, accommodating a wide range of material needs from durable automotive components to thin-gauge packaging.

Smooth Customization of the Design

Vacuum forming makes it simple to easily customize complex designs. It is possible to accomplish intricate textures, undercuts, and forms without the requirement for costly tool adjustments. Vacuum forming is a great option for creating aesthetically pleasing and useful items in a variety of sectors, including consumer electronics, car interiors, and signs, because of its adaptability in design customization.

Lightweight Goods

Because vacuum-formed materials by vacuum forming manufacturer are lightweight by nature, they are appropriate for uses where weight is a crucial consideration. This benefit is especially pertinent to the aerospace and automobile sectors, where weight reduction may improve overall performance and fuel economy. Additionally, vacuum-formed items' lightweight design makes handling, shipping, and installation simpler.

Next: Investment Casting Offers Both Versatility and Precision

#Vacuum Forming#Vacuum Forming Process#vacuum forming manufacturer China#vacuum forming manufacturer#Vacuum Forming Companies#Custom Vacuum Forming

2 notes

·

View notes

Text

RGG/Yakuza/Judgement in the Entertainment Industry

YAKUZA

Kiryu: Ascended singer/back up dancer now a professional fighter. With Nishiki he was part of the Sunflower Boys Club (like Disney micky mouse club ya dig). In his younger he even had a (successful) duo with Nishiki named (idk the name fam but their duo would be a male japanese 80’s duo WINK). But this only created a gap between the two where Kiryu was getting noticed more and contacted by various types of deals (commercials, mc host deal, acting, etc,), the public treated Nishiki like a side dish (the Beyonce treatment).

The deal sealed itself at the death of their company owner Kazama, and closely after when their manager Kashiwagi resigned from its position and the industry as a whole. After a long break and reflection, Kiryu still wanted to reunite the duo and rebrand into something more mature, but Nishiki refused and broke his contract to go his own way. Kiryu did the same in professional fighting where he is at the top of what they have to offer

Nishiki: once known as everyone boyfriend, the lovely Nishiki (play BOYFRIEND – Love Style). Rebranded with his whole name Akira Nishikiyama as a professional racer leaving all his links with kazama’s company behind him. He plays it lowkey and he is actually not bad (more like a silver or bronze type of good but not the top game). Nishiki remained petty and hate any discussions about Kiryu with the media/public especially since Nick Ogata leaked out that a girl was the main reason and the source of the duo’s breakup and Nishiki’s bitterness towards Kiryu Yumi: Actress Kashiwagi: Manager (precisely Nishiki and Kiryu’s), now retired. Haruka: Idol (off course) Majima: MC and variety show host and part-time fighter. Actually, most of his wealth comes from owing stuff (most people don’t know the depth of what he owns). His occasional fights with Kiryu gets the most ratings. We can even catch him on baking competitions and dancing with the stars and the local drag race, yah majima the funky ‘’businessman’’ Saejima: MMA Fighter. Akiyama: Funky & Rich golf player. Tachibana: Real estate owner. Jun Oda: Tachibana’s bodyguard Daigo: rookie but hella successful news presenter Mine: Lawyer attached to famous cases especially defending the guilty. The dude the girlies are simping for on Tik Tok. Shinida: Baseball player.

Nishida: Cameraman or TV crew member Majima keeps calling his assistant. Ryuji: grown Disney kid who ascended to legit model-hood but loves to puts his nose in everything. Rumors says he spent time in jail. Somehow has hella cash and people on social media likes him. His rants get millions of view, He always beefing with someone on Twitter and in real life (guilty or not). Aside from his antics, he has his hand in ownership of many brands and large businesses mostly coming from his father’s heritage and shady business practices. People loves to undermine his talent when it comes to investments and overall finance. Reina: professional guitarist of an indie jazz band rikiya: aspiring actor, currently everyone sweetheart and part of all the series famous with the youth these days. Part of the main cast from series trending on Netflix. Hana: kpop group coordinator (the girl who do the clothes)

Baba: Aspiring but still struggling SoundCloud rapper

Mayumi: center of a girl group. HyunA of a group with the aesthetic of the girl group SECRET.

Date: a famous lawyer always involved in big cases.

YAKUZA 7/LIKE A DRAGON

Ichiban: Athlete, (I see soccer). Using his name into it: Ichiban is always number one. Here’s goes the lighting bringing the fire in the place. He is the one, he is number one, ICHIBANNNNNNNNNN, GOALLLLLLLLLL

Nanba: high-scale gardener or theater actor Saeko: Ascended girl group member who branched off from the duo she was doing with her sister Nanoha. Dipping into acting. I would see as a professional dancer too a regular at dancing with the stars type stuff

Adachi: Senior Actor.

Eri: News presenter?

Han Joongi: Visual of kpop group (group the caliber of DBSK or ZE:A)

Zhao: Son of a rich Chinese businessman, nobody is sure where he actually lies since he touches a little bit at everything. But he is a heavy and popular presence in social media. You can find in all kinds of variety show/reality tv but he getting more credits for his cooking skills and inventions getting him top class restaurants. RGG’s Huang Zi Tao.

Masumi Arakawa: Japanese morgan freeman

Masato Arakawa/ ryo aoki: A son of a wealthy man who seems to do well with his acting career.

Ishioda: Rival MC of various shows.

Jo sawashiro: Lawyer

Mabuchi: architect

Seoghui: Solo singer/dancer with her back up dancers. Hajime Ogasawara: Kpop member turned actor

Nick ogata: MC of all types of shows. Radio host. Walking TMZ.

JUDGES EYES/LOST JUDGEMENT

Yagami: Actor or baseball player.

Kaito: Boxer Tesso: Olympic athele (mhhhh gymnastics or athletism)

Higashi: Classical musical player or conductor, people still scratiching their head how the heck he met kaito

Sugiura: new generation kpop group member. Like the new hot stuff these days (ATEEZ, Stray Kids type stuff) Tsukumo: music composer like yasutaka Nakata or a really lucrative indie gamer/youtuber

Hamura: Senior Actor (who can get away with sexual assault charges)

Kuroiwa: Top class actor with a Gold-tier PR team.

Kyoko amasawa: that girl who lead in show like idol school, aspiring top scale idol praised for being rebellious and not caring what people think of her. In a group like Le Sserafim.

Kengo: Professional BMX-er and your rapper who somehow made it trough shows like show me the money. Hoshino: overlooked k-pop band member

Akutsu: basketball player

Soma: a dude full of cash who owns a lot of stuff (like akutsu’s basketball team)

Sawa-sensei: Miss meteo.

#judgement headcanons#judge eyes#lost judgment#rgg#yakuza#rgg headcanons#rgg imagines#yakuza imagines#lost judgement headcanons#like a dragon#ryu ga gotoku#ryu ga gotoku headcanons#imagines#headcanons#kiryu kazuma#majima goro

10 notes

·

View notes

Text

5 Hints For Selecting A Sump Pump

A sump pump is a vital tool for home owners that would like to secure their cellars or crawl spaces coming from flooding. It assists to prevent water damage and maintain a dry, relaxed residing atmosphere. However, selecting the right sump pump for your details necessities may be a complicated job. Within this resource, our company'll offer you along with 5 recommendations to take into consideration when choosing a sump pump to create the method simpler and also ensure that you choose the most ideal one for your condition.

Determine Your Pushing Capability Demands

Some of the most essential factors in deciding on a sump pump is actually understanding your pumping capability requirements. This depends upon elements like your geographic site, the measurements of your basement or even crawl space, as well as the normal water inflow fee during the course of massive rainfalls or hurricanes. Sump pumps are actually normally ranked through their quarts per minute (GPM) or even quarts per hr (GPH) capacity. It's vital to pick a battery backup sump pump that can easily handle your particular water removal requires without overworking or underutilizing the pump. If you're uncertain, speak with an expert to calculate your requirements precisely.

Opt For the Right Kind Of Sump Pump

There are many forms of sump pumps available, consisting of completely submersible as well as pedestal pumps. Submersible pumps are placed within the sump pit as well as are completely submersed in water. They are quieter as well as even more very discreet, making them a prominent choice for finished basements. Alternatively, pedestal pumps have the electric motor above the sump pit, creating all of them much easier to company yet noisier. Your option of pump type ought to depend on your cellar or crawl space format and private choices. Completely submersible pumps are generally highly recommended for many home applications as a result of their performance and peaceful operation.

Look At Data Backup and also Redundancy

youtube

A sump pump failure may lead to flooding as well as costly harm. To reduce this danger, consider investing in a backup body. Battery-operated backup pumps, water-powered pumps, or a combination of both may provide added defense throughout electrical power blackouts or key pump malfunctions. It's essential to possess a back-up option in position to ensure continuous water elimination and confidence. Also, on a regular basis test as well as preserve your back-up pump to guarantee its own dependability.

Check for Toughness as well as Top quality

When choosing a sump pump, focus on top quality and also longevity. A dependable outdoor sump pump needs to be actually designed from top quality components that can easily hold up against the needs of regular operation and also visibility to water. Try to find models with a cast-iron or even stainless steel construction for longevity. In addition, consider pumps with a sealed and also oil-cooled electric motor, which gives better security and also life expectancy. Read item reviews, seek suggestions, and buy from trustworthy suppliers to guarantee that you are actually acquiring a reliable as well as lasting sump pump.

Noise Amount as well as Installation

The sound level of a outdoor sump pump is actually a vital aspect if your cellar is a lifestyle or leisure area. Completely submersible pumps are actually usually quieter than pedestal pumping systems, but it is actually still vital to inspect the decibel ranking of the version you are actually taking into consideration. In addition, take into consideration the ease of installment. Some sump pumps might call for professional installation, while others are actually extra DIY-friendly. Read the maker's guidelines and also evaluations to assess the complication of the setup procedure and also choose if it's something you may take care of or if you require qualified help.

Conclusion

Selecting the right sump pump for your home is actually a selection that should not be hurried. By considering your pumping capability demands, the sort of sump pump, back-up options, sturdiness, as well as noise level, you may bring in a knowledgeable choice that makes certain the defense of your basement or even crawl space from possible flooding. Keep in mind that normal routine maintenance and testing are vital to maintain your sump pump in outstanding operating state, delivering you along with peace of mind as well as a dry, secure residing atmosphere.

2 notes

·

View notes

Text

Account Based Marketing (ABM) Case Studies: How Top Companies Are Using ABM to Drive Growth

In the fast-paced world of B2B marketing, staying ahead of the curve is paramount. One strategy that's making waves and driving impressive results is Account-Based Marketing (ABM). In this comprehensive guide, we'll explore what ABM is, its benefits, and why top companies are harnessing its potential to drive growth. We'll also delve into valuable lessons learned from ABM case studies and provide actionable steps to implement ABM in your own business. Get ready to revolutionize your B2B marketing strategy and propel your company toward exponential growth!

What is Account-Based Marketing (ABM)?

Account-Based Marketing, commonly known as ABM, is a strategic approach in which marketing and sales teams collaborate to target and engage specific high-value accounts with personalized marketing efforts. Instead of casting a wide net to capture leads, ABM focuses on treating individual accounts as their unique markets.

The Benefits of ABM

ABM is gaining prominence in the B2B world for several compelling reasons:

Higher ROI: ABM consistently delivers a higher return on investment due to its precision targeting.

Enhanced Conversion Rates: Personalized content and messaging tailored to target accounts result in better engagement and conversion rates.

Strengthened Customer Relationships: ABM fosters deeper relationships with existing clients, reducing churn and promoting loyalty.

Optimized Resource Allocation: ABM ensures marketing resources are directed where they will have the most significant impact.

Why Top Companies Are Using ABM to Drive Growth

Top-tier companies have recognized the potential of ABM as a growth driver. Here are the lessons learned from ABM case studies that reveal why ABM is indispensable:

1. Aligning Marketing and Sales Teams

Successful ABM requires seamless collaboration between marketing and sales teams. Both teams must work together towards common goals, with shared strategies and objectives.

2. Personalized Content and Messaging

ABM thrives on personalization. Tailoring content and messaging to address the unique needs of target accounts is essential for engaging prospects effectively.

3. The Power of Intent Data

Intent data is a game-changer in ABM. It allows you to identify companies actively researching your products or services, enabling you to engage with key decision-makers effectively.

4. Tracking and Measuring Results

Measuring the impact of your ABM efforts is crucial. Tracking metrics such as engagement rates, conversion rates, and revenue generated helps identify areas for improvement.

How to Implement ABM in Your Own Business

Ready to harness the potential of ABM for your business? Here are the steps to get you started:

1. Identify Your Target Accounts

Begin by identifying high-value accounts that align with your ideal customer profile (ICP). Prioritize these accounts based on their revenue potential.

2. Create Buyer Personas

Develop detailed buyer personas for each target account. These personas should capture the unique pain points, preferences, and motivations of your target audience within each account.

3. Develop Targeted Content and Messaging

Tailor your content and messaging to address the specific challenges and interests of each buyer persona within your target accounts.

4. Use Intent Data

Leverage intent data to identify key decision-makers within your target accounts and engage with them effectively.

5. Orchestrate Multi-Channel Campaigns

Craft coordinated marketing campaigns that reach your target accounts through multiple channels, ensuring consistent and compelling messaging.

6. Align Your Marketing and Sales Teams

Establish close collaboration between your marketing and sales teams to provide a seamless buying experience for your prospects.

7. Track and Measure Results

Monitor metrics such as engagement rates, conversion rates, and revenue generated to gauge the success of your ABM efforts. Use this data to identify areas for improvement.

Account-Based Marketing (ABM) is a powerful strategy for driving growth in the competitive B2B landscape. Top companies have demonstrated their effectiveness, and by following the tips and lessons learned from ABM case studies, you can implement ABM in your own business to achieve remarkable results.

3 notes

·

View notes

Text

Leading Steel Casting Companies for High-Quality Stainless Steel Investment Casting

Looking for reliable steel casting companies? We specialize in stainless steel investment casting, delivering precision-engineered components for various industries. Our advanced casting techniques ensure durability, accuracy, and superior surface finishes. Whether you need complex parts or large-scale production, our expertise in stainless steel investment casting guarantees high-quality results. Trust us for cost-effective and custom casting solutions tailored to your needs. Contact us today for premium steel casting services!

0 notes

Text

Latin America Industrial Silica Sand Market Outlook and Forecast 2025-2032

Industrial silica sand refers to high-purity silica sand that has been specifically processed for industrial applications. It is characterized by controlled particle size distribution, shape, and chemical purity levels to meet stringent industry requirements. The key applications of industrial silica sand include glass manufacturing, metal casting, chemical production, and construction materials. These applications demand precise specifications to ensure optimal performance in respective industries.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286439/latin-america-industrial-silica-s-market-2025-2032-490

Market Size

The Latin America industrial silica sand market was valued at US$ 764 million in 2024 and is projected to reach US$ 1.00 billion by 2030, growing at a CAGR of 4.6% from 2024 to 2030. The demand for industrial silica sand is being driven by its increasing use in glass production, rising construction activities, and the growing foundry industry across Latin America.

Market Dynamics

Drivers

Download a free Sample Report PDF

Expanding Glass Industry: The glass industry accounts for approximately 38% of industrial silica sand consumption in Latin America. The demand for glass in the automotive, construction, and packaging industries is fueling market growth.

Rise in Infrastructure Development: Rapid urbanization and infrastructure projects are increasing the need for silica-based materials in cement, concrete, and coatings.

Technological Advancements in Manufacturing: Automation and improved processing techniques are enhancing silica sand quality, increasing its suitability for high-end industrial applications.

Restraints

Environmental Concerns and Regulations: Strict regulations on silica mining and dust emissions pose challenges for manufacturers, leading to increased compliance costs.

Supply Chain Disruptions: The availability and cost of industrial silica sand can be affected by supply chain issues, particularly in remote mining locations.

Opportunities

Growth in Renewable Energy Sector: Increasing solar panel production, which requires high-purity silica, is creating new growth avenues for the market.

Advancements in Filtration Technology: Industrial silica sand is being increasingly used in water filtration and wastewater treatment, offering significant market potential.

Challenges

Resource Optimization: The need to optimize extraction processes and ensure sustainable sourcing remains a critical challenge for industry players.

Market Competition: The presence of both regional and international suppliers intensifies competition, requiring companies to differentiate through quality and pricing strategies.

Regional Analysis

Brazil

Brazil dominates the Latin American industrial silica sand market due to its strong glass and construction industries.

Large silica sand reserves and major mining operations in São Paulo and Minas Gerais contribute to high production levels.

Mexico

Mexico is experiencing rapid market growth due to increasing investments in the automotive sector and rising demand for flat glass in construction.

The country’s proximity to the U.S. also drives export opportunities for silica sand.

Argentina

Argentina has moderate market share, with steady demand from metal casting and glass industries.

Expansion of infrastructure projects is expected to drive future demand.

Other Regions

Chile, Colombia, Peru, and Venezuela collectively account for the remaining market share, with growing applications in ceramics, refractories, and filtration systems.

Competitor Analysis (in brief)

Key players in the Latin American industrial silica sand market include:

Sibelco – Leading supplier with strong presence in silica mining and processing.

Quartz y Silice – Focuses on high-purity silica sand for specialized applications.

U.S. Silica – Offers advanced silica products for multiple industrial sectors.

Fairmount Santrol – Known for its high-quality silica for glass and foundry use.

Badger Mining Corporation – Specializes in industrial minerals for filtration and coatings.

Hi-Crush Partners – Supplies silica sand for the energy sector and glass production.

Market Segmentation (by Application)

Glass Manufacturing – Accounts for the largest share, driven by demand in construction and automotive industries.

Construction – Used in concrete, coatings, and specialty cement applications.

Filtration – Growing adoption in water purification and wastewater treatment.

Foundry – High-quality silica sand is essential for mold and core making in metal casting.

Ceramics & Refractories – Increasing use in ceramic tiles, bricks, and refractory materials.

Market Segmentation (by Type)

Less than 40 Mesh – Fine silica used in high-end industrial applications.

40-70 Mesh – Versatile segment, widely used in glass and filtration.

More than 70 Mesh – Coarse silica used in construction and foundry applications.

Key Company

Sibelco

Quartz y Silice

U.S. Silica

Emerge Energy Services

Fairmount Santrol

Badger Mining Corporation

Hi-Crush Partners

Saint Gobain

Mitsubishi Corporation

Tochu Corporation

Geographic Segmentation

Brazil

Mexico

Argentina

Chile

Colombia

Peru

Venezuela

FAQ

1. What is the current market size of the Latin America Industrial Silica Sand Market?

➣ The market was valued at US$ 764 million in 2024 and is projected to reach US$ 1.00 billion by 2030 at a CAGR of 4.6%.

2. Which are the key companies operating in the Latin America Industrial Silica Sand Market?

➣ Major companies include Sibelco, U.S. Silica, Quartz y Silice, Fairmount Santrol, and Mitsubishi Corporation.

3. What are the key growth drivers in the Latin America Industrial Silica Sand Market?

➣ Growth in the glass industry, infrastructure development, and filtration technologies are primary drivers.

4. Which regions dominate the Latin America Industrial Silica Sand Market?

➣ Brazil leads with a 42% market share, followed by Mexico (28%) and Argentina (15%).

5. What are the emerging trends in the Latin America Industrial Silica Sand Market?

➣ Key trends include process automation, environmental compliance, quality enhancement, and resource optimization.

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Industrial Silica Sand revenues in Latin America market, 2019-2024 (Estimated), ($ millions)

Key companies Industrial Silica Sand revenues share in Latin America market, 2023 (%)

Key companies Industrial Silica Sand sales in Latin America market, 2019-2024 (Estimated),

Key companies Industrial Silica Sand sales share in Latin America market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Latin America and country-wise market of Industrial Silica Sand

It describes present situation, historical background and future forecast

Comprehensive data showing Industrial Silica Sand capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on Industrial Silica Sand manufacturers

Industrial Silica Sand forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286439/latin-america-industrial-silica-s-market-2025-2032-490

0 notes

Text

Discover the sustainability benefits of precision investment casting for green manufacturing. Reduce waste, energy, and carbon footprint & improve product lifespan.

0 notes

Text

Automotive Crankshaft Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Crankshaft Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Crankshaft Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Crankshaft Market is experiencing robust growth driven by the expanding globally. The Automotive Crankshaft Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Crankshaft Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Crankshaft Market Size, Share & Industry Analysis, By Type (Flat Plane, Cross Plane), By Material (Cast Steel, Forged Iron/steel), By Vehicle type (Passenger Cars, Commercial Vehicles) Others and Regional Forecast, 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/102231

Key Strategies

Key strategies in the Automotive Crankshaft Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Crankshaft Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Crankshaft Market.

Major Automotive Crankshaft Market Manufacturers covered in the market report include:

Some of the major companies that are present in the automotive crankshaft market include Thyssenkrupp AG, Nippon Steel Integrated Crankshaft LLC, Braynt Racing Inc., Arrow Precision Ltd., Maschinenfabrik Alfing Kessler GmbH, Mahindra CIE, Tianrun Crankshaft Co., Ltd., among others.

The crankshaft in the diesel engine has to serve higher strength and vibrations. Owing to this, many crankshaft manufacturers are developing advanced crankshaft with improved fatigue strength, reliability, and quality. Also, the crankshafts are manufactured with the latest trend of steelmaking processes by materials with high strength, and this factor is also expected to drive the automotive crankshaft market.

Trends Analysis

The Automotive Crankshaft Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Crankshaft Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Crankshaft Market Solutions.

Regions Included in this Automotive Crankshaft Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Crankshaft Market.

- Changing the Automotive Crankshaft Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Crankshaft Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Crankshaft Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Crankshaft Market?

► Who are the prominent players in the Global Automotive Crankshaft Market?

► What is the consumer perspective in the Global Automotive Crankshaft Market?

► What are the key demand-side and supply-side trends in the Global Automotive Crankshaft Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Crankshaft Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Crankshaft Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Crankshaft Market#Automotive Crankshaft Market Share#Automotive Crankshaft Market Size#Automotive Crankshaft Market trends#Automotive Crankshaft Market Growth#Automotive Crankshaft Market Insights

0 notes

Text

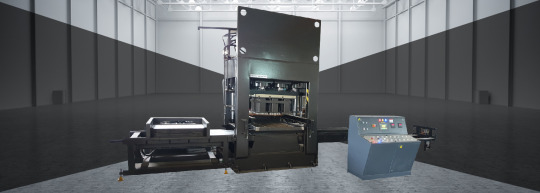

Effortless Precision: The 10-Ton C-Type Power Press by Mankoo Presses

In the world of industrial machinery, reliability, precision, and durability are key. Mankoo Presses Pvt. Ltd., a name synonymous with excellence, continues to set benchmarks with its robust and versatile 10-ton C-Type Power Press Machine. Designed for efficiency and built with the finest materials, this machine caters to the diverse needs of industries ranging from automotive to electronics and beyond. Let’s delve deeper into why Mankoo Presses’ 10-ton C-Type Power Press stands out as the ultimate solution for your pressing needs.

Introduction to Mankoo Presses Pvt. Ltd.

With decades of expertise in the manufacturing of high-quality press machines, Mankoo Presses Pvt. Ltd. has earned a stellar reputation in the industry. Headquartered in Ludhiana, Punjab, India, the company specializes in creating state-of-the-art mechanical and hydraulic press machines, tailored to meet the evolving demands of modern industries. Their unwavering commitment to quality, innovation, and customer satisfaction has made them a trusted partner for businesses across the globe.

Understanding the 10-Ton C-Type Power Press

The 10-ton C-Type Power Press by Mankoo Presses Pvt. Ltd. is a compact yet powerful machine, ideal for applications requiring precision and consistency. Its C-frame design ensures easy accessibility and operational flexibility, making it a preferred choice for industries with diverse fabrication needs.

Key Features

Robust Design: The machine’s open-frame design ensures excellent rigidity while maintaining a compact footprint. Crafted from high-grade steel or cast iron, it minimizes vibrations and ensures a long service life.

Superior Precision: The 10-ton pressing capacity provides unparalleled accuracy for operations like punching, cutting, and embossing. Designed to handle delicate and complex tasks with ease.

Adjustable Stroke Length: Customizable stroke length allows operators to perform a variety of operations with precision.

Ergonomic and Safe: User-friendly controls and an ergonomic design ensure operator comfort and productivity. Equipped with safety features such as protective guards and emergency stop buttons to prioritize workplace safety.

Energy-Efficient Motor: Powered by an efficient electric motor, the machine ensures consistent performance while reducing energy consumption.

Technical Specifications

Applications of the 10-Ton C-Type Power Press

The versatility of the 10-ton C-Type Power Press makes it indispensable across various industries. Here are some common applications:

Automotive Industry: Precision pressing for manufacturing vehicle components. Ideal for tasks like stamping, cutting, and forming metal parts.

Electronics: Used for creating precise enclosures and components for electronic devices.

Hardware Industry: Essential for producing locks, hinges, and other hardware items with consistent quality

Sheet Metal Fabrication: Facilitates operations like punching, bending, and embossing in sheet metal processing.

Packaging Industry:

Useful for creating metal containers and lids.

Why Choose Mankoo Presses Pvt. Ltd.?

When investing in a power press machine, you want a partner who understands your requirements and delivers unmatched quality. Here’s why Mankoo Presses Pvt. Ltd. should be your first choice:

Proven Expertise: With years of experience in the field, Mankoo Presses has honed its craft to perfection.

Quality Assurance: Each machine undergoes rigorous testing and quality checks to ensure optimal performance.

Customizable Solutions: Mankoo Presses offers the flexibility to customize machines to meet specific industry needs.

Global Reach: Trusted by clients worldwide, the company has a strong presence in both domestic and international markets.

After-Sales Support: Mankoo Presses provides excellent customer support, ensuring smooth operations and minimal downtime.

Benefits of the 10-Ton C-Type Power Press

Enhanced Productivity: High speed and accuracy improve operational efficiency.

Cost-Effective: Durable construction and energy-efficient design reduce maintenance and operational costs.

Versatility: Handles a wide range of tasks, eliminating the need for multiple machines.

Long-Term Investment: Engineered for longevity, providing excellent value for money over time.

Maintenance Tips for Optimal Performance

To ensure your 10-ton C-Type Power Press performs at its best, follow these maintenance tips:

Regular Lubrication: Keep all moving parts well-lubricated to minimize wear and tear.

Inspect for Wear: Regularly check components for signs of wear and replace them as needed.

Cleanliness: Keep the machine clean to prevent dust and debris from affecting its performance.

Operator Training: Ensure operators are trained to use the machine safely and effectively.

Scheduled Servicing: Follow the manufacturer’s recommended servicing schedule for optimal results.

Conclusion

The 10-ton C-Type Power Press from Mankoo Presses Pvt. Ltd. is a testament to precision engineering and reliability. Whether you’re a small-scale manufacturer or part of a large industrial operation, this machine is designed to meet your pressing needs with unmatched efficiency and accuracy.

Investing in Mankoo Presses’ 10-ton C-Type Power Press means choosing quality, durability, and peace of mind. With its proven track record and commitment to excellence, Mankoo Presses Pvt. Ltd. is your ideal partner for industrial success.

Ready to elevate your production capabilities? Contact Mankoo Presses Pvt. Ltd. today and experience the difference! Visit their official website or call their expert team for personalized guidance.

0 notes

Text

Three Ear-Worthy Canadian Podcasts: The Connectors; Toronto Mike'd; Five Random Questions

Most Americans don't have a good understanding that their nation is not number one in everything. It's an arrogance only growing more deeply ingrained with political upheaval in the nation.

In podcasting, the U.S. is close, but no cigar. Statistics from various sources reveal that Australian listeners top U.S. listeners for length of time listening to a podcast and a percentage of the population who listen to podcasts.

Canada also has a thriving podcasting community. An excellent source to learn more about Canadian podcasting is the Pod The North Substack by Kattie Laur.

A good place to start is Kattie's December article: The 10 Best Canadian Podcasts of 2024.

Anyway, I think Canadians should be recognized for their superb podcasting skill. When you have such talented people as Mike Boon, Danny Brown,Kattie Laur, Jolyn Showalter, and Quentin Sheriff, Canada has much to be proud of in podcasting.

As proof of Canada's vibrant podcasting community, the Canadian Podcast Awards were held on December 30, 2024, proudly celebrating another incredible year, honoring the talent, passion, and dedication that define Canada’s podcasting community. With over 2,300 votes cast and participation from more than 1,000 individuals, this year’s event highlighted the continued growth and influence of Canadian podcasts.

The event was made possible through the significant support of Shure, whose ongoing contributions continue to elevate the Canadian podcasting industry. Additionally, Recycle My Electronics generously supported the Business, Society & Culture, and Technology categories.

“Every voice has its unique frequency, and every story resonates differently,” said John Leschinski. “Shure’s involvement signifies an enduring commitment to capturing these voices with clarity and precision.”

Erika Casupanan, the first Canadian winner of CBS’s Survivor and a first-time podcaster, took home two awards in her debut year: Debut and Television & Film.

“It is such an honor to have joined this community. I felt so loved. I felt so supported.” said Erika Casupanan.

Other multiple standout wins included “Geist” excelling in Arts and Original Music, and “Lullaby: The Fear Podcast” taking home awards for People’s Choice and Production.

Listed below are three of the many excellent Canadian podcasts that are indeed award-worthy.

*******************************************************************

The Connectors

A podcast about connections among people is a topic in which a large podcast network -- we're calling it iWontifyXM -- would hire an actor who starred on a network show 20 years ago and would host this new show with a script written and questions for the weekly guest already prepared.

Thankfully for listeners, an independent podcast called The Connectors employs that concept like a concert pianist, playing all the right notes in a pleasing harmony.

Co-hosts Jolyn Showalter from London, Ontario and Quinten Sheriff from Montreal can tell you about their podcast: "We explore the importance of making meaningful connections for personal and professional growth and happiness. We explore how building and recognizing strong connections in life can help you achieve your goals, find personal fulfillment, and how you can create opportunities to build a purposeful and fulfilling future."

The first episode was released in March 2023 with over 50 episodes produced and released so far.

On the podcast, Jolyn Showalter and Quinten Sheriff create a sonic enclave where listeners can feast on the concept of cultivating a thriving community built on authenticity, growth, and the power of connection. It is obvious that they enjoy each other's company and their connection is strong and infiltrates the vibes of the show.

My favorite episodes include the August 23, 2024, show that focuses on the vital role of human performance in business success. While many companies invest in technology and office upgrades, true growth comes from investing in people.

Nurdan Tokoz, founder of Nurdanpinar Solutions for Human Performance, who spent over 20 years in Learning & Development within large corporations, launched her consulting business to help organizations fully utilize their workforce's potential.

Check out The Connectors podcast. The show and co-hosts have a fresh approach -- bringing people together instead of splitting them apart via artificially constructed political views, fabricated cultural value differences or extremist conspiracy theories.

**********************************************************

Toronto Mike'd podcast

Mike Boon bills himself on his LinkedIn page as the "Canadian Godfather of Podcasting." After researching all that he's accomplished on Canadian podcasting, I think we are ready to kiss the ring.

Toronto Mike has produced over 1,600 episodes, which is an amazing feat.

On his Toronto Mike'D podcast, Boon discusses various issues of the day and chats with interesting guests about the serious and not-so-serious. It's authentic controlled chaos with a Toronto spin. What I really admire about Toronto Mike is that he acts like a de facto local newspaper. Want to know what's going on in Toronto? Listen to Toronto Mike'd. He truly has the pulse of the city.

In December, Toronto Mike'd aired an episode that moved me deeply. In that show, Mike spoke to former NHL player Luke Sellars about his life of substance abuse, depression, assault, the near loss of a leg, failed NHL dreams, and a suicide attempt before redemption. It was a show that will make you think about the stresses in professional sports. You don't have to be Canadian to enjoy Toronto Mike'd. It seems like he's an institution in the Toronto area. I enjoyed his insights, his humor, his openness, and his longevity.

If you visit Toronto, you should hit the key tourist sites, such as CN Tower, Casa Loma, and the Hockey Hall Of Fame. I think that Trip Advisor should add "listening to at least one episode of Toronto Mike'd" to that list of must-do things while in the city.

Who knows? Toronto Mike'd must even have you on his show!

**********************************************************************

5 Random Questions

The interview podcast is the most common form of podcasting. It's the easiest format to set up and sustain, and requires the least amount of research and money. Whether it's true-crime, comedy, or just a gabfest, over 70 percent of all podcasts are somebody interviewing somebody else.

Yet, leave it to a podcasting pro like Danny Brown to put a surprise twist on the tried-and-true interview podcast.

Welcome to 5 Random Questions with host, Danny Brown. Each week, Danny sits down with his special guest and uses a random question generator to come up with five unpredictable, thought-provoking, and sometimes downright hilarious questions. No topic is off-limits as Danny and his guests dive into their answers, sparking lively discussions filled with laughter, surprises, and occasional deep insights.

As a special twist, every guest gets to turn the tables and ask Danny any random question they like, putting him on the spot and keeping things fresh and fun.

The podcast began in June 2024 and has already received a lot of listener attention and buzz. Here's just an appetizer to some of the randomly generated questions Danny has asked in the first five episodes. These responses include a poop-dropping neighbor from hell, why one guest would love to be splashing around with an umbrella, a preference for wet dog smells, and the person most likely to die by the guest's hand.

Whether you're looking for a good laugh, some unexpected wisdom, or just an entertaining chat, 5 Random Questions is the podcast for listeners who want their ears to hear something "completely different." As Danny Brown says: "Tune in for a mix of humor and heart, and discover something new with every episode!"

**************************************************

Other Canadian podcasts that will appeal to your ears include The Ryan Holtz Show,Alright, Now What?(Canadian Women's Foundation), and Canardian from (Pod the North).

1 note

·

View note

Text

Auto Pallet Stacker System manufacturer in coimbatore

Introducing the Auto Pallet Stacker System - 15 Bricks, a highly efficient solution for automating the pallet stacking process. Designed and manufactured by a leading Auto Pallet Stacker System manufacturer in Coimbatore, this advanced system is engineered to improve the productivity and accuracy of stacking operations. With a range of powerful features, it is an ideal choice for industries looking to enhance their material handling.

Equipped with a 15 H.P/11.25 KW hydraulic motor, the Auto Pallet Stacker System ensures smooth operation, while the 3 H.P/2.25 KW conveyor system optimizes material flow. The system also includes a high-performance pan mixer machine and a hopper vibrator for greater efficiency. The stacker is powered by a robust 3 H.P/2.25 KW hydraulic motor and features a travel motor of the same power for reliable movement and positioning. It has a pallet chain conveyor and hydraulic-free fill system to simplify stacking tasks, cutting down on labor requirements significantly.

The machine's control is managed through a PLC system, providing precise control over its operations. With a stacker cycle time of 15 seconds and a robust hydraulic pump, the Auto Pallet Stacker System Coimbatore ensures high output with minimal downtime. The system is designed with durable components, including grained hard chromed sliding rods and steel casting sliding bushes, ensuring longevity and optimal performance.

As trusted Auto Pallet Stacker System exporters in Coimbatore, India, we take pride in offering a high-quality product designed to meet the demanding needs of modern industries. With a land requirement of 1.5 acres and a production capacity of 12 laborers per shift, the Auto Pallet Stacker System is an investment that improves operational efficiency and productivity. Experience the benefits of automation with our advanced system, tailor-made for the evolving industrial landscape.

For more details on the Auto Pallet Stacker System, feel free to contact us today!

Website Link : -http://www.bennyenterprises.net/

Contact no : - 9360623765

Mail id : - [email protected]

Address :- Site No:13, Thadagam Road,K.N.G.Pudur Pirivu,

Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108,Tamil Nadu, India

Socail media link

facebook link :- https://www.facebook.com/Bennyindustries

short describiton :- Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

#Auto Pallet Stacker System#Auto Pallet Stacker#Auto Pallet Stacker System manufacturer in Coimbatore#Benny Enterprises

0 notes

Text

Competitive Advantages for Businesses Through Digital Marketing.

1. Precise Targeting and Audience Segmentation

Digital marketing allows businesses to target their ideal customers with a high degree of precision. Tools like Google Ads, Facebook Ads, Instagram Ads, and data analytics platforms enable businesses to segment their audiences based on demographics, interests, behavior, location, and more. This ensures that marketing campaigns are reaching the most relevant and interested consumers rather than casting a wide, less focused net.

Example: An e-commerce business can target women aged 25-35 in urban areas with ads for trendy clothing sales, rather than relying on generalized advertising methods.

2. Cost-Effectiveness and Budget Optimization

Digital marketing is far more affordable compared to traditional marketing channels like print, TV, or radio. Campaigns can be scaled up or down depending on budget and goals, and tools allow businesses to analyze performance and adjust strategies in real-time. This leads to better utilization of marketing budgets and a higher return on investment (ROI).

3. Real-Time Performance Tracking & Data Analysis

Digital marketing platforms provide real-time insights into campaign performance using tools like Google Analytics, Facebook Insights, SEMrush, or HubSpot. These insights give businesses a clear understanding of metrics such as website traffic, engagement rates, conversion rates, and customer behavior. This data allows companies to make informed decisions quickly, optimizing strategies for success.

Example: If a business notices a decline in ad performance, they can adjust copy, visuals, or targeting in real time.

4. Flexibility & Adaptability

Digital marketing provides the flexibility to adapt to market trends, consumer preferences, and campaign outcomes. Businesses can test various campaigns, messaging styles, or platforms and pivot their strategies based on results. Unlike traditional campaigns that require weeks of preparation, digital strategies allow for quick responses and experimentation.

5. Global Reach and Scalability

One of the most significant competitive advantages of digital marketing is the ability to scale operations and connect with global markets. Digital platforms like search engines, social media, and email allow brands to connect with customers from anywhere in the world at any time.

6. Enhanced Customer Engagement & Relationship Building

Digital marketing creates opportunities for real-time interaction with customers through social media, email campaigns, and content marketing. Social media platforms, for example, allow brands to engage in conversations, answer customer queries, and strengthen brand trust by being accessible and relatable.

Example: A company that uses social media polls or user-generated content campaigns encourages customer participation and builds loyalty.

#certified digital marketer#digital marketer in mumbai#digital marketing services#digital marketer expert#digital marketing services in mumbai#digital marketer near me#digital Vignesh Gaikwad

1 note

·

View note