#Polyurethane Resins

Explore tagged Tumblr posts

Text

Biomass-based Polycarbonatediol “BENEBiOL” Adopted for the Watch Band of Citizen Watch

The Mitsubishi Chemical Group’s biomass-based polycarbonatediol (PCD) BENEBiOL was selected by Citizen Watch Co. for use in its fall/winter 2024 CITIZEN PROMASTER model. BENEBiOL™ will be used as a raw material for polyurethane for the watch band. Continue reading Biomass-based Polycarbonatediol “BENEBiOL” Adopted for the Watch Band of Citizen Watch

View On WordPress

0 notes

Text

"Nobody’s Perfect Chair" Collection,

Gaetano Pesce, published by Zerodisegno in 2003,

Polyurethane resin and molded plastic dyed in yellow, black and yellow, black and blue, green... mass.

Length : 19.69 in / 50 cm, Height : 35.43 in / 90 cm, Width : 17.72 in / 45 cm

#art#design#sculpture#furniture#seat#chair#forms#nobody's perfect#gaetano pesce#zerodisegno#2003#polyurethane#resin#molded#plastic#yellow#blue#red

47 notes

·

View notes

Text

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

Unique FAQs

Are synthetic resin adhesives suitable for outdoor applications?

How do synthetic resin adhesives compare to traditional adhesives?

What safety precautions should be taken when using synthetic resin adhesives?

Can synthetic resin adhesives be used underwater?

Are there eco-friendly alternatives to synthetic resin adhesives?

#synthetic resin adhesives#construction adhesives#acrylic adhesive#industrial adhesives#flooring installation#adhesive properties#durability#polyurethane adhesive

2 notes

·

View notes

Text

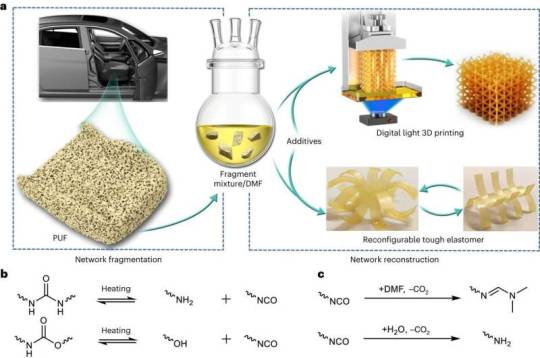

Converting polyurethane foams to 3D printing resins

A team of chemical engineers at Zhejiang University, in China, has developed a way to convert polyurethane foams to 3D printing resins. In their paper published in the journal Nature Chemistry, the group describes their technique and possible ways the resins could be used. Polyurethane foams (also known as foam rubber) of the types that are found inside of car seats, couches and mattresses are used to make products more comfortable. They are actually a type of plastic that is made to expand by forcing gas bubbles into mixtures using a blowing agent. Such foams are notoriously difficult to recycle because of the curing process that is used to make them. Current approaches, as the researchers note, tend to be economically unattractive and also lead to the production of subpar byproducts. Because of that, most such products wind up in a landfill. In this new effort, the team in China has developed a novel approach to recycling such materials—one that they claim is both inexpensive and scalable. They describe it as an example of chemical upcycling, where typically discarded materials are converted to high-value products.

Read more.

13 notes

·

View notes

Text

“Limb”

Dan Lam’s Radiant Otherworldly Sculptures Evoke Interstellar Phenomena in ‘Cosmic Shake’

Oozing over the edges of shelves and dolloping tendrils across flat surfaces, Dan Lam’s vibrant sculptures (previously) play with form and space. Using polyurethane foam, epoxy resin, and acrylic, the Dallas-based artist makes otherworldly sculptures that appear like alien substances from outer space, apropos to the pieces in her upcoming solo exhibition, Cosmic Shake.

All images © Dan Lam, courtesy of Chefas Projects

“Dark Side”

“Nebula”

“Waxing”

#dan lam#artist#art#sculptor#sculpture#cosmic shake#polyurethane foam#epoxy resin#acrylic#dallas-based artist#chefas projects

3 notes

·

View notes

Note

i need to hold him

You need to look up red cornetfish

OUUGUGUGGUHHHHHH YOU GOTTA BE KIDDING ME

TRUMPET GUY

#that thing is completely fake and made of resin or some other translucent polyurethane#i am become a cornetfish truther#i need to see this in real life

32K notes

·

View notes

Text

Polyurethane Resin for Inks | Uniform Synthetics

Uniform Synthetics manufacturers premium quality polyurethane resin, which can be used for reverse printing Gravure and Laminating Inks. We follow environmentally-sustainable manufacturing processes.

0 notes

Text

Epoxy Flooring Cost & Price Per Sq Ft

Learn about RachTR’s epoxy flooring cost & price per sq ft, and get a customized quote. Our industrial epoxy flooring solutions are tailored for various industries.

#epoxy flooring#Epoxy Floor#epoxy floor price per sq ft#epoxy flooring price per sq ft#Polyurethane Flooring#resinous flooring#adhesives for tiles#tile adhesives#rachtr#industrial flooring#industrialepoxyflooring#efficientflooring

0 notes

Text

n-Butanol Prices Trend | Pricing | News | Price | Database

The global n-Butanol market has seen significant fluctuations in prices over the past few years, driven by a combination of supply and demand dynamics, production costs, and geopolitical factors. n-Butanol, an important alcohol used in the production of plastics, paints, coatings, pharmaceuticals, and as a solvent in various industrial processes, plays a crucial role in the global chemical industry. Its price trends are influenced by several factors, including raw material costs, technological advancements in production methods, and global economic conditions. Understanding the factors that affect n-Butanol prices is essential for industry stakeholders to navigate the market effectively and make informed decisions.

One of the key drivers of n-Butanol price fluctuations is the supply and demand balance. The demand for n-Butanol is heavily linked to the performance of key end-user industries, including automotive, construction, and consumer goods. A surge in construction activities, particularly in emerging markets, or increased automotive production, can lead to higher demand for n-Butanol as it is used in the production of coatings and adhesives. Similarly, the demand for pharmaceuticals and personal care products, which also rely on n-Butanol as a solvent, can further influence its price. Conversely, a slowdown in these sectors or a shift towards alternative materials can lead to a reduction in demand, causing prices to stabilize or decline.

Get Real time Prices for n-Butanol: https://www.chemanalyst.com/Pricing-data/n-butanol-78

Another critical factor influencing n-Butanol prices is the cost of raw materials used in its production. n-Butanol is primarily produced through two methods: the Oxo process and the direct hydration of propylene. The Oxo process involves the hydroformylation of propylene, a process that requires synthesis gas, while the direct hydration method uses propylene oxide. Fluctuations in the prices of key raw materials, such as propylene, synthesis gas, and natural gas, can directly impact the cost of n-Butanol production, leading to price variations in the market. Additionally, the availability and cost of feedstock are highly influenced by regional production capabilities and transportation costs, adding another layer of complexity to the pricing structure.

Geopolitical events also play a significant role in shaping the price trends of n-Butanol. Changes in trade policies, economic sanctions, and disruptions in the global supply chain can lead to price volatility. For instance, tensions in major oil-producing regions can cause fluctuations in the prices of crude oil and natural gas, which are key inputs in the production of n-Butanol. Moreover, tariffs and trade restrictions between countries can hinder the free flow of raw materials and finished products, further disrupting the supply-demand equilibrium and driving up prices. These geopolitical challenges have led to heightened market uncertainty, making it essential for companies to keep a close watch on international developments that may affect the n-Butanol market.

Technological advancements in n-Butanol production have also played a role in shaping the price landscape. Over the past few years, there has been a shift towards more sustainable production methods, such as the bio-based production of n-Butanol. Companies are investing in alternative processes, such as fermentation-based technologies, to reduce their reliance on petrochemical feedstocks. While these technologies are still in the early stages of development, they hold the potential to lower production costs and reduce the environmental footprint of n-Butanol manufacturing. As these technologies mature and gain wider adoption, they may drive down production costs, which could, in turn, lead to more competitive pricing in the global market.

Market competition among producers is another factor that impacts n-Butanol prices. The market is characterized by a few dominant players who control a significant portion of the production capacity. These companies have the ability to influence pricing through their production strategies, capacity expansions, and partnerships. Additionally, regional producers may have a competitive advantage due to lower production costs, access to local raw materials, and proximity to key consumer markets. As the market continues to evolve, consolidation among producers and the entry of new players may alter the competitive landscape, potentially leading to price adjustments.

Seasonality also plays a role in the n-Butanol price market, with certain periods of the year seeing higher demand for n-Butanol-based products. For example, during the summer months, the demand for coatings and paints typically increases as construction projects ramp up, leading to a higher demand for n-Butanol. Similarly, the end-of-year holidays may drive up demand for personal care and pharmaceutical products, influencing the price of n-Butanol. These seasonal variations in demand can cause short-term price fluctuations, particularly in regions with high production or consumption levels.

Regional differences in n-Butanol prices are also important to consider. Prices can vary depending on the region’s production capabilities, availability of raw materials, and proximity to key markets. In regions where n-Butanol production is concentrated, such as North America, Europe, and parts of Asia, prices may be lower due to economies of scale and established supply chains. In contrast, regions with limited production capacity or those reliant on imports may experience higher prices due to transportation costs and import tariffs.

The environmental and regulatory landscape is also an important factor influencing n-Butanol prices. Governments around the world are increasingly focusing on reducing carbon emissions and promoting sustainable practices within the chemical industry. As regulations become stricter, companies may face higher compliance costs, which could be passed on to consumers in the form of higher prices. Furthermore, pressure from environmental groups and consumers to adopt greener practices could encourage the development of bio-based alternatives to n-Butanol, potentially altering market dynamics and pricing structures in the future.

In conclusion, the n-Butanol market is influenced by a complex interplay of supply and demand factors, raw material costs, geopolitical events, technological advancements, market competition, and environmental considerations. While short-term fluctuations in price are common, the long-term trend of n-Butanol prices will depend on the ability of producers to manage production costs, navigate changing market conditions, and respond to shifts in consumer preferences. Industry players must remain adaptable and stay informed about the global factors that impact the n-Butanol market to make sound business decisions and maintain competitiveness in this dynamic market.

Get Real time Prices for n-Butanol: https://www.chemanalyst.com/Pricing-data/n-butanol-78

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyurethane Resin#Polyurethane Resin Price#Polyurethane Resin Prices#Polyurethane Resin Pricing#Polyurethane Resin News#Polyurethane Resin Price Monitor

0 notes

Text

Epoxy Gang

At Epoxy Gang, we get that every place has its own vibe and story, and that's why we're all about offering a whole bunch of services to match your style. Whether you're jazzing up your cozy home, setting up shop in a cool commercial space, or need some heavy-duty goodness for an industrial setup, we've got the skills to make your floors shine.

Phone: 0800 086 2924

Address: 46 St Ann's Cl, Newcastle upon Tyne NE1 2QR

Email: [email protected]

Website

Facebook

Twitter

Pinterest

#Resin Flooring#Resin Flooring For Homes#Commercial Resin Flooring#Industrial Resin Flooring#Polyurethane Resin Flooring

1 note

·

View note

Text

Organix: Revolutionizing Waterproofing with Polyurethane Injection Resin

Organix Building System LLC offers the best Polyurethane Injection Resin in Dubai, setting the industry standard with high-quality and reliable products. Our Polyurethane Injection Resin is designed to provide exceptional waterproofing and sealing for a variety of applications, including structural repairs and crack filling. With a commitment to innovation and excellence, we ensure that our products deliver superior performance and long-lasting results. Our expert team provides tailored solutions to meet the specific needs of each project, making Organix us the preferred choice for professionals seeking top-notch Polyurethane Injection Resin in Dubai.

0 notes

Text

Adcos Asia - The Pros and Cons of Using PU Resin for Structural Repairs

Among the many structural repair materials, polyurethane (PU) resin has earned a name for itself due to its adaptability and efficiency. The utilisation of PU resin, specifically through methods like PU grout injection, has become a norm in today's construction and repair sector.

Discover the pros and cons of employing PU resin for structural repairs.

Advantages of Using PU Resin for Structural Repairs

1. High Strength and Durability

PU resin is known for its high strength and durability, making it an excellent choice for structural repairs. It can withstand significant stress and load, ensuring long-term stability and reliability of the repaired structure.

2. Versatility in Application

One of the main benefits of PU resin is its versatility. This material can be used for various structural repairs, including concrete cracks, joints, and voids. This adaptability makes it a go-to solution for many repair scenarios.

3. Effective Waterproofing

PU resin is highly effective in waterproofing applications. When used in PU grout injection, it can seal cracks and joints, preventing water ingress and subsequent damage. This property is critical for maintaining the integrity of structures exposed to moisture.

4. Fast Setting Time

PU resin has a relatively fast setting time compared to other materials. This characteristic is beneficial for repair projects that require quick turnaround times, minimising downtime and disruptions to the structure's usage.

5. Strong Adhesion Properties

The adhesion properties of PU resin are superior, ensuring that it bonds well with various substrates. This strong adhesion helps create a seamless repair that integrates well with the existing structure, enhancing its overall strength.

6. Chemical Resistance

PU resin is resistant to various chemicals, including acids, bases, and solvents. This chemical resistance makes it suitable for repairs where exposure to harsh substances is typical.

Disadvantages of Using PU Resin for Structural Repairs

1. Cost Considerations

One of the primary disadvantages of using PU resin is its cost. PU resin can be more expensive than other repair materials, which might be a limiting factor for some projects, especially those with tight budgets.

2. Health and Safety Concerns

The application of polyurethane resin involves health and safety risks. The chemicals used in PU resin can be hazardous, requiring proper handling, protective equipment, and ventilation. Failure to adhere to safety protocols can result in health issues for workers.

3. Limited Temperature Tolerance

PU resin may have limited temperature tolerance. Extreme temperatures can affect its performance, potentially leading to degradation over time. This limitation needs to be considered in environments subject to significant temperature fluctuations.

4. Complexity in Application

Applying PU resin through PU injection methods can be complex and may require skilled labour. The precision needed for successful application means that untrained personnel might not achieve the desired results, leading to subpar repairs.

5. Potential for Shrinkage

PU resin can experience shrinkage during the curing process. This shrinkage can create gaps or reduce the effectiveness of the repair, necessitating careful monitoring and, in some cases, additional applications to ensure a complete fix.

6. Environmental Impact

The production and use of PU resin have environmental implications. The chemicals involved in its manufacture and application can contribute to environmental pollution if not managed properly. This factor is increasingly important as the industry moves towards more sustainable practices.

Conclusion

PU resin application, which encompasses methods like PU injection, provides many benefits for structural repairs. These advantages include exceptional strength, versatility, and efficient waterproofing. Nevertheless, it is also essential to acknowledge the drawbacks associated with its use, such as the expenses involved, health and safety considerations, and potential environmental consequences. Gaining a comprehensive understanding of these pros and cons is vital to making well-informed choices when selecting repair materials and techniques.

Visit Adcos International to enhance the strength and longevity of your structures with our advanced repair solutions.

0 notes

Text

25/3.2024 (3) - love this floor

0 notes

Text

Polyurethane resin manufacturers in india

Discover top-notch polyurethane resin manufacturers in India delivering high-quality products for diverse industrial applications. With advanced technology and stringent quality control, these companies offer reliable solutions tailored to your specific needs. Explore their extensive range of polyurethane resins to elevate your production processes and achieve superior results.

#Polyurethane resin manufacturers in india#Top Chemical Distributors In India#Iron Oxide Suppliers In Delhi#Polyol Distributors In India#Castor Oil Distributors In India#Vegacid 1880 Suppliers In India

0 notes

Text

Unleash the Potential of Your Floors with IC PRECIFLOOR!

Engineered for durability and performance, IC PRECIFLOOR offers unmatched strength and resilience for all your flooring needs. With its high-strength formulation and easy application, achieve flawless results every time. Elevate your spaces with IC PRECIFLOOR and experience the difference! To know more about floor repairs mortars in India and high strength flooring mortars visit: https://capaindia.in/product/ic-precifloor/

#top building materials companies in india#tile adhesives for vitrified tiles#top tile adhesive brands in india#best tile adhesive in india#block jointing mortar manufacturers in india#high strength flooring mortars#tile adhesive companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#floor repairs mortars in india#best waterproofing mineral mortars in india#tile adhesive brands in india#tile and stone adhesive#cement based tile adhesive#affordable waterproofing solutions#aliphatic polyurethane waterproofing coating#epoxy resin adhesives manufacturers#epoxy grouts in india#epoxy adhesive manufacturers

0 notes

Link

SINOYQX melamine foam has excellent comprehensive properties and is widely used in architectural acoustics, professional acoustics, rail vehicles, automobile manufacturing, shipbuilding, aerospace applications, pipeline insulation, high temperature insulation, low temperature insulation, power stations, filtration applications, large equipment manufacturing, anti-static, 5G base stations, white appliances, supercapacitors, industrial cleaning, daily cleaning, furniture manufacturing and other fields.

#melamine foam#polyurethane foam#melamine resin foam#cleaning materials#sound-absorbing foam#thermal insulation materials#sound-absorbing materials#white melamine foam#gray melamine foam

0 notes