#Deutsches Institut für Normung

Explore tagged Tumblr posts

Text

Normenausschussbenennungsnormen des Deutschen Instituts für Normung

Alles begann eines schönes Tages als auf dem Wikipediaartikels des Deutschen Instituts für Normung - kurz DIN, kennt man von Papierformaten, aber die machen Normen für so ziemlich alles.

Wer rausfinden möchte wie das dazu führte, dass ich enorm lange Excel Tabellen in meiner Freizeit erstelle ... bleibt dran >:))

In jenem Wikipediaartikel gibt es eine Liste mit einer Auswahl von Normenausschüssen und dem normierungsbegeisterten Betrachter fällt schnell auf das die nicht alle nach dem selben Muster benannt sind. Einmal heißt es "DIN-Normenstelle Elektrotechnik (NE)", und dann "DIN-Normenausschuss Bauwesen (NABau)" oder "DIN-Normenausschuss Feuerwehrwesen (FNFW)". Die Abkürzungen sind meiner Meinung nach hier das größte Fragezeichen: werden Doppelworte als Gesamtwort (Elektrotechnik -> E) oder nach Teilworten abgekürzt (Feuerwehrwesen -> FW) oder was auch immer bei NABau passiert ist? Ist Normenausschuss kurz N oder NA? Wofür steht überhaupt FN bzw F? (Letzteres hab ich bis heute nicht verstanden, falls es jemandem einleuchtet sagt mir bitte Bescheid 🥲)

Alle diese Abkürzungsregeln sind an sich (fast alle) völlig valide, es ist nur komplett absurd verschiedene Abkürzungsregeln auf der selben Liste zu benutzen und dann auch noch quasi für jeden Ausschuss eine andere Abkürzungsregel! Und das alles nicht von Irgendwem sondern vom DIN selbst, die machen ja nichts anderes als zu normen! Mir kann da keiner erzählen, dass das keine Absicht ist. Ich bin überzeugt, dass die beim DIN einfach extrem lustig sind und sich absichtlicht neue Abkürzungen für ihre Normenausschüsse ausdenken und ich bin großer Fan.

Deswegen wollte ich dann genau wissen wie viele verschiedene Abkürzungsregeln - bzw Normenausschussbenennungsnormen könnte man auch sagen - es auf der Liste gibt. Ich habe also den einzig logischen Schritt gemacht und mit auf der Seite des DIN eine Liste mit deren Normenausschlüssen heruntergeladen und in Excel abgetippt :)

[Bildbeschreibung: 2 Bildschirmfotos von der unfertigen Tabelle. Naben der Liste der Ausschüsse sind vielle wirre Notizen zu Unterscheidungen. /Ende BB]

Bei der Liste fällt direkt auf, dass alle Normenausschlüsse eine Kennnummer haben und deswegen nicht auf ihren Namen zur Identifizierung Verlass haben müssen. Ich hab dann versucht jede vorkommende Art der Benennung und Abkürzung zu identifizieren und habe dazu einen Klassifikationsschlüssel vergeben. Der hat für mich Sinn ergeben, aber ich glaube er ist evtl. ein bisschen überkompliziert also erklär ich einfach die Ergebnisse. Hier ist die fertige Klassifizierung:

[Bildbeschreibungen: Die vollständige Tabelle der Normenausschüsse und Klassifizierung. Auswertung folgt im Text. /Ende BB]

Die insgesamt 69 Normenausschüsse werden auf 30 verschiedene Arten abgekürzt!! *Klatschen und Beifallrufe*

alph# ist die Laufnummer für alphabetische Sortierung nach Fachbereich, so wie sie aus der offiziellen Liste entnommen wurde.

NA # ist die offizielle Kennnummer des Ausschusses. Ich gehe davon aus die werden bei Entstehung vergeben und würden demnach eine zeitliche Sortierung ergeben. Die Nummern sind sehr viel größer als 69, da sich Kennnummern nicht doppeln oder ändern dürfen, vermutlich sind viele Nummern an NAs vergeben, die ist inzwischen nicht mehr gibt. Ist aber alles nur Mutmaßung, ich weiß nicht mit Sicherheit wo die Zahlen herkommen.

Normenausschluss (NA) ist der volle Name der NAs in Worten.

Abkürzung ist jeweils die offizielle Abkürzung.

Der Rest ist mein Klassifizierungsschlüssel, der darstellen sehr wie sehr die Bennenung von der Norm abweicht. A# ist die Abkürzungsnummer, die ich als Laufnummer für jeden möglichen Schlüssel vergeben hat. Wenn ich sage es gibt 30 verschiedene Abkürzungsregel gibt es also A#0 bis A#29 die jeweils für eine bestimmt Abkürzungsregel steht.

WICHTIG: Norm bzw normal ist in diesem Kontext immer darüber definiert wie häufig die Abkürzungsregel in der Liste vorkommt. 0 steht immer für die am häufigsten Vorkommende Art, 1 bis 3 sind Varianten mit zunehmender Obskurität, und ? ist in der Regel einzigartig.

Es gibt drei Teile, die hier unabhängig voneinander bewertet werden: "Name" bezieht sich auf den Namen in Worten. 0 wird vegeben für NAs, die nach dem Muster "DIN-Normenausschuss [Fachbereich]" benannt sind und bildet 92,8% der Liste (64/69). 1 steht für "DIN/VDI-Normenauschluss [Fachbereich]" und kommt einmal vor, 2 steht für "DIN-Normenstelle [Fachbereich]" und kommt zweimal vor. ? wurde ebenfalls zweimal vergeben für "VDI/DIN-Kommission Reinhaltung der Luft (KRdL) - Normenausschuss" und "DKE Deutsche Kommission Elektrotechnik Elektronik Informationstechnik in DIN und VDE". Hält sich noch in Grenzen mit der Obskurität, man kann sich auch noch vorstellen warum es hier Abweichungen gibt.

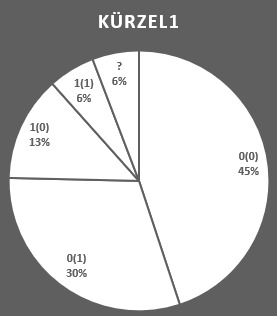

Kürzel1 kürzt den "Normenausschuss/-stelle" Teil ab und hat 4 häufige Varianten: 0(0)/"NA" in 31/69 also 44,9%, 0(1)/"N" in 21/69 also 30,4%, 1(0)/"FN" in 9/69 also 13,0% und 1(1)"F" in 4/69 also 5,8%. Die restlichen 4 sind einzigartig. Ich weiß wie gesagt nicht wofür das F steht :(

[Bildbeschreibung: 3 Kreisdiagramme die die Anteile der Varianten in jeweils "Name", "Kürzel1" und "Kürzel2" zeigen. Auswertung im Text. /Ende BB]

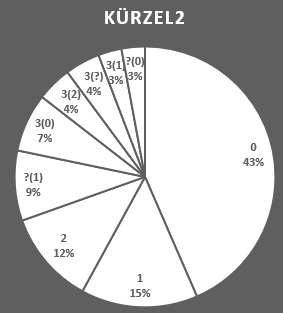

Bei Kürzel2 wirds kreativ! Hier wird der Fachbereich abgekürzt.

0 ist mit 43,5% (bzw 30/69) die Abkürzung mit dem ersten Buchstaben aller großgeschreibenen Worte. Bsp: "Maschienenbau" -> M, "Eisen-, Blech- und Metallwaren" -> EBM, "Kommunale Technik" -> KT

1 (14,5%, 10/69) ist wie 0, aber mit den ersten Buchstaben der Teilworte. Bsp: "Materialprüfung" -> MP, "Wälz- und Gleitlager" -> WGL

2 (11,6%, 8/69) ist wie 0, aber unvollständig. Hier ist fast immer nur das erste Wort benutzt ("Luft- und Raumfahrt" -> L), außer bei "Federn, Stanzteile und Blechformteile" -> FS. Wenn ich pingelig wäre könnte man hier noch ne Extrakategorie aufmachen ...

3 steht dafür wenn mehr als der erste Buchstabe vorkommt. Hier werden auch Kleinbuchstaben verwendet. Unterkategorien sind:

3(0) (7,2%, 5/69) heißt die ersten drei Buchstaben: "Ergonomie" -> Erg

3(1) (2,9%, 2/69) ist wie 3(0) aber mit einem Buchstaben mehr oder weniger als drei: "Tankanlagen" -> Tank und "Kältetechnik" -> Kä. (Auch hier könnte noch eine Pingeligskeitkategorie entstehen)

3(2) (4,3%, 3/69) ist 2 Buchstaben, aber ... nicht korrekt abgekürzt. Damit meine ich, dass ich oben in die 2 gesteckt hätte. Bsp: "Papier, Pappe und Faserstoff" -> Pa. (Wenn man "falsch" als unzugenügende Kategorisierung betrachtet sind hier nochmal +2 Pingeligkeitskategorien, da dann alle einzigartig sind)

3(?) (4,3%, 3/69) sind eindeutig einzigartig. "Sport- und Freizeitgeräte" -> Sport und "Dental" -> DENT

? hat diesesmal auch Unterkategorien! Nur ?(1) ist einzigartig, denn ?(0) wurde für etwas vergeben, dass es genau zweimal gibt: Abkürzung mit dem ersten Buchstaben inklusive kleingeschriebender Worte: "Kommission Reinhaltung der Luft" -> KRdL und "Feinmechanik und Optik" -> FuO. Also nicht einzigartig, sondern nur eigenartig :o)

Alles mit ?(1) (8,7%, 6/69) gibt es aber nur einmal! Hierunter sind viele meiner Favoriten: "Erdöl- und Erdgasgewinnung" -> ÖG (ergibt NÖG. macht Spaß zu sagen.), "Stahldraht und Stahldrahterzeugnisse" -> D, "Textil und Textilmaschinen" -> Textil, "Automobiltechnik" -> Automobil, und nun mein Albtraum in der Kategorisierung: "Grundlagen der Normungsarbeit" -> GLN und "Grundlagen des Umweltschutzes" -> GUS. Beides zwei Doppelwörter wovon eines als Gesamtwort und eines nach Teilworten abgekürzt sind. Aber trotzdem weigere ich ich die in die selbe Kategorie zupacken, weil sie sich so dreist die Mühe machen es doch jeweils anders zu machen obwohl sie beide mit "Grundlagen" anfangen.

So.

Meine persönlichen Lieblinge der Absurdität sind "DIN-Normenausschuss Textil und Textilmaschinen" -> Textilnorm, "DIN-Normenausschuss Gießereiwesen" -> GINA und "DIN-Normenausschuss Verpackungswesen" -> NAVp. Erklär mir bitte einer nach welcher Logik man Verpackungswesen zu Vp abkürzt. Und natürlich "DIN-Normenausschuss Grundlagen der Normungsarbeit" -> NAGLN ... der Normungsnormennormungsausschuss <3

Aber die eigentliche Norm wäre ja "DIN-Normenauschuss [Fachbereich]" -> NA + erster Buchstabe aller großgeschreibenen Worte, richtig? Ne.

Bei Kürzel1 und Kürzel2 ist die 0 nicht der Großteil also unter 50% der NAs, so viel also zur "Norm". Aber tatsächlich ist A#0 also [0; 0(0); 0] nicht nur unter 50%, sondern mit 14,5% noch nicht mal die häufigste Variante. Das ist A#11 - [0; 0(1); 0] mit 15,9% (wobei Kürzel1=0(1) ja nicht häufiger als Kürzel1=0(0) ist). Also kann man sich jetzt streiten ob die wahre Häufigkeitsnorm nicht doch "DIN-Normenauschuss [Fachbereich]" -> N + erster Buchstabe aller großgeschreibenen Worte ist.

Jedenfalls kommt mit 20 einzigartigen Abkürzungsregeln nur ein Drittel überhaupt mehr als einmal vor.

[Bildbeschreibung: Tabelle mit allen Abkürzungsnummern und zugehörigen Schlüsseln, Häufigkeit und Prozenten. Auswertung ging vorraus. /Ende BB]

Und was für einen Schluss kann man jetzt aus der ganzen Sache ziehen? ... Äh. Ääääähm. Also ich hatte Spaß :)

#das ist der wichtigst beitrag meines lebens glaub ich#uyld: deutsch#Deutsches Institut für Normung#cebo talks#at length#excelposting

2 notes

·

View notes

Text

Not to be confused with DIN freaks, who are very conservative in the non-political sense.

"DNI: freaks" do you realize how conservative you look

108K notes

·

View notes

Text

All About Flange-Udhhyog

Q1: What are the different types of flanges, and how do I choose the right one for my application?

A1: There are several types of flanges, including:

Weld Neck Flanges: Designed for high-pressure applications and welded to the pipe, providing a strong connection.

Slip-On Flanges: Slide over the pipe and are welded both inside and outside, ideal for low-pressure applications.

Blind Flanges: Used to close the end of a piping system, preventing the flow of fluids.

Socket Weld Flanges: For small-diameter pipes, where the pipe is inserted into the flange and welded.

Lap Joint Flanges: Used with a stub end, allowing for easier disassembly.

To choose the right flange, consider the application pressure, temperature, pipe size, and the type of connection required.

Q2: How do flange standards vary by country, and what should I know about them?

A2: Flange standards can vary significantly between countries. For instance:

ANSI (American National Standards Institute): Commonly used in the USA, focusing on pressure ratings and dimensions.

DIN (Deutsches Institut für Normung): Widely used in Europe, specifying metric dimensions and pressure ratings.

JIS (Japanese Industrial Standards): Used in Japan, similar to ANSI but with different specifications.

When selecting flanges, be aware of the applicable standards in your region to ensure compatibility with existing piping systems.

Q3: What materials are commonly used for flanges, and what are their advantages?

A3: Common materials for flanges include:

Mild Steel (MS): Cost-effective and suitable for low-pressure applications.

Stainless Steel: Corrosion-resistant and ideal for high-pressure and high-temperature applications.

Carbon Steel: Offers strength and durability for industrial applications.

Alloy Steel: Used for specialized applications requiring high strength and resistance to wear and corrosion.

The choice of material should be based on the operating environment, pressure, temperature, and the medium being transported.

Q4: How can I prevent leakage in flange connections?

A4: To prevent leakage in flange connections:

Use Quality Gaskets: Select the right gasket material based on the application and ensure proper installation.

Ensure Proper Alignment: Misalignment can lead to leaks; ensure that flanges are correctly aligned before tightening.

Tighten Bolts Uniformly: Follow the manufacturer's specifications for bolt torque to ensure even pressure distribution.

Regular Maintenance: Inspect flanges periodically for wear or damage and replace gaskets as necessary.

Q5: What are the most common applications for MS flanges in various industries?

A5: MS flanges are commonly used in:

Oil and Gas: Connecting pipelines and equipment.

Water Supply: Used in municipal and industrial water systems.

Construction: In various structural applications for strength and support.

Manufacturing: In machinery and equipment to facilitate fluid flow and pressure control.

Q6: How does the price of flanges fluctuate in the current market?

A6: The price of flanges can fluctuate based on several factors:

Material Costs: Increases in raw material prices can lead to higher flange costs.

Supply Chain Issues: Disruptions in manufacturing or transportation can affect availability and pricing.

Market Demand: Increased demand in specific industries can drive prices up.

Regularly monitoring market trends and supplier prices can help you anticipate changes.

Q7: What are the benefits of using stainless steel flanges over mild steel flanges?

A7: Benefits of using stainless steel flanges include:

Corrosion Resistance: Stainless steel can withstand harsh environments, making it suitable for chemical and coastal applications.

Strength and Durability: Offers better strength-to-weight ratios and longevity compared to mild steel.

Aesthetic Appeal: Stainless steel has a polished finish that is visually appealing in exposed applications.

However, stainless steel flanges are typically more expensive than mild steel flanges.

Q8: How do I determine the right flange size for my piping system?

A8: To determine the right flange size:

Measure the Pipe Diameter: Determine the outer diameter of the pipe.

Check Pressure Ratings: Ensure that the flange matches the pressure rating of the piping system.

Refer to Standards: Use ANSI, DIN, or other relevant standards to find the corresponding flange dimensions for your pipe size and pressure requirements.

Q9: What is the significance of flange pressure ratings?

A9: Flange pressure ratings indicate the maximum pressure a flange can withstand at a specified temperature. They are essential for:

Safety: Ensuring that the flange can handle the operational pressures without failing.

Compatibility: Matching flanges with piping and equipment rated for similar pressures prevents leaks and accidents.

Understanding pressure ratings helps in selecting appropriate flanges for your application.

Q10: Are there any recent advancements in flange manufacturing technology?

A10: Recent advancements in flange manufacturing technology include:

3D Printing: Allowing for rapid prototyping and customized designs.

Improved Materials: Development of new alloys that enhance corrosion resistance and strength.

Automation: Use of automated machinery for precision and efficiency in flange production.

Quality Control Technologies: Enhanced inspection techniques using non-destructive testing methods to ensure product integrity.

These advancements contribute to better quality, reduced production times, and cost savings in flange manufacturing.

#Flanges#MSFlanges#FlangeManufacturing#PipingSolutions#IndustrialEquipment#PipingIndustry#FlangeDesign#FlangeStandards#FlangeApplications#MechanicalEngineering#MildSteel#StainlessSteel#CarbonSteel#AlloySteel#OilAndGas#Construction#WaterSupply#Manufacturing#Engineering#ManufacturingInnovation#IndustrialSupply#QualityControl#SafetyFirst#TechAdvancements

5 notes

·

View notes

Text

Procura aço DIN 1.2631 (Chipper Knife) em #Portugal? O aço DIN 1.2631 é um aço para ferramentas de trabalho a frio com alto teor de carbono e alto teor de cromo, usado principalmente na fabricação de ferramentas de corte, punções e matrizes. Também é conhecido por outras designações como X50CrMoW9-1-1 ou aço AISI A8.

A designação "DIN 1.2631" refere-se ao grau de aço de acordo com o Deutsches Institut für Normung (DIN), que é o Instituto Alemão de Normalização. O sistema DIN é comumente usado na Europa para designar tipos de aço específicos.

A EDELSTAHL VIRAT IBÉRICA é o maior stock e fornecedor de Aços Grau 1.2631. Nós fornecemos Metal Steel Grau 1.2631 STEEL ALLOY TOOL PLATE é um molde de aço, usado em moldes de extrusão, moldes de fundição a quente. como produção de alumínio, molde de corte de alumínio ….

Consulte a nossa equipa que o ajudará na consulta do aço DIN 1.2631 (Faca Picadora) também para locais como… #Valbom #Canidelo #SenhoradaHora #OliveiradoDouro #Ribeira #Bolhão #Guimarães #Braga

PARA SABER MAIS >> https://moldsteel.eu/steel-products/chipper-knife-steel/

Chat WhatsApp: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#Valbom#Bolhão#Ribeira#Guimarães

2 notes

·

View notes

Text

How did you find DIN 1.2714 Steel in India? If you need a tool steel that can handle high temperatures, pressures, and stresses, look no further than DIN 1.2714 Steel. It’s the best in class for close die forgings.

DIN 1.2714 is a Hot Work Tool Steel that conforms to the German DIN (Deutsches Institut für Normung) standard. It is also known by other designations such as 55NiCrMoV7 or L6 in different international standards.

DIN 1.2714 (DB6 Steel) is a tool steel grade that is commonly used in the manufacturing of forging dies and plastic molds. It belongs to the group of hot work tool steels and is known for its high-temperature stability, wear resistance, and toughness. DIN 1.2714 (DB6 Steel) is often used in applications where the material needs to withstand elevated temperatures during the manufacturing process, such as in forging and die-casting operations.

The chemical composition of DIN 1.2714 (DB6 Steel) typically includes elements such as:

Carbon (C): 0.50-0.60% Silicon (Si): 0.10-0.40% Manganese (Mn): 0.60-0.90% Chromium (Cr): 1.00-1.50% Nickel (Ni): 1.00-1.50% Molybdenum (Mo): 0.20-0.30% Vanadium (V): 0.10-0.30%

These alloying elements contribute to the steel's properties, such as hardness, strength, and heat resistance. The specific composition may vary slightly depending on the manufacturer and the standard to which it adheres.

Virat Special Steels is the largest stockiest and supplier of #DB6/ DIN 2714 in flat, square and round bar. We provide steel in all sizes as your requirements.

To know about more specific details of DIN 1.2714 ( DB6 Steel ), please visit the website. https://www.viratsteels.com/din-2714.html https://www.viratsteels.com/db6.html

Email us: [email protected] Call Us Now: +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#db6 steel#db6#din 2714#aisil6#tool steel suppliers#forging#close die forging

2 notes

·

View notes

Text

Van Bi Nối Bích Inox – Tiêu chuẩn DIN

Van bi nối bích inox chuẩn DIN được đúc từ chất liệu inox cao cấp có độ bền cao với kiểu kết nối mặt bích theo đúng tiêu chuẩn Deutsches Institut für Normung e.V. của Đức giúp thiết bị có thể điều tiết và đóng/ mở dòng chảy trên hệ thống đường ống hiệu quả. Thiết bị được ứng dụng trên rất nhiều hệ thống đường ống nước dùng trong gia đình hay các khu dân cư hiện nay.

#vanbiinoxdinnoibich #vanbinoibichinoxchuandin #vanbi #vancongnghiep #anphuthanh

Link tham khảo: https://anphuthanh.vn/san-pham/van-bi-inox-din-noi-bich

3 notes

·

View notes

Text

Top 5 Benefits of Choosing High-Quality Metal Fittings Over Low-Cost Alternatives

When it comes to construction, plumbing, or industrial projects, the choice of materials directly influences the final product's quality, safety, and longevity. A critical decision lies in selecting the right metal fittings, components that serve as the backbone of many systems. While low-cost alternatives may appear tempting due to their initial affordability, high-quality metal fittings offer long-term advantages that far outweigh their upfront cost.

Top 5 Benefits of Investing in Superior Metal Fittings

1. Enhanced Durability and Longevity

High-quality metal fittings are designed to withstand rigorous conditions, including extreme temperatures, high pressure, and corrosive environments.

a. Material Grades: Superior fittings often use grades such as SS 304 or 316 stainless steel, which are rust and corrosion resistant, making them ideal for industrial and marine applications. Duplex stainless steel (2205) is another high-performance grade used in applications requiring even greater strength and resistance.

b. Performance Standards: To ensure top-notch durability, look for fittings that comply with international standards like ASTM (American Society for Testing and Materials), EN (European Norms), and ISO (International Organization for Standardization).

c. Heat Treatment: High-quality fittings often undergo processes like annealing to elevate their toughness and stress resistance.

2. Superior Safety and Reliability

Substandard metal fittings can lead to failures under pressure, potentially causing leaks, downtime, or even catastrophic accidents.

a. Load-Bearing Capacity: High-quality fittings are engineered to handle specific load requirements, securing consistent performance under stress. For example, Class 150, 300, and 600 fittings are designed to withstand varying pressure levels in industrial systems.

b. Leak Prevention: Precision manufacturing processes, such as CNC machining, eliminate irregularities, provide a tighter seal and reduce the risk of leaks.

c. Hydrostatic and Pneumatic Testing: High-quality fittings are often subjected to pressure testing to verify their performance under real-world conditions, ensuring reliability in high-stress environments.

3. Better Resistance to Wear and Tear

Low-cost alternatives often use inferior materials prone to corrosion, wear, and fatigue. Over time, these defects lead to inefficiencies and increased maintenance costs.

a. Coatings and Treatments: High-quality fittings frequently feature protective coatings, such as galvanisation, epoxy powder coating, or electroplating, which guarantee resistance to corrosion and wear. PTFE (Teflon) lining is used in fittings exposed to highly corrosive chemicals.

b. Testing Procedures: Premium fittings undergo stringent quality tests, including salt spray testing, impact resistance testing, and tensile strength testing, ensuring their resilience in demanding environments.

c. Material Selection: Alloys such as Inconel, Monel, and Hastelloy provide exceptional resistance to chemical and environmental wear, making them indispensable in industries like oil and gas.

4. Improved Compatibility and Precision

Inconsistent dimensions and subpar threading are common issues with low-cost fittings, leading to poor connections and potential system failures.

a. Precision Manufacturing: High-quality fittings are produced using advanced technologies, such as CNC lathes, laser cutting, and 3D modelling, providing accurate dimensions and threading.

b. Standardisation: Superior fittings often adhere to universal sizing standards like ANSI (American National Standards Institute), BS (British Standards), or DIN (Deutsches Institut für Normung), allowing seamless integration with other components.

c. Surface Finish: High-grade fittings typically have superior surface finishes (e.g., Ra < 0.8 µm for hygienic applications), making sure better flow and reduced contamination in systems like food processing and pharmaceuticals.

5. Cost-Effectiveness in the Long Run

While high-quality fittings may have a higher upfront cost, their long-term benefits, such as durability, reliability, and reduced maintenance needs, offer significant savings.

a. Maintenance Costs: Superior materials and precision engineering minimise the need for repairs or replacements, especially in critical systems like hydraulic lines and high-pressure pipelines.

b. Operational Efficiency: Fewer disruptions due to equipment failure lead to uninterrupted workflows and better productivity.

c. Energy Savings: In systems like HVAC and plumbing, well-fitted components reduce energy loss, translating into lower utility bills. For example, low-friction fittings assure optimised fluid dynamics, reducing pumping energy.

Why Choose high-quality Metals from Online FIttings:

Choosing the Right Metal Fittings for Your Construction Projects is an investment in durability, safety, and overall project success. By prioritising superior materials and precision manufacturing, businesses can avoid costly repairs, reduce downtime, and achieve long-term operational excellence.

Ready to elevate your projects with premium metal fittings? Contact Online Fittings today and experience the difference in quality and service. Let’s build a stronger, more reliable future together.

0 notes

Text

Understanding BIS, DIN, ASTM, and API Standards in Lubricants - Sigma Lubricants Pvt ltd Chennai

Lubricants play a critical role in ensuring the smooth operation of machinery, engines, and industrial equipment. But not all lubricants are created equal. To guarantee performance, quality, and safety, organizations worldwide have established standards for lubricant manufacturing and testing. Among the most recognized standards are BIS, DIN, ASTM, and API. This blog delves deep into these standards, their significance, and their applications in the lubricant industry. Visit Sigma Lubricants to learn more about our premium-grade lubricants that meet these global standards.

What Are Lubricant Standards?

Lubricant standards ensure that oils, greases, and other lubricants meet specific performance, safety, and environmental criteria. These standards are benchmarks that manufacturers and consumers rely on for consistency, reliability, and efficiency. Standards like BIS, DIN, ASTM, and API guide the formulation, testing, and certification processes of lubricants, ensuring compatibility and effectiveness for different applications.

BIS Standards in Lubricants

Overview of BIS

The Bureau of Indian Standards (BIS) is India’s national standardization body. BIS establishes guidelines for various products, including lubricants, ensuring they meet quality and safety benchmarks.

Key BIS Standards for Lubricants

IS 13656:1993 – Automotive Diesel Engine Oils.

IS 1448 – Methods of Test for Petroleum and Its Products.

IS 9436:1980 – Performance Guidelines for Automotive Gear Lubricants.

Importance of BIS Standards

Safety and Performance: BIS ensures that lubricants can withstand India’s diverse climatic conditions.

Consumer Protection: It safeguards consumers from substandard products.

Compliance: BIS certification is mandatory for certain lubricant products in India.

Learn more about BIS-compliant lubricants at Sigma Lubricants.

DIN Standards in Lubricants

Overview of DIN

Deutsches Institut für Normung (DIN) is Germany’s standardization body, known for its rigorous testing and high-quality benchmarks. DIN standards are widely recognized in Europe and globally.

Key DIN Standards for Lubricants

DIN 51524 – Hydraulic Fluids.

DIN 51517 – Gear Oils.

DIN 51825 – Lubricating Greases.

Why DIN Standards Matter

Precision and Quality: DIN-certified lubricants are synonymous with superior quality.

International Compatibility: These standards ensure that lubricants meet global industrial requirements.

Eco-friendliness: Many DIN standards emphasize environmental protection.

Explore high-performance DIN-standard lubricants on our product page.

ASTM Standards in Lubricants

Overview of ASTM

The American Society for Testing and Materials (ASTM) is a globally recognized organization that develops and publishes voluntary consensus standards. In the lubricant industry, ASTM standards ensure consistency and reliability.

Key ASTM Standards for Lubricants

ASTM D445 – Kinematic Viscosity of Transparent and Opaque Liquids.

ASTM D92 – Flash and Fire Points by Cleveland Open Cup.

ASTM D2270 – Viscosity Index Calculation.

Significance of ASTM Standards

Global Acceptance: ASTM standards are widely adopted in international markets.

Technical Rigor: They involve precise testing methodologies.

Versatility: Applicable across automotive, industrial, and marine sectors.

For ASTM-compliant lubricants, visit Sigma Lubricants.

API Standards in Lubricants

Overview of API

The American Petroleum Institute (API) is a leading authority in establishing performance standards for lubricants, particularly for automotive engines.

API Classification System

API S-series: Designed for gasoline engines (e.g., API SN, API SP).

API C-series: Developed for diesel engines (e.g., API CJ-4, API CK-4).

Why API Standards Are Crucial

Engine Protection: API-certified lubricants ensure optimal engine performance and longevity.

Emission Control: They help engines meet emission regulations.

Consumer Trust: API standards are widely trusted by vehicle manufacturers and consumers.

Discover API-certified engine oils at Sigma Lubricants.

Comparative Analysis of BIS, DIN, ASTM, and API Standards

StandardRegion of OriginFocus AreaKey IndustriesBISIndiaSafety & QualityAutomotive, IndustrialDINGermanyPrecision & QualityHydraulic, IndustrialASTMUSATesting & ReliabilityAutomotive, MarineAPIUSAEngine PerformanceAutomotive

How to Choose the Right Lubricant Standard for Your Needs

Application: Identify whether the lubricant is for automotive, industrial, or marine use.

Environmental Factors: Consider climatic conditions and operating environments.

Manufacturer Recommendations: Follow OEM guidelines for compliance with specific standards.

Visit Sigma Lubricants for expert guidance in selecting the right lubricant.

The Role of Standards in Sustainable Lubricant Development

Global standards like BIS, DIN, ASTM, and API also contribute to sustainable practices. They emphasize reduced environmental impact, energy efficiency, and the development of bio-based lubricants.

For more insights on sustainable lubricants, check out this informative article on Sustainability in the Lubricant Industry.

Why Sigma Lubricants?

Sigma Lubricants is committed to providing top-quality products that meet BIS, DIN, ASTM, and API standards. Our advanced manufacturing processes and rigorous quality checks ensure that our lubricants deliver unmatched performance and reliability.

Our Product Categories:

Automotive Lubricants

Industrial Lubricants

Specialty Lubricants

For more details, explore Sigma Lubricants’ website or call us at +91-XXXXXXXXXX.

Conclusion

Understanding BIS, DIN, ASTM, and API standards is essential for choosing the right lubricant for your needs. These standards not only ensure product quality and performance but also contribute to safety, efficiency, and sustainability. At Sigma Lubricants, we take pride in offering products that align with these global benchmarks, ensuring our customers receive nothing but the best.

Explore our extensive range of lubricants at Sigma Lubricants and experience the difference that quality and standards can make.

0 notes

Text

Neue DIN Normungsroadmap Bauwerke

„…Das Deutsches Institut für Normung (DIN) hat im Dezember 2024 eine neue Normungsroadmap Bauwerke veröffentlicht. Die neue Normungsroadmap (NRM) dient als interdisziplinärer Branchenleitfaden, der den zukünftigen Fahrplan für die Normung im Bauwesen formuliert. Ziel ist es, die Branche flexibler, nachhaltiger und digitaler zu machen. Die Roadmap wurde in einem transparenten und partizipativen…

0 notes

Text

How Yarn Testing Ensures Compliance with ISO and Other International Standards?

In the competitive textile industry, maintaining high standards of product quality and performance is crucial to business success. One of the most effective ways to ensure these standards is through yarn testing. Yarn testing plays an essential role in verifying that yarn meets various performance criteria, particularly ISO (International Organization for Standardization) and other internationally recognized standards. Whether the yarn is used for fashion apparel, industrial fabrics, or home textiles, adhering to these quality standards guarantees that the final product performs as expected, meets regulatory requirements, and satisfies customer expectations.

In this blog, we will explore how yarn testing ensures compliance with ISO and other international standards, the importance of testing in maintaining quality control, and how it helps textile manufacturers remain competitive in global markets.

The Importance of Yarn Testing in the Textile Industry

Yarn is the fundamental building block of most textile products. It is the raw material used to create everything from simple clothing to complex industrial fabrics. Because yarn is responsible for a significant portion of a product’s quality, consistency, and durability, ensuring that it complies with recognized standards is crucial for manufacturers.

Yarn testing involves evaluating a variety of characteristics that affect the yarn’s performance, including its tensile strength, elasticity, fiber composition, and evenness. Through standardized testing methods, yarn can be measured for these properties, helping manufacturers identify potential issues early in the production process and address them before the yarn is used in final fabric production.

Ensuring that yarn complies with international standards helps manufacturers achieve uniformity, safety, and reliability. Testing is vital not only for compliance but also for achieving consumer satisfaction, maintaining market competitiveness, and facilitating international trade.

ISO and International Standards for Yarn Testing

ISO standards are globally recognized and play a critical role in determining the quality and safety of products across various industries, including textiles. For yarn, ISO 9001 (Quality Management Systems), ISO 2076 (Yarn Classification), and ISO 2061 (Determination of the Linear Density of Yarns) are some of the most relevant standards. These standards cover various aspects of yarn production, testing, and performance and are used to ensure that yarns meet the desired specifications for strength, durability, and uniformity.

In addition to ISO standards, other international organizations, such as the ASTM (American Society for Testing and Materials), BSI (British Standards Institution), and DIN (Deutsches Institut für Normung), provide regulations and testing methods that ensure yarn quality across different markets. Compliance with these standards helps textile manufacturers align with global expectations for product quality, safety, and environmental sustainability.

How Yarn Testing Ensures Compliance with ISO and Other International Standards

1. Verification of Fiber Composition

The first step in ensuring yarn quality is verifying the fiber composition. For example, ISO 2076 provides guidelines for yarn classification, including identifying the type of fibers in the yarn (e.g., cotton, wool, polyester, or blends). Compliance with this standard ensures that the yarn meets the required specifications and can be accurately classified. For manufacturers, fiber testing allows them to verify that the yarn is made from the correct fiber content, ensuring consistency in the end product's appearance, performance, and durability.

Tests such as microscopic analysis and burning tests are commonly used to verify fiber composition. These methods help determine the origin and type of fibers present in the yarn, ensuring the yarn meets the standards set by international regulatory bodies.

2. Strength Testing

Tensile strength is a key property of yarn that determines how much load the yarn can withstand before breaking. This property is crucial for ensuring the durability and reliability of the fabric created from the yarn. ISO 2062 specifies the method for testing the tensile strength of yarns, which helps manufacturers assess the yarn’s ability to withstand mechanical stresses.

Tensile testing is conducted by measuring the force required to break the yarn, which provides data on its strength, elongation, and resistance to tension. Yarn that passes strength tests is more likely to be durable, offering better performance in both woven and knitted fabrics. By adhering to ISO 2062, manufacturers ensure that their yarn complies with internationally accepted strength requirements, which is particularly important for applications such as outdoor textiles, performance wear, and industrial fabrics.

3. Uniformity and Evenness Testing

Another critical aspect of yarn quality is uniformity. ISO 1833 specifies methods for assessing the evenness of yarn, ensuring that it is consistent in diameter and texture along its length. Inconsistent yarn can result in fabric defects, such as weak spots or uneven dye absorption. By adhering to uniformity standards, manufacturers can ensure that the yarn used in fabric production is smooth, consistent, and suitable for its intended purpose.

Unevenness tests help identify any variations in the yarn’s thickness and texture, allowing manufacturers to correct issues before the yarn is used in fabric production. This not only ensures compliance with ISO 1833 but also helps prevent defects that could affect the appearance, functionality, or strength of the final product.

4. Twist Testing

The twist in yarn is another important factor that impacts its overall performance. Twist influences the yarn's strength, elasticity, and texture. ISO 2061 provides methods for determining the twist in yarns, ensuring that it meets the requirements for consistent performance in textile applications.

Proper twist testing ensures that yarns have the correct twist level, which in turn affects how the yarn behaves when woven or knitted into fabrics. If the yarn is twisted incorrectly, it could lead to issues such as poor fabric stability, pilling, or even yarn breakage during fabric production. Therefore, testing the twist ensures that yarn meets international standards for textile quality.

5. Dyeing and Finish Consistency

Yarn testing also helps ensure that the yarn will perform well during dyeing and finishing processes. Yarn must absorb dyes uniformly and react predictably to finishing chemicals. The evenness of the yarn affects how well it takes dye, leading to a consistent color in the final fabric.

Standards like ISO 105 specify how to test the colorfastness and dye absorption properties of textiles, including yarn. Compliance with these standards ensures that the yarn will maintain its appearance and performance in the final fabric, whether it’s exposed to washing, light, or abrasion.

6. Compliance with Environmental and Sustainability Standards

In addition to performance standards, ISO 14001 (Environmental Management Systems) and other sustainability-related standards are becoming increasingly important in the textile industry. Many textile manufacturers are now required to ensure that their processes, including yarn production and testing, meet environmental guidelines that minimize waste, reduce energy consumption, and ensure safe working conditions.

By testing yarn for environmental and sustainability factors, manufacturers can ensure compliance with these standards, helping to meet both consumer demand for eco-friendly products and regulatory requirements.

The Benefits of Complying with ISO and International Standards

Ensuring compliance with ISO and other international standards through yarn testing offers a range of benefits for textile manufacturers, including:

Improved product quality: Regular testing ensures that yarns are consistently high-quality, which translates into better finished textiles.

Market access: Compliance with internationally recognized standards opens up access to global markets, as many countries require that imported products meet these standards.

Consumer trust: Meeting recognized standards helps build consumer confidence in the quality, safety, and reliability of the product.

Reduced waste: By identifying defects early, yarn testing minimizes the risk of producing defective yarn that could lead to fabric waste.

Sustainability: Compliance with environmental standards demonstrates a commitment to sustainability, which is increasingly important to consumers and regulatory bodies alike.

Conclusion

Yarn testing is an essential process for ensuring that yarns meet ISO and other international standards. By verifying key properties such as fiber composition, strength, uniformity, twist, and dyeing consistency, yarn testing ensures that textile products meet global quality standards. Manufacturers who adhere to these standards not only ensure product quality and safety but also gain a competitive edge in the global market.

As the textile industry continues to evolve, compliance with ISO and other international standards will remain crucial for manufacturers aiming to produce high-quality, durable, and sustainable yarns that meet the ever-growing demands of consumers and industries worldwide.

0 notes

Text

BCI vs. DIN Codes: Unlock the Secrets to Battery Cross-Referencing Like a Pro

Choosing the right battery for your vehicle can feel overwhelming with all the codes and specifications out there. Have you ever wondered what those labels—BCI and DIN—actually mean? These codes are essential for identifying the right battery, ensuring it fits perfectly, and powers your vehicle efficiently. By mastering the car battery size chart, you’ll be able to navigate these codes like a pro and make informed decisions with ease.

Battery Codes

Shopping for a car battery can feel like trying to decipher a foreign language. You’ve probably noticed codes like “BCI Group 35” or “DIN 57412” on battery labels and wondered what they mean. These codes aren’t just random—they hold the key to finding a battery that fits your vehicle perfectly. Let’s decode the mystery of these labels and help you master the art of cross-referencing.

What Are BCI and DIN Codes?

BCI (Battery Council International) and DIN (Deutsches Institut für Normung) are two different standards used to classify car batteries. Think of them as two roadmaps for the same journey—they get you to the right battery, but the paths are slightly different.

BCI Codes: Common in North America, focusing on group sizes based on dimensions and terminal placements.

DIN Codes: Popular in Europe, with a focus on compatibility for European vehicle models.

Knowing which system your car follows is the first step to finding the right battery.

Why Do These Codes Matter?

Imagine trying to fit a square peg in a round hole—that’s what it’s like using the wrong battery. The right code ensures:

Proper Fit: The battery fits snugly in the compartment.

Correct Terminal Placement: Avoids wiring issues.

Optimal Performance: Matches your vehicle’s power requirements.

Understanding these codes can save you time, money, and frustration.

Understanding BCI Codes

BCI codes are all about group sizes. For example:

Group 24: Common in midsize vehicles.

Group 35: Often used in compact cars.

Group 31: Designed for heavy-duty trucks and industrial use.

Each code provides the battery’s dimensions, terminal placement, and capacity, making it easy to find the perfect fit for your vehicle.

Breaking Down DIN Codes

DIN codes focus on European standards and often include a numerical sequence, like “57412.” Here’s how to interpret them:

57: Battery capacity in amp-hours.

4: Indicates the physical design.

12: Refers to the battery’s length in centimeters.

While DIN codes may look more complicated than BCI codes, they provide equally important details for matching batteries to European vehicles.

Key Differences Between BCI and DIN Codes

The main differences between these systems are:FeatureBCI CodesDIN CodesRegionNorth AmericaEuropeFocusDimensions and terminalsCapacity and lengthExamplesGroup 24, Group 3557412, 61038

Understanding these distinctions helps when cross-referencing between the two systems.

How to Use a Car Battery Size Chart

A car battery size chart bridges the gap between BCI and DIN codes, making cross-referencing a breeze. To use one:

Identify Your Vehicle’s Code: Check the owner’s manual or old battery.

Find Equivalent Sizes: Match the BCI group to the corresponding DIN code.

Confirm Compatibility: Double-check dimensions, capacity, and terminal placement.

This chart is your secret weapon for navigating global battery standards.

Finding the Right Battery for Your Vehicle

Choosing a battery isn’t just about size—it’s also about performance. Look for:

Voltage: Most cars require a 12-volt battery.

Capacity: Ensure the amp-hour rating matches your vehicle’s needs.

Fit: Confirm the dimensions align with your battery compartment.

Comparing Battery Dimensions

Both BCI and DIN codes provide dimensions, but the measurements differ slightly:

BCI Codes: Dimensions are listed in inches (e.g., 10.25 x 6.8125 x 8.875 inches).

DIN Codes: Dimensions are often in centimeters, focusing on length and height.

Use a conversion tool if needed to ensure the battery fits.

Matching Terminal Placement

Incorrect terminal placement can lead to wiring issues or short circuits. Always ensure the positive and negative terminals align with your vehicle’s wiring. This is particularly important when cross-referencing between BCI and DIN codes.

The Role of Cold Cranking Amps (CCA)

Cold Cranking Amps (CCA) measure a battery’s ability to start in cold weather. If you live in a region with harsh winters, prioritize batteries with high CCA ratings. Both BCI and DIN standards include this information, so look for it when cross-referencing.

The Impact of Climate on Battery Selection

Hot and cold climates affect battery performance differently:

Hot Weather: Accelerates wear and reduces lifespan. Choose heat-resistant batteries.

Cold Weather: Reduces starting power. High CCA ratings are essential.

Consider your local climate when selecting a battery.

Cross-Referencing Tips for Global Vehicles

If you’re driving an imported car, you may need to cross-reference between BCI and DIN codes. Here’s how:

Identify the Original Code: Check your owner’s manual or old battery.

Use a Cross-Reference Chart: Match the code to its equivalent in the other system.

Verify Fit and Performance: Double-check dimensions, capacity, and terminal placement.

Avoiding Common Mistakes in Battery Selection

Here are some pitfalls to avoid:

Choosing Based on Price Alone: Cheaper batteries might not meet your vehicle’s needs.

Ignoring Climate: Not all batteries perform well in extreme temperatures.

Overlooking Terminal Placement: Mismatched terminals can damage your vehicle.

Conclusion: Master Battery Cross-Referencing with Ease

BCI and DIN codes might seem like a puzzle at first, but with the right tools—like a car battery size chart—you can easily navigate the world of automotive batteries. By understanding the differences and knowing how to cross-reference, you’ll always find the perfect battery for your vehicle.

0 notes

Text

Procura aço DIN 1.2631 (Chipper Knife) em #Portugal?

O aço DIN 1.2631 é um aço para ferramentas de trabalho a frio com alto teor de carbono e alto teor de cromo, usado principalmente na fabricação de ferramentas de corte, punções e matrizes. Também é conhecido por outras designações como X50CrMoW9-1-1 ou aço AISI A8.

A designação "DIN 1.2631" refere-se ao grau de aço de acordo com o Deutsches Institut für Normung (DIN), que é o Instituto Alemão de Normalização. O sistema DIN é comumente usado na Europa para designar tipos de aço específicos.

A EDELSTAHL VIRAT IBÉRICA é o maior stock e fornecedor de Aços Grau 1.2631. Nós fornecemos Metal Steel Grau 1.2631 STEEL ALLOY TOOL PLATE é um molde de aço, usado em moldes de extrusão, moldes de fundição a quente. como produção de alumínio, molde de corte de alumínio ….

Consulte a nossa equipa que o ajudará na consulta do aço DIN 1.2631 (Faca Picadora) também para locais como… #Valbom #Canidelo #SenhoradaHora #OliveiradoDouro #Ribeira #Bolhão #Guimarães #Braga

PARA SABER MAIS >> https://moldsteel.eu/steel-products/chipper-knife-steel/

Chat WhatsApp: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#edelstashlviratibrica#viratsteels#b2b#din2738#Valbom#Canidelo#SenhoradaHora#OliveiradoDouro#Ribeira#Bolhão#Guimarães#Braga#din2631#Chipper Knife

2 notes

·

View notes

Text

Tiêu chuẩn DIN, BS, JIS: Những tiêu chuẩn công nghiệp hàng đầu thế giới

Trong thế giới sản xuất và thương mại quốc tế, việc áp dụng các tiêu chuẩn công nghiệp là vô cùng quan trọng để đảm bảo chất lượng, an toàn và tính tương thích của sản phẩm. Tiêu chuẩn DIN, BS, JIS là ba trong số những tiêu chuẩn công nghiệp hàng đầu thế giới, được áp dụng rộng rãi trong nhiều lĩnh vực. Bài viết này sẽ cung cấp cho bạn cái nhìn tổng quan về ba tiêu chuẩn này, giúp bạn hiểu rõ hơn về nguồn gốc, lĩnh vực áp dụng và tầm quan trọng của chúng.

I. Giới thiệu

Tiêu chuẩn công nghiệp là tập hợp các quy định, thông số kỹ thuật được thiết lập bởi các tổ chức tiêu chuẩn quốc gia hoặc quốc tế. Việc áp dụng tiêu chuẩn giúp thống nhất cách thức sản xuất, kiểm tra chất lượng, đảm bảo tính tương thích giữa các sản phẩm và thúc đẩy thương mại quốc tế.

DIN, BS, JIS là ba bộ tiêu chuẩn công nghiệp được sử dụng rộng rãi trên thế giới, xuất xứ từ Đức, Anh và Nhật Bản. Các tiêu chuẩn này bao gồm nhiều lĩnh vực, từ cơ khí, xây dựng đến điện tử, môi trường,...

>>> Xem thêm chi tiết tại đây: Tiêu chuẩn DIN, BS, JIS

II. Tiêu chuẩn DIN

DIN là viết tắt của Deutsches Institut für Normung, tức Viện Tiêu chuẩn Đức. Đây là tổ chức tiêu chuẩn quốc gia của Đức, chịu trách nhiệm xây dựng và ban hành các tiêu chuẩn kỹ thuật cho sản phẩm, dịch vụ và quy trình.

Lịch sử hình thành và phát triển:

DIN được thành lập vào năm 1917, ban đầu với tên gọi Normenausschuss der deutschen Industrie (NADI).

Năm 1926, NADI được đổi tên thành Deutscher Normenausschuss (DNA).

Năm 1975, DNA chính thức trở thành Deutsches Institut für Normung (DIN).

Các lĩnh vực áp dụng:

Tiêu chuẩn DIN được áp dụng trong rất nhiều lĩnh vực, bao gồm:

Cơ khí: Bulong, ốc vít, ren, bánh răng,...

Xây dựng: Vật liệu xây dựng, kết cấu thép, hệ thống cấp thoát nước,...

Điện tử: Linh kiện điện tử, thiết bị điện,...

Môi trường: Xử lý nước thải, khí thải,...

Ưu điểm của tiêu chuẩn DIN:

Tính chính xác và độ tin cậy cao.

Đảm bảo chất lượng và an toàn cho sản phẩm, dịch vụ.

Thúc đẩy sản xuất và thương mại, tạo điều kiện thuận lợi cho xuất nhập khẩu.

Ví dụ về một số tiêu chuẩn DIN phổ biến:

DIN 476: Tiêu chuẩn về kích thước giấy.

DIN 931: Tiêu chuẩn về bulong lục giác.

DIN 933: Tiêu chuẩn về ốc vít lục giác.

III. Tiêu chuẩn BS

BS là viết tắt của British Standards Institution, tức Viện Tiêu chuẩn Anh. Đây là tổ chức tiêu chuẩn quốc gia của Vương quốc Anh, chịu trách nhiệm xây dựng và ban hành các tiêu chuẩn kỹ thuật.

Lịch sử hình thành và phát triển:

BSI được thành lập vào năm 1901, ban đầu với tên gọi Engineering Standards Committee.

Năm 1918, tổ chức này được đổi tên thành British Engineering Standards Association.

Năm 1931, chính thức trở thành British Standards Institution (BSI).

Các lĩnh vực áp dụng:

Tiêu chuẩn BS cũng được áp dụng rộng rãi trong nhiều lĩnh vực tương tự như tiêu chuẩn DIN, bao gồm cơ khí, xây dựng, điện tử, môi trường,...

Ưu điểm của tiêu chuẩn BS:

Tương tự như ưu điểm của tiêu chuẩn DIN.

Ví dụ về một số tiêu chuẩn BS phổ biến:

BS 1387: Tiêu chuẩn về ống thép mạ kẽm nhúng nóng.

BS EN 10255: Tiêu chuẩn về ống thép không hàn.

IV. Tiêu chuẩn JIS

JIS là viết tắt của Japanese Industrial Standards, tức Tiêu chuẩn Công nghiệp Nhật Bản. Đây là hệ thống tiêu chuẩn quốc gia của Nhật Bản, được áp dụng trong tất cả các ngành công nghiệp.

Lịch sử hình thành và phát triển:

JIS được thiết lập vào năm 1921, ban đầu với tên gọi Japanese Engineering Standards (JES).

Sau Chiến tranh Thế giới thứ hai, JES được cải cách và đổi tên thành Japanese Industrial Standards (JIS).

Các lĩnh vực áp dụng:

Tiêu chuẩn JIS cũng được áp dụng trong nhiều lĩnh vực tương tự như tiêu chuẩn DIN và BS.

Ưu điểm của tiêu chuẩn JIS:

Tương tự như ưu điểm của tiêu chuẩn DIN và BS.

Ví dụ về một số tiêu chuẩn JIS phổ biến:

JIS G3445: Tiêu chuẩn về ống thép cacbon hàn cho mục đích chung.

JIS B2301: Tiêu chuẩn về mặt bích thép.

V. So sánh tiêu chuẩn DIN, BS, JIS

Nhìn chung, ba tiêu chuẩn DIN, BS, JIS đều có những ưu điểm tương đồng về chất lượng, độ tin cậy và tính an toàn. Sự khác biệt chủ yếu nằm ở xuất xứ và một số chi tiết kỹ thuật cụ thể.

VI. Tầm quan trọng của việc áp dụng tiêu chuẩn DIN BS JIS

Việc áp dụng tiêu chuẩn DIN, BS, JIS mang lại nhiều lợi ích cho doanh nghiệp, người tiêu dùng và toàn xã hội:

Đối với doanh nghiệp:

Nâng cao chất lượng sản phẩm, tăng tính cạnh tranh.

Nâng cao uy tín thương hiệu.

Mở rộng thị trường xuất khẩu.

Đối với người tiêu dùng:

Đảm bảo an toàn và chất lượng sản phẩm.

Dễ dàng lựa chọn sản phẩm phù hợp.

Đối với xã hội:

Thúc đẩy phát triển kinh tế.

Bảo vệ môi trường.

Nâng cao chất lượng cuộc sống.

VII. Kết luận

Tiêu chuẩn DIN, BS, JIS là những tiêu chuẩn công nghiệp quan trọng, đóng góp vào sự phát triển của nền kinh tế toàn cầu. Tuấn Hưng Phát Valve khuyến khích các doanh nghiệp nên tìm hiểu và áp dụng các tiêu chuẩn này để nâng cao chất lượng sản phẩm, hiệu quả sản xuất và khả năng cạnh tranh trên thị trường.

0 notes

Text

Hydraulic Hose Assemblies: The Backbone of Fluid Power Systems

In the world of industrial hydraulics, hydraulic hose assemblies play a critical role in ensuring the smooth operation of machines and equipment. Whether you’re dealing with construction machinery, manufacturing plants, or any equipment using hydraulic oil, these assemblies are essential for efficient fluid transmission under both low and high pressures.

Applications of Hydraulic Hose Assemblies

Hydraulic hose assemblies are used across various industries to circulate hydraulic oil, ensuring optimal performance in systems requiring precise power transmission. They are designed to handle a wide range of pressures and flow rates, making them suitable for:

Construction Equipment: Excavators, bulldozers, and loaders rely on hydraulic systems to lift, dig, and move materials.

Agricultural Machinery: Tractors and harvesters require hydraulic assemblies to operate efficiently.

Industrial Automation: Hydraulic hose assemblies power robotic arms, presses, and other machinery in manufacturing.

Marine Applications: Ships and vessels use hydraulics for steering, hoisting, and winch control systems.

Regardless of the application, hydraulic hose assemblies provide the necessary flexibility, durability, and resistance to high-pressure environments.

Construction and Materials

At Rubber Hose India LLP, our hydraulic hose assemblies are engineered for durability and performance, built with precision and care to meet industry standards. We offer a variety of construction options, depending on the application’s pressure and environmental requirements:

Wire Braided Hoses: These hoses are reinforced with layers of steel wire for increased strength and pressure tolerance. Ideal for medium to high-pressure systems.

Spiral Hoses: Built with multiple layers of wire, spiral hoses can handle very high pressure, making them suitable for heavy-duty applications.

Yarn Braided Hoses: These are lighter and more flexible, used in low-pressure systems where flexibility is paramount.

Each assembly is fitted with high-quality carbon steel or stainless steel end fittings, which are crimped securely to ensure leak-proof connections.

Available Sizes

At Rubber Hose India LLP, we offer hydraulic hose assemblies in a range of sizes, from 3/16” to 3”, allowing you to choose the right fit for your system’s specific requirements. The variety in sizes ensures compatibility with different hydraulic systems, making our hoses versatile and reliable for diverse applications.

End Fittings and Customization

Our hydraulic hose assemblies come equipped with various standard end fittings, including:

JIC (Joint Industry Council)

BSP (British Standard Pipe)

ORFS (O-Ring Face Seal)

SAE O-Ring Fitting

DIN (Deutsches Institut für Normung)

Additionally, flanged ends and non-standard fittings can be provided upon request, ensuring that you get the exact specifications your system requires. Whether you need a specific thread type or a custom-built hose assembly for a unique application, we’ve got you covered.

Why Choose Rubber Hose India LLP?

With over 30 years of experience in the industry, Rubber Hose India LLP is a leading provider of high-quality hydraulic hose assemblies in India. We pride ourselves on offering products that meet the highest standards of durability, safety, and efficiency.

Expertise: Our team is highly skilled in designing and manufacturing hose assemblies tailored to your needs.

Quality Assurance: Every hose assembly undergoes rigorous testing to ensure it performs under the most demanding conditions.

Customization: We offer flexible customization options to meet your unique requirements, whether it’s a specific size or a non-standard fitting.

Conclusion

Hydraulic hose assemblies are an essential component in any system that relies on hydraulic power. At Rubber Hose India LLP, we provide high-quality, customizable solutions that cater to a wide range of industries and applications. With our robust construction, variety of sizes, and customizable fittings, we ensure that your hydraulic systems remain efficient, reliable, and leak-proof.

For more information or to discuss your specific requirements, contact Rubber Hose India LLP today.

0 notes

Text

Shadows of Integrity: Architecture as a Living Document of Memory and Time

In the architecture of history, the document controller becomes a custodian of both the physical and philosophical dimensions of design, embodying a role that resonates with the heritage of luminaries like Daniel Libeskind. Libeskind’s assertion that architecture is the “biggest unwritten document of history” reflects his broader legacy, rooted in memory and identity. His works, such as the Jewish Museum Berlin, navigate the relationship between form, shadow, and historical narrative, where space becomes an envelope for collective memory.

Similarly, the DIN (Deutsches Institut für Normung) format, originally a German standard, has become a global framework that structures not just architectural drawings but the way we communicate and preserve the technical language of architecture. It reflects the precision and universality that architecture demands, creating an international order that sustains the integrity of designs across time and space.

Folding, envelopes, and shadows are not merely design elements but metaphors for how architecture engages with time. The envelope, in this context, holds not just the physical space but the intangible—shadows that represent the invisible forces at play in architecture: memory, culture, and historical weight. The shadow, in its fleeting nature, offers a counterpoint to the permanence of built forms, much like the document controller’s role in preserving architectural truth against the ravages of time.

This abstract honorus the versatile architect who, like Libeskind, navigates the tensions between time and memory, form and shadow, and the document controller who ensures that the architectural narrative remains honest. In doing so, they protect the sanctity of architecture as a living record—one where shadows and folds are not erasures but layers that enrich our understanding of history and its projection into the future. The architect’s war with time is ultimately a battle for the integrity of this unwritten document, where every preserved drawing, every shadow cast, becomes part of a larger architectural legacy that speaks to our shared heritage and future.

#ArchitectureHistory #DanielLibeskind #ArchitecturalLegacy #DINStandards #MemoryAndIdentity #ArchitecturalPhilosophy #TimeAndSpace #DocumentController #ShadowsAndFolds #BuiltHeritage #ArchitecturalIntegrity #EnvelopeOfShadows #ArchitectureAndTime #CulturalMemory #PreservingArchitecture

1 note

·

View note

Text

Steel Screw Manufacturer: Comprehensive Guide

Introduction

Steel screws are indispensable parts used in construction, engineering, manufacturing, and day-to-day applications. These small but vital fasteners ensure structural integrity, which allows robust connections across materials. As a leading Steel Screw Manufacturer, we provide screws of superior quality and precision, which can meet the requirements of industries across the globe with reliability and durability.

This blog delves into the world of screws, covering their types, standards, and the significance of choosing a reliable manufacturer like Ananka Group.

The Role of a Screw Manufacturer

At Ananka Group, we specialize in producing high-quality steel screws that conform to international standards. From selecting the finest raw materials to employing advanced manufacturing techniques, our processes guarantee durability and precision.

A screw manufacturer designs, produces, and provides screws according to the needs of industries and business. Manufacturers meet international requirements by providing screws with definite size, tensile strength, and resistance to corrosion. As industry leaders, we also act as Screw Stockists, Suppliers, and Exporters, thereby meeting demands in various markets.

Types of Screws

1. Machine Screws

These are screws that are used in machines and have a thread that matches tapped holes to provide precise contact.

2. Wood Screws

They are made specifically for use in wood and have a sharp thread to hold up wooden structures.

3. Self-Tapping Screws

They can tap their own threads into soft materials like plastic or thin metal.

4. Socket Head Screws

These screws are usually used in heavy machinery and provide a high torque value and strength.

5. Hex Head Screws

Hexagonally shaped, they are very popular for structural connections because of their strength.

6. Sheet Metal Screws

Ideal for joining thin metal sheets, they come with sharp threads for effective penetration into the metal.

7. Set Screws

These fully threaded screws with no head are used to fasten pieces such as pulleys and gears to shafts.

Screw Standards

A screw is manufactured in global standards to ensure consistency. Examples of key standards are:

International Organization for Standardization

For metric screws, these ensure screw compatibility worldwide.

DIN (Deutsches Institut für Normung): German standards widely recognized worldwide.

ASTM (American Society for Testing and Materials): Defines material and mechanical properties for screws.

ANSI (American National Standards Institute): Ensures standardization for industrial screws.

BS (British Standards): Defines standards for screws in the UK.

Advantages of Steel Screws

High Durability: Crafted with precision, our screws withstand extreme conditions.

Corrosion Resistance: Made from premium steel, they resist rust, ensuring longevity.

Wide Applications: Suitable for diverse sectors such as construction, automotive, and manufacturing.

Customizable Options: Available in various sizes, finishes, and coatings.

Global Standards: Compliant with international standards, ensuring consistency and quality.

Why Choose Ananka Group?

Global PresenceWe are a leading screw supplier and exporter, serving industries across the globe.

Custom ManufacturingOur team designs screws tailored to client specifications, ensuring they meet unique project requirements.

Certified QualityAll our screws adhere to international standards, ensuring safety and reliability.

Extensive InventoryAs a trusted screw stockist, we maintain a diverse range of screws in various sizes, grades, and finishes.

Eco-Friendly PracticesOur production processes are sustainable and environmentally friendly.

Conclusion

Screws are indispensable in numerous applications, and their quality directly impacts the success of a project. Choosing a reliable screw manufacturer like Ananka Group ensures you receive products that meet the highest standards of quality and performance. With a wide variety of screws and a global presence, we are committed to delivering excellence in every fastening solution.

Frequently Asked Questions (FAQ)

1. What materials are used to manufacture screws?

Screws are usually available in various materials such as steel, stainless steel, brass, aluminum, and other alloys depending on their application.

2. Machine screws versus self-tapping screws.

Machine screws usually require a pre-threaded hole whereas self-tapping screws cut their own thread when they go into the material.

3. Are your screws customized to order?

We manufacture customized screws according to particular industrial requirements or size, material, and also coating.

4. Are your screws international standards compliant?

Yes, all our screws are manufactured according to ISO, ASTM, DIN, ANSI, and BS standards.

5. What finishes are available for screws?

We offer finishes like zinc plating, galvanizing, black oxide, and more to enhance durability and appearance.

#Screw#ScrewFasteners#Fasteners#FastenersManufacturer#Ananka#AnankaFasteners#supplier#manufacturer#mumbai#hex#bolt#usa#uk#Article#blog

0 notes