#Nickel 200 Washers Manufacturers

Explore tagged Tumblr posts

Text

Nickel 200 Washers Exporters Manufactures Suppliers In India

Nascent Pipe & Tubes is a top distributor and stockist of high-quality Nickel Alloy 200 Fasteners (Washers), renowned for their versatility in pressure vessel construction, withstanding temperatures up to 300°C. Theseflat washers represent age-hardenable Cu-Ni casting alloys, with the inclusion of aluminum, chromium,or beryllium enhancing their properties. Notably, Nickel 200 Lock Washers with 2% Al offer flexibility for both as-cast and post-age hardening applications, with beryllium additions maximizing strength post-hardening

Nickel 200 washers are widely used in everyday life for their reliability and versatility. They are found in household appliances like washing machines and dishwashers, ensuring parts stay securely fastened. In plumbing systems, they create tight seals in faucets and pipes, preventing leaks. Automotive applications rely on them for securing engine components and exhaust systems. In construction, Nickel 200 washers help hold together structures like bridges and steel framing. They also play roles in electronics, medical equipment, and industrial machinery, contributing to the functionality and safety of various products and systems.

However, industrialized nations like the United States, Germany, Japan, China, and India, with strong manufacturing sectors, likely have significant demand for Nickel 200 washers. Additionally, regions with extensive construction and infrastructure projects, such as the Middle East and Southeast Asia, may also use a considerable amount of Nickel 200 washers

Industries with significant demand for Nickel 200 Washers

Nascent Pipe & Tubes is a top distributor and stockist of high-quality Nickel Alloy 200 Fasteners (Washers), renowned for their versatility in pressure vessel construction, withstanding temperatures up to 300°C. Theseflat washers represent age-hardenable Cu-Ni casting alloys, with the inclusion of aluminum, chromium,or beryllium enhancing their properties. Notably, Nickel 200 Lock Washers with 2% Al offer flexibility for both as-cast and post-age hardening applications, with beryllium additions maximizing strength post-hardening

Nickel 200 washers are widely used in everyday life for their reliability and versatility. They are found in household appliances like washing machines and dishwashers, ensuring parts stay securely fastened. In plumbing systems, they create tight seals in faucets and pipes, preventing leaks. Automotive applications rely on them for securing engine components and exhaust systems. In construction, Nickel 200 washers help hold together structures like bridges and steel framing. They also play roles in electronics, medical equipment, and industrial machinery, contributing to the functionality and safety of various products and systems.

However, industrialized nations like the United States, Germany, Japan, China, and India, with strong manufacturing sectors, likely have significant demand for Nickel 200 washers. Additionally, regions with extensive construction and infrastructure projects, such as the Middle East and Southeast Asia, may also use a considerable amount of Nickel 200 washers

Industries with significant demand for Nickel 200 Washers

Nascent Pipe & Tubes is a top distributor and stockist of high-quality Nickel Alloy 200 Fasteners (Washers), renowned for their versatility in pressure vessel construction, withstanding temperatures up to 300°C. Theseflat washers represent age-hardenable Cu-Ni casting alloys, with the inclusion of aluminum, chromium,or beryllium enhancing their properties. Notably, Nickel 200 Lock Washers with 2% Al offer flexibility for both as-cast and post-age hardening applications, with beryllium additions maximizing strength post-hardening

Nickel 200 washers are widely used in everyday life for their reliability and versatility. They are found in household appliances like washing machines and dishwashers, ensuring parts stay securely fastened. In plumbing systems, they create tight seals in faucets and pipes, preventing leaks. Automotive applications rely on them for securing engine components and exhaust systems. In construction, Nickel 200 washers help hold together structures like bridges and steel framing. They also play roles in electronics, medical equipment, and industrial machinery, contributing to the functionality and safety of various products and systems.

However, industrialized nations like the United States, Germany, Japan, China, and India, with strong manufacturing sectors, likely have significant demand for Nickel 200 washers. Additionally, regions with extensive construction and infrastructure projects, such as the Middle East and Southeast Asia, may also use a considerable amount of Nickel 200 washers

Industries with significant demand for Nickel 200 Washers

Chemical Processing: They resist corrosion in acidic and alkaline environments.

Aerospace: They offer high-temperature performance and mechanical strength.

Electronics: They provide electrical insulation and conductivityPower Generation: They withstand high temperatures and corrosion in turbines and heat exchangers.

Oil and Gas: They resist corrosion in offshore drilling equipment and pipelines.

Medical Equipment: They are biocompatible and corrosion-resistant in surgical instruments and implants.

Automotive: They secure components in engines, exhaust systems, and suspensions

Nickel 200 Washer Specifications

Specifications

IS / BS / ASTM

Standard

ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472

Length

M02 to M30

Size

3 mm to 200 mm

Type

Flat Washer, Lock Washer, Sealing Washer, Split Washer, Slot Washer, Machine Washer, Star Washer SPRINGS – Wire Spring & Flat Spring

Conclusion

Nickel 200 Washers are in high demand across industries seeking superior corrosion resistance, high-temperature tolerance, and dependable mechanical strength. These washers play a pivotal role in preserving the longevity and efficiency of equipment and structures across diverse sectors. With their adaptability and reliability, Nickel 200 Washers remain essential components in various industrial applications, significantly enhancing the effectiveness and resilience of critical systems globally.

#Nickel 200 Washers#Nickel 200 Washers Manufacturers#Nickel 200 Washers Suppliers#Nickel 200 Washers Stockists#Nickel 200 Washers Exporters#Nickel 200 Washers Manufacturers in India#Nickel 200 Washers Suppliers in India#Nickel 200 Washers Stockists in India#Nickel 200 Washers Exporters in India

0 notes

Text

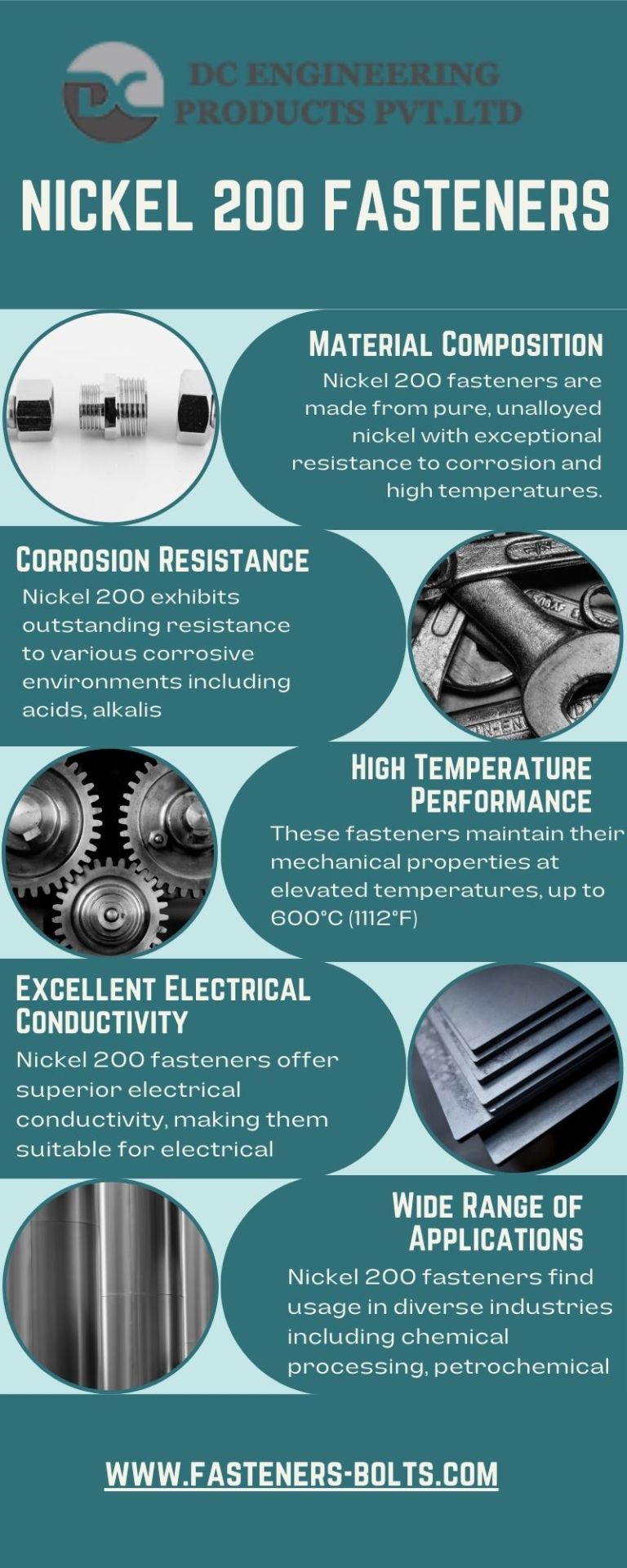

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

Incoloy 825 Fasteners Exporters

In the realm of industrial fasteners, one name stands out for its remarkable resilience and dependability—Incoloy 825. Used across a variety of sectors, from chemical processing to marine engineering, these fasteners are known for their unmatched performance in demanding environments. But what exactly makes Incoloy 825 fasteners so special, and why should you consider them for your projects? Let’s dive into the unique features and benefits of these high-performance fasteners.

What are Incoloy 825 Fasteners? Incoloy 825 fasteners are made from a nickel-iron-chromium alloy known for its exceptional resistance to various corrosive elements. The alloy is further enriched with molybdenum, copper, and titanium, which enhance its resistance to pitting, crevice corrosion, and stress-corrosion cracking. These fasteners are designed to perform in highly aggressive environments, such as chemical processing plants, offshore oil and gas facilities, and seawater applications.

Key Properties of Incoloy 825 Fasteners Corrosion Resistance: Incoloy 825 exhibits outstanding resistance to both reducing and oxidizing acids, making it ideal for use in environments with sulfuric acid, phosphoric acid, and other corrosive chemicals. High Temperature Tolerance: The alloy maintains its mechanical strength and corrosion-resistant properties even at elevated temperatures, which makes it suitable for heat-exposed applications. Durability and Strength: Incoloy 825 fasteners provide high mechanical strength and are known for their long lifespan, reducing the need for frequent replacements. Resistance to Pitting and Crevice Corrosion: Thanks to the molybdenum content, these fasteners can withstand pitting and crevice corrosion in chloride-containing environments.

Specifications of Incoloy 825 Fasteners Standards: DIN, ASTM, BS, and all international standards Size Range: 3 mm to 200 mm Bolt/Screw Size: M3 - M56 | 3/6" to 2" | Custom sizes available Nut Size: M3 - M56 | 3/6" to 2" | Custom sizes available Washer Size: M1 - M64 | #4 to 3" | Custom sizes available Length: M02 to M33 Types: Includes nuts, bolts, screws, sockets, studs, hex head bolts, machine screws, marine anchors, eye bolts, foundation bolts, structural bolts, and more. Benefits of Incoloy 825 Fasteners Long-Term Cost Savings: Their durability and resistance to harsh chemicals reduce the frequency of replacements, leading to long-term savings. High Corrosion Resistance: Ideal for applications exposed to saltwater, acidic, and alkaline environments. Wide Range of Applications: Used in multiple industries, from chemical processing and oil & gas to marine engineering. Easy Customization: Available in various sizes and shapes, with custom sizes upon request to meet specific project requirements. Consistency and Reliability: Conforms to international standards ensuring dependable performance across diverse applications.

Applications of Incoloy 825 Fasteners Incoloy 825 fasteners are utilized in various industries due to their remarkable properties. Some of the key applications include:

Chemical Processing: Used in processing plants dealing with sulfuric, phosphoric, and other aggressive acids. Oil & Gas Industry: Suitable for offshore drilling, oil refining, and gas extraction, where exposure to corrosive environments is common. Marine Engineering: Employed in shipbuilding, marine hardware, and seawater desalination plants due to their resistance to saltwater corrosion. Pollution Control Equipment: Ideal for use in components exposed to polluted or contaminated environments. Heat Exchangers: These fasteners hold up well in heat exchangers and other equipment that operates at high temperatures.

Why Choose Sankalp Alloys Overseas for Incoloy 825 Fasteners? Sankalp Alloys Overseas is a trusted leader in the manufacturing, exporting, stocking, and supply of Incoloy 825 fasteners in India and internationally. Here’s why you should consider partnering with them:

Expertise and Experience: With years of experience in the industry, Sankalp Alloys Overseas has developed a reputation for delivering high-quality fasteners that meet the stringent requirements of various industrial applications. Wide Range of Products: They offer an extensive selection of Incoloy 825 fasteners, including custom sizes and configurations to suit specific needs. Quality Assurance: Sankalp Alloys Overseas adheres to international quality standards such as DIN, ASTM, and BS, ensuring that their products consistently deliver exceptional performance. Competitive Pricing: They provide cost-effective solutions without compromising on quality, ensuring that you get the best value for your investment. Global Reach: As exporters, they serve clients not only in India but around the world, ensuring prompt and efficient delivery regardless of location. Customer-Centric Approach: Committed to customer satisfaction, they offer personalized services, including technical support and product recommendations tailored to your specific requirements.

Conclusion When it comes to industrial fasteners, Incoloy 825 fasteners stand out for their superior corrosion resistance, high strength, and versatility across a range of applications. Whether you are dealing with harsh chemicals, high temperatures, or seawater environments, these fasteners offer unmatched performance. For the best quality and service, Sankalp Alloys Overseas is your go-to partner. With their expertise, comprehensive product range, and commitment to quality, you can trust them to meet all your fastening needs.

Contact Details For inquiries, quotations, or more information, get in touch with Sankalp Alloys Overseas:

Contact Number: +91-8828369483 Email: [email protected] Website: https://www.sankalpalloys.com

Sankalp Alloys Overseas is your reliable source for top-quality Incoloy 825 fasteners—delivering excellence and precision for all your industrial requirements.

#Incoloy 825 Fasteners Exporters#Incoloy 825 Fasteners Exporters in India#Incoloy 825 Fasteners Manufacturers#Incoloy 825 Fasteners Manufacturers in India#Incoloy 825 Fasteners#Fasteners#exporter#suppliers#business#exporters#innovation#stockists#manufacturers#metalwork#sankalpalloys#india#mumbai#uae

1 note

·

View note

Text

Monel K500 Washers Manufacturers

Monel K500 is a nickel-copper alloy that stands out for its exceptional corrosion resistance, high strength, and durability, even in harsh environments. These characteristics make it an essential material for various industries, particularly in the manufacturing of washers. Monel K500 washers are widely used in marine, chemical, oil and gas, and aerospace industries, where they play a critical role in ensuring the reliability and longevity of assemblies.

The Importance of Quality Monel K500 Washers

Washers are small, flat rings that are used to distribute the load of a threaded fastener, such as a screw or nut. In many applications, the choice of material for washers can have a significant impact on the performance and safety of the entire assembly. Monel K500 washers are particularly valued for their ability to resist corrosion, even in saltwater or acidic environments, which makes them ideal for use in marine and chemical processing applications.

Moreover, the alloy’s high tensile strength and hardness ensure that Monel K500 washers maintain their integrity under extreme conditions, such as high pressure or temperature. This reliability is crucial in industries like oil and gas, where the failure of a single component can lead to catastrophic results.

The Role of Exporters in the Global Supply Chain

Exporters of Monel K500 washers play a vital role in the global supply chain, ensuring that these critical components are available to industries around the world. The demand for Monel K500 washers is global, with significant markets in North America, Europe, Asia, and the Middle East. Exporters must navigate complex logistics, international trade regulations, and varying quality standards to deliver products that meet the exacting specifications of their clients.

Chhajed Steel Limited is one of the renowned makers and suppliers of Monel K500 Washers, which are precipitation cementing washers manufactured from copper nickel composite with development of titanium and aluminum. With the parts of aluminum and titanium, Monel K500 Flat Washers offers the wonderful insurance from utilization of Alloy 400; with raised quality, hardness, breaking down security and oxidation shortcoming assurance. We make a wide scope of Monel K500 Machined Washers in all shapes and sizes. We moreover give passivation, quality covering in Monel K500 Punched Washers also dealing with as per client's need. All our delivered Monel K500 Round Washers are according to national and furthermore overall models. Monel K500 Square Washers are into two halves string and full string length with arranged movement, material in stock.

MONEL ALLOY K500 WASHERS SPECIFICATION

Material

Specification

Standards

Size

Length

Monel Alloy K500

IS

BS

ASTM

ASTM B865-04

3 mm to 200 mm

M02 to M33

MONEL ALLOY K500 WASHERS GRADE DESIGNATION

Alloy

Common Name

Related Specification

British

European

ASTM

UNS

Alloy K500

Monel K500 ®

BS 3076 NA18

4.4375

B865-04

N05500

Conclusion

Monel K500 washers are indispensable in various high-performance applications, and choosing the right exporter is crucial to ensuring that these components meet the stringent demands of your industry. By focusing on quality, experience, supply chain capabilities, and customer support, you can find a reliable partner to supply you with Monel K500 washers that deliver optimal performance and durability in your specific applications.

For More Information:

Visit Our Website -https://www.chhajedfastners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Nickel 200 Washers Manufacturers

When it comes to industrial components, washers play a crucial role in enhancing the functionality and longevity of machinery. Among the various materials available, Nickel 200 stands out for its exceptional properties, making it a preferred choice for washers in demanding applications. At Nascent Pipe and Tubes, we take pride in offering high-quality Nickel 200 washers that meet the rigorous standards of diverse industries.

Why Choose Nickel 200?

Nickel 200 is a commercially pure nickel alloy with a composition of 99.6% nickel. This unique composition gives it outstanding corrosion resistance, particularly in reducing environments. Here are some of the reasons why Nickel 200 is an excellent choice for washers:

Corrosion Resistance: Nickel 200 exhibits excellent resistance to corrosion in both acidic and alkaline environments. This makes it ideal for use in chemical processing, food processing, and marine industries.

Thermal and Electrical Conductivity: Nickel 200 has high thermal and electrical conductivity, making it suitable for applications that require efficient heat and electrical transfer.

Ductility and Malleability: The material's ductility and malleability allow for easy fabrication into various shapes and sizes, ensuring a perfect fit for different industrial requirements.

Magnetic Properties: Nickel 200 retains its magnetic properties even at elevated temperatures, which can be advantageous in specific applications.

Resistance to Oxidation: This alloy provides good resistance to oxidation, enhancing the lifespan of components used in high-temperature settings.

Applications of Nickel 200 Washers

Nickel 200 washers are used in a wide range of industries due to their versatility and reliability. Some of the common applications include:

Chemical Processing: With their ability to withstand harsh chemicals, these washers are used in equipment that handles acids, alkalis, and other corrosive substances.

Aerospace and Defense: The excellent mechanical properties and resistance to extreme environments make Nickel 200 washers suitable for aerospace applications.

Electrical and Electronics: Their high electrical conductivity makes them ideal for use in electrical components and assemblies.

Oil and Gas: In this sector, Nickel 200 washers are used in equipment exposed to harsh offshore and onshore environments.

Why Nascent Pipe and Tubes?

At Nascent Pipe and Tubes, quality and customer satisfaction are our top priorities. Our Nickel 200 washers are manufactured using state-of-the-art technology and undergo stringent quality checks to ensure they meet international standards. We offer a wide range of sizes and customizations to cater to the specific needs of our clients.

Our team of experts is dedicated to providing technical support and guidance, ensuring you select the right washers for your applications. With a commitment to excellence and innovation, Nascent Pipe and Tubes continues to be a leader in the supply of premium Nickel 200 washers.

Conclusion

Nickel 200 washers from Nascent Pipe and Tubes offer unparalleled performance and durability, making them an essential component in various industries. With their exceptional properties and our unwavering commitment to quality, these washers provide a reliable solution for your industrial needs. Contact us today to learn more about our products and how we can help you achieve operational excellence.

0 notes

Text

Inconel 625 Fasteners Exporters In India

INTRODUCTION:-

Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2008. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications.

DESCRIPTION:-

Among manufacturers, suppliers, and exporters of inconel 625 fasteners, Shasan Piping Solution is the most reputable. Among the conventional-grade fasteners, these are the workhorse of the Inconel family. We keep all of the cutting-edge quality fasteners in stock in a variety of standards and non-standard materials. We establish ourselves as a reliable, conscientious Manufacturer of clear explanation fasteners for a vast array of organizing and current work applications. Our unit has an endless supply of current fasteners in various subtleties, tasks, and unique viewpoints. We perform creation with the aid of sophisticated machinery and other items. Everyone completes the process of gathering by big standards. Our workforce executes creation according to the most recent plan codes.

It contains chromium, molybdenum, and nickel. It is incredibly strong at temperatures as high as 1500 °F. Its development is generally less than that of other strong strategy-reinforced composites at higher temperatures. The remarkable oxidation resistance of these fasteners extends to 980 °C. Although these fasteners provide excellent protection against wet usage, stream-grade fasteners cannot be used. These fasteners have incredible welding and shaping capabilities. These are shipped or heated worked, and the temperature is kept between 1800 °F and 2150 °F. Hot working development is carried out in the lower temperature range in order to regulate both improvement and grain size. It can adapt more readily; It is quickly framed by interesting work duties in this way. Because of how quickly these fasteners set up, variable supporting medications are ridiculous for intricate component framing. Parts that have been hot or cold worked should be built up and quickly chilled in order to restore the optimal property equilibrium. Both manual and modified welding techniques are used to weld these fasteners. The plant is provided with these fasteners in its Stainless state. For optimal qualities, this composite is frequently water-smothered or rapidly cooled to district thickness. Heat medicine techniques are carried out based on the final application's basic course of action. Certain plant solidifying medications work by causing part of the second-stage mixture to precipitate.

SPECIFICATION:-

Standard : DIN, ASTM, BS and all International Standards

Size : 3 mm to 200 mm

Bolt / Screw Size : M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size : M3 - M56 | 3/6" to 2" | Custom Sizes

Washers Size : M1 - M64 | #4 to 3" | Custom Sizes

Length : M02 to M33

Types : Nuts, Bolts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, Structural Bolts.

BENEFITS:-

High Temperature Resistance: Inconel 625 demonstrates exceptional resistance to high temperatures, maintaining its mechanical properties at temperatures up to 2000°F (1093°C). This property makes it suitable for use in applications such as aerospace, marine engineering, and chemical processing where elevated temperatures are encountered.

Corrosion Resistance: Inconel 625 provides outstanding resistance to corrosion in harsh environments, including seawater, acidic solutions, and chloride-containing media. This corrosion resistance makes it ideal for marine applications, chemical processing equipment, and oil and gas industry components.

Excellent Strength and Toughness: Inconel 625 offers high tensile strength and toughness, providing reliability and durability in demanding conditions. It can withstand high mechanical loads and impacts without compromising its integrity.

Fatigue Resistance: Inconel 625 exhibits excellent fatigue resistance, making it suitable for applications subjected to cyclic loading and high-stress conditions, such as turbine blades, springs, and fasteners.

Weldability: Inconel 625 can be readily welded using various welding techniques, allowing for easy fabrication and repair of components without sacrificing performance.

Creep Resistance: Inconel 625 maintains its structural integrity even under prolonged exposure to high temperatures, providing resistance to creep deformation in applications such as high-temperature bolting and turbine components.

CONCLUSION:-

Inconel 625 is a highly versatile and reliable alloy known for its exceptional combination of high temperature resistance, corrosion resistance, and mechanical properties. Its ability to withstand extreme environments makes it indispensable in industries such as aerospace, marine engineering, chemical processing, and oil and gas exploration.

CONTACT US:- PHONE: +91-88797-09191/ +91-22-6651 8642 E-MAIL:- [email protected]

#Inconel 625 Fasteners Manufacturers In India#Inconel 625 Fasteners Suppliers In India#Inconel 625 Fasteners Stockists In India#Inconel 625 Fasteners Exporters In India

0 notes

Text

Nitronic 50 Fasteners Manufacturers In India

INTRODUCTION:-

Shasan Piping Solution is a basic Manufacturers and exporters of the ferrous and nonferrous things. We likewise manage the whole family stainless steel and Nitronic 50 and XM 19 Fasteners.

We anyway, gathering the changed kind of the thing according to the bearing from the client and course. Nitronic 50 and XM 19 fastener are made with substance sytheses like carbon, nickel, silicon, manganese, chromium, aluminum, and sulfur.

DESCRIPTION:-

In the dynamic landscape of industrial fasteners, Nitronic 50 emerges as a top contender, renowned for its exceptional properties. In India, a cohort of manufacturers has embraced the challenge of producing Nitronic 50 fasteners to cater to diverse industrial needs.

BENEFITS:-

Corrosion Resistance: Exceptional resistance to corrosion in harsh environments, including seawater and chemical processing plants.

High Strength: Superior strength levels, even at elevated temperatures, making them suitable for high-stress applications.

Durability: Long-lasting performance due to its robust composition, ensuring reliability over extended periods.

Versatility: Suitable for a wide range of industries, including marine, aerospace, chemical, and pharmaceutical sectors.

Resistance to Galling: Reduced risk of galling and seizing, ensuring smooth operation and easy maintenance.

SPECIFICATION:-

ASTM: ASTM A 193/194 / ASME SA 193/194

Dimension Standard: DIN, ASTM, BS and all International Standards

Length: 3 mm to 200 mm

Bolt / Screw Size: M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size: M02 to M33 | Custom Sizes

Washers Size: M3 - M56 | 3/6" to 2" | Custom Sizes

PRODUCT OVERVIEW:-

Types: Bolts, nuts, screws, washers, and studs, among others.

Sizes and Dimensions: Available in various sizes and dimensions to accommodate different applications.

Applications: Widely used in critical applications such as marine components, aerospace structures, chemical processing equipment, and medical devices.

Specialized Coatings: Optional coatings like passivation or electropolishing may enhance corrosion resistance further.

CONCLUSION:-

These fastener are sturdily organized and best for use in the substance district. These fastener are helpful in clinical updates on account of the properties like low charming porousness, use, opposition, and all the more clear strength. These fastener are adaptable, silly and Stainless for use in the savage conditions.

These safeguarded need to go through many tests, for example, influence test, hardness test, substance test, mechanical test, hydrostatic test, radiography test, radiating test, fixing test, etc also.

CONTACT US:-+91 22-6651 8642 EMAIL ID: [email protected] WEBSITE: https://www.shasanpiping.com/nitronic-50-fasteners-manufacturers-exporters-suppliers-stockists.html

#Nitronic 50 Fasteners Manufacturers#Nitronic 50 Fasteners Suppliers#Nitronic 50 Fasteners Stockists#Nitronic 50 Fasteners Exporters

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words! As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

The Strength of Nickel Alloy 200/201 Washers | Anand steels

Because in their wonderful electricity, resistance to corrosion, and flexibility, nickel alloys have become more and more utilized in a huge variety of industries. For use in Nickel Alloy 200/201 nuts, Nickel Alloy 200/201 bolts, Nickel Alloy 200/201 washers, Nickel Alloy 200/201 screws, and other Nickel Alloy 200/201 fasteners, Nickel Alloy is an extremely reliable alloy. In this blog, we're going to examine the sturdiness and strength of Nickel Alloy 200/201 washers in addition to their advantages and packages in numerous industrial programs.

Understanding approximately Nickel Alloy 200/201

Commercially pure wrought nickel grades 200 and 201 have precise homes that lead them to be appropriate for quite a few programs. These alloys have a wonderful track file for not corroding easily in a number of situations, inclusive of acids and alkalis.

Nickel Alloy 200/201 Fasteners:

Fasteners are crucial additives of many commercial strategies, and that they need to be crafted from substances which can be every structurally sound and proof against terrible environments. Fasteners, which include Nickel Alloy 200/ 201 screws, Nickel Alloy 200/ 201 bolts, and Nickel Alloy 200/ 201 nuts, are essential in sectors wherein resistance to corrosion is crucial. These fasteners are in particular useful for naval programs, petrochemical industries, and chemical processing facilities.

Because of Nickel Alloy 200/201's durability, these fasteners are ideal for locations with corrosive materials, strong chemical compounds, and high temperatures. Even under annoying running instances, their first-rate resistance to corrosion guarantees sturdiness and dependability.

Nickel Alloy 200/201 Washers:

Nickel Alloy 200/201 washers, with their unique fabric residences, add an extra layer of reliability to the fastening gadget.

High Temperature Applications: Nickel Alloy 200/201 washers show off tremendous thermal balance, making them suitable for packages related to expanded temperatures. This function is particularly beneficial in industries consisting of aerospace, automobile, and production, wherein components are uncovered to varying degrees of warmth pressure.

Chemical Processing: In chemical processing plant life, wherein publicity to competitive chemical substances is regular, Nickel Alloy 200/201 washers show valuable. Their resistance to corrosive materials makes them a preferred preference in chemical reactors, storage tanks, and pipelines.

Sealing Properties: Nickel Alloy 200/201 washers provide powerful sealing, stopping leakage in joints and connections. This feature is vital in industries like oil and fuel, in which retaining a leak-unfastened surroundings is essential for safety and operational performance.

Applications Across Industries:

The versatility of Nickel Alloy 200/201 washers extends to various industries, making them a favored preference for critical programs. Let's discover how these washers are utilized in distinct sectors:

Chemical Processing: Nickel Alloy 200/201 washers discover giant use in chemical processing flowers for sealing joints and connections in reactors, vessels, and piping structures. Their resistance to corrosive materials ensures the reliability of these vital additives.

Aerospace and Defense: The aerospace and protection industries demand materials that may face up to extreme situations. Nickel Alloy 200/201 washers, with their excessive-temperature resistance and corrosion resilience, are applied in planes, missiles, and other protection programs.

Marine Engineering: In marine engineering, in which publicity to saltwater and harsh climate situations is regular, Nickel Alloy 200/201 washers offer vital corrosion safety. They are utilized in shipbuilding, offshore platforms, and marine infrastructure.

Manufacturing and Construction: The manufacturing and creation sectors enjoy the power and durability of Nickel Alloy 200/201 washers in numerous applications. Whether it is securing structural elements or ensuring leak-free connections, these washers make contributions to the general reliability of the built surroundings.

Anand Steels – Your Trusted Partner in Nickel Alloys:

Their commitment to great and client pleasure units them apart with:

Comprehensive Product Range: Anand Steels gives a huge range of merchandise, which include sheets, plates, coils, foils, round bars, and more. This complete product range allows them to offer tailored solutions for various applications throughout industries.

Duplex and Super Duplex Sheets and Plates: Serving as a stockist of duplex and remarkable duplex sheets and plates, Anand Steels caters to the precise desires of industries requiring durable and corrosion-resistant substances.

Unwavering Commitment to Quality: Anand Steels' dedication to exceptionalism is obvious in each product they provide. They try for excellence, ensuring that their clients get hold of the very best fine chrome steel solutions. This commitment extends to their nickel alloy products, which include Nickel Alloy 200/201 screws.

Customer-Centric Approach: Anand Steels prioritizes consumer satisfaction and takes satisfaction in their customer-centric approach. They work intently with clients to apprehend their needs, providing personalized answers and ensuring that the delivered products meet the highest requirements.

Conclusion:

In summary, the energy and sturdiness of Nickel Alloy 200/201 washers are fundamental components in numerous industries. Their corrosion resistance, high-temperature stability, and sealing homes make contributions to the reliability of fastening structures in vital programs. Anand Steels, as a depended on provider of nickel alloys and stainless steel solutions, sticks out for its dedication to nice and patron delight. For all your chrome steel and nickel alloy needs, which includes Nickel Alloy 200/201 washers, Anand Steels is the associate you could depend upon. Contact them these days to revel in the distinction that includes years of industry information and unwavering willpower to quality.

#Nickel Alloy 200/201 Fasteners#Nickel Alloy 200/201 Nuts#Nickel Alloy 200/201 Bolts#Nickel Alloy 200/201 Screws#Nickel Alloy 200/201 Washers

0 notes

Text

Hastelloy B3 Fasteners Suppliers

The Deep Steel Center is one of the extraordinary Suppliers and Manufacturers of Hastelloy B3 Fasteners. We give the entire level of adding in different points of view, sizes, types, and decisions. Our offered Fasteners have huge security from hydrochloric staggering at all concentrations and temperatures. Hastelloy B3 Fasteners are made by utilizing ideal-quality, unrefined substances. These things are utilized in decreasing acid affiliations and locking the fasteners of warming stuff. Hastelloy B3 Secure Fasteners are conveyed using a mix containing nickel and molybdenum as the base part and movements of cobalt and tungsten. Our offered substances are normal for exceptional hydrochloric harming, sulfuric acids, hydrobromic shocking, acidic deplorable, phosphoric harming, and formic harming. These grains offer mind-blowing strength and goodness in any acidic or decreasing medium.

Hastelloy B3 Fasteners push smooth coordination through welding gear and diminish tipping in contact tips. We are a proactive connection that offers Hastelloy B3 Fasteners and other quality things that meet and beat client unequivocal necessities and, as such, affirm full-scale satisfaction. We provide an enormous level of materials, like Hastelloy B3 Fasteners. Our offered Fasteners show sensational security from pitting, opening, disintegrating, and stress-use breaking in any chloride-containing conditions.

Standard Specification For Hastelloy B3 Fasteners

Specifications

ASTM B574 / ASME SB574

Fasteners size

Bolt / Screw Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Nuts Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Washers Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Machine Screws Size : M1.6 – M12 Self Tapping Screw Size : No.2 – No. 14

Fasteners Length

3 mm to 200 mm

Fastener Threads

UNF, BSW, BSF, METRIC, UNC or as required

Standard of High Nickel Alloy Fasteners

DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M as per defined in ASME B16.5 standard Stud Bolt length ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts

Dimensions

DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3

Surface Coating

Ptfe Coated High Nickel Alloy Fasteners Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating

Fasteners Finishing

High Nickel Alloy : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), High Nickel Alloy, Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide.

For more information:

Visit website: https://www.deepsteelalloys.com/hastelloy-alloy-b3-fasteners-supplier.html

#Hastelloy B3 Fasteners Manufacturers#Hastelloy B3 Fasteners Suppliers#Hastelloy B3 Fasteners Stockists#Hastelloy B3 Fasteners Exporters#Hastelloy B3 Fasteners Manufacturers in India#Hastelloy B3 Fasteners Suppliers in India#Hastelloy B3 Fasteners Stockists in India#Hastelloy B3 Fasteners Exporters in India#Hastelloy B3 Fasteners Manufacturers in Mumbai#Hastelloy B3 Fasteners Suppliers in Mumbai#Hastelloy B3 Fasteners Stockists in Mumbai#Hastelloy B3 Fasteners Exporters in Mumbai

0 notes

Text

Stainless Steel Nuts Fasteners Suppliers in Chennai

304 and 316 Stainless Steel Bolts are comprised of an austenitic Stainless steel that is consumption-safe and solid. Divine Metal and Alloys is the main Manufacturers and Suppliers of various sorts, for example, 316 Stainless Steel Screws in various sizes and norms. The particulars are ASTM and ASME A193 and 194. There are various guidelines as per the Racket, ASTM, BS, and UNS S30400 and UNS S31600 Bolt types.

The material has chromium, nickel, and molybdenum with different Alloys in the system. This gives the 304 and 316 nut Stainless steel fasteners and Nuts a high return strength of 205 MPa and up to 515 MPa of least elasticity. The clasp ranges in length from 3mm to 200mm. The nuts reach from M3 to M56 alongside the screws. There are various kinds of clasps, for example, the SS 316 Screws and Nuts, hex coupling nuts, hex nuts, square nuts, domed nuts, etc. The various details, for example, the A4 316 Stainless Steel Rod Supplements, are utilised in unambiguous applications. The material has high temperature resistance and is used in most marine and natural applications. The molybdenum content makes the 316-Stainless steel stud bolts impervious to chloride particle erosion and breaking. As the main provider and maker, we produce the Fasteners in different kinds, grades, and scales. If it's not too much trouble, go ahead and get in touch with us for the different Fasteners, for example, the 316 Stainless Steel Rod Bar and the valuing.

Specification Stainless Steel Nuts Fasteners

Dimensions Standard and SpecificationASTM A193 / SA 193, ASTM A194 / SA 194International SpecificationsDIN, ASTM, BS and all International StandardsAvailable Length3 To 200 MMNuts Size rangeM3 To M56 3/6" to 2"Bolts or Screw SizesM3 To M56 3/6" to 2"Washers SizesM3 To M56 3/6" to 2"Tensile Strength205 MPAYield Strength515 MPA

Chemical Properties Stainless Steel Nuts Fasteners

GradeCMnSiPSCrMoNiNSS 316 FastenersMin---0-16.02.0010.0-Max0.082.00.750.0450.0318.03.0014.00.10

Mechanical Properties Stainless Steel Nuts Fasteners

MaterialUNS NoOld BritishEuronormSwedish SSJapanese JISBSEnNoNameSS 316 BoltsS31600316S3158H, 58J1.4401X5CrNiMo17-12-22347SUS 316

0 notes

Text

Nickel 200 Washers Exporters In India

Nascent Pipe & Tubes is one of the prominent stockiest and distFlangesutor of quality Nickel 200 Washers Exporters In India , which can be used in pressure vessel construction up to 300 Degree C. Nickel 200 Washers Exporters is age – hardenable Cu – Ni casting alloys with additions of aluminium, chromium or beryllium must also be mentioned. Nickel 200 Lock Washer with 2 % Al can be used in the as – cast state or age – hardened, where the largest increase of strength is achieved by adding beryllium – after age hardening.

Nickel 200 Washers Manufacturers In India, Nickel 200 Washers Suppliers In India, Nickel 200 Washers Stockists In India, Nickel 200 Washers Exporters In India

Like other alloys, Nickel 200 Washers Exporters In India possess excellent mechanical properties at low temperatures, which are shown for an alloy containing 20 % Ni. Tensile strength in Nickel 200 Machine Washers decreases with falling temperature without a marked reduction of elongation and reduction of area.

Nickel 200 Washer Specifications

Specifications IS / BS / ASTM

Standard ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472

Length M02 to M30

Size 3 mm to 200 mm

Type Flat Washer, Lock Washer, Sealing Washer, Split Washer, Slot Washer, Machine Washer, Star Washer SPRINGS – Wire Spring & Flat Spring

For more Information Visit website: https://www.nehametalalloys.com Email: [email protected] Contact: 8779038854

#Nickel 200 Washers#Nickel 200 Washers Manufacturers#Nickel 200 Washers Suppliers#Nickel 200 Washers Stockists#Nickel 200 Washers Exporters#Nickel 200 Washers Manufacturers in India#Nickel 200 Washers Suppliers in India#manufacturers#exporters#steel#metal#suppliers

0 notes

Text

Nickel Aluminium Bronze NES 833 Part 2 - Ananka Fasteners

Ananka Group is a leading Aluminium Bronze Fasteners Manufacturer in India, producing a wide range of Aluminium Bronze Fasteners in various sizes, grades, and scales. Our Aluminium Bronze Fasteners are manufactured by national & international standards. C614 Aluminum Bronze Studs are alloyed with zinc and have higher corrosion resistance to high-velocity seawater. Ananka Group is a manufacturer of all kinds of metal products. We are in the industry for several years.

Our Aluminum Bronze Threaded Rod can be used in high wear and tear applications. We offer various sizes of studs, screws, rods, and fasteners in the aluminum bronze range. We produce the most popular grade C63000 Aluminium Bronze Bolts And Nuts which are used in seawater applications and marine applications for high shock resistance and abrasion resistance.

Specifications of Aluminum Bronze Fasteners

Aluminum Bronze Alloy Fasteners Material Specification:- C63000 Nickel Aluminum Bronze Plow Bolts, UNS C62300 Bolts

Aluminum Bronze Fasteners / Bolts Standard:- DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards

C61400 Aluminum Bronze Fasteners/ Bolts Size:- M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160

Length of C955 Aluminum Bronze Hex Cap Screw:- 3 mm to 200 mm

C614 Aluminum Bronze Bolts, Studs Threads:- METRIC, BSW, BSF, UNC, UNF or as required

C630 Nickel Aluminum Bronze Allen Cap Screw Standard:- ANSI – American National Standards Institute - ANSI B 18.2.4 2M, ANSI B 28.2.4 1M, Aluminum Bronze Alloy Stud Bolt length are defined in ASME B16.5 standard, Aluminum Bronze Hex nuts are defined in ASME B18.2.2, ASME B18.5 DIN: 931, 933, 934, 970 UTS – Unified Thread Standard: UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization: ISO 4032, ISO 4033, JIS standards

Source of Raw Materials to Manufacture Cual10ni5fe4 Aluminum Bronze Socket Cap Screw:- Tata Steel, JSPL, RINL, Usha Martin, Dhamm Steel, Mukund Steel, etc.

Scope:- Manufacturer of Hot Forged C955 Nickel Aluminum Bronze Hex Cap Screws, Nut / Bolt; up to M36 / 1-1/2” Dia, up to 1100mm lg, Manufacturer of CNC Machined Aluminum Bronze Fasteners, Nut / Bolt; up to M100 / 4” Dia, up to 1500mm lg

Uns C61400 Aluminum Bronze U Bolt in Form Of:- Hex, Square, Round, Threading as per Gauge Etc.

Head Drive:- Phillips, Slotted, Phillips/Slot, Six-Lobe, etc.

Aluminum Bronze Alloy Hex Bolt Thread:- Metric Coarse

Aluminum Bronze Bolting Test Certificate:- Manufacturer Test Certificate as per EN 10204 / 3.1

C63000 Nickel Aluminum Bronze Bolts Types:- Aluminum Bronze Alloy Hex Bolts, Flange Bolts, Hex Head Bolts, Lag Bolts, Square Bolts, Eye Bolts, U Bolts, T Bolts, Countersunk Bolts, etc.

C955 Aluminum Bronze Nut Types:- Aluminum Bronze Alloy Hex Head Nut, Eye Nut, Dome Nut, Wing Nut, T Nut, Panel Nut, Lock Nut, Coupling Nut, Square Nut, Acorn Nut, etc.

Aluminum Bronze Alloy Screws Types:- Aluminum Bronze Alloy Hex Head Cap Screws, Socket Set Screws, Anchor Screws, Blind Rivet, Socket Head Screws, Concrete Screws, Shoulder Screws, Panel Screws, Threaded Screws, Machine Screws, etc.

Aluminum Bronze Washer Types:- Aluminum Bronze Alloy Machine Washers, Flat Washer, Star Washers, Sealing Washer, Lock Washer, Split Washer in India

Nickel Aluminum Bronze Alloy Fasteners Packing:- IN BULK: canton, pallet, Small Box’s / carton/pallet, or customer request

Ready Stock Available Metric Aluminum Bronze Fasteners Aluminum Bronze Alloy Bolts M16 x 65mm DIN933 Aluminum Bronze Bolts M16 x 45mm DIN933 C61400 Aluminum Bronze Hex Nut M16 C63000 Aluminum Bronze Washer M16 C614 Aluminum Bronze Bolts M16 X 60mm C959 Aluminum Bronze Bolts M16 X 55mm C62300 Aluminum Bronze Bolts M16 X 35mm C63000 Nickel Aluminum Bronze Bolts M12 X 90mm C955 Aluminum Bronze Bolts M12 X 70mm C630 Nickel Aluminum Bronze Bolts M20 x 70mm Cual10ni5fe4 Aluminum Bronze Bolts M20 x 75mm

Source:- https://anankafasteners.com/aluminium-bronze-fasteners-manufacturer-india/ Call & WhatsApp:- +91 83690 74984 Mail:- [email protected] Website:- https://anankafasteners.com/

#nickel#bronze#aluminum#hex#screw#hdg#manufacturer#supplier#fasteners#ananka#anankafasteners#screwhead#uk#usa#uae#mumbai#gujarat#chennai#delhi#russia#italy#france

2 notes

·

View notes

Text

Uses and Applications of Hastelloy Fasteners

What are hastelloy fasteners?

Hastelloy Bolts are a nickel molybdenum chromium superalloy with iron and tungsten additions that have excellent corrosion resistance at high temperatures. Hastelloy Fastener is also available in a variety of grades. The majority of these Hastelloy Screws were created with high temperature applications in mind.

Aashish Steel is a prominent Hastelloy Fastener Manufacturer in India. Hastelloy Fasteners are versatile products that are available in a wide range of specifications and categories. We manufacture Hastelloy Bolts, Hastelloy Nuts, Hastelloy Screws, Hastelloy Washers, and other Hastelloy Fasteners. Hastelloy fasteners have an exceptional corrosion resistance, ensuring that they remain unaffected in industrial settings. It is resistant to chlorine, sulfuric acid, phosphoric acid, and other harmful chemicals.

Variety of Hastelloy Fastener

Stainless Steel washer

In Mumbai, India, Aashish Steel is a reputable washer manufacturer, supplier, and exporter. The family of fasteners includes washers. The washer is a thin plate that distributes the load from the thread fasteners. It has a hole in the centre. The exceptional strength and corrosion resistance of stainless steel washers make them perfect for usage in challenging conditions. Bolts or nuts are frequently used with washers because they increase strength and aid in load distribution in high-pressure applications. When used with a washer to handle pressure, nuts offer greater longevity, and a rubber washer can also dampen vibration. To suit the various application needs of our customers, we offer every category of washer.

Stainless Steel Screw

Aashish Steel is Mumbai, India's largest Screw Manufacturer, Supplier, and Exporter. Fasteners include screws. Stainless steel screws are popular because they contain chromium and molybdenum, which enable them to withstand harsh conditions. Screws resist corrosion and stress corrosion. It is a bolt-like fastener used to hold materials together while preventing pressure pull-outs. We have a large selection of Screws at a reasonable price for a variety of fits and applications. A tool can twist a screw with a head on one end of one side to make it easier to assemble or disassemble attached items.

Stainless Steel Bolts

Aashish Steel is a leading bolts manufacturer in India. Bolts are classified as fasteners. Bolt is used in many industries' supply and transportation systems. It is simple to use, can be quickly created and removed, and is used to connect or combine things. Because of their high yield strength and ability to withstand compression fittings, high-tensile bolts are essential in the development of steel structures. Bolts are available in a variety of sizes. Dimensional changes such as thickness, length, shape, size, and diameter are preferred for a variety of industrial applications.

Hastelloy Fastener Specifications:

Material: Hastelloy Alloy Fasteners

Hastelloy Fasteners ASTM / ANSI: ASTM B574 / ASME SB574

Size of Hastelloy Fasteners:M02 to M160

Length of Hastelloy Fasteners:3 mm to 200 mm

Hastelloy Fasteners Threads: BSW, UNC, BSF, UNF METRIC, or as required

Widely Use Hastelloy Studs Types: Hastelloy Double Ended Studs, Threaded Rod, Tie Bars, Tie Rodsetc.

Packing of Hastelloy Fasteners: In Bulk: pallet, Canton, Small Carton / Boxes / Pallet, or customer request

Application & Uses Of Hastelloy Fasteners

Hastelloy Fasteners used in Petroleum Industry

Hex Nut used in Aerospace Industry

Square Nut used in Chemical Industry

Dome Nut used in oil & Gas Industry

Nylock Nut used in Nuclear Energy Sector

Wing Nut used in Automotive Industries

0 notes

Text

Jmiks Fastenersss316 Bolt Specificationssupplier and Manufacturers

Jmiks Fasteners is one of the known supplier and manufacturers of Stainless Steel 316/316 H/ 316L/316Ti Bolts, where the prime attributes of these products are corrosion resistance and used for the industries.

Our 316L stainless steel fasteners are of superior quality and are used in various industries such as food processing plants and components, sea and sea water applications, petrochemical industries and also in the aerospace industry. These SS 316L hex bolts are a chromium-nickel alloy with molybdenum. The addition of molybdenum makes the creep resistance of 316L stainless steel studs higher with better anti-corrosion properties. There is also a lower carbon version of the same material. SS 316L nuts and bolts are made from the lower carbon version of the material and are less corrosive and highly weldable. Nutbolt 1.4404 is the specification for grade 316 and 316L bolts, nuts and other fasteners. Our 316L stainless steel threaded rods and studs are stronger and more durable. ASTM A193 316L fasteners are slightly more expensive than SS 304 bolts, but are high performance and tensile strength with additional anti-corrosion properties and high weldability. Therefore, our UNS S31603 bolts and nuts are preferred in high cost applications. You can get a complete list of products and prices by contacting us.

ss316 bolt specifications

316 Stainless Steel Bolts Specification :

Material

316 Stainless Steel Bolts

Size

M02 to M33

Standards

ASTM / ASME - A/ SA 193 / 193

Length

3 mm to 200 mm

Specification

IS, BS, ASTM

Manufacturer

GKW, Unbrako, Kundan, APL, Sundaram Precision, EBY Fastener Etc.

Conclusion:-

Generally, 316 stainless steel nut bolts used in various industries, including pulp and paper, textiles, sugar, rubber, etc., prefer to use coated. The coating used on the surface of these A4 grade 316 threaded rods improves wear resistance while reducing corrosion resistance to some extent. Normally, materials like zinc, phosphate coating, galvanizing, Teflon can be used to coat nuts, bolts, washers, etc. The application of a coating can serve as a pretreatment to paint screws, threaded rods or hex bolts. Buy directly it from Jmiks Fasteners the Stainless Steel 316 Fasteners manufacturer in India for prime quality & best price.

0 notes

Photo

We manufacture bolts, nuts, anti-theft bolts & nuts, studs, foundation bolts, U-bolts, plain and spring washers in Nickel 200 material in India. Nickel 200 Socket Head Cap Screws are most popular fastener & can come with large cylindrical heads that have recessed hex-shaped drives. Due to this quality these Nickel 200 Screws are mainly in demand by the applications where clearance is limited, and sockets and wrenches can't be used. The size of a Nickel 200 metric Screws or Bolts is specified as diameter, pitch and length, in millimeters (millimeters is abbreviated "mm"). The size of Nickel 200 Bolts, will appear as diameter and pitch.

0 notes