#Normung

Explore tagged Tumblr posts

Text

50 Jahre Normenvertrag

Deutschland: „…Normen schaffen Verbindlichkeit und Verlässlichkeit – in volatilen Zeiten mehr denn je. Der Normenvertrag bildet die Grundlage dafür, dass DIN gemeinsam mit Expertinnen und Experten aus Wirtschaft, Wissenschaft, Verwaltung und Zivilgesellschaft Regeln erarbeitet, die Sicherheit, Innovation und Wettbewerbsfähigkeit sicherstellen und fördern. Gerade in diesem Jubiläumsjahr wird die…

#DIN#Grundlage#Normenvertrag#Normung#Normungsorganisation#Rahmenbedingungen#Verbindlichkeit#Vrlässlichkeit#Wirtschaft

0 notes

Text

Not to be confused with DIN freaks, who are very conservative in the non-political sense.

"DNI: freaks" do you realize how conservative you look

109K notes

·

View notes

Text

All About Flange-Udhhyog

Q1: What are the different types of flanges, and how do I choose the right one for my application?

A1: There are several types of flanges, including:

Weld Neck Flanges: Designed for high-pressure applications and welded to the pipe, providing a strong connection.

Slip-On Flanges: Slide over the pipe and are welded both inside and outside, ideal for low-pressure applications.

Blind Flanges: Used to close the end of a piping system, preventing the flow of fluids.

Socket Weld Flanges: For small-diameter pipes, where the pipe is inserted into the flange and welded.

Lap Joint Flanges: Used with a stub end, allowing for easier disassembly.

To choose the right flange, consider the application pressure, temperature, pipe size, and the type of connection required.

Q2: How do flange standards vary by country, and what should I know about them?

A2: Flange standards can vary significantly between countries. For instance:

ANSI (American National Standards Institute): Commonly used in the USA, focusing on pressure ratings and dimensions.

DIN (Deutsches Institut für Normung): Widely used in Europe, specifying metric dimensions and pressure ratings.

JIS (Japanese Industrial Standards): Used in Japan, similar to ANSI but with different specifications.

When selecting flanges, be aware of the applicable standards in your region to ensure compatibility with existing piping systems.

Q3: What materials are commonly used for flanges, and what are their advantages?

A3: Common materials for flanges include:

Mild Steel (MS): Cost-effective and suitable for low-pressure applications.

Stainless Steel: Corrosion-resistant and ideal for high-pressure and high-temperature applications.

Carbon Steel: Offers strength and durability for industrial applications.

Alloy Steel: Used for specialized applications requiring high strength and resistance to wear and corrosion.

The choice of material should be based on the operating environment, pressure, temperature, and the medium being transported.

Q4: How can I prevent leakage in flange connections?

A4: To prevent leakage in flange connections:

Use Quality Gaskets: Select the right gasket material based on the application and ensure proper installation.

Ensure Proper Alignment: Misalignment can lead to leaks; ensure that flanges are correctly aligned before tightening.

Tighten Bolts Uniformly: Follow the manufacturer's specifications for bolt torque to ensure even pressure distribution.

Regular Maintenance: Inspect flanges periodically for wear or damage and replace gaskets as necessary.

Q5: What are the most common applications for MS flanges in various industries?

A5: MS flanges are commonly used in:

Oil and Gas: Connecting pipelines and equipment.

Water Supply: Used in municipal and industrial water systems.

Construction: In various structural applications for strength and support.

Manufacturing: In machinery and equipment to facilitate fluid flow and pressure control.

Q6: How does the price of flanges fluctuate in the current market?

A6: The price of flanges can fluctuate based on several factors:

Material Costs: Increases in raw material prices can lead to higher flange costs.

Supply Chain Issues: Disruptions in manufacturing or transportation can affect availability and pricing.

Market Demand: Increased demand in specific industries can drive prices up.

Regularly monitoring market trends and supplier prices can help you anticipate changes.

Q7: What are the benefits of using stainless steel flanges over mild steel flanges?

A7: Benefits of using stainless steel flanges include:

Corrosion Resistance: Stainless steel can withstand harsh environments, making it suitable for chemical and coastal applications.

Strength and Durability: Offers better strength-to-weight ratios and longevity compared to mild steel.

Aesthetic Appeal: Stainless steel has a polished finish that is visually appealing in exposed applications.

However, stainless steel flanges are typically more expensive than mild steel flanges.

Q8: How do I determine the right flange size for my piping system?

A8: To determine the right flange size:

Measure the Pipe Diameter: Determine the outer diameter of the pipe.

Check Pressure Ratings: Ensure that the flange matches the pressure rating of the piping system.

Refer to Standards: Use ANSI, DIN, or other relevant standards to find the corresponding flange dimensions for your pipe size and pressure requirements.

Q9: What is the significance of flange pressure ratings?

A9: Flange pressure ratings indicate the maximum pressure a flange can withstand at a specified temperature. They are essential for:

Safety: Ensuring that the flange can handle the operational pressures without failing.

Compatibility: Matching flanges with piping and equipment rated for similar pressures prevents leaks and accidents.

Understanding pressure ratings helps in selecting appropriate flanges for your application.

Q10: Are there any recent advancements in flange manufacturing technology?

A10: Recent advancements in flange manufacturing technology include:

3D Printing: Allowing for rapid prototyping and customized designs.

Improved Materials: Development of new alloys that enhance corrosion resistance and strength.

Automation: Use of automated machinery for precision and efficiency in flange production.

Quality Control Technologies: Enhanced inspection techniques using non-destructive testing methods to ensure product integrity.

These advancements contribute to better quality, reduced production times, and cost savings in flange manufacturing.

#Flanges#MSFlanges#FlangeManufacturing#PipingSolutions#IndustrialEquipment#PipingIndustry#FlangeDesign#FlangeStandards#FlangeApplications#MechanicalEngineering#MildSteel#StainlessSteel#CarbonSteel#AlloySteel#OilAndGas#Construction#WaterSupply#Manufacturing#Engineering#ManufacturingInnovation#IndustrialSupply#QualityControl#SafetyFirst#TechAdvancements

5 notes

·

View notes

Text

Procura aço DIN 1.2631 (Chipper Knife) em #Portugal? O aço DIN 1.2631 é um aço para ferramentas de trabalho a frio com alto teor de carbono e alto teor de cromo, usado principalmente na fabricação de ferramentas de corte, punções e matrizes. Também é conhecido por outras designações como X50CrMoW9-1-1 ou aço AISI A8.

A designação "DIN 1.2631" refere-se ao grau de aço de acordo com o Deutsches Institut für Normung (DIN), que é o Instituto Alemão de Normalização. O sistema DIN é comumente usado na Europa para designar tipos de aço específicos.

A EDELSTAHL VIRAT IBÉRICA é o maior stock e fornecedor de Aços Grau 1.2631. Nós fornecemos Metal Steel Grau 1.2631 STEEL ALLOY TOOL PLATE é um molde de aço, usado em moldes de extrusão, moldes de fundição a quente. como produção de alumínio, molde de corte de alumínio ….

Consulte a nossa equipa que o ajudará na consulta do aço DIN 1.2631 (Faca Picadora) também para locais como… #Valbom #Canidelo #SenhoradaHora #OliveiradoDouro #Ribeira #Bolhão #Guimarães #Braga

PARA SABER MAIS >> https://moldsteel.eu/steel-products/chipper-knife-steel/

Chat WhatsApp: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#Valbom#Bolhão#Ribeira#Guimarães

2 notes

·

View notes

Text

How did you find DIN 1.2714 Steel in India? If you need a tool steel that can handle high temperatures, pressures, and stresses, look no further than DIN 1.2714 Steel. It’s the best in class for close die forgings.

DIN 1.2714 is a Hot Work Tool Steel that conforms to the German DIN (Deutsches Institut für Normung) standard. It is also known by other designations such as 55NiCrMoV7 or L6 in different international standards.

DIN 1.2714 (DB6 Steel) is a tool steel grade that is commonly used in the manufacturing of forging dies and plastic molds. It belongs to the group of hot work tool steels and is known for its high-temperature stability, wear resistance, and toughness. DIN 1.2714 (DB6 Steel) is often used in applications where the material needs to withstand elevated temperatures during the manufacturing process, such as in forging and die-casting operations.

The chemical composition of DIN 1.2714 (DB6 Steel) typically includes elements such as:

Carbon (C): 0.50-0.60% Silicon (Si): 0.10-0.40% Manganese (Mn): 0.60-0.90% Chromium (Cr): 1.00-1.50% Nickel (Ni): 1.00-1.50% Molybdenum (Mo): 0.20-0.30% Vanadium (V): 0.10-0.30%

These alloying elements contribute to the steel's properties, such as hardness, strength, and heat resistance. The specific composition may vary slightly depending on the manufacturer and the standard to which it adheres.

Virat Special Steels is the largest stockiest and supplier of #DB6/ DIN 2714 in flat, square and round bar. We provide steel in all sizes as your requirements.

To know about more specific details of DIN 1.2714 ( DB6 Steel ), please visit the website. https://www.viratsteels.com/din-2714.html https://www.viratsteels.com/db6.html

Email us: [email protected] Call Us Now: +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#db6 steel#db6#din 2714#aisil6#tool steel suppliers#forging#close die forging

2 notes

·

View notes

Text

Understanding Hydraulic Hose Fittings: Types, Applications, and Selection Guide

Hydraulic hose fittings are essential components in fluid power systems, ensuring secure connections between hoses, tubes, and hydraulic machinery. These fittings play a crucial role in maintaining system integrity, preventing leaks, and ensuring efficient power transmission in various industrial, agricultural, and construction applications.

Choosing the right hydraulic hose fittings is critical for system performance, safety, and longevity. This guide explores the different types of fittings, their applications, materials, and key factors to consider when selecting the best option for your hydraulic system.

Types of Hydraulic Hose Fittings

1. Permanent vs. Reusable Fittings

Permanent (Crimped) Fittings: These are crimped onto the hose using specialized tools, providing a strong, leak-proof connection. They are ideal for high-pressure applications.

Reusable Fittings: These can be disassembled and reused, making them cost-effective for maintenance and repairs. However, they may not withstand extreme pressures as well as permanent fittings.

2. Thread Types in Hydraulic Hose Fittings

Different thread standards ensure compatibility with global hydraulic systems:

NPT (National Pipe Tapered): Common in North America, these tapered threads create a seal through thread deformation.

BSP (British Standard Pipe): Used in Europe and Asia, available in parallel (BSPP) and tapered (BSPT) versions.

Metric Threads: Standard in many international systems, measured in millimeters.

SAE (Society of Automotive Engineers): Common in automotive and industrial applications.

3. Common Hydraulic Hose Fitting Styles

JIC (Joint Industry Council): 37-degree flared fittings for high-pressure applications.

ORFS (O-Ring Face Seal): Uses an O-ring for a leak-proof seal, ideal for high-vibration environments.

NPTF (National Pipe Tapered Fuel): Dry-seal threads for fuel and hydraulic systems.

DIN (Deutsches Institut für Normung): German standard fittings with precise dimensions.

Push-to-Connect Fittings: Allow quick connections without tools, suitable for low-pressure systems.

Materials Used in Hydraulic Hose Fittings

The material of hydraulic hose fittings affects durability, corrosion resistance, and compatibility with fluids:

Carbon Steel: Strong and cost-effective but prone to rust without coatings.

Stainless Steel: Highly corrosion-resistant, ideal for harsh environments.

Brass: Resistant to corrosion and suitable for low-pressure applications.

Aluminum: Lightweight and corrosion-resistant but less durable than steel.

Applications of Hydraulic Hose Fittings

Hydraulic hose fittings are used across multiple industries:

Construction & Mining: Excavators, loaders, and bulldozers rely on durable fittings for heavy-duty operations.

Agriculture: Tractors and irrigation systems use hydraulic fittings for fluid transfer.

Manufacturing: Hydraulic presses and assembly lines depend on leak-free connections.

Aerospace & Defense: High-pressure hydraulic systems in aircraft require precision fittings.

Marine: Saltwater-resistant fittings prevent corrosion in ship hydraulic systems.

How to Choose the Right Hydraulic Hose Fittings

Selecting the correct hydraulic hose fittings involves several considerations:

1. Pressure Rating

Ensure the fitting can handle the system’s maximum pressure to avoid failures.

2. Temperature Compatibility

Some materials degrade under extreme heat or cold, affecting performance.

3. Fluid Compatibility

Hydraulic fluids, oils, and chemicals may react with certain metals or seals.

4. Size & Thread Type

Incorrect sizing leads to leaks or fitting failures—always match thread standards.

5. Environmental Conditions

Corrosive or high-vibration environments require specialized fittings like stainless steel or ORFS types.

Installation and Maintenance Tips

Proper installation ensures longevity and safety:

Use the Right Tools: Crimping machines for permanent fittings, wrenches for threaded types.

Inspect for Damage: Check for cracks, corrosion, or wear before installation.

Follow Torque Specifications: Over-tightening can damage threads, while under-tightening causes leaks.

Regular Maintenance: Replace worn fittings and inspect hoses periodically.

1 note

·

View note

Text

In the modern industrial field, steel pipes are widely used in various industries such as construction, machinery manufacturing, oil and gas, automotive manufacturing, chemical engineering, shipbuilding, energy, and more. Due to differences in production standards, testing methods, and quality requirements among different countries and regions, a series of authoritative international steel pipe standards have been established, such as ASTM (USA), DIN (Germany), JIS (Japan), GB (China), etc. These standards provide detailed requirements for the material, dimensions, performance, manufacturing processes, and quality inspection methods of steel pipes, ensuring product consistency and reliability.

This article will briefly analyze the characteristics, applicable scopes, and main contents of the four major standards: ASTM, DIN, JIS, and GB.

I. ASTM Standards (American Society for Testing and Materials)

1. Introduction to ASTM

The American Society for Testing and Materials (ASTM), established in 1898, is one of the most influential material testing and standard-setting organizations globally. ASTM standards cover a wide range of industries, including metals, plastics, petrochemicals, construction, and environmental sectors.

In the steel pipe industry, ASTM standards are the most authoritative technical specifications in both the U.S. domestic and international markets. They encompass various types of steel pipes for different applications, such as carbon steel pipes, stainless steel pipes, alloy steel pipes, high-pressure boiler pipes, structural pipes, and fluid pipes.

2. Common ASTM Steel Pipe Standards

3. Characteristics of ASTM Standards

Uses inch (inch) and pound (lb) units, aligning with the U.S. market.

Strict quality inspection requirements, covering chemical composition, mechanical properties, dimensional tolerances, and non-destructive testing (NDT).

Suitable for applications in extreme environments, such as high temperature, high pressure, and corrosion resistance.

II. DIN Standards (German Industrial Standards)

1. Introduction to DIN The Deutsches Institut für Normung (DIN), established in 1917, is the national standardization body of Germany. DIN standards have a broad influence in Europe and globally, particularly in fields such as machinery manufacturing, automotive industry, construction engineering, and steel industry.German industrial standards are known for their rigor, precision, and durability. DIN-standard steel pipes are widely used in automotive manufacturing, mechanical equipment, and pipeline engineering.

2. Common DIN Steel Pipe Standards

3. Characteristics of DIN Standards

Uses metric units (mm, kg), aligning with European market requirements.

Stringent quality requirements, with a focus on mechanical properties, dimensional accuracy, and chemical composition control.

Suitable for industries with high precision requirements, such as automotive manufacturing, precision machinery, and boiler pipelines.

III. JIS Standards (Japanese Industrial Standards)

1. Introduction to JIS The Japanese Industrial Standards (JIS), developed by the Japanese Industrial Standards Committee (JISC), are the national standard system of Japan. JIS standards have a profound impact in the Asian market and are widely used in construction, automotive, shipbuilding, and petrochemical industries.

2. Common JIS Steel Pipe Standards

3. Characteristics of JIS Standards

Uses metric units, suitable for the Asian market.High-quality standards, emphasizing welding performance, corrosion resistance, and dimensional accuracy.Suitable for industries such as high-temperature boilers, structural engineering, and shipbuilding.

IV. GB Standards (Chinese National Standards)

1. Introduction to GB GB (Guobiao Standards) are the national standards of China, issued by the Standardization Administration of China (SAC). GB standards are widely applicable to domestic markets in construction, energy, machinery, chemical engineering, and other industries. In recent years, they have gradually aligned with international standards.

2. Common GB Steel Pipe Standards

3. Characteristics of GB Standards

Suitable for the Chinese market, covering industries such as construction, energy, and transportation.

Quality requirements align with international standards, meeting the needs of Chinese engineering projects.

Summary

The four major standards—ASTM, DIN, JIS, and GB—dominate the global steel pipe industry, each catering to different markets and application environments. In international trade, correctly understanding and selecting the appropriate standard is crucial to improving project quality, reducing costs, and enhancing market competitiveness.

0 notes

Text

Neue DIN Normungsroadmap Bauwerke

„…Das Deutsches Institut für Normung (DIN) hat im Dezember 2024 eine neue Normungsroadmap Bauwerke veröffentlicht. Die neue Normungsroadmap (NRM) dient als interdisziplinärer Branchenleitfaden, der den zukünftigen Fahrplan für die Normung im Bauwesen formuliert. Ziel ist es, die Branche flexibler, nachhaltiger und digitaler zu machen. Die Roadmap wurde in einem transparenten und partizipativen…

0 notes

Text

Fasteners Standards: A Complete Guide

Fasteners are essential parts utilized in nearly every sector, ranging from construction and automobiles to aerospace and manufacturing. For reliability, consistency, and safety, fasteners must comply with specific quality levels this is where fastener standards are utilized. These standards establish specifications for material properties, size, mechanical properties, surface treatments, as well as performance requirements.

In this blog, we'll explore the various fasteners standards, their importance, key organizations involved, and widely recognized global standards in the industry.

What are Fasteners Standards?

Fastener standards are written specifications agreed upon by international or national standardization bodies. These specifications enable engineers, manufacturers, and suppliers to ensure that fasteners have the necessary performance and safety requirements. Fasteners standards address a wide set of parameters, including:

Material composition

Mechanical properties (e.g., tensile strength, hardness)

Dimensional tolerances

Surface treatments and coatings

Thread types and pitch

Corrosion resistance

Importance of Fasteners Standards

Interchangeability: Standardized fasteners allow for easy replacement and interoperability between systems and suppliers.

Quality Assurance: Adhering to standards ensures consistent product performance.

Compliance: Many industries require fasteners to meet specific standards to comply with legal or industry-specific regulations.

Safety: Standards help minimize the risk of fastener failure under stress or environmental conditions.

Major Fasteners Standards Organizations

A number of national and international organizations are accountable for creating and sustaining fastener standards. Following are some of the most notable ones:

1. ASTM International

ASTM is a globally recognized organization that develops technical standards for a wide range of materials and products, including fasteners.

Standards: ASTM A193, ASTM A194, ASTM A307

Scope: Defines both chemical composition and mechanical properties of fasteners used in various industrial applications, particularly in high-temperature and high-pressure environments

2. ASME (American Society of Mechanical Engineers)

Used mostly in mechanical and pressure equipment

ASME B18 series is well utilized for fasteners dimensions and tolerances

3. ISO (International Organization for Standardization)

Provides globally accepted fastener standards

Popular standards: ISO 898 (mechanical properties of fasteners), ISO 4014 (hex bolts)

4. DIN (Deutsches Institut für Normung)

One of the earliest organizations to standardize industrial products

Examples: DIN 933 (hex bolts), DIN 912 (socket head cap screws)

5. SAE (Society of Automotive Engineers)

Widely applied in the automotive and aerospace sectors.

Example: SAE J429 – Specifies the mechanical and material properties for bolts, screws, and studs.

6. BS (British Standards)

Frequently used in UK and Commonwealth countries

Example: BS 3692 – Establishes the mechanical and dimensional requirements for ISO metric bolts, screws, and nuts.

Common Fastener Standards and Their Applications

Metric vs Imperial Standards

Fasteners are classified under either metric or imperial systems:

Metric standards: ISO, DIN, JIS, and BS are primarily metric-based.

Imperial standards: ASTM, ASME, and SAE primarily use inches and pounds.

Understanding the system in use is essential for compatibility and proper application.

How to Choose the Right Fastener Standard?

Selecting the right fasteners is critical to the safety and efficiency of your application. Keep the following key factors in mind:

Industry Standards and RequirementsEnsure compliance with industry-specific regulations and standardization (e.g., ASTM for construction, SAE for automotive).

Load and Mechanical StressConsider the tensile, shear, and fatigue strength needed to withstand the operational loads.

Environmental ConditionsEvaluate exposure to moisture, chemicals, temperature extremes, or corrosive environments, and choose materials and coatings accordingly.

Material CompatibilityMatch fasteners with compatible materials to prevent galvanic corrosion and maintain joint integrity.

Dimensional SpecificationsSelect fasteners with appropriate dimensions, thread types, and tolerances based on application design and fit.

Regional or Customer PreferencesSome projects or clients may require specific standards, such as ISO (metric) or ASME (imperial), depending on location or system compatibility.

Cost and AvailabilityBalance performance requirements with budget and lead times, ensuring reliable sourcing from certified suppliers.

Conclusion

Fastener standards play a critical role in providing reliability, safety, and interchangeability in engineering and production. Whether you're sourcing bolts for a bridge or screws for an aircraft, understanding the right standard is crucial to the success and safety of your project.

As a leading Fasteners Manufacturer & Supplier, Ananka Group ensures compliance with international standards like ASTM, ASME, ISO, DIN, SAE, BS, and JIS. Our extensive inventory and custom manufacturing solutions make us your go-to partner for high-quality, certified fasteners.

FAQs on Fasteners Standards

Q1. What is the difference between ASTM and ISO standards for fasteners?A: ASTM is a US-based standard, often used in the Americas, while ISO is internationally recognized and metric-based. They may specify different materials and testing requirements for similar applications.

Q2. Are DIN standards still in use?A: Yes, although many DIN standards have been superseded by ISO standards, DIN references are still widely used, especially in Europe and German-engineered systems.

Q3. What are high-strength fastener standards?A: Standards like ASTM A193 Grade B7, SAE Grade 8, and ISO 898-1 Class 10.9 or 12.9 define high-strength fasteners used in structural and heavy-duty applications.

Q4. Can I interchange metric and imperial fasteners?A: No, metric and imperial fasteners differ in thread pitch and dimensions. Interchanging them can result in poor fit and potential failure.

Q5. Do all industries use the same fastener standards?A: No. Different industries adopt specific standards that best suit their regulatory and performance needs. For example, aerospace often uses SAE and NAS standards, while construction might prefer ASTM or ISO.

#ananka#anankafasteners#fasteners#fastenersstandard#standards#material#materialgrade#blog#articles#astm#astmgrade#iso#isostandard#manufacturer#supplier#mumbai#bolt#hex#tumblr blog#tumblr

0 notes

Text

DIN Fasteners Manufacturer & Supplier in India – Akbar Fasteners

Introduction to DIN Fasteners

Fasteners play a critical role in engineering and construction, and their reliability can make or break an application. Among the many types of global fasteners, those built to DIN (Deutsches Institut für Normung) standards are recognized for their accuracy, strength, and international acceptance. DIN fasteners conform to specifications set by the German national organization for standardization and are used in countless applications worldwide. Akbar Fasteners is a trusted DIN Fasteners Manufacturer & Supplier in India known for its precision-engineered products and commitment to quality.

What Are DIN Fasteners?

DIN fasteners include a wide variety of bolts, nuts, screws, and washers that conform to the exacting German DIN specifications. These standards cover everything from thread pitch and head shape to material strength and surface treatment. They ensure universal compatibility and high-performance standards across engineering and construction sectors globally.

Importance of German DIN Standards

Adherence to DIN standards means your fasteners are compatible with machinery and components manufactured in Germany, across the EU, and in many parts of the world. These standards ensure dimensional accuracy, reliable performance, and consistent quality, making DIN fasteners a popular choice for critical installations.

Benefits of Using DIN Standard Fasteners

International Compatibility

One of the biggest advantages of DIN fasteners is their global compatibility. Components made in Europe, Asia, and North America are often designed using DIN specifications, making these fasteners suitable for multinational projects and cross-border engineering tasks.

High-Precision Engineering

Every DIN fastener is manufactured with attention to detail. Whether it's a bolt, nut, or washer, the dimensions and threads are tightly controlled. This reduces installation errors, improves safety, and ensures a long-lasting fit in mechanical assemblies.

Akbar Fasteners’ Range of DIN Fasteners

DIN Bolts, Nuts, Screws, Washers, Studs

At Akbar Fasteners, we manufacture a complete range of DIN-standard products including DIN 933 hex bolts, DIN 934 hex nuts, DIN 125 washers, and DIN 976 threaded rods. As a reputed DIN Fasteners Manufacturer, Supplier & Exporter in India, we also supply custom and specialty fasteners to meet specific customer demands.

Specialty and Custom Fasteners

We also offer specialized DIN components for industries such as automotive, power generation, and heavy machinery. These include tamper-proof fasteners, DIN 603 carriage bolts, and stainless steel socket head cap screws for high-strength applications.

Popular DIN Fastener Numbers and Their Applications

DIN 933, DIN 934, DIN 912, etc.

DIN 933 bolts and DIN 934 nuts are among the most commonly used fasteners in engineering projects. DIN 912 socket head cap screws are favored for their clean appearance and high torque capacity. Each number corresponds to a specific design standard, allowing engineers to match fasteners precisely to their project requirements.

Industry-Specific Use Cases

DIN 558 bolts are commonly used in steel structures and construction equipment, while DIN 125 flat washers are used to distribute load and prevent damage to surfaces. As a top-rated DIN 558 bolts manufacturer in India, Akbar Fasteners provides components trusted by civil engineers and industrial contractors.

Materials and Finishes Offered

Stainless Steel, Carbon Steel, Alloy Steel

We manufacture fasteners in a wide range of materials to suit different operating environments. For high corrosion resistance, our Stainless Steel DIN Fasteners are ideal, especially for outdoor or marine applications. Carbon steel is chosen for strength and cost-effectiveness, while alloy steel is used in high-stress applications.

Zinc, Black Oxide, Galvanized Coatings

To enhance performance, we offer various coatings such as electro-zinc plating, black oxide for minimal corrosion resistance, and hot-dip galvanizing for durability in aggressive environments.

Industrial Applications of DIN Fasteners in India

Automotive and Rail

India’s growing automotive sector heavily relies on DIN fasteners for chassis assembly, engine mounting, and structural joints. Rail projects, including coaches and signaling systems, also utilize standardized DIN bolts and nuts for safety and maintenance ease.

Construction and Heavy Machinery

In large-scale construction and infrastructure projects, DIN fasteners help hold together heavy beams, support structures, and industrial machinery. They are trusted for their uniform strength and compatibility with international engineering practices.

Quality Control and Certification Standards

ISO 9001:2015, ASTM, EN, and DIN Compliance

Akbar Fasteners operates a quality management system certified to ISO 9001:2015. Our products also meet or exceed ASTM and EN equivalents where applicable. As a DIN Fasteners, DIN Bolts, DIN Nuts Manufacturer, our commitment to quality ensures client confidence across India and overseas.

In-House Testing Capabilities

We conduct thorough testing including tensile strength, elongation, hardness, and thread checks. Our in-house lab supports MTC generation and third-party inspection to guarantee every product meets its specifications.

Why Choose Akbar Fasteners for DIN Fasteners

Experience and Technical Support

With decades of experience, Akbar Fasteners understands the intricacies of fastener production. Our knowledgeable team assists clients in selecting the right DIN standard, material, and surface finish for their project needs. Whether it’s DIN 933 or DIN 912, we provide the right solution, every time.

Bulk Supply and Custom Packaging

We cater to large-scale industrial projects with bulk orders of standardized or custom fasteners. We also offer OEM services including private labeling, barcode printing, and branded packaging—ideal for resellers and project suppliers seeking ready-to-shelf inventory.

Nationwide Delivery and Export Capabilities

Fast Supply Within India

We have established a strong distribution network to deliver orders promptly across major Indian cities including Mumbai, Delhi, Pune, Ahmedabad, and Bangalore. For buyers searching for Din fasteners manufacturer & supplier in India price, Akbar Fasteners offers both competitive rates and consistent quality.

Global Shipping and Documentation Support

As a leading fastener exporter, we handle shipping and documentation for clients across the Middle East, Southeast Asia, and Europe. From container load shipments to small consignments, we ensure hassle-free logistics and timely deliveries.

Client Testimonials and Industry Reputation

We’re proud to have earned the trust of contractors, engineers, and project managers across diverse sectors. Many of our clients are repeat customers who appreciate our commitment to product quality, responsive service, and on-time delivery. Our long-standing reputation as a Top DIN Fasteners Manufacturer & Supplier in India is built on performance and professionalism.

Frequently Asked Questions (FAQs)

1. What are DIN fasteners used for? DIN fasteners are used in automotive, construction, electrical, mechanical, and industrial applications where standardization and reliability are essential.

2. Do you supply stainless steel DIN fasteners? Yes, we supply stainless steel fasteners in grades like SS 304 and SS 316, ideal for corrosion-prone environments.

3. Can I get DIN fasteners in bulk? Absolutely. We specialize in bulk manufacturing and export, with tailored pricing for project and distributor quantities.

4. Do you offer custom fasteners under DIN standards? Yes, we can customize size, threading, finish, and packaging while still adhering to DIN specifications.

5. What coatings are available on DIN bolts? Coatings include zinc, black oxide, hot-dip galvanizing, and PTFE depending on environmental and mechanical requirements.

6. How can I get pricing and delivery timelines? You can contact our sales team directly for quotations, technical queries, or order tracking.

Contact Akbar Fasteners

For inquiries or bulk orders, reach out to:

Contact Person: Barkat Phone: +91 99192 04560 Email: [email protected] Address: Kurla West, CST Road, India, India 400070

Explore our catalog and services at Akbarali Fasteners.

Conclusion

DIN fasteners bring unmatched consistency, safety, and performance to your engineering projects. Akbar Fasteners is proud to be your dependable partner as a DIN Fasteners Manufacturer & Supplier in India. Whether you're sourcing bolts for a construction site or screws for a machine assembly line, trust us to deliver standardized, high-quality products that meet your expectations.

0 notes

Text

DIN Collets Manufacturers in India – High-Precision Tooling Solutions

India is home to some of the world’s most reputed DIN collets manufacturers, offering premium-quality collets that meet international standards. These manufacturers produce DIN collets designed for high accuracy, excellent gripping force, and superior durability, making them ideal for CNC machining, milling, drilling, and turning operations.

Why Choose Indian DIN Collets Manufacturers?

Superior Quality & Compliance Leading DIN collets manufacturers in India adhere to stringent quality control measures and comply with DIN (Deutsches Institut für Normung) standards to ensure precision-engineered products. These collets provide exceptional concentricity, ensuring minimal runout and optimal tool performance.

Advanced Manufacturing Techniques Indian manufacturers utilize cutting-edge CNC technology and high-quality raw materials such as alloy steel, spring steel, and carbide to manufacture DIN collets that offer extended tool life and consistent accuracy.

Customization & Versatility Renowned DIN collets manufacturers in India provide a wide range of collets, including ER collets, TG collets, R8 collets, SK collets, and more, catering to diverse industrial applications. They also offer custom collets tailored to specific customer requirements.

Cost-Effective & Efficient Solutions Compared to global competitors, DIN collets manufacturers in India offer cost-effective solutions without compromising quality, making them a preferred choice for industries such as aerospace, automotive, medical, and general machining.

Types of DIN Collets Available in India

DIN 6499 ER Collets – Ideal for high-speed machining, these collets provide excellent gripping force and precision.

DIN 6388 Collets – Designed for tool holding applications in CNC machines, ensuring high accuracy.

DIN 6343 Collets – Used in lathe and milling machines, offering enhanced durability.

DIN 6499B Sealed Collets – Suitable for coolant-through applications, preventing tool contamination.

Industries Served by DIN Collets Manufacturers in India

CNC Machining – Precision collets ensure optimal tool performance in high-speed machining.

Aerospace & Automotive – High-tolerance collets contribute to the efficiency of critical component manufacturing.

Medical Equipment Manufacturing – DIN collets help achieve micron-level precision required in medical devices.

Metalworking & Tooling – Ensuring secure and accurate clamping for improved productivity.

Top Features of DIN Collets from Indian Manufacturers

✅ High concentricity for reduced tool wear ✅ Excellent gripping strength for enhanced performance ✅ Heat-treated & precision-ground for extended durability ✅ Available in various sizes and configurations ✅ Custom collet solutions for unique machining needs

Why Are Indian DIN Collets Preferred Globally?

Stringent Quality Assurance – Each collet undergoes rigorous inspection and testing.

Competitive Pricing – Affordable solutions without sacrificing precision.

Fast Production & Delivery – Efficient manufacturing processes ensure timely supply.

Strong Global Presence – Exporting to Europe, the USA, and Asia.

FAQs About DIN Collets Manufacturers in India

1. What are DIN collets, and why are they important?

DIN collets are precision-engineered tool-holding devices designed as per Deutsches Institut für Normung (DIN) standards. They ensure secure clamping, minimal runout, and enhanced machining accuracy.

2. Which industries require DIN collets?

Industries such as aerospace, automotive, CNC machining, tool & die making, and medical device manufacturing extensively use DIN collets for their precision and reliability.

3. How do I choose the right DIN collet for my application?

Selecting the right collet depends on factors like tool size, gripping force, material, and application requirements. Consult with DIN collets manufacturers in India for expert guidance.

4. Are Indian DIN collets as good as those from Europe?

Yes! DIN collets manufacturers in India follow strict quality standards, use advanced materials, and implement modern manufacturing techniques, ensuring products that match or exceed global standards.

5. Can I get customized DIN collets from Indian manufacturers?

Absolutely! Indian DIN collets manufacturers offer customized solutions based on specific dimensions, materials, and applications.

6. Where can I buy high-quality DIN collets in India?

You can source premium-quality collets from leading DIN collets manufacturers in India, who provide both standard and custom solutions to meet your machining needs.

Conclusion

If you are looking for high-quality DIN collets, Indian manufacturers provide cost-effective, precision-engineered solutions tailored to various industrial needs. With advanced manufacturing processes, strict quality control, and competitive pricing, DIN collets manufacturers in India continue to be a trusted choice worldwide.

0 notes

Text

Procura aço DIN 1.2631 (Chipper Knife) em #Portugal?

O aço DIN 1.2631 é um aço para ferramentas de trabalho a frio com alto teor de carbono e alto teor de cromo, usado principalmente na fabricação de ferramentas de corte, punções e matrizes. Também é conhecido por outras designações como X50CrMoW9-1-1 ou aço AISI A8.

A designação "DIN 1.2631" refere-se ao grau de aço de acordo com o Deutsches Institut für Normung (DIN), que é o Instituto Alemão de Normalização. O sistema DIN é comumente usado na Europa para designar tipos de aço específicos.

A EDELSTAHL VIRAT IBÉRICA é o maior stock e fornecedor de Aços Grau 1.2631. Nós fornecemos Metal Steel Grau 1.2631 STEEL ALLOY TOOL PLATE é um molde de aço, usado em moldes de extrusão, moldes de fundição a quente. como produção de alumínio, molde de corte de alumínio ….

Consulte a nossa equipa que o ajudará na consulta do aço DIN 1.2631 (Faca Picadora) também para locais como… #Valbom #Canidelo #SenhoradaHora #OliveiradoDouro #Ribeira #Bolhão #Guimarães #Braga

PARA SABER MAIS >> https://moldsteel.eu/steel-products/chipper-knife-steel/

Chat WhatsApp: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#edelstashlviratibrica#viratsteels#b2b#din2738#Valbom#Canidelo#SenhoradaHora#OliveiradoDouro#Ribeira#Bolhão#Guimarães#Braga#din2631#Chipper Knife

2 notes

·

View notes

Text

З радістю повідомляємо, що маски зварювальні STANLEY знову доступні для покупки.

☎️Задати питання 050-340-06-81(Telegram, Viber)

✅Модель STANLEY 90368 з регулюванням ступеня затемнення у діапазоні 9-13 DIN ✅Модель STANLEY 90371 без регулювання ступеня затемнення, фіксований параметр 11 DIN

DIN це рівень затемнення у німецькій системі DIN (Deutsches Institut für Normung), Німецький інститут стандартизації. Діапазон затемнення буває: •DIN 9-13 – стандартний діапазон для автоматичних зварювальних масок •DIN 5-8 – для різання та пайки •DIN 14 – для потужного зварювання (наприклад, при зварюванні на високих струмах)

Зварювальне обладнання STANLEY замовляє у італійського концерну AWELCO, який займає одну з провідних ролей у світі зі зварювання.

Ці засоби індивідуального захисту забезпечують безпеку під час роботи з металом. Забезпечте свій захист сьогодні.

📢 Приєднуйтесь до нашого телеграм-каналу, щоб бути в курсі останніх новин та оновлень. 🛠🔧

0 notes

Text

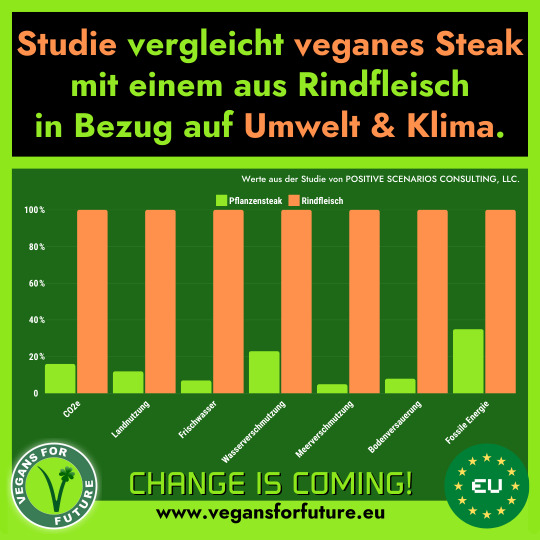

Eine aktuelle Studie der "Positive Scenarios Consulting LLC.", welche diese im Auftrag von Beyond Meat durchführte, vergleicht ein klassisches Steak aus Rindfleisch mit einem aus Pflanzenfleisch. Dabei zeigt sich, dass die Auswirkungen auf Klima & Umwelt beim veganen Steak in sämtlichen Bereichen deutlich unterhalb des Rindfleischs liegen! 👍😎🌱

Vegconomist dazu: "Die Ökobilanzstudie zu Beyond Steak wurde gemäß den Empfehlungen der Internationalen Organisation für Normung (ISO) durchgeführt und einer kritischen Überprüfung durch Dritte unterzogen.

Die Ergebnisse zeigen, dass Beyond Steak im Vergleich zu vorgekochten Steakspitzen auf Rindfleischbasis: - 84 % weniger Treibhausgasemissionen erzeugt, - 93 % weniger Wasserverbrauch benötigt, - 88 % weniger Landnutzung benötigt und - 65 % weniger nicht erneuerbare Energie benötigt.

Die Ökobilanzstudie „Beyond Steak“ umfasst auch neue Auswirkungsattribute, um potenzielle Auswirkungen auf die Natur und ausgewogene Ökosysteme abzuschätzen, wie „terrestrische Versauerung“, „Meereseutrophierung“ und „Süßwassereutrophierung“ (Reaktionen in der Natur, die die Gesundheit von Land-, Küsten-, Meeres- und Süßwasserökosystemen bedrohen).

Im Vergleich zu vorgekochten Steakspitzen auf Rindfleischbasis verursacht Beyond Steak 94 % weniger terrestrische Versauerung, 95 % weniger Meereseutrophierung und 77 % weniger Süßwassereutrophierung."

Quellen: ➡ LINK 1 ➡ LINK 2 ➡ LINK 3

CHANGE IS COMING! 😊💚

#vegansforfuture#vegan#fridaysforfuture#landwirtschaft#ernährungswende#agrarwende#vegetarisch#pflanzenfleisch#klimaschutz

1 note

·

View note

Text

How Yarn Testing Ensures Compliance with ISO and Other International Standards?

In the competitive textile industry, maintaining high standards of product quality and performance is crucial to business success. One of the most effective ways to ensure these standards is through yarn testing. Yarn testing plays an essential role in verifying that yarn meets various performance criteria, particularly ISO (International Organization for Standardization) and other internationally recognized standards. Whether the yarn is used for fashion apparel, industrial fabrics, or home textiles, adhering to these quality standards guarantees that the final product performs as expected, meets regulatory requirements, and satisfies customer expectations.

In this blog, we will explore how yarn testing ensures compliance with ISO and other international standards, the importance of testing in maintaining quality control, and how it helps textile manufacturers remain competitive in global markets.

The Importance of Yarn Testing in the Textile Industry

Yarn is the fundamental building block of most textile products. It is the raw material used to create everything from simple clothing to complex industrial fabrics. Because yarn is responsible for a significant portion of a product’s quality, consistency, and durability, ensuring that it complies with recognized standards is crucial for manufacturers.

Yarn testing involves evaluating a variety of characteristics that affect the yarn’s performance, including its tensile strength, elasticity, fiber composition, and evenness. Through standardized testing methods, yarn can be measured for these properties, helping manufacturers identify potential issues early in the production process and address them before the yarn is used in final fabric production.

Ensuring that yarn complies with international standards helps manufacturers achieve uniformity, safety, and reliability. Testing is vital not only for compliance but also for achieving consumer satisfaction, maintaining market competitiveness, and facilitating international trade.

ISO and International Standards for Yarn Testing

ISO standards are globally recognized and play a critical role in determining the quality and safety of products across various industries, including textiles. For yarn, ISO 9001 (Quality Management Systems), ISO 2076 (Yarn Classification), and ISO 2061 (Determination of the Linear Density of Yarns) are some of the most relevant standards. These standards cover various aspects of yarn production, testing, and performance and are used to ensure that yarns meet the desired specifications for strength, durability, and uniformity.

In addition to ISO standards, other international organizations, such as the ASTM (American Society for Testing and Materials), BSI (British Standards Institution), and DIN (Deutsches Institut für Normung), provide regulations and testing methods that ensure yarn quality across different markets. Compliance with these standards helps textile manufacturers align with global expectations for product quality, safety, and environmental sustainability.

How Yarn Testing Ensures Compliance with ISO and Other International Standards

1. Verification of Fiber Composition

The first step in ensuring yarn quality is verifying the fiber composition. For example, ISO 2076 provides guidelines for yarn classification, including identifying the type of fibers in the yarn (e.g., cotton, wool, polyester, or blends). Compliance with this standard ensures that the yarn meets the required specifications and can be accurately classified. For manufacturers, fiber testing allows them to verify that the yarn is made from the correct fiber content, ensuring consistency in the end product's appearance, performance, and durability.

Tests such as microscopic analysis and burning tests are commonly used to verify fiber composition. These methods help determine the origin and type of fibers present in the yarn, ensuring the yarn meets the standards set by international regulatory bodies.

2. Strength Testing

Tensile strength is a key property of yarn that determines how much load the yarn can withstand before breaking. This property is crucial for ensuring the durability and reliability of the fabric created from the yarn. ISO 2062 specifies the method for testing the tensile strength of yarns, which helps manufacturers assess the yarn’s ability to withstand mechanical stresses.

Tensile testing is conducted by measuring the force required to break the yarn, which provides data on its strength, elongation, and resistance to tension. Yarn that passes strength tests is more likely to be durable, offering better performance in both woven and knitted fabrics. By adhering to ISO 2062, manufacturers ensure that their yarn complies with internationally accepted strength requirements, which is particularly important for applications such as outdoor textiles, performance wear, and industrial fabrics.

3. Uniformity and Evenness Testing

Another critical aspect of yarn quality is uniformity. ISO 1833 specifies methods for assessing the evenness of yarn, ensuring that it is consistent in diameter and texture along its length. Inconsistent yarn can result in fabric defects, such as weak spots or uneven dye absorption. By adhering to uniformity standards, manufacturers can ensure that the yarn used in fabric production is smooth, consistent, and suitable for its intended purpose.

Unevenness tests help identify any variations in the yarn’s thickness and texture, allowing manufacturers to correct issues before the yarn is used in fabric production. This not only ensures compliance with ISO 1833 but also helps prevent defects that could affect the appearance, functionality, or strength of the final product.

4. Twist Testing

The twist in yarn is another important factor that impacts its overall performance. Twist influences the yarn's strength, elasticity, and texture. ISO 2061 provides methods for determining the twist in yarns, ensuring that it meets the requirements for consistent performance in textile applications.

Proper twist testing ensures that yarns have the correct twist level, which in turn affects how the yarn behaves when woven or knitted into fabrics. If the yarn is twisted incorrectly, it could lead to issues such as poor fabric stability, pilling, or even yarn breakage during fabric production. Therefore, testing the twist ensures that yarn meets international standards for textile quality.

5. Dyeing and Finish Consistency

Yarn testing also helps ensure that the yarn will perform well during dyeing and finishing processes. Yarn must absorb dyes uniformly and react predictably to finishing chemicals. The evenness of the yarn affects how well it takes dye, leading to a consistent color in the final fabric.

Standards like ISO 105 specify how to test the colorfastness and dye absorption properties of textiles, including yarn. Compliance with these standards ensures that the yarn will maintain its appearance and performance in the final fabric, whether it’s exposed to washing, light, or abrasion.

6. Compliance with Environmental and Sustainability Standards

In addition to performance standards, ISO 14001 (Environmental Management Systems) and other sustainability-related standards are becoming increasingly important in the textile industry. Many textile manufacturers are now required to ensure that their processes, including yarn production and testing, meet environmental guidelines that minimize waste, reduce energy consumption, and ensure safe working conditions.

By testing yarn for environmental and sustainability factors, manufacturers can ensure compliance with these standards, helping to meet both consumer demand for eco-friendly products and regulatory requirements.

The Benefits of Complying with ISO and International Standards

Ensuring compliance with ISO and other international standards through yarn testing offers a range of benefits for textile manufacturers, including:

Improved product quality: Regular testing ensures that yarns are consistently high-quality, which translates into better finished textiles.

Market access: Compliance with internationally recognized standards opens up access to global markets, as many countries require that imported products meet these standards.

Consumer trust: Meeting recognized standards helps build consumer confidence in the quality, safety, and reliability of the product.

Reduced waste: By identifying defects early, yarn testing minimizes the risk of producing defective yarn that could lead to fabric waste.

Sustainability: Compliance with environmental standards demonstrates a commitment to sustainability, which is increasingly important to consumers and regulatory bodies alike.

Conclusion

Yarn testing is an essential process for ensuring that yarns meet ISO and other international standards. By verifying key properties such as fiber composition, strength, uniformity, twist, and dyeing consistency, yarn testing ensures that textile products meet global quality standards. Manufacturers who adhere to these standards not only ensure product quality and safety but also gain a competitive edge in the global market.

As the textile industry continues to evolve, compliance with ISO and other international standards will remain crucial for manufacturers aiming to produce high-quality, durable, and sustainable yarns that meet the ever-growing demands of consumers and industries worldwide.

0 notes

Text

BCI vs. DIN Codes: Unlock the Secrets to Battery Cross-Referencing Like a Pro

Choosing the right battery for your vehicle can feel overwhelming with all the codes and specifications out there. Have you ever wondered what those labels—BCI and DIN—actually mean? These codes are essential for identifying the right battery, ensuring it fits perfectly, and powers your vehicle efficiently. By mastering the car battery size chart, you’ll be able to navigate these codes like a pro and make informed decisions with ease.

Battery Codes

Shopping for a car battery can feel like trying to decipher a foreign language. You’ve probably noticed codes like “BCI Group 35” or “DIN 57412” on battery labels and wondered what they mean. These codes aren’t just random—they hold the key to finding a battery that fits your vehicle perfectly. Let’s decode the mystery of these labels and help you master the art of cross-referencing.

What Are BCI and DIN Codes?

BCI (Battery Council International) and DIN (Deutsches Institut für Normung) are two different standards used to classify car batteries. Think of them as two roadmaps for the same journey—they get you to the right battery, but the paths are slightly different.

BCI Codes: Common in North America, focusing on group sizes based on dimensions and terminal placements.

DIN Codes: Popular in Europe, with a focus on compatibility for European vehicle models.

Knowing which system your car follows is the first step to finding the right battery.

Why Do These Codes Matter?

Imagine trying to fit a square peg in a round hole—that’s what it’s like using the wrong battery. The right code ensures:

Proper Fit: The battery fits snugly in the compartment.

Correct Terminal Placement: Avoids wiring issues.

Optimal Performance: Matches your vehicle’s power requirements.

Understanding these codes can save you time, money, and frustration.

Understanding BCI Codes

BCI codes are all about group sizes. For example:

Group 24: Common in midsize vehicles.

Group 35: Often used in compact cars.

Group 31: Designed for heavy-duty trucks and industrial use.

Each code provides the battery’s dimensions, terminal placement, and capacity, making it easy to find the perfect fit for your vehicle.

Breaking Down DIN Codes

DIN codes focus on European standards and often include a numerical sequence, like “57412.” Here’s how to interpret them:

57: Battery capacity in amp-hours.

4: Indicates the physical design.

12: Refers to the battery’s length in centimeters.

While DIN codes may look more complicated than BCI codes, they provide equally important details for matching batteries to European vehicles.

Key Differences Between BCI and DIN Codes

The main differences between these systems are:FeatureBCI CodesDIN CodesRegionNorth AmericaEuropeFocusDimensions and terminalsCapacity and lengthExamplesGroup 24, Group 3557412, 61038

Understanding these distinctions helps when cross-referencing between the two systems.

How to Use a Car Battery Size Chart

A car battery size chart bridges the gap between BCI and DIN codes, making cross-referencing a breeze. To use one:

Identify Your Vehicle’s Code: Check the owner’s manual or old battery.

Find Equivalent Sizes: Match the BCI group to the corresponding DIN code.

Confirm Compatibility: Double-check dimensions, capacity, and terminal placement.

This chart is your secret weapon for navigating global battery standards.

Finding the Right Battery for Your Vehicle

Choosing a battery isn’t just about size—it’s also about performance. Look for:

Voltage: Most cars require a 12-volt battery.

Capacity: Ensure the amp-hour rating matches your vehicle’s needs.

Fit: Confirm the dimensions align with your battery compartment.

Comparing Battery Dimensions

Both BCI and DIN codes provide dimensions, but the measurements differ slightly:

BCI Codes: Dimensions are listed in inches (e.g., 10.25 x 6.8125 x 8.875 inches).

DIN Codes: Dimensions are often in centimeters, focusing on length and height.

Use a conversion tool if needed to ensure the battery fits.

Matching Terminal Placement

Incorrect terminal placement can lead to wiring issues or short circuits. Always ensure the positive and negative terminals align with your vehicle’s wiring. This is particularly important when cross-referencing between BCI and DIN codes.

The Role of Cold Cranking Amps (CCA)

Cold Cranking Amps (CCA) measure a battery’s ability to start in cold weather. If you live in a region with harsh winters, prioritize batteries with high CCA ratings. Both BCI and DIN standards include this information, so look for it when cross-referencing.

The Impact of Climate on Battery Selection

Hot and cold climates affect battery performance differently:

Hot Weather: Accelerates wear and reduces lifespan. Choose heat-resistant batteries.

Cold Weather: Reduces starting power. High CCA ratings are essential.

Consider your local climate when selecting a battery.

Cross-Referencing Tips for Global Vehicles

If you’re driving an imported car, you may need to cross-reference between BCI and DIN codes. Here’s how:

Identify the Original Code: Check your owner’s manual or old battery.

Use a Cross-Reference Chart: Match the code to its equivalent in the other system.

Verify Fit and Performance: Double-check dimensions, capacity, and terminal placement.

Avoiding Common Mistakes in Battery Selection

Here are some pitfalls to avoid:

Choosing Based on Price Alone: Cheaper batteries might not meet your vehicle’s needs.

Ignoring Climate: Not all batteries perform well in extreme temperatures.

Overlooking Terminal Placement: Mismatched terminals can damage your vehicle.

Conclusion: Master Battery Cross-Referencing with Ease

BCI and DIN codes might seem like a puzzle at first, but with the right tools—like a car battery size chart—you can easily navigate the world of automotive batteries. By understanding the differences and knowing how to cross-reference, you’ll always find the perfect battery for your vehicle.

0 notes