#PlateHeatExchangers

Explore tagged Tumblr posts

Text

Learn about the usefulness of Plate Heat Exchangers in various industries. Know which is the best type for your particular application: Gasketed, Brazed, or Welded. For more, visit our website.

0 notes

Text

Galaxy Industrial Equipment Pvt. Ltd. is the top heat exchanger manufacturer in Pune, India. We are well known for our creative designs and are experts in the delivery and maintenance of a wide range of heat exchangers, including plate, shell, and tube, semi-welded, and welded plate exchangers. Durability and peak performance are guaranteed by our dedication to quality and excellence. Galaxy prioritizes client satisfaction and offers specific services to satisfy a range of industrial demands, all supported by unmatched knowledge and assistance. For dependable, effective, and high-performing heat exchanger solutions, go with Galaxy.

#GalaxyIndustrial#HeatExchangers#PuneManufacturing#IndustrialEquipment#EngineeringExcellence#HeatTransferSolutions#ShellAndTubeExchangers#PlateHeatExchangers

0 notes

Text

How To Pick The Best Plate Heat Exchanger For Your Needs

Do you need a plate heat exchanger but do not know where to start? Don't worry we've got you covered! In this post, we'll tell you how can you pick the best heat exchanger according to your needs.

Plate heat exchangers are really helpful for heating or cooling fluids in various industries. They are widely used in chemical plants, food processing facilities, HVAC systems, etc. The market offers a wide range of options for selecting the ideal heat exchanger for your business's needs. It might be difficult to decide which one to choose, and sometimes the most well-liked choice isn't ideal for your requirements. So before buying any plate heat exchanger consider below mention points.

Type Of Plate Heat Exchanger

There are several types of plate heat exchangers available in the market. Choose wisely for the right type that can fulfil your requirements.

Select The Right Size

Different sizes of plate heat exchangers are used to accomplish different tasks. The size of the heat exchanger depends on the factors like flow rate, temperature differential, and pressure drop. Select the size that is the right fit for you.

Choose The Correct Brand

Purchase the device from a reputable brand which ensures the quality and longevity of the device. Check out their reviews and services before making any decision.

Evaluate The Pros and Cons of Plate Heat Exchanger

Weigh the benefits and cons of the plate heat exchanger you are considering buying. Once you evaluate each and every pros and cons it will become easy to pick the right heat exchanger based on your needs.

In conclusion, plate heat exchangers are a great help in improving heat transfer efficiency. But it will only be helpful if you choose the correct one for your industrial needs. Consider above mentioned point before making a purchase. If you are still confused then read this blog "What You Need To Know Before Buying A Plate Heat Exchanger". You will find valuable tips from here that will help you make an informed decision.

#PlateHeatExchangers#PlateHeatExchangersIndia#PlateHeatExchangerTypes#BuyPlateHeatExchanger#HeatExchangers

0 notes

Text

Bliss flow systems Group are one of the Best supplier and distributor of Industrial Boilers, Hot Water Generators, Thermal Fluid Heaters, Steam Boilers, Valve Supplier etc.

Just Dial: +971 58 5837600.

#industrialboiler#steamboiler#ValveSupplier#solenoidvalve#industrialequipment#plateheatexchanger#bestSupplier#blissflowsystems

1 note

·

View note

Text

AMAN REFRIGERATION- PLATE HEAT EXCHANGER SERVICES PROVIDER

Aman Refrigeration stands as a pioneering force in the realm of Plate Heat Exchanger Services, showcasing unparalleled expertise and innovation. As a leading provider, we excel in delivering top-notch solutions tailored to meet diverse industrial needs. Our commitment to precision and efficiency sets us apart, ensuring that your plate heat exchangers operate at peak performance. Trust Aman Refrigeration for unparalleled excellence in Plate Heat Exchanger services, where expertise meets reliability.

AMAN REFRIGERATION: PIONEERING EXCELLENCE IN PRESSURE VESSEL MANUFACTURERS

Aman Refrigeration has emerged as a stalwart, setting the benchmark for excellence in Pressure Vessel Manufacturers. With an unwavering commitment to quality, innovation, and customer satisfaction, Aman Refrigeration has carved a niche for itself as the go-to manufacturer for top-tier pressure vessel.

Unparalleled Expertise:

Aman Refrigeration boasts a team of seasoned engineers and experts who bring a wealth of knowledge and experience to the table. The company’s expertise lies in the design and fabrication of pressure vessels that meet and exceed industry standards. From concept to completion, Aman Refrigeration ensures meticulous attention to detail at every stage of the manufacturing process.

Cutting-edge Technology:

At the heart of Aman Refrigeration’s success lies its investment in cutting-edge technology. The company employs state-of-the-art manufacturing facilities equipped with the latest machinery and tools. This commitment to technological advancement enables Aman Refrigeration to produce pressure vessels with precision, efficiency, and consistency.

Customization and Innovation:

Recognizing the diverse needs of its clientele, Aman Refrigeration offers customized solutions for pressure vessel. The company collaborates closely with clients to understand their specific requirements and designs tailor-made vessels that align with their unique applications. Aman Refrigeration’s commitment to innovation ensures that its pressure vessels incorporate the latest advancements in materials and design, staying ahead of the curve in an ever-evolving industry.

AMAN REFRIGERATION: CRAFTING EXCELLENCE IN PRESSURE VESSELS

At Aman Refrigeration, we are renowned for our unwavering commitment to quality and precision in manufacturing pressure vessels. As a leading name in the industry, we offer a wide range of pressure vessels that meet the rigorous demands of various applications across different sectors.

Key Attributes of Aman Refrigeration’s Pressure Vessels:

Engineering Excellence: Our Pressure Vessels are engineered with the utmost precision and adherence to industry standards. They are built to perform reliably under varying pressure and temperature conditions.

Custom Solutions: We understand that different industries have unique needs. Aman Refrigeration takes pride in offering custom-designed pressure vessels to suit specific requirements, whether for chemical processing, pharmaceuticals, or energy production.

Safety and Compliance: Safety is a top priority. Our pressure vessel are designed with multiple safety features to ensure the well-being of personnel and to comply with strict regulatory guidelines.

Robust Construction: Our pressure vessels are constructed from the finest materials, guaranteeing durability and long service life. They are built to withstand the rigors of industrial use.

Quality Assurance: Quality is at the core of our manufacturing process. Every Pressure Vessels undergoes rigorous quality testing to ensure it meets the highest industry standards.

0 notes

Text

Unrivaled Precision: Kinetic Engineering Corporation's Plate Heat Exchangers

Kinetic Engineering Corporation impresses with its plate heat exchangers, epitomizing excellence in industrial heat transfer solutions. The meticulous design and performance of their equipment showcase a commitment to quality. Businesses seeking reliable and efficient plate heat exchangers find a trusted ally in Kinetic Engineering Corporation. Visit here:

0 notes

Video

youtube

(via Small Room Heater Blower India 2022 Shut Off)

0 notes

Video

youtube

Plate Heat Exchanger, How it works - working principle hvac industrial engineering

0 notes

Text

THE HEAT IS ON AT VALVEFORCE

Over the past few years our specialist range of on-site supporting services has been enhanced and expanded to meet the changing needs of our customers. Time and time again we have been asked to extend our skill-set so we can fully service not only plate heat exchangers on-site but also shell & tube exchangers, air handling units, heater batteries, coolers and coils. We have listened, and last summer we invested significantly and set up a comprehensive Heat Exchanger division and fabrication workshop in-house. More importantly we now have a dedicated team led by a very capable and experienced Heat Exchanger specialist, namely Richard Evans. Heatxforce offers a full range of products and services from concept design through to the supply and installation of heat exchanger packages. We are supporting our customers with: • Full cleaning and testing services • On and off-site repairs and maintenance • Plate heat exchanger strip, re-gaskets and re-builds • Shell & tube, testing, replacing return bends, blanking off leaking tubes and re-tube • Full design and consultation services through to the fabrication, installation, controls and commissioning We cover all applications and industries including but not limited to Schools & Universities, Hospitals & Prisons, Energy & Power and general utilities. For every stage of your project or on-site needs, you can rely on Heatxforce. With the best level of service, independent expert technical advice and the benefit of a multi-disciplinary team, we guarantee the performance of your plant and process. We will be in touch to talk to you about your specific needs, if in the mean time you would like to discuss any aspect of your heater exchange and servicing requirements please do not hesitate to contact us. Read the full article

0 notes

Text

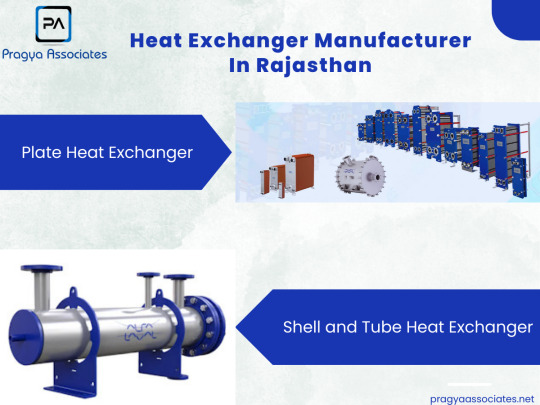

Heat Exchanger Manufacturer In Rajasthan

Pragya Associates is a leading heat exchanger manufacturer in Rajasthan. We manufacture a wide range of heat exchangers including plate heat exchangers and shell and tube heat exchangers. We use the highest quality raw materials and cutting-edge technology to manufacture our exchangers and spare parts in accordance with international standards. Our heat exchangers are well-known for their ease of installation, fine finish, and trouble-free operation. Additionally, our quality controllers thoroughly inspect these products based on a number of quality check parameters to guarantee an absolute quality product. Get in touch with us now to learn more about our high-quality heat exchangers.

#HeatExchangerManufacturer#TopHeatExchangerManufacturerInRajasthan#HeatExchangerInRajasthan#PlateHeatExchanger#ShellAndTubeHeatExchanger

0 notes

Text

Manufacturer of phe gaskets, phe plates, butterfly valves liners, 'O' Rings, union gaskets, other rubber products of nbr, hnbr, silicon, viton & viton g

PHE ENGINEERING WORKS, plate heat exchanger #pheplates #phegaskets #phegasketsworld #phegasketworld #vinodpaswan #plateheatexchanger #pheengineeringworks

PHE GASKETS WORLD

PHE GASKETS WORLD

1 note

·

View note

Text

Bliss flow systems Group are one of the Best supplier and distributor of Industrial Boilers, Hot Water Generators, Thermal Fluid Heaters, Steam Boilers, Valve Supplier etc.

Just Dial: +971 58 5837600.

Visit Us- www.blissflowsystems.com/industrial-boilers/

#industrialboiler#steamboiler#ValveSupplier#solenoidvalve#industrialequipment#plateheatexchanger#bestSupplier#blissflowsystems

1 note

·

View note

Photo

AlloyO can Provide more #corrosionresistant Metals for #PlateHeatExchanger industry, materials as following: Ti-1, Ti-Pd, Ni201, #S31254, #N08904, #N10276... Corrosion resistant special metal stock, All in AlloyO. Details are available at http://specialmetalstock.com

0 notes

Link

Ship machinery suppliers sell various different parts of ship machinery to be used in the ship. You can get best deals on various ship equipments such as ship machinery, Engine Spare Parts Exporter, Crankshafts and Cylinder Blocks supplier, Engines & DG Sets Wholesaler etc. from Ababil Marine. We provide you with new and reconditioned marine hydraulics which are sourced from some of the most renowned brands such as Alfa Laval, Sondex, APV, Swap, GEA Ecoflex etc.

#Shipmachinerysuppliers#EngineSparePartsExporter#CrankshaftsandCylinderBlockssupplier#Engines&DGSetsWholesaler#marineturbocharger#plateheatexchangers#shipmachineryparts

0 notes

Text

Bliss Flow Systems DESCO has combined its plate heat exchanger expertise with traditional shell and tube heat exchanger technologies to further develop and refine the shell and plate welded heat exchanger. We design and supply this technology to the markets we serve to provide a solution for our customer’s high temperature and high pressure heat transfer needs.

This heat exchanger contains a fully welded circular plate pack consisting of round plates pressed with specific embossed patterns and then completely welded together. Fluid is carried in and out of the plate pack through nozzles and is referred to as the “plate side” flow path. The plate pack is installed into an outer shell that creates the other flow path known as the “shell side” flow path. Contact Us- +65 82029100

Visit us- www.blissflowsystems.com/product/shell-plate-heat-exchanger/

0 notes

Link

Bliss Flow Systems DESCO has combined its plate heat exchanger expertise with traditional shell and tube heat exchanger technologies to further develop and refine the shell and plate welded heat exchanger. We design and supply this technology to the markets we serve to provide a solution for our customer’s high temperature and high pressure heat transfer needs.

0 notes