#Paper Kraft Tape Manufacturers

Explore tagged Tumblr posts

Text

How to Choose the Right Paper Kraft Tape for Your Needs

Paper kraft tape has become a popular choice for packaging and various other applications due to its eco-friendly nature and versatility. However, with a wide range of options available, selecting the right paper kraft tape can be overwhelming. In this blog post, we'll guide you through the key factors to consider when choosing the perfect paper kraft tape for your specific needs.

Understanding Paper Kraft Tape

Paper kraft tape is a type of adhesive tape made from kraft paper, a strong, durable paper known for its tensile strength and tear resistance. It's often coated with a pressure-sensitive adhesive, making it easy to apply and remove.

Key Factors to Consider

Adhesive Strength:

Light-Duty: Suitable for light-duty packaging and sealing applications.

Medium-Duty: Ideal for general-purpose packaging and shipping.

Heavy-Duty: Perfect for securing heavy or bulky items.

Thickness:

Thin: Lightweight and economical, suitable for delicate items.

Medium: Offers a good balance of strength and flexibility.

Thick: Provides maximum strength and durability for heavy-duty applications.

Width:

The width of the tape should be appropriate for the size and shape of the items you're packaging.

Color:

Brown: The classic choice, offering a natural and earthy look.

White: Provides a clean and professional appearance.

Custom Colors: Available for branding and specific applications.

Printing:

Plain: Unprinted tape for a minimalist look.

Printed: Customized with your logo, branding, or messaging.

Tips for Choosing the Right Paper Kraft Tape

Consider the weight and size of the items you're packaging.

Think about the environment in which the package will be stored or shipped.

Determine the level of security and tamper-evidence required.

Choose a tape that is easy to apply and remove.

Opt for a tape that is durable and long-lasting.

MAS Corporation: Your Trusted Partner for Paper Kraft Tape

MAS Corporation is a leading Paper Kraft Tape Manufacturers in Mumbai. Our products are designed to meet the diverse needs of businesses and individuals. Whether you're looking for a simple solution for personal use or a robust tape for industrial applications, we have the perfect product for you.

By carefully considering these factors and working with a reputable supplier like MAS Corporation, you can ensure that you choose the right paper kraft tape for your specific needs.

#Paper Kraft Tape Manufacturers#Paper Kraft Tape Manufacturers in Mumbai#Paper Kraft Tape Manufacturers in Navi Mumbai

0 notes

Text

Panamax top-quality kraft paper tape manufacturers. Find eco-friendly solutions for packaging and sealing needs. Explore reliable suppliers for your business today!

0 notes

Text

#Kraft Paper Tape in Chakan#Kraft Paper Tape Manufacturers in Chakan#Kraft Paper Tape Suppliers in Chakan#Kraft Paper Tape Dealers in Chakan#Kraft Paper Tape in Chakan MIDC#Kraft Paper Tape Manufacturers in Chakan MIDC#Kraft Paper Tape Suppliers in Chakan MIDC#Kraft Paper Tape Dealers in Chakan MIDC#Kraft Paper Tape in Shirwal#Kraft Paper Tape Manufacturers in Shirwal#Kraft Paper Tape Suppliers in Shirwal#Kraft Paper Tape Dealers in Shirwal#Kraft Paper Tape in Shirwal MIDC#Kraft Paper Tape Manufacturers in Shirwal MIDC#Kraft Paper Tape Suppliers in Shirwal MIDC#Kraft Paper Tape Dealers in Shirwal MIDC

0 notes

Note

I love your art so much!!! I've also been starting to paint with gouache, and I'd love to know a little more about your process! What kind of paints do you use, do you sketch first or start with paint, do you paint in layers over several day or all at once?

Hi and thank you! I hope you don't mind me answering this publicly and apologies for length, but:

MY ART PROCESS!

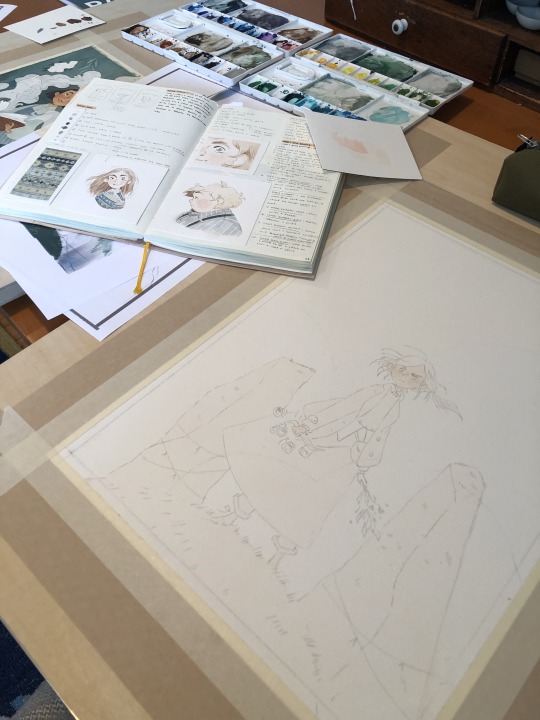

Supplies: I use winsor and newton gouache and arches cold press paper blocks, usually 140 lbs (the lime green ones) and sometimes 300 lbs (the teal green ones). Even though this paper comes pre-stretched in blocks, I actually take the sheets off and stretch them myself because I've found arches' glue isn't as strong as it used to be. This is how you get watercolor paper to lay flat! I recommend youtubing some videos on how to do it -- there's a lot of great tutorials out there. Also, I use princeton brushes, and kraft paper tape and these boards to stretch my paper. (these aren't affiliate links, I just shop at blick)

A word about art supplies: these are the exact tools I use but everyone uses supplies differently and two people with the exact same supplies might get different results! A lot of it is about what works for you and what you like, so I always suggest that gouache/watercolor beginners just buy a few tubes from a couple of different paint companies and some small pieces of paper from different manufacturers to see what you like. Just changing one ingredient in the above has created massively different results for me, but maybe that'll end up being something you'd like! The first step in learning a new medium imo is to play. Just have fun!

ALSO: gouache isn't super light permanent, check your tubes for which ones hold up to sunlight. Here is winsor and newton's color chart explaining which ones will fade when exposed to sunlight -- all manufacturers will give you this. I only use the colors rated A and AA, and I still frame my pieces with UV glass just to be safe. Not all gouache is re-wettable, but winsor and newton is. I just put it in my palettes and refill my palettes if it runs low. AND SOME PAINT IS TOXIC. A lot of paints have cadmium and cobalt in them. I don't use any of the toxic colors, but if you do, make sure you don't eat while working and wash your hands thoroughly afterwards. This information is also usually available on manufacturer's websites. As more people are rejecting cadmium paint, you'll see more tubes labeled things like cadmium-free yellow. This is why. More artists should be aware that their tools can be dangerous. You don't need that many tubes of paint to begin, just a warm and cool red, warm and cool yellow, warm and cool blue, white and black. I have around 50 colors and use 20 regularly. I always mix all my colors myself, and never use straight tube paint. Most of my colors have about 5-6 different tube colors mixed together. If you use re-wettable paint a tube of paint will last you years; even as a professional I only buy new paints every 5 years or so.

Process: I ALWAYS start with a sketch first. Not everyone has to, but because I do illustration work -- where sometimes a client gets input on a drawing -- I always do a lot of preliminary work before I even begin to paint. At this point, even my personal work usually involves the exact same process:

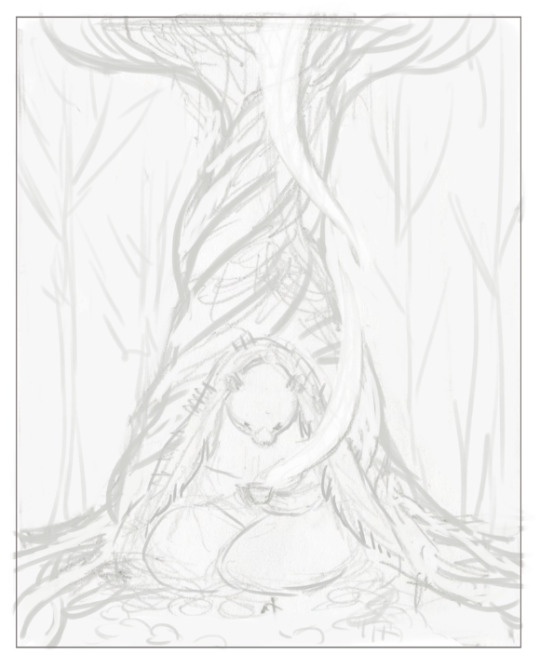

I start with a 3" or so thumbnail that I scan (left; I traced it quickly digtally for clarity to myself here) and then either clean up digitally or print out and clean up traditionally with tracing paper (right):

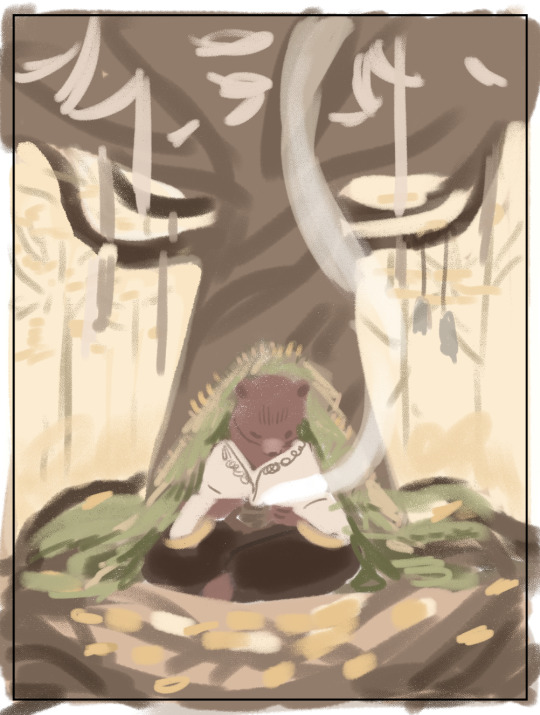

Then I scan the cleaned sketch in and color rough it digitally (left, this was for a gallery show, so no one had to approve my color roughs, so it's messy!) then I transfer my sketch to my paper (with either carbon transfer paper or a light table), stretch my paper, and paint (right):

I obviously changed my mind about the color of the ribbon in the trees, ha, and made everything a lot more vibrant. The benefit again of gallery work is no pre-approval!

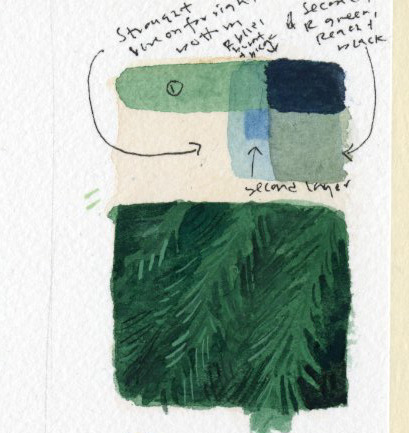

You are correct, I paint in a series of washes, going from lightest to darkest, where I apply the same color beneath all shapes that are the same warmth (cools under all upcoming cools, warms under all upcoming warms). I paint a piece usually in one or two days, depending on complexity. I didn't take pictures of the above painting, but here's a different painting to show you a little bit what I mean:

I painted the peach color under everything (and twice for skin tones), and the gray color of the sky under everything that would be grayish (the rocks, trees, her pants, her skirt, and coat). I do this to stop me from getting darker lines where two different colors butt up against each other, and also for color harmony. I have step by step photos of this in my process stories highlight on my instagram; also check my FAQ and tip highlights for more info on all this stuff. Most pieces take around 25-30 washes before I start adding in the details (sometimes I add in face details early though because if I mess those up it's not worth finishing the rest of the painting! 😅)

All this might seem like a lot of work (...it is) but I do it so that I can show clients previews of the final piece and so I don't have to repaint the finals. I also used to pre-test all of my washes on scrap paper like this:

I still recommend doing this if you're just beginning! But at this point I only do it when testing techniques because I know my paints really well. (the above was my test for the pine boughs in this piece)

Painting by far is the longest part of the process, so I do more work up front to not have to do it twice. Every piece takes about 6-24 hrs of actual work time to produce. Stretching watercolor paper takes about 24 hrs to dry, and because I sell most of my originals in galleries, they need to be flawless, so planning ahead is useful and in the end saves me time.

And to conclude this novel of an explanation, don't be overwhelmed by all the information I've given you! I put it here so that people at various stages of their artistic journey can maybe find something useful in it. But seriously, the first step to learning how to paint whether it's traditionally or digitally is just to have fun. Try it out, see what's working and what isn't, and then try to solve specific issues that you're struggling with. I've been doing this for a loooooong time at this point, but here's my first watercolor piece from when I was re-teaching myself how to paint traditionally nine years ago:

Obviously, I was destined for greatness. Ha, yeah, no. If you scroll back through my tumblr archive, you can see me learning how to use these paints in real time. And keep in mind that I'd been working digitally for years before then, and years before that where I didn't post my work online at all.

So for anyone who needs to hear it: there's no such thing as talent, just hard work, patience, and trying again and again and again...and sometimes again. What I do is a skill and anyone can learn it. Sometimes, progress is slow. I'm 38. I only really feel like my art was half-way decent starting a few years ago, but I've been making art my entire life, and I went to art school at 18. 20 years later I'm kind of figuring it out.

The best advice I can give, whether it's about art or not, is find the thing you love so much that you'll keep at it even when you suck at it, because most skills you'll suck at to begin with -- and perhaps for a long time. I sucked at art for yeeeaaaaarrrrs. On top of the usual learning curve, I struggled with fine motor control and dexterity. But I loved it so much I kept trying every time I failed. If I can do it, so can all of you, no matter what stage of art you're at now, and no matter how old you are.

Anyway, thank you to those still reading this deep in. I wish you all the best on your artistic journey. Art can kick your butt sometimes, but it's also pretty dang rewarding 💛

536 notes

·

View notes

Text

5 Different Types Of Custom Logo Tape

Delivering products to distant locations has become easier today, thanks to the plethora of e-commerce entities. The brick-and-mortar stores are not far behind either. Most physical stores also offer delivery services as long as the customer pays the shipping costs. Thus, such businesses must ensure the perfect packaging of the producers, especially when delivering them to another state or even internationally. Sourcing sturdy tapes to secure the cartons/boxes properly is a requirement that cannot be overlooked. While many consumers buy plain tapes directly from retailers, others may order personalized tapes in bulk by getting in touch with the best custom tape company serving the area Sure, the logo and the message to be included on the tape need to be provided to the company that will use quality tapes to fulfill the needs of their clients. The customer is free to pick and choose the right type of packaging tape to ensure security and perfect shipping despite multiple points in between. It is interesting to note that the best companies known for manufacturing durable and long-lasting tapes with admirable adhesives have the following on offer:

1. Polypropylene Tape- This is one of the most popular tapes that can be customized to suit the customer's requirements. Packagers working with corrugated cardboard boxes find the tapes to be perfect for securing products. It comes with a hot melt adhesive and has a glossy finish making it look most attractive. Moreover, the logo or graphics can be done in three distinct colors without looking smudged. Notably, the senders find this type of tape to be cost-effective when ordered in bulk

2. Custom Paper Tape- This traditional paper tape can keep old dusty cardboard boxes tightly packed and secured. Created out of Kraft paper, the tape is also known for its strength, thus ensuring the perfect packaging of big boxes. The paper is also recyclable, making it an environmentally friendly option. The adhesive does not need melting by heat. It can adhere perfectly to the surface after being wet with water.

3. Custom PVC Tape- Available in standard and heavy-duty options, this tape makes little or no noise when pulling it off the package. The natural rubber adhesive makes it capable of being used on multiple surfaces. The semi-glossy appearance can ensure perfect visibility of the logo and tagline, which is essential for branding. 4. Hi-Tack Freezer Tape- This type of polypropylene tape uses hot, melted adhesive for perfect adhesion to the surface. It is ideal for packaging perishables, pharmaceuticals, and cosmetics that need to be stored at low temperatures. The tapes are available as clear, transparent products or in white. The printed message and cautionary advice may be in a variety of colors.

5. Flatback Tape- This type of tape may be put on and removed without effort. There is no residue left behind, either. It is usually used as a masking, edging tape, or for splicing and binding The custom logo tape has become extremely popular today, especially for B2B purposes.

0 notes

Text

Water Activated Tape Market Analysis: Global Industry Trends and Forecast (2023-2032)

The Water Activated Tape Market is projected to grow from USD 37.76 million in 2024 to USD 70.15 million by 2032, reflecting a compound annual growth rate (CAGR) of 8.05%.

Water-activated tape (WAT), also known as gummed tape, is a durable, eco-friendly packaging solution primarily used in sealing corrugated boxes. Made from kraft paper and reinforced with a starch-based adhesive that becomes sticky when moistened, this tape provides a strong, tamper-evident seal. WAT is gaining popularity due to its superior bonding strength, as it adheres firmly to corrugated surfaces, providing a secure closure that withstands the rigors of shipping. Additionally, it is biodegradable and recyclable, aligning with the growing demand for sustainable packaging materials. Its effectiveness in safeguarding packages makes it a preferred choice for e-commerce and logistics industries.

Here are key challenges in the Water Activated Tape (WAT) market:

Higher Initial Cost: WAT is generally more expensive than traditional pressure-sensitive tapes, which can be a significant deterrent for businesses, especially smaller enterprises with tight budgets.

Specialized Dispenser Requirement: The need for water-activated dispensers to apply the tape adds an extra layer of cost and complexity to operations, making it less attractive for some users.

Limited Market Awareness: Many businesses and consumers are unfamiliar with WAT, resulting in a preference for more commonly used packaging solutions, which slows the adoption rate.

Operational Changes: Transitioning from traditional tapes to WAT requires changes in packaging operations, including training staff to use the new dispensers, which can be a hurdle for companies.

Competition from Eco-Friendly Alternatives: The rise of alternative sustainable packaging options, such as biodegradable plastic tapes, provides stiff competition, potentially limiting WAT’s market growth.

Environmental Sensitivity: WAT’s performance can be influenced by environmental factors like humidity, which is necessary for activating the adhesive, leading to concerns about consistency in varying climates.

Supply Chain Dependence: The production of WAT relies on specific raw materials, such as kraft paper and starch-based adhesives, which could be vulnerable to supply chain disruptions.

Packaging Design Constraints: WAT may not be suitable for all types of packaging designs, particularly those requiring flexible or transparent materials, limiting its applicability in certain industries.

Consumer Resistance to Change: End-users may be resistant to changing their packaging methods, especially if they are accustomed to pressure-sensitive tapes that don’t require additional equipment.

Regulatory Challenges: As sustainability regulations evolve, WAT manufacturers may face challenges in ensuring that their products meet new environmental standards, which could affect market dynamics.

The Water Activated Tape (WAT) market is characterized by a mix of established players and emerging companies, each striving to capture a share of the growing demand for eco-friendly and secure packaging solutions. The competitive landscape is marked by innovation in product offerings, strategic partnerships, and a focus on sustainability. Here’s a competitive analysis of the WAT market:

Competitive Strategies:

Innovation and Product Development: Companies are heavily investing in research and development to create WAT products with superior bonding strength, enhanced durability, and environmental benefits. Innovations such as temperature-resistant tapes and multi-layered reinforcement are key differentiators in the market.

Sustainability Initiatives: With the increasing focus on environmental responsibility, companies are emphasizing the use of biodegradable materials and eco-friendly adhesives. This trend is driven by consumer demand for sustainable packaging solutions, giving companies with strong green credentials a competitive advantage.

Customization and Branding: Offering custom-printed WAT for branding purposes is a growing trend among manufacturers. This allows businesses to enhance their brand visibility and provides an additional value proposition, helping companies differentiate themselves in a competitive market.

Strategic Partnerships and Acquisitions: Leading players are engaging in strategic partnerships and acquisitions to expand their market presence and product offerings. For instance, the acquisition of Better Packages by IPG has allowed for a more comprehensive offering of both tape and dispensing solutions.

Geographical Expansion: Companies are expanding their presence in emerging markets, particularly in Asia-Pacific and Latin America, where the demand for secure and eco-friendly packaging is growing. This geographical diversification helps mitigate risks associated with market saturation in developed regions.

Key Player Analysis

Apollo Industries

Advance Tapes International

Bagla Group

Berry Global, Inc.

Can-Do National Tape

Intertape Polymer Group Inc

Nitto Denko Corporation

Papertec Inc.

Phoenix Inc.

Powerpack LLC

Primetac Corporation

Pro Tapes & Specialties, Inc.

Shurtape

3M Company

Vibac Group S.p.a

World Packaging Co., Inc.

More About Report- https://www.credenceresearch.com/report/water-activated-tape-market

Here are some innovative trends shaping the Water Activated Tape (WAT) market:

Eco-Friendly Materials: Manufacturers are increasingly focusing on using more sustainable and biodegradable materials in WAT production. This includes incorporating recycled kraft paper and eco-friendly adhesives to meet growing consumer demand for green packaging solutions.

Customization and Branding: There's a rising trend in offering custom-printed WAT, allowing businesses to incorporate branding elements such as logos, colors, and messaging directly on the tape. This not only enhances brand visibility but also provides a tamper-evident seal that can deter theft and fraud.

Smart Tape Integration: Some companies are experimenting with integrating RFID chips or QR codes into WAT. This innovation allows for enhanced tracking and inventory management, providing real-time data on package location, handling conditions, and delivery status.

Enhanced Adhesive Formulations: Advances in adhesive technology are leading to the development of WAT with superior bonding strength that performs well across various environmental conditions. These enhanced formulations are designed to improve durability, ensuring that packages remain securely sealed during transit.

Automated Dispensing Systems: The development of advanced, automated dispensing systems is making it easier for businesses to adopt WAT. These systems are designed to improve efficiency, reduce waste, and streamline the packaging process by automatically cutting and applying the tape with precision.

Multi-Layered Reinforcement: To increase the strength and durability of WAT, manufacturers are introducing multi-layered tapes with fiber reinforcement. This innovation provides additional tear resistance, making it ideal for heavy-duty packaging applications.

Temperature-Resistant Tapes: There's a growing trend towards developing WAT that can withstand extreme temperatures. These tapes are designed to maintain their adhesive properties in both hot and cold environments, making them suitable for various industries, including food and pharmaceuticals.

User-Friendly Designs: Innovations in tape dispensers are making WAT more accessible and easier to use. These dispensers are being designed with ergonomic features, such as easy-to-load mechanisms and adjustable water flow settings, to enhance user experience.

Biodegradable Adhesives: Research and development are focused on creating fully biodegradable adhesive formulations that break down more quickly in natural environments, aligning with global sustainability goals and reducing the environmental impact of packaging waste.

Hybrid Tape Solutions: Some companies are developing hybrid tapes that combine the benefits of WAT with other sealing technologies, such as pressure-sensitive adhesives. These hybrid solutions offer the security of WAT with the convenience of traditional tapes, catering to a wider range of packaging needs.

Segments:

Based on Material:

Paper

Polypropylene

Glassine

Polyester

Coated Fabric

Based on End Use:

Food

Pharmaceutical

Cosmetic

Retail

E-commerce

Shipping and Logistics

Construction

Based on Adhesive Side:

Wet Side

Dry Side

Browse the full report – https://www.credenceresearch.com/report/water-activated-tape-market

Browse Our Blog: https://www.linkedin.com/pulse/water-activated-tape-market-projections-global-industry-analysis-opzrf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Premium Reinforced Kraft Sealing Tape for Secure Packaging

Ensuring the safety and integrity of packaged goods is a critical aspect of any business that deals with shipping and logistics. One of the most reliable solutions to achieve this is using premium reinforced kraft sealing tape. This article delves into the myriad benefits, applications, and best practices of using reinforced kraft sealing tape, highlighting its pivotal role in secure packaging.

What is Reinforced Kraft Sealing Tape?

Reinforced kraft sealing tape is a type of packaging tape that combines the natural strength of kraft paper with reinforced filaments or fibers. These fibers, often made of fiberglass or polyester, provide additional tensile strength, making the tape significantly more durable than standard packaging tapes. This combination ensures that the tape can withstand heavy loads and resist tearing, ensuring that packages remain sealed and secure throughout their journey.

Benefits of Using Reinforced Kraft Sealing Tape

There are several compelling reasons to choose reinforced kraft sealing tape over other sealing solutions:

Strength and Durability: The reinforcement fibers within the tape provide exceptional strength, preventing the tape from tearing or breaking under stress. This is especially important for heavy or bulky packages.

Eco-Friendliness: Kraft paper is biodegradable and recyclable, making this type of tape an environmentally responsible choice. Many reinforced kraft tapes are also designed to be water-activated, reducing the need for plastic-based adhesives.

Enhanced Security: The robust nature of the tape makes it difficult for tampering or unauthorized opening without leaving visible evidence. This is crucial for maintaining the integrity of the contents.

Temperature Resistance: Reinforced kraft sealing tape performs well under a wide range of temperatures, ensuring that it maintains its adhesion and integrity in various shipping conditions.

Applications of Reinforced Kraft Sealing Tape

Reinforced kraft sealing tape is versatile and finds applications across numerous industries:

E-commerce and Retail: Securely seals boxes and packages, ensuring that products reach customers in perfect condition.

Manufacturing: Ideal for bundling and securing heavy parts or materials during transport.

Food and Beverage: Used for sealing cartons and boxes, ensuring that perishable items are securely packaged.

Pharmaceuticals: Provides an added layer of security for sensitive and high-value shipments.

How Reinforced Kraft Sealing Tape Enhances Packaging Security

The enhanced security features of reinforced kraft sealing tape are pivotal for industries where package integrity is paramount. The tape's strength and durability make it resistant to punctures, tears, and breakage, which are common issues with standard tapes. Additionally, the water-activated adhesive used in many reinforced kraft tapes creates a bond that is difficult to peel off cleanly, providing a clear indication if tampering has occurred.

Types of Reinforced Kraft Sealing Tape

There are various types of reinforced kraft sealing tape available, each designed to meet specific needs:

Fiberglass Reinforced: Offers maximum strength and is ideal for heavy-duty applications.

Polyester Reinforced: Provides a balance between strength and flexibility, suitable for a wide range of packaging needs.

Water-Activated: Requires water to activate the adhesive, creating a strong, tamper-evident seal.

Comparison with Other Types of Sealing Tape

Compared to standard packing tapes, duct tapes, and other sealing solutions, reinforced kraft sealing tape stands out for its strength, durability, and environmental benefits. Standard packing tapes may suffice for light-duty applications, but they often fail under heavier loads. Duct tapes, while strong, are typically not recyclable and can leave a sticky residue. Reinforced kraft sealing tape combines the best of both worlds—strength and sustainability.

Choosing the Right Reinforced Kraft Sealing Tape

Selecting the right reinforced kraft sealing tape depends on several factors:

Weight of the Package: Heavier packages require stronger reinforcement, such as fiberglass.

Type of Adhesive: Water-activated adhesives are ideal for high-security needs.

Environmental Considerations: Opt for eco-friendly options that align with your company's sustainability goals.

Cost: While premium reinforced kraft tapes may be more expensive initially, their durability and effectiveness often lead to cost savings in the long run.

Environmental Impact of Reinforced Kraft Sealing Tape

One of the significant advantages of reinforced kraft sealing tape is its positive environmental impact. Kraft paper is made from natural fibers and is biodegradable and recyclable, reducing the environmental footprint of packaging materials. Furthermore, many reinforced kraft tapes use water-activated adhesives, eliminating the need for synthetic, plastic-based adhesives that can be harmful to the environment.

Innovations in Reinforced Kraft Sealing Tape

The packaging industry continually evolves, and reinforced kraft sealing tape is no exception. Recent innovations include the development of stronger, more flexible reinforcement fibers, and adhesives that provide even greater security and ease of use. Additionally, manufacturers are exploring ways to make the production of these tapes more sustainable, further reducing their environmental impact.

Case Studies: Successful Use of Reinforced Kraft Sealing Tape

Real-world examples illustrate the effectiveness of reinforced kraft sealing tape. For instance, a major e-commerce company switched to fiberglass reinforced kraft tape for their heavy-duty shipments, resulting in a significant reduction in package damage and customer complaints. Similarly, a food and beverage company found that using water-activated reinforced kraft tape improved the security and integrity of their shipments, ensuring that perishable goods arrived in optimal condition.

How to Apply Reinforced Kraft Sealing Tape Correctly

Applying reinforced kraft sealing tape correctly is essential to maximizing its benefits:

Surface Preparation: Ensure that the surface is clean, dry, and free of dust and debris.

Application: For water-activated tape, moisten the adhesive side with a sponge or a water-activated tape dispenser. For pressure-sensitive tapes, apply firm, even pressure along the tape's length.

Sealing: Press the tape firmly to the surface, ensuring complete adhesion without air bubbles or gaps.

Common Mistakes to Avoid When Using Reinforced Kraft Sealing Tape

To ensure optimal performance, avoid these common mistakes:

Insufficient Moistening: For water-activated tape, not moistening the adhesive properly can lead to weak seals.

Improper Storage: Store the tape in a cool, dry place to maintain its adhesive properties.

Incorrect Application: Applying the tape too loosely or not pressing firmly can result in inadequate sealing.

Reinforced Kraft Sealing Tape for E-commerce Packaging

In the rapidly growing e-commerce sector, the need for secure and reliable packaging solutions is paramount. Reinforced kraft sealing tape offers a robust solution that ensures packages reach customers without damage or tampering. Its strength and durability make it ideal for handling the rigors of shipping and handling, providing peace of mind for both sellers and buyers.

Cost-Effectiveness of Reinforced Kraft Sealing Tape

While reinforced kraft sealing tape may have a higher upfront cost compared to standard tapes, its durability and reliability often result in long-term cost savings. By reducing the risk of package damage and the need for additional protective materials, businesses can lower their overall packaging expenses. Additionally, the enhanced security features can minimize losses due to theft or tampering.

FAQs about Reinforced Kraft Sealing Tape

Can reinforced kraft sealing tape be recycled? Yes, reinforced kraft sealing tape is typically made from recyclable materials, making it an environmentally friendly choice.

Is reinforced kraft sealing tape suitable for heavy packages? Absolutely. The reinforcement fibers provide exceptional strength, making it ideal for heavy-duty applications.

How does water-activated reinforced kraft tape work? Water-activated tape requires moisture to activate the adhesive. Once moistened, it forms a strong bond with the package surface.

Does reinforced kraft sealing tape leave a residue? No, unlike many plastic-based tapes, reinforced kraft sealing tape does not leave a sticky residue, making it easier to handle and more environmentally friendly.

Can I use reinforced kraft sealing

0 notes

Text

Kraft Paper Tape Market Size, Global Industry Trend Analysis and Forecast 2024-2030

This report is a detailed and comprehensive analysis for global Kraft Paper Tape market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided.

The overall report focuses on primary sections such as – market segments, market outlook, competitive landscape, and company profiles. The segments provide details in terms of various perspectives such as end-use industry, product or service type, and any other relevant segmentation as per the market’s current scenario which includes various aspects to perform further marketing activity. The market outlook section gives a detailed analysis of market evolution, growth drivers, restraints, opportunities, and challenges, Porter’s 5 Force’s Framework, macroeconomic analysis, value chain analysis and pricing analysis that directly shape the market at present and over the forecasted period. The drivers and restraints cover the internal factors of the market whereas opportunities and challenges are the external factors that are affecting the market. The market outlook section also gives an indication of the trends influencing new business development and investment opportunities.

The Primary Objectives in This Report determine the size of the total market opportunity of global and key countries,assess the growth potential for Kraft Paper Tape and competitive factors affecting the marketplace,forecast future growth in each product and end-use market. Also,this report profiles key players in the global Kraft Paper Tape market based on the following parameters - company overview, sales quantity, revenue, price, gross margin, product portfolio, geographical presence, and key developments.

Kraft Paper Tape market is split by Type and by Application. For the period 2019-2030, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets.

Market segment by region, regional analysis covers North America (United States, Canada, and Mexico),Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe),Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa).

The report provides insights regarding the lucrative opportunities in the Kraft Paper Tape Market at the country level. The report also includes a precise cost, segments, trends, region, and commercial development of the major key players globally for the projected period.

The Kraft Paper Tape Market report comprehensively examines market structure and competitive dynamics. Researching the Kraft Paper Tape market entails a structured approach beginning with clearly defined objectives and a comprehensive literature review to understand the current landscape. Methodologies involve a mix of primary research through interviews, surveys, and secondary research from industry reports and databases. Sampling strategies ensure representation, while data analysis utilizes statistical and analytical techniques to identify trends, market sizing, and competitive landscapes. Key areas of focus include trend analysis, risk assessment, and forecasting. Findings are synthesized into a detailed report, validated through peer review or expert consultation, and disseminated to stakeholders, with ongoing monitoring to stay abreast of developments.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Cardboard Boxes - Buy Carton Boxes directly from Manufacturer in India - Papers Gallery

Carton packaging boxes come in various shapes, sizes, and materials to accommodate a wide range of products and shipping needs. Here's a breakdown of some common types:

Corrugated Boxes: These are perhaps the most widely used type of carton packaging boxes for shipping. They are made of corrugated cardboard, which consists of a fluted inner layer sandwiched between two flat outer layers. Corrugated boxes provide excellent strength and cushioning, making them ideal for protecting fragile items during transit

Folding Cartons: These are lightweight, non-corrugated boxes typically used for retail packaging rather than shipping. They are often made of solid bleached sulfate (SBS) board or solid unbleached sulfate (SUS) board and are suitable for packaging items like cosmetics, food products, and small electronics.

Rigid Boxes: Also known as set-up boxes, rigid boxes are made of thick paperboard and offer superior durability and aesthetics. They are commonly used for luxury packaging, such as high-end electronics, jewelry, and cosmetics, and are not typically used for shipping.

Mailer Boxes: Mailer boxes are designed for easy assembly and are often used for e-commerce shipping. They usually feature a self-locking or adhesive closure and are available in various sizes to accommodate different products.

Heavy-Duty Boxes: These boxes are designed for shipping heavy or bulky items. They are constructed from extra-strong corrugated cardboard and may feature reinforced edges or double-walled construction for added strength.

Custom Boxes: For unique or specialized packaging needs, custom boxes can be designed and manufactured to exact specifications. This allows businesses to create packaging that perfectly fits their products and brand image.

When choosing carton packaging boxes, consider factors such as the size and weight of your products, the level of protection required during shipping, and any specific branding or aesthetic considerations. When selecting carton packaging boxes for shipping, there are a few key factors to consider to ensure your items are protected during transit:

Size: Choose a box size that fits your items snugly. Too much extra space can lead to movement and potential damage during shipping, while a box that's too small may not provide enough protection.

Strength: Opt for corrugated cardboard boxes, as they offer better durability and crush resistance compared to regular cardboard boxes. Consider the weight and fragility of your items when selecting the box strength.

Closure: Select boxes with secure closures, such as flaps that can be taped shut or interlocking tabs. This ensures that the box remains closed during transit and prevents items from falling out.

Padding: Use appropriate padding materials, such as bubble wrap, packing peanuts, or kraft paper, to cushion your items and prevent them from shifting inside the box.

Labeling: Clearly label the boxes with shipping information, including both the sender's and recipient's addresses, as well as any handling instructions or fragile stickers.

Environmental Considerations: If possible, choose boxes made from recycled materials and that are recyclable themselves to minimize environmental impact.

By considering these factors, you can select the most suitable carton packaging boxes for shipping your items safely and securely.

1 note

·

View note

Text

Which Custom Tape Should Your Business Use?

In the world of packaging and branding, choosing the right custom tape for your business is a crucial decision. Custom tape not only serves the practical purpose of sealing packages but also acts as a powerful branding tool. With a plethora of options available in the market, selecting the tape that aligns with your business needs and objectives is essential. In this article, we’ll explore the factors to consider when choosing custom tape and highlight some popular options.

Which custom tape to use for your business?

In this article, Mr Gaurav Jalan, Founder of Packman Packaging India’s leading custom tapes manufacturer for retail and e-commerce businesses shares ideas for choosing custom tape. Let us what it is about.

Consider Your Branding: Custom tape is an excellent opportunity to extend your brand identity beyond the confines of your product. Consider the colors, logo, and overall aesthetic of your brand when designing custom tape. Whether you opt for a bold and eye-catching design or a subtle and sophisticated look, the tape should reflect the essence of your brand. Material Matters: The material of the custom tape plays a crucial role in its functionality and appearance. Common materials include polypropylene, PVC, and paper. Polypropylene is durable and cost-effective, making it a popular choice for general packaging. PVC offers a higher level of strength and is resistant to moisture and chemicals. Paper tape, on the other hand, is eco-friendly and provides a rustic appeal. Choose a material...

Read Here: https://www.packman.co.in/blog/buy-custom-logo-printed-tape/

Gaurav Jalan, CEO & Director, Packman Packaging

Mr. Gaurav Jalan is the Founder and Director of Packman Packaging, one of the largest Indian packaging company that has been serving some of the world’s eminent technology, pharmaceutical, retail, fast-moving consumer goods, food, courier, publication, Jewellery, fashion, e-commerce organizations for the past 30 years.

A brilliant academic, a good graphic designer and a graduate from India’s top management institutes, Mr. Jalan is a visionary businessman and an eminent spokesperson on matters related to the Indian Packaging industry. Under the leadership of Mr Gaurav Jalan, Packman.co.in (Packman’s official website) became India’s first e-commerce store for packaging solutions in the year 2002 (5 years before Flipkart was launch).

Today, Packman Packaging manufactures more than one lakhs of corrugated rolls, corrugated boxes, high-quality bubble sheets, safety/courier bags and more from it state of art manufacturing unit, located in Delhi NCR region. The manufacturing unit uses advanced packaging machinery and printing technology that ensures Packman’s customers get fast and efficient delivery, high-quality brand representation through their product packaging.

Packman Packaging Top Offerings

Custom Corrugated Boxes – Packman Packaging is one of the largest manufacturers of 3 ply corrugated boxes in India, 5 ply corrugated boxes, and 7 ply corrugated boxes along with corrugated rolls in India. At Packman’s online store you can customize (with your logo, graphics, shipping instruction) and buy corrugated boxes at the Best Manufacturer Rates and at Best Quality, Get PAN India Delivery, Free Shipment, Discounts on Bulk orders

Tamper Proof Courier Bags – You can buy Tamper Proof 60 Microns Security Courier Bags and 50 microns security at the Best Manufacturer Rates and at Best Quality, Get PAN India Delivery, Free Shipment, Discounts on Bulk Orders.

Stand Up Pouches – You can buy all kinds of customized and non-customized Stand-Up Pouches at the best wholesaler Rates and at the Best Qualities. Some of best seller stand up pouches at Packman store are:

Transparent Pouches with Zip Lock Kraft Finish Stand Up Pouches with Zip Lock Custom Printed Stand Up Pouches Oval Window Stand Up Pouches. Silver Standup Pouches with Zip Lock Stand Up Pouches with Nozzle for Handwash, Ketchup and for Food Paste packaging.

#buy corrugated boxes#packman packaging#buy courier bags online#corrugated box manufacturers#corrugated boxes#packmanpackaging#buy corrugated boxes online#tamper proof courier bags#corrugated box suppliers#corrugated box wholesalers#flipkart printed tapes#best brown tapes in india#best customized tape manufacturer india#buy custom logo printed tapes#buy brown tapes online

0 notes

Text

Understanding the Benefits of Self-Seal Paper for Shipping and Mailing

Self-seal paper, also known as cohesive paper, is a type of paper that has an adhesive coating applied to one side, allowing it to stick to itself without the need for additional tape or glue. This innovative packaging solution offers a range of benefits for businesses and consumers alike, particularly when it comes to shipping and mailing items.

One of the primary benefits of self-seal paper for shipping and mailing is its durability. Self-seal paper is tear-resistant and water-resistant, providing excellent protection for items during transit. This is particularly important for fragile items such as electronics, glassware, and ceramics, which require extra protection during shipping to prevent damage.

Another key benefit of self-seal paper is its eco-friendliness. Unlike traditional packaging materials such as plastic and bubble wrap, self-seal paper is made from 100% recyclable materials and is biodegradable. This means that it can be recycled or composted after use, reducing the amount of waste that ends up in landfills. This is an important consideration for businesses that are looking to reduce their environmental impact and meet the demands of environmentally conscious consumers.

Self-seal paper is also a cost-effective option for businesses. It is lightweight and easy to handle, which can help to reduce shipping costs. It is also customizable, allowing businesses to print their logos or other branding on the paper for a professional look. This can help to enhance brand recognition and make a positive impression on customers.

In addition to its cost-effectiveness, self-seal paper is also a convenient option for both businesses and consumers. It is easy to use, with no need for additional tape or glue, and can be quickly and easily applied to packages. This can help to streamline the shipping and mailing process, saving time and effort for businesses and ensuring that packages are delivered on time.

Self-seal paper is also safer and more user-friendly than other packaging materials. Unlike plastic packaging, which can be sharp and pose a risk of injury, self-seal paper is made from paper and is therefore safer to handle. This can help to reduce the risk of accidents and injuries during the packaging and shipping process. honeycomb kraft paper

Another benefit of self-seal paper is its versatility. It can be used for a wide range of items, from small and delicate items to larger and more bulky products. This makes it an ideal choice for businesses of all sizes and industries, from e-commerce retailers to manufacturers and wholesalers.

Overall, self-seal paper is an innovative and sustainable packaging solution that offers a range of benefits for businesses and consumers alike. Its durability, eco-friendliness, cost-effectiveness, convenience, safety, and versatility make it an attractive option for shipping and mailing items of all kinds. As more businesses adopt self-seal paper as their preferred packaging solution, we can expect to see a positive impact on the environment and on the efficiency and profitability of the shipping and mailing industry.

For More Info: packing slip envelopes

safety caution tape

bopp packing tapes

0 notes

Text

#Kraft Paper Tape in Mumbai#Kraft Paper Tape Manufacturers in Mumbai#Kraft Paper Tape Suppliers in Mumbai#Kraft Paper Tape Dealers in Mumbai

0 notes

Text

INDUSTRIAL ADHESIVE TAPE

As one of the professional industrial tape manufacturers in China, Egret supplies many types of industrial adhesive tape. Particularly, applied to refrigerator, air conditioning, ducting work, building, insulation industries. Not to mention our advantage of coating abilities, we also have capabilities to slit, cut, rewind, die cutting and other converting services. Important to realize, our strong adhesive tape is aluminum foil tape, PE tape, po film, PET tape, MOPP/TPP tape, PVC non-adhesive tape.

Choose Egret as Your Industrial Adhesive Tape Supplier

Choose Egret as Your Industrial Adhesive Tape Supplier. Egret mfg offers many kinds of adhesive tapes, including Aluminum foil tape, PE white tape, PET blue tape, Masking paper tape, Cloth tape, PVC air conditioner tape, Vinyl electrical tape, Double-sided tissue tape, TPP/MOPP tape, Foam tape (VHB,PE,PU, EPDM, NBR, PVC,EVA,etc), BOPP packing tape, Kraft paper tape, PE protective film, PVC duct tape, etc. We mix and produce our own formula adhesive to save cost & improve adhesion.

Moreover, Egret has 10 adhesive coating lines. Likewise, 15 slitting machines with huge capacity. Additionally, our products certified with UL, ROHS, REACH, BS, CE, etc.

Furthermore, we’re Top 1 seller for aluminum foil tape in refrigerator industry in China. Especially, Egret is a golden supplier of Samsung, Toshiba, Haier, Midea, Arcelik, Hisense, etc

Features Of Industrial Adhesive Tape

What are the benefits & features of Egret adhesive tape?

Egret adhesive tape can replace of the bolts and nuts, to make it clean looking.

High adhesion and excellent tack

Good aging resistance for both indoor & outdoor use

Joints/seams sealing against moisture and vapor barrier

Easy hand tear for workers to use on-site

Excellent heat & light reflecting of aluminum foil backing

Combination of baking material ensures high flexibility and conformability

Extremely easy for hand-tear, easy-used by workers

Neat and invisible looking to be excellent alternative to metal fasteners, welding

0 notes

Text

Pluses of Sourcing The Flatback Tape

Finding the right tape for securing packages and binding items is not challenging. It is essential to source the best possible product to obtain its benefits. Indeed flatback tape comes with many pluses that cannot be ignored. It is essential to inquire about the properties and only be convinced when the concerned product matches the specifications. It is also heartening to know that the best tapes are equipped with a top-notch thermoplastic rubber adhesive that is extremely strong yet amazingly flexible. Such Kraft paper tapes are suitable for all kinds of packaging, splicing, and tabbing applications. Moreover, the flatback product resists spills as it is resistant to liquids. Further, it comes with pressure adhesive backing that allows it to lay flat on the surface it covers. It limits curling and abrasion considerably, thus keeping the package intact. It is regarded as a standard shipping tape and is used extensively worldwide.

Ordering the tape in bulk can make it cost-effective. It helps to understand that almost every courier company and e-commerce entities rely heavily on such tapes that are the number1choice for shipping light and bulky packages to far-off destinations. The packaging industry reports its efficacy in all related sectors with the following advantages driving their sales positively:

· Unique Features- The versatile features make it a must-have for every business owner that hopes to make its presence felt. Being solvent, with effective resistance, the tendency to curl as needed, strength, and easy residue removal make it a unique product that can be used easily when the demand for packaging large volumes of containers becomes imperative. The ability of the tapes to remain intact in outdoor surroundings adds to its popularity. The logistics, as well as the construction industry, relies heavily on the use of flatback tapes

· Sustainable Solution- It is important to remember that this type of tape is made from Kraft paper. This makes the product biodegradable and recyclable. The demand has increased as a result. The buyers feel compelled to use it because it is not remotely connected to plastic. More and more customers are eager to use these tapes to remain compliant with government regulations. The end-user can also comply with the waste disposal standards by opting for paper adhesive tapes.

· Ideal Alternative- The advancement of technology has given rise to the manufacture of multiple alternatives that may be used for packaging. With the packaging industry developing incredibly fast, the popularity and demand for flatback tapes have soared, paling the other alternatives completely. Apart from such packages being used by retailers and kitting companies, the tape has benefited the healthcare product delivery, aerospace, consumer electronics, and automotive industries by improving their customer satisfaction index.

There are challenges galore in every sector today. The packaging industry is not immune to it either. One of the best ways to beat the competition for the sellers is to invest in custom packaging tape that not only keeps the content safe but also creates brand awareness at the same time.

0 notes

Text

Printed kraft paper tape printing technology introduction

Printed kraft paper tape printing technology introduction

Nowadays, printed kraft paper tape are more and more widely applying into various industry fields. Its application is very convenient, but its printing process is not easy. To the kraft paper tape manufacturer, there are some small details should pay attention to.

1. Since the color of light brown ink is soft and dark, sometimes it is difficult to achieve the desired effect of light brown on the printed kraft paper tape. If necessary, you can add a little white ink into the brown ink, it will help to achieve the desired soft tone or light color. This is a useful experience from the kraft paper tape manufacturer.

2. Normally, flexographic printing is better than offset printing machine for full-scale printing on kraft paper tape. Because the surface of printed kraft paper tape is rough, the texture is soft, the ink absorption is strong. So, the color of the printed kraft paper tape is not glossy, and the printing ink will pull down the paper fiber (also known as the paper wool).

3. As for most kraft paper tape manufacturer, during the production process of paperboard, the raw printed kraft paper tape is easy to produce dust due to its loose, porous and large volume. Therefore, the kraft paper tape manufacturer should pay attention to prevent and reduce the dust and avoid harm people and environment.

4. In post press die-cutting process, because the special structure of primary color printed kraft paper tape, its strength is higher and its fiber characteristics are predictable. So it has better processing properties such as embossing, die cutting and die engraving. However, for the primary color fiber with high strength and toughness, we must make the kraft paper tape pass through deep indentation line to avoid rebound.

5. The resin adhesive with high solidity and viscosity is suitable for low temperature bonding. It needs to be cooled before it attach to printed kraft paper tape. Moreover, it can not penetrate into the paperboard in large quantity. The traditional hot melt adhesive is also suitable for kraft paper tape and kraft paper after polyester polishing, and the effect is better. Many kraft paper tape manufacturers are using these two kinds of adhesives. Due to its light weight, kraft paper tape is suitable for high-speed box pasting and folding machine.

1 note

·

View note

Link

At Holland Manufacturing, we deliver quality at scale with the sophisticated manufacturing controls and production equipment of a global enterprise, backed by continuous research and testing conducted in-house.

#Tape Manufacturing#Total Packaging Solution#Water Activated Tape#Reinforced Kraft Papers#Carpet Film

1 note

·

View note