#filler machine

Explore tagged Tumblr posts

Text

"From Water to Juice: Seppa’s Flexible RFC Machines Handle It All"

Seppa Solutions' Rinser Filler Capper (RFC) machines revolutionize bottled water packaging with sustainability, flexibility, and efficiency at the core. Designed for various beverages like water, juices, and dairy, the EVATS-1000 series boasts eco-friendly features such as reduced plastic use, "no bottle, no fill" technology, and compatibility with diverse bottle shapes and sizes. SEPPA ensures adaptability and durability with intuitive touchscreens, modular designs, and robust stainless-steel construction. These machines cater to cold and hot filling needs, handling products with or without pulp. SEPPA’s cutting-edge RFC machine enables manufacturers to enhance productivity, reduce costs, and stay competitive in a dynamic market.

#rfc machine manufacturer#rinser filler capper machine manufacturer#rinser machine#rfcmachine#filler capper machine#filler capper#filler machine#non contact filling#non contact filler#non contact filling machine#non contact filling machinery

0 notes

Text

Safflower Oil Filling Machine Manufacturer from Ahmedabad - Shiv Shakti Machtech

#manufacturer#ahmedabad#exporter#safflower oil filling machine#oil filling machine#edible oil filling machine#mustard oil filling machine#filler machine#filler#filling technlogy#servo filling machine#gear pump filling machine#servo pump filling machine

0 notes

Text

The Importance of a Hydraulic Filler Machine

Introduction:

- A hydraulic filler machine is a vital piece of equipment in various industries, including food and beverage, pharmaceuticals, and cosmetics.

- This article will discuss the benefits and features of a hydraulic filler machine, highlighting why it is an essential investment for businesses.

2. Increased Efficiency and Productivity

- One of the main advantages of a hydraulic filler machine is its ability to significantly increase efficiency and productivity.

- With automated filling processes, this machine can fill a large number of containers accurately and consistently.

- This automation reduces manual labor and speeds up the production line, resulting in higher output and increased profits.

3. Accurate and Precise Filling

- Accuracy and precision are crucial when it comes to filling containers with liquids or semi-liquids.

- A hydraulic filler machine utilizes advanced technology to ensure precise filling levels, minimizing product wastage and maximizing product quality.

- It allows for adjustable filling volumes, catering to the specific needs of different products and containers.

4. Versatility in Filling Applications

- Hydraulic filler machines are versatile and can handle various types of containers, such as bottles, jars, tubes, and cans.

- They can fill a wide range of products, including liquids, creams, gels, pastes, and even solids.

- This versatility makes it a valuable asset for businesses dealing with multiple products or experiencing frequent product changes.

5. Hygienic and Clean Filling Process

- Maintaining hygiene and cleanliness is essential, especially in industries such as food and beverage and pharmaceuticals.

- Hydraulic filler machines are designed with materials that are easy to clean and sanitize to meet stringent hygiene standards.

- They often feature stainless steel construction, ensuring durability, corrosion resistance, and compliance with industry regulations.

6. Easy Operation and Minimal Maintenance

- Many hydraulic filler machines are user-friendly and require minimal training to operate.

- They come with intuitive controls and interfaces, making it easy for operators to set up and monitor the filling process.

- Additionally, these machines are designed for low maintenance, minimizing downtime and reducing maintenance costs.

7. Cost-Effective Investment

- Investing in a hydraulic filler machine often pays off in the long run due to increased productivity and reduced labor costs.

- By automating the filling process, businesses can optimize their production efficiency and reduce the need for manual labor.

- This efficiency translates to higher production volumes, improved product quality, and ultimately, greater profitability.

8. Conclusion: Why You Need a Hydraulic Filler Machine

- A hydraulic filler machine offers numerous advantages, including increased efficiency, accurate filling, versatility, hygiene, ease of operation, and cost-effectiveness.

- Whether you are a small business or a large-scale manufacturer, investing in a hydraulic filler machine can significantly enhance your productivity and profitability.

- Consider the specific needs of your industry and evaluate the available options to find the right hydraulic filler machine that suits your business requirements.

#hydraulic filler machine#filler machine#Sausage filler machine#filler machine price#filler machine for sale

0 notes

Text

Manufacturer of Active Packaging's Digital Weigh Fillers To ensure accurate product filling, our weigh metric filling machine makes use of cutting-edge weight measurement technology. By doing this, any possibility of error with volumetric filling equipment is eliminated. You can change the filling speed, weight parameters, and other settings according to your unique needs thanks to its configurable options.

With simple instructions and intuitive controls, our Automatic Digital Weigh Filler Machine Suppliers in Pune are made to be user-friendly. This cuts down on training time and lowers the likelihood of operational errors.

0 notes

Note

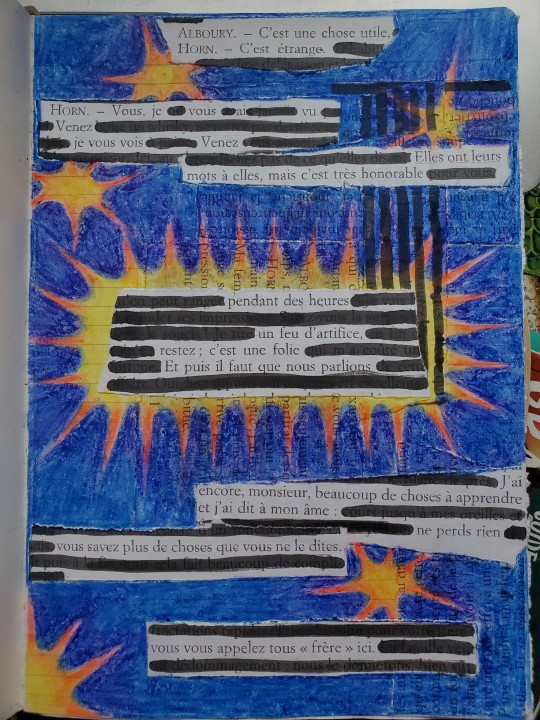

Hi ! I love your art and took inspiration from you to do the front page of my notebook for my theater lessons !

I unfortunately had to do it on the paper from the notebook directly instead of drawing paper so I'm a little disappointed with the results but I like what I did when I was figuring it out, on the drawing paper (and also on tracing paper for some reason ?)

Overall I'm so happy I could kind of replicate your technique for the light while using cheap wax pencils (stinginess wins 💪)

Anyway, thank you for posting your art it altered my brain chemistry 👍

YEAAAAAÁHÆHHHHH WOOO THE COLORS!!!!!!!!!!

#500% support using cheap tools#they are harder to use typically but if u take some time to figure them out u can make sick art#im talking abt crayola supplies like theyre some complex machine lmao#they are just harder to use bc they have more filler and less pigment than Expensive Artist Pencil so its harder to get color out of them#kinda counterintuitive that art supplies for children are harder to use than art supplies for Serious Artists lol

147 notes

·

View notes

Text

Here’s an assortment of Bendy boy sketches that were going to be cute at first but they slowly got worse and worse as you can see, happy April 1st

I might do more but I am going on a very very long road trip so we’ll see!

Here’s also this!

Some Wandering Sin variations that I think I’ll incorporate into the pre-game events of OOTIM! Animators were known to go completely off-model sometimes and make these sorts of eerie frames. There are many different variants but one of the most common was a Bendy with human eyes and teeth. Others include anatomically human bodies, animal bodies, necks, spiral tails, one or no eyes, and explosions of ink on frames caused by holding a fountain pain extremely hard to the paper.

#cw body horror#tw body horror#body horror#batim au#ootim#out of the ink machine#bendy au#bendy and the ink machine#toon bendy#bendy#wandering sin#sinny#filler#image description in alt

70 notes

·

View notes

Text

thumb luck

Backing up to the preceeding spash panel, and notice that the filled in fashion of thigh high boots worn by the women are nowhere in any of the completed head to toe figures drawn by Fernando Ruiz. This is a footwear fashion favored by the indicia filler alone. (Though, Dan Parent's favoring of them in 2010 was nixed.)

One tediously minute blip in coloring on Betty's short shirt. Also now get the whites of their eyes.

#Archie Comics#Archie Andrews#Betty Cooper#Movie theatre#Gumball machine#footwear#Shoes#thigh high boots#Midriff#Fernando Ruiz#1995#Indicia filler#Eyes wide open#The Spirit?

5 notes

·

View notes

Text

Sometimes. You gotta make a lumpy cube

#my art#cube#sorta#sewing#project 1#cut foam sucks as a filler and I hate it#but i love project 1 dearly#first time using a sewing machine!

2 notes

·

View notes

Text

Hey speaking about music with vocals have you listened to this rendition of Niko and The World Machine because if not you should

youtube

#oneshot game#video#this is not mine im just boosting it bc i feel like a teen again listening to covers of instrumental music from OSTs#niko and the world machine#my burden is light#dont look past this point if u wanna listen to the song fully blind#sdfghjlñpoiuytresdcvbnm#loiuytrf filler tags#OK BUT THE FACT THAT IT'S A DUET AND EACH OF THEM ARGUES TO PICK AN OPTION AND#And yet they still come to the conclusion that the choice is up to you jasfhkjasbjhas and the song reflects that#also honestly I find the people who voice act for projects like this admirable#its the sort of thing ive always wanted to do but i dont have the tech or the knowledge to do it properly#or a good place to record#Youtube

3 notes

·

View notes

Text

This really is just a journal now. Oopsie xD

Angel and I got in... something. I don't know what to call it. We walked away and then tried to talk it out before it became what I'd consider a fight or even an argument.

Tldr, I wanted to talk about a medical thing with her and she gave me a suggestion, and then my response made her feel like her input wasn't wanted or wasn't helpful. I made her feel like I was shutting her down. Which sucks, and was not my intention, but the impact was still there, and I'm sorry for that.

Except... I don't understand why that was the impact. I don't understand what else I was supposed to have said. I don't know what to do differently next time. She made a suggestion I had already looked at, so I was sharing what I already knew. Until she emotionally shutdown and literally stopped herself from speaking, I thought we were having a normal conversation with sharing things back and forth. I still don't know what else I was supposed to say.

There's also an issue in that her reply wasn't really what I was trying to ask. I figured out that one was an issue with my phrasing though, wherein I said "What's the point of X?" while meaning, what's the purpose or goal of doing the thing? That's just not how she took it, which, okay cool I gotta fix that script.

I told her I don't understand what I did exactly, and she suggested I ask some other people to decipher her messages. She also said I need to be more open to a conversation, which just confuses me more because how do I be more open to a conversation when I thought we were having a conversation until she shut down??

I've asked two people so far and they haven't been able to help me understand either. I think without her explaining what about my response made it feel like I was shutting her down, it's not something that can be solved, which terrifies me cuz I'm just gunna do whatever again without realizing.

Anywhore. Here's hoping I can bring it up at therapy next time. I tried to this last time but we hit some other things instead. Oh well.

#pers#journal#angel#tag talking#buried#filler tag so its less likely ppl will dig#cuz i need specifc notes for my memory sake#it was the sleep apnea thing#i wanted to know what the point was if i couldnt get a machine anyway#and she suggested things to do to see if i can get a machine#so yea idk what to do

4 notes

·

View notes

Text

#Pouch filling#Automatic packaging#Vertical form fill seal (VFFS)#Horizontal form fill seal (HFFS)#Multih uch packaging materials#Pouch packaging designs#Pouch packaging industry#Pouch packaging equipmen#ead weigher#Auger filler#Rotary packing machine#Bagging machine#Packaging automation#Pouch sealing#Sachet packing#pouch packing machine#buy pouch packing machine#pouch packing machine seller#pouch packing machine manufecturer#automatic packing machine#FFS packing machine#chips packing machine#namkeen packing machine#snacks packing machine

2 notes

·

View notes

Text

"Why the Seppa Solutions RFC Machine is the Perfect Fit for High-Demand Production Lines"

The Seppa Solutions Rinser Filler Capper (RFC) Machine optimizes packaging efficiency across food, beverage, pharmaceutical, and cosmetic industries. With advanced rinsing, precise filling, and dependable capping, it upholds high standards in product quality, hygiene, and leak prevention. Its modular design enables scalability while an intuitive interface enhances productivity. Engineered for durability, the RFC Machine reduces maintenance needs and downtime, making it ideal for rigorous production demands. Whether ensuring secure filling in food applications or accurate dosing in pharmaceuticals, it delivers a versatile, cost-effective packaging solution that meets strict industry requirements for automation and quality.

#rfc machine manufacturer#rinser filler capper machine manufacturer#rinser machine#rfcmachine#rfc machine#filler capper machine#filler capper#filler machine#non contact filling#non contact filler#non contact filling machine#non contact filling machinery

0 notes

Text

Canola Oil Filling Machine Manufacturer from Ahmedabad

#manufacturer#ahmedabad#exporter#filling machine#oil filling machine#canola oil filling machine#edible oil filling machine#filler machine#servo filling machine#gear pump filling machine#servo pump filling machine

1 note

·

View note

Photo

Water ice making equipment, squeeze-up tubes filler, ice cream cone filling machine, ice cream cup making machine, machine in ice cream factory, processing equipments

#Ice Cream Machine#ice cream factory#ice cream production line#ice cream plant#ice cream filler#ice cream filling machine

2 notes

·

View notes

Text

Single Loader Semi Automatic Capsule Filling Machine

For precise filling and manufacturing of pharmaceutical capsule filling, a single loader semi automated capsule filling machine is ideal. Compared to its manual predecessor, this machine delivers a higher and superior degree of automation. This semi-auto capsule filling machine has had to be your first choice if you’re searching for a machine that fills capsules of various sizes with granules, powders, and pellets.

Our semi-automatic capsule filler complies with GMP standards and is made of premium stainless steel. It can produce up to 25,000 to 45,000 capsules per hour. The machine’s filling table can achieve great dose accuracy with ease. Thanks to the variable speed system that’s installed. This machine’s drug hopper has an in-feed system that eliminates the chance of weight variance.

0 notes

Text

Lady loyall Clinic Services

Lady Loyall Clinic is formed by clinic doctor who has 17-20 years of experience in clinical medicine. Their clinical experience provides innovative solution and expertise to the clinic. Lady Loyall Clinic is a clinic with skin treatments like Hydra Facial in Jaipur, Carbon Laser, Photo Facial, Laser Hair Removal, Botox and Filler Treatments, Microdermabrasion, Chemical Peels, Carbon Laser Treatment, Microdermabrasion Skin Treatment and BB Glow Treatment Clinic in Jaipur. Lady Loyall Clinic is a clinic with healthcare facility which primarily focuses on advanced non surgical cosmetic and rejuvenating facial skin and hair treatment modalities.

Laser Hair Removal in Jaipur

Botox and Filler Treatments in Jaipur

Hydra Facial in Jaipur

Carbon Laser in Jaipur

Photo Facial in Jaipur

BB Glow in Jaipur

BB Glow treatment in Jaipur

BB Glow facial in Jaipur

Microdermabrasion in Jaipur

Chemical Peel Treatment in Jaipur

Best Laser Hair Removal Clinic in Jaipur

Affordable Botox Treatment in Jaipur

Top Hydra Facial Clinics in Jaipur

Carbon Laser Treatment Cost in Jaipur

Best Photo Facial Center Near Me in Jaipur

BB Glow Benefits in Jaipur

Microdermabrasion Skin Treatment in Jaipur

Laser hair removal by Alma machine

Scar acne and tattoo removal by Alma machine

Bridal aesthetic package for brides and grooms

#Laser Hair Removal in Jaipur#Botox and Filler Treatments in Jaipur#Hydra Facial in Jaipur#Carbon Laser in Jaipur#Photo Facial in Jaipur#BB Glow in Jaipur#BB Glow treatment in Jaipur#BB Glow facial in Jaipur#Microdermabrasion in Jaipur#Chemical Peel Treatment in Jaipur#Best Laser Hair Removal Clinic in Jaipur#Affordable Botox Treatment in Jaipur#Top Hydra Facial Clinics in Jaipur#Carbon Laser Treatment Cost in Jaipur#Best Photo Facial Center Near Me in Jaipur#BB Glow Benefits in Jaipur#Microdermabrasion Skin Treatment in Jaipur#Laser hair removal by Alma machine#Scar acne and tattoo removal by Alma machine#Bridal aesthetic package for brides and grooms

0 notes