#Plastics in Consumer Electronics Market Market

Explore tagged Tumblr posts

Text

Plastics in Consumer Electronics Market: Impact of Lightweight and Durable Materials

Plastics in Consumer Electronics Market Growth Strategic Market Overview and Growth Projections

The global plastics in consumer electronics market size was valued at USD 5.9 billion in 2022 and is projected to reach USD 8.39 billion by 2031, registering a CAGR of 4.5% during the forecast period (2023-2031).

The latest Global Plastics in Consumer Electronics Market by straits research provides an in-depth analysis of the Plastics in Consumer Electronics Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Plastics in Consumer Electronics Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Plastics in Consumer Electronics Market are

Trinseo S.A

Covestro AG

Celanese Corp

SABIC

Lotte Chemical Corp

L.G. Chem

Mitsubishi Chemical Corp

SAMSUNG SDI Co. Ltd.

Koninklijke DSM N.V.

Qingdao Gon Science and Technology Co. Ltd

Get Free Request Sample Report @ https://straitsresearch.com/report/plastics-in-consumer-electronics-market/request-sample

The Plastics in Consumer Electronics Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Plastics in Consumer Electronics Market: Segmentation

The Plastics in Consumer Electronics Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Product

Polycarbonate (P.C.)

Liquid Crystal Polymer (LCP)

Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) Glass Filled Resin

Bio-based Polycarbonate

Thermoplastic Elastomers (TPE)

Polyamide (P.A.)

By Application

V. Frames

Laptop Monitor Enclosures

LCD Panels

Portable Hand-held Devices

Wearables

Mobile Phone Bodies

Appliances and White Goods

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/plastics-in-consumer-electronics-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Plastics in Consumer Electronics Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Plastics in Consumer Electronics Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Plastics in Consumer Electronics Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Plastics in Consumer Electronics Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

Plastics in Consumer Electronics Market Growth Strategic Market Overview and Growth Projections

The global plastics in consumer electronics market size was valued at USD 5.9 billion in 2022 and is projected to reach USD 8.39 billion by 2031, registering a CAGR of 4.5% during the forecast period (2023-2031).

The latest Global Plastics in Consumer Electronics Market by straits research provides an in-depth analysis of the Plastics in Consumer Electronics Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Plastics in Consumer Electronics Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Plastics in Consumer Electronics Market are

Trinseo S.A

Covestro AG

Celanese Corp

SABIC

Lotte Chemical Corp

L.G. Chem

Mitsubishi Chemical Corp

SAMSUNG SDI Co. Ltd.

Koninklijke DSM N.V.

Qingdao Gon Science and Technology Co. Ltd

Get Free Request Sample Report @ https://straitsresearch.com/report/plastics-in-consumer-electronics-market/request-sample

The Plastics in Consumer Electronics Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Plastics in Consumer Electronics Market: Segmentation

The Plastics in Consumer Electronics Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Product

Polycarbonate (P.C.)

Liquid Crystal Polymer (LCP)

Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) Glass Filled Resin

Bio-based Polycarbonate

Thermoplastic Elastomers (TPE)

Polyamide (P.A.)

By Application

V. Frames

Laptop Monitor Enclosures

LCD Panels

Portable Hand-held Devices

Wearables

Mobile Phone Bodies

Appliances and White Goods

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/plastics-in-consumer-electronics-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Plastics in Consumer Electronics Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Plastics in Consumer Electronics Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Plastics in Consumer Electronics Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Plastics in Consumer Electronics Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Plastics in Consumer Electronics Market Market#Plastics in Consumer Electronics Market Market Share#Plastics in Consumer Electronics Market Market Size#Plastics in Consumer Electronics Market Market Research#Plastics in Consumer Electronics Market Industry#What is Plastics in Consumer Electronics Market?

0 notes

Link

According to this latest publication from Meticulous Research®, the global bioplastics market is expected to grow at a CAGR of 13.1% from 2022–2029 to reach $25.93 billion by 2029. The growth of this market is attributed to the increasing consumer preference for biobased products over synthetic products, the rising research and development in bioplastics, the growing adoption of bioplastics in the packaging industry, and the increased utilization of flexible packaging by the food & beverages industry.

#bioplastics market#Packaging#biodegradable#bioplastics#plastic#business#chemicals#materials#bioplastics market Packaging Automotive Consumer Electronics Construction Agriculture Bioplastics Market trends Bioplastics Market growth bi#printing and packaging#agriculture#construction

1 note

·

View note

Text

All These Devices Are Now In Your Pocket

Select photos from the Uncanon Valley Museum's installation of the same name, intended to show youngsters just how much utility has been compressed into a single device, and how much the market has narrowed because of it.

By Row:

Martel InstaKlik Camera (1984) / Melinoë Industries GPS-2s (2001)

Fatholla Light Meter (1977) / Issac's Brand Underwater MP3 Player (2003)

Klaxaxabaxan™ Handheld Game (1994) / "Prince Adrian" Platinum Edition Speak & Spell, Tiffany's (1966)

Edison High-Freq K3030 Camera (1973) / L700 Four-Demon Chest, Panasonic (1981)

Splap-it! Game, traditional (1922) / Demiurgical Responder Engine, J.W. Welles & Company (1873)

L'l Farnsy Vacuum-Tube Radiotrox (3022), Poch Ackaoch Perpendicular Receiver (1971)

The images above in this post were made using an autogenerated prompt and/or have not been modified/iterated extensively. As such, they do not meet the minimum expression threshold, and are in the public domain.

Process under the fold:

Lotta prompts here, so I'm going to just go over my process with these.

I took a number of pictures of consumer electronics, along with some wild card objects, and ran them through with Midjourney's /describe feature.

I then shuffled the resulting prompts, separating them with :: marks, resulting in prompts like the following example:

a gold and red medallion located on a white background, in the style of rangercore, konica auto s3, curved mirrors, shuzo oshimi :: the skull in a purple outfit is made from a plastic, orange and green, in the style of m42 mount, terrorwave, packed with hidden details, destroyed gadgets sculptures, katsuhiro otomo, toy camera effects, science academia

The :: marks are used to denote weights normally, but if you don't weight them, MJ tends to blend the concepts. So after that I just appended:

:: electronic device photograph on white background

The example prompt was for the "Edison High-Freq K3030 Camera (1973)" image.

#unreality#alternate universe#uncanon valley#midjourney#midjourney ai#generative art#public domain#public domain artwork#electronics#gadgets#camera#handheld

63 notes

·

View notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Text

Chemical Manufacturing Companies in Houston

The Role of Chemical Manufacturing Companies in Houston

Introduction

Houston, Texas, is a powerhouse in the world of energy and industrial production, with a particularly strong reputation in the chemical manufacturing sector. The city is often referred to as the "Energy Capital of the World," but it’s also a critical hub for chemical production, contributing significantly to the global supply chain. Chemical manufacturing companies in Houston are at the forefront of innovation, producing a wide range of chemicals that are essential for numerous industries, from healthcare and agriculture to electronics and automotive manufacturing. This article delves into the importance of these companies, the range of products they create, and their impact on both the local and global economy.

The Significance of Houston’s Chemical Manufacturing Industry

Houston’s strategic location near the Gulf of Mexico, coupled with its extensive infrastructure, makes it an ideal location for chemical manufacturing. The city is home to the largest petrochemical complex in the United States, and this has fostered a robust ecosystem of chemical manufacturing companies. These companies benefit from the proximity to raw materials, such as oil and natural gas, which are essential inputs for chemical production. Additionally, the city’s well-established logistics network, including ports, railways, and highways, facilitates the efficient distribution of chemical products both domestically and internationally.

The chemical manufacturing industry in Houston is not only a major contributor to the local economy but also plays a critical role in supporting other industries. The chemicals produced in Houston are used in the production of plastics, pharmaceuticals, fertilizers, and countless other products that are integral to modern life. Without the chemicals manufactured in Houston, many industries would struggle to maintain their current levels of production and innovation.

Key Players in Houston's Chemical Manufacturing Sector

Several major companies dominate the chemical manufacturing landscape in Houston, each contributing to the industry’s strength and diversity. These companies range from multinational corporations to specialized firms that focus on niche markets.

Dow Chemical Company: One of the largest chemical manufacturers in the world, Dow has a significant presence in Houston. The company produces a vast array of chemicals, including plastics, performance materials, and agricultural products. Dow’s Houston operations are integral to its global supply chain, enabling the company to meet the demands of industries across the globe.

ExxonMobil Chemical: As a division of one of the largest oil companies in the world, ExxonMobil Chemical plays a crucial role in the production of petrochemicals. The company’s Houston facilities produce a wide range of products, including polyethylene, polypropylene, and other polymers that are used in packaging, automotive components, and consumer goods. ExxonMobil Chemical’s innovations in polymer technology have helped drive advancements in material science, contributing to the development of lighter, stronger, and more sustainable products.

LyondellBasell: This company is one of the largest plastics, chemicals, and refining companies in the world. With its headquarters in Houston, LyondellBasell is a key player in the production of polypropylene, polyethylene, and advanced polymers. The company’s products are used in a variety of applications, from packaging and textiles to automotive parts and medical devices. LyondellBasell is also a leader in sustainability, with initiatives aimed at reducing plastic waste and promoting circular economy practices.

BASF Corporation: A subsidiary of the German chemical giant BASF SE, BASF Corporation operates several facilities in the Houston area. The company produces a wide range of chemicals, including those used in agriculture, automotive, and construction industries. BASF is known for its commitment to innovation, investing heavily in research and development to create new and improved chemical products that meet the evolving needs of its customers.

The Impact of Chemical Manufacturing on the Local Economy

The chemical manufacturing industry is a major driver of economic activity in Houston. The sector provides thousands of high-paying jobs, ranging from engineers and chemists to skilled laborers and logistics professionals. These jobs not only support the livelihoods of those directly employed by chemical manufacturing companies but also create a ripple effect throughout the local economy. For example, the presence of a strong chemical manufacturing sector attracts other businesses, such as suppliers, contractors, and service providers, further boosting economic growth in the region.

In addition to job creation, chemical manufacturing companies in Houston contribute significantly to the city’s tax base. The revenue generated from these taxes helps fund essential public services, such as education, healthcare, and infrastructure development. Furthermore, the industry’s emphasis on innovation and sustainability has led to the development of new technologies and processes that have the potential to reduce environmental impact and improve efficiency across various sectors.

Environmental and Safety Considerations

While the chemical manufacturing industry in Houston is vital to the economy, it also presents challenges, particularly in terms of environmental impact and safety. The production of chemicals involves the use of hazardous materials, and if not properly managed, these materials can pose risks to both human health and the environment.

To address these concerns, chemical manufacturing companies in Houston are subject to stringent regulations enforced by federal and state agencies, such as the Environmental Protection Agency (EPA) and the Texas Commission on Environmental Quality (TCEQ). These regulations govern everything from emissions and waste disposal to workplace safety standards. Companies are required to implement comprehensive safety and environmental management systems to minimize risks and ensure compliance with these regulations.

Many chemical manufacturers in Houston have gone beyond regulatory requirements, adopting best practices in sustainability and safety. For instance, companies like LyondellBasell and BASF have implemented programs to reduce greenhouse gas emissions, minimize waste, and promote the use of renewable energy sources. These initiatives not only help protect the environment but also enhance the companies’ reputations and appeal to customers who prioritize sustainability.

The Future of Chemical Manufacturing in Houston

The chemical manufacturing industry in Houston is poised for continued growth, driven by advancements in technology, increasing demand for chemicals, and the city’s strategic advantages. However, the industry will also need to navigate challenges related to environmental sustainability, regulatory compliance, and global competition.

One of the key trends shaping the future of chemical manufacturing in Houston is the shift towards sustainability. As consumers and businesses become more environmentally conscious, there is increasing pressure on chemical manufacturers to reduce their carbon footprints and adopt more sustainable practices. This shift is likely to drive innovation in areas such as green chemistry, renewable feedstocks, and circular economy models.

Another important trend is the growing role of digitalization in chemical manufacturing. Companies are increasingly using digital technologies, such as data analytics, artificial intelligence, and automation, to improve efficiency, optimize production processes, and enhance safety. These technologies have the potential to transform the industry, enabling companies to operate more sustainably and respond more quickly to changing market demands.

Conclusion

Chemical manufacturing companies in Houston play a critical role in the global supply chain, producing essential chemicals that support a wide range of industries. The city’s strategic location, robust infrastructure, and access to raw materials make it an ideal hub for chemical production. As the industry continues to evolve, driven by trends in sustainability and digitalization, Houston’s chemical manufacturers will be at the forefront of innovation, contributing to economic growth and helping to address some of the world’s most pressing challenges.

In conclusion, the chemical manufacturing industry in Houston is a vital part of the city’s economy and a key player on the global stage. By continuing to prioritize innovation, sustainability, and safety, these companies will not only maintain their competitive edge but also contribute to a more sustainable and prosperous future for all.

2 notes

·

View notes

Text

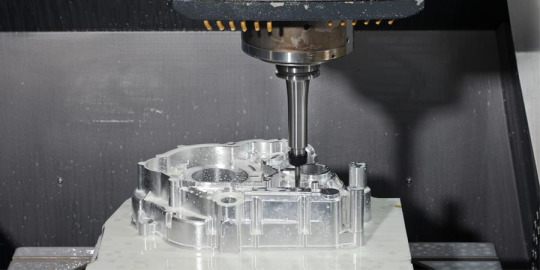

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

“Sweat equity is the most valuable equity there is. Know your business and industry better than anyone else in the world. Love what you do, or don’t do it.” – Mark Cuban (Entrepreneur)

Putting the consumer first in all you do as a business and prioritizing their satisfaction over short-term gains. You stay in close contact with your clients' needs and develop items to meet their needs.

When designing a product, we must evaluate our consumer groups. Who is our target market? Given that our product is a portable cooling system that uses solar power energy, it is suitable for travelers, hot climate regions, eco-conscious customers, single renter customers, and boarding students who want to keep leftover goods to avoid rotting.

We employed marketing and advertising, an online e-commerce platform, and a physical store as business platforms. Building the customer relationship involves providing individualized online/phone support, maintenance services, and—most importantly—putting the needs of the customer first in everything you do as a business. By putting the needs of the customer ahead of short-term profit, you can stay in close contact with your clients' needs and create products that cater to them. We will also provide a guarantee and a free demonstration of how to utilize our product; we will test its temperature, power, and durability during the demo to pique our customer's curiosity.

For the key activities, we can partner with a manufacturer who will surely give us quality and durable materials, which will lessen our work and also allow us to possibly get a discount for a bundle of items, then our marketing and advertisements can be done through an online platform, and we can partner with any known company to endorse our product to increase customer engagement, such as trusted company like Citi hardware, Cooling System and Aircon Electronics.

For the total expenses, we break down the amount of each item used to build the product, such as the solar panel, 23x36cm, plastic and steel, temperature regulator, wire, ac plug, bag, and shipping fee, which would total 2,624.67php, and the cost of the product would be 3,899php, with a profit gain of 1274.33 for each product purchased.

I must emphasize that in selecting our consumer target, as a producer, you must create a significant influence on the market in order to be trusted and maintain the growth of your firm. After winning their trust, you can innovate more items that may be useful to the masses and widen your target market so that the company can grow and acquire access to more manufacturers and distributors over time.

The journey of an entrepreneur will never be easy: there will be moments when one must face failure in order to learn and relearn from experience; because life is full of gambles, we often overlook the fact that it takes sacrifice to obtain abundance and prosperity. "The biggest risk is not taking any risk… In a world that's changing really quickly, the only strategy that is guaranteed to fail is not taking risks." - Mark Zuckerberg, CEO of Facebook.

2 notes

·

View notes

Text

Unleashing Manufacturing Potential: The Strength of Materials.

Introduction: In the dynamic world of manufacturing, the choice of materials plays a vital role in delivering high-quality products quickly and flexibly. From acrylic/plexiglass to PETG, polycarbonate, polystyrene, polyethylene, polypropylene, sheet metal, wire, wood, and printing, each material brings unique attributes to the production process. This blog post explores the power of these materials, housed under one roof, enabling companies to excel with short lead times and unparalleled adaptability.

Acrylic/Plexiglass: Acrylic, also known as plexiglass, is a lightweight, impact-resistant material used extensively for signage, display cases, and protective barriers. Its transparency and ease of molding make it perfect for complex designs.

PETG: PETG is a durable and transparent plastic with excellent impact resistance. Its versatility and chemical resistance make it a popular choice in packaging, displays, and medical devices.

Polycarbonate: Renowned for its outstanding impact resistance and transparency, polycarbonate finds applications in automotive parts, safety glasses, and architectural glazing. Its strength and aesthetic appeal are unmatched.

Polystyrene: With its lightweight nature and affordability, polystyrene is a go-to material for packaging, consumer electronics, and insulation. Its moldability and insulating properties are key advantages.

Polyethylene and Polypropylene: Polyethylene and polypropylene offer exceptional chemical resistance, durability, and flexibility. They are commonly used in food packaging, automotive components, medical equipment, and piping systems.

Sheet Metal and Wire: Sheet metal and wire provide structural integrity to machinery, enclosures, and architectural elements. Their strength and reliability are crucial for various manufacturing applications.

Wood: Wood adds warmth and aesthetic appeal to furniture, cabinetry, and other products. Its natural beauty, strength, and sustainability make it a popular choice.

Printing: Printing techniques enhance the appearance and functionality of manufactured goods. From branding to decorative elements, printing personalizes and differentiates products in the market.

Conclusion: In the manufacturing industry, the selection of materials can make all the difference. Acrylic, PETG, polycarbonate, polystyrene, polyethylene, polypropylene, sheet metal, wire, wood, and printing enable companies to achieve short lead times and adapt to changing market needs. The power of these materials ensures the production of high-quality, customized products that meet customer demands efficiently. With a diverse range of materials under one roof, manufacturers can thrive in today's fast-paced environment.

Website:- https://acrylicplexiglass.ca/

Phone no.:- (647)774-7623, (647)825-1324

Address:- 622 Magnetic Dr, North York, ON M3J 3J2, Canada

E- Mail:- [email protected]

Gmail:- [email protected]

2 notes

·

View notes

Text

Injection Moulding Machines Market

Injection Moulding Machines Market Size, Share, Trends: Engel Austria GmbH Leads

Shift Towards All-Electric Injection Moulding Machines Enhances Efficiency and Precision

Market Overview:

The Injection Moulding Machines Market is expected to develop at a 4.2% CAGR from 2024 to 2031. The market value is predicted to rise from XX USD in 2024 to YY USD in 2031. Asia-Pacific currently leads the industry, with key data suggesting robust manufacturing activity and technical breakthroughs. The market is growing steadily, owing to rising demand from numerous end-use sectors, technological advancements, and a growing trend towards automation in manufacturing processes.

The market is expanding rapidly due to the growing demand for plastic components, especially from the automotive industry. Technological advancements in injection moulding processes and equipment are further propelling market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The injection moulding machine market is experiencing a considerable shift towards all-electric equipment. Compared to hydraulic machines, these machines are more energy efficient, precise, and clean. All-electric machines offer greater control over the moulding process, resulting in higher quality products and lower scrap rates. Furthermore, they run more silently and require less maintenance, making them increasingly popular in a variety of industries. The trend is especially significant in areas that require very precise components, such as medical devices and electronics.

Market Segmentation:

All-electric injection moulding machines have emerged as the market's dominating category, accounting for a sizable market share. All-electric devices are popular because they offer several benefits such as energy savings, precision, and cleanliness. These machines consume up to 70% less energy than hydraulic machines, leading to significant long-term cost benefits for manufacturers.

All-electric machines' precision is especially valuable in industries that require high-accuracy components, such as medical devices and electronics. A renowned industry group discovered that all-electric machines may attain precision levels of up to 0.01mm, compared to 0.05mm for hydraulic machines. This level of accuracy is essential for making complex, high-quality parts with few flaws.

Recent technological developments have accelerated the introduction of all-electric injection moulding equipment. For example, the incorporation of Industry 4.0 technology like IoT sensors and improved control systems has increased the capability of these devices. A leading market research agency reported that the market share of all-electric machines climbed from 30% in 2019 to 45% in 2023, and this trend is projected to continue in the following years.

Market Key Players:

Engel Austria GmbH

Arburg GmbH + Co KG

Sumitomo (SHI) Demag Plastics Machinery GmbH

Haitian International Holdings Limited

KraussMaffei Group GmbH

Nissei Plastic Industrial Co., Ltd.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

UV Cured Acrylic Foam Tapes Market Trends Revolutionizing Construction and Assembly Processes

The UV cured acrylic foam tapes market has shown significant momentum in recent years, primarily driven by innovations in adhesive technology and the growing demand for versatile, high-performance bonding solutions. These tapes are designed with acrylic foam and cured using ultraviolet light, offering enhanced bonding strength, durability, and resistance to harsh environmental factors. As industries seek more efficient and reliable solutions for bonding and sealing applications, UV cured acrylic foam tapes are emerging as a preferred choice.

Key Trends Driving the UV Cured Acrylic Foam Tapes Market

Technological Advancements in Adhesive Solutions

One of the most prominent trends in the UV-cured acrylic foam tapes market is the continued evolution of adhesive technology. Manufacturers are focused on developing tapes with superior bonding strength, higher resistance to temperature fluctuations, and improved UV stability. This has resulted in the introduction of specialized UV-cured acrylic foam tapes tailored for a variety of applications in automotive, electronics, and construction. These advancements are helping to meet the increasing demand for high-performance bonding solutions, particularly in industries requiring durable, long-lasting adhesion.

Sustainability and Eco-Friendly Materials

As sustainability becomes a more significant concern across industries, the UV-cured acrylic foam tapes market is also undergoing changes to reduce its environmental impact. Manufacturers are increasingly using eco-friendly materials and developing processes that reduce energy consumption during production. UV curing, in particular, is considered a more energy-efficient curing method compared to traditional heat-based curing processes. This contributes to lower emissions and less resource consumption, making UV-cured acrylic foam tapes an environmentally friendly choice for companies aiming to meet sustainability goals.

Expanding Applications in the Automotive Industry

The automotive industry is one of the largest adopters of UV-cured acrylic foam tapes, with applications ranging from exterior bonding, sealing, and mounting to interior trim and noise reduction. The trend toward lightweight, fuel-efficient vehicles is driving the demand for tapes that provide strong, reliable adhesion while minimizing the weight of the final product. These tapes are also preferred for their ability to bond dissimilar materials, such as metal, glass, and plastics, which is essential in modern automotive design. As electric vehicles (EVs) and advanced vehicle systems continue to evolve, the demand for high-performance adhesives is expected to increase.

Increasing Demand in Electronics and Consumer Goods

Another major trend influencing the market is the rising demand for UV-cured acrylic foam tapes in the electronics and consumer goods sectors. These tapes are widely used in the assembly of electronic devices such as smartphones, computers, and televisions. They offer high-strength bonding for components like screens, touch panels, and internal parts, as well as excellent resistance to moisture and temperature variations. As consumer electronics become more sophisticated, there is a growing need for advanced adhesive solutions that provide clean, efficient, and durable bonding. The trend toward miniaturization in electronic devices also contributes to the increasing use of UV-cured acrylic foam tapes.

Focus on Enhanced Durability and Performance

Durability is a key factor driving the adoption of UV-cured acrylic foam tapes in several industries. These tapes provide exceptional resistance to UV light, moisture, chemicals, and temperature extremes. Manufacturers are focused on enhancing these properties further, allowing UV-cured acrylic foam tapes to perform in even the most challenging environments. This trend has led to the development of tapes that offer long-term performance in applications such as outdoor signage, building materials, and heavy-duty industrial equipment.

Global Expansion and Market Growth

As the global demand for UV-cured acrylic foam tapes increases, manufacturers are expanding their presence in emerging markets. The growth of industries such as construction, automotive, and electronics in regions like Asia-Pacific, Latin America, and Middle East & Africa is driving demand for high-performance adhesive solutions. In particular, rapid industrialization and infrastructure development in these regions are expected to further boost market growth. To meet this demand, manufacturers are investing in regional production facilities and expanding their distribution networks to ensure a consistent supply of UV-cured acrylic foam tapes worldwide.

Customization and Tailored Solutions

Customization is another growing trend in the UV-cured acrylic foam tapes market. Manufacturers are increasingly offering tailored adhesive solutions to meet the unique needs of different industries. Customizable features include varying levels of thickness, bonding strength, and resistance to specific environmental factors. This trend allows manufacturers to create bespoke products for clients in diverse sectors, from automotive and construction to electronics and consumer goods. As industries continue to evolve, there will be an increasing need for highly specialized adhesive products that cater to specific applications.

Challenges in the UV Cured Acrylic Foam Tapes Market

Despite the rapid growth and technological innovations, the UV-cured acrylic foam tapes market faces several challenges. One major obstacle is the high cost of production compared to other types of adhesive tapes. The use of advanced materials and UV curing technology often requires higher initial investments, which can make these tapes less affordable for smaller manufacturers. Additionally, while the market is expanding globally, companies must navigate regulatory challenges related to environmental standards and manufacturing processes.

Conclusion

The UV-cured acrylic foam tapes market is evolving with strong growth driven by technological advancements, sustainability, and a broadening range of applications. As industries demand more durable, high-performance adhesive solutions, manufacturers are meeting these needs with innovative products designed to withstand extreme conditions while promoting environmental responsibility. Moving forward, the trend of sustainability, coupled with global expansion and technological advancements, will shape the future of this market, offering new opportunities for companies and consumers alike.

#UV Cured Acrylic Foam Tapes Market#UV Cured Acrylic Foam Tapes#UV Cured Acrylic Foam Tapes Market trends

0 notes

Text

Polycarbonate Composites Market: Lightweight and Durable Innovations Driving Industrial Use up to 2033

The Polycarbonate Composites Market focuses on materials created by combining polycarbonate (PC) resin with reinforcing agents such as glass fibers, carbon fibers, or other fillers. These composites are well-known for their excellent impact resistance, high strength-to-weight ratio, optical clarity, and flame-retardant properties. The versatility of polycarbonate composites makes them widely used in applications across automotive, electronics, aerospace, construction, and healthcare industries.

To Know More @ https://www.globalinsightservices.com/reports/polycarbonate-composites-market

The polycarbonate composites market is anticipated to expand from $2.1 billion in 2023 to $4.3 billion by 2033, achieving a CAGR of 7.4%.

Market Outlook The Polycarbonate Composites Market is experiencing strong growth due to the increasing demand for lightweight yet durable materials in key industries. The automotive sector, in particular, is a significant driver, as manufacturers are seeking materials that reduce vehicle weight to improve fuel efficiency and meet stringent emission standards. Polycarbonate composites are becoming a preferred choice for automotive components such as headlamp lenses, interior parts, and glazing solutions due to their exceptional strength and lightweight characteristics.

In the electronics and electrical industry, the demand for polycarbonate composites is also surging. The materials’ excellent electrical insulation properties and high heat resistance make them suitable for producing enclosures, connectors, and electronic device casings. The growth of the consumer electronics market and the rising adoption of smart devices are contributing to increased usage of polycarbonate composites in this sector.

Aerospace and defense industries are turning to polycarbonate composites for applications that require high performance and safety, such as aircraft interiors, cockpit canopies, and ballistic-grade materials. The aerospace sector’s focus on weight reduction for fuel efficiency and enhanced durability further drives the demand for polycarbonate composites. Additionally, the construction industry is leveraging these materials for glazing applications and structural components where impact resistance and transparency are essential.

The market is witnessing innovations in composite manufacturing processes, such as the development of thermoplastic composites that offer advantages in recyclability and faster production cycles. Advancements in nanotechnology and surface modification techniques are also enhancing the properties of polycarbonate composites, expanding their application range and performance capabilities.

Environmental sustainability is a growing trend in the Polycarbonate Composites Market. Companies are investing in research and development to produce eco-friendly composites using bio-based polycarbonates and recycled materials. The push for sustainable materials aligns with global efforts to reduce plastic waste and promote the circular economy.

Asia-Pacific is expected to dominate the Polycarbonate Composites Market, driven by rapid industrialization, urbanization, and growing automotive and electronics manufacturing. Countries like China, Japan, and South Korea are leading in both production and consumption of polycarbonate composites. North America and Europe are also key markets, with strong demand from the automotive and aerospace sectors.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS32456

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request For Report Customization @ https://www.globalinsightservices.com/request-customization/GIS32456

Market Segmentation

In 2023, the Polycarbonate Composites Market demonstrated robust performance, with a market volume of 600 million metric tons and projections to reach 900 million metric tons by 2033. The automotive sector dominates the market share at 45%, driven by the industry’s demand for lightweight and durable materials. The electronics segment follows with a 30% share, benefiting from the increasing use of polycarbonate composites in consumer electronics. The construction segment holds a 25% share, supported by the material’s strength and versatility. Key players such as Covestro AG, SABIC, and Teijin Limited maintain substantial market presence, influencing sector dynamics.

Competitive pressures and regulatory frameworks significantly impact the Polycarbonate Composites Market. Companies are investing in sustainable production methods to comply with stringent environmental regulations. The EU’s Green Deal and similar policies worldwide are pushing for eco-friendly manufacturing processes. Future projections indicate a 10% annual increase in R&D expenditure, targeting innovations in recycling and material efficiency. The market outlook remains optimistic, with growth driven by advancements in composite technology and expanding applications across various industries. However, challenges such as fluctuating raw material prices and the need for technological advancements persist, necessitating strategic collaborations and investments in cutting-edge technologies.

Major Players

SABIC Innovative Plastics

Covestro

Teijin Limited

Mitsubishi Chemical Corporation

Chi Mei Corporation

LG Chem

Trinseo

Lotte Chemical

Asahi Kasei Corporation

Idemitsu Kosan

RTP Company

Plazit Polygal

PolyOne Corporation

Ensinger

Bayer MaterialScience

A. Schulman

SABIC

Sumitomo Chemical

Toray Industries

Mitsui Chemicals

Request For Discounted Pricing @ https://www.globalinsightservices.com/request-special-pricing/GIS32456

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

For In-Depth Competitive Analysis, Buy Now @ https://www.globalinsightservices.com/checkout/single_user/GIS32456

About Us

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Text

Molded Plastic Market: Segmentation, Growth Trends, and Key Insights

The global molded plastic market is poised for significant growth, with a projected valuation of USD 1218.39 billion by 2033, up from USD 715.07 billion in 2024. This growth, driven by rising demand across various industries, including automotive, packaging, and electronics, underscores the importance of molded plastics as a critical component in modern manufacturing and consumer goods production.

Market Definition and Latest Trends

Molded plastics refer to plastic products manufactured using molding techniques such as injection molding, blow molding, and extrusion. These products are lightweight, durable, and cost-effective, making them ideal for various applications, including automotive parts, consumer goods, packaging materials, and electrical components. The molded plastic market includes various product types such as polyethylene, polypropylene, polystyrene, and polyethylene terephthalate, among others.

The latest trends in the molded plastic market reflect the ongoing shift toward sustainability, technological advancements, and the increasing demand for high-performance plastics in emerging applications. Notable trends include:

Sustainability Focus: As the world becomes more environmentally conscious, manufacturers are turning to bio-based and recyclable plastics, especially in packaging and automotive applications. The push toward circular economy models is expected to accelerate innovation in sustainable molded plastics.

Smart Plastics: The growing adoption of smart technologies in industries such as electronics and automotive is creating a demand for molded plastics with integrated functions like sensors, lighting, and communication capabilities. These advanced molded plastics are contributing to the development of the Internet of Things (IoT) and autonomous vehicles.

Technological Advancements: Newer, more efficient molding technologies, including 3D printing and multi-component injection molding, are enabling manufacturers to produce more complex and customized plastic components at a lower cost.

Growing Automotive Sector: The automotive industry remains a major consumer of molded plastics, especially with the rise in electric vehicles (EVs) and lightweight materials to improve fuel efficiency and reduce carbon emissions.

Get Free Request Sample Report @ https://straitsresearch.com/report/molded-plastic-market/request-sample

Growth Factors in the Molded Plastic Market

The molded plastic market is expected to experience strong growth due to several key factors:

Rapid Industrialization: As industries such as automotive, packaging, and construction continue to grow globally, the demand for molded plastic products is expanding. Manufacturers are increasingly turning to plastics to replace traditional materials like metals and glass due to the lightweight, cost-effective, and versatile properties of molded plastics.

Demand for Packaging Materials: The global packaging industry is one of the largest end-users of molded plastics. The rise in e-commerce and retail, especially in the food and beverage sector, has increased the need for plastic packaging solutions. The convenience, durability, and flexibility of molded plastics make them ideal for use in bottles, containers, and protective packaging.

Technological Advancements in Molding Techniques: The advancement of molding technologies such as injection molding and blow molding has improved the production efficiency, precision, and scalability of molded plastics, enabling manufacturers to meet increasing demand across multiple sectors.

Urbanization and Infrastructure Development: The growing urbanization and infrastructure development in emerging economies are fueling demand for plastic pipes, sheets, and other molded plastic products used in construction, plumbing, and electrical systems.

Opportunities in the Molded Plastic Market

The molded plastic market offers substantial opportunities for growth and innovation:

Sustainable Plastics: There is a growing demand for environmentally friendly plastics, including biodegradable, recyclable, and renewable materials. Companies that invest in developing sustainable molded plastics will have a competitive advantage as consumers and regulatory bodies continue to push for eco-friendly alternatives.

Emerging Applications: The growing adoption of electric vehicles (EVs), renewable energy systems, and medical devices provides ample opportunities for the molded plastic market. Lightweight, durable, and cost-effective plastic components are essential in EVs, solar panels, wind turbines, and medical equipment.

Expansion into Emerging Markets: Emerging economies in Asia-Pacific, Latin America, and the Middle East are seeing an increase in industrialization and consumer spending, driving demand for molded plastic products. Companies that expand their presence in these regions can benefit from the growing demand across various industries.

Buy Now @ https://straitsresearch.com/buy-now/molded-plastic-market

Key Players in the Molded Plastic Market

The molded plastic market is competitive, with several leading companies dominating the global landscape. These key players include:

LyondellBasell (Netherlands)

SABIC (Saudi Arabia)

INEOS (Switzerland)

DuPont (US)

ExxonMobil (US)

Sinopec (China)

Dow Inc (US)

BASF SE (Germany)

Eastman Chemical Company (US)

Chevron Corporation (US)

Formosa Plastics Corporation (Taiwan)

Solvay (Belgium)

China Plastics Extrusion Ltd. (China)

Lanxess AG (Germany)

Versalis (Italy)

LG Chem (South Korea)

Reliance Industries (India)

These companies are investing in research and development, focusing on innovations in molding technologies, sustainability, and expanding their global reach to maintain leadership in the market.

Market Segmentation of the Molded Plastic Market

The molded plastic market can be segmented based on product type, technology, and application.

By Product Type:

Polyvinyl Chloride (PVC)

Polypropylene (PP)

Polystyrene (PS)

Polyethylene (PE)

Polyurethane (PU)

Polyethylene Terephthalate (PET)

Others

By Technology:

Injection Molding

Blow Molding

Extrusion

Others

By Applications:

Packaging

Film

Automotive Parts

Corrugated Sheets

Bags and Pouches

Battery Cases

Bottles and Vials

Pipes

Containers

Filament Yarn

Wires and Cables

Others

Conclusion

The molded plastic market is on the verge of remarkable expansion, driven by technological advancements, growing demand across a wide range of industries, and an increased focus on sustainability. As businesses continue to innovate in molding technologies and sustainable materials, the market will continue to evolve and offer ample opportunities for both established players and new entrants.

For more information, please contact:

Straits Research Email: [email protected] Website: www.straitsresearch.com

This comprehensive report on the molded plastic market provides valuable insights into growth trends, opportunities, and the competitive landscape, offering critical information for stakeholders to make informed decisions in this evolving industry.

0 notes

Text

Plastic Waste Management Market: Role of Public-Private Partnerships

The Plastic Waste Management Market is projected to witness substantial growth, driven by increasing environmental concerns, regulatory pressures, and advancements in recycling technologies. With the global emphasis on sustainability, there is a growing demand for effective waste management solutions to mitigate plastic pollution and promote circular economy practices.

Read Complete Report Details of Plastic Waste Management Market: https://www.snsinsider.com/reports/plastic-waste-management-market-2929

Market Segmentation

By Polymer

PET (Polyethylene Terephthalate)

Widely used for beverage bottles and food containers.

High recyclability makes PET a focus area for waste management initiatives.

Polyvinyl Chloride (PVC)

Utilized in construction, medical devices, and packaging.

PVC waste poses unique challenges due to its chemical composition, leading to increased research in safe disposal and recycling methods.

Polypropylene (PP)

Common in packaging, automotive components, and textiles.

Recycling of PP is growing due to its widespread use in consumer goods.

High-density Polyethylene (HDPE)

Used for rigid containers, pipes, and grocery bags.

HDPE is valued for its high durability and ease of recycling.

Low-density Polyethylene (LDPE)

Found in films, wraps, and plastic bags.

Recycling of LDPE is challenging but increasingly prioritized.

Polyurethane (PU)

Used in furniture, automotive interiors, and insulation.

PU waste management is advancing with innovative recycling methods like chemical depolymerization.

Others

Includes specialty polymers like ABS, polystyrene, and bioplastics.

Recycling efforts for these materials are gaining traction due to technological innovations.

By Service

Collection

The first and most critical step in waste management.

Increasing adoption of structured collection systems in residential and industrial areas.

Incineration

Used for energy recovery from non-recyclable plastic waste.

Faces criticism for its environmental impact, but advancements in clean incineration technologies are addressing these concerns.

Landfills

A traditional method for plastic waste disposal.

Efforts to reduce landfill dependency are fueling alternative waste management solutions.

Recycling

Includes mechanical and chemical recycling methods.

Recycling is the most sustainable option and a primary focus for governments and industries worldwide.

By Source

Industrial

Includes waste generated from manufacturing processes.

Industrial plastic waste often has higher recyclability due to its relatively clean and homogenous nature.

Residential

Includes plastic waste from households, such as packaging and single-use plastics.

Residential waste management systems are expanding, particularly in urban areas.

Commercial

Includes plastic waste from businesses, retail, and hospitality sectors.

Commercial sources often generate significant amounts of packaging and disposable plastics.

By Application

Building & Construction

Plastic waste is generated from construction materials like PVC pipes, insulation, and flooring.

Recycling initiatives focus on reusing durable materials and reducing construction waste.

Consumer Products

Includes waste from items like electronics, furniture, and clothing.

Growth in e-waste recycling contributes significantly to this segment.

Packaging

The largest contributor to plastic waste globally.

Innovations in biodegradable and recyclable packaging are reshaping the segment.

Electrical & Electronics

Plastic is widely used in electronic casings and components.

Recycling efforts focus on recovering valuable materials from electronic waste.

Others

Includes automotive, agriculture, and healthcare applications.

Increasing attention to specialized recycling programs for niche industries.

By Region

North America

Focus on advanced recycling technologies and strict regulations.

The U.S. and Canada are key markets with robust waste management systems.

Europe

Leading the way in sustainable waste management practices.

EU directives and policies are driving innovations in recycling and circular economy adoption.

Asia-Pacific

The largest generator of plastic waste due to high population density and rapid industrialization.

Significant investments in waste management infrastructure in countries like China, India, and Japan.

Latin America

Growing awareness and government initiatives are driving improvements in waste collection and recycling.

Middle East & Africa

Developing waste management systems to tackle rising plastic pollution.

Increasing interest in waste-to-energy solutions.

Market Trends and Opportunities

Circular Economy Initiatives: Emphasis on designing products for recyclability and reusability to reduce waste generation.

Technological Advancements: Innovations in chemical recycling and AI-driven waste sorting systems are revolutionizing the market.

Government Regulations: Policies like single-use plastic bans and extended producer responsibility (EPR) are encouraging sustainable practices.

Consumer Awareness: Growing demand for eco-friendly products and recycling programs is reshaping the market landscape.

Corporate Commitments: Companies are pledging to use recycled plastics and improve waste management within their operations.

Market Outlook

The Plastic Waste Management Market is set to grow significantly as industries and governments collaborate to address global plastic pollution. Advances in recycling technologies, coupled with stricter regulations, are driving the adoption of sustainable practices. While challenges such as high costs and limited infrastructure remain, the rising awareness of environmental issues and increasing investments in waste management solutions will sustain market growth. The shift toward a circular economy model offers immense potential for innovation and development in this sector.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Vietnam Trade Data: 2024: A Brief Insight

Vietnam has continued to confirm its position in the global trading system, reshaped its trading partners and faced new challenges even in 2024. Due to its strategic position in international trade and commerce, Vietnam’s economic position and operation has become a centre of focus to investors, policy makers and even the world’s leading economists. This blog focuses on Vietnam’s trade figures in 2024 through comprehensive and evaluated analysis of export/import turnover, main partners, sectors, and impact of the global economy policy on Vietnam. Key Highlights: - The growth of imports contributed to an increase in surplus of $2 billion in October 2024.

- The exports rose by 14.9% to $335.59bn in January-October 2024.

- Vietnam’s export market in 2024 is made up of Electronics, Textiles, Footwear, Agriculture products.

- Vietnam will shine in global commerce in 2024: U.S., China, EU, and Southeast Asia.

- Trade risks encompass the potential of the U.S. preparing to impose tariffs, shifts in supply chain and regional trade agreements.

Trade Balance and General Behavior

According to Vietnam trade data, Vietnam’s trade showed a surplus of $ 2 bln in October 2024, the lowest value since May due to the faster import growth. Export rose to $ 25.4 billion at an annual rate of 10.1 while imports stood at $ 39.5 billion at an annual rate of 13.6. About 93.6% of the total general import included raw materials to be used for manufacturing purposes. Exports of goods were up to $335.59 billion from $295.12 billion, a 14.9% rise for the period of January-October while imports were up by $312.28 billion from $269.22 billion a 16.8% increase.

Major Export Commodities

As per Vietnam's export data in 2024, Vietnam has been dominated by several key commodities:

Electronics and Electrical Products: This category such as computers and smartphones remains one of Vietnam’s most significant exports, this being occasioned by the influx of large amounts of foreign direct investments besides the transfer of production facilities by other countries.

Textiles and Garments: The textile sector continues to be a major participant, Vietnamese apparel products also enjoying popularity in other demanding markets such as the United States and the European Union.

Footwear: Vietnam has established itself as a strong player in the global footwear exports market, and you will find shoes in the luxury and the economy segment.

Agricultural Products: Products like coffee, rice and seafood still remain the key export products area with export giving direction for increase in flow from Asia and Europe. Major Import Commodities

As per Vietnam import data, Vietnam's primary commodities include:

Machinery and Equipment: Also required for developing the manufacturing and construction industries that are still emerging in this country.

Raw Materials: Which are fabrics, plastics and metals required for the manufacture of exported products in Kenya.