#Phase Change Materials (PCM)

Explore tagged Tumblr posts

Text

Understanding Phase Change Materials (PCM): Why Tan90’s PCM Stands Out

Introduction

The ice cream industry faces unique challenges when it comes to temperature control, both in retail settings and during the delivery process. From maintaining the perfect cold temperature in freezers to ensuring the product stays frozen during transportation, there is constant pressure to minimize operational costs while maintaining product quality. Tan90’s innovative Phase Change Material (PCM) solutions offer a smart way to reduce energy consumption, optimize storage, and streamline delivery systems, making them an invaluable asset for the ice cream industry.

Optimizing Ice Cream Freezers with PCM Panels

One of the most significant challenges for retailers in the ice cream business is keeping freezers at the right temperature. Ice cream freezers are energy-intensive, requiring constant cooling to maintain low temperatures. However, maintaining these temperatures 24/7 can lead to high operational costs.

Tan90’s PCM technology provides an effective solution. PCM panels can be strategically placed along the walls of ice cream freezers to enhance temperature regulation. These panels absorb excess heat during the warmer parts of the day and release it when the temperature drops, stabilizing the internal temperature of the freezer. This helps the freezer maintain the optimal temperature for ice cream storage, without needing to constantly run the cooling system at full capacity.

By using PCM panels, businesses can significantly reduce their energy consumption and cooling costs. The panels act as an energy buffer, providing passive cooling that reduces the load on the refrigeration unit. This means less energy is required for cooling, translating into lower electricity bills and a more sustainable operation.

PCM Packs for Efficient Ice Cream Movement and Storage

The movement of ice cream, especially in bulk, poses another challenge for maintaining product integrity. Whether it’s transferring ice cream from the production facility to retail freezers or between distribution centers, it’s essential to keep the product frozen during transportation. PCM technology can play a crucial role here as well.

Tan90’s PCM packs are designed to move with the ice cream and maintain the required low temperatures during transit. These packs work alongside the cooling panels to ensure that the ice cream stays frozen, even during long transportation periods. The packs absorb heat from the surrounding environment, preventing the ice cream from thawing and ensuring that it arrives at its destination in perfect condition.

These PCM packs can be strategically placed within the ice cream boxes or alongside the product in storage containers. As the ice cream moves through the supply chain, the PCM packs will continue to provide passive cooling, minimizing the need for additional refrigeration and reducing the overall energy footprint of the transportation process.

Efficient Last-Mile and Mid-Mile Delivery of Ice Cream

The final stretch of delivery—known as last-mile and mid-mile delivery—poses the greatest challenge for ice cream distributors. The primary concern here is maintaining the product’s frozen state until it reaches the customer or retail store. PCM technology can be a game changer in this part of the supply chain.

For last-mile delivery, Tan90’s PCM solutions can be integrated into the delivery vehicles, reducing the reliance on costly refrigeration units. By incorporating PCM panels and packs within the delivery boxes or vehicles, the ice cream remains frozen for longer periods, ensuring that it reaches the customer in the best possible condition.

Similarly, during mid-mile delivery, where ice cream is transferred between distribution hubs or warehouses, PCM can be used to reduce the cooling burden on refrigeration units. With the passive cooling support from PCM, refrigeration units can be used less frequently, which not only cuts down on energy usage but also increases operational efficiency.

In both cases, PCM technology reduces the need for constant, high-energy cooling, enabling ice cream businesses to lower their operational costs while maintaining product quality.

Benefits of PCM in the Ice Cream Industry

Cost Savings: By reducing the need for constant refrigeration, PCM technology helps businesses lower their energy consumption and operational costs. The passive cooling provided by PCM panels and packs ensures that refrigeration units work more efficiently, leading to significant savings on energy bills.

Improved Product Quality: PCM technology helps maintain the ideal storage temperature for ice cream, preventing thawing or melting during storage and transportation. This results in higher-quality products reaching customers and retailers.

Sustainability: By reducing the need for energy-intensive refrigeration and using PCM as a passive cooling solution, ice cream businesses can operate more sustainably. PCM is an environmentally friendly technology that minimizes energy use and reduces carbon emissions.

Operational Efficiency: PCM helps optimize the entire supply chain, from storage in freezers to transportation, reducing the strain on refrigeration systems and streamlining operations. Businesses can scale their operations efficiently and meet the demands of the market without worrying about cooling-related challenges.

Conclusion

Tan90’s PCM technology offers a groundbreaking solution for ice cream retailers, distributors, and manufacturers. Whether it’s optimizing energy use in ice cream freezers, maintaining perfect temperatures during transport, or ensuring efficient last-mile and mid-mile delivery, PCM offers a flexible and sustainable approach to temperature management. By integrating PCM into the storage and transportation of ice cream, businesses can reduce energy costs, improve product quality, and create a more efficient, environmentally friendly operation.

In the competitive world of ice cream production and delivery, Tan90’s PCM technology provides businesses with the edge they need to stay cool—while also saving money and reducing their environmental impact.

#caas#cold chain solutions#cooling as a service#caas model works#cold chain#cold chain market#cold storage#cooling solutions#pcm cold chain solution india#phase change materials#Phase Change Materials#PCM packs#PCM Panels

0 notes

Text

0 notes

Text

The RMIT team, led by Professor David Mainwaring, and including Professor Robert Shanks, developed a jacket that is filled with solid phase change material (PCM, figure 7.23).

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#ice jacket#phase change material#pcm#rmit#robert shanks#david mainwaring#research

0 notes

Text

At temperatures below about 18 °C, the PCM exists as a waxy semi-solid in which the chains of the alkane molecules are aligned.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quote#chemistry#nonfiction#textbook#phase change material#pcm#semi solid#alkane#molecules#aligned#cooling jacket#innovation

0 notes

Text

Transforming Industries: Phase Change Materials Market Insights

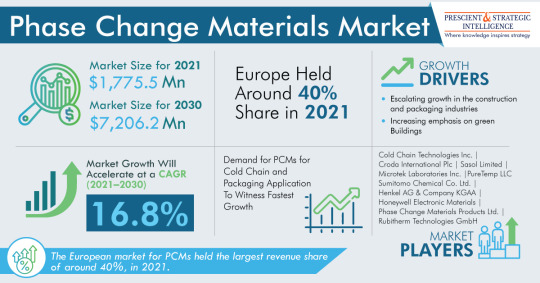

As stated by P&S Intelligence, the total revenue generated by the phase change materials market was USD 1,775.5 million in 2021, which will power at a rate of 16.8% by the end of this decade, to reach USD 7,206.2 million by 2030.

This has a lot to do with the increasing growth in the construction and packaging sectors and increasing importance on green buildings.

Cold chain and packaging category will grow at the highest rate, of above 17%, in the years to come. This can be mostly because of the surge in PCM requirement to sustain precise temperatures through the supply chain while lowering the emissions of carbon dioxide. Using ACs and electric fans to stay cool contributes to approximately 20% of the total electricity employed in buildings globally. The increasing requirement for space cooling is straining quite a few countries' power infrastructure, along with bringing about increased emissions.

With the enormous increase in the requirement for energy-efficient ACs, the requirement for PCMs will soar, as the electrical consumption of modified ACs with PCMs could be brought down by 3.09 kWh every day.

Europe dominated the industry with a share, of about 40%, in the recent past. The predisposition toward the acceptance of eco-friendly materials will power the PCM industry in the region. European regulatory associations, such as the SCANVAC, took more than a few initiatives for developing and promoting and effective building mechanical solutions and increase awareness pertaining to PCM applications.

The convenience of paraffin at a wide range of temperatures is a major reason for its appropriateness as an energy storage medium. Likewise, paraffin-based PCM is called a waxy solid paraffin, safe, dependable, noncorrosive, and economical material.

HVAC systems had the second-largest share, of about 30%, in phase change materials market in the recent past. This has a lot to do with the fact that PCM installation decreases fluctuations of temperature. HVAC with PCM supports in maintaining a steadier temperature and eliminating thermal uneasiness caused by alterations in temperature. It is because of the emphasis on green buildings, the demand for phase change materials will continue to rise considerably in the years to come.

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Growth#Phase change materials (PCMs)#Thermal energy storage#Energy efficiency solutions#Heat management technology#Sustainable materials#Building insulation#HVAC systems#Thermal regulation#Cold chain logistics#Renewable energy storage#Temperature-sensitive packaging

0 notes

Note

Oh wise bed guru, any advice for a couple that has different temperature needs when sleeping? I'm as hot as a blast furnace and my husband dumps heat like he's part lizard. It's gotten way worse since I got CPAP machine and I need to find a way to stay cool without turning him into a popsicle. I'm thinking about getting a 2 zone heated mattress pad and a wool duvet, but do you have any advice or specific brand recommendations?

There’s a thing in some beds now called Phase Change Material or PCM. Basically it’s added to foam and it stores your excess heat and releases it when your temperature goes down. Theres a science explanation but that involves solid and liquid states but it’s basically just magic.

Our current bed has it. It will be chilly for ten minutes then just keep temperature regulated after that. Could be a good solution, but bedding focused on meeting both your different needs can work too.

97 notes

·

View notes

Text

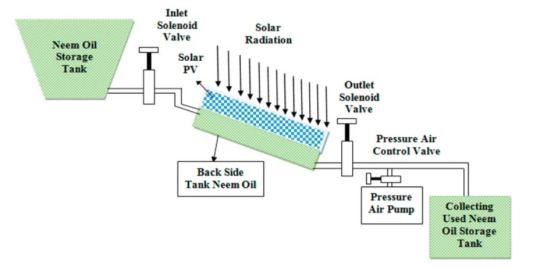

A group of scientists led by Kongu Engineering College in India investigated the use of waste neem oil as a cooling solution for PV modules. Neem oil is extracted from the seeds of the neem tree and is commonly used as a medicine for some skin diseases.

The researchers explained that this oil acts like phase-changing materials (PCMs), which can absorb, store, and release large amounts of latent heat over defined temperature ranges. PCMs have often been used at the research level for PV module cooling and the storage of heat.

“The neem oil has a good thermal range, is physically high in density, is chemically stable and noncorrosive, is environmentally pollution-free, reusable, and recyclable, and is economically low-cost and easy to dispose of,” they added. “Commonly, any PCM used for cooling purposes should have low thermal conductivity, stability, and cycling. The neem oil has fulfilled all the limitations.”

9 notes

·

View notes

Text

Aerogel-based phase change materials improve thermal management, reduce microwave emissions in electronic devices

Electronic devices are getting more and more complex as they are built to carry out an ever-increasing number of functions. This can be seen in the increased functionality in our personal devices such as our phones, tablets and watches, let alone in industrial devices. However, their growing complexity can lead to performance and safety issues. These issues include device overheating or emitting microwaves that can result in health issues and that can reduce a device's performance and interfere with other devices. Chinese scientists from Beijing Normal University have been working on building shielding for electronic devices using multifunctional composite phase change materials (PCMs) to address these performance issues. PCMs are man-made materials built by combining different types of elements, allowing the creation of a new material with very specific purpose driven characteristics. In this case, the researchers are looking to improve thermal management, solar-thermal conversion and microwave absorption in the electronic devices.

Read more.

16 notes

·

View notes

Text

Ok PCM's (phase change materials) as a way to buffer heat is soooooo wild. I may end up with a ridiculous 200lb salt heat sink before long

3 notes

·

View notes

Text

Global Building Thermal Insulation Material Market to Witness Significant Growth Amid Rising Demand for Energy-Efficient Buildings

Global Building Thermal Insulation Material Market to Witness Significant Growth Amid Rising Demand for Energy-Efficient Buildings

Market Overview

The Global Building Thermal Insulation Material Market is projected to witness robust growth from 2018 to 2028, driven by rising energy efficiency standards, increasing construction activities, and growing awareness of sustainable building practices. Building thermal insulation materials play a crucial role in reducing energy consumption, enhancing indoor comfort, and minimizing carbon footprints, making them an integral part of modern residential, commercial, and industrial structures.

Governments worldwide are implementing stringent energy codes and green building certifications, further boosting the demand for high-performance insulation materials. Innovations in eco-friendly, lightweight, and high R-value materials are revolutionizing the industry, ensuring better thermal regulation and reducing dependence on heating and cooling systems.

Free Sample Report:- https://www.researchallied.com/request-sample/61264-global-building-thermal-insulation-material-market

Market Insights & Trends

Rising Focus on Energy Efficiency & Sustainability: Increasing global efforts to reduce energy consumption and carbon emissions are pushing builders toward adopting advanced thermal insulation materials.

Innovation in Eco-Friendly & High-Performance Materials: The market is seeing the rise of bio-based insulation, aerogels, vacuum insulation panels, and recycled materials as alternatives to traditional insulation.

Government Regulations & Building Codes: Strict enforcement of energy efficiency standards such as LEED, BREEAM, and ENERGY STAR is accelerating the adoption of high-quality insulation materials.

Growth in Construction & Retrofitting Projects: Rapid urbanization and the renovation of existing buildings to improve thermal efficiency are major drivers of market expansion.

Rising Adoption of Smart Insulation Solutions: The integration of intelligent thermal regulation systems and phase-change materials (PCM) is enhancing insulation performance.

Increasing Demand for Lightweight & Fire-Resistant Materials: Innovations in non-combustible and lightweight insulation panels are addressing both safety concerns and ease of installation.

Key Players in the Market

The Global Building Thermal Insulation Material Market is highly competitive, with major players investing in advanced insulation technologies, eco-friendly materials, and global expansion. Leading companies include:

Saint-Gobain S.A.

BASF SE

Owens Corning

Kingspan Group

Rockwool International A/S

Johns Manville Corporation

Knauf Insulation

Huntsman Corporation

Covestro AG

Dow Inc.

These companies are focusing on product innovation, strategic partnerships, and sustainability initiatives to enhance their market presence and meet evolving customer demands.

Full Report:- https://www.researchallied.com/report/61264-global-building-thermal-insulation-material-market/

Regional Insights

North America: The United States and Canada are witnessing strong demand for energy-efficient insulation solutions, driven by strict building codes, high energy costs, and sustainable construction practices.

Europe: Countries like Germany, the UK, and France lead the market due to high energy efficiency regulations, widespread adoption of green buildings, and extensive retrofitting initiatives.

Asia-Pacific: The fastest-growing region, driven by rapid urbanization, infrastructure development, and government initiatives for sustainable construction in China, India, and Japan.

Middle East & Africa: Rising investments in energy-efficient infrastructure, smart city projects, and climate-adaptive buildings are creating growth opportunities.

South America: Increasing construction activities and rising awareness about insulation benefits in Brazil, Argentina, and Chile are driving market expansion.

Market Outlook & Growth Prospects

The Global Building Thermal Insulation Material Market is expected to grow at a CAGR of over 6% from 2018 to 2028, fueled by:

Expanding green building initiatives and energy efficiency mandates

Technological advancements in high-performance and eco-friendly insulation materials

Increasing retrofitting and renovation of aging buildings to enhance insulation

Growing demand for fire-resistant, lightweight, and soundproof insulation solutions

Advancements in smart insulation and intelligent thermal regulation systems

Enquire Before Buy:- https://www.researchallied.com/enquire-before/61264-global-building-thermal-insulation-material-market

Top Trending Reports

Global More Electric Aircraft Market

Nigeria Oil and Gas Upstream Activities Market

Global Industrial Plastic Bags Market

0 notes

Text

Understanding Organic Phase Change Materials: Properties and Applications

In the quest for energy efficiency and sustainable solutions, Organic Phase Change Materials (PCMs) have gained significant attention. These materials play a crucial role in thermal energy storage (TES) systems by absorbing, storing, and releasing heat during phase transitions. This blog delves into the fundamentals of organic PCMs, their practical properties, and their applications across various industries.

What Are Organic Phase Change Materials?

Organic PCMs are substances that undergo a phase transition (solid-liquid or liquid-gas) at specific temperatures, enabling them to store and release latent heat. They are primarily derived from paraffin, fatty acids, and esters, making them ideal for environmentally friendly thermal management. Unlike inorganic PCMs, which often suffer from supercooling and phase separation, organic variants offer superior stability, non-corrosiveness, and recyclability.

Practical Properties of Organic PCMs

To better understand the effectiveness of organic PCMs, let's explore some of their key practical properties:

1. High Thermal Stability

Organic PCMs exhibit excellent thermal stability over multiple heating and cooling cycles. This makes them ideal for long-term energy storage solutions.

2. Non-toxic and Biodegradable

Many organic PCMs, especially bio-based fatty acids, are eco-friendly, biodegradable, and non-toxic, making them safer alternatives for building insulation, textiles, and food preservation.

3. Wide Melting Point Range

Organic PCMs can be engineered to have customized melting points, ranging from low-temperature (below 0°C) to high-temperature (>100°C) applications.

4. High Latent Heat Storage Capacity

They offer efficient heat absorption and release, ensuring optimal thermal regulation in HVAC, solar energy, and thermal packaging systems.

5. Chemical Compatibility and Non-Corrosiveness

Unlike inorganic PCMs (like salt hydrates), organic PCMs do not corrode metals, making them more suitable for integrating heat exchangers and encapsulation systems.

Applications of Organic PCMs

The versatility of organic phase change materials has led to their widespread adoption in various industries, including:

Building & Construction: Used in insulated panels, roofing, and walls to enhance thermal comfort and reduce energy consumption.

Renewable Energy: Integrated with solar power storage systems to store excess heat for later use.

Textiles & Clothing: Embedded in smart fabrics and thermal wear to regulate body temperature.

Pharmaceutical & Food Storage: Maintains temperature-sensitive products, ensuring safe transportation and extended shelf life.

Automotive & Aerospace: Enhances thermal management inelectric vehiclesand spacecraft.

Future Trends in Organic PCM Development

With the rising demand for energy-efficient technologies, research is focused on:

Improving thermal conductivity by integrating nanomaterials.

Enhancing phase stability through advanced encapsulation techniques.

Developing bio-based PCMs for sustainable energy applications.

Conclusion

Organic Phase Change Materials offer a sustainable and efficient solution for thermal energy storage, significantly impacting various industries. Their non-toxicity, stability, and high latent heat capacity make them superior choices for environmentally friendly energy solutions. As advancements continue, organic PCMs will play a pivotal role in shaping the future of sustainable energy management.

#Advanced thermal regulation#Fatty acid PCMs#HVAC energy savings#Latent heat storage#Paraffin-based PCMs#Renewable energy storage solutions#Thermal energy storage

0 notes

Text

The Next Step in Cold Chain Logistics: Why IN-CAAS is the Future of Cooling

Introduction

The ice cream industry faces unique challenges when it comes to temperature control, both in retail settings and during the delivery process. From maintaining the perfect cold temperature in freezers to ensuring the product stays frozen during transportation, there is constant pressure to minimize operational costs while maintaining product quality. Tan90’s innovative Phase Change Material (PCM) solutions offer a smart way to reduce energy consumption, optimize storage, and streamline delivery systems, making them an invaluable asset for the ice cream industry.

Optimizing Ice Cream Freezers with PCM Panels

One of the most significant challenges for retailers in the ice cream business is keeping freezers at the right temperature. Ice cream freezers are energy-intensive, requiring constant cooling to maintain low temperatures. However, maintaining these temperatures 24/7 can lead to high operational costs.

Tan90’s PCM technology provides an effective solution. PCM panels can be strategically placed along the walls of ice cream freezers to enhance temperature regulation. These panels absorb excess heat during the warmer parts of the day and release it when the temperature drops, stabilizing the internal temperature of the freezer. This helps the freezer maintain the optimal temperature for ice cream storage, without needing to constantly run the cooling system at full capacity.

By using PCM panels, businesses can significantly reduce their energy consumption and cooling costs. The panels act as an energy buffer, providing passive cooling that reduces the load on the refrigeration unit. This means less energy is required for cooling, translating into lower electricity bills and a more sustainable operation.

PCM Packs for Efficient Ice Cream Movement and Storage

The movement of ice cream, especially in bulk, poses another challenge for maintaining product integrity. Whether it’s transferring ice cream from the production facility to retail freezers or between distribution centers, it’s essential to keep the product frozen during transportation. PCM technology can play a crucial role here as well.

Tan90’s PCM packs are designed to move with the ice cream and maintain the required low temperatures during transit. These packs work alongside the cooling panels to ensure that the ice cream stays frozen, even during long transportation periods. The packs absorb heat from the surrounding environment, preventing the ice cream from thawing and ensuring that it arrives at its destination in perfect condition.

These PCM packs can be strategically placed within the ice cream boxes or alongside the product in storage containers. As the ice cream moves through the supply chain, the PCM packs will continue to provide passive cooling, minimizing the need for additional refrigeration and reducing the overall energy footprint of the transportation process.

Efficient Last-Mile and Mid-Mile Delivery of Ice Cream

The final stretch of delivery—known as last-mile and mid-mile delivery—poses the greatest challenge for ice cream distributors. The primary concern here is maintaining the product’s frozen state until it reaches the customer or retail store. PCM technology can be a game changer in this part of the supply chain.

For last-mile delivery, Tan90’s PCM solutions can be integrated into the delivery vehicles, reducing the reliance on costly refrigeration units. By incorporating PCM panels and packs within the delivery boxes or vehicles, the ice cream remains frozen for longer periods, ensuring that it reaches the customer in the best possible condition.

Similarly, during mid-mile delivery, where ice cream is transferred between distribution hubs or warehouses, PCM can be used to reduce the cooling burden on refrigeration units. With the passive cooling support from PCM, refrigeration units can be used less frequently, which not only cuts down on energy usage but also increases operational efficiency.

In both cases, PCM technology reduces the need for constant, high-energy cooling, enabling ice cream businesses to lower their operational costs while maintaining product quality.

Benefits of PCM in the Ice Cream Industry

Cost Savings: By reducing the need for constant refrigeration, PCM technology helps businesses lower their energy consumption and operational costs. The passive cooling provided by PCM panels and packs ensures that refrigeration units work more efficiently, leading to significant savings on energy bills.

Improved Product Quality: PCM technology helps maintain the ideal storage temperature for ice cream, preventing thawing or melting during storage and transportation. This results in higher-quality products reaching customers and retailers.

Sustainability: By reducing the need for energy-intensive refrigeration and using PCM as a passive cooling solution, ice cream businesses can operate more sustainably. PCM is an environmentally friendly technology that minimizes energy use and reduces carbon emissions.

Operational Efficiency: PCM helps optimize the entire supply chain, from storage in freezers to transportation, reducing the strain on refrigeration systems and streamlining operations. Businesses can scale their operations efficiently and meet the demands of the market without worrying about cooling-related challenges.

Conclusion

Tan90’s PCM technology offers a groundbreaking solution for ice cream retailers, distributors, and manufacturers. Whether it’s optimizing energy use in ice cream freezers, maintaining perfect temperatures during transport, or ensuring efficient last-mile and mid-mile delivery, PCM offers a flexible and sustainable approach to temperature management. By integrating PCM into the storage and transportation of ice cream, businesses can reduce energy costs, improve product quality, and create a more efficient, environmentally friendly operation.

In the competitive world of ice cream production and delivery, Tan90’s PCM technology provides businesses with the edge they need to stay cool—while also saving money and reducing their environmental impact.

#caas#cold chain solutions#cooling as a service#caas model works#cold chain#cold chain market#cooling solutions#pcm cold chain solution india#phase change materials#cold storage#PCM technology#PCM solutions#PCM Panels#Ice cream freezers

0 notes

Text

Battery pack cooling methods

1. Air cooling

Air cooling uses air as a heat transfer medium and is divided into two methods: passive air cooling and active air cooling. Passive air cooling directly uses external air for heat exchange, has a simple structure, and is low in cost, but has limited cooling effect. Active air cooling pre-processes external air before it enters the battery system, such as heating or cooling, to improve cooling efficiency. However, the thermal conductivity of air cooling is low, and it is difficult to meet the thermal management requirements of high energy density batteries.

2. Liquid cooling

Liquid cooling uses coolant as a heat transfer medium, which is usually circulated in the battery pack through a pump and piping system. According to the contact method, liquid cooling can be divided into direct contact and indirect contact. Direct contact directly immerses the battery pack in the coolant, while indirect contact arranges cooling pipes or jackets between battery modules. Liquid cooling has the advantages of high cooling efficiency and good temperature uniformity, but it has high requirements for the sealing of the system and increases the complexity and weight of the system.

3. Heat pipe cooling

Heat pipe cooling uses the latent heat of phase change materials during evaporation and condensation to transfer heat. The heat pipe consists of an evaporation section, an insulation section, and a condensation section, which can quickly conduct heat and achieve efficient cooling. However, the heat pipe has a complex structure, high manufacturing cost, and the heat transfer performance may decrease after long-term use. It has not yet been widely used in battery thermal management systems.

4. Phase change material cooling

Phase change material (PCM) absorbs or releases a large amount of heat by changing its physical state within a specific temperature range. When PCM is applied to a battery thermal management system, it can absorb heat and reduce the battery temperature when the battery temperature rises. However, PCM has a low thermal conductivity and may have a risk of leakage. It needs to be used in combination with other cooling methods to improve the cooling effect.

5. Immersion cooling

Immersion cooling directly immerses the battery in the coolant, which has the advantages of simple structure, rapid cooling, and good temperature uniformity. Compared with traditional indirect liquid cooling, air cooling, and phase change cooling, immersion cooling shows good application prospects in the thermal management of high power density batteries.

Effective battery pack cooling technology is essential to improve battery performance, extend service life, and ensure safety. As battery energy density and charge and discharge rates increase, a single cooling method is difficult to meet the demand, and composite cooling technology shows broad application prospects. Future research should focus on developing efficient, lightweight, and cost-controlled cooling systems to adapt to the rapid development of electric vehicles and energy storage systems.

0 notes

Text

Innovative Technologies in Auckland’s Prefab Home Market: From Modular Construction to Smart Home Integration

The demand for prefab homes in Auckland is skyrocketing as homeowners seek affordable, sustainable, and efficient housing solutions. From advanced modular construction techniques to smart home integration, the industry is embracing innovation like never before.

This blog delves into the latest technologies transforming Auckland’s prefab home sector, ensuring that modern homeowners get high-quality, cost-effective, and energy-efficient homes tailored to their needs.

1. Modular Construction: The Future of Homebuilding

1.1 Precision Engineering with BIM (Building Information Modeling)

Building Information Modeling (BIM) is reshaping how modular homes are designed and built. This digital technology enables to creation of 3D models that enhance precision, reduce errors, and optimize material usage.

Key Benefits of BIM in Prefab Construction:

Accurate Design Simulation – Eliminates structural flaws before manufacturing.

Improved Collaboration – Ensures smooth communication between architects, engineers, and builders.

Cost and Time Efficiency – Reduces waste and accelerates project completion.

1.2 Off-Site Manufacturing for Faster Construction

Unlike traditional homebuilding, prefab homes are manufactured in controlled factory environments.

Why Off-Site Construction is Game-Changing?

✔ Reduces Construction Time – Prefab homes can be assembled 50% faster than traditional homes. ✔ Minimizes Waste – Precise manufacturing results in 30-40% less material waste. ✔ Improves Quality Control – Factory conditions eliminate weather-related construction delays and defects.

2. Sustainable & Energy-Efficient Prefab Homes

2.1 Passive House Design for Energy Savings

Prefab homes in Auckland are increasingly adopting Passive House standards, ensuring maximum insulation, airtight construction, and energy efficiency.

Triple-glazed windows for temperature control.

Ventilation with heat recovery systems to minimize energy loss.

Solar panel integration for sustainable power solutions.

2.2 Smart Materials: The Future of Prefab Homes

Innovative building materials are revolutionizing the modular home market. Some of the advanced materials are:

Cross-laminated timber (CLT) – Provides superior strength, fire resistance, and sustainability.

Aerated Concrete Panels – Lightweight yet durable, offering excellent insulation.

Phase-Change Materials (PCMs) – Absorbs and releases heat, reducing energy consumption.

3. Smart Home Integration in Prefab Homes

3.1 AI-Powered Home Automation

The future of prefab homes is smart living. It offers advanced AI-driven home automation systems that enhance convenience, security, and energy efficiency.

Smart Home Features for Modern Prefab Homes

Automated Lighting – Adjust brightness based on natural light availability.

Smart Security Systems – Facial recognition and remote access control.

AI-Enabled Climate Control – Automatically adjusts heating and cooling based on weather conditions.

3.2 IoT-Enabled Prefab Homes

Internet of Things (IoT) technology connects home devices for seamless operation. Prefab homeowners can control appliances, security cameras, and thermostats through smartphone apps.

4. Sustainable Prefab Housing Trends in Auckland

4.1 Off-Grid Living Solutions

With rising energy costs, many homeowners are shifting to off-grid prefab homes.

Solar Power Systems – Generate and store renewable energy.

Rainwater Harvesting – Sustainable water management for home use.

Greywater Recycling – Reduces water wastage in households.

4.2 Prefabricated Tiny Homes for Affordable Living

Tiny homes are an emerging trend in Auckland’s prefab housing market. These compact, fully functional homes offer:

Affordable Housing Solutions – Lower land and construction costs.

Minimalist Lifestyle – Encourages sustainable and clutter-free living.

Mobility & Flexibility – Can be relocated or expanded as needed.

5. Why Choose Module Made for Your Prefab Home?

As a trusted name in Auckland’s prefab home industry :

✔ Custom-Designed Modular Homes – Tailored to your needs and lifestyle. ✔ Sustainable and Smart Solutions – Future-ready, energy-efficient homes. ✔ Faster, Cost-Effective Construction – Quality homes built in record time. ✔ Advanced Technology Integration – AI, IoT, and smart materials for enhanced living.

Conclusion

The prefab home market in Auckland is evolving with cutting-edge innovations in modular construction, smart home technology, and sustainable materials. Whether you’re looking for a modern modular home, an off-grid solution, or a smart prefab house.

#module made#modular homes#prefab homes auckland#3 bedroom prefab homes#module homes#module homes auckland#architectural prefab homes nz

0 notes

Text

0 notes