#Polycarbonate Pricing

Explore tagged Tumblr posts

Text

Polycarbonate Prices | Pricing | Trend | News | Database | Chart | Forecast

Polycarbonate prices have been a significant topic of interest in industries like automotive, electronics, construction, and consumer goods manufacturing. Polycarbonate is a versatile thermoplastic known for its transparency, durability, and high impact resistance, making it a popular choice for various applications. However, the market for polycarbonate is subject to fluctuations due to multiple factors, and understanding these dynamics can help businesses and consumers make informed decisions.

One of the primary factors influencing polycarbonate prices is the cost of raw materials, particularly bisphenol A (BPA) and phosgene. These materials are essential components in the production of polycarbonate, and any fluctuations in their availability or cost can have a direct impact on the price of the final product. For example, when there is a disruption in the supply chain for bisphenol A, such as a shortage or an increase in production costs, manufacturers often pass these costs on to the consumers, leading to higher prices for polycarbonate. Additionally, the price of oil, which is a key ingredient in the production of many chemicals including polycarbonate, can also affect pricing. As oil prices rise, so too can the cost of polycarbonate production, which in turn raises the market price.

Another significant factor affecting polycarbonate prices is supply and demand dynamics. The demand for polycarbonate has been growing steadily over the past few years, particularly in sectors such as electronics, automotive, and construction. This is largely due to the material's desirable properties, such as its lightweight nature, impact resistance, and optical clarity. However, when demand outpaces supply, prices can surge. For example, during periods of economic growth, there is often increased demand for durable goods such as automobiles and electronics, which leads to higher demand for polycarbonate. Conversely, during economic downturns, demand may decrease, potentially leading to a reduction in prices as suppliers compete to maintain market share.

Geopolitical factors also play a role in polycarbonate pricing. Trade tensions, tariffs, and other regulatory measures can disrupt the global supply chain, making it more expensive to produce and transport polycarbonate. For instance, the imposition of tariffs on imports of raw materials used in polycarbonate production can lead to higher costs for manufacturers, which are often passed on to consumers. Additionally, political instability in regions that are major producers of raw materials can lead to supply disruptions, further driving up prices. On the other hand, favorable trade agreements and stable political environments can help keep prices more consistent by ensuring a steady supply of raw materials and finished products.

Get Real Time Prices for Polycarbonate: https://www.chemanalyst.com/Pricing-data/polycarbonate-47

Technological advancements in the production process can also influence polycarbonate prices. As manufacturers invest in new technologies that increase efficiency and reduce waste, the cost of producing polycarbonate can decrease. These savings are often passed on to consumers in the form of lower prices. However, the initial investment in new technology can be substantial, and manufacturers may need to recoup these costs by keeping prices steady or even raising them temporarily. Over time, as the technology becomes more widespread and production processes become more efficient, these costs typically decrease, resulting in lower prices for polycarbonate.

Environmental regulations and sustainability concerns are becoming increasingly important factors in the polycarbonate market. Governments around the world are implementing stricter environmental regulations, which can increase the cost of production. For example, regulations that require the reduction of greenhouse gas emissions or the use of more environmentally friendly raw materials can add to the production costs of polycarbonate. These costs are often passed on to consumers, resulting in higher prices. Additionally, consumers and businesses are increasingly demanding more sustainable products, which has led some manufacturers to invest in greener production processes. While these efforts are beneficial for the environment, they can also contribute to higher production costs and, consequently, higher prices for polycarbonate.

The global economic climate also has a significant impact on polycarbonate prices. During periods of economic growth, demand for polycarbonate tends to increase as industries such as automotive, construction, and electronics ramp up production. This increased demand can drive prices higher, particularly if supply is unable to keep pace. Conversely, during economic downturns, demand for polycarbonate may decrease as industries cut back on production, leading to lower prices. Inflation, currency fluctuations, and interest rates can also affect polycarbonate prices by influencing the cost of raw materials and production.

Regional differences in production and consumption can lead to variations in polycarbonate prices across different markets. For example, regions that are major producers of polycarbonate, such as Asia-Pacific, may have lower prices due to the proximity of production facilities and lower transportation costs. In contrast, regions that rely heavily on imports, such as Europe and North America, may experience higher prices due to the added costs of shipping and tariffs. Additionally, regional differences in demand can affect pricing. For example, in regions where demand for polycarbonate is particularly high, such as in rapidly developing economies, prices may be higher due to increased competition for limited supply.

Finally, seasonal variations can influence polycarbonate prices. Certain industries, such as construction, experience seasonal fluctuations in demand, which can impact the demand for polycarbonate. For example, during the warmer months, construction activity tends to increase, leading to higher demand for polycarbonate used in building materials such as roofing and glazing. This increased demand can lead to higher prices during these periods. Conversely, during the colder months, construction activity may slow down, leading to a decrease in demand and potentially lower prices.

In conclusion, polycarbonate prices are influenced by a complex interplay of factors, including raw material costs, supply and demand dynamics, geopolitical factors, technological advancements, environmental regulations, and the global economic climate. Understanding these factors can help businesses and consumers make more informed decisions when purchasing polycarbonate products. As the market continues to evolve, keeping a close eye on these trends will be essential for staying ahead of potential price fluctuations and ensuring that procurement strategies are both cost-effective and sustainable.

Get Real Time Prices for Polycarbonate: https://www.chemanalyst.com/Pricing-data/polycarbonate-47

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polycarbonate#Polycarbonate Price#Polycarbonate Prices#Polycarbonate Pricing#Polycarbonate News#Polycarbonate Price Monitor

0 notes

Text

Polycarbonate Diols Market to Hit $0.3 Billion by 2032

The global Polycarbonate Diols Market was valued at USD 0.2 Billion in 2024 and it is estimated to garner USD 0.3 Billion by 2032 with a registered CAGR of 6.2% during the forecast period 2024 to 2032.

The report throws light on the competitive scenario of the global Polycarbonate Diols Market to know the competition at global levels. Market experts also provided the outline of each leading player of the global Polycarbonate Diols Market for the market, considering the key aspects such as the areas of operation, production, and product portfolio. In addition, the companies in the report are studied based on vital factors such as company size, market share, market growth, revenue, production volume, and profit.

The global Polycarbonate Diols Market is fragmented with various key players. Some of the key players identified across the value chain of the global Polycarbonate Diols Market include Ube Industries Ltd., Mitsubishi Chemical Corporation, Asahi Kasei Corporation, Covestro Ag, Tosoh Corporation, Daicel Corporation, Perstorp Group, Saudi Arabian Oil Co., GRR Fine Chem Pvt. Ltd., Chemwill Asia Co. Ltd. etc. Considering the increasing demand from global markets various new entries are expected in the Polycarbonate Diols Market at regional as well as global levels.

Download Polycarbonate Diols Market Sample Report PDF: https://www.vantagemarketresearch.com/polycarbonate-diols-market-1109/request-sample

Top Competitors:

Ube Industries Ltd., Mitsubishi Chemical Corporation, Asahi Kasei Corporation, Covestro Ag, Tosoh Corporation, Daicel Corporation, Perstorp Group, Saudi Arabian Oil Co., GRR Fine Chem Pvt. Ltd., Chemwill Asia Co. Ltd.

Understanding the Industry's Growth, has released an Updated report on the Polycarbonate Diols Market. The report is mixed with crucial market insights that will support the clients to make the right business decisions. This research will help new players in the global Polycarbonate Diols Market to sort out and study market needs, market size, and competition. The report provides information on the supply and market situation, the competitive situation and the challenges to the market growth, the market opportunities, and the threats faced by the major players.

Regional Analysis

-North America [United States, Canada, Mexico]

-South America [Brazil, Argentina, Columbia, Chile, Peru]

-Europe [Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland]

-Middle East & Africa [GCC, North Africa, South Africa]

-Asia-Pacific [China, Southeast Asia, India, Japan, Korea, Western Asia]

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/polycarbonate-diols-market-1109/0

Full Analysis Of The Polycarbonate Diols Market:

Key findings and recommendations point to vital progressive industry trends in the global Polycarbonate Diols Market, empowering players to improve effective long-term policies.

The report makes a full analysis of the factors driving the development of the market.

Analyzing the market opportunities for stakeholders by categorizing the high-growth divisions of the market.

Questions answered in the report

-Who are the top five players in the global Polycarbonate Diols Market?

-How will the global Polycarbonate Diols Market change in the next five years?

-Which product and application will take the lion's share of the global Polycarbonate Diols Market?

-What are the drivers and restraints of the global Polycarbonate Diols Market?

-Which regional market will show the highest growth?

-What will be the CAGR and size of the global Polycarbonate Diols Market during the forecast period?

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/polycarbonate-diols-market-1109

Reasons to Purchase this Polycarbonate Diols Market Report:

-Analysis of the market outlook on current trends and SWOT analysis.

-The geographic and country level is designed to integrate the supply and demand organizations that drive industry growth.

-Polycarbonate Diols Industry dynamics along with market growth opportunities in the coming years.

-Polycarbonate Diols Market value (million USD) and volume (million units) data for each segment and sub-segment.

1 year consulting for analysts along with development data support in Excel. Competitive landscape including market share of major players along with various projects and strategies adopted by players in the last five years.

Market segmentation analysis including qualitative and quantitative analysis including the impact on financial and non-economic aspects.

Complete company profiles that include performance presentations, key financial overviews, current developments, SWOT analyzes and strategies used by major Polycarbonate Diols Market players.

Check Out More Reports

Global Recombinant DNA Technology Market: Report Forecast by 2032

Global Phosphate Fertilizers Market: Report Forecast by 2032

Global Marché de l’acide lévulinique: Report Forecast by 2032

Global Reverse Logistics Market: Report Forecast by 2032

Global Military Aerospace & Defense Lifecycle Management Market: Report Forecast by 2032

#Polycarbonate Diols Market#Polycarbonate Diols Market 2024#Global Polycarbonate Diols Market#Polycarbonate Diols Market outlook#Polycarbonate Diols Market Trend#Polycarbonate Diols Market Size & Share#Polycarbonate Diols Market Forecast#Polycarbonate Diols Market Demand#Polycarbonate Diols Market sales & price

0 notes

Text

Creating an indoor greenhouse can be an exciting and rewarding project, especially for gardening enthusiasts. One of the best materials to consider for constructing your greenhouse is polycarbonate hollow sheets. These sheets offer excellent insulation, durability, and light diffusion, making them ideal for creating a controlled environment for your plants. In this guide, we’ll explore the benefits of using Polycarbonate hollow sheets, how to choose the right materials, and tips for installation.

0 notes

Text

The Role of PC Hollow Sheets in Modular Construction

Introduction to Modular Construction

Modular construction has revolutionized the building industry by offering a faster, more efficient, and cost-effective method of constructing buildings. This technique involves prefabricated sections of a building in a factory setting, which are then transported to the construction site and assembled into a complete structure. One of the critical components in modular construction is the use of polycarbonate (PC) hollow sheets. These sheets provide numerous advantages, from durability to thermal insulation, making them an ideal material for modern construction needs.

Understanding PC Hollow Sheets

PC hollow sheets, also known as polycarbonate hollow sheets, are lightweight, durable, and versatile materials widely used in construction. They consist of multiple layers of polycarbonate, creating air pockets that enhance their insulation properties. These sheets are known for their high impact resistance, transparency, and UV protection, making them suitable for various applications, including roofing, skylights, and wall partitions. The lightweight nature of PC hollow sheets also facilitates easier handling and installation, which is particularly beneficial in modular construction.

Benefits in Modular Construction

The use of PC hollow sheets in modular construction offers several advantages. Firstly, their excellent thermal insulation properties help maintain a consistent indoor temperature, reducing the need for excessive heating or cooling. This leads to significant energy savings and contributes to the overall sustainability of the building. Secondly, PC hollow sheets are highly durable and resistant to weathering, ensuring a long lifespan and minimal maintenance requirements.

Enhanced Aesthetic Appeal

In addition to their functional benefits, PC hollow sheets also enhance the aesthetic appeal of modular buildings. This feature is particularly valuable in residential and commercial buildings, where natural light can improve the occupants' well-being and productivity. Furthermore, PC hollow sheets are available in various colors and finishes, providing architects and designers with the flexibility to create visually striking structures.

Role of Exporter of PC Hollow Sheet

The growing demand for PC hollow sheets in the construction industry has led to the emergence of numerous PC hollow sheet exporters. These exporters play a crucial role in supplying high-quality polycarbonate sheets to various parts of the world. By partnering with reputable hollow sheet polycarbonate suppliers, they ensure that builders and contractors have access to the best materials for their projects. The availability of reliable exporters has significantly contributed to the widespread adoption of PC hollow sheets in modular construction.

Cost Considerations of PC hollow sheet

While the benefits of PC hollow sheets are clear, it is essential to consider the cost implications. The Hollow polycarbonate sheet price can vary based on factors such as thickness, size, and quality. Generally, these sheets are competitively priced compared to traditional building materials like glass. However, the long-term savings in energy costs, maintenance, and replacement expenses make them a cost-effective investment. Builders and developers should carefully evaluate the total cost of ownership when choosing materials for their projects.

Environmental Impact and Sustainability

PC hollow sheets contribute to environmental sustainability in several ways. Firstly, their insulation properties reduce energy consumption, leading to lower greenhouse gas emissions. Secondly, polycarbonate is a recyclable material, which means that at the end of its life cycle, it can be repurposed rather than ending up in a landfill. Additionally, the lightweight nature of PC hollow sheets reduces transportation emissions, further enhancing their eco-friendly credentials.

Challenges and Solutions

Despite their numerous advantages, the use of PC hollow sheets in modular construction is not without challenges. One of the primary concerns is the potential for thermal expansion, which can lead to warping or deformation. However, this issue can be mitigated by using proper installation techniques and allowing for thermal movement in the design. Another challenge is the need for specialized cutting and handling tools, which may require additional investment. Nonetheless, the benefits far outweigh these challenges, making PC hollow sheets a worthwhile choice for modular construction.

Innovations and Future Trends

The field of modular construction is continually evolving, and so are the materials used. Innovations in PC hollow sheets are expected to further enhance their performance and application. For instance, advancements in manufacturing techniques may lead to even better insulation properties and increased strength. Additionally, the development of smart polycarbonate sheets with integrated solar panels or self-cleaning surfaces could revolutionize the construction industry. Staying abreast of these trends will be crucial for builders and developers looking to leverage the latest technologies in their projects.

Case Studies

Several successful case studies highlight the effectiveness of PC hollow sheets in modular construction. For example, a residential project in Europe utilized PC hollow sheets for roofing and wall cladding, resulting in a modern, energy-efficient home. The use of these sheets allowed for rapid construction and reduced the overall project timeline. In another instance, a commercial building in Asia incorporated PC hollow sheets in its facade, creating a visually appealing and environmentally friendly structure. These examples demonstrate the versatility and practicality of PC hollow sheets in various construction scenarios.

Conclusion

In conclusion, PC hollow sheets play a pivotal role in the advancement of modular construction. Their unique combination of durability, insulation, and aesthetic appeal makes them an ideal material for modern building projects. The support of PC hollow sheet exporters and Hollow sheet polycarbonate suppliers ensures that high-quality materials are readily available to meet the growing demand. While the hollow polycarbonate sheet price may be a consideration, the long-term benefits in terms of energy savings, maintenance, and sustainability make them a valuable investment. As innovations continue to emerge, the future of modular construction looks promising, with PC hollow sheets set to play an increasingly significant role. Frequently Asked Questions (FAQs) Are PC hollow sheets suitable for outdoor use? Yes, PC hollow sheets are suitable for outdoor use. They offer excellent UV protection, preventing degradation and ensuring long-lasting performance even when exposed to the elements.

Are PC hollow sheets environmentally friendly? Yes, PC hollow sheets are environmentally friendly. They are fully recyclable, and their excellent thermal insulation properties contribute to lower energy consumption, reducing the overall environmental impact of a building project.

0 notes

Text

Midas Awnings Singapore

Discover the excellence of Midas Awning Singapore for all your awning needs. We specialize in installing high-quality awnings in Singapore for homeowners looking for a retractable awning, an awning roof, or even a stylish awning canopy. Our expertise in awning design ensures that our awning services not only serve their functional purpose but also enhance the aesthetic appeal of your space. With the help of our skilled professionals, you can enjoy the versatility and convenience of your retractable awning in Singapore or ACP awning and adapt easily to changing weather conditions. Not only do we offer competitive prices that provide great value for money without compromising on quality, but our range of awning options is perfect for those seeking durable and modern designs.

Explore our different awning types including glass awning, outdoor awnings, door awnings, and aluminum awnings to find the perfect match for your property. If you need window awnings to protect your interiors from the sun, a balcony awning to create a shaded retreat, or a polycarbonate awning for durability and style, our awning contractors have the expertise to deliver outstanding results. Our collection also includes high-quality awning fabrics, cassette awnings, and fixed awnings for those looking for a permanent, stylish shading solution. For those seeking a robust and versatile option, we also have polycarbonate roof and outdoor canopy selections which is ideal for those looking to install canopy in Singapore. Trust Midas Awning Singapore to provide exceptional craftsmanship and unmatched customer service for all your awning needs. Contact us today via WhatsApp at +65 8241 0032 to transform your space with our premium awning solutions.

1090 Lower Delta Road #04-06U, Singapore 169201

Phone # +65 6232 6750

#awnings#awning singapore#awning sg#retractable awning#awning roof#retractable awning singapore#acp awning#retractable awning singapore price#awning design#awning canopy#polycarbonate roof#canopy singapore#polycarbonate awning#outdoor canopy#glass awning#outdoor awnings#aluminum awnings#window awnings#balcony awning#awning fabric#fixed awnings#awning contractor#cassette awning#door awning

1 note

·

View note

Text

Who Should Opt for Polycarbonate Awnings in Pune?

As a leading manufacturer of polycarbonate awnings in Pune, Iris is here to help you understand who can benefit the most from these versatile and durable awnings.

Homeowners:

Homeowners looking to enhance their outdoor spaces should consider polycarbonate awnings. These awnings provide excellent protection from the sun and rain while allowing natural light to filter through, making patios, balconies, and windows more comfortable and usable year-round.

Businesses:

Businesses such as cafes, restaurants, and retail stores can greatly benefit from polycarbonate awnings. These awnings create inviting and sheltered outdoor seating or display areas, attracting more customers and enhancing the overall aesthetic of the business premises.

Educational Institutions:

Schools and colleges can use polycarbonate awnings in Pune from Iris to cover walkways, playgrounds, and assembly areas. This not only protects students and staff from harsh weather conditions but also creates more functional outdoor spaces for various activities.

youtube

Healthcare Facilities:

Hospitals and clinics can install polycarbonate awnings over entrances, waiting areas, and walkways. This provides patients and visitors with protection from the elements, ensuring a more comfortable experience.

Industrial Buildings:

Factories and warehouses can use polycarbonate awnings to cover loading docks and employee break areas. The durability and weather resistance of polycarbonate make it an ideal choice for such high-traffic and industrial settings.

Public Spaces:

Municipalities can install polycarbonate awnings in parks, bus stops, and public seating areas. These awnings provide protection and comfort to the public while enhancing the visual appeal of public spaces.

At Iris, we specialize in designing and manufacturing high-quality polycarbonate awnings tailored to meet the unique needs of both residential and commercial properties in Pune. Our expertise ensures that you get a durable, stylish, and functional solution that enhances your space.

Contact us today to explore our wide range of polycarbonate awnings in Pune.

Contact:

Name- Iris Enterprises awning in Pune | awning manufacturers in Pune | awning dealers in Pune | canopy in Pune | canopy manufacturers in Pune | invisible grill Pune | tensile structure manufacturer in Pune

Address- Kiran Shubhlabh, Mohan Nagar, Near Bitwise Tera Tower, Baner Pune, Maharashtra 411045

Phone Number- 9922909701

#polycarbonate awning in pune#awning dealers in pune#awning manufacturers in Pune#awning price in pune#awning roof in pune#awning for terrace in pune#balcony awning in pune#awning for balcony in pune#awning terrace in pune#terrace awning in pune#pvc sun shade for balcony in pune#house balcony roof design in pune#iris enterprises pune#pune#Youtube

0 notes

Text

Imporve Your Project with Top-Quality Polycarbonate Sheets from Kapoor Plastics

Polycarbonate sheets, renowned for their exceptional qualities, have become a fundamental element in pioneering projects throughout India, from Delhi to Mumbai and Vadodara.

#Polycarbonate sheets#coloured polycarbonate sheets#transparent polycarbonate sheets#Lexan polycarbonate sheets#Lexan polycarbonate sheet price list

0 notes

Text

High-Quality Polycarbonate Sheets for Your Projects

Discover the perfect solution for your project needs with Tilara Polyplast's range of high-quality polycarbonate sheets. Engineered to withstand harsh weather conditions and maintain optical clarity over time, Tilara Polyplast sheets offer unmatched performance and reliability. Choose Tilara Polyplast for superior quality and reliability in every project.

0 notes

Text

Your Trusted Pc Resin Partner - Kapoor Sales Corporation

Check out our competitive polycarbonate resin prices in India and experience the Kapoor advantage.

0 notes

Text

Awnings have been a well-known expansion to homes for a long time and good explanation. These flexible awning structures give help from the burning sun and add a bit of style to your property while assisting you with saving money on energy costs. In this complete conversation, we'll dig into the horde advantages of overhangs, investigating how they upgrade your home's solace, feel, and monetary reserve funds.

#awning price in delhi#motorized awning#Plastic Awning#Polycarbonate Awning#awning supplier#awnings in delhi

0 notes

Text

Polycarbonate Prices Trend | Pricing | Database | Index | News | Chart

Polycarbonate Prices is a versatile thermoplastic known for its durability, transparency, and impact resistance, making it a favored material in various industries. As of recent updates, polycarbonate prices have experienced fluctuations influenced by factors such as raw material costs, market demand, and global economic conditions. The pricing dynamics of polycarbonate are closely tied to the prices of its key raw materials, particularly bisphenol A (BPA) and phosgene, which impact production costs significantly.

The market demand for polycarbonate plays a crucial role in price fluctuations, with high demand often driving prices up. Industries such as automotive, electronics, construction, and healthcare contribute significantly to this demand due to the material's desirable properties. Conversely, economic downturns or shifts in consumer preferences can lead to periods of oversupply, causing prices to stabilize or even decrease.

Global economic conditions also influence polycarbonate prices, as the material is traded internationally. Currency exchange rates, trade tariffs, and geopolitical tensions can all impact the cost of polycarbonate resin, affecting both manufacturers and end-users worldwide. For instance, disruptions in supply chains due to geopolitical events or natural disasters can cause temporary spikes in prices as supply tightens.

Get Real Time Prices of Polycarbonate : https://www.chemanalyst.com/Pricing-data/polycarbonate-47

Environmental regulations and sustainability initiatives are increasingly shaping the polycarbonate market. As regulations tighten around the use of certain chemicals and the environmental impact of plastic production becomes a greater concern, manufacturers may face additional costs associated with compliance and eco-friendly practices. These factors can contribute to upward pressure on prices, as companies invest in sustainable practices and technologies.

Innovation in polycarbonate production processes also influences pricing trends. Advancements in manufacturing techniques, such as more efficient polymerization methods or the development of bio-based alternatives to traditional raw materials, can impact production costs and subsequently, market prices. Such innovations not only aim to reduce costs but also address environmental concerns and improve product performance.

Regional factors further add complexity to polycarbonate pricing. Different regions may have varying levels of demand, production capacity, and regulatory environments, all of which can affect local pricing dynamics. For example, regions with high industrial activity or strong manufacturing bases may see more stable pricing due to localized supply chains and demand patterns.

Market forecasting and analysis play a crucial role for stakeholders in navigating polycarbonate price fluctuations. Manufacturers, suppliers, and end-users often rely on market intelligence and trend analysis to anticipate changes in pricing and adjust their strategies accordingly. This proactive approach helps mitigate risks associated with volatile pricing and ensures a more stable supply chain for businesses reliant on polycarbonate materials.

Looking ahead, the future of polycarbonate pricing will likely continue to be influenced by these multifaceted factors. As industries evolve and global challenges such as climate change and resource scarcity come to the forefront, the demand for sustainable materials like polycarbonate may increase, impacting pricing dynamics in unforeseen ways. Adapting to these changes requires a balance of innovation, market insight, and strategic planning to ensure the resilience and competitiveness of the polycarbonate industry in a dynamic global economy.

Get Real Time Prices of Polycarbonate : https://www.chemanalyst.com/Pricing-data/polycarbonate-47

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polycarbonate#Polycarbonate Price#Polycarbonate Prices#Polycarbonate Pricing#Polycarbonate News#Polycarbonate Price Monitor

0 notes

Text

Polycarbonate Sheet NZ, Polycarbonate Sheets Auckland | Rangi

Polycarbonate sheet nz, Polycarbonate sheets auckland - Rangi’s polycarbonate (PC) panels allow for beautiful diffused light inside your outdoor space. Our roofing panels are 3 mm thick and with UV protection on both sides.

#polycarbonate sheet new zealand#polycarbonate roofing prices nz#polycarbonate sheet nz#polycarbonate sheets auckland#aluminium awnings nz#aluminium pergola auckland

0 notes

Text

Rolling Shutter with Wicket Door Manufacturers in Delhi

Vijay Shutter Enterprises is a reputable manufacturer based in Delhi, specializing in the production of rolling shutters with wicket doors. They offer a comprehensive range of high-quality rolling shutters that are designed to provide security and convenience. These shutters are equipped with wicket doors, allowing easy pedestrian access without having to fully open the shutter. Vijay Shutter Enterprises prioritizes precision and durability, ensuring that their products are made from top-grade materials and undergo rigorous quality checks. With their expertise in manufacturing rolling shutters with wicket doors, they have gained a solid reputation as a trusted provider of security solutions in Delhi.

Read more:- https://rollingshuttersmanufacturers.business.blog/2023/05/17/understanding-the-benefits-of-rolling-shutters-with-wicket-doors-a-complete-guide/

#Rolling Shutter with Wicket Door Manufacturers in Delhi#rolling shutter with wicket door#rolling shutter with wicket door manufacturers in delhi#Mechanical Gear Rolling Shutters delhi#perforated rolling shutters manufacturers in delhi#pull and push rolling shutter in delhi#pull & push rolling shutter manufacturers#shutter manufacturers in delhi#mechanical gear rolling shutter manufacturers#perforated rolling shutters manufacturers#rolling shutter manufacturers in delhi#rolling shutter manufacturer in delhi#motorized rolling shutter manufacture in delhi#Pull & Push Type Rolling Shutters#Pull & Push Rolling Shutters#perforated rolling shutter price#Grill Type Rolling Shutters#Mechanical Gear Type Rolling Shutters#Polycarbonate rolling shutter#fancy rolling grill manufacturers in delhi#polycarbonate rolling door#aluminium rolling shutter manufacture#rolling shutters manufacturers#grill rolling shutters#Aluminium motorized rolling shutter#transparent polycarbonate roller shutter#aluminium rolling shutter#automatic rolling shutter for home#aluminium roller shutter doors#aluminium roller shutter

1 note

·

View note

Text

What Are PC Hollow Sheets and Why Use Them?

Introduction to Polycarbonate Hollow Sheets

Polycarbonate hollow sheet, often referred to simply as PC hollow sheets, are innovative building materials made from polycarbonate, a durable and versatile thermoplastic. These sheets are characterized by their unique structure, which features a series of hollow channels that run through the material. This design not only contributes to their lightweight nature but also enhances their insulation properties, making them an ideal choice for various applications in construction, horticulture, and signage.

Composition and Structure of Polycarbonate Sheets

The primary component of polycarbonate hollow sheets is polycarbonate resin, which is known for its high impact resistance and optical clarity. Unlike traditional glass, polycarbonate is shatter-resistant, making it a safer option for environments where breakage is a concern. The hollow channels within the sheet create an insulating barrier, allowing for thermal efficiency while reducing overall weight. This structure also provides flexibility in design, enabling architects and builders to use the material in a range of applications.

Benefits of Using Polycarbonate Hollow Sheets

Durability and Strength

One of the standout features of polycarbonate sheets is their impressive durability. They can withstand extreme weather conditions, including heavy rain, hail, and high winds. The high impact resistance means they are less likely to crack or shatter compared to other materials like glass or acrylic. This resilience makes polycarbonate hollow sheets a long-lasting option for various construction projects.

Thermal Insulation

The hollow design of these sheets enhances their thermal insulation capabilities. The air trapped within the channels acts as an insulating layer, reducing heat transfer and improving energy efficiency. This feature is particularly beneficial for greenhouses, where maintaining a stable temperature is crucial for plant growth, as well as for buildings looking to reduce energy costs.

Lightweight and Easy to Install

Polycarbonate hollow sheets are significantly lighter than glass, which makes them easier to handle and install. This lightweight nature can lead to reduced shipping costs and simpler installation processes, saving time and labor expenses. Their flexibility allows them to be cut and shaped according to specific project needs, further enhancing their usability.

UV Resistance

Another critical advantage of polycarbonate hollow sheets is their UV resistance. Most manufacturers treat these sheets with a special coating that protects against harmful UV rays, which can degrade materials over time. This UV protection ensures that the sheets maintain their clarity and structural integrity even after prolonged exposure to sunlight.

Common Applications of Polycarbonate Hollow Sheets

Greenhouses and Agricultural Structures

One of the most common uses for polycarbonate hollow sheets is in the construction of greenhouses. The excellent light transmission capabilities combined with thermal insulation make them ideal for creating a controlled environment for plants. These sheets allow for maximum sunlight penetration while minimizing heat loss, promoting healthy growth year-round.

Roofing and Canopies

Polycarbonate sheets are increasingly popular for roofing applications, especially in commercial and residential projects. Their lightweight nature and durability make them perfect for canopies, awnings, and patio covers. These structures benefit from the transparency of polycarbonate, allowing natural light to flood the area while providing protection from the elements.

Partition Walls and Interiors

In modern architectural design, polycarbonate hollow sheets are often used for interior partition walls. Their versatility allows for creative and functional space designs, while their light weight simplifies installation. The option for customizable colors and finishes makes them suitable for various aesthetics, from sleek modern designs to more traditional looks.

Signage and Display Cases

Polycarbonate hollow sheets are also utilized in signage and display cases due to their clarity and durability. They can be easily molded into different shapes and sizes, making them ideal for custom signage. Their resistance to breakage ensures that signs remain intact and readable over time, even in outdoor environments.

Comparing Polycarbonate Sheet Prices

When considering the use of polycarbonate hollow sheets, it’s essential to evaluate the Polycarbonate sheet price. Prices can vary significantly based on several factors, including thickness, size, and any additional treatments, such as UV protection or color tinting. Generally, while polycarbonate sheets may have a higher upfront cost than materials like acrylic or PVC, their longevity and performance often justify the investment. Over time, the savings in energy costs and replacement expenses can offset the initial expenditure.

Choosing the Right Polycarbonate Sheet

Thickness and Structure

When selecting Polycarbonate sheet for a specific project, it’s crucial to consider the thickness and structural configuration of the sheets. Thicker sheets provide better insulation and impact resistance, while thinner sheets may be more suitable for lightweight applications. The number of hollow channels can also affect insulation properties and overall performance.

Color and Transparency

Polycarbonate hollow sheets are available in various colors and levels of transparency. Clear sheets allow maximum light penetration, while tinted options can provide shade and reduce glare. When choosing sheets for a greenhouse, for example, clear sheets are often preferred, whereas darker sheets might be better for roofing applications where heat retention is desired.

Manufacturer and Quality

Quality matters when it comes to polycarbonate sheets. Always choose products from reputable manufacturers who offer warranties and clear specifications on their sheets. This ensures that you receive a product that meets your performance expectations and can withstand the test of time.

Conclusion: The Versatility of PC Hollow Sheets

In conclusion, polycarbonate hollow sheets are a remarkable building material that offers a multitude of benefits, including durability, thermal insulation, and UV resistance. Their lightweight nature and versatility make them suitable for a wide range of applications, from greenhouses and roofing to interior partitions and signage. While the polycarbonate sheet price may initially seem higher than alternatives, the long-term savings and performance advantages often make them the better choice. As construction and design continue to evolve, polycarbonate hollow sheets are likely to play an increasingly vital role in innovative building solutions.

FAQs About Polycarbonate Hollow Sheets

1. What are polycarbonate hollow sheets?

Polycarbonate hollow sheets, or PC hollow sheets, are lightweight, durable panels made from polycarbonate resin. They feature a unique hollow channel structure that enhances insulation and impact resistance, making them ideal for various applications, such as greenhouses, roofing, and signage.

2. What are the benefits of using polycarbonate hollow sheets?

Polycarbonate hollow sheets offer several advantages, including:

Durability: They are highly resistant to impact and weather conditions.

Thermal Insulation: The hollow channels provide excellent thermal efficiency.

Lightweight: Easier to handle and install compared to glass.

UV Resistance: Many sheets are treated to resist UV rays, preventing degradation over time.

3. How do polycarbonate sheets compare in price?

The polycarbonate sheet price can vary based on thickness, size, and any additional features like UV protection or tinting. While they may have a higher initial cost compared to materials like acrylic or PVC, their durability and energy efficiency can lead to savings in the long run.

0 notes

Text

#rodent bait box#polycarbonate bird spikes#fly insect killer machine#flies killer machine#fly machine killer#flying insect killer machine price#insect fly killer machine#cat cage#fly catcher machine

0 notes

Text

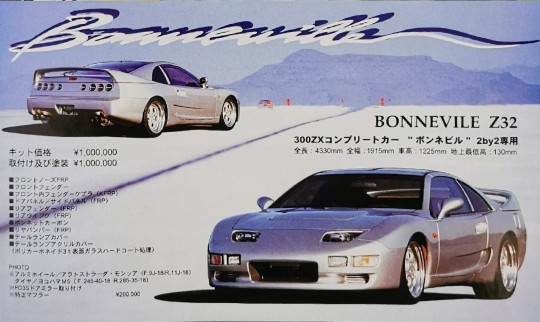

D-Speed Bonneville aero kit for the Z32 300ZX 2by2.

Kit price ¥1,000,000

Installation and painting ¥1,000,000

■Front nose FRP.

■Front fender

■Front inner fender Keppra (KFRP)

■Door panel/side panel (FRP)

■Rear fender (FRP)

■Rear wing (FRP)

■Bonnet carbon

■Rear bumper (FRP)

■Tail lamp cover

■Tail lamp acrylic cover

(Polycarbonate 3 + surface glass hard coat treatment)

*Aluminum wheels/Autostrada Mongua

(F.9J-18/R.11J-18)

Tire/Yokohama M5 (F.245-40-18 R.285-35-18)

*FD3S door mirror installation

*Custom muffler ¥200,000

BONNEVILE Z32

300ZX Complete Car Bonneville" 2by2 exclusive

Overall length: 4330mm Overall width: 1915mm Vehicle height: 1225mm Ground clearance: 130mm

22 notes

·

View notes