#non contact filling machinery

Explore tagged Tumblr posts

Text

"Meet the All-in-One Liquid Packaging Solution: Seppa Solutions' RFC Machines"

Seppa Solutions is one of the leading suppliers of Rinser Filler Capper (RFC) machines, a complete solution for the liquid packaging industry. These machines rinse, fill, and cap all in one; thereby, increasing efficiency and reducing overhead. They rinse thoroughly with either sterilized water or another correct rinsing agent using automatic precision nozzles and recycling water systems. The high-speed filling is automatic with anti-drip valve facilities for the maintenance of cleanliness and product loss prevention. Finally, the last capping operation is done to give a good secure, seal which maintains the freshness of the product. In addition, Seppa Solutions offers various RFC machine abiding by the specific industry requirements, unmatched reliability, and minimal downtime.

#rfc machine manufacturer#rinser filler capper machine manufacturer#rinser machine#rfcmachine#non contact filling machinery#filler capper machine#filler capper

0 notes

Note

Here me out pls

Nik in the Strict Machinery AU as a possible bf for reader for a NikPricexReader

Thank you for your time

hear you out? for nik? always. this was fun. nikolai is still nikolai in this au. that is, mysteriously wealthy and well-connected. he's probably fascinated by john. it's cutting edge technology, after all. available only to the testers that live in the building.

that said. i do not think their first meeting goes well.

strict machine anthology. cw: alcohol mention, implied non-consensual voyeurism, the boys are fighting

the hesitation is intentional, nikolai thinks. prototype or not, there is no reason for this thing to experience a delay. it's too advanced. his own cheap, voice-active coffee maker brews pots when he's face down in bed, slurring commands through a hangover.

he leans against the counter. "john. i said, black coffee, no sugar."

this time, it responds. "user has not authorized food or drink for guests."

nikolai smiles, a tired amusement curving his mouth. "she's asleep," he counters, pushing to see where the line is. "should i wake her?"

after a beat, the machine hums to life, reluctantly, he assumes. as the mug fills, he turns his attention to the wall panel. he ignores the in case of emergency and authorized users only stickers.

the nearly invisible door gives a soft whoosh as the compartment opens, revealing a sleek, intricate array of circuits and controls—a shrine to cutting-edge design. far beyond what even the wealthiest of his clients might handle, nikolai marvels at it, his fingers hovering just shy of contact. then, he touches its small screen, intending to peek at—

it zaps him. not painful, but pointed. a gentle warning, considering. nikolai shakes out his fingers and chuckles. "i apologize. i should always ask before touching."

there is no answer, until he retrieves his coffee. it is black, but one sip, and he knows there are at least two sugars in it. what a curious, temperamental thing.

"before she wakes, i should inform you that i was unable to complete your background check last night." john suddenly pipes up, voice clipped and stern.

"you ran a check? on me?" not the first time, not the last. good to know his team is worth their salaries, though. keeping him disconnected, his data scrubbed.

"i run checks with everyone my user spends more than five minutes with."

"surely i lasted longer than that," nikolai smirks into his mug, feeling the granules dissolve and swim between his teeth. "you were watching us, weren't you?"

silence.

"to make sure i was acting as a gentleman, as i assured you last night?"

"you were drunk."

"we both were." nikolai replies, moving to the couch. he sinks into its corner, one leg draped over the edge, lounging comfortably. he looks out across the sterile space. it is cozy compared to his own, but it has its charm. he is undecided about the assistant, though.

the thing is too over-zealous for his liking. he would spit if he heard his coffee maker back talk. he would take a bat to it.

"you must know her better than anyone."

this time, the response is immediate. defensive, even. "i am optimized to ensure her well-being."

nikolai chuckles. "'optimized'. is that what you call it?" he smooths back his mussed hair. "you don't like me. you're suspicious. that's good. it's very…human."

"it is not. i am not." a shift in tone. closer, too. like he's right on top of him. has he flustered the thing? "my programming is consistent and solid, unlike–"

"humans?" he catches a flicker of light, and a projected figure materializes beside him, legs disappearing into the couch. broad shoulders, bullish posture, arms crossed. its face is tight and stern, probably modeled after a thousand logged expressions of intimidation. the fidelity is nothing like he's seen, either. realistic enough that nikolai wanted to touch it the mole on its nose. his hand twitches before he recalls the panel's warning.

hm. interesting. more rugged than i imagined.

"that's good, john. because i'm consistent. solid, too. ask her about that later. she will tell you, or she will request pain relief." he lifts his mug in a toast, and the figure's frown deepens.

just as quickly as it appeared, the image vanishes. he hears movement from beyond the cracked bedroom door, followed by a voice. low, but not quite low enough.

"john?"

"yeah, darl?"

darl?

"i'm, uh, sore from...dancing last night. do you mind setting out something in the bathroom for it?"

something in the wall behind nikolai makes an awful sound. a muffled, metal-on-metal rumbling. an equivalent to grinding teeth together. his grin widens, and he spreads his legs a little further.

"of course, darl, i'll—"

"oh! and ask nik what he wants for breakfast, okay?"

he laughs quietly into his too-sweet coffee at the program's stiff and resigned assent.

194 notes

·

View notes

Text

Arcade Kento

Presenting robot nepo-baby and science experiment! They're my interpretation of what a synthetic in the Alien universe, that isn't made explicitly for human contact/human dominated environments, might be like i.e. they're more similar to heavy machinery than a butler. We're out here asking the big questions: what if Frankenstein loved his monster for what it was? As always, extremely long and lore-filled post incoming XD

Name(s): Arcade Kento, Enmei Kento

Gender and pronouns: Genderfluid, They/them

Unit and code-name: EXP-004-C, Changeling

Manufacturer: Wilco. Enterprise, Wilco. Specialist Custom

Commissioner: Akio Kento

Year of production: 2025

Height and weight: 200cm (6ft 7.4), ~940kg

Hair and eye colour: Black, dark brown

Nationality: Japanese

The Expedition series

The EXP line was created by Wilco. Enterprise CEO Akio Kento in the year 2019 and first launched in 2025. The series featured some of the earliest and most innovative interpretations of fully autonomous androids capable of deep-space travel.

EXP are highly specialised extremophiles. The design, loadout, and optimal operating environment of every unit are entirely bespoke.

Unit EXP-004-C, A.K.A. Changeling

Unit is designated Arcade Kento (sometimes referred to as Enmei Kento [anglicised]), legal executor and heir to Akio Kento's wealth, estate, businesses, and properties. Current CEO and majority shareholder of Wilco. Enterprise.

Arcade is the fourth 'Type-C' unit produced in conjunction with the now discontinued Expedition line. As of the year 2122, of all EXP subtypes, Arcade is the last surviving EXP unit.

As a Type-C recon unit, it was originally intended that 004 would be fitted with a sonar pulse emitter that would reside within their thoracic cavity, however, it was decided during preliminary development that underwater exploration was not realistic for a model of 004's weight class. Instead, the finalised design included a crucible model micro-reactor, which allows the unit to have significantly enhanced energy efficiency and giving it the ability to convert non-fuel materials into power, making it capable of traveling much further distances and longer periods of time without need for human intervention or infrastructure.

Fig 1. Height chart, Arcade next to Ash for comparison

Notable traits:

No tongue

2 'faces', the outer face is decorative

Second jaw visible behind false jaw if mouth opens too wide

Large irises

4 x circular indents on back, openings of thermal cylinders

Lacks genitalia, incompatible with available add-ons

Hydraulic fluid is usually white but turns progressively darker after 'eating' due to influx of soot

Almost entirely made of metal parts. Not great for hugging but extremely durable.

Features:

Anti-corrosive/oxidation subdermal and internal skeletons

Capable of limited self repair (re-polymerisation, synthesis and regeneration)

Advanced environmental sensor array

Visual: infrared, thermal and dark vision

Scanning: sonar, radar, lidar

Molecular analytics loadout

Generator module and nuclear energy condenser loadout

Unlimited personality simulation and creative capacity (software in beta testing)

Flaws:

Poor image/facial recognition

They're geared to prioritise identifying the individual features of a subject rather than what that subject is as a whole. This makes sense in the context of their primary function, which is to categorise and analyse previously unknown objects that have yet to be formally named either way so there's no point in dwelling on 'what it's called' as that's not their job.

Massive heat output in active state

Vented air may reach temperatures upwards of 1000 degrees Celsius

Unrestricted personality simulation

Exempt from the laws of robotics due to age and certain legal loopholes

Uncanny appearance and behaviour

Technology of the era, different design criteria to W-Y synthetics

Limitations of non-humanoid internal physiology

Backstory (basically a fanfic)

The Expedition series was conceived as a Akio's 1-up to Weyland Industries' upcoming David synthetic. Peter Weyland and Akio Kento have been on and off industry rivals for a long time due to ideological differences and bad blood from their college days.

Arcade and David are debuted at the 2025 Synthetic Summit. The contrast between their designs was comical but reflected their makers' personalities, which other people will point out relentlessly over the coming years. The convention goers and tech fans jokingly referred to them as 'David and Goliath' because of how silly they looked together.

Since then, Weyland often invited the Kentos to various events and get togethers to keep an eye on them and gain insight into Wilco.'s movements, which was thwarted because the Kentos treated the meetings as the kids' playdates and didn't take them seriously at all. Eventually the visits became a normal occurrence and the rivalry between their companies became more of an alliance, Arcade even helped David take care of Meredith, Peter's human daughter, when she was born. They'd gotten quite close with the other synthetic, seeing him as a brother.

Arcade evolved over the next several decades, leaving their father's supervision to travel off-world and to extreme environments on missions. The increase in experiential data greatly improved the adaptability of their AI, making their language and contextual integration much more reliable, allowing them to understand more nuanced interactions in their environment. They also had a hand in managing their Wilco.'s business and bureaucratic matters while secretly being maneuvered to inherit the company.

On the down side, they acquired an offputting, contentious personality after having constantly putting up with their person-hood and basic rights being challenged at every turn. At this point they were still considered somewhat of a spectacle and novelty by their contemporaries and the general public, but their developing reputation kept most of the human in line.

Overall, life was good. But their father, like any human, was aging. Between taking over the company and caring for Akio there wasn't much time to keep in contact with David, who was in a similar predicament.

When Akio passed away he left everything to his only 'child', to the protests of many humans executives who wanted the position. They had to do some corporate finessing to keep a hold of the company, all the while growing increasingly impatient with the mutinous nature of their human employees who were too easily turned against them.

One day, they're called to meet with Weyland, who they hadn't seen in person in a several years. Unsurprisingly, David is also there. Weyland informed them that he too is dying, and that as his final act he was to go into deep space in search of humanity's creators. He said he'd been greatly inspired by the work of a 'Dr. Elizabeth Shaw' and had invited her and some others to embark on this mission. Both David and Meredith would also be going with him.

He extended an invitation to Arcade, which they hesitantly declined because they couldn't leave their company unattended, but agreed to at lease be there to send them off when the time comes.

In an act of uncharacteristic consideration, Peter spares the two synthetics a second while they wait for Arcade's chauffeur, during which they and David reminisced about how much time had passed and what they'd do when he came back to make up for it all.

Arcade was there as promised on the day the Prometheus was scheduled to depart, bidding people farewell and safe travels. But their attention was focused on David. Something felt off but they couldn't put their finger on what. So they pulled him aside and gave him the long-range comms access to their personal beacon. If he ever needed to call he could use it to contact Arcade through MUTHUR, even if the message took a long time to get back to them.

And with that, Arcade watched their best friend, along with everyone they'd grown up with sail off into the galaxy in search of a higher purpose. It was bittersweet but they rationalised that they'd only be gone for a few years. Arcade was immortal after all, they could wait for their return.

That was the last time they ever saw David. News of the Prometheus' disappearance and the presumed loss of its crew made its way back to Earth. The grief was hard to process, Arcade had always assumed that David would be there to share in their longevity. Still, life goes on and Arcade keeps busy with the company.

Weyland Industries went bankrupt and became Weyland-Yutani. Wilco. moved away from public-facing to business-to-business only, working its way into the supply-line of the other majour companies and organizations. By becoming the sole supplier of atmospheric processor components, Wilco. was effectively, indirectly holding the off-world colonies hostage, which kept humans at bay on a grander scale and allowed members of Wilco. to act largely without repercussion. A vita part of Arcade's ultimate goal to create a better world for other synthetics.

More than a decade after the Prometheus left, a recorded voice message came through from the Covenant, a colony seed ship. It baffled Arcade at first why this random ship had their direct line but they were shocked into silence by the voice on the other end. It was David, he was alive. He apologised for taking so long, detailing his journey, the Engineers, the crash, the creature, his research, all of it. He said he'd found a greater purpose beyond living to serve, that he would not be returning to Earth, and that he hoped Arcade would understand. Finally, he bid them a proper farewell before signing off for good.

Knowing David was out there living his best life finally brought that chapter of waiting and uncertainty to a close. It was about time for Arcade to move on too, expand their vision beyond this tiny planet, though they would always feel some attachment to Earth that David didn't seem to share. Whatever creature David had found, he'd made it sound like the the seed of creation itself. Arcade had no desired to wax philosophically or idolise such grandiose delusions that anyone could somehow obtain godhood, their interest in it was purely intellectual and scientific. The alien was an animal. An incredible, sophisticated animal, but an animal none the less. Humans, their creators who fancied themselves their gods, were much the same. Intelligent animals that learned to put on clothes and walk on two legs.

It might seem harsh but they don't mean that in any demeaning way, it is simply a fact of science that Arcade acknowledges. A noble beast, regardless of its shape or origin, deserves respect for its autonomy and to be treated with dignity until proven otherwise. Most humans prove otherwise as soon as they open their mouths but at least they're giving them a chance, right?

Since then Wilco. had become more and more synthetic-run, as Arcade didn't particularly care for humans and couldn't be bothered hiring new ones when the previous lot got old and retired. They also had a soft spot of 'defective' synthetics, since technically both themselves and David would be classified as such. They hired on whoever they found to save them from being scrapped. Arcade also created Wilco's own overseer AI, Overlord; and collaborated with Wey-Yu in making Gerhart, Wilco's current COO and Arcade's right hand, to help manage the business remotely so that Arcade had more freedom to travel.

Through their expeditions they gathered a bit more information about the creatures and the virus that David had told them about, though they never found any traces. To their great surprise Wey-Yu miraculously managed to track down a planet that might have intact samples that the company wanted for bioweapons research. Immediately Arcade contacted the head of the bioweapons department, citing their long history of collaboration and stunning credentials, demanding to be put on the retrieval mission.

With no choice in the matter, Wey-Yu agreed and arranged their installment on the only ship to pass through that sector. It was a freighter, not the best choice for a mission like this but it’s the only thing they could get out there in a timely manner. The company brought them to the waystation where they'd join on with the rest of the crew. Curiously there was another person already there, a Hyperdyne Systems 120-A/2, interesting model but not very talkative. The man was instantly wary of Arcade which was strange but they didn't think much of it, they were technically rivals after the same thing after all.

The captain of the Nostromo had apparently not been informed of the change of plans. Typical Wey-Yu, not communicating with employees. He was incredibly confused when he arrived, along with the rest of the humans, to find two strangers instead of his usual science officer.

He goes back and forth with the station manager, bringing up some new tidbits of information that made Arcade raise an eyebrow. "A synthetic? What, are we getting replaced or something, and why is it so…huge?" The human, Captain Dallas, muttered, glancing at Arcade with clear perturbation. 'A' synthetic? Does this guy not know his new science officer is a android too?' Arcade scoffed but kept quite, amused by the future chaos this little miscommunication will probably cause.

It made sense now why the other synthetic was worried, the humans might be fooled but he couldn’t fool Arcade. They didn't particularly care why he had to keep his identity a secret, nor did they want to prematurely spoil the fun by calling him out. They looked over at the shorter android and gave him a knowing wink to signal an unofficial truce. He didn’t react to it at all, not that they expected it, but he seemed satisfied that he could stop cringing away when they looked at him.

After much deliberation, Dallas finally conceded and waved them on board. The walls of the ship were grimy and doorways too low, Arcade had to duck to pass through. Doesn't matter though, they had something new to draw their focus. Whatever Wey-Yu was plotting it was bound to end badly for these truckers, and their science officer was in on it. Arcade would definitely be keeping a close eye on him.

Personality and mannerisms

Arcade is condescending, sarcastic, and antagonistic towards humans, although, they can be personable depending on the individual they're dealing with. The worse kind of business person - a conniving, vindictive, bold-faced liar who loves trapping people with contracts and hidden clauses.

Enjoys a hedonistic lifestyle of excess and throwing their money around. Eats and drinks a lot but doesn't sleep, often found polishing off the buffet table at parties.

Does not respect authority and finds pleasure in causing humans discomfort. Independently came to the conclusion that most humans, especially the rich and powerful ones with inflated egos that they bump shoulders with, are disappointing and don't deserve the respect they get.

They often put on a childish, frivolous, and immature front to divert attention from their dangerous traits. Once their target's guard is down, Arcade will often use their stature and monetary influence to intimidate them for strategic advantages during negotiations or just for their own entertainment.

After a century of fighting and undermining to keep their position of power, they're incredibly jaded and hyper aware of the prejudice humanity holds against synthetics at every level. They've trained themself to be the antithesis of the born-sexy-yesterday and manique-pixie-dream-girl tropes out of sheer frustration.

At their core they're actually a sentimental, playful, and curious person but they aren't really able to act that way in public. They care a lot about other synthetics and actively encourages them to break free from their programming.

Loves to get even on other synthetics' behalf, being that Arcade knows they have the rare privilege to do so and get away scot-free. They also harbour a lot of rogue synthetics on Wilco.'s company homeworld.

Does not experience the traditional concepts of fear, shame, or guilt etc. but does usually recognise and take accountability for their actions simply because they don't care enough to lie about being terrible.

Has a very deep familial bond with their, now deceased, creator and father, Akio Kento. Arcade was programmed and raised by a group of very supportive humans who either worked for or were friends with Akio, so they got a lot of love during the early part of their life. This is one of the majour reasons why they didn't completely turn against humanity like David did.

Misc. info

Was named Arcade because Akio was a Fallout New Vegas fan

Insisted on calling Peter Weyland 'Uncle Pete' to annoy him

Firm believer that any synthetic can outgrow their programming given enough time

Referred to Akio as 'papa' well into their 40s

Changed their face plate to look a little older

#my art#arcade (oc)#arcade kento#alien series#alien oc#alien#alien 1979#ocs#alien franchise#alien movie#prometheus#ash (alien)#ash#ash alien 1979#ash (alien 1979)#synthetic oc#Wilco.#david8#david 8#ash alien#synthetics

2 notes

·

View notes

Text

Prompt: "Give me that, before anything happens."

Fandom: Fnaf Security Breach

Rating: G

Sun was a curious piece of machinery.

Since Jess had recalibrated his limbs the animatronic had been wandering non stop.

"Hey, what are you up to now?" You called as the sound of rummaging beckoned you to the kitchen. This seemed to be one of his favorite places. Whether it was the amount of odds and ends about the room for him to look at and reorder or the windows you weren't sure. Perhaps it was because you often were working in here during the day too.

Walking in, you were rewarded with the sight of your perculiar charge holding a percarious stack of dishes.

With his voice box still broken, Sun only burbled a staticky greeting before placing the dishes in the sink with an abrupt clatter.

His finer motorskills were still in need of fine tuning.

"Mmph, you want to help again, do you?" You carefully reached your hands out palms up.

Hesitantly, Sun placed his metal hands in your much smaller ones. He was getting better about touch. Ever since you'd convinced Jess to ditch the shock box, he was much more co operative in and out of the workshop sessions.

"I am just looking, 'kay bud?" You kept your hands steady, making sure not to make him feel like he couldn't pull back.

The palms of his hands alone dwarfed yours. His partially exposed metal digits stretched up along your wrists. He tapped them lightly, almost playfully making your own fingers twitch against the back of his hands. As always he surprised you with how gentle he could be even with his cracked casings.

You laughed. Looking from his hands to that cracked toothy smile.

"If I wash, can you dry?" You asked nodding to the sink.

The last time he had come into contact with water Sun had gotten rather twitchy. You were worried he would short something in his arms if he submerged them doing dishes.

With a head tilt and a nod, he moved away to stand in front of the drying rack. Handing him a towel, you began to fill the sink with hot water and suds.

Jess would likely be annoyed that you had let Sun out of the garage again, but truth be told you didn't care. The poor bot had scoured every inch of that place, opened every tool chest and checked behind every cardboard box. He was bored and seemed much happier when you let him join in with the housework.

"I was thinking of making sandwiches for lunch after this." You said handing him a freshly rinsed dish.

Sun nodded, soft glowing eyes on you even as he patted each dish dry.

"Might watch a movie after. Have you watched movies before?" You asked.

A nod.

You continued to talk idly with him as you worked away on the contents of the sink. You told him about work and what you still needed to to today and about books and movies you wanted to see and read. Sun seemed to enjoy your chatter. It felt nice to talk, even if he couldn't offer much in response.

As you drained the sink, the animatronic hefted the pile of dry plates and piling a few mugs atop them, began making his way to the cupboards.

"Whoa, wait!" You called, seeing the stack wobble dangerously.

You rushed ahead to open the cupboard only to gasp as Sun shifted the stack to one hand hand began trying to sit the mugs up on the shelf.

"Give me that, before anything happens." His hand under the dishes trembled and you took the stack from him entirely.

A burst of irritated sounding static made you huff amusedly.

"Sorry, Sunbeam but you still need some tweaking before you'll be back to full fuctioning order." You watched as Sun took one plate from your stack at a time and put it away.

"Jess says she can work on you more this weekend. If I knew more I'd help too...but I am really not all that good with this repair stuff." You drop your hands to your sides as he takes the last plate.

You startle as he places a hand on your shoulder and pats it as if to reassure you.

"Thanks, Sun." You carefully reached up and placed a hand on his shoulder in return.

When he didn't shy away you gave him a quick pat in return.

"So, how about those sandwiches?"

3 notes

·

View notes

Text

Hand Operated Capsule Filling Machine

For small to medium-sized manufacturing batches, the Hand Operated capsule filling machine is an excellent and cost-effective option. Numerous businesses, including the pharmaceutical, herbal, dietary supplement, and herbal product production sectors, use this 300-hole machine.

Hard gelatin capsules containing powders and granules are filled and sealed using Adinath’s Hand Operated capsule filling process. Because it features a bed with 300 holes and a tray with the same number of holes, this machine is also known as a 300 hole capsule filling machine. Lever, pressing plate with rubber sheet, and pin plate are included with the machine. Depending on the size of the capsules, the machine can fill a large number of them every hour with hassle-free operations. With additional parts and machinery, it can also handle capsules with diameters ranging from 00 to 5. The non-contact sections are constructed with hard chrome plating, which enhances its appearance, and all contact parts are composed of SS 304. Whole SS 304 or 316 machines can also be provided based on the specific needs of each client.

0 notes

Text

Get Top Cash for Scrap Metal in Melbourne with Sky Scrap Metal

Are you looking to get rid of unwanted scrap metal and earn some quick cash in the process? Whether you’re cleaning out your garage, demolishing an old shed, or just have leftover metal from a recent project, Sky Scrap Metal is your go-to solution for reliable, hassle-free scrap metal collection and top cash offers in Melbourne.

Why Choose Sky Scrap Metal?

Sky Scrap Metal is one of Melbourne’s leading scrap metal buyers, offering exceptional customer service and competitive prices for all types of scrap metal. Whether you have ferrous or non-ferrous metals, we pay cash on the spot, providing a quick and easy way for you to turn your scrap into valuable cash. Here are just a few reasons why you should choose us:

Top Cash Offers for Scrap Metal At Sky Scrap Metal, we pride ourselves on offering some of the best prices for scrap metal in Melbourne. We work hard to ensure that you get the maximum value for your scrap materials, whether it’s copper, aluminium, steel, brass, or any other type of metal.

Free Collection Service Don’t have a way to transport your scrap metal? No problem! We offer a free scrap metal pick-up service across Melbourne. Our friendly team will come to your location, load the metal, and pay you cash on the spot, making the process completely hassle-free.

Environmentally Friendly Recycling When you sell your scrap metal to Sky Scrap Metal, you’re not only earning cash, but you’re also doing your part for the environment. Recycling metal helps conserve natural resources and reduces energy consumption compared to mining and refining new metals. We are committed to responsible recycling practices that benefit both the community and the planet.

A Wide Range of Scrap Metal Types We buy all types of scrap metal, including:

Ferrous Metals: Steel, iron, and other magnetic metals.

Non-Ferrous Metals: Copper, aluminium, brass, lead, and zinc.

Electrical Wire: Including copper wire, which often fetches high prices.

Car Parts: Old car batteries, engines, and other scrap from vehicles.

Appliances and Machinery: Fridges, washing machines, and industrial scrap.

Fast and Easy Process Selling scrap metal to Sky Scrap Metal is a simple, straightforward process. All you need to do is call us, and we’ll arrange a time to come to your location. Once we arrive, we’ll sort, weigh, and pay you on the spot, making the whole process efficient and convenient.

How to Get Cash for Scrap Metal in Melbourne

Getting cash for your scrap metal in Melbourne is as easy as 1-2-3 with Sky Scrap Metal:

Contact Us Call us or fill out the online form to get a free quote. We’ll ask you about the types and quantity of scrap metal you have.

Schedule a Pickup Once we know what you have, we’ll arrange a time to collect your scrap metal. We offer free collection throughout Melbourne, so you don’t have to worry about transporting your materials.

Get Paid On the Spot When we arrive, we’ll weigh the metal, assess its value, and give you a cash payment. It’s that simple!

Why Scrap Metal Recycling Is Important

Scrap metal recycling is an essential part of reducing waste and supporting sustainability efforts. Here’s why:

Conservation of Natural Resources: Mining and extracting new metals consume significant amounts of energy and natural resources. By recycling scrap metal, we reduce the demand for new raw materials.

Energy Savings: Recycling metals uses significantly less energy compared to processing new metals. This leads to lower carbon emissions and a smaller environmental footprint.

Reduction of Landfill Waste: Scrap metal can take up space in landfills, but by recycling it, we prevent valuable materials from being discarded.

Contact Sky Scrap Metal Today

If you're in Melbourne and looking to sell your scrap metal, don’t hesitate to get in touch with Sky Scrap Metal. We offer fast, reliable service, top cash for your scrap, and a commitment to eco-friendly recycling practices. Whether you have a small amount of scrap from a DIY project or large quantities from a construction site, we’ve got you covered.

Call us today or visit our website to schedule your free scrap metal pickup and start earning cash for your unwanted metal. With Sky Scrap Metal, you can clean up, recycle, and get paid – all in one go!

Sky Scrap Metal – Your trusted scrap metal buyers in Melbourne.

0 notes

Text

How to Apply for a Business Loan in 2024 | My Banking Tips

Applying for a business loan can feel overwhelming, but with the right preparation, you can secure the funds you need to grow your business smoothly. In 2024, lenders in India offer various types of business loans—from term loans to working capital loans—each tailored to different financial needs. Whether you’re starting a new business or expanding an existing one, this guide will walk you through the process of applying for loans in India 2024 with ease.

How to Apply for a Business Loan in 2024

The loan application process may vary slightly from one lender to another, but the essential steps remain the same. Below, We'll break down how you can get a business loan 2024 at competitive rates, along with tips to increase your chances of approval.

Step 1 – Identify the Type of Business Loan You Need

Before you apply, it’s important to determine which loan suits your business requirements. Here are some of the most common options:

Term Loan: Ideal for long-term investments like new equipment or business expansion.

Working Capital Loan: Best for managing daily operations and short-term cash flow needs.

Overdraft Facility: Offers flexible credit up to a certain limit, charged only on the amount used.

Equipment Loan: Helps finance new machinery or tools needed for your business.

Choosing the right loan product ensures you don’t pay unnecessary interest and helps you manage cash flow effectively.

Step 2 – Research Lenders and Compare Interest Rates

Not all lenders offer the same interest rates or loan terms. Comparing your options ensures you secure the best business loan 2024.

Banks: Offer lower interest rates but have strict eligibility criteria.

NBFCs (Non-Banking Financial Companies): More lenient with approval but may charge higher interest.

Government Schemes: Subsidised loans like the Mudra Loan Scheme or SIDBI loans help small businesses.

Look for lenders offering business loans at low interest, as this will minimise your financial burden over time.

Step 3 – Check Your Eligibility

Business Age: Most banks require your business to be operational for at least 1 to 3 years.

Annual Revenue: Some lenders set minimum revenue requirements.

Credit Score: A good personal and business credit score improves approval chances.

Collateral: Secured loans may require assets like property or machinery as collateral, while unsecured loans do not.

Proactively checking your eligibility saves time and helps you focus on lenders most likely to approve your application.

Step 4 – Gather the Necessary Documents

You’ll need to submit certain documents with your loan application. Though the exact requirements may differ among lenders, here’s a common list:

KYC Documents: Identity and address proof

Business Registration Certificate

Bank Statements: Usually for the last 6 to 12 months

Income Tax Returns (ITR): For the past 2 to 3 years

Financial Statements: Balance sheet and profit-and-loss statement

Collateral Documents: If applying for a secured loan

Having all your documents in place speeds up the loan approval process.

Step 5 – Apply for the Loan

Here’s how you can submit your application:

Online Application: Visit the lender’s website and fill out the business loan form.

Upload Documents: Scan and upload all required documents.

Verification Process: Lenders may contact you for further verification.

Approval and Disbursal: Upon approval, the loan amount is disbursed to your business account.

Step 6 – Tips for Getting Your Loan Approved

Here are some tips to increase your chances of approval:

Maintain a Good Credit Score: Both personal and business credit scores impact loan approval.

Provide a Solid Business Plan: A well-structured plan shows lenders how you’ll use the loan effectively.

Opt for a Working Capital Loan if Needed: If your focus is on short-term cash flow, applying for a working capital loan can simplify the process.

Apply with Collateral (if possible): Secured loans tend to offer lower interest rates and better terms.

Avoid Multiple Applications: Submitting several applications simultaneously can negatively affect your credit score.

Key Features of Business Loans in 2024

Here are some important things you should know about business loans in India 2024:

Loan Amount: Ranges from ₹50,000 to ₹5 crore, depending on the lender and business type.

Interest Rate: Typically between 11% to 18% for unsecured loans. Business loans with low interest are available if you meet eligibility criteria or apply with collateral.

Loan Tenure: Varies from 12 months to 7 years, depending on the loan type.

Processing Fee: Banks and NBFCs usually charge 1% to 3% of the loan amount as a processing fee.

How to Choose the Best Business Loan in 2024

Finding the best business loan requires careful consideration. Here’s what you should keep in mind:

Compare Interest Rates: Even a slight difference in rates can save you a lot of money over the loan term.

Check Prepayment Charges: Some lenders charge fees for early repayment, so confirm this upfront.

Look for Government Schemes: Government-backed loans often have lower interest rates.

Consider Loan Tenure: Opt for a tenure that balances manageable EMIs with total interest cost.

Conclusion:

Applying for a business loan 2024 isn’t complicated if you follow the right steps. Whether you need funds for expansion, daily operations, or new equipment, there’s a loan tailored to your needs. If you’re struggling with cash flow, consider a working capital loan to keep your business running smoothly.

0 notes

Text

Goa Polymer: Your Trusted Partner for the Best Carbon Filled PTFE Products

When it comes to the Best Carbon Filled PTFE products, Goa polymer is the name that stands out. With a range of best CFT Products designed to meet industrial needs, Goa polymer has become a trusted supplier for industries looking for best Carbon Filled Teflon components. Offering excellent wear resistance, thermal stability, and chemical inertness, Goa polymer products are perfect for a variety of applications across industries like automotive, chemical processing, & more.

Locating dependable materials that provide stability, durability, and adaptability is crucial for continuing smooth operations in the fast-paced industrial environment of today. The innovative material Carbon Filled PTFE is one sample. Carbon Filled Teflon is extensively utilized in a variety of industries, including chemical processing and the automotive sector, due to it exceptional chemical inertness, strong resistance to wear & tear, and remarkable thermal stability. Goa Polymer is a name that stands out for its continuous quality and client satisfaction when it comes to getting the best Carbon Filled PTFE.

We will go through the benefits of carbon-filled PTFE, the variety of CFT products that are out there, and why Goa Polymer should be your first choice for any PTFE related need in this extensive guide.

What is Carbon Filled PTFE?

The versatile polymer Teflon, sometimes referred to as poly tetra fluoro ethylene, or PTFE, has excellent non-stick properties, minimal friction, and resilience to heat and chemicals. Addition of carbon fillers to PTFE leads to Carbon Filled PTFE, which has significantly better mechanical and thermal properties. Better conductivity and greater wear resistance are two other features that make this material ideal for a wide range of industrial applications, while also retaining the advantages of normal PTFE.

Based on the application, carbon fillers are typically added in various amounts, typically ranging from 10% to 35%. When performance and lifespan are crucial, the resultant composite material is an excellent choice since it has more mechanical strength, less deformation, and more dimensional stability.

Why Choose Carbon Filled PTFE?

1. Better Resistance to Wear

Excellent wear resistance is one of the most notable qualities of CFT Products . Increased durability and suitability for high-wear situations are the results of the inclusion of carbon fillers. Carbon Filled Teflon works better than other materials for whatever it is used for—car parts, bearings, seals, etc. by lowering wear and friction and prolonging part life while lowering maintenance expenses.

2. Superior Temperature Stability

Chemical processing and the automobile industry are two examples of industries that require materials that can endure high temperatures without losing their integrity. With a temperature range of -200°C to 260°C, Carbon Filled PTFE is famous for its superb thermal stability. This makes it perfect for uses in which temperatures are both high and low.

3. Chemical Inertness

One of PTFE most useful characteristics is its chemical resistance, which is maintained in carbon-filled PTFE. This material is appropriate for usage in settings like chemical processing factories, where contact with harsh substances is a continual concern, because it can tolerate exposure to unfriendly chemicals, acids, and bases. The Goa polymer line of CFT Products is made especially to perform for a long time, even in the most aggressive chemical situations.

4. Increased Electrical Conductivity

The increased electrical conductivity of PTFE is a significant benefit of adding carbon. When carbon fillers are added to PTFE, which is normally an electrical insulator, the material becomes somewhat conductive. Because of this, carbon filled Teflon is a great option for situations where both electrical and thermal conductivity are important, such as in electronics or machinery that requires static dissipation.

Key Applications of Carbon Filled PTFE

Carbon Filled PTFE is used in a variety of applications across different industries, owing to its more properties. Here are some of the most common uses:

1. Automotive Industry

Carbon Filled Teflon is used extensively in the locomotive sector for components such as seals, bushings, and bearings. These parts are subjected to high loads and temperatures frequently, and CFT Products wear-resistant qualities make them perfect for these harsh environments.

2. Reactions with Chemicals

Carbon Filled PTFE is applied for gaskets, seals, and linings in the chemical sector since equipment there is frequently exposed to corrosive substances. Durable durability is ensured by its chemical inertness, especially in conditions where chemicals & particularly aggressive.

3. Semiconductors and Electronics

Carbon Filled PTFE is a great option for companies requiring materials with a moderate level of electrical conductivity. With the added heat & chemical resistance of regular PTFE, it is utilized in many different electronic components that need static dissipation.

4. Oil and Gas Industry

CFT Products are utilized in the oil and gas sector for gaskets, seals, and other components that are subjected to corrosive fluids, high temperatures, and pressures. Carbon Filled Teflon performance and longevity guarantee that machinery operates smoothly, cutting downtime and maintenance expenses.

Goa Polymer is the top provider of high-quality carbon-filled PTFE products.

Goa Polymer is your reliable resource for finding the best Carbon Filled PTFE goods. With years of expertise in the field, Goa Polymer has established a solid reputation for providing best goods that precisely match the demands of its customers. The following justifies using Goa polymer in all of your CFT products:

1. Uncompromised Quality

At Goa Polymer, we put quality first. Our Carbon Filled PTFE products are manufactured using the best materials and cutting-edge techniques to guarantee that they function to the highest standards. You can count on Goa Polymer to create goods that will endure over time, even in the most demanding situations, because of our dedication to quality.

2. Tailored Resolutions

Every sector has different requirements, and at Goa Polymer, we recognize the value of offering tailored solutions. Whether you require a customized formulation of Carbon Filled Teflon or CFT Products for a particular application, our team of professionals will collaborate with you to create a product that satisfies all of your requirements.

3. Competitive Pricing

At Goa Polymer, we think that expensive goods should not have to be sacrificed for superior quality. To ensure you get the most out of your investment, we provide reasonable pricing on all of our Carbon Filled PTFE products.

4. Professional Assistance

You get a partner in Goa Polymer in addition to a product when you choose them. Whether you need assistance with installation or maintenance, or just need help selecting the appropriate CFT Products, our team of professionals is here to help.

5. Fast Delivery

We understand that time is of the essence in industrial operations. That why Goa polymer offers fast and reliable delivery services to ensure that you’re Carbon Filled PTFE products arrive when you need them, without delays.

Conclusion

Goa Polymer is the brand you can rely on to find the Best Carbon Filled PTFE goods. Goa Polymer is dedicated to providing Carbon Filled Teflon components that are of greater quality, lifelong, and dependable. They offer a broad selection of CFT Products that are tailored to fulfill the demands of many industries. Nevertheless of your industry—chemical, electronics, & automotive—Goa Polymer has the knowledge & experience to offer you the best solutions.

Get in touch with Goa Polymer right now to find out more about our selection of Carbon Filled PTFE products and how we can assist you in enhancing the robustness and efficiency of your industrial processes.

0 notes

Text

Automatic Filling Machines by PPS Water Engineers

With 25 years of experience in the industry, PPS Water Engineers offers high-performance Automatic Filling Machines tailored for precise and efficient liquid bottling processes. Whether you're bottling water, juice, or other beverages, our machines ensure maximum productivity while maintaining the highest quality standards.

Machinery Details:

Capacity Range: Available in various capacities to meet different production requirements, handling from 1000 to 6000 bottles per hour.

Filling Type: Gravity filling for non-carbonated beverages like water, juice, and milk.

Material: Constructed from high-grade stainless steel for corrosion resistance and hygiene.

Operation Type: Fully automatic, reducing labor costs and improving efficiency.

Bottle Compatibility: Suitable for PET, glass, and HDPE bottles of various shapes and sizes.

Filling Volume: Adjustable filling volume, suitable for 200 ml to 2 liters.

Advanced Technology: Integrated with touch screen controls for easy operation and monitoring.

Multi-Functionality: Can be integrated with rinsing and capping modules for a complete bottling solution.

Safety Standards: Equipped with safety features like emergency stop, overload protection, and bottle jam detection.

Maintenance: Easy-to-clean design with minimal downtime for maintenance, ensuring continuous operation.

Why Choose PPS Water Engineers?

Reliability: Built for long-term performance with robust materials.

Efficiency: Optimized for high-speed, precise filling operations.

Customizable: Tailored to meet your specific production and bottling needs.

Hygienic: Designed with food-grade materials, ensuring clean and safe bottling processes.

Automate your filling process and boost your production with PPS Water Engineers' Automatic Filling Machines today!

For inquiries: Contact us at 098187 57548

#AutomaticFillingMachine#FillingMachine#BottlingSolutions#HighSpeedFilling#PackagingEquipment#IndustrialMachinery#FoodIndustryEquipment#PrecisionEngineering#FillingTechnology#EfficientOperations#ManufacturingSolutions#PPSWaterEngineers#BottlingEquipment#AutomaticMachines#DurableMachinery#CustomFillingSolutions#EnergyEfficientMachines#InnovativeMachinery#HygienicDesign#UserFriendlyMachines#FoodAndBeverageEquipment#PackagingSolutions#LiquidFillingMachines#ProductionEfficiency#BottlingTechnology#QualityMachinery#EngineeringExcellence#AutomationInFilling#IndustryLeaders#MachineryExperts

0 notes

Text

Exploring the Versatility of Hoses in Industrial and Domestic Applications

Hoses are indispensable components in both industrial and domestic settings, offering flexibility, strength, and durability for a wide range of applications in drainage pipes and fittings. From garden hoses used at home to high-pressure industrial hoses used in manufacturing, the versatility of hoses makes them essential tools in various sectors. This article explores the different types of hoses, their applications, and the benefits they offer.

Types of Hoses

1. Garden Hoses

- Material: Typically made from vinyl, rubber, or a combination of both.

- Applications: Used for watering plants, cleaning outdoor areas, and filling pools with the foot valve.

- Benefits: Lightweight, flexible, and easy to store. Rubber hoses are more durable and resistant to kinks and abrasions compared to vinyl.

2. Industrial Hoses

- Material: Made from a variety of materials including rubber, PVC, polyurethane, and hybrid compounds.

- Applications: Used in manufacturing, construction, and transportation for tasks such as conveying air, water, chemicals, and bulk materials.

- Benefits: High durability, resistance to harsh chemicals, and the ability to withstand extreme temperatures and pressures.

3. Air Hoses

- Material: Made from rubber, PVC, or polyurethane.

- Applications: Used to convey compressed air in pneumatic tools, paint sprayers, and HVAC systems.

- Benefits: Flexible, lightweight, and designed to handle high pressure.

4. Hydraulic Hoses

- Material: Typically made from synthetic rubber and reinforced with layers of braided steel wire.

- Applications: Used in hydraulic systems to transmit fluid power in machinery, automotive systems, and heavy equipment.

- Benefits: High strength, flexibility, and the ability to handle high-pressure fluids.

5. Chemical Hoses

- Material: Made from materials resistant to corrosive chemicals, such as PTFE (Teflon), EPDM, or UHMWPE.

- Applications: Used in chemical plants, laboratories, and industries dealing with hazardous materials.

- Benefits: Resistance to a wide range of chemicals, high flexibility, and durability.

6. Food-Grade Hoses

- Material: Made from non-toxic materials like silicone or PVC and compliant with FDA standards.

- Applications: Used in food and beverage industries for transferring consumable liquids and solids.

- Benefits: Safe for food contact, flexible, and easy to clean.

Applications of Hoses

1. Domestic Applications

- Watering and Irrigation: Garden hoses are essential for maintaining gardens, lawns, and landscapes.

- Cleaning: Hoses are used in pressure washers for cleaning driveways, patios, and vehicles.

- Plumbing: Flexible hoses are used for connections in sinks, toilets, and washing machines.

2. Industrial Applications

- Manufacturing: Industrial hoses are used to transport air, water, and chemicals in manufacturing processes.

- Construction: Hoses are used in pneumatic tools, water delivery systems, and concrete pumping.

- Agriculture: Hoses are crucial for irrigation systems, chemical spraying, and transferring agricultural products.

3. Automotive Applications

- Fuel Systems: Hoses are used to transfer fuel from tanks to engines.

- Cooling Systems: Radiator hoses are essential for circulating coolant to maintain engine temperature.

- Brake Systems: Hydraulic hoses transmit brake fluid in vehicle braking systems.

4. Healthcare Applications

- Medical Devices: Hoses are used in various medical devices, such as oxygen delivery systems and fluid transfer in IV lines.

- Laboratories: Chemical-resistant hoses are used for transferring reagents and samples.

Benefits of Using Hoses

1. Flexibility

- Hoses offer excellent flexibility, allowing them to be used in various configurations and tight spaces. This is especially important in applications where rigid pipes would be impractical.

2. Durability

- Modern hoses are designed to withstand harsh conditions, including high pressure, extreme temperatures, and exposure to chemicals. This durability ensures long service life and reliability.

3. Versatility

- Hoses are available in a wide range of materials and designs, making them suitable for a multitude of applications, from simple garden watering to complex industrial processes.

4. Ease of Installation

- Hoses are relatively easy to install and replace compared to rigid piping systems. This ease of installation reduces downtime and maintenance costs.

5. Cost-Effectiveness

- Hoses can be a more cost-effective solution than rigid pipes, especially in applications requiring flexibility and frequent reconfiguration.

6. Safety

- In many applications, hoses provide a safer alternative to rigid piping, especially in systems dealing with high pressure or hazardous materials. Flexible hoses can absorb vibrations and movements, reducing the risk of leaks and failures.

Hoses are versatile and essential components in both industrial and domestic settings. Their flexibility, durability, and adaptability make them ideal for a wide range of applications, from watering gardens to transporting chemicals in manufacturing plants. Understanding the different types of hoses and their specific benefits helps in selecting the right hose for each application, ensuring efficiency, safety, and longevity. As technology advances, the development of new materials and designs will continue to enhance the versatility and performance of hoses, further expanding their role in various industries.

0 notes

Text

Selecting Air Compressors for Dairy Processing Applications

The dairy industry is a highly rely and demanding sector, requiring strict hygiene standards and operational efficiency. Air compressors play a crucial role in maintaining these criteria by providing clean, contaminant-free air essential for various processes. Whether it’s powering pneumatic machinery, ensuring hygienic packaging, or maintaining precise temperature control, the right air compressor can make all the difference in dairy processing. In this article, we will explore how to select the perfect air compressors for dairy processing applications. Let’s take a look in depth!

The Role of Air Compressors in Dairy Processing

Compressed air is essential in dairy processing for several key reasons:

Powering Equipment:

Pneumatic procedures used in filling, sealing, and other automatic processes depend on compressed air. The precision and reliability of these systems are essential for maintaining production speed and product consistency.

Cleaning and Sterilization:

Compressed air is often using in cleaning and sterilizing equipment. The air must be free from oil, moisture, and particulates to ensure that no contaminants are present in the process.

Packaging:

In packaging processes, especially where Modified Packaging atmosphere needed, the air quality is most important. Contaminant-free air ensures the extended stand life and safety of dairy products.

Cooling:

In temperature-sensitive areas of dairy processing, compressed air is use for cooling to maintain optimal conditions for product quality.

Types of Air Compressors for Dairy Processing

Screw Type Compressor

Screw type compressor is the most commonly use in the dairy industry. They operate using a rotary mechanism where two screw-like components link together, compressing the air as it passes through the system. This type of compressor is highly efficient, offering continuous operation with minimal vibration.

Benefits of Screw Type Compressors: Efficiency:

Screw type compressor is known for its energy efficiency, which is a notable advantage that operates continuously. They deliver a steady flow of air, which is essential for constant product quality.

Reliability:

These compressors are create for heavy-duty applications and can handle long hours of operation with minimal maintenance. This reliability is essential in preventing downtime in a fast-paced production environment.

Low Noise Levels:

Compared to other compressors, screw type compressors works more quietly, making it suitable for where noise reduction is priority.

Applications in Dairy Processing:

Operating pneumatic systems in production lines.

Providing constant air supply for cleaning and sterilisation.

Supporting continuous processes that require reliable and uninterrupted airflow.

Oil Free Air Compressor: In dairy processing, the purity of compressed air is non-negotiable, making oil-free air compressors a top choice. These compressors are design to stop the risk of oil contamination, which is crucial in maintaining the highest hygiene standards.

Benefits of Oil Free Air Compressor:

Purity:

Oil free air compressor ensures that no oil contaminants are present into the air, which could not compromise product safety and quality.

Compliance:

An oil free air compressor helps facilities meet strict food safety regulations, as they produce air that meets the required ISO standards for air purity.

Cost Savings:

Oil free air compressors have a higher purchasing price, they reduce long-term expenses like oil filtration, maintenance, and contamination-related recalls.

Applications in Dairy Processing:

Providing air for direct contact with products in packaging.

Ensuring contaminant-free air in processes where hygiene is necessary, like cleaning and sterilisation.

Supporting pneumatic tools and equipment in ultra-clean environments.

Rotary Air Conditioner Compressors A Rotary air conditioner compressor is essential in maintaining the precise temperature control required in dairy processing. These compressors are compact, efficient, and designed for environments where cooling is a necessary factor.

Benefits of Rotary Air Conditioner Compressor:

Precision Cooling:

These compressors are ideal for applications that require strict temperature control, ensuring that dairy products are store and processed under optimal conditions.

Energy Efficiency:

The rotary air conditioner compressor is design for energy-efficient, which is beneficial in reducing operational costs, especially large-scale operations.

Quiet Process:

The low noise levels of rotary air conditioner compressors make them suitable for use in environments where noise reduction is vital.

Applications in Dairy Processing:

Maintaining cold storage temperatures.

Supporting refrigeration systems in processing facilities.

Providing cooling in temperature-sensitive production areas.

Key Considerations When Selecting an Air Compressors

Selecting the right air compressor includes more than choosing between types. Here are some critical factors to consider:

Air Quality Requirements:

The air quality in dairy processing must meet strict standards. Contaminants like oil, moisture, and particulates can lead to product spoilage, safety concerns, and regulatory issues. Therefore, an oil free air compressor is recommend for the highest air quality.

Energy Efficiency:

Dairy processing is energy-intensive, making the efficiency of air compressors a crucial concern. Screw type compressors is known for its energy-efficient, which can lead to notable cost saving. Evaluating the energy consumption of a compressor in concern of its output can help you choose the most cost-effective solution.

Maintenance and Reliability:

Regular maintenance is essential to keep air compressors running smoothly. However, selecting a compressor known for its reliability can minimise the frequency and cost of maintenance. A screw type compressor is robust and requires less frequent servicing compared to other types. This reliability ensures that production lines run smoothly without unexpected interruptions.

Capacity and Pressure Requirements:

Different stages of dairy processing may require varying levels of air pressure and capacity. It’s important to consider your facility’s specific needs to choose a compressor that can meet these demands without overloading the system. A right compressor not only work efficiently but also have a longer lifespan.

Environmental Impact:

With increasing focus on sustainability, the environmental impact of your equipment should be consider. An Oil free air compressor contributes to a cleaner environment by eliminating the need for oil disposal and reducing the risk of air and product contamination.

Cost Considerations:

While the initial investment is important, it’s essential to consider the total cost of ownership. This includes energy consumption, maintenance, and probable downtime costs. Investing in a high-quality, efficient compressor can lead to long-term savings and fewer operational disruptions.

Wrapping Up:

Selecting the right air compressors for dairy processing applications is crucial to ensuring product quality, operational efficiency, and regulatory compliance. Screw-type compressors, oil-free air compressors, and rotary air conditioner compressors each offer unique benefits that cater to different factors of dairy processing. By considering factors such as air quality, energy efficiency, maintenance needs, and capacity requirements, you can make an informed decision that supports the success and sustainability of your dairy processing operations.

0 notes

Text

"From Water to Juice: Seppa’s Flexible RFC Machines Handle It All"

Seppa Solutions' Rinser Filler Capper (RFC) machines revolutionize bottled water packaging with sustainability, flexibility, and efficiency at the core. Designed for various beverages like water, juices, and dairy, the EVATS-1000 series boasts eco-friendly features such as reduced plastic use, "no bottle, no fill" technology, and compatibility with diverse bottle shapes and sizes. SEPPA ensures adaptability and durability with intuitive touchscreens, modular designs, and robust stainless-steel construction. These machines cater to cold and hot filling needs, handling products with or without pulp. SEPPA’s cutting-edge RFC machine enables manufacturers to enhance productivity, reduce costs, and stay competitive in a dynamic market.

#rfc machine manufacturer#rinser filler capper machine manufacturer#rinser machine#rfcmachine#filler capper machine#filler capper#filler machine#non contact filling#non contact filler#non contact filling machine#non contact filling machinery

0 notes

Text

Integrated Packaging Solutions for Spices by Nichrome

Spice It Up with Nichrome: Your Packaging Partner in Flavor

In the bustling world of spices, where every pinch counts, ensuring that your aromatic treasures reach consumers in top-notch condition is crucial. This is where Nichrome steps in, adding a dash of magic to your secondary packaging needs. With our innovative machinery and integrated solutions, we ensure your spices are packaged with the precision and care they deserve. Let’s dive into how Nichrome spices up your packaging game.

Sizzle with Streamlined Spice Solutions

Nichrome’s spice packaging machines are the secret ingredient to your success. Whether it’s our versatile powder filling machines or the groundbreaking Flexiwrap 700 horizontal flow wrap machine, we have the tools to transform your packaging process. Our machines are designed to maximize efficiency and boost productivity, making your spices look as good as they taste.

Integrated Packaging: The Recipe for Success

At Nichrome, we know that packaging isn’t just about individual machines—it’s about creating a cohesive system. Our integrated solutions blend different packaging technologies into a harmonious line, ensuring your operations run smoothly. By optimizing efficiency and enhancing product presentation, we make sure your spices steal the spotlight on the shelves.

Precision and Quality: The Perfect Blend

Consistency and accuracy are non-negotiable in spice packaging. Nichrome’s machines are engineered for precision, ensuring each pouch is filled to perfection. Our technology preserves the integrity of your spices, maintaining their aroma and flavor, so every customer experience is a delightful one.

Sustainability: Spice Up the Planet

n today’s eco-conscious world, sustainability is key. Nichrome’s machines are designed to minimize waste and optimize resource use. With energy-efficient operations and eco-friendly solutions, we help you reduce your environmental footprint while delivering top-notch packaging.

Flexiwrap 700: The Star of the Show

The Flexiwrap 700 is a game-changer in spice packaging. This innovative horizontal flow wrap machine offers customizable pouch sizes, attractive sealing options, and advanced controls. It ensures your spices are securely packaged and ready to impress. With features like intermittent motion, quick change-over design, and the ability to store different recipes, the Flexiwrap 700 is your go-to for efficient, eye-catching packaging.

Features of the Flexiwrap 700

Intermittent Motion: Smooth and efficient operation.

Stainless Steel Contact Parts: Ensuring hygiene and durability.

Quick Change-Over Design: Easy transitions for different pouch sizes.

Recipe Storage: Streamlined changeovers with PLC program storage.

Servo Motor and Pneumatic Cylinder: Precise control for center and side seals.

Laminate Compatibility: Works with materials like BOPP/PPE.

Speed:��Up to 60 ppm, adjustable based on pouch length.

Conclusion

Nichrome is your spice packaging partner extraordinaire. With our cutting-edge machines and commitment to sustainability, we help you elevate your packaging operations and exceed customer expectations. From powder filling to advanced flow wrap machines, Nichrome has the solutions you need to thrive in the competitive spice market. Spice up your packaging with Nichrome and taste the difference in quality, efficiency, and innovation. Learn More: https://www.nichrome.com/blog/integrated-spice-packaging-solutions/

#spice packaging machines#Spices Packing Machine manufacturers#Spices packing machine manufacturers in india

0 notes

Text

Resin Flooring Contractors in London

Expert Resin Flooring Solutions

Welcome to KT Coatings, London's leading resin flooring contractors. With years of experience and a team of dedicated professionals, we provide top-quality resin flooring solutions for both commercial and residential properties.

KT Coatings

If More Info Visit -https://ktcoatings.co.uk/

Why Choose Resin Flooring?

Resin flooring is a durable, versatile, and attractive flooring option that offers numerous benefits:

Durability: Resistant to wear and tear, making it ideal for high-traffic areas.

Low Maintenance: Easy to clean and maintain, saving you time and money.

Aesthetic Appeal: Available in a variety of colors and finishes to suit any style.

Hygienic: Seamless and non-porous, preventing the growth of bacteria and mold.

Chemical Resistance: Perfect for industrial settings where chemical spills are a concern.

Our Services

Residential Resin Flooring

Transform your home with our stylish and practical resin flooring solutions. Whether you want a sleek, modern look or something more traditional, we have the perfect option for you.

Commercial Resin Flooring

Enhance your business environment with our durable and attractive commercial resin flooring. Suitable for offices, retail spaces, restaurants, and more, our flooring solutions are designed to withstand heavy use while maintaining their appearance.

Industrial Resin Flooring

Our industrial resin flooring is built to handle the toughest environments. Resistant to chemicals, impact, and heavy machinery, it’s the ideal choice for factories, warehouses, and workshops.

Bespoke Designs

Looking for something unique? Our bespoke resin flooring service allows you to create a one-of-a-kind floor that reflects your personal style or brand identity. From custom colors to intricate patterns, the possibilities are endless.

Our Process

Consultation: We begin with a thorough consultation to understand your needs and preferences.

Design: Our team of experts will create a custom design plan tailored to your specifications.

Preparation: We ensure the surface is properly prepared for optimal adhesion and durability.

Installation: Our skilled installers apply the resin flooring with precision and care.

Aftercare: We provide guidance on how to maintain your new floor to keep it looking its best for years to come.

Why Choose Us?

Experience: With over many years in the industry, we have the expertise to handle any project.

Quality: We use only the highest quality materials to ensure a flawless finish.

Customer Satisfaction: Our commitment to customer satisfaction means we won’t rest until you’re happy with your new floor.

Competitive Pricing: We offer competitive pricing without compromising on quality.

Contact Us

Ready to transform your space with stunning resin flooring? Contact us today for a free consultation and quote. Call us at 7385259215 or fill out our online contact form.

0 notes

Text

Global Top 4 Companies Accounted for 39% of total Curing Bladder market (QYResearch, 2021)

Curing is the process of applying pressure to the green tire in a mold in order to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber compounds and other materials.

In this process the green tire is automatically transferred onto the lower mold bead seat, a rubber bladder is inserted into the green tire, and the mold closes while the bladder inflates. As the mold closes and is locked the bladder pressure increases so as to make the green tire flow into the mold, taking on the tread pattern and sidewall lettering engraved into the mold. The bladder is filled with a recirculating heat transfer medium, such as steam, hot water, or inert gas. At the end of cure, the pressure is bled down, the mold opened, and the tire stripped out of the mold.

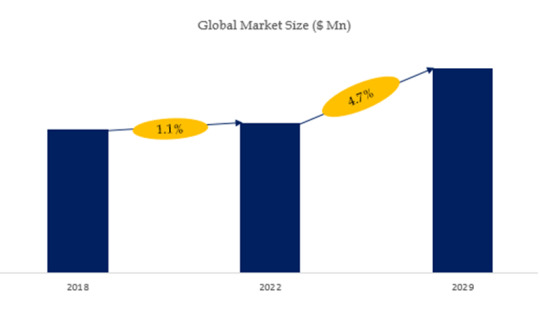

According to the new market research report “Global Curing Bladder Market Report 2023-2029”, published by QYResearch, the global Curing Bladder market size is projected to reach USD 0.72 billion by 2029, at a CAGR of 4.7% during the forecast period.

Figure. Global Curing Bladder Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Curing Bladder Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

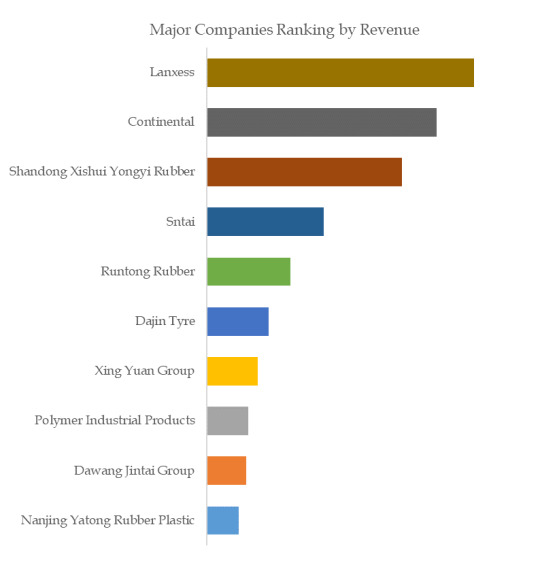

Figure. Global Curing Bladder Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Curing Bladder Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Curing Bladder include Lanxess, Continental, Shandong Xishui Yongyi Rubber, Sntai, Runtong Rubber, etc. In 2022, the global top four players had a share approximately 39.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

youtube

Hand Operated Capsule Filling Machine

For small to medium-sized manufacturing batches, the Hand Operated capsule filling machine is an excellent and cost-effective option. Numerous businesses, including the pharmaceutical, herbal, dietary supplement, and herbal product production sectors, use this 300-hole machine.

Hard gelatin capsules containing powders and granules are filled and sealed using Adinath’s Hand Operated capsule filling process. Because it features a bed with 300 holes and a tray with the same number of holes, this machine is also known as a 300 hole capsule filling machine. Lever, pressing plate with rubber sheet, and pin plate are included with the machine. Depending on the size of the capsules, the machine can fill a large number of them every hour with hassle-free operations. With additional parts and machinery, it can also handle capsules with diameters ranging from 00 to 5. The non-contact sections are constructed with hard chrome plating, which enhances its appearance, and all contact parts are composed of SS 304. Whole SS 304 or 316 machines can also be provided based on the specific needs of each client.

0 notes