#Plastic Compounds for Electronics

Explore tagged Tumblr posts

Text

The Future of the Plastic Compounds Market: Innovations and Growth Opportunities

The plastic compounds market is poised for significant growth, driven by the increasing demand for innovative materials across industries such as automotive, packaging, electronics, and construction. Plastic compounds, which are materials made by combining polymers with additives, fillers, and reinforcements, are widely used for their versatility, performance, and ability to be customized to meet specific needs.

With the global focus on sustainability and environmental responsibility, manufacturers are also looking for solutions that contribute to greener and more efficient production. This blog explores key trends shaping the plastic compounding industry, as well as opportunities and challenges ahead.

Key Growth Drivers in the Plastic Compounds Market

Demand from the Automotive Industry The automotive plastic compounds sector is a key driver of market growth. The increasing use of lightweight materials in vehicle production is vital for improving fuel efficiency and reducing emissions. Thermoplastic compounds like polypropylene and polyethylene, known for their strength, durability, and lightweight properties, are replacing metals in various automotive components, from dashboards to bumpers. Additionally, high-performance plastic compounds such as nylon and polycarbonate are finding applications in areas requiring enhanced durability, heat resistance, and impact protection. As electric vehicles (EVs) gain popularity, the demand for specialized plastic compounds in battery casings, connectors, and interior components is expected to surge.

Rising Demand for Sustainable and Biodegradable Compounds The trend toward sustainability is influencing the plastic compounds market. Consumers and industries alike are focusing on reducing plastic waste and improving recyclability. Biodegradable plastic compounds are gaining traction as eco-friendly alternatives, particularly in the packaging industry, where they reduce the environmental footprint. Recycled plastic compounds are another area of interest. Manufacturers are incorporating post-consumer recycled content into new products to meet regulatory requirements and corporate sustainability goals. For example, plastic compounds for electronics are increasingly made from recycled plastics, reducing dependency on virgin materials.

Growing Applications in Packaging The plastic compounds in packaging industry are experiencing robust demand as companies seek to improve product protection while minimizing weight and material usage. Flexible packaging, in particular, benefits from the use of specialty plastic compounds that offer high-performance barrier properties, ensuring product freshness and extending shelf life. Plastic packaging compounds also play a role in reducing environmental impact. Sustainable plastic compounds developed for packaging are designed to be recyclable or compostable, reducing waste generation and supporting circular economy initiatives.

Advancements in Electronics and Construction The electronics industry is increasingly adopting plastic compounds for electronics applications. These compounds offer excellent electrical insulation, heat resistance, and flame retardancy, making them ideal for use in smartphones, laptops, and other consumer electronics. Moreover, flame retardant plastic compounds are critical for ensuring safety in electrical and electronic applications. In the construction industry, plastic compounds for construction are being used in pipes, window frames, insulation, and flooring materials due to their durability, resistance to corrosion, and ease of installation. PVC compounds are a popular choice, offering cost-effective solutions for a variety of building materials.

Healthcare Applications The plastic compounding industry is also seeing increased use in healthcare, especially in medical devices and equipment. Plastic compounds for medical applications need to meet strict regulations for biocompatibility, sterility, and resistance to chemicals. Polyethylene, polypropylene, and PVC compounds are frequently used in medical tubing, syringes, and surgical instruments.

Market Challenges and Opportunities

Environmental Concerns One of the biggest challenges facing the plastic compounds market is the growing concern over plastic pollution. Single-use plastics, in particular, contribute significantly to waste generation, leading to increased pressure on manufacturers to develop sustainable plastic compounds that reduce their environmental impact. To address these concerns, companies are focusing on creating biodegradable plastic compounds and enhancing recycling technologies. However, the high cost of producing biodegradable and recycled materials remains a barrier to widespread adoption.

Innovation in Plastic Additives Innovation in plastic additives plays a crucial role in enhancing the performance of plastic compounds. Additives can improve properties such as UV resistance, flame retardancy, and strength, making plastic compounds suitable for a wider range of applications. The development of additives that enhance the recyclability of plastics is also an area of active research, offering opportunities for growth.

Emerging Markets Rapid industrialization and urbanization in emerging economies are creating significant opportunities for the global plastic compounds market. Countries in Asia-Pacific, particularly China and India, are witnessing increased demand for plastic compounds in construction, packaging, and automotive applications. In addition, the growing middle class in these regions is driving demand for consumer goods, further boosting the need for high-quality plastic compounds. This trend is expected to continue, with the Asia-Pacific region leading the global market in the coming years.

Download PDF Brochure :

The plastic compounds market is undergoing rapid evolution, driven by the demand for lightweight, durable, and sustainable materials across industries. From automotive plastic compounds that improve fuel efficiency to plastic compounds in packaging industry applications that reduce waste, the market is full of innovation and opportunity.

As manufacturers continue to invest in R&D and new technologies, recycled plastic compounds, biodegradable plastic compounds, and sustainable plastic compounds will play an increasingly important role in meeting both consumer demand and environmental regulations. For businesses involved in plastic compounding, the future holds immense potential, provided they can navigate challenges related to cost, environmental impact, and innovation.The plastic compounding industry is on the cusp of significant growth, with advancements in materials, additives, and applications opening new avenues for market expansion. With a strong focus on sustainability and performance, the industry is well-positioned to meet the evolving needs of modern industries and consumers alike.

#Plastic Compounds Market#Thermoplastic Compounds#Biodegradable Plastic Compounds#Recycled Plastic Compounds#Automotive Plastic Compounds#Sustainable Plastic Compounds#Plastic Compounds for Electronics

1 note

·

View note

Text

Captain_CumShot - Chapter 3

Welcome to Raven's Reading Nook - a small corner of this blog dedicated to cozy story times. Take a seat on the chaise lounge, plug your electronic device in so you can enjoy this multi-chapter, full blown smut story. The Captain is the snack and sadly, I have nothing to offer to soothe the yearning. As always, links to Wattpad and AO3 at the bottom. Enjoy, from your favorite loyal, cabin hoe♥

Summary: The Captain is sponsored for his birthday!

Minors DNI you will be blocked - for adult audiences only.

<new video alert>

Unwrapping/unboxing video

<press play>

“A little birdie whispered into a local sex shop’s ear and that same shop has sent me a sponsorship package for my birthday. I’m touched. Or, I will be. Soon,” Kid’s smirk graced the screen before the camera focus zoomed out to show the chaotic background.

A pile of half wrapped and opened boxes were towering on a pull out table – packing peanuts and tissue paper littered the floor which he kicked away as he stepped beside the display. Grabbing at random, he dangled collars and gags between his thick fingers before repeating the motion in a different box. Cock rings and bullet vibrators made heavy thunking sounds as he let them fall from his hand back to the box.

“There’s honestly so much, I think I’ll try out a few pieces, model a bit and give one or five toys some testing. This is technically also a review video.”

Sinking into steady chair he had pulled out, he sighed as he unbuttoned his black vest and pants.

“Ok, to make it interesting, I’m gonna do random grabs from a giant tub. Hold on.”

The video cut to the next frame, where Kid was unceremoniously dumping products into a 50 gallon tub. A colorful waterfall of silicone, plastic, metals churned around roughly a few times before he was satisfied.

“Let’s get this party started,” he snapped the first item off the top – a collar with a bell. He let out a chuckle, shrugged and buckled it on.

“I’m into pet play – I’m not usually the pet,” he winked at the camera.

Using his metal hand, he plunged it deep into the tub and rummaged for a second, pulling out a set of restraints and clamps.

“Sure, whatever,” he snorted, cuffing his flesh hand but leaving it dangling. He let out a quiet grunt as he clamped his nipples, the fine metal connecting the twin clamps allowed him to adjust the tension.

Letting out a shivered growl, “I can’t put all these on, maybe I’ll save some for future vids.

Dipping another hand into the tub, he hummed in surprise when he saw the sleeve. It was a silicon model of lips, a self-masturbation toy. The mouth was partially opened and it had a set of top row teeth that appeared stiffer to the touch as Kid’s fingers played with the trim.

“Pray I pull some lube next,” he laughed, scooping his metal hand once more. This time, he came away with multiple items. The lubricant, a ball gag, and an anal plug.

“I’d ask if God was there but I’m pretty sure this is the work of darker forces,” he almost cackled, face crinkled in entertainment.

Sticking by his promise, Kid poured the water-based compound in his hands and rubbed his fingers against his palm to warm it up. He smeared the lube generously around the plug, yanked his pants off, and turned so the camera would see his side profile. So his viewers could watch him slightly bend and work the toy in his ass.

“Want proof?” he barked and turned so his backside was exposed, and nestled between his enormous, sculpted glutes was the top of the plug. It had gone in swiftly.

Shrugging, “Surprised I’m a whore? You must be new here.”

Standing, Kid poured the lube into the mouth cock sleeve and rimmed the lips, teeth, and chin with the leftover sleek. Taking the side profile again, he teased his bulbous head with the top row of teeth, sliding it over the ridge of his tip. He slowly dipped into the sleeve without giving much reaction, at least not until he was fully sheathed.

“The inside feels nice, but its kinda firm and strict to move through.”

He powered through, partially closing his eyes as he uncovered himself and started pumping the sleeve up and down his girth, attempting to wear it in some. He found a good rhythm for a while before moving on.

“I dunno, maybe a heated lube or a warm wash to make the material more accommodating. The teeth felt nice though, realistic and kinda cute.”

Kid kissed the messy hole and tongued it lewdly, “How wet or hard did that just make you?” Laughing, he set the toy aside and returned to the tub.

The next gift set was pack of lingerie sets, one in red and the other in a deep wine color.

“Nice. Red’s always been my color,” he smiled, tearing the silk from the package. He let the material run against his skin teasingly before formally putting the thong on, snapping the rear line against the plug base. “Ok last grab, I’m use both hands.”

Behind the tub, Kid dramatically leaned over and plunged both arms elbows deep as he shuffled through items like a drag line wading along the sea’s bottom. With a triumphant grin, he yanked backwards and hauled a cellophane wrapped package.

“No. Fucking. WAY!” he shouted in excitement as he tore the plastic with his teeth. “The Mega Milker Masturbator,” he crowed as he held out the sex doll.

It was only half a doll, just the bubbly butt and with realistic looking skin and inviting holes. Holding it in one hand, he slapped the ass and it jiggled and trembled in place. He firmly gripped the fleshy material and dug his fingertips in. The doll sunk with the lightest amount of pressure. Kid was so pleased he let out a mewl.

“I’ve seen the ads but damn never thought about getting it for myself. Shiiiitt.” He whistled. As he described the specs and features, he slowly pumped his cock and lubed the orifices.

“Let’s see how well—” he paused, then a look came over his face. Stepping away, he came back with the wine colored lingerie and prepped the doll.

Sweeping the table with his arm, he stuck the doll down and moved the camera stand to have a better angle. He picked up the small control that was wired to the bubbly flesh, turning it on and a quiet motor made the doll shake and bounce with impressive speed settings as Kid flipped through them.

“I’ll try and leave a cum shot but this is The Mega Milker model – this might just become a straight cream pie vid. Shit, did you see my cock throb at that? Yeah, gonna give you an extra special dessert, since its my birthday and all.”

Making more adjustments, the edge of a microphone was placed beside the camera – to enhance the output.

“Happy birthday to me,” he tossed his head back as he sunk he erection all the way inside the doll. Gasping in pleasure as he switched the vibrations on and the hairs on his pelvis began to visibly tremble from the force.

“Oh fuck,” he cried before pulling out all the way, slapping the silicone material cheeks and sinking back in. The table legs scraped against the floor as he fucking into the doll. Pussy to ass over and over, his grunts becoming louder as he treated himself.

“Fuuuuccckkk me the vibrations are strong, especially if I—” he sighed as his hands squeezed the bubbly ass around his shaft. “Ohhh godsdamn she’s an ANIMAL!” he roared and laughed.

His thrusting grew harsher and the table squealed in protest as his hips banged against the top.

“Here. I. Cuuuummmm,” he moaned, stilling himself for a moment to let his ejaculation wash over him. Not finished, he pulled out and sheathed himself in the doll’s asshole and rutted against the material, wearing the motor down as he pinned it to the table.

With a low groan and head tilt, Kid pulled out and braced his back on the table, legs spread open for the camera and cock flopped on his lower stomach. His core was still shaking and the plug tightened and loosened as he came down.

Holding the doll above him, his semen and the lube trickled out and sprawled over his stomach as he emptied it out.

“I think this is my new favorite toy. I’m gonna name her,” he tilted forward to kiss the creamy pussy lips. Flicked his tongue between the folds and showed the camera his swallow technique.

“Nah nah, it can’t end like this. This toy, that’s not good enough for her. One cumshot, coming up,” he chortled.

Using his own seed to fluff himself, he stuffed his erect cock into the doll once more. He shifted on the table so his feet were planted on the ground and his torso was partially up. Holding the doll as he would a lover in reverse cowgirl, Kid turned the vibration setting to medium speed and began fucking the doll again.

“I’m taking name suggestions in the comments,” he groaned out, stroking himself with the toy. Switching the speed to the highest setting less than a minute later, Kid’s jaw gaped as his entire body tensed.

“Oh my fuuuuck, fuck f….---” he bit his lip and moaned.” The vibrations are making the plug tremble!”

Kid braced himself against the weary table and used all his force to slam the doll down on his cock until the fake flesh was pushing forcefully against his muscles as he fucked impossibly deep into it. Feet splayed and strained, Kid bit down harder as he held the doll, letting the vibrations bounce his cock so hard that the plug was shaking enough to make him feel shocks of pleasure run up his spine.

Letting out a guttural howl, Kid pulled the doll off and held it in front of him, strings of pearly cum shot out of his tip and splattered against the doll’s abused skin. Beading and rolling down the curves as Kid’s body shook from the pleasure.

Setting it down on the table, Kid gently removed the plug from his ass and inserted it into the doll’s ass.

“I’m a man of my word – I tested the fuck outta that doll and it has all the fucking stars a product can and should receive. How much was this worth?! I gotta step up my toy making skills!”

Kid slapped the fake doll’s ass one last time and droplets of cum flew off the jiggling mass before the video ended.

Leave a vote/kudos/like to tip OR hit bookmark/add to reading list/reblog to subscribe.

Read More on Wattpad | AO3 And check out my new eustass kid blog dedicated to the whoreniest of posts @thecaptainsdeck

#eustass kid#Captain_CumShot#onlyfans fanfic#firstmatesimp#one piece fanfiction#eustass kid smut#one piece eustass kid#ao3 author#wattpad author#eustasscaptainkid#kid pirates#swampstew stories#swampstew

40 notes

·

View notes

Text

Genetically Modified Bacteria Produce Energy From Wastewater

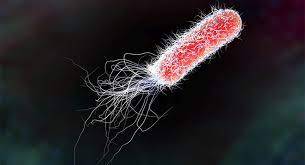

E. Coli is one of the most widely studied bacteria studied in academic research. Though most people probably associate it with food/water borne illness, most strains of E. Coli are completely harmless. They even occur naturally within your intestines. Now, scientists at EPFL have engineered a strain of E. Coli that can generate electricity.

The survival of bacteria depends on redox reactions. Bacteria use these reactions to interconvert chemicals in order to grow and metabolize. Since bacteria are an inexhaustible natural resource, many bacterial reactions have been industrially implemented, both for creating or consuming chemical substrates. For instance, you may have heard about researchers discovering bacteria that can break down and metabolize plastic, the benefits of which are obvious. Some of these bacterial reactions are anabolic, which means that they need to be provided external energy in order to carry it out, but others are catabolic, which means that the reactions actually create energy.

Some bacteria, such as Shewanella oneidensis, can create electricity as they metabolize. This could be useful to a number of green applications, such as bioelectricity generation from organic substrates, reductive extracellular synthesis of valuable products such as nanoparticles and polymers, degradation of pollutants for bioremediation, and bioelectronic sensing. However, electricity producing bacteria such as Shewanella oneidensis tend to be very specific. They need strict conditions in order to survive, and they only produce electricity in the presence of certain chemicals.

The method that Shewanella oneidensis uses to generate electricity is called extracellular electron transfer (EET). This means that the cell uses a pathway of proteins and iron compounds called hemes to transfer an electron out of the cell. Bacteria have an inner and outer cell membrane, so this pathway spans both of them, along with the periplasmic space between. In the past, scientists have tried to engineer hardier bacteria such as E. Coli with this electron-generating ability. It worked… a little bit. They were only able to create a partial EET pathway, so the amount of electricity generated was fairly small.

Now, the EPFL researchers have managed to create a full pathway and triple the amount of electricity that E. Coli can produce. "Instead of putting energy into the system to process organic waste, we are producing electricity while processing organic waste at the same time -- hitting two birds with one stone!" says Boghossian, a professor at EPFL. "We even tested our technology directly on wastewater that we collected from Les Brasseurs, a local brewery in Lausanne. The exotic electric microbes weren't even able to survive, whereas our bioengineered electric bacteria were able to flourish exponentially by feeding off this waste."

This development is still in the early stages, but it could have exciting implications both in wastewater processing and beyond.

"Our work is quite timely, as engineered bioelectric microbes are pushing the boundaries in more and more real-world applications" says Mouhib, the lead author of the manuscript. "We have set a new record compared to the previous state-of-the-art, which relied only on a partial pathway, and compared to the microbe that was used in one of the biggest papers recently published in the field. With all the current research efforts in the field, we are excited about the future of bioelectric bacteria, and can't wait for us and others to push this technology into new scales."

148 notes

·

View notes

Text

Organic compound boosts solar cell stretchability without sacrificing power

A solar cell developed by RIKEN physicists can be stretched without greatly affecting its ability to convert light into electricity. It is thus promising for powering the next generation of wearable electronics. Today's smart watches can monitor an impressive array of health metrics, while more-specialist wearable devices are being developed for specific medical applications. But such devices need to be recharged periodically. To eliminate this need, researchers are seeking to develop flexible, wearable solar cells. However, it is vital to ensure that the performance of these solar cells doesn't drop off when they are stretched by body movements during everyday life. "We're focusing on making very thin, flexible devices. But such devices don't have intrinsic stretchability," explains Kenjiro Fukuda of the RIKEN Center for Emergent Matter Science. "Rather, they're similar to plastic wrap used to wrap food—you can maybe stretch them by 1% or 2%, but 10% is impossible since they tear easily."

Read more.

23 notes

·

View notes

Text

Cyanide Poison

Let's start by understanding exactly how cyanide kills you. In simple terms, cyanide prevents cells from using oxygen to make energy molecules.

The cyanide ion, CN-, binds to the iron atom in cytochrome C oxidase in the mitochondria of cells. It acts as an irreversible enzyme inhibitor, preventing cytochrome C oxidase from doing its job, which is to transport electrons to oxygen in the electron transport chain of aerobic cellular respiration. Now unable to use oxygen, the mitochondria can't produce the energy carrier adenosine triphosphate (ATP). Tissues that require this form of energy, such as heart, muscle cells, and nerve cells, quickly expend all their energy and start to die. When a large enough number of critical cells die, you expire as well. Death usually results from respiratory or heart failure.

Immediate aymptoms include headaches, nausea and vomiting, dizziness, lack of coordination, and rapid heart rate. Long exposure symptoms include unconsciousness, convulsions, respiratory failure, coma and death.

A person exposed to cyanide may have cherry-red skin from high oxygen levels, or dark blue coloring, from Prussian blue (iron-binding to the cyanide ion). In addition to this, skin and body fluids may give off an almond odor.

The antidotes for cyanide include sodium nitrite, hydroxocobalamin, and sodium thiosulfate.

A high dose of inhaled cyanide is lethal too quickly for any treatment to take effect, but ingested cyanide or lower doses of inhaled cyanide may be countered by administering antidotes that detoxify cyanide or bind to it. For example, hydroxocobalamin, natural vitamin B12, reacts with cyanide to form cyanocobalamin, which leaves the body in urine.

These antidotes are administrated via injection, or IV infusion.

Cyanide is actually a lot more common than you'd think. It's in pesticides, fumigants, plastics, and electroplating, among other things. However, not all cyanide are so poisonous. Sodium cyanide (NaCN), potassium cyanide (KCN), hydrogen cyanide (HCN), and cyanogen chloride (CNCl) are lethal, but thousands of compounds called nitriles contain the cyanide group, yet aren't as toxic. They still aren't terribly good for you, so I wouldn't go around ingesting other cyanide compounds, but they're not quite as dangerous as the lethal kind.

Thank you for reading, have a lovely day :)

#cyanide#poison#cyanide poison#tw poison#poisons#chemistry#?#if it counts lmao#crime#criminal#investigation#forensics#scienceblr#science#sherlock#sherlock holmes

42 notes

·

View notes

Text

Ways to practice eco-friendly living in your home

1. Reduce energy consumption:

- Install energy-efficient appliances and LED light bulbs.

- Turn off lights and unplug electronics when not in use.

- Use natural light as much as possible.

- Set your thermostat to a lower temperature in winter and higher in summer.

- Insulate your home properly to reduce heating and cooling needs.

2. Save water:

- Fix any leaks in faucets and toilets promptly.

- Install low-flow showerheads and faucets.

- Collect rainwater for watering plants.

- Only run the dishwasher and washing machine with full loads.

- Use a broom instead of a hose to clean outdoor spaces.

3. Practice waste reduction:

- Recycle paper, plastic, glass, and metal.

- Compost kitchen scraps and yard waste.

- Opt for reusable products instead of disposable ones (e.g., cloth napkins, rechargeable batteries).

- Avoid single-use plastics, such as plastic bags and water bottles.

- Use a reusable shopping bag.

4. Use eco-friendly cleaning products:

- Choose natural, non-toxic cleaning products or make your own using ingredients like vinegar, baking soda, and lemon juice.

- Avoid products containing harmful chemicals that can harm the environment and your health.

5. Grow your own food:

- Plant a garden to grow vegetables, fruits, and herbs.

- Use organic and natural fertilizers instead of synthetic ones.

- Compost food scraps to enrich the soil.

6. Opt for sustainable materials:

- Choose furniture made from sustainable materials like bamboo or reclaimed wood.

- Use eco-friendly flooring options like bamboo, cork, or reclaimed hardwood.

- Select paint and other finishes that have low or no volatile organic compounds (VOCs).

7. Reduce plastic waste in the kitchen:

- Use glass or stainless-steel containers for food storage instead of plastic.

- Replace plastic wrap with beeswax wraps or reusable silicone covers.

- Use refillable water bottles and avoid buying bottled water.

8. Conserve energy in the kitchen:

- Use energy-efficient appliances.

- Cook with lids on pots and pans to retain heat and reduce cooking time.

- Opt for smaller appliances like toaster ovens instead of full-sized ovens when possible.

9. Encourage sustainable transportation:

- Use public transportation, walk, or bike whenever possible.

- Carpool or arrange a car-sharing service with neighbors or colleagues.

- Transition to an electric or hybrid vehicle if feasible.

10. Educate and involve your family:

- Teach your family about the importance of eco-friendly practices and involve them in the decision-making process.

- Encourage everyone to adopt sustainable habits and lead by example.

- Discuss environmental issues and brainstorm new ideas for greener living.

#home improvement#work from home#make money from home#homebrew#ecology#ecofriendly#sustainability#home design#home#acne treatment#homedesign#homemade#home decor#home business#home & lifestyle#homestuck#welcome home#homens de sunga#homeinterior#homestyle#cozyplaces#cozy glow#cozyhome#cozy cozy#cozy living#cozyvibes#cozy autumn#cozy fall#cozy mystery#cozycore

88 notes

·

View notes

Text

"The authors also detected the banned compound deca-BDE, which was typically used in electronics casings before it was banned. It was found widely on the kitchen utensils tested, with the authors noting that the 'estimation of exposure to BDE-209 from contaminated kitchen utensils indicated users would have a median intake of 34,700 ng/day, exceeding estimates for intake from dust and diet.'"

#black#black color#black plastic#kitchen#kitchenware#home appliances#cook#cooking#food#drinks#dessert#recipe of the day#cancer

3 notes

·

View notes

Text

Excerpt from this story from Anthropocene:

In a new spin on green electronics, researchers have made a biodegradable electronic circuit board from tree leaves. Such leaf-based electronics, or “leaftronics” as the team from Dresden University of Technology (TU Dresden) has dubbed it, could reduce millions of tons of waste that humans produce every year.

Today, the world produces over 50 million metric tons of electronic waste a year. That number that is slated to double by 2050. And printed circuit boards (PCBs) – the flat boards onto which all the circuit chips, wires and other components of an electronic gadget are soldered–-constitute a big share of this e-waste.

PCBs are typically made of fiberglass or a composite plastic. The material is difficult to recycle and is usually either dumped in landfills or burned to separate the valuable metals for reuse.

As detailed in the journal Science Advances, the team used the veiny, webbed skeleton of leaves to create their biodegradable substrates. This fine branched structure is made of the same lignocellulose compounds that give its toughness. Postdoctoral researcher Rakesh Nair and colleagues started by stripping away the cells of a magnolia leaf to leave behind the white veined skeleton. They dipped the scaffold into ethyl cellulose, a tough biodegradable polymer.

The resulting leaftronics substrate is smooth, flexible, transparent, and can handle high temperatures. In that sense it rivals plastic and glass, Nair says, but is biodegradable. The researchers could use a laser to cut the substrate, print circuits on it, as well as solder electronic components on top.

To degrade the substrate, the researchers placed it in an ultrasonic acid bath to remove the metals and circuit components. The boards began to degrade after about a month in compost.

“Up until now,��substrates made of biodegradable polymers could not be used for electronic device or circuit fabrication, since they naturally do not handle elevated temperatures well,” Nair says. There are ways to improve the thermal and mechanical properties of biodegradable polymers. But, he says, they “often result in these polymers either no longer being biodegradable or requiring complex, high carbon-footprint, chemical processes,” he says.

Others have also made degradable PCBs using paper, silk, and mushroom skins. But the new method that relies on dipping a leaf scaffold in a biodegradable polymer is much simpler and should allow researchers to make specific biodegradable substrates with superior properties.

6 notes

·

View notes

Text

What are the Uses of Custom Plastic Manufacturing ?

In this day and age, custom plastic manufacturing has turned into a foundation of current industry, giving custom-made solutions across a wide cluster of areas. From medical services to auto, the versatility of plastics and the accuracy of custom manufacturing methods have made it conceivable to address explicit issues with unmatched productivity. We should probably dig into the main purposes of custom plastic manufacturing and grasp its effect on different businesses.

1. Medical and Healthcare Applications

Custom plastic manufacturing is reforming the medical services industry. Medical gadgets, prosthetics, and parts of symptomatic machines are progressively being produced using custom-planned plastics. A plastic manufacturing company offers a few benefits, including solidness, lightweight properties, and the capacity to be cleaned. Custom plastic parts are utilized in creating needles, IV cylinders, catheters, and, surprisingly, perplexing parts of medical imaging machines. The accuracy presented by custom manufacturing guarantees that these parts fulfill severe medical guidelines, adding to better understanding consideration and results.

2. Automotive Industry

In the automotive sector, custom plastic parts are fundamental for both execution and style. From dashboard parts to many-sided motor parts, custom plastics give arrangements that assist with lessening the general load of vehicles, further developing fuel efficiency. They also offer resistance to corrosion and wear, enhancing the longevity of parts. Custom plastics are used in manufacturing bumpers, interior trims, and even under-the-hood components. Their versatility, akin to the innovations seen with plastic bottle manufacturers, allows for innovative designs and improved safety features, making modern vehicles more reliable and efficient.

3. Consumer Electronics

The consumer electronics industry depends intensely on custom plastic assembling for making solid and smooth items. Cell phones, workstations, and domestic devices frequently consolidate custom plastic parts that are intended to fit definitively and capability perfectly. These parts need to withstand day to day wear and tear while keeping an engaging look. Custom plastics are utilized in housings, buttons, connectors, and different inward parts, offering both underlying respectability and plan adaptability.

4. Packaging Solutions

Custom plastic manufacturing assumes an urgent part in the packaging business. It empowers the formation of packaging arrangements that are custom fitted to secure and protect items during transportation and capacity. Custom plastic packaging can be intended to meet explicit necessities, for example, being lightweight, strong, and impervious to dampness and synthetics. This is especially significant in the food and refreshment industry, where keeping up with the newness and security of items is principal. Custom packaging likewise takes into consideration creative shapes and plans that upgrade brand character and purchaser advance.

5. Industrial and Mechanical Parts

Businesses that require hearty and high-performance components frequently go to custom plastic manufacturing. Plastics can be designed to display properties like high rigidity, protection from outrageous temperatures, and compound strength. This makes them ideal for making parts utilized in apparatus, gear, and different modern applications. Custom plastic pinion wheels, orientation, seals, and lodgings are normally utilized in manufacturing settings, adding to the productivity and dependability of modern tasks.

6. Aerospace and Defense

In aerospace and defense, the demand for lightweight yet solid materials is basic. Custom plastic manufacturing meets this need by providing components that can withstand harsh environments while reducing the overall weight of aircraft and defense equipment. From interior cabin parts to specialized components in satellites and military gear, custom plastics offer the necessary performance characteristics and design flexibility required in these high-stakes applications.

Ely Global Pte. Ltd - Leaders in Custom Plastic Manufacturing

Ely Global Pte. Ltd spends significant time in custom plastic manufacturing, giving fitted solutions to different businesses. With state of the art innovation and a pledge to quality, they convey accurately designed plastic parts that meet explicit client needs, upgrading item execution and productivity across multiple sectors.

#plastic manufacturing company#wholesale plastic bottle suppliers#plastic water bottle caps recyclable

2 notes

·

View notes

Text

The Mulch

Look down and you’ll see it; ragged scraps of bills, collection notices creased from being shoved, unopened, into a back pocket. Broken pieces of electronics I couldn’t afford, their black plastic carapaces cracked and spilling wire innards. Candy wrappers and take-out cartons bearing traces of the once edible, bearing formic footprints. Pennies and dimes, the odd ripped five-dollar bill. Post-it notes with half-legible fragments of poems, due dates, names and numbers. Broken-spined paperbacks missing nine-tenths of their covers and eight pages from chapter twelve, receipts and discarded cards, cans, manuals and school assignments… all mashed or trodden together into a more-or-less uniform compound of neglect. The mulch of my inattention, pregnant with conflicts avoided, decisions yet-to-be made, churned periodically by last-minute, panicked fumbling for a vital document, a vape pen, a pill.

It’s with me everywhere I go; maybe not at first, but soon enough it catches up. It is predictable, recognizable, varying only in fine detail. It occupies dark corners – a closet floor, a desk drawer, the bottom of a bag. It grows while I’m not looking, and, if I’m honest, while I am looking, my eyes drifting over and off of it, back to the screen, the ceiling, your face. It moves with me in banker’s boxes with mismatched lids, their slumping cardboard eventually braced against a closet wall. It gets beaten back, sometimes, when it threatens to spill into your life, but never fully; there’s always a corner, a reservoir of chaos waiting to reseed the newly fallow spaces.

If you want to know me, know what it’s like in here behind these dark circles, look down and you’ll see it. If you want to know what you’re getting into, dig into the mulch.

8 notes

·

View notes

Text

I hope this helps somebody.

Overall, rodents comprise over 2,000 species of warm-blooded nuisance animals including rats, mice, and squirrels. ..

rats may carry diseases on their own through saliva, urine, and feces.

Bay leaf – The chemical compound of bay leaves can be lethal to rats.

Instant mashed potatoes – If rats eat dehydrated mashed potatoes, the flakes will expand in their stomachs until they die of bloating

Snap Traps/Spring Traps

The best known types of traps, these currently come in two varieties. The traditional trap (usually made of wood and steel wire) contains a spring-loaded bar that snaps down when a rat removes bait from a trigger. A newer, plastic version bears a set of sharp jaws snap shut when triggered.

Glue Traps

A type of live trap, glue traps consist of a plastic or wooden platform coated with adhesive that is laid out (and sometimes baited) in places where rats are known to travel, such as basements, pantries, and attics, in order to entice rats to get stuck on them. These tend not to be true live traps, as it is often impossible to remove a rat once it is trapped, and trapped rats will eventually die of dehydration. This also means that unlike most other traps, glue traps can only be used once.

Electric/Electronic Traps

These traps work like cages, but when the bait entices rats to enter, these traps detect the rat and send a lethal electric shock into the cage

Poisons

The bait and poison available at stores will usually be in pellet form and can also be bought in bulk in order to refill trays or bait stations.

Wherever you decide to place poisons, rodents will feed off of them and go elsewhere to die.

Bromethalin-Based Poisons

These fast-acting neurotoxins need, more than most poisons, to be kept out of the way of children and pets, but they are especially effective.

2 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

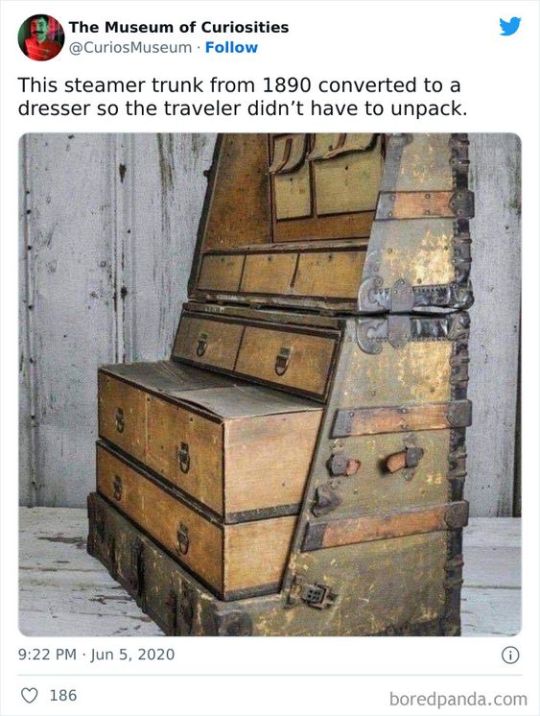

I think part of the point of the OP was also quality. In particular, the suitcase/wardrobe trunk example—that folding modern suitcase? Garbage in a few years. It’s made mostly of plastics and plastic fiber cloths that will tear or crack and not be repaired. It will be discarded and likely sent to a landfill where it will break down and leech toxic chemicals into the environment along with all the other plastic trash we’ve dumped. Meanwhile, more are being mass produced with the intention of endlessly repeating the consumeristic cycle of buy-discard-repeat.

The old trunk shown by OP? It was likely used for years, repaired as necessary, and has solid enough construction to have lasted to modern day in very good shape. It may weigh a lot, but it was not made to be easily discarded either. It was made to be used and loved and passed on through generations of people. And if it finally was discarded? The wood would rot and the metal would rust and both would decompose and return their natural compounds to the ground, forming new deposits of minerals (iron, copper, lead, etc) and fertile soil. No lab-made plastics. Nothing harmful to local wildlife or plants or the climate. And after it’s use was done, maybe the new generation would commission a local craftsman to make a new, equally beautiful piece to replace it.

On the surface level it may not appear that we’ve lost technology, but as someone studying archaeology and material culture of the past, I can tell you there is plenty we’ve lost. It’s not a new phenomenon to cheapen products for the sake of profit. That goes back to the Gilded Age and the rise of industrial manufacturing, if not earlier. But we’re in a new sort of gilded age. Electronics designed with higher prices and shortening lifespans; fast fashion pieces that fall apart after one or two washes; furniture that chips just from assembly and won’t survive a move between houses, let alone persist over multiple generations’ lifetimes.

We no longer make things to last through time. People who still value craftsmanship and quality rarely have the money to support the people who make those high quality items. In turn, people who make those items can’t afford to survive on income from exclusively selling their work. As time goes on, more and more skills and techniques are lost. From woodworking to metalworking and casting to ink making and rug weaving. Across every culture there are trades at risk and techniques already lost to time because they were passed from craftsman to craftsman until the craft was drowned out by cheaper, mass-manufactured products meant to be disposed of in a fraction of the time.

59K notes

·

View notes

Text

Methylhexahydrophthalic Anhydride (MHHPA) Market, Global Outlook and Forecast 2024-2030 Professional Edition

The global Methylhexahydrophthalic Anhydride market size was valued at US$ 234.5 million in 2024 and is projected to reach US$ 345.6 million by 2030, at a CAGR of 6.7% during the forecast period 2024-2030.

The United States Methylhexahydrophthalic Anhydride market size was valued at US$ 61.5 million in 2024 and is projected to reach US$ 88.7 million by 2030, at a CAGR of 6.3% during the forecast period 2024-2030.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/281193/global-methylhexahydrophthalic-anhydride-forecast-edition-market-2024-2030-842

Chemical compound used as a curing agent in epoxy systems, providing specific cure characteristics and performance properties in electrical and electronic applications.

Report Overview

MHHPA is a hardener for epoxy resins as well as a raw material for polyurethane/polyester resins.

This report provides a deep insight into the global Methylhexahydrophthalic Anhydride (MHHPA) market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Methylhexahydrophthalic Anhydride (MHHPA) Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Methylhexahydrophthalic Anhydride (MHHPA) market in any manner.

Global Methylhexahydrophthalic Anhydride (MHHPA) Market: Market Segmentation Analysis

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Key Company

Lindau Chemical

Polynt

New Japan Chemical

Alpharm Chemical Technology

Ruiji Chemical

NAN YA PLASTICS

Puyang Huicheng Electronic Material

Market Segmentation (by Type)

Purity Above 99%

Purity Below 99%

Market Segmentation (by Application)

Epoxy Resin Harder

Epoxy Resin Composite

Adhesive

Other

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Methylhexahydrophthalic Anhydride (MHHPA) Market

Overview of the regional outlook of the Methylhexahydrophthalic Anhydride (MHHPA) Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Customization of the Report

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Methylhexahydrophthalic Anhydride (MHHPA) Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment (product type and application) in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/281193/global-methylhexahydrophthalic-anhydride-forecast-edition-market-2024-2030-842 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Methylhexahydrophthalic Anhydride (MHHPA) 1.2 Key Market Segments 1.2.1 Methylhexahydrophthalic Anhydride (MHHPA) Segment by Type 1.2.2 Methylhexahydrophthalic Anhydride (MHHPA) Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Methylhexahydrophthalic Anhydride (MHHPA) Market Overview 2.1 Global Market Overview 2.1.1 Global Methylhexahydrophthalic Anhydride (MHHPA) Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Methylhexahydrophthalic Anhydride (MHHPA) Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Methylhexahydrophthalic Anhydride (MHHPA) Market Competitive Landscape 3.1 Global Methylhexahydrophthalic Anhydride (MHHPA) Sales by Manufacturers (2019-2024) 3.2 Global Methylhexahydrophthalic Anhydride (MHHPA) Revenue Market Share by Manufacturers (2019-2024) 3.3 Methylhexahydrophthalic Anhydride (MHHPA) Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Methylhexahydrophthalic Anhydride (MHHPA) Average Price by Manufacturers (2019-2024) 3.5 Manufacturers Methylhexahydrophthalic Anhydride (MHHPA) Sales Sites, Area Served, Product Type 3.6 Methylhexahydrophthalic Anhydride (MHHPA) MarCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

Types of metal detection coils are not just technical components, but rather the main factor that determines the device's performance and efficiency in detecting metals of various shapes and sizes. Metal detection coils are one of the most important basic elements that any metal detection device relies on. These coils are the element responsible for creating magnetic fields and interacting with buried metals, allowing the metal detectors to accurately locate them. Each type of coil has distinct characteristics that make it suitable for specific applications, whether it is searching for coins or jewelry or even for heavy industrial uses.

What are metal detection coils?

They are the main component that generates the magnetic field inside metal detectors. These coils are designed to be sensitive to changes in the magnetic field resulting from the presence of metals underground or in objects. When a conductive metal approaches the coil, an eddy current is generated inside the metal, leading to noticeable changes in the surrounding magnetic field, and these changes are detected by the device.

Detection coils are used in many applications, from prospecting for precious metals such as gold, to industrial uses such as detecting metal objects buried in concrete or soil, as well as in security fields to detect weapons. Metal detection coils vary in design and function, including circular coils, bi-directional coils, and coils designed for deep detection.

How metal detection coils work

The mechanism of operation of metal detectors depends mainly on the types of metal detection coils and their role in generating magnetic fields to detect metal objects. The device begins by producing an alternating electric current through the primary coil, which leads to the generation of an oscillating magnetic field. When a metal object approaches, the field causes eddy currents to be produced inside this object, which generates an opposite magnetic field.

The secondary coil in the device senses this change and signals are sent to the electronic system to analyze them and determine the type or size of the metal. The devices use different techniques to measure changes in frequencies resulting from interaction with metals. Some devices rely on high frequencies to detect small or low metals to search at greater depths.

Types of metal detection coils in terms of manufacturing

Types of metal detection coils in terms of manufacturing vary based on the materials used and designs that affect their performance in identifying metals, including:

Dual coils

Made of two overlapping coils that create a wide magnetic field.

Copper wires are used coated with an insulating material such as plastic to withstand environmental conditions.

They are characterized by the ability to work in mineral-rich soils while reducing interference.

Interlaced coils

Consist of two precisely centered circular coils.

Made of copper covered with a protective layer such as ceramic or polymers.

Effective for surface search and accurately identifying small metal objects.

Deep search coils

A circular coil provides wide coverage and is suitable for detecting heavy metals at depth.

Relies on thick wires to withstand high electrical pressure.

Used for prospecting for precious metals such as gold in the ground.

Grid coils

Consist of a complex network of wires to provide superior sensitivity.

Relies on advanced fibers that are resistant to corrosion and harsh conditions.

Effective for detecting very small grains of metals.

Compound coils

Combine multiple designs to provide balanced performance.

Made of copper reinforced with fiberglass to provide strength and light weight.

Suitable for a wide range of uses from surface search to deep prospecting.

Types of metal detection coils by size

Types of metal detection coils by size vary to suit different uses, from surface detection of small objects to deep prospecting for heavy metals. The choice of size depends on the purpose of use and the nature of the environment in which the search is conducted, as follows:

Small coils (up to 15 cm)

Used to detect very small metal objects such as coins or jewelry.

Ideal for areas with high mineral soil or tight spaces.

It also provides high accuracy and better pinpointing of the location of metals.

Reduces interference from electromagnetic interference.

Medium coils (16 to 25 cm)

Balance between accuracy and coverage, making them suitable for general searching.

Effective in detecting medium-sized metal objects such as old tools or large coins.

Provides wider coverage than small coils while maintaining reasonable accuracy.

Suitable for individuals searching for metals in parks or beaches.

Large coils (greater than 26 cm)

Dedicated to detecting heavy metals and large objects buried at great depths.

Used in industrial prospecting and searching for buried treasures.

Provides wide coverage, making it effective in searching in open areas.

Able to reach depths beyond the capacity of small and medium coils.

The most important features of metal detection coils

The types of metal detection coils are characterized by a set of characteristics that make them essential tools for detecting metals in many fields, and the most important of these features are the following:

They are characterized by their ability to accurately identify metals, as they can distinguish between different types of metals such as: iron, gold, and copper.

They are used in various fields including airport security to detect weapons, archaeological excavation, and the mining field to discover natural resources such as raw gold and precious metals.

The coils are designed to work efficiently in different environments such as desert soil or rocky areas, making them ideal for searching in harsh conditions.

These coils work very quickly, as they respond immediately upon passing over a metal object, ensuring time savings during search operations.

Most coils come in a comfortable and lightweight design for easy carrying And use it for long periods.

FAQs

Can search coils be changed for metal detection?

Yes, search coils can be changed provided that they are compatible with the detector.

What is the importance of different metal detection coils?

The importance of coils varies according to their design and size, as each type allows them to adapt to different search environments, such as surface detection or deep excavation, and helps in identifying metals with high accuracy.

How do you test a metal detector coil?

It can be tested by placing a known piece of metal in front of it and moving it at different distances, and observing the accuracy and response of the signal. You can also review the connections and test the electrical resistance.

What is a DD coil on a metal detector?

It is a type of search coil that is characterized by wider coverage and better accuracy in distinguishing between metals. It is especially used in mineral soil or places with high interference.

0 notes

Text

Dental Articulators: $6.8B by 2034 with Strong Growth

Dental Articulators Market is projected to experience substantial growth, expanding from $3.9 billion in 2024 to $6.8 billion by 2034, with a compound annual growth rate (CAGR) of 5.8%. This market is dedicated to the manufacturing and supply of devices that simulate the temporomandibular joint, which is essential for dental professionals in diagnosing and planning procedures, particularly in prosthodontics and orthodontics. The market includes various types of articulators, ranging from simple hinge models to more advanced semi-adjustable and fully adjustable systems. These devices allow for the precise replication of jaw movements, enhancing treatment accuracy, improving patient outcomes, and increasing overall patient satisfaction.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10574 &utm_source=SnehaPatil&utm_medium=Article

The dental articulators market is experiencing robust growth, driven by technological advancements in the dental field and an increasing demand for precision in dental procedures. Among the sub-segments, semi-adjustable articulators are the top performers, appreciated for their versatility and accuracy in replicating jaw movements. Fully adjustable articulators follow closely in demand due to their wide range of motion, making them especially valuable for complex dental restorations. Regionally, North America leads the market, supported by a well-established healthcare infrastructure and a high prevalence of dental disorders. Europe ranks second, benefiting from increased investments in dental care and a growing elderly population. Within these regions, the United States stands out as the dominant player, while Germany emerges as a key market in Europe, driven by technological advancements and a strong focus on dental education. These regional trends highlight the market’s potential for further innovation and expansion.

Buy Now : https://www.globalinsightservices.com/checkout/single_user/GIS10574/?utm_source=SnehaPatil&utm_medium=Article

Market segmentation within the dental articulators industry includes various types, such as semi-adjustable articulators, fully adjustable articulators, and fixed/hinge articulators. The product range includes mechanical and electronic articulators, as well as accessories. Technological advancements in 3D printing, CAD/CAM systems, and digital articulation are shaping the future of the market. Applications for dental articulators span orthodontics, prosthodontics, restorative dentistry, and implantology. Material types used in manufacturing include metal, plastic, and composite materials. The market also caters to dental laboratories, clinics, and academic institutions, with functionalities ranging from articulated models and simulated jaw movements to occlusal analysis. Installation types can be portable or fixed, and equipment options include manual and motorized articulators. The market also offers both custom and standard articulation solutions.

In 2023, the Dental Articulators Market was estimated to have a volume of 1.2 million units. The semi-adjustable articulators segment dominated, holding a 55% market share, driven by their cost-effectiveness and versatility. Fully adjustable articulators captured 30% of the market share, while non-adjustable articulators, commonly used in academic settings, held the remaining 15%. The dominance of semi-adjustable articulators is attributed to their balance of affordability and functionality, making them popular among dental professionals and educational institutions. Leading players in the market include Whip Mix Corporation, Amann Girrbach AG, and SAM Dental, each of which is leveraging technological advancements to enhance their product offerings.

The competitive dynamics of the dental articulators market are influenced by ongoing technological innovation and the regulatory frameworks governing the industry. Companies are investing heavily in research and development to create digital solutions that integrate seamlessly with CAD/CAM systems, thereby improving precision. Regulatory bodies such as the FDA and EU MDR impose stringent compliance and quality standards, which shape the strategies of market players. Future projections suggest a 10% increase in market growth by 2033, driven by the expansion of digital dentistry and the rising demand for precision prosthetics. Despite the market’s potential, challenges such as high initial costs and the need for skilled professionals to operate advanced systems remain. However, emerging markets and the integration of AI in dental procedures are expected to provide new growth opportunities.

Geographically, the North American dental articulators market is robust, driven by an increase in dental procedures and technological innovations. The United States leads the market, supported by a strong healthcare infrastructure and a demand for sophisticated dental equipment. Canada also contributes to the market, focusing on high-quality dental care. Europe’s dental articulators market is significant, with countries like Germany and France leading the way. These nations emphasize dental health and have well-established healthcare systems, with increasing demand for precise dental tools driven by an aging population and growing awareness of oral health.

In the Asia Pacific region, rapid urbanization and rising disposable incomes are fueling the growth of the dental articulators market. Key players like China and India are contributing to this growth, thanks to their expanding middle class and increasing healthcare investments. The market in this region is expected to grow rapidly, supported by technological advancements and a growing emphasis on dental aesthetics. Latin America is an emerging market, with Brazil and Mexico at the forefront. These countries are seeing an increase in dental tourism and a rising middle class, driving demand for advanced dental solutions, although economic challenges may impact growth.

#DentalArticulators #Prosthodontics #Orthodontics #DentalTechnologies #DigitalDentistry #CADCAM #DentalCare #DentalEquipment #PrecisionDentistry #DentalRestorations #InnovativeDentalSolutions #DentalProsthetics #SemiAdjustableArticulators #FullyAdjustableArticulators #DentalClinics #DentalLabs #SmartDentistry #AgingPopulation #DentalTourism #DentalMarketGrowth #OralHealth

0 notes