#Nodular Iron Casting

Explore tagged Tumblr posts

Text

Nodular Iron Casting is widely used in a wide range of applications due to its strength and durability. Explore the step-by-step guide on how manufacturers make Nodular Iron Casting. Learn about every steps in details.

0 notes

Text

High Recovery for Ferro Silicon Magnesium: Boosting Output and Quality

Ferro Silicon Magnesium (FeSiMg) is a vital alloy in the steel and foundry industries, principally utilized as an inoculant and nodulizer in the manufacturing of ductile iron and cast iron. The efficiency of this alloy, however, relies greatly on the recovery rate of magnesium during the alloying process. A high recovery for ferro silicon magnesium not only assures effective use of raw materials but also increases the overall quality and production of the end product.

Importance of High Recovery in Ferro Silicon Magnesium

In metallurgical operations, the word "recovery" refers to the proportion of a certain element or compound that is maintained during smelting, refining, or alloying. In the case of FeSiMg, excellent magnesium recovery is crucial for numerous reasons:

Maximizing Material Efficiency: Magnesium is volatile at high temperatures, which may lead to considerable losses during alloying. A greater recovery rate decreases these losses, ensuring that more of the magnesium existing in the alloy contributes to the final product. This leads in cost savings and more effective use of resources.

Enhancing Product Quality: The proportion of magnesium maintained directly effects the quality of ductile iron. Higher magnesium concentration facilitates the production of nodular graphite structures in cast iron, which boosts the mechanical qualities such as strength, ductility, and resistance to wear. Consistently obtaining high recovery provides consistency in the product quality.

Boosting Output: When the recovery of magnesium is improved, the necessity for rework or corrections is considerably minimized. This leads to greater production rates, shorter process times, and fewer disruptions in operations. By obtaining high recovery, organizations may reach their production objectives more effectively.

Factors Affecting Magnesium Recovery in FeSiMg Production

Achieving high recovery rates for ferro silicon magnesium necessitates controlling numerous factors throughout the manufacturing process. Key elements include:

Temperature Control: Maintaining the optimum temperature throughout the alloying process is vital for limiting magnesium evaporation. Overheating may cause magnesium to evaporate, while inadequate heat may impede complete integration into the iron.

Addition Methods: The technique utilized to inject FeSiMg into the melt may substantially impact the recovery rate. Proper timing and regulated addition guarantee that magnesium is absorbed well into the alloy, eliminating waste.

Alloy Composition: The balance of silicon, magnesium, and other components in the alloy plays a critical function. Using FeSiMg with the proper composition enhances the possibility of good recovery and steady performance in casting.

Melt Chemistry: The chemical composition of the molten metal impacts the absorption of magnesium. Maintaining the proper amounts of carbon, sulfur, and other components is crucial for ensuring that magnesium is preserved.

Techniques for Improving Recovery Rates

To increase magnesium recovery in ferro silicon magnesium, many strategies and best practices may be implemented:

Optimizing Furnace Operations: Maintaining constant and accurate management of furnace settings helps to decrease magnesium losses. Adjusting factors such as furnace atmosphere, pressure, and temperature may dramatically increase recovery.

Using High-Purity Raw Materials: The purity of both the ferro silicon and the magnesium used in the alloy may impact recovery. High-purity materials prevent contamination and boost the reaction efficiency, resulting to superior outcomes.

Advanced Alloy Additives: Certain additives may be utilized to stabilize magnesium throughout the alloying process. These additives assist prevent magnesium from vaporizing, allowing for increased retention in the alloy.

Pre-treatment of the Melt: Conducting pre-treatment activities to eliminate undesirable constituents such as sulfur might produce more suitable circumstances for magnesium absorption, enhancing recovery rates.

Benefits of High Recovery in Ferro Silicon Magnesium

By concentrating on high recovery for FeSiMg, firms may get many major benefits:

Cost Savings: Reducing the quantity of magnesium lost during manufacturing decreases the total cost of materials, resulting to a more affordable production process.

Improved Mechanical qualities: With improved magnesium retention, the resultant ductile iron displays enhanced mechanical qualities, enhancing its performance in important applications such as automotive components, equipment, and infrastructure.

Sustainable manufacturing: Efficient utilization of raw materials contributes to a more sustainable manufacturing process, decreasing waste and the environmental imprint of activities.

Conclusion Achieving high recovery for ferro silicon magnesium is critical for boosting production, enhancing the quality of ductile iron, and assuring optimal use of resources. By optimizing manufacturing processes, managing furnace temperatures, and employing high-purity materials, enterprises may considerably boost magnesium recovery, resulting to higher-quality products and more simplified operations.

0 notes

Text

Ferro Silicon Magnesium: A Key Inoculant for Superior Ductile Iron Castings

In the world of metallurgy, ductile iron has become a preferred material due to its superior mechanical properties, including high strength, ductility, and impact resistance. These properties make it an ideal choice for applications in the automotive, construction, and machinery industries. However, attaining the desired qualities in ductile iron is not automatic; it requires meticulous control of the alloy’s composition and microstructure. This is where Ferro Silicon Magnesium (FeSiMg) comes into action as a critical inoculant for producing high-quality ductile iron castings.

What is Ferro Silicon Magnesium? Ferro Silicon Magnesium is an alloy comprised predominantly of silicon, magnesium, and iron. It is used extensively in foundries to modify the graphite structure of molten iron, assisting to produce the desired spheroidal (nodular) graphite, which is a defining characteristic of ductile iron. By introducing small quantities of magnesium into the solution, the graphite shape transitions from a granular form (as seen in grey iron) to a rounded, spheroidal form. This transformation is essential to conferring the enhanced mechanical properties of ductile iron.

The Role of FeSiMg as an Inoculant Inoculation refers to the addition of certain materials to molten iron to control its solidification structure. The introduction of FeSiMg into the molten metal modifies the iron’s microstructure, facilitating the formation of spheroidal graphite. This change in graphite morphology substantially enhances the material’s durability, tensile strength, and elasticity.

Ferro Silicon Magnesium functions by increasing the number of nucleation sites for graphite nodules to form. This leads to a uniform distribution of graphite particles throughout the iron matrix, which is essential for assuring consistent mechanical properties across the casting. Without appropriate inoculation, graphite would form in undesirable shapes, compromising the strength and durability of the final product.

Benefits of Using Ferro Silicon Magnesium in Ductile Iron Castings Improved Mechanical Properties FeSiMg inoculation enables ductile iron to attain enhanced mechanical properties such as higher tensile strength, improved ductility, and greater impact resistance. These attributes make ductile iron more reliable and efficient for various demanding applications, such as in heavy-duty machinery, automotive components, and pipelines.

Enhanced Machinability The controlled formation of spheroidal graphite not only improves strength but also enhances the machinability of ductile iron. Parts cast from ductile iron inoculated with FeSiMg are simpler to manufacture, reducing production costs and enhancing overall efficiency.

Consistency in Castings Consistent inoculation with Ferro Silicon Magnesium results in uniform distribution of graphite nodules, leading to more predictable performance in the final castings. This uniformity is critical for industries that require reliable and reproducible components.

Reduction in Casting Defects Inoculation with FeSiMg helps mitigate common casting defects such as shrinkage and porosity. The refined microstructure reduces the risk of fracture or failure in service, assuring the long-term durability of cast parts.

Cost-Effectiveness While the initial cost of using FeSiMg may be marginally higher than other alloys, the benefits it provides in terms of improved casting quality, reduced defects, and enhanced machinability contribute to significant cost savings in the long run.

Applications of FeSiMg in Ductile Iron Ferro Silicon Magnesium is essential in the production of a wide range of ductile iron castings. Some of the common applications include:

Automotive Parts: Engine blocks, suspension components, and crankshafts rely on the strength and durability of ductile iron to withstand extreme operating conditions. Pipelines and Fittings: Ductile iron pipelines inoculated with FeSiMg are known for their durability, corrosion resistance, and ability to manage high-pressure water and gas transport. Heavy Machinery: Gearboxes, frames, and other structural components made from ductile iron benefit from the alloy’s high tensile strength and abrasion resistance. Agricultural Equipment: Harvester and tractor parts require durable, wear-resistant materials, and ductile iron impregnated with FeSiMg is commonly used in these applications. Conclusion Ferro Silicon Magnesium is an indispensable inoculant in the production of superior ductile iron castings. By enhancing the formation of spheroidal graphite, FeSiMg significantly enhances the mechanical properties of ductile iron, making it a versatile and cost-effective material for industries spanning from automotive to heavy machinery. Its function in generating homogenous, durable, and high-performing ductile iron components ensures that FeSiMg will continue to be a vital material in the foundry industry.

0 notes

Text

Materials in Hammer Union Construction: A Comparative Analysis for Durability

In the oil and gas industry, hammer unions are crucial components used to connect pipes and other equipment in high-pressure environments. The choice of materials in the construction of hammer unions significantly affects their durability, performance, and safety. This article provides a comparative analysis of various materials used in hammer union construction, offering insights into their strengths and weaknesses.

Understanding Hammer Unions

Before diving into the materials, it's essential to understand the role of hammer unions. These fittings are designed to connect or disconnect pipe sections quickly, making them indispensable in drilling, cementing, and fracturing operations. They need to withstand extreme conditions, including high pressure, temperature fluctuations, and exposure to corrosive substances.

Common Materials Used in Hammer Union Construction

Carbon Steel

Overview: Carbon steel is one of the most widely used materials in hammer union construction due to its strength and cost-effectiveness. It contains carbon as the main alloying element, which enhances its hardness and tensile strength.

Durability: Carbon steel offers excellent durability under high-pressure conditions. However, it is prone to corrosion if not properly treated, which can reduce its lifespan, especially in environments exposed to moisture or chemicals.

Applications: It is commonly used in applications where cost is a concern, and the operating environment is not excessively corrosive.

Stainless Steel

Overview: Stainless steel is another popular material, known for its resistance to corrosion and oxidation. It contains chromium, which forms a passive layer on the surface, protecting the material from rust.

Durability: Stainless steel is highly durable and resistant to wear and tear, making it ideal for harsh environments. It is less prone to corrosion than carbon steel, which makes it suitable for use in corrosive environments like offshore drilling.

Applications: Stainless steel hammer unions are often used in marine and chemical processing industries, where exposure to corrosive substances is common.

Alloy Steel

Overview: Alloy steel is steel that has been alloyed with other elements like chromium, nickel, or molybdenum to enhance its mechanical properties. This material offers a good balance between strength, toughness, and corrosion resistance.

Durability: Alloy steel is known for its excellent toughness and ability to withstand high-stress environments. It provides better performance than carbon steel in terms of corrosion resistance and durability.

Applications: Alloy steel hammer unions are used in high-pressure environments where the risk of corrosion and mechanical stress is high, such as in subsea applications.

Brass

Overview: Brass, an alloy of copper and zinc, is sometimes used in hammer union construction, particularly in applications where corrosion resistance is critical.

Durability: Brass offers good corrosion resistance and is relatively easy to machine. However, it is not as strong as steel, which limits its use in high-pressure environments.

Applications: Brass hammer unions are typically used in lower-pressure applications or where the risk of corrosion from chemicals or saltwater is high.

Ductile Iron

Overview: Ductile iron, also known as nodular cast iron, contains graphite in a nodular form, which gives it higher ductility compared to other types of cast iron.

Durability: Ductile iron is highly durable and resistant to impact and fatigue. However, it is more brittle than steel, making it less suitable for extremely high-pressure applications.

Applications: It is often used in applications where shock resistance is more critical than tensile strength, such as in some hydraulic systems.

Comparative Analysis of Material Durability

When comparing the durability of these materials, several factors come into play, including resistance to corrosion, strength under pressure, and ability to withstand wear and tear.

Corrosion Resistance: Stainless steel and brass offer the best corrosion resistance, making them ideal for environments where exposure to moisture, chemicals, or saltwater is frequent.

Strength and Toughness: Alloy steel provides the best combination of strength and toughness, making it suitable for the most demanding environments. Carbon steel, while strong, requires proper treatment to prevent corrosion.

Cost-Effectiveness: Carbon steel is the most cost-effective option, but its susceptibility to corrosion may lead to higher long-term costs due to maintenance and replacement. Stainless steel and alloy steel, while more expensive upfront, offer better durability, potentially reducing long-term expenses.

Commercial Considerations

For businesses and engineers, choosing the right material for hammer union construction involves balancing cost, performance, and environmental factors. While carbon steel may be the most budget-friendly option, the long-term benefits of using stainless or alloy steel in terms of durability and reduced maintenance costs cannot be overlooked. Furthermore, in industries where safety and reliability are paramount, the investment in higher-quality materials like stainless steel or alloy steel can prevent costly failures and downtime.

Conclusion

Selecting the right material for hammer union construction is critical to ensuring the durability and performance of the equipment. While carbon steel offers a cost-effective solution for less demanding environments, stainless steel and alloy steel provide superior durability and resistance to corrosion, making them ideal for more challenging applications. Understanding these material properties helps engineers and businesses make informed decisions that balance cost with long-term performance and safety.

For students and professionals interested in learning more about material science and engineering applications in the oil and gas industry, consider exploring courses and certifications that dive deeper into these topics. Investing in education can open doors to specialized roles in this vital industry.

0 notes

Text

The Top Benefits of Using Ductile Iron in Construction

The construction industry constantly seeks materials that offer superior strength, durability, and cost-efficiency. Among these, ductile iron has emerged as a preferred choice for a wide range of construction applications. Ductile iron products boast an impressive array of mechanical properties and practical benefits that make them indispensable in modern construction projects. Here are some of the top advantages of using ductile iron in construction.

1. Exceptional Strength and Durability

Ductile iron, also known as nodular cast iron, possesses enhanced strength due to its unique microstructure. Unlike traditional cast iron, which is brittle and prone to cracking under stress, ductile iron is formulated to withstand significant strain without failing. This strength is crucial in construction, where materials must endure heavy loads and resist environmental stresses. The durability of ductile iron products means they often outlast materials like concrete and PVC, especially in applications such as underground pipes and structural supports.

2. Superior Corrosion Resistance

One of the standout features of ductile iron is its exceptional resistance to corrosion. This characteristic is particularly valuable in environments exposed to aggressive soils and corrosive fluids. Ductile iron's ability to resist oxidation not only extends the lifespan of the materials but also reduces maintenance costs over time. This makes ductile iron products an economical choice for municipal infrastructure projects, including water and sewage systems.

3. High Impact Resistance

Ductile iron’s ability to absorb and dissipate energy makes it highly resistant to impact and shock. This quality is essential in areas susceptible to mechanical stress or geological disturbances such as earthquakes. Structures and components made of ductile iron can endure sudden shocks without compromising their integrity, providing an added layer of safety and reliability to buildings and other structures.

4. Versatility in Applications

The versatility of ductile iron is another significant benefit. It can be cast into virtually any shape, size, or thickness, which is a tremendous advantage when custom components are required. This flexibility allows for the design and creation of specialized parts tailored to specific construction needs, from large beams and columns to intricate fittings and fasteners. Additionally, the aesthetic appeal of ductile iron, with its smooth and often paintable surface, can be a visual advantage in exposed applications.

5. Cost-Effectiveness

Considering its longevity and minimal maintenance requirements, ductile iron is a cost-effective option for both initial installation and long-term operation. The material's inherent qualities reduce the need for replacements and frequent repairs, translating into savings for construction projects. Furthermore, the efficiency of producing ductile iron products ensures that they remain an affordable option compared to many other materials with similar or lesser capabilities.

6. Environmental Sustainability

Ductile iron is increasingly recognized for its environmental benefits. It is made from recycled iron and steel, making it a more sustainable choice in an industry looking to reduce its carbon footprint. Additionally, the durability and recyclability of ductile iron products contribute to less frequent material turnover and waste, aligning with the goals of sustainable construction practices.

Conclusion

Ductile iron products represent a confluence of strength, durability, and efficiency, making them an excellent choice for various construction applications. Whether for piping systems, structural supports, or decorative elements, ductile iron offers a range of benefits that meet the demands of modern construction. Its ability to perform under pressure, resist environmental challenges, and remain cost-effective over time ensures that ductile iron will continue to play a critical role in building and maintaining our physical infrastructure. Brands like AKP Ferrocast underscore this point by providing high-quality ductile iron products that construction professionals rely on. As the construction industry evolves, the attributes of ductile iron position it as a material not just for today but for the future.

0 notes

Text

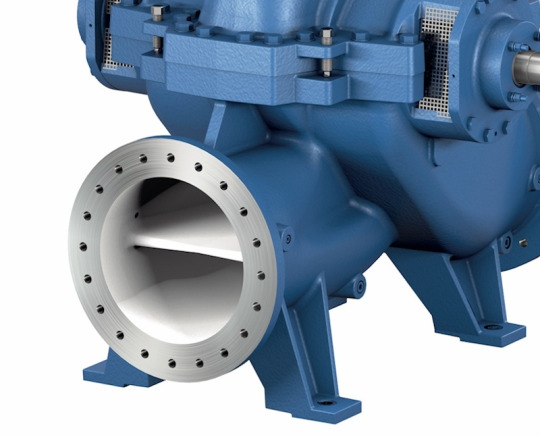

Range of high-performance water pumps expanded with flow rates of up to 20,000 m³/h at heads of up to 300 m

The growing scale of water transport systems in the past few years has resulted in a steady increase in the volume flow rates demanded of the pumps installed, which in turn has required ever larger pump sizes. Responding to this development, KSB Group has expanded its RDLO type series from 21 sizes to 33.

With twelve new sizes the RDLO type series has been significantly expanded in line with the trend towards ever larger pumps for water transport. (© KSB SE & Co. KGaA, Frankenthal) The pump sets are axially split volute casing pumps primarily used for clean water transport. Their extreme durability is the main reason why they are used in pumping stations all over the world. A casing with double volute compensating radial forces and a double-entry impeller compensating axial forces are key to a long service life. As a result, the generously dimensioned rolling element bearings are subjected to a minimum load only. “Excellent efficiencies guarantee low energy costs over the pumps’ entire service life”, acc. an KSB information. Low-vibration operation is ensured by solid bearing brackets bolted to the upper part of the casing and a rigid shaft. The loads on the rolling element bearings, the mechanical seals and the coupling between pump and motor are thus significantly reduced. Ease of service played an important role when designing this type series. The self-centring upper part of the casing and the spring-loaded rotor enable cover and rotor mounting without any further adjustments. Thanks to the expansion of the type series, flow rates of up to 20,000 m³ per hour at heads of up to 300 m can now be achieved. As RDLO pumps are also capable of transporting seawater, the materials used include duplex steels alongside standard materials such as grey cast iron and nodular cast iron. www.ksb.com Read the full article

0 notes

Text

High Purity Pig Iron Market's Integral Role in Elevating Steel Quality Standards

The global high purity pig iron market size is expected to reach USD 17.09 billion by 2030, according to a new report by Grand View Research, Inc, expanding at a CAGR of 8.5% over the forecast period. Investments in wind power generation are expected to benefit the industry growth from 2022 to 2030. HPPI is the principal raw material used in the production of nodular cast iron components, which are deployed in industries, such as wind energy, automotive & transportation, etc. Increasing emissions and limited potential for fossil fuels have led to the focus on energy production from renewable sources, such as wind and solar. HPPI finds applications in different wind turbine components, such as rotors, shafts, frames, and blades among others.

High Purity Pig Iron Market Report Highlights

The energy application segment is projected to register the fastest CAGR over the forecast period. A shift towards renewable energy is anticipated to promote the usage of nodular cast iron components and benefit HPPI demand

Automotive & transportation was the largest application segment in 2021. Investments for new plants and capacity additions are projected to boost the demand for HPPI products in casting parts

Asia Pacific was the leading region in 2021 due to offshore wind projects and industrial production in China, India, and Japan

India is anticipated to register a lucrative growth rate, in terms of revenue, over the forecast period due to the growing focus on domestic manufacturing to cater to the growing demand from various end-use industries

For More Details or Sample Copy please visit link @: High Purity Pig Iron Market Report

China, a leader in wind energy installations, aims to double its wind and solar capacity by 2025. The pollution levels are also high in China compared to other countries around the world, therefore it is necessary to increase renewable power generation. As per the central economic plan of the country, nearly 33% of power supply will come from renewable sources by 2025, an increase from 29% in 2020. Recently, Siemens Gamesa Renewable Energy received an order for 14 offshore wind turbines from a Green Power Investment firm in Japan. This Ishikari offshore project is likely to produce 112 MW of wind energy wherein installations are planned to start in July 2023. The turbines have ClassNK certification ensuring stringent technical standards. Similar investments in wind energy are expected to provide a boost to the HPPI products demand.

Automotive & transportation is a key application segment, wherein nodular cast iron components made using HPPI are used. This segment is likely to register a growth of 8.3%, in terms of revenue, from 2022 to 2030. A rise in the production capacities for vehicles is projected to attract the demand for HPPI products. For instance, Kia Motors in India is expected to increase its production capacity to 400,000 units by the end of 2022. Increasing utilization of steel scrap in foundries, especially in China, is projected to remain a favorable factor for the industry players. The increasing shift towards electric furnaces compared to blast furnaces requires high purity iron to reduce the impurities in the melt. This is anticipated to benefit in the reduction of carbon emissions and, thus, protect the environment.

HighPurityPigIron #PigIron #Metallurgy #SteelProduction #MetalManufacturing #IronSmelting #PureIron #MetallurgicalProcesses #PremiumSteel #IronQuality #FoundryMaterials #SteelQuality #AlloyProduction #MetalInnovation #IronandSteel #SmeltingTechnology #HighPerformanceMetals #MetalsIndustry #SteelStandards #SteelManufacturing #MetalExcellence

#High Purity Pig Iron#Pig Iron#Metallurgy#Steel Production#Metal Manufacturing#Iron Smelting#Pure Iron#Metallurgical Processes#Premium Steel#Iron Quality#Foundry Materials#Steel Quality#Alloy Production#Metal Innovation#Iron and Steel#Smelting Technology#High Performance Metals#Metals Industry#Steel Standards#Steel Manufacturing#Metal Excellence

0 notes

Text

Detroit Speed FN988 Assembled Center Sections

Looking for the strength of a Ford 9-inch but the reduced noise and increased efficiency of an 8.8-inch? Now you can have the best of both worlds with Detroit Speed’s FN988 center section; a 9-inch housing utilizing 8.8-inch internal components in 5 different gear ratios. Features/Benefits: - Patent-pending design utilizes an 8.8 gear set, which is quieter and more efficient than standard 9-inch components - High-strength nodular cast iron case - Available in the following gear ratios: 3.08, 3.27, 3.55, 3.73, and 4.10 - Forged alloy steel carrier bearing caps - 31-spline Eaton Truetrac 8.8-inch differential - Premium ring & pinion utilizing ARP ring bolts with safety wire - 1350 forged steel pinion yoke and U-bolt kit - Threaded jack bolt holes in mounting flange ease case removal from axle housing - Case includes mounting holes for bolt-on accessories - Continous lubrication of pinion bearings provided by internal oil channels - Solid pinion preload spacer - Designed and engineered at DSE and made in USA Is it possible to have a Ford 9-inch without an annoying amount of gear whine? Of course, but at what cost? How much time and money are you going to spend chasing down the issue when you can now simply bolt an 8.8-inch center section into your 9-inch housing thanks to the engineers at DSE? Detroit Speed now offers five different gear ratios and a complete assembly that will bolt directly into your 9-inch housing. Complete with forged alloy steel carrier bearing caps, a high-strength nodular case, safety-wired ARP hardware, a 1350 forged steel pinion yoke, and a 31-spline Eaton Truetrac differential, it’s built to handle some serious power and deliver it quietly and more efficiently than any 9-inch. Read the full article

0 notes

Text

Understanding the Role of Materials in Railway Parts Manufacturing

The manufacturing of railway parts is a complex and intricate process that requires a deep understanding of various elements, particularly when it comes to critical components like crankshafts. A fundamental aspect that significantly influences the performance and reliability of railway engines is the choice of materials used in their construction. In this blog, we will delve into the crucial role of materials in the manufacturing of railway parts, with a specific focus on crankshafts.

Crankshafts, being essential components of any railway engine, play a pivotal role in converting reciprocating motion into rotational motion, powering the wheels and propelling the locomotive forward. The efficiency, durability, and overall performance of the engine heavily rely on the properties of the materials employed in crafting the crankshaft. By exploring the relationship between crankshaft manufacturing and materials, we can gain valuable insights into how residual stress, manufacturing technology, and material selection impact its performance.

To comprehend the significance of these aspects, we will analyze the diagram showing the intricate design and composition of a crankshaft, shedding light on how specific materials are strategically utilized in various sections to optimize strength, weight, and stress distribution.

Join us on this informative journey as we unravel the mysteries behind the selection of suitable materials, the effects of residual stress on performance, and the latest manufacturing technologies shaping the railway industry. Understanding the interplay between materials and the manufacturing process is vital for ensuring safe, efficient, and reliable railway operations in the modern era.

Role of Materials in Railway Parts Manufacturing

The railway industry is a cornerstone of modern transportation, and the efficiency and safety of railway systems heavily depend on the quality and durability of the components that make up the intricate network. One critical aspect of railway part manufacturing is the selection and utilization of appropriate materials. This holds true particularly for components like crankshafts, which play a pivotal role in the functioning of locomotive engines. In this discourse, we delve into the nuances of crankshaft manufacturing, the significance of materials, and the impact of manufacturing technologies on the final product.

Crankshaft Manufacturing: An Overview

A crankshaft is an essential mechanical component in the engine of a locomotive, responsible for converting reciprocating motion into rotational motion. As the engine pistons move up and down, the crankshaft translates this linear motion into the circular motion needed to drive the wheels. Given the high stresses and loads involved, crankshaft materials must exhibit superior mechanical properties to ensure reliable performance and longevity.

Material Selection for Crankshaft Manufacturing

The choice of materials for crankshaft manufacturing is a critical factor that directly affects the component’s performance and service life. Traditionally, materials like cast iron were used due to their robustness and ease of manufacturing. However, advancements in materials science have led to the adoption of more sophisticated materials, such as forged steel and even specialized alloys.

Forged steel offers improved strength, fatigue resistance, and better impact properties compared to cast iron. Its homogeneous structure, achieved through controlled manufacturing processes, ensures consistent material properties throughout the crankshaft. Moreover, specialized alloys, like nodular cast iron, provide a balanced combination of tensile strength, ductility, and fatigue resistance. The right choice of material depends on factors such as the engine’s power output, operational requirements, and the desired service life of the crankshaft.

Role of Materials in Performance

The materials used in crankshaft manufacturing significantly influence the overall performance of the engine. The mechanical properties of the material dictate its ability to withstand the cyclic stresses and high loads that occur during engine operation. High-strength materials contribute to enhanced durability, minimizing the risk of catastrophic failures that could disrupt railway services.

One crucial aspect to consider is residual stress. During the manufacturing process, various techniques such as heat treatment and surface finishing can induce residual stresses in the material. Residual stresses can impact fatigue life, leading to premature failures. Proper material selection, combined with controlled manufacturing processes, can help mitigate the negative effects of residual stress, ensuring a longer lifespan for the crankshaft and the engine as a whole.

Managing Technology’s Influence

Advancements in manufacturing technology have brought about substantial improvements in the quality and precision of crankshaft manufacturing. Computer Numerical Control (CNC) machining, for instance, allows for intricate shaping and accurate dimensioning of crankshafts. CNC technology not only enhances the final product’s geometry but also plays a role in optimizing material usage, reducing waste, and improving overall efficiency.

Furthermore, the use of finite element analysis (FEA) has revolutionized the design and validation of crankshafts. FEA enables enterprises to simulate real-world operating conditions and predict how different materials will behave under various loads and stress conditions. This simulation-driven approach empowers manufacturers to refine material selection and manufacturing processes before physically producing the component, ultimately saving time and resources while ensuring optimal performance.

The Visual Representation of Crankshaft Material

A diagram shows the cross-section of a crankshaft, highlighting the layered composition of the material. The outer layer, often composed of a hardened alloy, provides resistance against wear and surface fatigue. Beneath this layer, the core material exhibits a balance between strength and ductility, allowing it to withstand the bending and torsional stresses imparted by the engine’s operation. The careful selection of materials for both layers is crucial in ensuring the crankshaft’s reliability and longevity.

The role of materials in railway parts manufacturing, particularly in components like crankshafts, cannot be overstated. The choice of materials directly impacts the component’s performance, durability, and overall reliability. With the ever-evolving landscape of materials science and manufacturing technologies, businesses and manufacturers have a wider array of options to choose from, enabling them to optimize the design, fabrication, and performance of railway components. As the industry continues to evolve, a deep understanding of materials and their behaviour will remain pivotal in shaping the future of railway transportation.

Conclusion

In conclusion, the role of materials in railway parts manufacturing, particularly in the context of crankshafts, holds paramount importance in ensuring the efficiency, reliability, and safety of railway engines. The manufacturing of crankshafts demands a deep understanding of materials, their properties, and the impact of manufacturing technologies on their performance. By carefully selecting suitable materials and employing advanced manufacturing techniques, you can create crankshafts that optimize engine efficiency, reduce emissions, and enhance overall performance.

The significance of material selection in crankshaft manufacturing lies in achieving a delicate balance between strength, durability, and weight. High-performance materials, such as steel alloys, continue to play a crucial role, while advancements in material science continually present opportunities for further innovation.

Additionally, considering factors like residual stress is essential for ensuring the long-term reliability and safe operation of railway engines. Proper management of residual stress during manufacturing processes is critical to prevent premature failure and maintain the structural integrity of the crankshaft.

Visual representations, such as diagrams, provide invaluable insights into the complex design and material distribution within the crankshaft. These diagrams aid in making informed decisions during the manufacturing process, leading to the production of high-quality crankshafts that can withstand the rigors of railway operations.

As the transportation industry advances, a deep understanding of the interplay between crankshaft manufacturing, materials, and technology will continue to drive progress in the field. Embracing innovative materials and manufacturing techniques will pave the way for more efficient, environmentally friendly, and reliable railway systems, contributing to a sustainable future for rail transportation.

0 notes

Text

0 notes

Text

https://timesofrising.com/the-unique-qualities-of-nodular-iron-casting/

Nodular Iron Casting is used in various industries due to its wide range of applications. Discover their key qualities and factors to consider while selecting a reputable nodular iron casting supplier.

0 notes

Text

The Role of Ferro Silicon Magnesium Inoculants in Ductile Iron Production

The production of high-quality ductile iron is a critical process in contemporary foundries that necessitates the precise and meticulous management of metallurgical elements. The use of Ferro Silicon Magnesium as an inoculant is one of the most critical components in the production of superior ductile iron. This inoculant is indispensable in the refinement of the microstructure, the enhancement of mechanical properties, and the guarantee of the desired final product’s performance.

Comprehension of Ductile Iron

Ductile iron, also referred to as nodular iron or spheroidal graphite iron, is a form of cast iron that is distinguished by its extraordinary ductility, durability, and strength. Traditional cast iron is distinguished from ductile iron by its distinctive microstructure. This microstructure is accomplished by regulating the formation of graphite in the iron matrix, ensuring that it forms as nodules rather than particles, which are a defining feature of grey cast iron. The mechanical properties of ductile iron are considerably enhanced by the presence of nodular graphite, which increases its tensile strength and elongation. Consequently, it is well-suited for demanding industrial applications, including automotive components, pipelines, and apparatus parts.

Nevertheless, the addition of carbon to the molten iron is insufficient to achieve the desired microstructure. The formation of graphite nodules must be meticulously controlled, and this is where inoculants like Ferro Silicon Magnesium come into action.

The Function of Inoculants in Ductile Iron

Inoculant are added to molten iron to modify the solidification process, ensuring the formation of a desirable microstructure. In ductile iron, inoculation is a crucial stage because it directly influences the shape, size, and distribution of graphite nodules within the matrix. Without appropriate inoculation, the graphite may not form correctly, leading to inferior mechanical properties, reduced ductility, and increased brittleness.

Ferro Silicon Magnesium is one of the most effective inoculants used in the production of ductile iron. It is a combination of iron, silicon, and magnesium, with magnesium being the key element that promotes the formation of spheroidal (nodular) graphite. Silicon, on the other hand, functions as a deoxidizer and enhances the nucleation process, while iron serves as the base material.

How Ferro Silicon Magnesium Works as an Inoculant

Ferro Silicon Magnesium is typically added to the molten iron during the ladle treatment procedure, just before casting. The magnesium content in the inoculant reacts with the sulfur and oxygen present in the molten iron, forming magnesium sulfide and magnesium oxide. This reaction reduces the sulfur content and promotes the formation of graphite nodules instead of particles. By decreasing the sulfur levels, the inoculant prevents the formation of carbides, which can make the iron brittle and negatively impact its mechanical properties.

In addition to magnesium, the silicon content in Ferro Silicon Magnesium serves a vital function in stabilizing the structure. Silicon helps facilitate the nucleation of graphite, ensuring that the nodules are evenly distributed throughout the matrix. The balanced composition of the inoculant ensures that the molten iron solidifies with the desired microstructure, resulting in ductile iron with enhanced strength, ductility, and elongation.

Benefits of Using Ferro Silicon Magnesium Inoculant Enhanced Mechanical Properties: The principal benefit of using Ferro Silicon Magnesium as an inoculant is the enhancement in mechanical properties. The formation of spherical graphite nodules enhances the strength, ductility, and impact resistance of the ductile iron. This makes it suitable for applications that require both strength and ductility, such as in automotive components and heavy machinery.

Improved Castability: The use of Ferro Silicon Magnesium inoculant also enhances the castability of the iron, reducing defects such as contraction, porosity, and inclusions. This leads to higher-quality castings and minimizes the need for post-production refining or restorations.

Consistent Microstructure: Achieving a consistent and uniform microstructure is essential for the reliability of ductile iron components. Ferro Silicon Magnesium guarantees a more homogenous distribution of graphite nodules, leading to enhanced performance and durability in the final product.

Cost Efficiency: Proper inoculation with Ferro Silicon Magnesium helps optimize the production process by reducing waste and the likelihood of defects. This translates to cost reductions for foundries, as fewer defective castings mean less waste material and less need for revision.

Versatility in Applications: Ductile iron treated with Ferro Silicon Magnesium inoculants is highly versatile and suitable for a broad variety of industries, including automotive, construction, energy, and municipal infrastructure. Its enhanced mechanical properties make it an excellent choice for components like crankshafts, gearboxes, pipelines, and hydraulic components.

Challenges and Considerations While the benefits of using Ferro Silicon Magnesium as an inoculant in ductile iron production are well-established, there are some challenges and considerations that foundries must bear in mind. The appropriate dosage of the inoculant is critical to attaining the desired microstructure. Too little magnesium can result in incomplete nodule formation, while too much can lead to excessive oxidation and the formation of defects such as slag inclusions. Foundries must carefully monitor and control the inoculation process to ensure optimal results.

In addition, the grade of the inoculant itself is a significant factor. The composition of Ferro Silicon Magnesium must be consistent and free from impurities to ensure reliable performance in the foundry. This is why many foundries prefer to work with trusted suppliers that provide high-quality, precisely formulated inoculants.

Conclusion Ferro Silicon Magnesium inoculants serve a pivotal role in the production of high-quality ductile iron, ensuring the formation of nodular graphite that enhances the mechanical properties of the final product. By controlling the solidification process and fostering the formation of spheroidal graphite, Ferro Silicon Magnesium enhances the strength, flexibility, and durability of ductile iron, making it suitable for a wide range of industrial applications. As foundries continue to prioritize efficiency, quality, and performance, the use of advanced inoculants like Ferro Silicon Magnesium will remain essential in meeting the demands of modern manufacturing.

0 notes

Text

Unveiling the Craftsmanship of Casting Manufacturing: Exploring Casting Suppliers and the Diversity

Casting, an age-old method of shaping molten metal into desired forms, continues to be a cornerstone of modern manufacturing. This article delves into the realm of casting manufacturing, exploring the role of casting suppliers and the fascinating array of cast iron types that have fueled industries for generations.

Casting Supplier: Connecting Vision to Reality: In the intricate world of manufacturing, casting suppliers serve as the bridge between innovation and creation. These skilled artisans and companies specialize in transforming design concepts into tangible products using various casting methods. Whether it's sand casting, investment casting, or die casting, casting suppliers play a pivotal role in bringing diverse creations to life.

Types of Cast Iron: From Strength to Versatility: Cast iron, revered for its durability and versatility, comes in various forms that cater to distinct needs and applications. Some common types include:

Gray Cast Iron: Recognized for its excellent machinability and thermal conductivity, gray cast iron is used in engine blocks, pipes, and cookware.

White Cast Iron: Notable for its hardness and wear resistance, white cast iron is ideal for applications requiring abrasion resistance, such as grinding balls and rolls.

Ductile Cast Iron (Nodular Iron): Renowned for its high strength, ductile cast iron finds its way into components like crankshafts, gears, and structural parts.

Malleable Cast Iron: With its heat-treated properties, malleable cast iron is commonly used in pipe fittings and automotive parts.

Compacted Graphite Iron (CGI): CGI boasts superior strength and thermal conductivity, making it suitable for high-performance engine components.

Casting Manufacturing: An Art and Science Blend: Casting manufacturing seamlessly marries craftsmanship and science, transforming raw materials into intricate components. The process involves creating molds, melting metals to their liquid state, pouring the molten metal into molds, and allowing it to solidify. The result is a wide range of products that drive industries, from automotive and aerospace to construction and beyond.

Innovations in Casting Techniques: Shaping Tomorrow: Casting manufacturing is not stagnant; it evolves with technology. Advanced techniques like investment casting and additive manufacturing (3D printing) are pushing the boundaries of what's possible. These innovations offer precision, reduce waste, and open avenues for complex geometries.

Conclusion: A Tribute to Casting Excellence: Casting manufacturing is more than a process; it's a testament to human ingenuity and the ability to shape raw materials into functional and intricate creations. Casting suppliers, armed with expertise, bring concepts to life, while the diverse types of cast iron provide the foundation for industries to thrive. As technology propels casting techniques forward, the legacy of craftsmanship and innovation continues to leave an indelible mark on the world of manufacturing.

0 notes

Text

Exploring Types of Cast Iron and Choosing the Right Casting Supplier for Your Manufacturing Needs

Casting is a crucial process in various industries, where molten metal is poured into a mold to create complex shapes and components. One of the essential aspects of successful casting manufacturing is choosing the right casting supplier. In this blog, we will delve into the different types of cast iron and how finding the ideal casting supplier, such as JiangSu KRT Industry Co., Ltd, can significantly impact the quality of your cast iron products.

Understanding Types of Cast Iron

Gray Cast Iron: Gray cast iron is the most commonly used type due to its excellent castability, good machinability, and low cost. It contains graphite flakes that provide lubrication during machining, making it suitable for applications like engine blocks, pipes, and cookware.

White Cast Iron: This type of cast iron is formed by rapid cooling, resulting in cementite formation instead of graphite. White cast iron is incredibly hard and brittle, making it ideal for applications requiring wear resistance, like crushing machinery.

Ductile Cast Iron (Nodular Iron): Ductile cast iron contains small amounts of magnesium, which alters the graphite structure, giving it improved ductility and toughness. It is used in applications where strength and shock resistance are essential, such as automotive components and heavy machinery.

Malleable Cast Iron: Malleable cast iron is created by annealing white cast iron, transforming the hard carbide into irregular-shaped graphite particles. It is highly ductile and can be bent and shaped without fracturing, making it suitable for applications like pipe fittings and handrails.

Compacted Graphite Iron (CGI): CGI has characteristics that lie between gray and ductile cast iron. It contains vermicular graphite structures, providing higher strength and thermal conductivity than gray cast iron. It finds applications in engine blocks and cylinder heads.

Importance of Choosing the Right Casting Supplier Selecting the right casting supplier is critical for the success of your manufacturing endeavors. JiangSu KRT Industry Co., Ltd, as a reputable casting supplier, offers the following advantages:

Expertise and Experience: With years of experience in the industry, JiangSu KRT Industry Co., Ltd understands the nuances of different casting processes and materials, ensuring top-notch results for your cast iron components.

Quality Assurance: Reliable casting suppliers adhere to stringent quality control measures. JiangSu KRT Industry Co., Ltd takes pride in producing cast iron products that meet industry standards and your specific requirements.

Advanced Technology: Established casting suppliers utilize state-of-the-art technology and modern machinery to optimize the casting process, resulting in precise and consistent cast iron products.

Customization: Each industry may require unique cast iron components. JiangSu KRT Industry Co., Ltd works closely with clients to provide tailored solutions, meeting the diverse needs of various applications.

Timely Delivery: Meeting project deadlines is crucial in any manufacturing process. JiangSu KRT Industry Co., Ltd values punctuality and ensures on-time delivery of your cast iron components.

Conclusion

The choice of cast iron type plays a significant role in determining the success of your manufacturing applications. Understanding the properties and applications of different cast iron types empowers you to make informed decisions. Additionally, partnering with a reliable casting supplier like JiangSu KRT Industry Co., Ltd can streamline your manufacturing process, ensuring top-quality cast iron products that meet your requirements. So, whether you need gray cast iron for cookware or ductile cast iron for heavy machinery, make the right choice to boost the performance and durability of your products.

0 notes

Text

Proserv Tools 3 Fluted Predrill :

For opening out existing holes (core drilling) Used in Automotive Industry for: 1) Cylinder blocks, cylinder heads, cases, steering knuckles and brake cylinders. 2) Aluminum silicon alloys and all grades of cast iron, including GCI,CGI & nodular. 3) Pre-tapping hole sizes. 4) Chamfer holes and multiple-steps forms 5) Cast Iron 6)Non-Ferrous materials

1 note

·

View note

Text

sg iron foundry in india

We are one of the leading SG Iron Casting Manufacturers in India. We supply low/medium/high volume, small/medium/large sized machined Nodular Iron Castings. The parts are manufactured as per the specification of our customers. Contact us for SG iron Foundry in India

0 notes