#Piston Ring Manufacturers

Explore tagged Tumblr posts

Text

Best Piston manufacturer and supplier in India: Dasset Engineering

Dasset Engineering is a leading piston manufacturer and supplier, offering a wide range of high-performance pistons for various applications. From heavy-duty engines and gas engines to commercial vehicles powered by diesel or gasoline, Dasset Engineering delivers quality, reliability, and advanced solutions that meet the demands of the automotive and industrial sectors. With a commitment to precision, durability, and innovation, Dasset ensures that every piston it produces meets the highest industry standards.

Comprehensive Range of Pistons for All Needs

At Dasset Engineering, we specialize in providing pistons that cater to a diverse range of applications, including heavy-duty engines, commercial vehicles, and gasoline/diesel engines. Whether you need pistons for large-scale industrial operations or smaller commercial purposes, we have the right solutions for you.

Our pistons are designed and manufactured with the utmost precision to ensure optimal performance, even in the most demanding conditions. Whether it's high compression for heavy-duty engines or fuel efficiency for gasoline engines, Dasset’s pistons are engineered to perform consistently and reliably.

Quality You Can Trust

What sets Dasset Engineering apart is our focus on quality and affordability. Every piston we manufacture undergoes stringent quality checks, ensuring that only the best products reach our customers. From the most basic designs to advanced pistons with specialized metallic compositions and finish grades, our pistons meet or exceed industry standards.

Our piston rings and piston pins are designed to work seamlessly with our pistons, offering enhanced durability and reduced friction for prolonged engine life. These components are essential to the efficiency and smooth operation of any engine, and our products provide unmatched performance in these areas.

Advanced Metallic Compositions and Finish Grades

Dasset Engineering takes pride in using advanced metallic compositions and finish grades to craft high-quality pistons. By employing cutting-edge technology and superior materials, our pistons deliver excellent strength, thermal stability, and wear resistance. This ensures longer service life, even under extreme conditions like high temperatures and pressures.

With advanced finishing techniques, we optimize piston surfaces to reduce friction and increase efficiency, improving fuel consumption and extending the lifespan of engines.

Affordable Pricing and Strong Lead Times

In addition to offering premium-quality pistons, Dasset Engineering ensures affordable pricing without compromising quality. We understand the importance of balancing cost and performance, which is why we strive to offer competitive pricing across all our piston ranges.

Our commitment to customer satisfaction extends beyond product quality to efficient lead times. We know that in many industries, time is of the essence, which is why we maintain strong lead times to deliver our pistons promptly. Dasset’s streamlined production processes and dedicated team allow us to meet the needs of our clients in a timely and efficient manner.

Conclusion

When it comes to piston manufacturing and supply, Dasset Engineering stands out as a reliable partner. With a wide selection of high-performance pistons for heavy-duty engines, gas engines, and commercial vehicles, we combine top-tier quality, affordability, and prompt delivery to meet the varied needs of our clients. Whether you require piston rings, piston pins, or specialized metallic compositions, Dasset Engineering delivers products that guarantee performance and reliability for a wide range of applications.

#Piston manufacturer#High-performance pistons#Piston supplier#Heavy-duty engine pistons#Piston rings manufacturer#Piston pins supplier#Gasoline engine pistons#Diesel engine pistons#Commercial vehicle pistons#Engine piston supplier#Advanced piston technology#High-quality pistons#Affordable pistons for engines#Piston for industrial engines#Piston manufacturing company#Engine pistons for gas engines#Metallic composition pistons#Precision pistons for engines#Piston rings and pins supplier#Piston supplier for diesel engines

0 notes

Text

The piston ring, a small but mighty guardian, seals the power within, igniting the spirit of every engine's heartbeat.

0 notes

Photo

TVR Tuscan 2S

First released in 1999 and manufactured up until 2006 the TVR Tuscan was available in various specifications with varying performance. Being a 2S the car is fitted with the 4 liter Speed-Six TVR engine and revised suspension for increased handling performance. A full engine rebuild was completed resulting in a reliable smooth engine that produces just north of 400BHP. The completed work includes -Syvecs engine management system -Aluminium radiator -FFF EVO2 cylinder head -Billet crankshaft -H section conrods -Up-rated cylinder block -Simplex timing sprockets and chain -Modified half time bearing -New piston rings and bearings -Lightened flywheel -New clutch -Race proven clutch slave cylinder -De-cat exhaust -SC engine mounts -AST suspension -Suspension poly bush kit -Silicone hoses This work completed ensures that this TVR is not only fabulous to drive but most importantly reliable.

200 notes

·

View notes

Text

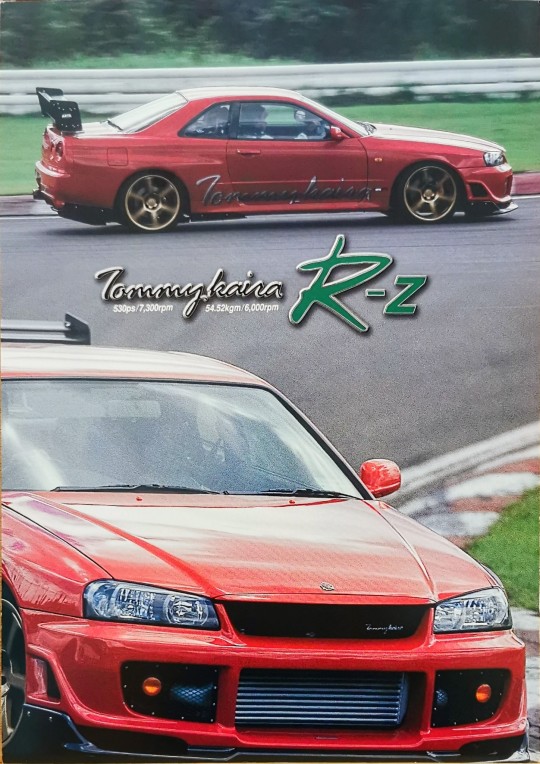

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Engine Repair Instruction Full Guide

Engines are the heart of any vehicle, powering everything from your daily commute to long road trips. Knowing how to repair an engine can be a game-changer, whether you're an enthusiast who loves getting your hands dirty or someone looking to save money on mechanic bills. This guide will walk you through the entire process of engine repair, from diagnosing problems to reassembling your engine and ensuring it runs smoothly.

Understanding the Basics of an Engine

Before diving into the repair process, it’s crucial to understand how an engine works. Most vehicles use an internal combustion engine, which combines fuel and air, ignites it, and transforms that explosion into mechanical energy.

Components of an Internal Combustion Engine

The main components include:

Cylinder Block: The engine's core where combustion occurs.

Cylinder Head: Houses the valves and spark plugs.

Pistons: Move up and down to create the force needed to turn the crankshaft.

Crankshaft: Converts the pistons' up-and-down movement into rotational motion.

Camshaft: Controls the opening and closing of the valves.

Valves: Regulate the flow of fuel and air into the engine and exhaust gases out.

How an Engine Works: A Simple Explanation

An engine works by pulling in a mixture of air and fuel, compressing it, igniting it with a spark (in gasoline engines), and then expelling the exhaust gases. This cycle—intake, compression, power, and exhaust—happens in each cylinder and repeats hundreds of times per minute.

Tools and Equipment Needed for Engine Repair

Whether you're performing a basic repair or diving into more complex work, having the right tools is essential.

Essential Tools for Basic Repairs

Socket Set: For removing and tightening bolts.

Wrenches: Different sizes for various engine parts.

Screwdrivers: Flathead and Phillips for screws and clips.

Pliers: For handling wires and small parts.

Torque Wrench: Ensures bolts are tightened to the correct specifications.

Specialized Equipment for Advanced Engine Work

Engine Hoist: For removing the engine from the vehicle.

Cylinder Hone: Prepares cylinders for new piston rings.

Compression Tester: Checks the health of each cylinder.

OBD-II Scanner: Diagnoses engine codes and issues.

Safety Gear and Precautions

Gloves: Protect your hands from cuts and chemicals.

Safety Glasses: Shield your eyes from debris.

Work Boots: Offer protection against heavy parts or tools.

Diagnosing Engine Problems

Accurately diagnosing engine problems is the first step in any repair process. Understanding the symptoms can save time and prevent unnecessary work.

Common Symptoms of Engine Issues

Check Engine Light: Indicates a problem detected by the car's computer.

Strange Noises: Knocking, tapping, or grinding sounds can signal internal damage.

Excessive Smoke: Blue smoke might mean burning oil, while white could suggest a coolant leak.

Loss of Power: Often linked to fuel or air delivery issues.

Step-by-Step Diagnostic Process

Listen and Observe: Note any unusual sounds, smells, or behaviors.

Check Engine Light Codes: Use an OBD-II scanner to retrieve error codes.

Perform Compression Test: Assesses the health of your engine’s cylinders.

Inspect Fluids: Look for contamination or leaks in oil, coolant, and other fluids.

Step-by-Step Guide to Reassembly

Prepare Your Workspace: Ensure that your workspace is clean, organized, and well-lit. Lay out all the parts and tools you'll need in the order of reassembly. Keep the engine manual handy for specific torque specs and sequences.

Install the Crankshaft: Place the crankshaft back into the engine block, ensuring it is seated correctly. Use assembly lube on the main bearings to prevent damage during the initial startup. Torque the main caps to the manufacturer's specifications.

Insert the Pistons: Install the pistons and connecting rods. Be sure to align the piston rings correctly and use a ring compressor to insert the pistons into the cylinder bore. Attach the connecting rods to the crankshaft and torque the rod bolts to spec.

Install the Camshaft and Timing Components: If your engine uses a timing chain or belt, install it according to the timing marks on the camshaft and crankshaft gears. This step is crucial for ensuring the engine's valves open and close at the correct times.

Attach the Cylinder Head: Place the cylinder head gasket on the engine block, followed by the cylinder head. Torque the head bolts in the correct sequence and to the proper specifications. This ensures a good seal and prevents head gasket failure.

Install Valves, Lifters, and Pushrods: If applicable, install the engine's valves, lifters, and pushrods. Make sure they are properly aligned and that the lifters are seated correctly in their bores.

Reassemble the Valve Train: Install the rocker arms and adjust the valve lash according to the engine manual. Proper valve lash is critical for engine performance and longevity.

Reattach External Components: Begin reattaching external components like the water pump, oil pump, timing cover, oil pan, and intake manifold. Replace any gaskets and seals during this process to prevent leaks.

Reconnect the Fuel and Ignition Systems: Reinstall the fuel injectors, spark plugs, and ignition wires. Ensure all electrical connections are secure and properly routed to avoid short circuits or malfunctions.

Final Checks: Before moving on, double-check all connections, bolts, and components. Make sure nothing is left loose or unconnected.

Applying Proper Torques and Specifications

Every engine has specific torque settings for each bolt. Over-tightening can strip threads or warp components, while under-tightening can lead to leaks or parts coming loose. Use a torque wrench and follow the manufacturer's specifications closely.

Double-Checking Work for Mistakes

It's easy to miss a step or make a mistake during reassembly. Double-check your work:

Ensure all components are installed in the correct order.

Verify all bolts are torqued to spec.

Check for any leftover parts or tools in the engine bay.

Testing the Repaired Engine

With the engine reassembled, the next step is testing it to ensure everything is functioning properly.

Preparing for Initial Startup

Before starting the engine, perform a few preparatory checks:

Prime the oil system: This can be done by cranking the engine with the fuel system disabled until oil pressure is achieved.

Fill the engine with fresh oil and coolant.

Double-check all electrical connections and fuel lines.

Checking for Leaks and Unusual Noises

Once you start the engine, pay close attention to any unusual noises or leaks:

Oil Leaks: Check around the oil pan, valve covers, and front and rear seals.

Coolant Leaks: Inspect the radiator, hoses, and water pump area.

Unusual Noises: Listen for knocking, tapping, or whining sounds, which could indicate an issue with the timing components or internal parts.

Fine-Tuning and Adjusting the Engine

After the initial startup, the engine may require some adjustments:

Timing Adjustments: Use a timing light to set the ignition timing.

Idle Speed: Adjust the idle speed according to the manufacturer’s specifications.

Fuel Mixture: On carbureted engines, you may need to adjust the air-fuel mixture for optimal performance.

Common Engine Repair Mistakes to Avoid

Engine repair is complex, and mistakes can be costly. Here are some common errors to watch out for:

Misalignments and Incorrect Torques

Misaligned timing components can lead to poor engine performance or damage.

Incorrectly torqued bolts can cause leaks, parts failure, or engine damage.

Overlooking Small Parts and Connections

Small parts like washers, clips, or gaskets are easy to overlook but crucial for preventing leaks and ensuring proper function.

Electrical connections: Double-check that all sensors and connectors are properly seated.

Skipping Diagnostic Steps

Skipping steps in the diagnostic process can lead to unnecessary repairs or missed issues. Always perform thorough diagnostics before and after repairs.

Maintaining Your Engine After Repair

Proper maintenance is key to ensuring the longevity of your newly repaired engine.

Importance of Regular Maintenance

Regular maintenance, such as oil changes, air filter replacements, and coolant checks, is essential to keep your engine running smoothly and prevent future problems.

Tips for Extending Engine Life

Use high-quality oil and filters.

Avoid hard driving until the engine is fully warmed up.

Regularly check and maintain fluid levels.

When to Seek Professional Help

While DIY repairs can save money, some issues are best left to professionals, especially if you encounter complex problems or lack the necessary tools and expertise.

Dealing with Advanced Engine Repairs

Some engine repairs are too complex for the average DIYer. Here's when to consider professional help:

Understanding When It’s Beyond DIY

Extensive internal damage: Cracked blocks or severely worn bearings usually require professional expertise.

Advanced electrical issues: Problems with engine management systems often need specialized diagnostic tools and knowledge.

Overview of Complex Repairs: Timing Belt, Engine Rebuilds

Timing Belt Replacement: Involves precise alignment of engine components and is critical for preventing engine damage.

Engine Rebuilds: This is a time-consuming and complex task that often requires professional machining and specialized tools.

Working with a Professional Mechanic

When the repair is beyond your capabilities, working with a professional mechanic ensures that the job is done correctly and safely. They have the tools, experience, and resources to handle complex engine repairs.

Cost Considerations in Engine Repair

Engine repair costs can vary widely depending on the scope of work, parts required, and whether you do it yourself or hire a professional.

Estimating Costs for DIY vs Professional Repair

DIY Repairs: Typically cost less but require an investment in tools and time.

Professional Repairs: Can be expensive but come with the assurance of experience and often a warranty.

Budgeting for Tools, Parts, and Time

Consider the cost of any special tools or equipment you might need, as well as the cost of replacement parts. Factor in the time required, especially if the vehicle is your daily driver.

Understanding the Cost of Mistakes

Mistakes can be costly. Stripping a bolt, breaking a part, or incorrect assembly can lead to additional expenses. Always weigh the risks before starting a major repair.

Conclusion

Recap of Key Points

Engine repair is a rewarding but challenging task that requires careful planning, the right tools, and attention to detail. Whether you’re fixing a minor issue or performing a complete rebuild, following the correct procedures is crucial for success.

Encouragement for DIY Enthusiasts

For those who love working on their vehicles, engine repair can be a satisfying and cost-effective way to maintain your car. With patience and persistence, even complex repairs can be tackled with confidence.

Final Thoughts on Engine Repair

Always approach engine repair with a clear plan and the right resources. Don’t hesitate to seek professional help when needed, and remember that regular maintenance is the best way to avoid major repairs.

FAQs

How do I know if my engine needs repair?

Common signs include unusual noises, excessive smoke, loss of power, and a check engine light. Regular diagnostics can help catch issues early.

Can I repair my engine without professional help?

Basic repairs like replacing gaskets or sensors can often be done at home with the right tools. However, more complex tasks like engine rebuilds may require professional expertise.

What are the signs of a failing engine?

Signs include knocking noises, excessive oil consumption, smoke from the exhaust, and persistent overheating.

How long does it take to repair an engine?

The time required varies greatly depending on the complexity of the repair. Simple repairs might take a few hours, while a full rebuild could take several days or longer.

2 notes

·

View notes

Text

🔸𝐎𝐂: 𝐈𝐧𝐟𝐞𝐫𝐧𝐮𝐬, 𝐭𝐡𝐞 𝐅𝐢𝐫𝐞 𝐑𝐞𝐚𝐩𝐞𝐫🔸

youtube

𝐋𝐨𝐫𝐞: Converted from an old deforestation machine, this hulking automaton strikes fear into its adversaries by charging them down like a bull before decimating them with its fire-based weaponry.

𝐁𝐚𝐜𝐤𝐬𝐭𝐨𝐫𝐲: As the urban areas of New Victoria expanded over the decades, certain regions of the surrounding wilderness needed to be deforested for housing and construction. Consequently, a line of automatons known as ‘fire reapers’ were manufactured to help expedite the process and work in conditions too dangerous for humans. Despite their slow, cumbersome movement, these machines proved to perform simple tasks like chopping lumber and setting prescribed fires with precision and efficiency.

While most operators rarely thought of their machines past their day’s labor, let alone life career, one employee by the name of Edgar Crain offered nearly half of his life savings to purchase one of the fire reaper units for himself. Subsequently, Edgar would spend the remainder of his savings on a single vial of Aetherium. Having been paraplegic and wheelchair-bound his entire life, Billy has been fascinated with Aetherium and its potential to have a human ‘live’ through an automaton. That night, when he finally began his telepathic-bonding with the machine, the thrill and surreal sensations that Edgar felt were beyond words. He could only later describe it as his body ‘melding’ into the metal, as if the robot’s gears and pistons were his very own joints and muscles.

After years of disciplined training, Edgar entered his first aether-ring tournament. Much to the audience’s surprise and his own incredible delight, Edgar's fire reaper dominated its first matches and quickly became the spectacle of the event. From then on, Edgar would only refine his skills and upgrade his fearsome automaton, climbing the ranks of the Aethosphere and eventually earning him the title ‘the Infernus.’

Song: 2WEI - War Lord (Escape Velocity)

#illustration#artoftheday#artistsoninstagram#digitalart#digitalartist#digitalillustration#lineart#drawing#artist#colors#artstationhq#deviantart#artprocess#timelapse#artreel#artshort#fantasy#scifi#steampunk#aether#mech#robot#fire#machine#dnd#oc#originalcharacter#artist on instagram#artist on tumblr#art

4 notes

·

View notes

Text

Caterpillar Diesel Tools for Efficient Maintenance

Introduction

Maintaining diesel engines requires specialized tools that ensure efficiency, durability, and precision. At Tillman Tools, LLC, we provide high-quality Caterpillar Diesel Tools designed to support professionals in performing effective maintenance and repairs. Whether you are working on heavy machinery, trucks, or industrial engines, using the right Cat Diesel Tools can significantly enhance performance and longevity.

Why Choose Caterpillar Diesel Tools?

Caterpillar is a leader in diesel engine manufacturing, and their tools are engineered to meet the highest industry standards. Here are some key benefits of Caterpillar Diesel Tools:

Exceptional Durability: Built to withstand tough working environments and repeated use.

Precision Engineering: Ensures accurate diagnostics and repairs for diesel engines.

Ergonomic Design: Reduces user fatigue and enhances efficiency during maintenance.

Comprehensive Tool Range: Covers all aspects of diesel engine servicing, from diagnostics to assembly.

Essential Caterpillar Diesel Tools for Efficient Maintenance

1. Caterpillar Diagnostic Tools

Identifying engine issues quickly is crucial for minimizing downtime. Cat Diesel Tools for diagnostics include:

Electronic Diagnostic Scanners – Detect engine faults and provide real-time data.

Compression Testers – Measure cylinder compression to assess engine health.

Fuel Pressure Gauges – Ensure optimal fuel system performance.

2. Caterpillar Wrenches and Sockets

Properly fitted wrenches and sockets are essential for diesel engine maintenance. Caterpillar Diesel Tools offer:

Torque Wrenches – Ensure precise torque application to prevent over-tightening.

Impact Sockets – Designed to handle high-torque operations.

Combination Wrenches – Provide versatility for various engine components.

3. Caterpillar Fuel System Tools

The fuel system plays a critical role in diesel engine performance. Specialized Cat Diesel Tools include:

Injector Pullers – Safely remove and install fuel injectors.

Fuel Line Disconnect Tools – Simplify the process of servicing fuel systems.

Diesel Particulate Filter (DPF) Cleaning Tools – Maintain emission control systems efficiently.

4. Caterpillar Engine Disassembly and Assembly Tools

Working on diesel engines requires tools that facilitate safe and precise disassembly. Must-have Caterpillar Diesel Tools include:

Piston Ring Compressors – Ensure proper installation of piston rings.

Valve Spring Compressors – Assist in removing and installing valve springs.

Crankshaft Alignment Tools – Maintain engine timing and precision.

5. Caterpillar Cooling System Tools

Overheating is a common issue in diesel engines. Proper maintenance of the cooling system requires:

Radiator Pressure Testers – Identify leaks and pressure issues in the cooling system.

Coolant Refractometers – Measure coolant concentration for optimal performance.

Thermostat Removal Tools – Facilitate easy replacement of engine thermostats.

6. Caterpillar Electrical System Tools

Diesel engines rely on a robust electrical system. Cat Diesel Tools for electrical maintenance include:

Multimeters – Test voltage, resistance, and continuity.

Battery Load Testers – Evaluate battery health and charge capacity.

Alternator Testers – Diagnose charging system problems efficiently.

7. Caterpillar Exhaust System Tools

Maintaining the exhaust system is essential for emission control and efficiency. Caterpillar Diesel Tools include:

Oxygen Sensor Wrenches – Easily remove and install O2 sensors.

Exhaust Pipe Expanders – Adjust and repair exhaust system components.

Clamp Pliers – Secure exhaust clamps without damage.

8. Caterpillar Tool Storage and Organization

Keeping tools organized enhances productivity. Cat Diesel Tools storage solutions include:

Heavy-Duty Tool Chests – Provide secure storage for essential tools.

Portable Toolboxes – Allow easy transport of necessary equipment.

Rolling Tool Carts – Offer mobility and accessibility in the workshop.

How to Maintain Your Caterpillar Diesel Tools

To maximize the lifespan and efficiency of your Caterpillar Diesel Tools, follow these maintenance tips:

Regular Cleaning: Remove dirt and oil after each use to prevent corrosion.

Lubrication: Keep moving parts well-oiled for smooth operation.

Proper Storage: Use designated storage solutions to avoid damage and misplacement.

Routine Inspection: Replace worn-out tools to maintain safety and efficiency.

Conclusion

Investing in the right Caterpillar Diesel Tools is essential for maintaining and repairing diesel engines with precision. At Tillman Tools, LLC, we provide high-quality Cat Diesel Tools to ensure professionals have everything they need for efficient and reliable maintenance. Whether you're working on construction equipment, heavy trucks, or industrial engines, our tools help enhance productivity and extend machinery lifespan.

0 notes

Text

Top Forging Manufacturers in India: Innovation & Excellence

India has become a global hub for manufacturing across various industries, and forging is no exception. The country is home to a wide range of forging manufacturers that cater to both domestic and international markets. With a rich industrial heritage, skilled labor force, and an expanding manufacturing sector, India is rapidly gaining prominence in the global forging industry. In this article, we’ll explore the key aspects of forging manufacturers in India, their capabilities, and why they are gaining international recognition.

What is Forging? Forging is a manufacturing process where metal is shaped by applying compressive forces, usually through the use of a hammer or press. This process is widely used for creating strong, durable, and high-performance components that are used in various sectors such as automotive, aerospace, construction, agriculture, and oil and gas. The forging process involves heating the metal to high temperatures and shaping it under controlled conditions to ensure the final product has enhanced strength, reliability, and structural integrity.

Types of Forging There are several types of forging processes that manufacturers in India specialize in:

Open Die Forging: This is one of the oldest and most common forms of forging, where the metal is shaped between two flat dies. Open die forging is used to create large and heavy parts for industries such as aerospace and defense.

Closed Die Forging: In this process, metal is placed in a die that completely encloses the material. The shape of the finished product is more intricate and precise. Closed die forging is often used for automotive parts, such as gears, shafts, and pistons.

Ring Rolling: This is a specialized forging process used to create round parts like rings and discs. This technique is commonly used in industries like aerospace, automotive, and energy.

Upset Forging: This method involves increasing the diameter of a specific area of the material to create components like bolts, nuts, and fasteners used in engineering applications.

Forging Manufacturers in India: Capabilities and Services State-of-the-Art Technology Many forging manufacturers in India invest in advanced forging technologies such as hydraulic presses, automated forging lines, and CNC (Computer Numerical Control) machines. These technological advancements enable manufacturers to produce high-quality components with greater precision, faster lead times, and at competitive prices.

Versatility Across Industries India’s forging manufacturers serve a wide array of industries, each with its unique needs. These include:

Automotive Industry: India’s forging sector plays a vital role in supplying components like crankshafts, axles, suspension parts, and engine blocks for the automotive industry, both domestically and for export. Aerospace and Defense: Forging is essential in aerospace and defense applications where precision and strength are paramount. Manufacturers in India produce critical components like turbine blades, landing gear parts, and structural elements for aircraft. Construction and Infrastructure: Large-scale forgings such as beams, girders, and custom-designed parts are used in construction and infrastructure development. Energy and Oil & Gas: India’s forging manufacturers produce components that are used in power generation plants, oil rigs, and pipelines, including valves, flanges, and pumps. Customization and R&D Capabilities Leading forging manufacturers in India often provide customized solutions tailored to the specific needs of their clients. Whether it’s a unique material, shape, or size, manufacturers can work closely with clients to deliver precisely what is required. Additionally, many of these manufacturers invest in research and development (R&D) to innovate and stay ahead in terms of material strength, lightweight options, and cost efficiency.

Competitive Pricing and Quality India has established itself as a global leader in cost-effective manufacturing, and the forging sector is no exception. By leveraging low labor costs, efficient production processes, and economies of scale, Indian forging manufacturers are able to offer competitive pricing without compromising on quality. This combination of quality and cost-effectiveness has made India an attractive outsourcing destination for forging needs worldwide.

Export Potential India’s forging industry is increasingly looking to cater to global markets. As a result, many manufacturers have obtained international certifications such as ISO, AS9100, and TS16949, ensuring they meet global quality standards. Countries in North America, Europe, and the Middle East have become key export markets for Indian forging manufacturers, with demand growing steadily.

Challenges and Opportunities for Forging Manufacturers in India Challenges:

Rising Raw Material Costs: The cost of raw materials like steel and aluminum can fluctuate, impacting production costs. Manufacturers need to manage these price variations effectively. Skill Development: Although India has a large labor force, there is a constant need to train workers in advanced forging techniques and technologies to stay competitive in the global market. Opportunities:

Technological Advancements: The adoption of Industry 4.0 technologies, including automation, AI, and IoT, presents an opportunity for manufacturers to further improve efficiency and product quality. Sustainability Initiatives: Growing global emphasis on sustainability is encouraging manufacturers to develop eco-friendly practices and explore the use of recycled materials in forging. Expanding Markets: With global demand for high-quality forged products on the rise, Indian manufacturers have the opportunity to penetrate more markets and build long-term relationships with international clients. Conclusion Forging manufacturers in India are playing a crucial role in meeting the global demand for high-quality, durable, and precisely engineered components. With a strong focus on technology, quality control, and customization, Indian manufacturers are making their mark across various industries. As the country continues to invest in infrastructure, research, and skill development, India’s forging sector is poised for further growth and innovation, offering immense potential for both domestic and international customers.

0 notes

Text

What is the P0303 Code and Why Does It Matter?

The P0303 code is an OBD-II diagnostic trouble code that indicates a misfire in cylinder 3 of your engine. This issue can stem from various causes, such as faulty spark plugs, ignition coils, fuel injectors, or even compression loss. Common symptoms include engine shaking, reduced performance, and increased fuel consumption. If left unaddressed, it can lead to more severe problems like catalytic converter damage or engine failure. To understand the root causes and solutions, check out this detailed guide.

How to Diagnose a P0303 Code

Diagnosing a P0303 code requires a systematic approach. Start by using an OBD-II scanner to confirm the code and review freeze frame data. Next, inspect the spark plugs and ignition coils for wear or damage. If the issue persists, test the fuel injectors or perform a compression test on cylinder 3. For example, low compression could point to worn piston rings or valve issues. For a step-by-step breakdown and expert tips, refer to our P0303 troubleshooting guide.

How to Fix the P0303 Code for Good

Fixing a P0303 code permanently often involves replacing faulty parts and performing regular maintenance. For instance, using OEM (original equipment manufacturer) ignition coils can reduce the risk of recurring issues. Additionally, cleaning the fuel system or replacing the air filter can prevent similar problems in the future. For cost-effective solutions and professional advice, explore our comprehensive P0303 guide to get your vehicle back on the road safely.

Key Features:

Links are naturally integrated into the flow of the text.

The article is reader-friendly and provides actionable advice.

Perfect for blogs, forums, or social media posts!

Let me know if you need further tweaks! 🚗✨

source : https://carautomobilehub.com/p0303-code/

1 note

·

View note

Text

Reciprocating Air Compressor Troubleshooting Guide and Expert Tips

A reciprocating air compressor is an essential tool in various industries, known for its efficiency and durability. However, like any mechanical equipment, these compressors can face operational issues that affect their performance. Whether it’s overheating, loss of pressure, or excessive noise, understanding how to troubleshoot these problems can save time, reduce maintenance costs, and extend the life of air compressors. In this article, we will discuss common air compressors reciprocating issues, their causes, and expert solutions, along with essential maintenance tips to ensure optimal performance.

Understanding reciprocating air compressors

Before tackling troubleshooting, it’s essential to understand how air compressors reciprocating function. These compressors operate by drawing air into a chamber and compressing it using a reciprocating piston mechanism. The compressed air is then stored in a tank and used for various applications, including industrial processes, automotive tools, and HVAC systems. A reciprocating air compressor has multiple moving parts, which are prone to wear and tear, making regular maintenance crucial.

Common reciprocating air compressor issues and fixes

Compressor not starting:

Possible causes:

Faulty power supply

Tripped circuit breaker

Defective pressure switch

Low oil levels (for lubricated models)

Overheating due to excessive load

Solution:

Check the power supply and reset the circuit breaker if needed.

Inspect the pressure switch and ensure it’s working properly.

Verify oil levels and refill if necessary.

Allow the compressor to cool before restarting if it has overheated.

Overheating compressor:

Possible causes:

Insufficient ventilation

Dirty or clogged air filters

Overuse beyond the recommended duty cycle

Faulty cooling system

High ambient temperature

Solution:

Ensure proper ventilation around the compressor.

Clean or replace air filters regularly.

Avoid continuous operation beyond the recommended duty cycle.

Inspect and clean the cooling system to prevent overheating.

Use the compressor in a temperature-controlled environment.

Excessive noise or vibrations:

Possible causes:

Loose parts or bolts

Worn-out bearings

Misaligned belt or pulley

Piston slap due to cylinder wear

Solution:

Tighten loose bolts and inspect for misalignments.

Lubricate or replace bearings as needed.

Align the belt and pulley correctly to reduce strain.

Check the cylinder and piston for wear and replace if necessary.

Loss of pressure or reduced air output:

Possible causes:

Leaking air hoses or fittings

Worn-out valves or gaskets

Clogged air filters

Faulty pressure regulator

Solution:

Inspect and seal leaks in hoses and fittings.

Replace worn-out valves and gaskets.

Clean or replace air filters regularly.

Adjust or replace the pressure regulator for constant output.

Oil carryover in compressed air:

Possible causes:

Worn piston rings

Overfilled oil reservoir

Incorrect oil type

Clogged separator element

Solution:

Replace worn piston rings to prevent oil leakage.

Maintain correct oil levels in the compressor.

Use reciprocating air compressor manufacturers-recommended oil.

Inspect and clean the separator element to prevent oil contamination.

A compressor shut down unexpectedly:

Possible causes:

Overload protection activation

High ambient temperature

Faulty pressure switch

Clogged or malfunctioning check valve

Solution:

Allow the compressor to cool down before restarting.

Ensure it operates in a well-ventilated area.

Inspect and replace the pressure switch if necessary.

Clean or replace the check valve for smooth operation.

Expert maintenance tips

To prevent breakdowns and maximize efficiency, follow these expert maintenance tips:

Daily inspections: Check for air leaks, abnormal sounds, and loose connections.

Lubrication: Change oil regularly and use the correct type of lubricant.

Filter cleaning: Keep air intake filters clean to maintain airflow and efficiency.

Drain moisture: Drain condensate from the air receiver tank daily to prevent corrosion.

Check belts and pulleys: Ensure proper tension and alignment for smooth operation.

Monitor temperature: Keep the compressor in a well-ventilated area to avoid overheating.

Tighten connections: Secure all nuts, bolts, and fittings to minimize vibrations.

Test safety valves: Regularly inspect and test pressure relief valves to avoid over-pressurization.

How to choose the right reciprocating air compressor

Selecting the right air compressors reciprocating depends on your specific application and industry requirements. Here are some factors to consider:

Compressor size: Choose a compressor with the appropriate tank capacity based on air demand.

Horsepower (HP): Ensure the motor power is sufficient for the required air pressure.

Oil vs. oil-free models: Lubricated models are more durable, while oil-free models require less maintenance.

Duty cycle: Check the duty cycle rating to avoid overuse and overheating.

Noise level: Opt for quieter models if the compressor is used in indoor environments.

Manufacturer reputation: Purchase from reliable reciprocating air compressor manufacturers for quality and durability.

Wrapping Up:

A well-maintained reciprocating air compressor is essential for seamless industrial operations. By following this troubleshooting guide and expert maintenance tips, you can minimize downtime, reduce repair costs, and extend the lifespan of your air compressors reciprocating. Regular inspections, proper lubrication, and timely repairs will ensure consistent performance and efficiency. If continued issues arise, consult professional reciprocating air compressor manufacturers for expert service. Staying proactive with maintenance and troubleshooting will ensure your compressor operates at peak efficiency, providing reliable performance for years to come!

#reciprocating air compressor manufacturers#reciprocating air compressor#reciprocating compressor#air compressors reciprocating

0 notes

Text

Hydraulic Cylinder Piston: The Heart of Your Hydraulic System

Hydraulic systems are the backbone of many modern machines, from heavy construction equipment to precision manufacturing machinery. At the heart of every hydraulic system is the hydraulic cylinder piston, a critical component that converts fluid pressure into mechanical motion. In this blog, we’ll delve into the world of hydraulic cylinder pistons, exploring their design, function, and importance in hydraulic systems.

What is a Hydraulic Cylinder Piston?

A hydraulic cylinder piston is a moving component within a hydraulic cylinder that converts fluid pressure into mechanical motion. The piston is typically a cylindrical piece of metal with seals and rings that move up and down within the cylinder, driven by fluid pressure.

How Does a Hydraulic Cylinder Piston Work?

The hydraulic cylinder piston works by using fluid pressure to generate force, which is then transmitted to the piston rod, causing it to move. The process can be broken down into the following steps:

1. Fluid Pressure: Hydraulic fluid is pumped into the cylinder, creating pressure that acts on the piston.

2. Piston Movement: The pressure forces the piston to move, which in turn moves the piston rod.

3. Mechanical Motion: The piston rod is connected to a mechanical load, such as a heavy object or a machine, which is then moved or actuated by the piston’s motion.

Types of Hydraulic Cylinder Pistons

There are several types of hydraulic cylinder pistons, each designed for specific applications and operating conditions. Some common types include:

1. Single-Acting Pistons: These pistons are designed for applications where the piston only needs to move in one direction.

2. Double-Acting Pistons: These pistons are designed for applications where the piston needs to move in both directions.

3. Telescoping Pistons: These pistons are designed for applications where a long stroke is required, such as in heavy construction equipment.

Importance of Hydraulic Cylinder Pistons

Hydraulic cylinder pistons are a critical component of hydraulic systems, and their importance cannot be overstated. Some of the key reasons why hydraulic cylinder pistons are so important include:

1. Efficiency: Hydraulic cylinder pistons enable hydraulic systems to convert fluid pressure into mechanical motion with high efficiency.

2. Reliability: Hydraulic cylinder pistons are designed to operate in harsh environments and withstand heavy loads, making them a reliable choice for many applications.

3. Customization: Hydraulic cylinder pistons can be custom-designed to meet the specific needs of an application, allowing for optimal performance and efficiency.

Conclusion

In conclusion, hydraulic cylinder pistons are the heart of every hydraulic system, converting fluid pressure into mechanical motion with efficiency and reliability. Their importance cannot be overstated, and their customization options make them an ideal choice for a wide range of applications. Whether you’re designing a new hydraulic system or maintaining an existing one, understanding the role and importance of hydraulic cylinder pistons is essential.

About the Author

GPM ENGINEERING is a Machining Components Manufacturer with extensive experience in the hydraulic industry. With a passion for sharing knowledge and insights, GPM ENGINEERING is committed to helping others understand the complexities of hydraulic systems and components.

Contact Us

If you have any questions or would like to learn more about hydraulic cylinder pistons, please don’t hesitate to contact us. Our team of experts is always available to provide guidance and support.

0 notes

Text

Automotive Piston Ring Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Piston Ring Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Piston Ring Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Piston Ring Market is experiencing robust growth driven by the expanding globally. The Automotive Piston Ring Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Piston Ring Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Piston Ring Market Size, Share & Industry Analysis, By Type (Ductile Iron, Grey Cast Iron, Steel), By Vehicle Type (Two Wheelers, Passenger Car, Commercial Vehicle) And Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105493

Key Strategies

Key strategies in the Automotive Piston Ring Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Piston Ring Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Piston Ring Market.

Major Automotive Piston Ring Market Manufacturers covered in the market report include:

Major players operating in the global automotive piston ring market include Federal Mogul Corporation, Shriram Pistons & Rings Ltd., IP Rings Ltd., MAHLE GmbH, Samkrg Pistons & Rings, Omega Pistons, Hunan ZhengYuanDongli Parts Co., Ltd., Anhui Huan Xin Group Co., Ltd., RIKEN CORPORATION, and NIPPON PISTON RING Co., Ltd. among others.

The emission standards set by the government such as the Euro 6 environmental standard in Europe and BSVI emission standard in India are the standards that aims to reduce the emission of vehicles, precisely the Nitrogen Oxide (NOx) and other particulate matters. Thus, these factors are expected to fuel the growth of the automotive piston rings market.

Trends Analysis

The Automotive Piston Ring Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Piston Ring Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Piston Ring Market Solutions.

Regions Included in this Automotive Piston Ring Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Piston Ring Market.

- Changing the Automotive Piston Ring Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Piston Ring Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Piston Ring Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Piston Ring Market?

► Who are the prominent players in the Global Automotive Piston Ring Market?

► What is the consumer perspective in the Global Automotive Piston Ring Market?

► What are the key demand-side and supply-side trends in the Global Automotive Piston Ring Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Piston Ring Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Piston Ring Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

Prolonging Reciprocating Air Compressor Life: Monitoring Essential Components Beyond Pistons

A reciprocating air compressor, also known as a piston compressor, is a positive displacement machine. The piston compresses the gas and delivers it at a high pressure. This process is repeated continuously, allowing the reciprocating compressor to provide a steady supply of compressed air for a wide range of applications. from powering pneumatic tools to supporting various industrial processes.

Multi-Stage Reciprocating Air Compressor is used primarily for filling vehicle tires, small paint jobs, commercial purposes, dust cleaning, and operating hand tools. oil refineries, gas pipelines, chemical industries, and many refrigeration and air conditioning systems are some of the industries that commonly use reciprocating air compressors.

Benefits of Using a Reciprocating Air Compressor There is a reason why professionals across industries choose a two-stage reciprocating air compressor over other types of air compressors. Some of the more obvious advantages of using a reciprocating air compressor are:

Higher pressure generation :

A reciprocating piston compressor can produce higher pressures than other compressors like rotary screw varieties.

Flexibility of use :

They come in both oil-flooded and oil-free varieties.

High efficiencies achieved :

Reciprocating compressors can produce higher pressures using less energy to run.

Efficiency of use in intermittent cycling :

Reciprocating compressors maintain high efficiency when running intermittently.

Challenges with Reciprocating Air Compressors Reciprocating air compressors are efficient to use and their versatility makes them a great choice of equipment in many different use cases. However, like any other equipment, they need care and maintenance to run smoothly for a long time. Some of the most common challenges one faces with Reciprocating air compressors are:

High discharge temperatures can lead to an insufficient coolant supply. Inadequate piston-to-head clearance can cause the piston to fail or lead to rod breakage. Vibration is a common issue that can lead to reciprocating compressor failure. A sudden spike in temperature can overheat the compressor, which can significantly reduce its overall lifespan. Energy loss is another issue that one can face while using a reciprocating compressor as they lose more energy to the friction and motion of their moving parts compared to rotary compressors. Due to the design and motion of the pistons, cylinder, and ring wear, reciprocating compressors have more internal leakage, which can reduce their efficiency. Technical Measures to Prolong the Life of Reciprocating Air Compressors To prolong the life of a reciprocating air compressor, certain specific and technical measures need to be taken:

Keeping the Air Compressor Clean :

Excess dirt and debris are major causes of premature compressor failure. Regular cleaning of dirt using a blower and removing contaminants using compressed air will ensure compressor components are clean and function smoothly without any energy loss

Minimising Vibrations: :

To reduce vibration, you can tightly secure the piston air compressor on a flat surface. One can also install vibration pads to help minimise vibration issues.

Monitoring Changes in Temperature :

A sudden spike in temperature during operation indicates that a compressor is running too hot. The single-stage reciprocating compressor operator should monitor the compressor temperature and turn it off to provide a periodic cooldown.

Maintaining Lubricant Level :

It is highly advisable to maintain the lubricant level as recommended by the manufacturer. One should regularly check the lubricant level of the reciprocating air compressor.

Replacing Filters :

The air filters are like the lungs of the compressor. They catch debris particles and dust, which can get stuck inside the air compressor and cause damage. Regular filter checks and changing the filter once a week will ensure that the compressor keeps serving your purpose for years to come.

Valve Maintenance: :

The compressor’s valves should perform with minimum resistance and should never have any blockage. A valve failure can cause systems to lag too soon and wear out internal components. Constant valve check is highly essential for the long life of the reciprocating air compressor.

ELGi’s reciprocating air compressors are designed for optimum efficiency without high maintenance requirements. They are known for their reliability and performance, which makes them a preferred choice for industrial applications. While ELGi’s single-stage reciprocating air compressors' uniquely integrated design makes them ideal for light-duty applications, the Dual-stage reciprocating compressors are used to maintain higher pressure in compressed air.

ELGi is one of the few reciprocating compressor manufacturers offering air compressor spare parts designed specifically for your air compressor. These spare parts cover all your service needs and maintain the integrity of the compressor.

The overall life cycle of your reciprocating air compressor system can be maximised by using filters and custom-made separators for ELGi compressors. ELGi offers an extensive after-sales network dedicated to providing world-class service and follow-ups

Conclusion In conclusion, to prolong the lifespan of your reciprocating air compressor, you must do regular maintenance and use quality compressors like those from ELGi. By monitoring essential components beyond the piston, you can ensure the longevity and efficiency of your compressor. By using genuine ELGi parts you can maximise productivity and minimise maintenance costs. ELGi has over 4,000 satisfied customers from over 10,000 installations across Africa and the Middle East region. ELGi’s efficient after-sales network, world-class service, and follow-ups allow customers to procure ELGi compressor parts easily for timely replacement and repair. By opting for ELGi’s original parts and care package, you can prolong your reciprocating air compressor’s life and

0 notes

Text

The Ultimate Guide to Hydraulic Seals manufacturer by Crown Rubber Works premium quality Industrial

In the world of mechanical engineering, hydraulic seals play a crucial role in ensuring the smooth operation of various hydraulic systems. From piston seals to rod seals, wiper seals to guide rings, each type of hydraulic seal has its own unique function and importance. Let's dive deeper into the world of hydraulic seals and explore the different types and applications of these essential components.

What are Hydraulic Seals? Hydraulic seals are designed to prevent leakage of fluid in hydraulic systems. They are used to seal the openings between various components in a hydraulic system, such as pistons, rods, and cylinders. By effectively sealing these gaps, hydraulic seals help to maintain the pressure and integrity of the system, ensuring its efficient operation.

Piston Seals Piston seals are used in hydraulic cylinders to prevent fluid from leaking past the piston as it moves back and forth. These seals are typically made of rubber or polyurethane and are designed to withstand high pressures and temperatures. Piston seals play a critical role in maintaining the efficiency and performance of hydraulic systems.

Rod Seals Rod seals are used to prevent leakage along the rod in a hydraulic cylinder. They are typically installed on the outer diameter of the rod and create a barrier between the rod and the cylinder wall. Rod seals help to maintain the integrity of the system and prevent contamination of the hydraulic fluid.

Wiper Seals Wiper seals, also known as scraper seals, are used to clean contaminants from the rod as it retracts into the cylinder. These seals help to prevent dirt, dust, and other particles from entering the system and damaging the components. Wiper seals are essential for ensuring the longevity and reliability of hydraulic systems.

Applications of Hydraulic Seals Hydraulic seals are used in a wide range of applications across various industries. From large diameter seals used in heavy machinery to TBM seals used in tunnel boring machines, these seals are essential components in hydraulic systems. Whether it's in construction equipment, agricultural machinery, or automotive vehicles, hydraulic seals play a vital role in ensuring the efficiency and reliability of hydraulic systems.

Guide Rings Guide rings are used to guide the piston or rod in a hydraulic cylinder, preventing side movement and ensuring smooth operation. These rings are typically made of nylon or PTFE and are designed to withstand high pressures and temperatures. Guide rings help to enhance the performance and longevity of hydraulic systems.

O-Rings and Backup Rings O-rings and backup rings are used in hydraulic systems to provide additional sealing and support. O-rings are typically made of rubber or elastomers and are used to seal static and dynamic joints in hydraulic systems. Backup rings are used in conjunction with O-rings to provide additional support and prevent extrusion under high pressure.

Conclusion In conclusion, hydraulic seals are essential components in hydraulic systems, playing a crucial role in preventing leakage and maintaining the integrity of the system. From piston seals to rod seals, wiper seals to guide rings, each type of hydraulic seal has its own unique function and importance. By understanding the different types and applications of hydraulic seals, engineers can ensure the efficient operation and reliability of hydraulic systems across various industries. Choose hydraulic seals wisely to ensure smooth operations without any leakage or contamination.

Meta Description:

Learn all about the different types and applications of hydraulic seals in this comprehensive guide. Explore the world of piston seals, rod seals, wiper seals, and more!

Remember, when it comes to hydraulic systems, choosing the right hydraulic seals is key to ensuring optimal performance and efficiency. So, next time you're working on a hydraulic system, make sure to consider the importance of hydraulic seals and their role in keeping everything running smoothly.

1 note

·

View note

Text

What is the most common problem on Volkswagen?

Volkswagen (VW) vehicles are renowned for their reliability, performance, and innovative engineering. However, like any automotive brand, they are not immune to issues. Among the various concerns reported by owners, one of the most common problems with Volkswagen vehicles involves the engine and its related components.

Understanding Volkswagen Engine Issues

Volkswagen engines are sophisticated, but their complexity can sometimes lead to recurring problems. Commonly reported issues include:

Oil Leaks

Oil leaks are a frequent complaint, particularly in older Volkswagen models or those with higher mileage. Leaks often originate from the valve cover gasket, oil pan, or rear main seal. If left unaddressed, they can cause severe engine damage or lead to a drop in oil levels, affecting overall performance.

Timing Chain Tensioner Failure

Some Volkswagen models are prone to timing chain tensioner issues. A failing tensioner can cause the chain to skip, leading to engine misfires or, in extreme cases, complete engine failure. This is particularly common in models equipped with turbocharged engines.

Excessive Oil Consumption

Many Volkswagen owners report excessive oil consumption, especially in models equipped with the 2.0T engine. This issue often stems from worn piston rings or problems with the turbocharger seals, requiring regular oil top-offs and, in some cases, extensive repairs.

Check Engine Light Triggers

The check engine light is a common occurrence in many VW models due to various reasons, including faulty oxygen sensors, misfires, or issues with the mass airflow sensor. While not always critical, these problems can affect fuel efficiency and emissions.

Transmission Troubles

Apart from engine-related issues, Volkswagens are also known to face transmission problems, particularly with the Direct Shift Gearbox (DSG). Symptoms include rough shifting, delayed response, or warning lights on the dashboard. Regular transmission fluid changes and software updates can help mitigate these issues.

Electrical System Glitches

Volkswagens are equipped with advanced electronics, but electrical problems can arise, especially in older models. Common complaints include faulty power windows, malfunctioning infotainment systems, or erratic dashboard lights. These issues often stem from failing sensors, wiring problems, or control module errors.

Addressing Common Volkswagen Problems

Preventive maintenance and timely repairs are the keys to avoiding costly issues. Here are some essential steps to keep your VW in optimal condition:

Regular Oil Changes: Ensure you use the manufacturer-recommended oil and stick to the recommended service intervals.

Inspect and Replace Components: Pay attention to signs of wear, especially in the engine, timing chain, and transmission.

Address Warning Lights Promptly: Don’t ignore the check engine light or other alerts. A quick diagnostic scan can identify the root cause.

Schedule Routine Service: Follow the factory-recommended maintenance schedule to prevent issues before they escalate.

Conclusion

While Volkswagen vehicles are built to offer a smooth and enjoyable driving experience, they can encounter issues like any other brand. Engine and transmission problems rank among the most common concerns, but regular maintenance and prompt repairs can minimize their impact. By staying proactive, you can enjoy the performance and longevity that Volkswagen vehicles are known for.

#volkswagen car#volkswagen car problems#volkswagen car maintenance#volkswagen car services#volkswagen service center

0 notes

Text

What Is Engine Oil for Cars and Why Is It Important for Vehicle Performance?

Engine oil is the lifeblood of your vehicle, playing a critical role in ensuring optimal performance, reliability, and longevity of your engine. This vital fluid serves multiple purposes, ranging from lubrication to heat management, and is a cornerstone of efficient automotive functioning. Understanding the intricacies of engine oil and its impact on your car's performance is essential for every vehicle owner.

What Is Engine Oil and Its Composition?

Engine oil is a specially formulated lubricant designed to reduce friction between the moving parts of an engine. It consists of two primary components:

Base Oil: The foundation, comprising about 70-90% of the oil, derived from crude oil or synthetic sources.

Additives: These are chemical compounds added to enhance the oil’s properties, such as viscosity modifiers, detergents, anti-wear agents, and corrosion inhibitors.

The combination of these elements ensures the oil can withstand the extreme conditions inside the engine while maintaining its protective qualities.

The Primary Functions of Engine Oil

1. Lubrication of Moving Parts

The engine consists of numerous moving components that operate at high speeds and temperatures. Engine oil forms a protective film over these surfaces, significantly reducing friction and preventing wear and tear. Proper lubrication not only enhances efficiency but also prolongs the lifespan of the engine.

2. Heat Dissipation

During operation, the engine generates intense heat. Engine oil absorbs and disperses this heat, preventing overheating and ensuring the engine maintains an optimal temperature for performance.

3. Cleaning the Engine

Modern engine oils contain detergents that help in removing sludge, carbon deposits, and microscopic debris. By keeping the engine clean, the oil ensures better fuel efficiency and reduces the risk of damage caused by blockages.

4. Protecting Against Corrosion

Engine oil acts as a barrier against moisture and contaminants, protecting the engine’s metal components from rust and corrosion.

5. Sealing and Compression

Engine oil enhances the sealing between the piston rings and cylinder walls, ensuring proper compression and optimal power generation.

Different Types of Engine Oil

Choosing the right engine oil is critical for vehicle performance. Here are the main types of engine oils available:

1. Conventional Oil

Derived from refined crude oil, this is the most basic form of engine oil. It is suitable for older vehicles and those with simple engine designs.

2. Synthetic Oil

Manufactured through a chemical process, synthetic oil offers superior performance, especially under extreme temperatures and pressures. It is ideal for high-performance engines.

3. Semi-Synthetic Oil

A blend of conventional and synthetic oils, semi-synthetic oil provides better performance than conventional oil at a lower cost than full synthetic options.

4. High-Mileage Oil

Designed specifically for vehicles with over 75,000 miles on the odometer, high-mileage oil includes additives that reduce leaks, oil consumption, and wear.

How Engine Oil Impacts Vehicle Performance

The type, quality, and condition of engine oil directly influence several aspects of vehicle performance:

1. Improved Fuel Efficiency

Clean and high-quality engine oil reduces friction in the engine, leading to smoother operation and better fuel economy.

2. Enhanced Engine Longevity

By minimizing wear and protecting against corrosion, engine oil extends the life of the engine components, saving you money on repairs and replacements.

3. Optimal Power Output

Proper lubrication ensures that all engine parts work harmoniously, resulting in maximum power generation and smoother acceleration.

4. Lower Emissions

A clean engine runs more efficiently, reducing harmful emissions and contributing to a cleaner environment.

Signs That Your Engine Oil Needs Attention

Regular maintenance and timely oil changes are crucial. Here are some signs indicating that your engine oil may need replacement:

Dark and Dirty Oil: Fresh oil is amber in color. If it appears dark and gritty, it’s time for a change.

Unusual Engine Noises: Increased friction due to degraded oil can lead to knocking or ticking sounds.

Oil Warning Light: This dashboard light indicates low oil pressure, often caused by insufficient or old oil.

Excessive Exhaust Smoke: Blue or gray smoke from the exhaust may signal oil burning within the engine.

Decreased Performance: Poor acceleration or reduced fuel efficiency can result from degraded oil quality.

How to Choose the Right Engine Oil for Your Vehicle

Selecting the appropriate engine oil depends on several factors:

1. Manufacturer’s Recommendations

Always refer to your vehicle’s manual for the recommended oil type and viscosity grade.

2. Driving Conditions

Consider factors such as climate, driving style, and load. For instance, synthetic oils perform better in extreme temperatures and high-stress conditions.

3. Engine Age

Older engines often benefit from high-mileage oils with seal conditioners and anti-wear additives.

4. Certification and Standards

Look for certifications like API (American Petroleum Institute) or ACEA (European Automobile Manufacturers’ Association) to ensure quality and compatibility.

The Importance of Regular Oil Changes

Changing engine oil at regular intervals is vital for maintaining vehicle performance. Neglecting this routine task can lead to:

Increased engine wear

Overheating

Poor fuel efficiency

Expensive repairs due to engine damage

Conclusion

Engine oil for cars is more than just a lubricant; it is a crucial component that directly impacts your car's performance, efficiency, and longevity. Regular oil maintenance, along with using the correct type and grade, ensures that your vehicle operates at its peak potential while reducing the risk of costly repairs.

0 notes