#Pharmaceutical Caps And Closures Market Size

Explore tagged Tumblr posts

Text

Pharmaceutical Caps And Closures Market Will Grow At Highest Pace Owing To High Adoption Of Safety And Tamper Evidence Features

The pharmaceutical caps and closures market caters to the capsule-filling needs of pharmaceutical companies for packing prescribed drugs. Capsules made from gelatin help improve bioavailability and protect the drug from moisture, which enhances shelf life. Closures such as screw caps offer tamper evidence and ensure safety. The demand for such caps and closures is rising globally due to an aging population and growing prevalence of lifestyle diseases.

The Pharmaceutical Caps And Closures Market is estimated to be valued at US$ 6.4 Bn in 2024and is expected to exhibit a CAGR of 6.7% over the forecast period 2024-2031.

Key Takeaways

Key players operating in the pharmaceutical caps and closures market are Aptar Pharma (AptarGroup), West Pharmaceutical Services, Datwyler Sealing Solutions (Datwyler Group), Lonstroff (Sumitomo Rubber Industries), and Ompi (Stevanato Group). Aptar Pharma and West Pharmaceutical Services collectively account for over 30% of the global market share.

The rising incidence of chronic diseases and increasing generic drug production are fueling demand for pharmaceutical capsules and closures globally. As per estimates, chronic diseases affect over 100 million people in the United States. This is prompting pharmaceutical companies to ramp up production.

Technological advancements are aiding capsule delivery systems. New gelatin compositions improve solubility and bioavailability, while innovative container closure combinations offer better tamper evidence. 3D printing technology is also being explored for high-quality capsule manufacturing.

Market Trends

Sustainability initiatives - Major market players are investing in eco-friendly closure and packaging solutions made from recycled PET and plant-based polymers to reduce plastic waste.

Digitalization - Pharma companies are digitizing packaging lines with track-and-trace solutions and integrating IoT sensors for automated inspection and quality control. This improves production efficiency.

Market Opportunities

Growth in emerging markets - With rising income levels, countries like India, Brazil and China offer lucrative opportunities for pharmaceutical supplies including caps and closures.

Personalized medicines - Tailored drugs require specialized delivery via advanced capsules, thus presenting attractive opportunities, especially in the orphan drug segment.

Impact Of COVID-19 On Pharmaceutical Caps And Closures Market

COVID-19 pandemic has disrupted all markets across the globe. The Pharmaceutical Caps And Closures market was also impacted severely due to disruptions in supply chain, trade restrictions, and lockdowns imposed by various governments. During the initial lockdown phase, production and operations were halted entirely. With restricted movement of goods, shortage of raw materials occurred which hampered manufacturing. Demand also dropped significantly from pharma companies as elective procedures and non-emergency treatments were postponed.

However, as the pandemic intensified, demand from pharmaceutical sector increased manifold for drugs, vaccines and medical supplies. Manufacturers ramped up production and worked on establishing alternative supply routes to meet the growing needs. Governments also took initiatives to support pharma industry and streamline approval processes. With vaccination drives currently underway worldwide, production of caps and closures is expected to remain high. Companies are making investments in expanding capacities and digitizing operations to ensure resilience against future crises. While short term impact was negative, COVID-19 has fast tracked industry’s overall growth trajectory in long run due to emphasis on health security.

In terms of geographical regions, North America region accounts for the largest share in Pharmaceutical Caps And Closures market in value terms currently. This is attributed to presence of major pharma companies, high healthcare spending and rapid adoption of new technologies. Asia Pacific region is expected to witness fastest growth during forecast period with rising incomes, healthcare reforms and increasing generic drug manufacturing in countries like India and China which will drive demand. Europe holds second largest regional market due to advanced pharmaceutical industry and strict quality and safety norms for packaging.

The United States accounts for majority value share within North American region for Pharmaceutical Caps And Closures market. This is because US is the largest pharmaceutical market globally and spends heavily on prescription drugs and medications. India from Asia Pacific region is poised to emerge as the fastest growing country level market during forecast period 2024-2031 backed by low cost manufacturing, government initiatives for domestic industry and changing disease patterns.

Get more insights on this topic: https://www.trendingwebwire.com/pharmaceutical-caps-and-closures-market-is-estimated-to-witness-high-growth-owing-to-innovations-in-tamper-evidence-solutions/

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

What Are The Key Data Covered In This Pharmaceutical Caps And Closures Market Report?

:- Market CAGR throughout the predicted period

:- Comprehensive information on the aspects that will drive the Pharmaceutical Caps And Closures's growth between 2024 and 2031.

:- Accurate calculation of the size of the Pharmaceutical Caps And Closures and its contribution to the market, with emphasis on the parent market

:- Realistic forecasts of future trends and changes in consumer behaviour

:- Pharmaceutical Caps And Closures Industry Growth in North America, APAC, Europe, South America, the Middle East, and Africa

:- A complete examination of the market's competitive landscape, as well as extensive information on vendors

:- Detailed examination of the factors that will impede the expansion of Pharmaceutical Caps And Closures vendors

FAQ’s

Q.1 What are the main factors influencing the Pharmaceutical Caps And Closures?

Q.2 Which companies are the major sources in this industry?

Q.3 What are the market’s opportunities, risks, and general structure?

Q.4 Which of the top Pharmaceutical Caps And Closures companies compare in terms of sales, revenue, and prices?

Q.5 Which businesses serve as the Pharmaceutical Caps And Closures’s distributors, traders, and dealers?

Q.6 How are market types and applications and deals, revenue, and value explored?

Q.7 What does a business area’s assessment of agreements, income, and value implicate?

*Note: 1. Source: Coherent Market Insights, Public sources, Desk research 2. We have leveraged AI tools to mine information and compile it

#Pharmaceutical Caps And Closures Market Trend#Pharmaceutical Caps And Closures Market Size#Pharmaceutical Caps And Closures Market Information#Pharmaceutical Caps And Closures Market Analysis#Pharmaceutical Caps And Closures Market Demand

1 note

·

View note

Text

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

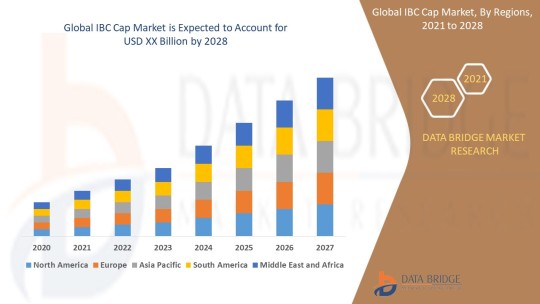

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Inverted Squeeze Bottle Market Insight | Outlook | Growth Analysis Report 2030

Inverted Squeeze Bottle Market Report has recently added by Value Market Research, this surveillance report establishing the facts based on current scenarios, historical records from 2022 to future forecast upto 2030. This report explicit data of various outlook such as market share, size, growth rates, and industry opportunities and offering an economical advantage for business success. It furnish the 360-degree overview of the competitive landscape of the global industries. Porter’s Five Forces Model analysis has been used to understand the industry’s structure, strength, weaknesses, opportunities, threats and challenges in front of the businesses. Moreover, the report also highlights a sudden occurrence of COVID 19 impact on Inverted Squeeze Bottle market to improve future capacities and other developments.

The research report also covers the comprehensive profiles of the key players in the market and an in-depth view of the competitive landscape worldwide. The major players in the inverted squeeze bottle market include Genesis Industries, Inc., IonWays, LLC, Midland Manufacturing Company, Inc., Kyoraku Co., Ltd., The Original Squeeze Company, Suzhou Innovation Packaging Materials Co.,Ltd, Illing Company, Inc., Kaufman Container Company etc. This section consists of a holistic view of the competitive landscape that includes various strategic developments such as key mergers & acquisitions, future capacities, partnerships, financial overviews, collaborations, new product developments, new product launches, and other developments.

Get more information on "Global Inverted Squeeze Bottle Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/inverted-squeeze-bottle-market/download-sample

Market Dynamics

The growing utilization of squeeze bottles in several industries such as food, drinks, healthcare, and personal care, pharmaceuticals, and so on is the major factor driving the inverted squeeze bottle market. The huge benefits are associated with squeeze bottles, such as it leaves less waste, Better control of food quantity, Easy fit into refrigerator door shelves, and require less space in the refrigerator, which might create high market demand in the coming years across the food industry. The rising popularity of fast food and Italian food like pasta and pizza among consumers across the globe is positively impacting the inverted squeeze bottle market’s growth. Moreover, the rapidly growing food and beverage industry across the globe is likely to create lucrative growth opportunities for key players of the Inverted squeeze bottle market in the coming years.

The research report covers Porter’s Five Forces Model, Market Attractiveness Analysis, and Value Chain analysis. These tools help to get a clear picture of the industry’s structure and evaluate the competition attractiveness at a global level. Additionally, these tools also give an inclusive assessment of each segment in the global market of inverted squeeze bottle. The growth and trends of inverted squeeze bottle industry provide a holistic approach to this study.

Browse Global Inverted Squeeze Bottle Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/inverted-squeeze-bottle-market

Market Segmentation

This section of the inverted squeeze bottle market report provides detailed data on the segments at country and regional level, thereby assisting the strategist in identifying the target demographics for the respective product or services with the upcoming opportunities.

By Closure Type

Flip Top Cap

Plug Orifice Cap

Screw Cap

Others

By Material Type

Polyethylene Terephthalate (Pet)

Polypropylene (Pp)

High Density Polyethylene (Hdpe)

Others

By Capacity

Up To 100 Ml

100 Ml To 250 Ml

250 Ml To 500 Ml

500 Ml To 750 Ml

Above 750 Ml

By End Use Industry

Food & Beverages

Automobile

Personal Care & Hygiene

Healthcare & Pharmaceutical

Chemicals

Others

Regional Analysis

This section covers the regional outlook, which accentuates current and future demand for the Inverted Squeeze Bottle market across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Further, the report focuses on demand, estimation, and forecast for individual application segments across all the prominent regions.

Purchase Complete Global Inverted Squeeze Bottle Market Research Report at https://www.valuemarketresearch.com/contact/inverted-squeeze-bottle-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

401/402, TFM, Nagras Road, Aundh, Pune-7.

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#Inverted Squeeze Bottle Market#Inverted Squeeze Bottle Market Report#Inverted Squeeze Bottle Industry#Inverted Squeeze Bottle Industry Report

2 notes

·

View notes

Text

Metal Closures Market Product Diversification Drives Innovation Across Multiple Industries with Sustainable Solutions

The metal closures market has undergone significant transformation over the last few years, driven by the increasing demand for high-quality, durable, and sustainable packaging solutions across industries. Metal closures, including caps, lids, and seals, are widely used in various sectors such as food and beverages, pharmaceuticals, personal care, and chemicals. While traditionally known for their reliability and durability, the market is experiencing a surge in product diversification, responding to evolving consumer demands and innovations in manufacturing technology.

1. Evolution of Metal Closures

Historically, metal closures were limited to simple designs such as bottle caps or jar lids. However, with technological advancements and shifting consumer preferences, manufacturers have embraced the need for diverse solutions. In the past decade, the global trend toward sustainable packaging has encouraged metal closure suppliers to innovate, combining aesthetics, convenience, and functionality.

The rising popularity of single-serve products, eco-conscious packaging, and the increasing demand for premium products have played a pivotal role in pushing manufacturers to offer a broader range of closure designs and materials. This diversification is not only meeting the varied needs of different industries but also improving operational efficiency and reducing environmental impacts.

2. Drivers of Diversification

Several factors are fueling the growth and diversification of the metal closures market:

Sustainability Trends: As consumers and companies become more environmentally aware, the demand for sustainable and recyclable materials has risen. Metal closures, especially aluminum and steel, are considered eco-friendly due to their recyclability, prompting manufacturers to innovate with designs that minimize material waste and maximize recyclability.

Aesthetic Appeal: Packaging has become a key element in product marketing. Metal closures are now available in a range of finishes, including matte, gloss, embossed, and custom-printed designs, offering brands an opportunity to differentiate their products in a competitive marketplace.

Customization and Convenience: The demand for customized, easy-to-use, and tamper-proof closures is growing across various industries. For instance, child-resistant closures in the pharmaceutical sector and easy-open tops for food and beverages are gaining traction.

Technological Advancements: Modern technologies like injection molding, stamping, and laser cutting have enhanced the versatility of metal closures, allowing for complex shapes, sizes, and functionalities. Smart closures, which offer tracking and authentication capabilities, are also emerging in the market, particularly in the luxury goods and pharmaceutical sectors.

3. Key Products and Innovations

The scope of product diversification in the metal closures market is vast. Some notable innovations include:

Multi-Function Closures: These closures offer more than just sealing functionality. Some products now feature built-in pourers, tamper-evident mechanisms, and child-proof locking systems, catering to specific industry needs.

Aerosol Closures: Aerosol cans are seeing a rise in demand, particularly in the personal care, household, and industrial sectors. Aerosol closures are being improved with better spray mechanisms, leak-proof designs, and environmentally friendly propellants.

Plastic-Combining Closures: Hybrid closures made from both metal and plastic components are growing in popularity. These closures combine the strength of metal with the convenience and flexibility of plastic, offering improved performance while maintaining the durability of metal.

Smart Closures: The integration of technology into closures, such as RFID tags or QR codes, is enhancing the security and traceability of products, especially in high-value or regulated industries like pharmaceuticals and luxury goods.

Sustainable Materials: With the increasing emphasis on sustainability, metal closures made from recycled aluminum or steel are becoming more common. Furthermore, some manufacturers are incorporating biodegradable or compostable components into their closures to align with circular economy practices.

4. Impact of Product Diversification on Different Sectors

The food and beverage sector has seen a significant shift in the metal closures market, with manufacturers focusing on developing tamper-evident and easy-to-open designs. Beverage caps, for example, are now available with convenience features like resealable designs, reducing wastage and enhancing user experience.

In the pharmaceutical sector, metal closures are playing a critical role in ensuring the integrity and safety of products. Child-resistant closures, tamper-evident seals, and dose-controlled packaging are becoming standard requirements to protect consumers.

The personal care industry is also benefiting from customized metal closures, with manufacturers offering various decorative and functional closures for premium products. Similarly, the chemical sector has seen innovation in closures designed to ensure leak-proof performance and withstand chemical exposure.

5. Challenges and Future Outlook

Despite the positive trends in product diversification, several challenges persist in the metal closures market. Fluctuating raw material prices, especially for metals like aluminum and steel, pose a threat to profit margins. Additionally, manufacturers must balance product innovation with environmental concerns to ensure that the closures remain recyclable and minimize waste.

However, the future looks promising for the metal closures market. Continued research and development in sustainable materials, smart technologies, and design innovations will likely drive further growth. Manufacturers who can adapt to these trends and offer tailored solutions to meet specific industry needs will hold a competitive edge in the evolving marketplace.

Conclusion

In conclusion, the metal closures market is expanding rapidly due to product diversification driven by consumer preferences, technological advancements, and sustainability trends. As manufacturers respond to these shifts with innovative solutions, the industry will continue to evolve, offering more versatile and functional products across various sectors.

0 notes

Text

Returnable Packaging Market Growth: Key Trends Driving the Future of the Industry

The global returnable packaging market size is expected to reach USD 173.05 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 6.0% over the forecast period. This is attributed to the expanding key end-use industries such as food & beverages, healthcare, and others.

Returnable packaging products offer numerous benefits to end-use companies, in comparison to single-use or expendable packaging products. Even though the procurement cost of returnable packaging is significantly higher than that of single-use packaging, it is reused multiple times, unlike single-use packaging, which will eliminate the recurring costs of packaging production. Besides, using similar containers for longer duration reduces the cost per trip and thus, returnable packaging proves to be cost-efficient in the longer term.

Food & beverages, pharmaceuticals, and automobiles are among the major end-use industries for returnable packaging. In these sectors, returnable packaging products such as pallets, crates, IBCs, dunnage, and others are mainly utilized for internal handling (within the manufacturing plant) of raw materials, semi-finished, and finished goods, as well as for the transportation of finished goods from the manufacturing plant to distribution and retail center. Therefore, expanding manufacturing and distribution activities within the food & beverages, pharmaceutical, and automobile industries is expected to directly fuel the demand for returnable packaging products.

Furthermore, the global pharmaceutical industry is expected to witness strong growth in the coming years. Growing aging population, especially in developed countries such as Japan, France, Germany, and others; increasing health consciousness among consumers; improving healthcare infrastructure, particularly in developing countries such as India, Brazil, and China; and high emphasis on the strengthening of the healthcare sector, coupled with the introduction of various healthcare insurance schemes by governments globally, are primarily driving the pharmaceutical industry.

Gather more insights about the market drivers, restrains and growth of the Returnable Packaging Market

Returnable Packaging Market Report Highlights

• Plastic has emerged as a dominating material in the market for returnable packaging with a majority share in 2022 and is expected to maintain a leading position by 2030, owing to its wide application in the food & beverage and healthcare industries, due to its unique properties such as anti-shock during shipping the products

• Pallets recorded the largest market share in 2022 in the products segment, due to their higher compatibility, structural integrity, and easy cleaning properties. However, the lack of international standards and uniformity in the sizes of pallets is expected to challenge material handling and transportation corporations

• The healthcare segment is expected to expand at a substantial CAGR of 6.9% during the forecast period. The pharmaceutical industry requires packing products like pallets, containers, FIBCs, drums, and barrels for the transportation of chemicals, medicines, drugs, and vaccines in bulk quantities

• The increasing aging population in countries like Japan, Germany, Italy, Portugal, and other European economies are expected to increase the demand for pharmaceutical products and healthcare equipment, which is expected to drive demand for returnable packaging from the healthcare end-use industry

• However, the growing adoption of single-use flexible packaging and several shortcomings of returnable packaging, such as expensiveness in comparison to other single-trip products, restrains the market growth to some extent

• New product developments, coupled with mergers & acquisitions and capacity expansions, are some of the strategies adopted by industry players. For instance, during the 2022 Plastics Caps & Closures conference in September, the Orbis Corporation showcased its reusable packaging solutions designed to address the unique requirements of the primary packaging supply chain that includes bulk containers, pallets, and boxes

Returnable Packaging Market Segmentation

Grand View Research has segmented the global returnable packaging market based on material, product, end-use, and region:

Returnable Packaging Material Outlook (Revenue, USD Billion, 2018 - 2030)

• Plastic

• Metal

• Wood

Returnable Packaging Product Outlook (Revenue, USD Billion, 2018 - 2030)

• Pallets

• Crates

• IBCs

• Drums & Barrels

• Dunnage

• Others

Returnable Packaging End-use Outlook (Revenue, USD Billion, 2018 - 2030)

• Food & Beverage

• Automotive

• Consumer Durables

• Healthcare

• Others

Returnable Packaging Regional Outlook (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o France

o U.K.

o Italy

o Spain

• Asia Pacific

o China

o India

o Japan

o South Korea

o Australia

• Central & South America

o Brazil

• Middle East & Africa

o South Africa

Order a free sample PDF of the Returnable Packaging Market Intelligence Study, published by Grand View Research.

#Returnable Packaging Market#Returnable Packaging Market Size#Returnable Packaging Market Share#Returnable Packaging Market Analysis#Returnable Packaging Market Growth

0 notes

Text

Metal Crown Closures Market Size, Trends, and Growth Forecast to 2025

The Metal Crown Closures Market is experiencing steady growth, driven by the increasing demand for durable and tamper-evident packaging solutions in the beverage industry.

Get free sample @ https://www.statsandresearch.com/request-sample/39399-global-metal-crown-closures-market

Market Overview:

Market Size and Growth: The global metal caps and closures market was valued at approximately USD 23.48 billion in 2023 and is projected to reach around USD 32.06 billion by 2032, reflecting a compound annual growth rate (CAGR) of about 3.5% during this period.

Key Players:

Prominent companies operating in the metal crown closures market include:

Crown Holdings, Inc.

Silgan Holdings Inc.

Guala Closures Group

Bericap GmbH & Co. KG

Amcor Limited

Alcoa Corporation

Mitsubishi Chemical Corporation

Meyer Seals Alu

Zeller Plastik

United Caps

Get full report @ https://www.statsandresearch.com/report/39399-global-metal-crown-closures-market/

Market Segmentation:

By Material Type:

Aluminum

Steel

By Closure Type:

Crown Caps

Screw Caps

Twist-Off Caps

Other Closure Types

By End-Use Industry:

Beverages

Food

Pharmaceuticals

Personal Care

Others

Regional Analysis:

North America: The metal caps and closures market in North America is expected to reach USD 6.53 billion in 2025 and grow at a CAGR of 3.81% to reach USD 7.87 billion by 2030.

Europe: The market in Europe is projected to grow at a CAGR of 2.70% during the forecast period, reaching an estimated value of USD 28.4 billion by 2034.

Asia-Pacific: The Asia-Pacific region is anticipated to witness significant growth, driven by the expanding beverage industry and increasing consumer demand for packaged drinks.

Market Trends and Challenges:

Sustainability: There is a growing trend towards eco-friendly and recyclable packaging solutions, prompting manufacturers to innovate and develop sustainable metal closures.

Technological Advancements: The development of tamper-evident and child-resistant closures is gaining traction, enhancing product safety and consumer confidence.

Economic Factors: Fluctuations in raw material prices, such as aluminum and steel, can impact production costs and pricing strategies.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/39399-global-metal-crown-closures-market

Trending Reports

Metal Mesh Glove Market

Metal Middle Frame Market

Metal Mold Thermal Shields Market

Metal Polish Product Market

Metal Security Door Market

0 notes

Text

Aluminium Caps & Closures Market: Demand for Premium Packaging Solutions

The Aluminium Caps & Closures Market is witnessing robust growth due to its sustainability, versatility, and widespread adoption across various industries. Aluminium closures are recyclable, lightweight, and offer excellent barrier properties, making them ideal for maintaining product integrity in diverse applications.

Read Complete Report Details of Aluminium Caps & Closures Market: https://www.snsinsider.com/reports/aluminium-caps-and-closures-market-2919

Market Segmentation

By Product Type

Easy Open Can Ends

Widely used in the beverage and canned food industries for convenience and consumer ease.

Features: Ease of use, tamper resistance, and durability.

Roll-on Pilfer Proof (ROPP) Caps

Commonly used for sealing bottles in the food, beverage, and pharmaceutical sectors.

Features: Tamper-evidence, resealability, and enhanced product security.

Non-Refillable Caps

Utilized primarily in the spirits and liquor industry to prevent counterfeiting.

Features: Anti-tampering mechanism and regulatory compliance.

Others

Icludes specialized caps and closures designed for niche applications or specific customer requirements.

By Size

Size Range: 17mm to 53mm

Includes standard closures for bottles and containers across industries.

Features: Compatibility with various bottle neck sizes and efficient sealing.

Height Range: 6mm to 12mm

Offers options based on container design and aesthetics.

Features: Customization for brand-specific designs and functional requirements.

By End Use

Food & Beverages

Largest segment driven by the need for safe, tamper-evident, and resealable closures.

Applications: Bottled water, soft drinks, alcoholic beverages, sauces, and canned goods.

Oil & Gas

Used in packaging lubricants and oils, providing spill-proof and secure sealing solutions.

Features: Durable and leak-resistant properties.

Personal Care

Used for packaging shampoos, lotions, and skincare products.

Features: Premium aesthetics and functionality.

Automotive

Utilized in packaging automotive fluids such as coolants, oils, and brake fluids.

Features: Resistance to corrosion and secure sealing.

Others

Includes applications in pharmaceuticals, chemicals, and other specialized industries.

By Region

North America

Growth driven by advancements in packaging technologies and high demand in beverages and personal care products.

Focus on sustainability initiatives boosting aluminium packaging adoption.

Europe

Strong emphasis on recyclable materials and eco-friendly packaging solutions.

Major markets include Germany, France, and the UK.

Asia-Pacific

Largest and fastest-growing market due to rising consumption in the food, beverage, and personal care sectors.

Significant contributions from emerging economies like China, India, and Southeast Asia.

Latin America

Growth influenced by expanding beverage and pharmaceutical industries.

Increasing focus on sustainable packaging solutions.

Middle East & Africa

Rising adoption in the food and beverage industry, coupled with growing demand for premium packaging in personal care.

Market Trends and Opportunities

Sustainability Focus: Aluminium caps and closures are 100% recyclable, aligning with global sustainability goals and increasing consumer preference for eco-friendly packaging.

Product Innovations: Development of lightweight, high-performance closures with improved tamper resistance and resealing capabilities.

Growing Beverage Industry: Expansion of the alcoholic and non-alcoholic beverage sectors is driving demand for high-quality aluminium closures.

Counterfeit Prevention: Increasing adoption of non-refillable caps to enhance product security and maintain brand integrity.

Premiumization: Growing trend for premium packaging, especially in personal care and alcoholic beverages, creating opportunities for customized designs.

Market Outlook

The Aluminium Caps & Closures Market is poised for substantial growth from 2024 to 2032, driven by increasing demand for sustainable and secure packaging solutions across various industries. Advancements in design and manufacturing technologies, coupled with the global push towards recyclability and reduced carbon footprint, will further enhance the market’s growth trajectory.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions. Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Metal Caps and Closures Market

Metal Caps and Closures Market Size, Share, Trends: Crown Holdings, Inc. Leads

Increasing Adoption of Smart and Connected Caps Enhances Product Security and Consumer Engagement

Market Overview:

The Metal Caps and Closures Market is projected to grow at a CAGR of 4.8% from 2024 to 2031, reaching a value of USD 9.2 billion by 2031. Asia-Pacific dominates the market, accounting for 38% of the global share. Key factors driving this growth include increasing demand for packaged food and beverages, a growing pharmaceutical industry, and advancements in metal cap and closure technologies.

The metal caps and closures market is expanding gradually due to rising global consumption of bottled beverages and packaged foods. This trend is encouraged by the increased use of metal caps, which offer superior sealing qualities, tamper-evident features, and recyclability.

DOWNLOAD FREE SAMPLE

Market Trends:

The integration of smart technologies into metal caps and closures is a significant market development. Manufacturers are increasingly incorporating NFC (Near Field Communication) tags, QR codes, and RFID chips into metal caps. These smart caps enhance product authenticity verification by enabling consumers to confirm the product's origin and ensuring it has not been tampered with. This technology provides brands with valuable insights into consumer behaviour and product usage trends. Smart caps can also offer interactive experiences, such as links to promotional content or product information when scanned with a smartphone. This approach is gaining popularity in the premium beverage and pharmaceutical sectors, where product authenticity and consumer engagement are critical. Some advanced smart caps even include sensors that can detect product freshness or indicate when a package has been opened, adding another layer of functionality and safety.

Market Segmentation:

Aluminium caps and closures dominate the metal caps and closures market due to their lightweight, corrosion-resistant, and easily recyclable properties. This segment's growth is driven by its widespread use in the beverage industry, particularly bottled water, soft drinks, and alcoholic beverages.

Recent advancements in aluminium cap technology have aimed to increase both sustainability and functionality. For example, in 2023, a leading packaging company introduced a new line of aluminium caps with enhanced oxygen barrier properties, extending the shelf life of sensitive beverages without the need for additional barrier materials. The global aluminium caps and closures market is expected to reach USD YY billion by 2031, growing at a 5.2% CAGR between 2024 and 2031. This growth is fueled by increased adoption in the wine industry, with aluminium screw caps anticipated to see a 25% rise in usage for premium wine bottles by 2023.

Market Key Players:

Prominent players in the metal caps and closures market include Crown Holdings, Inc., Silgan Holdings Inc., Closure Systems International (CSI), Guala Closures Group, Amcor plc, Nippon Closures Co., Ltd., Bericap GmbH & Co. KG, Berry Global Inc., Aptar Group Inc., and Tecnocap S.p.A. These companies are leading the market with their innovative approaches, extensive product portfolios, and global distribution networks, continuously setting industry standards and driving market growth.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Customisation in Effervescent Tube Manufacturing_ Meeting Diverse Industry Needs

Effervescent tubes are essential in the healthcare and pharmaceutical sectors, designed to preserve the quality and efficacy of effervescent tablets by shielding them from moisture, light, and air. While standardised manufacturing ensures consistency, the growing demand for tailored solutions has shifted the focus to customisation in effervescent tube manufacturing.

In a world where branding, functionality, and sustainability are paramount, customised effervescent tubes cater to diverse industry needs while maintaining high performance. This article delves into the significance, processes, and advantages of customisation in effervescent tube manufacturing, highlighting how it aligns with the demands of varied sectors.

What Is Customisation in Effervescent Tube Manufacturing?

Customisation in effervescent tube manufacturing refers to tailoring the design, size, material, and features of tubes to meet the specific requirements of brands or industries. It allows manufacturers to create unique packaging solutions that align with a company’s branding, usability, and sustainability goals.

Why Customisation Matters

1. Brand Identity and Recognition

Customised effervescent tubes enable businesses to distinguish their products in a competitive market. By incorporating unique colours, logos, and branding elements, companies can create packaging that resonates with their target audience.

2. Functional Requirements

Different industries and products have specific needs. For instance, pharmaceutical products may require child-resistant caps, while sports supplements may need larger tubes for multiple tablets. Customisation addresses these functional demands.

3. Consumer Convenience

Ease of use is a critical factor for consumer satisfaction. Customisation allows for user-friendly designs, such as easy-to-open caps or ergonomic shapes, enhancing the overall consumer experience.

4. Sustainability Goals

As businesses strive for eco-friendly solutions, customisation enables the use of biodegradable or recycled materials, aligning packaging with sustainability initiatives.

5. Global Market Requirements

Regulatory standards vary across regions. Customisation ensures compliance with local packaging laws, such as labelling and safety features, making products market-ready globally.

Key Features of Customised Effervescent Tubes

Variable Sizes and CapacitiesCustom tubes can accommodate different tablet quantities, from single-use packs to bulk packaging.

Material ChoicesManufacturers offer a range of materials, including:

Polypropylene (PP): Durable and moisture-resistant.

High-Density Polyethylene (HDPE): Lightweight and cost-effective.

Eco-Friendly Materials: Bioplastics and recycled plastics for sustainability.

Advanced Closure Systems

Child-Resistant Caps: For pharmaceutical safety.

Tamper-Evident Seals: Ensuring product integrity.

Easy Snap-On or Screw Caps: For convenience.

Customised Branding

Printed logos, graphics, and product details.

Colour-coded tubes for easy identification.

Innovative ShapesUnique designs, such as ergonomic shapes or compact tubes, make products stand out on shelves.

The Process of Customising Effervescent Tubes

Requirement AnalysisThe process begins with understanding the client’s specific needs, such as tablet size, quantity, branding elements, and functional features.

Design and Prototyping

3D Modelling: Digital models are created to visualise the design.

Prototyping: Physical samples are produced for client approval before mass production.

Material SelectionBased on durability, aesthetics, and environmental considerations, the appropriate material is chosen.

ManufacturingAdvanced injection moulding and extrusion techniques are used to create the customised tubes with precision.

Printing and FinishingHigh-quality printing methods, such as screen printing or digital printing, are applied for branding and labelling.

Quality ControlRigorous testing ensures the tubes meet industry standards for moisture resistance, durability, and safety.

Industries Benefiting from Customised Effervescent Tubes

1. Pharmaceuticals

Pharmaceutical companies rely on customised tubes to meet stringent safety and regulatory standards. Features like child-resistant caps and clear labelling ensure consumer safety and compliance.

2. Dietary Supplements

The growing market for health supplements demands visually appealing and functional packaging. Customised tubes cater to branding needs while ensuring the tablets' quality.

3. Food and Beverages

Effervescent drink tablets, such as electrolyte supplements, benefit from custom tubes that maintain freshness and convenience for on-the-go consumers.

4. Personal Care Products

Customised tubes are ideal for packaging effervescent bath bombs or skincare tablets, offering a premium look and feel.

5. Industrial Applications

Effervescent cleaning tablets used in industrial settings require durable and moisture-resistant packaging, tailored to specific environments.

Innovations in Customised Effervescent Tube Manufacturing

1. Smart Packaging

Integration of QR codes or NFC tags on tubes allows consumers to access product information or verify authenticity.

2. Eco-Friendly Solutions

Manufacturers are increasingly adopting biodegradable plastics and recycled materials to meet sustainability goals.

3. Advanced Printing Techniques

High-definition printing ensures vibrant colours and intricate designs, enhancing shelf appeal.

4. Multifunctional Caps

Innovations like integrated desiccants or dispensers add functionality to the packaging.

NBZ Healthcare: Leading the Way in Customised Effervescent Tubes

One of the standout names in the industry, NBZ Healthcare, has earned a reputation for delivering high-quality customised effervescent tubes. With a focus on innovation and sustainability, they cater to diverse industry needs with:

Tailored Designs: Meeting branding and functional requirements.

Eco-Friendly Manufacturing: Offering sustainable packaging solutions.

Global Reach: Ensuring compliance with international standards.

Advanced Technology: Leveraging state-of-the-art machinery for precision.

Whether it’s a pharmaceutical product needing child-resistant features or a dietary supplement requiring vibrant branding, NBZ Healthcare’s custom solutions have set new benchmarks in the industry.

Benefits of Customisation in Effervescent Tube Manufacturing

1. Enhanced Product Appeal

Custom designs attract consumer attention, boosting sales and brand loyalty.

2. Improved Functionality

Tailored features like tamper-evident seals and easy-to-use caps enhance user experience.

3. Market Competitiveness

Unique packaging differentiates products in crowded markets, offering a competitive edge.

4. Regulatory Compliance

Customisation ensures adherence to regional packaging standards, facilitating global market entry.

5. Sustainability

Eco-friendly materials and processes align with consumer and regulatory demands for green packaging.

The Future of Customised Effervescent Tube Manufacturing

As consumer preferences evolve and industries demand more specialised solutions, the future of customised effervescent tube manufacturing looks promising. Key trends include:

Sustainability: Increased adoption of biodegradable and recyclable materials.

Personalisation: Packaging tailored for individual consumer preferences.

Smart Features: Integration of digital elements for enhanced functionality.

Automation: Advanced machinery for faster, more efficient customisation processes.

Conclusion

Customisation in effervescent tube manufacturing is more than a trend—it’s a necessity in today’s dynamic market. By offering tailored solutions that meet the specific needs of industries, customised tubes enhance product appeal, functionality, and sustainability.

Companies like NBZ Healthcare are leading the charge, combining innovation, quality, and eco-conscious practices to deliver exceptional packaging solutions. As the demand for unique and efficient packaging grows, the future of customised effervescent tube manufacturing holds immense potential, ensuring it remains a cornerstone of modern industry.

0 notes

Text

Plastic Caps and Closures Market Size, Type, segmentation, growth and forecast 2023-2030

Plastic Caps and Closures Market Scenario and Scope

Plastic Caps and Closures are essential packaging components used to seal bottles, jars, and containers across various industries. These caps and closures ensure the safety and preservation of the contents, making them crucial in sectors such as beverages, pharmaceuticals, personal care, and more. The global Plastic Caps and Closures Market was valued at USD 16.90 billion in 2022 and is projected to reach USD 23.60 billion by 2030, registering a CAGR of 4.90% during the forecast period. The market's growth is driven by increasing consumer demand for convenience in packaging and the expansion of the packaging industry, particularly in emerging economies within the Asia Pacific region.

Get a Sample PDF of the Report: https://www.reportprime.com/enquiry/sample-report/367

Market Trends Influencing the Plastic Caps and Closures Market

Rising Demand for Convenient Packaging Solutions: The growth in consumer preference for packaging that offers ease of use, along with enhanced safety features, is a significant driver of the Plastic Caps and Closures Market.

Expansion of the Packaging Industry: With the continuous growth of the packaging industry, particularly in sectors like beverages and personal care, the demand for plastic caps and closures is on the rise.

Growth in Emerging Economies: The Asia Pacific region, led by countries like China and India, is expected to dominate the market due to rapid industrialization, urbanization, and increasing disposable incomes.

Sustainability Trends: Increasing environmental awareness is pushing manufacturers to innovate with more sustainable materials and designs, impacting the market dynamics.

Request a Free Sample PDF Brochure of Plastic Caps and Closures Market: https://www.reportprime.com/enquiry/sample-report/367

Plastic Caps and Closures Segment Analysis

Plastic Caps and Closures Market, by Type:

PP (Polypropylene) Caps and Closures

PE (Polyethylene) Caps and Closures

Handheld Plastic Caps and Closures

PP and PE caps and closures are expected to lead the market due to their widespread use in various applications, including beverages, pharmaceuticals, and personal care products. These materials are favored for their durability, flexibility, and cost-effectiveness, making them suitable for a broad range of packaging solutions.

Inquire or Share Your Questions If Any Before Purchasing This Report: |REPORT_PREORDER_URL|

Plastic Caps and Closures Market, by Application:

Beverage Industry

Pharmaceutical Industry

Personal Care Products

Pharma and Healthcare

Others

The beverage industry holds the largest share of the Plastic Caps and Closures Market, driven by the increasing consumption of bottled water, soft drinks, and other beverages. The pharmaceutical industry also represents a significant market segment due to the need for secure and tamper-evident packaging for drugs and medical products.

Plastic Caps and Closures Competitive Analysis

Bericap

Closure Systems International

Berry Global

Aptar Group

Silgan

ALPLA

THC

Mold Rite Plastics

Oriental Containers

Zijiang

Jinfu

ZhongFu

Blackhawk Molding

Mocap

The competitive landscape of the Plastic Caps and Closures Market is marked by the presence of key players like Berry Global, Closure Systems International, and Silgan. These companies are focusing on innovation, strategic mergers, and expanding their product portfolios to maintain their market positions. The Asia Pacific region is a significant growth area for these companies due to the rising demand for packaging solutions in the region.

Regulatory and Legal Factors

Regulatory and legal factors are crucial in the Plastic Caps and Closures Market, particularly in ensuring product safety, environmental compliance, and adherence to industry standards. Key regulations include:

FDA Regulations: In the U.S., plastic caps and closures used for food and pharmaceuticals must comply with FDA standards to ensure they are safe for use.

EU Regulations: The European Union mandates strict guidelines regarding the use of materials in food packaging, ensuring they do not pose any health risks.

Environmental Regulations: With growing concerns over plastic waste, regulations such as the EU's Single-Use Plastics Directive and various national laws are pushing for the use of recyclable and eco-friendly materials in plastic caps and closures.

ISO Certifications: These standards ensure that products meet global quality and safety requirements, which is crucial for market acceptance and competitiveness.

Compliance with these regulations is essential for market players to avoid legal challenges and maintain their reputation. Companies are increasingly focusing on sustainable practices and eco-friendly materials to align with global environmental goals and consumer expectations.

Buy this Report: https://www.reportprime.com/checkout?id=367&price=3590

0 notes

Text

#Pharmaceutical Caps And Closures Market Trend#Pharmaceutical Caps And Closures Market Size#Pharmaceutical Caps And Closures Market Information#Pharmaceutical Caps And Closures Market Analysis#Pharmaceutical Caps And Closures Market Demand

0 notes

Text

Asia-Pacific Metal Packaging Coatings Market - Forecast(2024 - 2030)

Asia-Pacific Metal Packaging Coatings Market Overview

Asia-Pacific Metal Packaging Coatings Market size is forecast to reach US$1,990.4 million by 2027, after growing at a CAGR of 7.3% during 2022-2027. The preference for metal food & beverage containers in the Asia-Pacific region has been increasing rapidly, owing to its range of benefits such as better product protection, durability, sustainability, affordability, light-weight, and more in comparison to other types of packaging. The development of new coating technologies which include Bisphenol A non-intent (BPA-NI) coatings are further fueling the growth of the market in the Asia-Pacific region. Moreover, increasing demand for metal packaging coatings from the pharmaceutical industry are further accelerating the growth of the market in the Asia-Pacific region. Also, strict regulations regarding the use of plastics in various countries across the Asia-Pacific region along with increasing product launches and developments associated with metal packaging is expected to increase the demand for metal packaging coatings for use in various end-use industries over the forecast period.

Covid-19 Impact

The COVID-19 outbreak led to major economic problems and challenges for the food & beverage, pharmaceutical, cosmetic, and other industries in the Asia-Pacific region. According to the International Monetary Fund (IMF), the GDP growth of the Asia declined by 1.3% and Australia by 2.4% as indicated in the graphs, owing to the economic impact of COVID-19. The governments all across the Asia-Pacific region announced strict measures to slow the spread of the coronavirus and only the production of essential commodities were allowed, which impacted the non-essential commodity industries, thereby impacting the production of metal packaging coatings as well. However, economic stimulus packages allotted for multiple sectors in the Asia-Pacific region and the start of industrial production activities since 2021 is improving the metal packaging coatings market growth in the Asia-Pacific region by its increasing utilization in various industries.

Report Coverage

The report: “Asia-Pacific Metal Packaging Coatings Market Report – Forecast (2022-2027)”, by IndustryARC, covers an in-depth analysis of the following segments of the Asia-Pacific metal packaging coatings industry.

By Packaging Types: Food (2 piece and 3 piece), Caps & Closure (External and Internal), and General Line (External and Internal) By Coating Types: Water based, Solvent based, and Powder based. By Resins Type: Acrylic, Fluoropolymer, Urethanes, Epoxy (BPA and Non-BPA), Amines, and Others. By Application: Food (Sea Food, Meat, Infant Nutrition & Dairy, Vegetables, Catering, Biscuits, Cookies & Confectionary, Fats & Oils, Toppings, and Others), Pharmaceutical, Cosmetics, Personal Care, and Others. By Country: China, Japan, Thailand, Vietnam, India, Indonesia, Malaysia, and Rest of Asia-Pacific.

Request Sample

Key Takeaways

China dominated the Asia-Pacific Metal Packaging Coatings Market in the year 2021. One of the key drivers driving the market is increasing use of metal packaging in food products such as fruits, vegetables, infant nutrition & dairy, bakery, and other similar products in order enhance the durability of metal packaging.

Increasing product launches for phenolic resins that are primarily used in a wide range of metal packaging coatings employed in food, pharmaceuticals, and other applications which require a smooth, durable, and spotless finish, has driven the market growth. For instance, In June 2020, companies such as Allnex GMBH, which has its presence in the Asia-Pacific region launched its new eco-friendly phenolic resin for use in BPAni application for metal packaging coatings.

Strict environmental regulations are driving metal packaging coating manufacturers in the Asia-Pacific region to adopt environmentally conscious practices, thus, the demand for water-based coatings are increasing significantly in the region.

Asia-Pacific Metal Packaging Coatings Market Segment Analysis – By Coating Types

The water based coating segment held the largest share in 2021 and is expected to grow at a CAGR of 8.2% by 2027. Water-based coating is an environmentally friendly surface treatment that disperses the resin used in the coatings using water as a solvent. They have a high degree of flexibility and reduce moisture and solar radiation absorption, thereby, resulting in fewer solvent emissions. The VOC (Volatile Organic Compounds) content in the water-based coating is significantly low, and since there are regulations restricting the high VOC content in Asia-Pacific is resulting in its increasing adoption by metal packaging coating manufacturers based in the region. For instance, in 2021, China launched its 14th Five-Year Plan, the chemical sector refocused its environmental protection goals on low-carbon transformation and comprehensive control of VOC emissions, as well as a considerable emphasis on encouraging low VOC products. Furthermore, as compared to solvent-based coatings, water-based coatings for metal packaging require less coating to cover the same surface area, cost less, and do not require any additives, thinners, or hardeners because they provide higher adherence. Thus, water-based barrier coatings are utilized to protect the metal packaging from external and internal effects by sealing the substrate surface.

Inquiry Before Buying

Asia-Pacific Metal Packaging Coatings Market Segment Analysis - By Application

Food sector held the largest share with 66% in the Asia-Pacific Metal Packaging Coatings Market in 2021 and is anticipated to grow at a CAGR of 7.4% during the forecast period 2022-2027. Metal packaging cans, containers, tins, and more are utilized for the packaging of the food because these types of packaging maintain the food filling's flavors and nutritional content ranging from months to several years. However, the direct contact between the metal packaging and food content filled inside the cans and other types of packaging are not safe. The direct contact between metal and food can degrade the food content, owing to this food-friendly coating are applied to safeguard the packaged food from corroding metal. The shifting the focus of Asia-Pacific packaging manufacturers from plastic to metal is expected to drive up the demand for metal packaging coatings for food cans. This is further projected to expand the market growth in the Asia-Pacific region. According to UACJ Corporation, between 2019 and 2022, global demand for aluminium used in cans will rise 11% to 6.61 million tons per year. Southeast Asian countries are likely to account for half of that demand, according to the report. Thus, rising demand for cans will accelerate the production for aluminium cans, which further benefits the metal packaging coatings demand.

Asia-Pacific Metal Packaging Coatings Market Segment Analysis – By Country

China dominated the Asia-Pacific Metal Packaging Coatings Market in terms of revenue with a share of 59% in 2021 and is projected to dominate the market during the forecast period (2022-2026). In China, the metal packaging coatings market is fueled by the growth of the country’s food & beverage sectors. For instance, according to the China Chain Store & Franchise Association, China’s food and beverage sector was valued at around US$ 595 billion in 2019, an increase of 7.8% in comparison to 2018. Metal cans offer a range of benefits such as better food protection, durability, sustainability, affordability, light-weight, and more in comparison to other types of packaging such as paper or plastic packaging. In August 2020, ORG technology, the Chinese manufacturer of food cans, launched its white paper on the strategic development of food cans. The company focused on coated iron metal cans with moisture-proof, environmental protection, safety, corrosion resistance, anti-extrusion, and other characteristics to gain traction in the market. In this way, such increasing food production along with the development of food cans in China, owing to its various benefits as mentioned above, is expected to increase the demand for metal packaging coatings to further enhance the durability of such food cans. This is expected to accelerate the growth of the market in China during the forecast period.

Schedule a Call

Asia-Pacific Metal Packaging Coatings Market Driver

Increasing Preference for Metal Containers in Food & Beverage Sector

Metal packaging coatings are primarily used to coat different metals such as steel, aluminum, tin-plate, and more that are used for food & beverage packaging in order to enhance its ability to resist corrosion. Metal containers offer a range of benefits such as better product protection, durability, sustainability, affordability, light-weight, and more in comparison to other types of packaging such as paper or plastic packaging. For instance, vegetables, fruits, pet food, soups, and meats are often packaged in metal cans. Canning foods help prolong their shelf life and can help people afford to make healthy dietary choices. Similarly, soda, beer, and even wine are usually packaged in aluminum cans since aluminum beverage cans are the most recycled category for aluminum products, with nearly 50 percent of all cans recycled annually. Thus, all of these benefits of metal containers are driving its demand over other types of packaging. As a result, many companies in the Asia-Pacific region have begun packaging their food & beverages in metal containers. For instance, in February 2021, Responsible Whatr, a brand based in India, launched spring water in aluminum beverage cans made by Ball Corporation, a leading manufacturer of aluminum packaging. The company intends to create a brand that signifies sustainability and become a significant contributor to the circular economy. In July 2020, Showa Aluminum Can Corporation (SAC), metal packaging manufacturer, launched its third aluminum can manufacturing facility in Vietnam with an overall plant capacity of 1.3 billion cans per year in order to meet the growing demand for metal packaging from the food & beverage sectors of the country. Thus, such increasing preference and use of metal containers in the Asia-Pacific region are expected to increase the demand for metal packaging coatings to further enhance the durability of the metal containers, thus, accelerating the growth of the market in the Asia-Pacific region.

Growing Demand from the Pharmaceutical Industry

Metal packaging coatings are primarily used in the pharmaceutical industry in order to provide protection to the metal from atmospheric corrosion and support decoration, labeling, and consumer information. Its range of benefits such as impermeability to light, moisture, gases, and water, durability, light-weight, and ease of printing labels directly onto the metal surface make them ideal for use in the pharmaceutical industry. Thus, an increase in pharmaceutical production in the Asia-Pacific region is expected to drive the market growth during the forecast period. According to Vietnam’s Ministry of Health, the pharmaceuticals industry is expected to grow at the rate of 10% per year from 2017 to 2028, owing to an increase in pharmaceutical production and sales in the country. Also, according to International Trade Administration, the local pharmaceutical production in Japan reached up to US$59,958 in 2017, US$62,570 in 2018, US$87,027 in 2019, and US$84,600 in 2020 respectively. thus, indicating an increase in pharmaceutical production in Japan per year. An increase in pharmaceutical production is expected to drive the demand for metal packaging coatings in the pharmaceutical industry, thus accelerating the growth of the market in the upcoming years.

Buy Now

Asia-Pacific Metal Packaging Coatings Market Challenges

Volatility of Raw Material Prices

Primary raw materials including resins, solvent, and more used in the production of metal packaging coatings are derived from crude oil. As a result, fluctuations in the prices of crude oil in the Asia-Pacific region may hinder the growth of the market. For instance, India’s Crude Oil Basket (COB) reached US$19.90 per barrel, which was the lowest record since February 2002. During the first 11 months of the year 2020-21, the average annual price of India’s COB was around US$42.72 per barrel, which decreased by 30% than the average COB price in 2019-20. Likewise, as per revised estimates for 2020-21, the COB has increased by around 35% from its initial budget estimate. Since October 2021, Vietnam has also witnessed a spike in demand for crude oil. According to the oil price, the price of light crude oil exceeded US$94.38 per barrel in February 2022, an increase of 3.63% that is equivalent to US$3.3, the highest record since November 2014. Similarly, the price of Brent crude oil also increased and reached up to US$95.39 per barrel, an increase of 1.98% which is equivalent to US$1.85.

Asia-Pacific Metal Packaging Coatings Industry Outlook

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Asia-Pacific Metal Packaging Coatings Market. Asia-Pacific metal packaging coatings top 10 players include:

The Sherwin Williams Company

PPG Industries Inc.

AkzoNobel N.V.

Kansai Paint Co., Ltd.

Altana AG (Actega)

Henkel AG & Co. KGaA

Axalta Coating Systems Ltd.

Eason & Co.

Toyochem Co., Ltd.

Kangnam Jevisco Co., Ltd. and Others.

Recent Developments

In June 2021, AkzoNobel has invested in research and development activities associated with packaging coatings. The research is primarily focused on development of a new, and recyclable coating through use of bio-derived polyelectrolytes. These polyelectrolytes are 100% natural and are extracted from shrimp shells or waste from the wood processing industry. The versatility of natural polyelectrolytes will allow the company to become less dependent on synthesized polymers for packaging coatings.

In May 2021, ALTANA completed its acquisition of the closure materials business of Henkel group, a chemical and consumer goods manufacturing company with a strong regional presence in the Asia-Pacific region. Within the ALTANA Group, the business will be integrated into the ACTEGA division and globally assigned to the metal packaging solutions business line including the Asia-Pacific region. The main objective of this acquisition is to strengthen the company’s focus on innovative specialty chemicals.

In March 2021, Toyochem launched a new line of Bisphenol A non-intent (BPA-NI) internal coatings for metal beverage bottles and cans. These coatings are based on acrylic emulsion and polyester resins. The new BPA-NI internal sprays and coil coatings for stay-on tab (SOT) ends are specially formulated to achieve the required performance results, while addressing BPA-related health and food safety concerns from regulators and consumers in the Asia-Pacific region and worldwide.

#Asia-Pacific Metal Packaging Coatings Market#Asia-Pacific Metal Packaging Coatings Market Share#Asia-Pacific Metal Packaging Coatings Market Size#Asia-Pacific Metal Packaging Coatings Market Forecast

0 notes

Text

Why Choose the Seppa Solutions Rinser Filler Capper Machine for Your Business?

We at Seppa Solutions recognize how vital efficiency and dependability are to the day-to-day operations of your company. With its unparalleled speed and accuracy in packaging solutions, our Rinser Filler Capper (RFC) Machine is destined to transform your production line. Our RFC Machine redefines automation and quality control for food, beverage, pharmaceutical, and cosmetics businesses.

Unparalleled Technology and Innovation

Advanced Rinser Technology

Modern rinser machine, included in the Seppa Solutions RFC Machine, guarantees that containers are thoroughly cleaned before filling. With configurable settings for various bottle kinds and sizes, our equipment ensures hygienic compliance while reducing maintenance downtime.

Precision Filling Capabilities

Our RFC Machine, equipped with precision fillers, provides precise measurements with each cycle. This accuracy is essential for preserving product quality and cutting waste, which will maximize your manufacturing expenses. Our equipment meets the highest industry standards by ensuring exact filling amounts, whether you're bottling pharmaceutical liquids, juices, sauces, or water.

Reliable Capping Mechanism

The capping process in our RFC Machine is designed to be reliable and efficient. Our adaptable capping system suits several closure types, from screw caps to press-on caps, without sacrificing seal integrity. This function is crucial for maintaining consumer happiness, adhering to regulations, prolonging the shelf life of products, and preventing leakage.

Key Features of Seppa Solutions RFC Machine

Modular Design for Scalability

Our RFC Machine is developed in a modular manner, allowing for seamless integration into existing manufacturing lines. You can modify our machine to match your unique throughput needs without compromising the effectiveness of your workflow, regardless of your size as a startup or established company.

User-Friendly Interface

Our user interface makes it easy to navigate complicated machinery. Operators may track production metrics, monitor and modify machine settings, and quickly detect problems. The design that prioritizes the needs of the user minimizes training time and increases operational productivity.

Robust Construction for Durability

The Seppa Solutions rinser filler capper machine is constructed with tough materials and precision engineering to sustain prolonged operation in harsh settings. Its longevity maximizes your return on investment over the machine's lifecycle by reducing maintenance expenses and downtime.