#Ferro SIlicon Magnesium

Explore tagged Tumblr posts

Text

India’s Top Inoculant Wire Feeder Producer | Superior Manufacturing

India’s metallurgical and foundry industries have experienced tremendous growth, particularly in the production of essential materials like inoculant wire feeders. These feeders play a crucial role in enhancing the quality of metal casting, especially in industries like automotive, aerospace, and heavy machinery.

Indian producers have earned a reputation for delivering top-notch products with a focus on precision, innovation, and reliability. In this article, we’ll explore why these feeders are important for industries reliant on metal casting, how Indian manufacturers have emerged as global leaders, and the unique qualities that set them apart in terms of production excellence.

Importance of Inoculants in Metal Casting

Inoculants play a vital role in the casting of metals such as cast iron and steel. They are added in small quantities to molten metal to modify its microstructure, which enhances its mechanical properties and reduces defects. In particular, inoculants help to control the solidification process, resulting in finer grain structures and improved overall performance of the cast product.

One of the most efficient ways to introduce inoculants into molten metal is through feeder systems, which ensure controlled and accurate dosing. This precise addition improves the quality of the metal, minimizes waste, and increases the efficiency of the casting process. The result is a more cost-effective production method and a higher-quality end product.

Key Benefits of Using These Systems:

Enhanced Material Strength: Inoculants help refine the grain structure of the metal, leading to stronger and more durable castings.

Reduction in Defects: By preventing the formation of carbides and other unwanted phases, inoculants help reduce common casting defects such as porosity and shrinkage.

Process Optimization: The accurate delivery of inoculants ensures uniformity in the final product, reducing the need for rework and lowering production costs.

Improved Surface Finish: Better solidification control leads to a smoother and more consistent surface on cast components.

Leading Indian Producers Inoculant Wire Feeders

Several Indian companies have become prominent producers in this field, gaining recognition for their advanced production processes and commitment to quality. These companies supply domestic and international markets with feeders that meet stringent industry requirements, contributing to the high performance of critical cast components in various industries.

1. Elkem India Pvt. Ltd.

A subsidiary of the global industry leader Elkem, Elkem India has built a strong presence in the Indian market by providing reliable and advanced solutions. The company’s commitment to research and development enables it to stay ahead of technological trends, offering efficient systems that improve the quality of castings in automotive, construction, and other industries.

2. Ferroglobe India

Ferroglobe India is known for producing a wide range of silicon-based products, including inoculants that enhance the quality of steel and iron castings. The company’s high-performance feeders are designed to meet the demands of industries requiring precision and consistency. With cutting-edge technology and a focus on sustainability, Ferroglobe India is a leader in this field.

3. IFGL Refractories Ltd.

IFGL Refractories Ltd. has established itself as a trusted name in India’s metallurgical industry. The company produces a variety of products for the foundry sector, with its feeders recognized for their role in optimizing casting processes. By focusing on customer satisfaction and consistent product quality, IFGL has earned a strong reputation both in India and abroad.

4. Simco Group

Simco Group is a prominent Indian manufacturer and exporter of advanced casting systems. Their products are widely used in industries that require high-performance materials, such as automotive and heavy machinery. Simco’s dedication to technological advancement and rigorous quality control ensures that its solutions meet the highest international standards.

5. Tata Steel Advanced Materials

Tata Steel, one of India’s largest and most respected companies, has expanded into producing advanced materials, including feeder systems. Known for its innovation and sustainability practices, Tata Steel’s products are designed to enhance the efficiency of casting operations, ensuring high-quality output with minimal environmental impact.

Why Indian Manufacturers Stand Out

Indian producers have gained a competitive edge in the global market for several reasons, positioning themselves as top suppliers in the casting industry for both feeder systems and alloys ferro silicon magnesium in India:

1. Advanced Manufacturing Technology

India’s leading manufacturers have invested in modern production facilities that allow for high-precision manufacturing. By incorporating automation and cutting-edge technologies into their processes, these companies ensure that their products meet the strict quality standards required by industries worldwide.

2. Innovation and R&D

Innovation is a key driver for success in the Indian alloy industry. Leading producers are continually developing new solutions that improve casting efficiency and product quality. By focusing on research and development, these companies stay ahead of industry trends, offering customized solutions that meet the unique needs of their customers.

3. Customization and Flexibility

Indian manufacturers are known for their ability to provide tailored solutions. Industries that require specific compositions or designs can rely on Indian companies to meet their exact requirements. This flexibility, combined with a strong focus on customer satisfaction, has helped Indian producers build long-term relationships with clients around the world.

4. Cost-Effectiveness

One of the key advantages Indian producers offer is the ability to provide high-quality products at competitive prices. By streamlining production processes and leveraging economies of scale, Indian manufacturers can offer cost-effective solutions without sacrificing quality. This makes them attractive suppliers for industries looking to optimize their production costs.

5. Sustainability Initiatives

Environmental responsibility is becoming increasingly important in the manufacturing industry, and Indian producers are leading the way in adopting sustainable practices. Many companies have implemented measures to reduce energy consumption, minimize waste, and use renewable resources, ensuring that their products are not only high-quality but also eco-friendly.

Global Reach and Future Prospects

The success of India’s leading manufacturers has extended far beyond the domestic market. These companies have established strong export networks, supplying high-quality products to industries around the world. As global demand for efficient and precise casting systems continues to rise, Indian producers are well-positioned to meet these needs, ensuring consistent growth and further expansion in the future.

Conclusion

India’s top inoculant wire feeder producers have earned their place in the global metallurgical industry through superior manufacturing practices, innovation, and a commitment to quality. By investing in advanced technologies and focusing on customer satisfaction, Indian manufacturers continue to meet the growing demand for high-performance inoculant wire feeders in industries worldwide. Their ability to provide cost-effective and sustainable solutions makes them the go-to choice for businesses seeking reliable and high-quality products.

#inoculant wire feeder#ferro silicon magnesium in india#ferro silicon magnesium#magnesium cored wire injection system#cored wire#manufacturers

0 notes

Text

Ferro Silicon Magnesium: A Key Inoculant for Superior Ductile Iron Castings

In the world of metallurgy, ductile iron has become a preferred material due to its superior mechanical properties, including high strength, ductility, and impact resistance. These properties make it an ideal choice for applications in the automotive, construction, and machinery industries. However, attaining the desired qualities in ductile iron is not automatic; it requires meticulous control of the alloy’s composition and microstructure. This is where Ferro Silicon Magnesium (FeSiMg) comes into action as a critical inoculant for producing high-quality ductile iron castings.

What is Ferro Silicon Magnesium? Ferro Silicon Magnesium is an alloy comprised predominantly of silicon, magnesium, and iron. It is used extensively in foundries to modify the graphite structure of molten iron, assisting to produce the desired spheroidal (nodular) graphite, which is a defining characteristic of ductile iron. By introducing small quantities of magnesium into the solution, the graphite shape transitions from a granular form (as seen in grey iron) to a rounded, spheroidal form. This transformation is essential to conferring the enhanced mechanical properties of ductile iron.

The Role of FeSiMg as an Inoculant Inoculation refers to the addition of certain materials to molten iron to control its solidification structure. The introduction of FeSiMg into the molten metal modifies the iron’s microstructure, facilitating the formation of spheroidal graphite. This change in graphite morphology substantially enhances the material’s durability, tensile strength, and elasticity.

Ferro Silicon Magnesium functions by increasing the number of nucleation sites for graphite nodules to form. This leads to a uniform distribution of graphite particles throughout the iron matrix, which is essential for assuring consistent mechanical properties across the casting. Without appropriate inoculation, graphite would form in undesirable shapes, compromising the strength and durability of the final product.

Benefits of Using Ferro Silicon Magnesium in Ductile Iron Castings Improved Mechanical Properties FeSiMg inoculation enables ductile iron to attain enhanced mechanical properties such as higher tensile strength, improved ductility, and greater impact resistance. These attributes make ductile iron more reliable and efficient for various demanding applications, such as in heavy-duty machinery, automotive components, and pipelines.

Enhanced Machinability The controlled formation of spheroidal graphite not only improves strength but also enhances the machinability of ductile iron. Parts cast from ductile iron inoculated with FeSiMg are simpler to manufacture, reducing production costs and enhancing overall efficiency.

Consistency in Castings Consistent inoculation with Ferro Silicon Magnesium results in uniform distribution of graphite nodules, leading to more predictable performance in the final castings. This uniformity is critical for industries that require reliable and reproducible components.

Reduction in Casting Defects Inoculation with FeSiMg helps mitigate common casting defects such as shrinkage and porosity. The refined microstructure reduces the risk of fracture or failure in service, assuring the long-term durability of cast parts.

Cost-Effectiveness While the initial cost of using FeSiMg may be marginally higher than other alloys, the benefits it provides in terms of improved casting quality, reduced defects, and enhanced machinability contribute to significant cost savings in the long run.

Applications of FeSiMg in Ductile Iron Ferro Silicon Magnesium is essential in the production of a wide range of ductile iron castings. Some of the common applications include:

Automotive Parts: Engine blocks, suspension components, and crankshafts rely on the strength and durability of ductile iron to withstand extreme operating conditions. Pipelines and Fittings: Ductile iron pipelines inoculated with FeSiMg are known for their durability, corrosion resistance, and ability to manage high-pressure water and gas transport. Heavy Machinery: Gearboxes, frames, and other structural components made from ductile iron benefit from the alloy’s high tensile strength and abrasion resistance. Agricultural Equipment: Harvester and tractor parts require durable, wear-resistant materials, and ductile iron impregnated with FeSiMg is commonly used in these applications. Conclusion Ferro Silicon Magnesium is an indispensable inoculant in the production of superior ductile iron castings. By enhancing the formation of spheroidal graphite, FeSiMg significantly enhances the mechanical properties of ductile iron, making it a versatile and cost-effective material for industries spanning from automotive to heavy machinery. Its function in generating homogenous, durable, and high-performing ductile iron components ensures that FeSiMg will continue to be a vital material in the foundry industry.

0 notes

Text

Trusted Synthetic Fluorspar Suppliers & Manufacturers in India

Synthetic Fluorspar is an essential mineral widely used in industries such as steel manufacturing, aluminum production, ceramics, and welding applications. With its excellent fluxing properties, high purity, and consistent chemical composition, synthetic fluorspar plays a crucial role in enhancing production efficiency and reducing energy consumption.

Leading Synthetic Fluorspar Suppliers in India

India is home to some of the top synthetic fluorspar suppliers, offering high-grade materials tailored to meet industrial demands. Companies like Tekor Minerals specialize in the production and distribution of premium synthetic fluorspar, ensuring superior quality, competitive pricing, and timely delivery to both domestic and international markets.

#Slag conditioner suppliers in india#ferro silicon magnesium manufacturers in india#Synthetic Fluorspar manufacturers#Synthetic Fluorspar suppliers

0 notes

Text

Why A-One Steels is the Go-To TMT Manufacturer in Bangalore

CTD Bars – The Foundation of Strength

A-One Steels India Limited has carved a niche in the steel industry by producing high-quality CTD bars (Cold Twisted Deformed bars) that are trusted for their unmatched tensile strength and durability. These bars are essential for construction projects that demand long-lasting and reliable reinforcement. Known for corrosion resistance and superior bonding with concrete, A-One’s CTD bars are preferred in residential, commercial, and infrastructure developments across Karnataka and beyond.

Ferro Silicon – Enhancing Steel Quality

One of the key raw materials used in A-One Steels’ manufacturing process is ferro silicon, an important alloying element that enhances the quality of steel. The company sources and uses high-grade ferro silicon to improve the hardness, elasticity, and overall performance of its TMT bars. With a clear focus on product quality and innovation, A-One ensures that every batch meets international standards and delivers consistent results.

Ferro Silicon Price – Competitive and Transparent

A-One Steels stands out not just for quality but also for cost-effectiveness. The ferro silicon price in the market fluctuates, but A-One maintains competitive pricing without compromising on quality. The company offers transparency in its pricing structure, helping clients plan their budgets efficiently. This price stability has made A-One a preferred partner for bulk buyers and contractors alike.

Ferro Silicon Magnesium – Precision and Performance

For specialty steel production, A-One Steels also utilizes ferro silicon magnesium, which plays a crucial role in the production of ductile iron. This alloy improves mechanical properties and enhances structural integrity. The use of ferro silicon magnesium showcases A-One’s technological edge and commitment to producing high-performance steel suitable for diverse industrial applications.

Ferro Silicon Uses – Driving Innovation

The wide range of ferro silicon uses in steel production, deoxidizing, and refining makes it an indispensable part of A-One’s operations. The company’s in-house R&D ensures optimal usage of this alloy for enhancing the quality of Indian TMT bar products. Whether it’s for construction or heavy engineering, A-One leverages ferro silicon uses for innovation and strength.

Tor Steel and Tor Bar Steel – Legacy of Reliability

A-One Steels also produces tor steel and tor bar steel, known for their high yield strength and elongation. These steel variants are ideal for seismic zones and heavy-duty structures. Their ability to withstand high stress and load-bearing capacity makes them a popular choice among architects and structural engineers across Bangalore.

Single Steel Pipe – Versatile and Durable

In addition to TMT bars, A-One manufactures single steel pipe products suitable for industrial and agricultural applications. These pipes are corrosion-resistant and engineered for long-term performance, reflecting the company’s focus on quality in every product segment.

Best TMT Saria in Karnataka – Trusted by Builders

When it comes to the best TMT saria in Karnataka, A-One Steels is the undisputed leader. The brand has built a reputation for delivering robust, flexible, and corrosion-resistant TMT bars, ideal for all types of construction projects. The company’s supply chain efficiency and customer-centric approach further elevate its standing in the market.

Iron and Steel Plant in Bangalore – State-of-the-Art Facility

A-One operates a cutting-edge iron and steel plant in Bangalore, equipped with advanced technology and eco-friendly processes. This facility is the backbone of the company’s operations, ensuring high-volume production while maintaining superior quality standards.

Indian TMT Bar – Strengthening the Nation

A-One Steels is a proud manufacturer of premium Indian TMT bar products, contributing to India’s infrastructure growth. Their bars are a symbol of strength, safety, and sustainability, making A-One the go-to choice for developers across the country.

0 notes

Text

Ferro Silicon Magnesium Manufacturers in India: Driving Quality in Alloy Production

India has emerged as a global hub for alloy manufacturing, with a growing demand for high-performance materials in foundry and steel industries. Among these, ferro silicon magnesium (FeSiMg) holds a crucial position due to its importance in producing ductile (nodular) iron. As industries push for quality, durability, and metallurgical performance, ferro silicon magnesium manufacturers in India are stepping up with advanced production techniques and global supply capabilities.

What is Ferro Silicon Magnesium?

Ferro silicon magnesium is a ferroalloy composed primarily of iron (Fe), silicon (Si), and magnesium (Mg), and is used predominantly as a nodulizer in ductile iron production. Its role is to modify graphite flakes into spheroids during solidification, significantly enhancing the mechanical properties of the final product—especially ductility, impact resistance, and toughness.

Applications of Ferro Silicon Magnesium

The alloy plays a central role in the casting and foundry industry. Key applications include:

Ductile iron production

Automotive castings

Water pipe systems

Agricultural machinery components

Railway parts

Wind and energy sector castings

Given its widespread utility, industries require ferro silicon magnesium that is both pure and consistent in composition.

Why India for Ferro Silicon Magnesium?

India is not only rich in mineral resources but also boasts a robust industrial infrastructure and skilled labor force. This makes it a favorable destination for the production of ferroalloys, especially ferro silicon magnesium. Here's why ferro silicon magnesium manufacturers in India are preferred by global buyers:

1. Cost-Effective Manufacturing

Indian manufacturers offer highly competitive prices without compromising on quality, making them attractive to both domestic and international markets.

2. Advanced Infrastructure

Many Indian plants are equipped with state-of-the-art induction furnaces, refining units, and automated packaging systems, ensuring a high degree of precision in alloy composition.

3. Customization and Quality

Whether you need standard grades or custom specifications, Indian producers are known for offering flexibility in product development and consistent quality through stringent QC measures.

4. Global Export Capabilities

Many ferro silicon magnesium manufacturers in India hold ISO certifications and follow international standards (such as ASTM, BIS, or JIS), enabling them to export to regions like the Middle East, Southeast Asia, Europe, and Africa.

Key Features to Look for in a Manufacturer

When choosing among the ferro silicon magnesium manufacturers in India, consider the following factors:

Purity and Consistency: Reliable manufacturers provide detailed composition sheets, ensuring a consistent balance of magnesium and silicon.

Production Capacity: Large-scale foundries and OEMs should prioritize manufacturers with high monthly tonnage capabilities.

Logistics and Packaging: Look for suppliers who offer moisture-proof, customizable packaging options to maintain product integrity.

Technical Support: Experienced manufacturers often provide technical consultancy to help optimize nodularization and improve casting yields.

Certifications and Compliance: Choose vendors that comply with ISO, BIS, or other relevant quality standards.

Top Locations for Ferro Silicon Magnesium in India

While ferroalloy manufacturing is spread across the country, key production zones include:

Jharkhand and Odisha – Known for mineral reserves and integrated alloy plants.

Chhattisgarh – A rising industrial zone with access to raw materials and energy.

Maharashtra and Gujarat – Leading export-oriented facilities and proximity to ports.

Punjab and Rajasthan – Growing centers for mid-sized and specialized alloy production.

The Future of Ferro Silicon Magnesium in India

With the government’s push on infrastructure, smart cities, and manufacturing through initiatives like Make in India, demand for ductile iron castings is on the rise. This growth will directly fuel the requirement for ferro silicon magnesium in both domestic and export markets.

Additionally, the increasing use of ductile iron in the renewable energy sector, automotive industry, and water management systems signals long-term opportunities for both buyers and suppliers of ferro silicon magnesium.

Conclusion

Choosing the right ferro silicon magnesium manufacturers in India can significantly impact your product quality and production efficiency. Thanks to cost-effectiveness, technological advancement, and a strong focus on quality, Indian manufacturers are well-positioned to meet global demands for high-performance ferroalloys.

Whether you're a foundry manager, procurement officer, or industrial buyer, partnering with a trusted Indian supplier ensures a reliable, consistent, and scalable solution for your nodular iron casting needs.

0 notes

Text

Driving Efficiency: Ferro Silicon Market Soars with Deoxidizer and Inoculants Applications

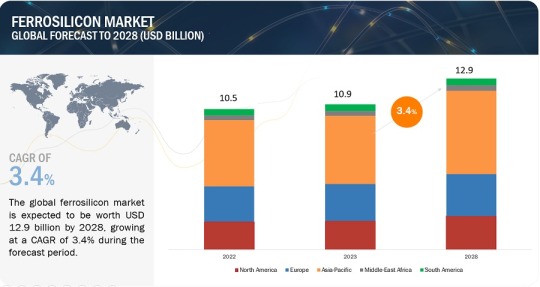

The report “Ferro Silicon Market by Type (Atomized Ferrosilicon, Milled ferrosilicon), Application (Deoxidizer, Inoculants), End-use Industry (Stainless Steel, Cast Iron, Magnesium), and Region (Asia Pacific, Europe, North America, MEA, SA) – Global Forecast to 2028″, is projected to reach USD 12.9 billion by 2028, at a CAGR of 3.4% from USD 10.9 billion in 2023. The ferrosilicon market is…

View On WordPress

#Atomized Ferrosilicon#Deoxidizer#Ferro Silicon#Ferro Silicon Alloy Market#Ferro Silicon Analysis#Ferro Silicon Consumption#Ferro Silicon Demand#Ferro Silicon Export Market#Ferro Silicon Growth#Ferro Silicon Industry#Ferro Silicon Manufacturer#Ferro Silicon Market#Ferro Silicon Market Dynamics#Ferro Silicon Market Forecast#Ferro Silicon Market Graph#Ferro Silicon Market Outlook#Ferro Silicon Market Research#Ferro Silicon Market Segmentations#Ferro Silicon Market Segments#Ferro Silicon Powder Market#Ferro Silicon Pricing#Ferro Silicon Production#Ferro Silicon Regional Growth#Ferro Silicon Supply#Ferro Silicon Trends#Global Ferro Silicon Market#Inoculants#Milled Ferrosilicon

0 notes

Text

What is the composition of ferro silicon magnesium?

Ferro silicon magnesium (FeSiMg) is an alloy used in the steelmaking industry to introduce magnesium and silicon into molten iron, improving the final properties of the steel. The composition of ferro silicon magnesium can vary depending on the specific requirements and application, but it typically consists of the following elements:

Iron (Fe): Iron is the base element in ferro silicon magnesium. It provides the majority of the alloy's composition.

Silicon (Si): Silicon is added to improve the strength and hardness of the steel. It also helps deoxidize the molten metal and remove impurities.

Magnesium (Mg): Magnesium is the primary alloying element in ferro silicon magnesium. It is added to promote the formation of graphite nodules in ductile iron, which enhances the material's mechanical properties and makes it more ductile.

The exact composition of ferro silicon magnesium can vary, but a common range for each element is as follows:

Iron (Fe): Typically makes up the majority of the alloy, ranging from around 45% to 75%.

Silicon (Si): Generally ranges from 1% to 15%.

Magnesium (Mg): Typically ranges from 4% to 12%.

Other impurities and trace elements may also be present in small amounts, depending on the manufacturing process and the source of the raw materials used.

It's important to note that the specific composition of ferro silicon magnesium can vary between different manufacturers and based on the intended application, so it's always a good idea to consult the product specifications or contact the manufacturer for precise information.

0 notes

Text

Find top-quality Ferro Silicon Magnesium and Ferro Silicon Magnesium cored wire at FerroSiliconMagnesium.com. As leading manufacturers in India, they offer reliable alloys for steel production. Visit www.ferrosiliconmagnesium.com to explore their range of products and enhance your steel manufacturing processes with their expertise and high-quality materials. ✉️: [email protected] 🌐https://www.ferrosiliconmagnesium.com/products.php

1 note

·

View note

Text

Nodularisers Suppliers {LATEST} Price in Chhattisgarh, India

Nodularisers, which is fundamentally magnesium treatment of solid metal, is a way to bestow sufficiency in microstructure and make castings more dependable in as cast conditions. Homogeneity and lesser isolation can be accomplished assuming the Nodularisers are of generally excellent quality.

Right blend of all components additionally contributes towards desulphurizing and deoxidizing of the fluid iron, subsequently giving better mechanical strength as well as steady and never-ending microstructure with high ingestion of Mg and lower MgO content.

By presenting some minor components like Ca, Ba, Bi, Sb, and so forth. Nodularisers can grant various properties to castings.

Website: https://www.ferrosiliconmagnesium.com/aboutus.php

0 notes

Text

Buy Premium FeSiMg Alloys and Inoculants | Direct from Manufacturer!

Looking to enhance the quality of your cast iron production? Buy premium FeSiMg alloys and inoculants at competitive prices. Our high-purity FeSiMg 6-8 & FeSiMg 8-10 alloys are ideal for spheroidization in ductile iron casting, ensuring superior strength and consistency. Paired with our effective inoculants, they help improve graphite structure and mechanical properties.

1. High magnesium recovery 2. Low impurities 3. Suitable for foundries and metallurgical industries 4. Available in various sizes and packaging options 5. Bulk orders and timely delivery across India & export markets

Get the best quality at factory-direct prices from a trusted Ferro Silicon Magnesium manufacturer in India.

Contact us today for samples, pricing, and specifications. Website: https://www.ferrosiliconmagnesium.com/ Email: [email protected] Mobile: +91 7610125164

0 notes

Text

Unlocking the Power of Barium Inoculant in Steel Production

In the realm of steel production, the keyword primary keyword is "Barium Inoculant." This innovative additive holds the key to enhancing the quality and properties of steel, revolutionizing the manufacturing process for numerous industries.

What is Barium Inoculant?

Barium inoculant is a crucial element in steelmaking, facilitating the refinement of steel's microstructure. By introducing small amounts of barium into the molten metal, manufacturers can achieve remarkable improvements in the final product's mechanical properties and performance.

Benefits of Barium Inoculant

Enhanced Machinability: Barium inoculant improves the machinability of steel, allowing for easier processing and shaping during manufacturing processes.

Increased Strength: Through the refinement of the steel's microstructure, barium inoculant enhances its strength, making it suitable for a wider range of applications that require durability and resilience.

Improved Surface Finish: Steel treated with barium inoculant exhibits a smoother surface finish, enhancing its aesthetic appeal and overall quality.

Reduced Defects: By promoting the formation of finer and more uniform grains, barium inoculant helps minimize defects such as porosity and shrinkage, resulting in higher-quality steel products.

Applications of Barium Inoculant

Barium inoculant finds widespread applications across various industries, including automotive, aerospace, construction, and machinery manufacturing. From structural components to precision tools, the enhanced properties of barium-treated steel make it indispensable in numerous sectors.

Barium Inoculant: A Sustainable Solution

In addition to its performance benefits, barium inoculant also offers environmental advantages. By optimizing the steel production process and reducing material waste, it contributes to sustainability efforts within the industry, aligning with global initiatives for a greener future.

Conclusion

In conclusion, the utilization of barium inoculant represents a significant advancement in steel production technology. Its ability to enhance the properties of steel, improve manufacturing efficiency, and support sustainability makes it a valuable asset for industries worldwide. For companies seeking to optimize their steel manufacturing processes and deliver high-quality products, integrating barium inoculant is a strategic choice.

Support Innovation with Bansal Brothers

For top-quality barium inoculant and other advanced materials for steel production, trust Bansal Brothers. With a commitment to excellence and innovation, Bansal Brothers stands as a leading provider in the industry, delivering solutions that empower businesses to thrive in today's competitive market.

0 notes

Text

Quality Ferro Silicon Magnesium Manufacturers in India

Looking for reliable Ferro Silicon Magnesium manufacturers in India? Look no further! Our high-quality products ensure superior performance in various applications. Trust Bansal Brothers for top-notch quality and unmatched reliability. Get in touch with us today for your ferro alloy needs.

For more Info: https://www.ferrosiliconmagnesium.com/

Address: Plot No 7 & 12, Borai Industrial Growth Centre, Rasmada, Durg, Chhattisgarh, 491001

Contact Us: 7610125164

0 notes

Text

Why Bangalore’s Structural Steel Market is Booming

Bangalore, known as India’s Silicon Valley, is witnessing rapid urbanization and infrastructural development, leading to a significant surge in the demand for iron and steel plant in Bangalore. The construction and manufacturing industries are fueling the growth of the Indian TMT bar sector, making the city a hub for structural steel production and trade.

Factors Driving the Structural Steel Market

1. Rising Urbanization and Infrastructure Projects

Bangalore is expanding with the construction of high-rise buildings, commercial complexes, and metro rail projects. These developments require high-quality tor steel and tor bar steel, which provide superior strength and durability. The need for robust steel structures in bridges, highways, and smart city projects further amplifies the demand for structural steel.

2. Increased Industrial and Manufacturing Activities

The city is home to multiple industries, including aerospace, automobile, and heavy machinery, all of which rely on single steel pipe and best TMT saria in Karnataka for manufacturing and structural applications. The growing number of industrial zones in and around Bangalore has driven the demand for premium-quality steel products.

3. Expanding Real Estate Sector

The real estate boom in Bangalore, with numerous residential and commercial projects, has significantly increased the consumption of ferro silicon and ferro silicon magnesium. These essential alloys enhance the quality and strength of steel, making them a crucial component in modern construction.

Role of Ferro Alloys in the Steel Market

Ferro Silicon and Its Uses

Ferro silicon is widely used in steelmaking to improve its corrosion resistance, hardness, and tensile strength. It also plays a key role in deoxidizing steel, making it an essential material for structural applications. The increasing ferro silicon price reflects its growing demand in Bangalore’s thriving steel market.

Ferro Silicon Magnesium for High-Quality Steel

Ferro silicon magnesium is crucial in producing ductile iron, which is extensively used in infrastructure projects and heavy engineering industries. The demand for high-quality ductile iron has surged due to Bangalore’s ongoing development projects.

Demand for TMT Bars and Pipes in Bangalore

Best TMT Saria in Karnataka

Thermo-Mechanically Treated (TMT) bars are an integral part of modern construction. The best TMT saria in Karnataka ensures high tensile strength, corrosion resistance, and earthquake-resistant properties. As Bangalore continues to grow, the need for premium-grade TMT bars will only rise.

Single Steel Pipe for Industrial Use

Single steel pipes are extensively used in oil and gas transportation, water pipelines, and structural applications. Their versatility and durability make them a preferred choice for industries in Bangalore.

CONCLUSION:

Bangalore’s structural steel market is booming due to rapid urbanization, industrial expansion, and real estate growth. The demand for ferro silicon, ferro silicon magnesium, tor steel, tor bar steel, single steel pipe, and best TMT saria in Karnataka is at an all-time high. With a robust iron and steel plant in Bangalore, the city is poised to become a key player in India’s steel industry, ensuring sustainable development and economic growth.

0 notes

Text

Ferro Silicon Magnesium Manufacturers in India: Powering the Foundry and Steel Industry

In the heart of modern metallurgy and casting industries lies a crucial alloy—Ferro Silicon Magnesium (FeSiMg). Widely used in the production of ductile iron (SG iron) and steel, this compound plays an essential role in enhancing mechanical properties, improving microstructures, and ensuring quality casting processes. As the demand for high-performance materials grows globally, the focus is shifting towards reliable and high-quality Ferro Silicon Magnesium manufacturers in India.

India, known for its strong metallurgical industry and growing global influence, is home to several top-tier manufacturers producing high-grade FeSiMg alloys. These companies supply both domestic and international markets, maintaining stringent quality standards and technological advancements.

In this blog, we’ll explore what makes Ferro Silicon Magnesium vital to the foundry sector, why India is a key manufacturing hub, and how to choose the right supplier for your industrial needs.

What is Ferro Silicon Magnesium?

Ferro Silicon Magnesium is a master alloy of iron, silicon, and magnesium, often containing trace elements like calcium and rare earth metals. It is mainly used in the nodularization process of cast iron to produce ductile iron, also known as SG (Spheroidal Graphite) iron.

When added during the molten metal stage, the magnesium content helps in converting flake graphite into spheroidal (nodular) shapes, resulting in improved strength, elasticity, and fatigue resistance in the final cast.

Key Applications of Ferro Silicon Magnesium

FeSiMg is indispensable in industries such as:

Automotive Casting: For producing engine blocks, gears, crankshafts, and suspension parts.

Heavy Machinery: Used in components requiring high tensile strength and wear resistance.

Steel Making: Functions as a deoxidizer and alloying agent to improve steel’s overall quality.

Pipe and Fitting Manufacturing: Especially in ductile iron water pipes and valves.

Why India is a Leading Ferro Silicon Magnesium Producer

India has rapidly become one of the largest producers and exporters of Ferro Silicon Magnesium alloys due to a combination of:

1. Raw Material Availability

With access to abundant reserves of iron ore and silicon materials, Indian manufacturers can produce cost-effective and high-quality alloys.

2. Advanced Manufacturing Facilities

Many Indian plants are equipped with state-of-the-art induction furnaces, automatic feeders, and quality control labs that ensure consistent composition and performance of alloys.

3. Skilled Workforce

India boasts a technically sound workforce with metallurgical expertise, making it easier to meet international production standards.

4. Export Capability

With robust logistics and port facilities, Indian manufacturers efficiently serve global markets in Asia, Europe, the Middle East, and Africa.

Leading Ferro Silicon Magnesium Manufacturers in India

Several Indian companies have established themselves as reliable suppliers, known for quality and competitive pricing. While the specific names may vary, top manufacturers typically offer:

Various grades (FeSiMg 5–8%, 8–10%, 10–12%, etc.)

Custom compositions tailored to client needs

Prompt delivery and consistent batch quality

Technical support and lab-tested certifications

When choosing a supplier, it’s essential to verify certifications like ISO, Bureau of Indian Standards (BIS) compliance, and third-party test reports to ensure reliability.

How to Choose the Right Ferro Silicon Magnesium Manufacturer

When sourcing Ferro Silicon Magnesium in India, consider the following:

✅ Quality Assurance:

Ensure the supplier uses advanced quality testing methods, such as spectrometry and thermal analysis.

✅ Experience and Reputation:

A well-established manufacturer with industry experience is more likely to deliver consistent product quality.

✅ Packaging & Logistics:

Look for suppliers who offer safe packaging, especially in 25kg, 1-ton jumbo bags, and reliable export documentation.

✅ Technical Support:

Top manufacturers provide after-sales service, technical assistance, and application guidance.

✅ Customization:

If your foundry needs a specific chemical composition or size range, ensure the manufacturer offers customization capabilities.

The Growing Global Demand for Indian FeSiMg

As developing economies expand their infrastructure, the demand for ductile iron castings is on the rise. Indian manufacturers are well-positioned to cater to this demand by offering cost-effective, high-quality Ferro Silicon Magnesium alloys that comply with international standards.

Global foundries are now looking to India as a long-term strategic supplier due to competitive pricing, consistent quality, and dependable logistics.

Final Thoughts

The importance of Ferro Silicon Magnesium manufacturers in India cannot be overstated. With increasing global demand for ductile iron and high-strength castings, the role of quality FeSiMg producers is critical in shaping industrial growth.

Whether you are a small foundry, a large steel manufacturer, or an international buyer, sourcing from India offers you both quality and value. By choosing a reliable Indian manufacturer, you’re not just buying an alloy—you’re investing in consistent production, metallurgical excellence, and long-term business growth.

0 notes

Text

0 notes