#Alloy Production

Explore tagged Tumblr posts

Text

High Purity Pig Iron Market's Integral Role in Elevating Steel Quality Standards

The global high purity pig iron market size is expected to reach USD 17.09 billion by 2030, according to a new report by Grand View Research, Inc, expanding at a CAGR of 8.5% over the forecast period. Investments in wind power generation are expected to benefit the industry growth from 2022 to 2030. HPPI is the principal raw material used in the production of nodular cast iron components, which are deployed in industries, such as wind energy, automotive & transportation, etc. Increasing emissions and limited potential for fossil fuels have led to the focus on energy production from renewable sources, such as wind and solar. HPPI finds applications in different wind turbine components, such as rotors, shafts, frames, and blades among others.

High Purity Pig Iron Market Report Highlights

The energy application segment is projected to register the fastest CAGR over the forecast period. A shift towards renewable energy is anticipated to promote the usage of nodular cast iron components and benefit HPPI demand

Automotive & transportation was the largest application segment in 2021. Investments for new plants and capacity additions are projected to boost the demand for HPPI products in casting parts

Asia Pacific was the leading region in 2021 due to offshore wind projects and industrial production in China, India, and Japan

India is anticipated to register a lucrative growth rate, in terms of revenue, over the forecast period due to the growing focus on domestic manufacturing to cater to the growing demand from various end-use industries

For More Details or Sample Copy please visit link @: High Purity Pig Iron Market Report

China, a leader in wind energy installations, aims to double its wind and solar capacity by 2025. The pollution levels are also high in China compared to other countries around the world, therefore it is necessary to increase renewable power generation. As per the central economic plan of the country, nearly 33% of power supply will come from renewable sources by 2025, an increase from 29% in 2020. Recently, Siemens Gamesa Renewable Energy received an order for 14 offshore wind turbines from a Green Power Investment firm in Japan. This Ishikari offshore project is likely to produce 112 MW of wind energy wherein installations are planned to start in July 2023. The turbines have ClassNK certification ensuring stringent technical standards. Similar investments in wind energy are expected to provide a boost to the HPPI products demand.

Automotive & transportation is a key application segment, wherein nodular cast iron components made using HPPI are used. This segment is likely to register a growth of 8.3%, in terms of revenue, from 2022 to 2030. A rise in the production capacities for vehicles is projected to attract the demand for HPPI products. For instance, Kia Motors in India is expected to increase its production capacity to 400,000 units by the end of 2022. Increasing utilization of steel scrap in foundries, especially in China, is projected to remain a favorable factor for the industry players. The increasing shift towards electric furnaces compared to blast furnaces requires high purity iron to reduce the impurities in the melt. This is anticipated to benefit in the reduction of carbon emissions and, thus, protect the environment.

HighPurityPigIron #PigIron #Metallurgy #SteelProduction #MetalManufacturing #IronSmelting #PureIron #MetallurgicalProcesses #PremiumSteel #IronQuality #FoundryMaterials #SteelQuality #AlloyProduction #MetalInnovation #IronandSteel #SmeltingTechnology #HighPerformanceMetals #MetalsIndustry #SteelStandards #SteelManufacturing #MetalExcellence

#High Purity Pig Iron#Pig Iron#Metallurgy#Steel Production#Metal Manufacturing#Iron Smelting#Pure Iron#Metallurgical Processes#Premium Steel#Iron Quality#Foundry Materials#Steel Quality#Alloy Production#Metal Innovation#Iron and Steel#Smelting Technology#High Performance Metals#Metals Industry#Steel Standards#Steel Manufacturing#Metal Excellence

0 notes

Text

For the business end of a block-buster. Bridgeport Brass Company ad - 1944.

#vintage illustration#vintage advertising#american industry#life during wartime#ww2#wwii#wwii era#ww2 era#the 40s#the 1940s#war production#military industrial complex#war supplies#world war ii#world war two#world war 2#u.s. military#bridgeport brass company#metal products#brass#metallurgy#bronze#copper#alloys#metals#blockbuster bomb#an-m56#blockbuster

9 notes

·

View notes

Text

sorry about the democracy polls i got distracted for a bit. i should make Union as a stellaris empire

#thinking probably. some flavor of Crusader Spirit#egalitarian xenophile militarist / fanatic egalitarian militarist#the militarist is only because i had to choose between Militarist Authoritarian and Spiritualist as prereqs for Crusader Spirit#stellaris#lancer rpg#tabletop#rpg#video games#i *could* always just do fanatic egalitarian and use Liberation War policy out of my own free will of course#but since i'll have to balance alloy production with Consumer Goods to afford Utopian Abundance#so the boosts from Crusader Spirit and Militarist might be just enough to make up for it

9 notes

·

View notes

Text

Flawless Rims in Winter! ❄️✨

A simple guide to keeping your car rims in top shape during winter! Discover how to tackle rain and snow without sacrificing style.

With these easy cares, face winter with confidence and ensure your sport rims look impeccable. Keep the style even in the coldest season!

#rims#car rims#automotive#automobile#cars#sport cars#car care tips#car care products#vehicle#suv#classic cars#cool cars#hot wheels#alloy rims restoration#winter#car accessories#car tires

2 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

5 Things about Stainless Steel 316H Forged Fittings manufacturer you will never know!

Stainless steel 316H forged fittings are widely used in a variety of industrial applications due to their exceptional strength, durability, and corrosion resistance properties. These fittings are made by a specialized manufacturer who uses advanced technology and techniques to produce high-quality components.

In this article, we will explore 5 things about stainless steel 316H forged fittings manufacturers that you may never have known before.

Expertise and Experience

SS 316H forged fittings manufacturer has extensive knowledge and experience in the field of metallurgy, engineering, and manufacturing processes. They have the expertise to produce customized fittings that meet specific customer requirements, such as dimensions, shapes, and materials. These manufacturers also have a deep understanding of the properties and characteristics of stainless steel 316H, which enables them to optimize the forging process and produce high-quality components.

High-Quality Standards

This manufacturer follows strict quality control measures to ensure that their products meet the highest industry standards. They use advanced testing and inspection techniques to verify the properties and characteristics of the components, such as hardness, tensile strength, and corrosion resistance. These manufacturers also use high-quality materials and production techniques to ensure that their products are durable and reliable.

Customization Capabilities

They also have the ability to produce customized components based on specific customer requirements. They can create fittings in a variety of shapes and sizes, including elbows, tees, couplings, and reducers. These manufacturers can also produce fittings with specific threads, such as NPT, BSP, or BSPT, and can create specialized components for unique applications.

Advanced Technology and Techniques

They also use advanced technology and techniques to produce high-quality components. They use computer-aided design (CAD) software to create 3D models of the fittings and simulate the forging process to optimize the production process. These manufacturers also use advanced forging equipment, such as hydraulic presses and hammers, to produce high-quality components with precise dimensions and properties.

Compliance with Industry Standards

Stainless steel 316H forged fittings manufacturers comply with various industry standards, such as ASTM, ASME, and ANSI. These manufacturers also adhere to various international standards, such as ISO and EN. Compliance with these standards ensures that the components produced by these manufacturers are safe, reliable, and meet the required specifications.

In conclusion, stainless steel 316H forged fittings manufacturers are experts in the field of metallurgy, engineering, and manufacturing processes. They use advanced technology and techniques to produce high-quality components that meet specific customer requirements. These manufacturers follow strict quality control measures and comply with various industry standards to ensure that their products are safe, reliable, and of high quality.

#Stainless Steel Pipe Fittings#Stainless Steel Forged Fittings#construction#buildings#alloy#steel products#plumbing#Water control system#engineering#civilengineering#SS 316H Pipe Fittings#SS Pipe Fittings#Stainless Steel Pipe Fitting Manufacturer in Mumbai#Stainless Steel Forged Fittings Supplier in India#Stainless Steel Pipe Fittings Price

5 notes

·

View notes

Note

.

Is spider silk being as strong as steel another lie from childhood? Bc you're able to break it pretty easily on accident. Genuinely asking.

spider silk IS actually significantly stronger pound-for-pound than the same amount of steel, but only in one direction! and coincidentally, it's the same exact direction that got a bunch of people killed in a submersible last month.

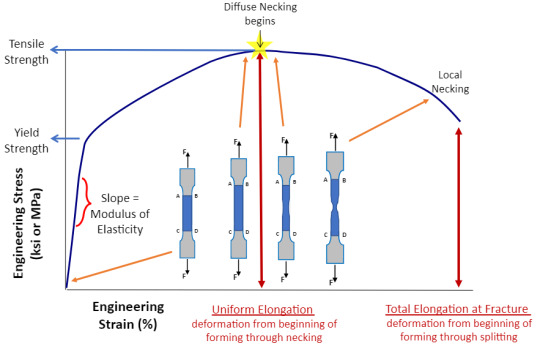

see, when people talk about the "strength" of spider silk versus steel, they're specifically talking about tensile strength:

which is specifically the measure of the strength of a material when two forces are pulling at it from the ends, like when a steel cable is holding up a bridge support, or crane cargo:

or like when a strand of silk is supporting the entire spider.

that's tensile strength, baby!

but there's another type of strength that's very important to take into consideration when you're actually building things like bridges and submersibles, and spider silk and similar materials like carbon fiber are absolutely garbage at it! and that's compressive strength.

this is basically the inverse of tensile strength, where instead of being yanked at from both ends, the forces are crushing inwards at the material from both directions instead.

you can expect to see these kinds of forces involved in road surfaces, vehicle engines, and again, submersibles.

now steel and its more competent cousin titanium are fucking GREAT at compressive strength! the harder the outside forces are compressing them, the stronger the metals get.

NOT TODAY, FUCKERS

but strand-based materials like spider silk and, again, carbon fiber, are fucking garbage at this. they can take a certain amount of pressure, but each round with compressive forces snaps some of the strands that makes up the material! and those don't grow back, so basically you're just gradually reducing your poor overstressed carbon-fiber hull into a completely useless shell of shattered thread fragments over time as the strands of fiber that actually give it strength die off one by one.

and eventually, something's gotta give! and then people die about it.

this is why, even though spider silk IS stronger than steel in one specific way, we're never going to stop using steel in industrial applications and switch over to spider silk or carbon fiber full time. these materials all have their areas of use, and steel just covers a wider base of applications.

and don't even get me started on shear strength. we'll be here all damn day.

#huh. i was going to take issue with the 'more competent cousin' statement#but titanium alloys have come a long way since my undergrad days#it seems they've resolved the fatigue limit issues and now the main barrier is cost#though i wonder if the hcp structure is as friendly to production techniques like knurling#machining is still a splosion hazard i think

5K notes

·

View notes

Text

Jay Steel Corporation - Trusted Titanium Alloy GR7 Sheets Exporters for High-Performance Solutions

When it involves high-performance substances that offer extremely good energy, corrosion resistance, and sturdiness, titanium alloy GR7 sheets stand out. Jay Steel Corporation, a leading name in the enterprise, is recognized as one of the most trusted titanium alloy GR7 sheets exporters. With a sturdy dedication to extraordinary and client pleasure, we provide high-performance titanium products that meet the needs of diverse industries.

In this blog, we’ll discover what makes Titanium Alloy GR7 plates & sheets so valuable, why we are the favoured preference and how we resource industries with advanced and the best titanium solutions.

What Are Titanium Alloy Grade 7 Sheets?

Titanium alloys are referred to for their excellent power-to-weight ratio and high-quality resistance to corrosion. Titanium alloy GR7 plates & sheets are specially designed to perform properly in difficult environments, together with marine, aerospace, and chemical industries. The alloy commonly includes titanium with small portions of palladium, which enhances its corrosion resistance, especially in acids, chlorides, and seawater. Titanium alloy GR7 plates, coils, & sheets are extensively applied in applications that require excessive energy, reliability, and prolonged-lasting fundamental normal overall performance beneath excessive situations.

Some first-rate competencies of Titanium Alloy GR7 or Ti-0.2Pd alloy sheets include:

Corrosion Resistance: GR7 titanium is relatively resistant to corrosion, making it nice to be used in aggressive environments.

High Strength: It gives a top-notch aggregate of electricity and lightweight features.

Good Weldability: This alloy is straightforward to weld; it truly is important for applications requiring custom styles and sizes.

Durability: Titanium or Ti Alloy GR7 Sheets are recognized for their lengthy lifespan, decreasing the need for commonplace replacements.

These unique features make Titanium or Ti Alloy GR7 Sheets a pass-to choice for several immoderate-widespread performance programs, which consist of chemical processing, marine, aerospace, and further.

Why Choose Jay Steel Corporation as Your Titanium Alloy GR7 Sheets Exporter?

We are one of the greatest titanium or Ti alloy GR7 sheet exporters. Our reputation for imparting remarkable titanium products has made us a favoured supplier for industries that require long-lasting and reliable materials. Here are some reasons why our corporation needs to be your provider of preference:

1. High-Quality Titanium Products

We apprehend the significance of fantastic in industrial substances. Our Titanium Alloy GR7 Sheets are sourced from respectable producers and go through strict satisfactory exams to make certain they meet global requirements. Every product we deliver is examined for durability, power, and corrosion resistance to make certain that it plays excellently under disturbing situations.

2. Wide Range of Titanium or Ti Alloy GR7 Sheets

As titanium alloy GR7 plate and sheet exporters, we provide an entire style of sizes and thicknesses to fulfill your specific requirements. Whether you want large sheets for number-one projects or smaller quantities for renovation, we've got the proper product to assist your dreams. Our stock consists of:

Titanium or Ti Alloy GR7 Sheets in numerous sizes

Custom-cut sheets for particular applications

Large and small batches counting on demand

This massive desire guarantees that you can find the right product for your task, irrespective of its scale.

3. Timely Delivery Across the Globe

We know that well-timed shipping is essential for our customers. We prioritize speedy and dependable shipping to ensure that you receive your Titanium alloy GR7 or Ti-0.2Pd alloy sheets on time, regardless of where you are located. Whether you’re operating on a time-sensitive project or need everyday materials, our efficient logistics business enterprise guarantees on-time shipping.

4. Competitive Pricing for High-Quality Materials

We are dedicated to supplying titanium or Ti alloy GR7 sheets at aggressive fees. We work carefully with relied-on suppliers to hold reasonably priced pricing without compromising on the pleasantness of our products. By presenting aggressive fees, we make sure that you get immoderate-average overall performance substances whilst staying inner your price range.

5. Expert Support and Guidance

Choosing the right product for your mission can be a complicated desire. Our organization of specialists is available to guide you in deciding on the best titanium or Ti Alloy GR7 sheets for your unique dreams. Whether you're uncertain about the desired grade or want recommendations on custom answers, we're here that help you make knowledgeable alternatives for the best consequences.

Industries That Benefit from Titanium Alloy GR7 Plates, Coils, & Sheets

Titanium Alloy GR7 plates, coils, & sheets are used at some stage in masses of industries that call for immoderate-general universal overall performance substances. Some of the crucial trouble industries we serve encompass:

Aerospace: Titanium or Ti Alloy GR7 Sheets are perfect for aerospace programs because of their lightweight and strong features. They are utilized in components such as turbine blades, airframes, and exceptional, immoderately accepted performance elements that need to withstand extreme strain and temperatures.

2. Chemical Processing: The advanced corrosion resistance of titanium alloy GR7 or Ti-0.2Pd alloy sheets makes them nice for the chemical processing business enterprise. These sheets are carried out in reactors, warm temperature exchangers, and piping systems that cope with aggressive chemicals and excessive temperatures.

3. Marine: The terrific resistance to seawater corrosion makes titanium or Ti alloy GR7 sheets a well-known choice within the marine commercial enterprise agency. These sheets are used in marine structures, deliver additives, and offshore devices that might be exposed to harsh marine environments.

4. Medical: In medical applications, the biocompatibility and electricity of titanium or Ti alloy GR7 sheets make them excellent for implants, prosthetics, and surgical devices.

5. Automotive: Titanium Alloy GR7 plates & sheets are applied in immoderate-traditional overall performance automobile elements that want to resist immoderate situations, together with exhaust structures and engine additives.

Conclusion: Choose Us for Your Titanium Alloy GR7 Sheets Needs

To conclude, Jay Steel Corporation is your dependent accomplice concerning sourcing terrific titanium or Ti alloy GR7 sheets. As important titanium alloy GR7 sheets exporters, we offer a wide range of products designed to satisfy the desires of various industries. With our willpower to provide nice, well-timed transport, competitive pricing, and a professional manual, we make sure that your initiatives enjoy the top-notch materials available. Choose us for all of your titanium alloy desires, and experience the distinction in first-rate and provider.

0 notes

Text

Nickel Flat Bar & Alloy Round Bars Supplier | OM Export India

Explore high-quality nickel flat bar and nickel alloy round bars from OM Export India. Your trusted supplier for durable and corrosion-resistant nickel bars, available in various sizes to meet all industrial needs.

#nickel alloy round bar#nickel flat bar#Inconel 600/601/625/718 Pipes & Tubes#Inconel 600/601/625/718 Pipes#Inconel 600/601/625/718 Tubes#high performance 253ma stainless steel pipe#high productivity 253ma stainless steel pipe#253ma pipe#really believable 253ma stainless steel pipe

0 notes

Text

We don’t just make the alloys we shape the perfection with every alloy. Contact us today and find the alloys as per your requirements.

See product details: https://snehmetals.com/our-products/

#brass components#brass products#sneh metal alloys#brass parts#brass fitting#commercial#brass scrap#business

0 notes

Text

High Performance 253MA Stainless Steel Pipe - Top Supplier in India | OM Export India

Looking for high performance 253MA stainless steel pipes? OM Export India offers top-quality 253MA pipes designed for extreme temperatures and high corrosion resistance. Explore our wide range and get the best deals today!

#high performance 253ma stainless steel pipe#high productivity 253ma stainless steel pipe#253ma pipe#really believable 253ma stainless steel pipe#nickel alloy round bar#nickel flat bar#Inconel 600/601/625/718 Pipes & Tubes#Inconel 600/601/625/718 Pipes#Inconel 600/601/625/718 Tubes

0 notes

Text

Zinc Alloy Fruit Slicer Is Creative And Portable

Zinc Alloy Fruit Slicer Is Creative And PortableFree shipping worldwide 👌 🌐 ❤ Shop now link products is here 👈👈👈👈

#Zinc Alloy Fruit Slicer Is Creative And Portable#Fruit Slicer#Trending products#For kitchen#All country#artists on tumblr#autumn#new arrivals#go viral now#new arrivals products

1 note

·

View note

Text

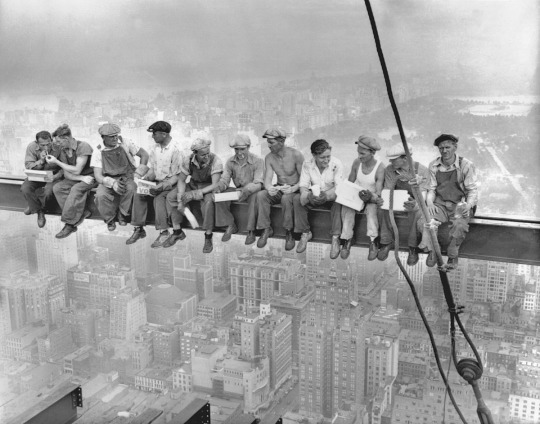

Hats off to the men of steel! Jenkins Valves ad - 1944.

#vintage illustration#vintage advertising#american industry#life during wartime#ww2#wwii#wwii era#ww2 era#the 40s#the 1940s#war production#military industrial complex#war supplies#world war ii#world war two#world war 2#u.s. military#jenkins valves#metal products#brass#metallurgy#bronze#copper#alloys#metals#valves

8 notes

·

View notes

Text

#Aluminum Alloy Manufacturing Company in India#Aluminum Alloy Manufacturer#Precision Alloy Production Company#top alloy manufacturing company in india

0 notes

Text

Sunny Health & Fitness Mini Stepper

Key Features:

Compact Design: Perfect for small spaces, making it easy to incorporate cardio and strength training at home.

Full-Body Workout: Offers stair-stepper exercises to target lower body muscles, while optional resistance bands engage the upper body.

Smart Technology:

Compatible with the SunnyFit App for tracking progress, viewing workout stats, and accessing guided exercise programs.

Durable Construction: Built to handle intense workouts while providing stability and safety.

Adjustable Resistance: Allows users to customize their workout intensity for both beginners and advanced users.

Multifunction Display: Tracks important stats like time, steps, and calories burned.

Portability: Lightweight and easy to move, making it a convenient choice for home use.

Ideal For:

People looking to improve cardiovascular health.

Those aiming for low-impact, joint-friendly workouts.

Individuals who want an affordable, space-saving exercise solution.

You can buy it now from Amazon.

#Brand#Sunny Health & Fitness#Color#Grey#Material#Alloy Steel#Number of Batteries#1 LR44 batteries required. (included)#Product Dimensions#16.1“L x 12.2”W x 13.5“H

0 notes

Text

Design points and precautions of three-plate mold style of plastic mold "two-color mold"

Primary Color Material: ABS Secondary Color Material: TPS Appearance of TPS elastomer is transparent or natural color particles, and hand feel is super soft or flexible. Hardness of material usually ranges from 30 to 90A. Hardness of TPS material for special applications can reach 0A, or 120A. TPS elastomer has rubber-like elasticity and wear resistance, and has a unique soft touch. TPS…

View On WordPress

#cold chamber die casting#die casting#die-cast aluminum alloy#die-casting process#die-casting production#hot chamber die casting#Zinc alloy die casting

0 notes