#Motorcontrolstrategies

Explore tagged Tumblr posts

Text

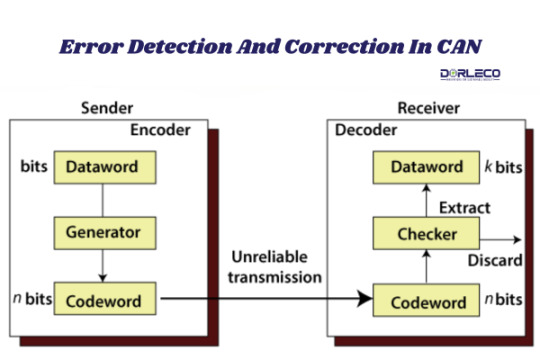

Error Detection And Correction In CAN

June 3, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

INTRODUCTION

Communication is vital in the ever-evolving world of automotive technology. Modern automobiles are outfitted with a variety of technical components that must work seamlessly together. One of the foundations of this communication is the Controller Area Network (CAN), a robust and dependable protocol that allows data to be sent across different components. However, mechanisms for error detection and correction in CAN are required to maintain this reliability. In this blog article, we will go extensively into the topic of error detection and repair in CAN, understanding how important these procedures are in ensuring the safety and dependability of modern vehicles.

The significance of CAN in contemporary automobiles

Before we go into error detection and correction in CAN, let’s look at how it works in modern automobiles.

What exactly does CAN stand for? The Controller Area Network, a robust serial communication protocol, enables vehicle electronic control units (VCUs) to connect. Why is it important? By allowing real-time data sharing between ECUs in charge of activities like as engine control, transmission management, and safety systems, CAN has emerged as the core of automotive communication.

1. The vulnerability of CAN.

Even though CAN is extremely reliable, errors can still occur. Several factors can result in communication mistakes, including:

Noise and interference: The electromagnetic interference created by multiple electrical components in the vehicle environment, which is noisy, can contaminate CAN signals. Defects in transceivers or other hardware components can cause CAN communication problems.

Electromagnetic Compatibility (EMC): Communication issues might arise when different ECUs and components are not compatible.

2. Basics of Error Detection in CAN

Various types of error detection CAN mechanisms are utilized to ensure dependability.

The Cyclic Redundancy Check (CRC) algorithm generates a checksum based on the transmitted data. To detect errors, the receiving node computes its CRC and compares it with the transmitted CRC.

The FCS field of the CAN frame, like the CRC, contains checksum information that is used to detect errors.

Bit Stuffing: You can use bit stuffing to ensure that the sender and receiver are in sync. The bit packing pattern may deviate, indicating an issue.

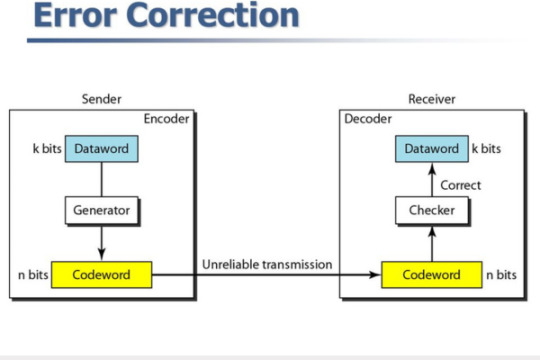

3. Error Correction in the Can

Error Detection in CAN is necessary, but it is not always sufficient. Error-correcting methods go one step further:

Retransmission: If an error is detected, the sender sends the message again. This ensures that the message is appropriately delivered to its intended recipient.

The CAN protocol includes an acknowledgment mechanism that allows the receiver to acknowledge that a message was properly received. If no acknowledgment is received, the sender retransmits, assuming an error.

4. Error Recovery and Handling.

It is critical to understand how to handle CAN faults and recover to assure system dependability.

Error Flags: CAN uses error flags to identify a variety of issues. These warning flags help you discover and fix problems. Error Passive and Error Active Modes: Depending on the number of errors detected, CAN nodes can switch between error passive and error active modes. This reduces the risk that errant nodes may disrupt the network as a whole.

5. Advanced Error-handling Strategies

Advanced error-handling mechanisms are occasionally utilized to ensure continuous communication.

Fault-Tolerant CAN (FTCAN) is a redundancy-based method that uses two CAN buses running concurrently to ensure that communication continues even if one bus fails. Flex Ray is a communication standard for automotive networks that improves error management; however, it is not a CAN protocol.

6. Security and Error Detection in CAN.

As linked and autonomous vehicles become more common, security concerns have grown. It is vital to understand how error detection relates to security.

Cyber security: To avoid unwanted access and manipulation, robust error detection in CAN and repair mechanisms are required. Malicious attacks on CAN networks are a possibility, emphasizing the need for these measures.

Intrusion Detection Systems: Advanced intrusion detection systems are being integrated into CAN networks to identify and respond to security threats.

7. Future Error Detection and Correction in CAN

The Future of Error Detection As vehicles get more intricate and networked, there are exciting improvements in CAN and CAN correction.

AI-based machine learning algorithms can help discover and rectify problems in real-time, as well as adjust to changing situations and threats.

Blockchain Technology: Researchers are looking into how blockchain may be used for tamper-proof and secure data collection and transfer.

Conclusion

The Heartbeat of Contemporary Vehicles

In conclusion, the Controller Area Network (CAN) is the unsung hero of modern automobiles because it enables critical electrical component communication. Error detection in CAN and corrective methods are unheralded heroes who fight behind the scenes to ensure that this communication is trustworthy, secure, and safe. The importance of effective error management in CAN will only grow as vehicles evolve and incorporate new technology. It’s critical to get from point A to point B safely, effectively, and with the confidence that all of your vehicle’s systems are working properly. This is made feasible by error detection in CAN and repair, which will remain critical to the industry’s future progress.

#CANKeypads#Autonomousdriving#Motorcontrolstrategies#emobilitycontrols#Dorleco#VCUProducts#Sensorfusion#Programablevcu

0 notes

Text

Can 2.0 and Can Fd: Controller Area Network

May 31, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction: Can 2.0 and Can FD.

The Controller Area Network (CAN) protocol has long been the standard method for exchanging data between electronic control units (ECUs) in automotive and industrial communication systems. This technology has evolved to meet the increasing demands of modern automobiles and industrial automation. The transition from CAN 2.0 (Controller Area Network 2.0) to CAN FD (CAN with Flexible Data Rate) is a watershed moment in this history.

In this blog post, we’ll look at the differences between CAN 2.0 and CAN FD, as well as the advantages they provide in terms of data speed, dependability, and adaptability. We will also investigate the causes that led to this decision.

1. Understanding CAN 2.0:

For many years, Controller Area Network 2.0, also known as Classical CAN, was the primary communication protocol used in the industrial and automotive sectors. CAN 2.0 was developed by Bosch in the 1980s to improve communication amongst vehicle ECUs. It was suited for scenarios requiring security and real-time data sharing since it provided a consistent and predictable communication channel.

2. Key Features of the CAN 2.0:

Fixed Data Rate: The fixed data rate of CAN 2.0 is undoubtedly its most significant disadvantage. It has a maximum speed of 1 Mbps, which was sufficient for early industrial and automotive applications but has subsequently become a bottleneck as data requirements have increased over time.

Message Length: CAN 2.0 allows a maximum message length of eight bytes per frame. While this was adequate for sharing simple data, as increasingly complex data, such as high-definition video and sensor data, needed to be conveyed, it became inadequate.

Deterministic and Reliable: One of the advantages of CAN 2.0 is its deterministic nature. Critical information always takes precedence since communications are sent in a precise order with priority. CAN 2.0 has error-checking tools to improve data dependability.

Why CAN FD Is Required: As technology advanced, the limitations of CAN 2.0 became increasingly obvious. The design of CAN FD was motivated by the need for higher data speeds, larger message payloads, and more adaptive communications.

Presenting CAN FD: The advent of CAN FD, or CAN with Flexible Data Rate, intended to address the shortcomings of CAN 2.0 while retaining its primary virtues of dependability and determinism. This new protocol represents significant progress in terms of data transport capabilities and applicability to modern applications.

3. Key Advantages of CAN-FD

Flexible Data Rates: The main advantage is already evident in the name: CAN FD offers flexible data rates. This means that it has a variety of working speeds, including a maximum data rate of 5 Mbps. The ever-increasing data requirements in today’s automobiles and industrial systems must be met, and adaptability is critical.

Extended Message Length: CAN FD allows for longer message payloads because frames can carry up to 64 bytes of data. This greater message length is required for sending complex data over the network, such as high-definition video.

Backward compatibility with CAN 2.0 is one of CAN FD’s brilliant design choices. This enables a smooth transition to the new protocol by allowing older ECUs that use CAN 2.0 to share the same network as newer CAN FD devices.

Increased Network Efficiency: By boosting data transmission rates and message sizes, CAN FD allows networks to be used more effectively, reducing latency and enhancing overall system performance.

4. Implementations of CAN-FD

The introduction of CAN FD has opened up new prospects in a variety of enterprises. Here are some examples of the impact this technology is having:

Can FD be a game changer in the auto industry? Modern automobiles contain a variety of sensors and electrical control units, all of which require a fast and reliable connection. Advanced driver assistance systems (ADAS) and autonomous driving features can send critical data thanks to CAN FD’s adjustable data rates and lengthy message lengths.

Commercial Automation: Can FD provide a dependable industrial automation solution where real-time data transfer is critical? Robots and manufacturing equipment can easily communicate, allowing for accurate control and monitoring of production processes. The protocol’s flexibility allows it to suit the diverse data needs of numerous industrial applications.

Aviation and Defense: Aerospace and defense applications require high levels of dependability and data integrity. CAN FD is an excellent choice for avionics and military systems because of its better error-checking methods and ability to handle large data payloads.

5. Challenges and Things to Consider

Even though CAN-FD has various advantages, there are some issues and factors to consider:

Cost: Updating hardware and software may be required for CAN FD deployment, which can be costly, particularly in industries with large installations.

Complexity: Because of CAN FD’s increased flexibility, network management may become more complicated. For optimal performance, adequate setup and monitoring are required.

Transition Period: For sectors that currently have CAN 2.0 networks in place, the transition to CAN FD may necessitate careful planning to avoid interruptions and ensure backward compatibility.

Conclusion:

Can FD become a crucial invention in the ever-changing realm of automotive and industrial communications? It addresses the drawbacks of its predecessor, CAN 2.0, by allowing for configurable data speeds, larger message durations, and enhanced error detection.

CAN FD’s adaptability and durability make it a critical technology for the future as data transfer demands in both automotive and industrial systems increase? Although the transition from Can 2.0 and Can Fd may be tough, the benefits in terms of speed, efficiency, and adaptability make the investment worthwhile for industries seeking to stay on the cutting edge of technology.

Get to know more about Can 2.0 and Can FD. Checkout for best VCU Products and Services for further details mail us at [email protected] or visit our website, Dorleco.com

#CAN2.0#CANFD#Autonomousdriving#AWD#Motorcontrolstrategies#emobilitycontrols#Dorleco#VCUProducts#Sensorfusion#Programablevcu

0 notes

Text

Motor Control Strategies For All-wheel Drive Systems

May 30, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction:

All-wheel drive (AWD) systems, which improve grip, stability, and performance, have become an essential component of many automobiles in the world of automotive engineering. Motor Control Strategies are fundamental to these AWD systems. In this blog post, we will look at the many types of motor control techniques used in AWD systems, including their benefits and how they boost driving dynamics and safety in different weather and road conditions.

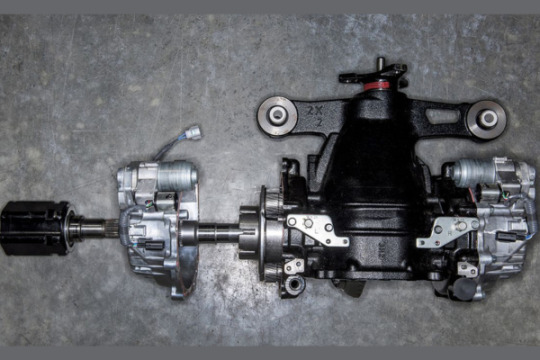

The Fundamentals of All-Wheel Drive (AWD) Systems

It is critical to understand the principles of AWD systems before delving into motor control techniques. AWD systems are designed to convey power to all four wheels at the same time, as opposed to conventional two-wheel drive (2WD) cars, which only send power to two of the four wheels. Motor control strategies are used to transfer power among the wheels.

Types of AWD Systems:

Full-Time AWD: These systems permanently distribute power to all four wheels. They are commonly found in crossovers and SUVs. Full-time AWD provides consistent stability and traction, making it ideal for a wide range of driving situations, including rain, snow, and off-road terrain.

Part-time AWD: Systems with part-time AWD allow the driver to switch between two- and all-wheel drive as needed. Off-road vehicles and pickup trucks typically use these systems. When conditions deteriorate, such as on off-road tracks or slick ground, the driver can select AWD.

On-Demand AWD: To save gasoline, on-demand AWD systems generally run in two-wheel drive mode. However, they can instantly and automatically engage the other two wheels to add more traction when wheel slip is detected. Many contemporary sedans and small automobiles use this technique regularly.

Motor Control Strategies for Systems with AWD:

The motor determines strategies in AWD systems that determine how much power is given to each wheel. These approaches are critical for maximizing traction, stability, and performance. Several of the key motor control strategies used in AWD systems are described below.

Open Differential: The simplest and most common type of differential used in automobiles is the open differential. An open differential in an AWD system distributes power equally between the front and rear wheels. While this is effective under typical driving conditions, it may not be the best solution if one wheel loses traction. In these circumstances, the wheel with less traction may get the majority of the power, causing the wheel to spin.

Limited-Slip Differential (LSD): Open differentials have various disadvantages, which limited-slip differentials aim to address. LSDs allow for some variation in wheel speeds, providing the wheel with more power and better traction. They can be mechanical or electronic, and some cutting-edge AWD systems include electronic LSDs that can adjust power distribution in real time based on a variety of factors, like wheel speed, steering input, and throttle position.

Torque Vectoring: Torque vectoring is a more advanced motor control approach than just splitting power between the front and back wheels. It also controls the amount of power sent to the left and right wheels. Torque vectoring improves a vehicle’s handling, cornering, and stability by precisely controlling the torque given to each wheel.

Active AWD Systems: Modern AWD systems usually employ a multitude of sensors and control units to continuously analyze road conditions and driver inputs. When necessary, these systems may easily switch from 2WD to AWD by altering power distribution in real-time. They can also adjust the power distribution between the wheels based on variables such as wheel slip, steering angle, and acceleration.

Advantages of Advanced Motor Control Strategies.

Improved Traction: Advanced Motor Control Strategies improve traction by directing power to the wheels with the most grip. This is especially useful when the ground is sticky from rain, snow, or mud.

Improved Stability: Torque-vectoring AWD systems can improve a car’s stability in tight corners and during quick maneuvers. They reduce the potential for over- or under-steering by controlling power delivery to each wheel.

Optimized Fuel Efficiency: To save petroleum, many modern AWD systems are designed to run mostly in 2WD mode. They maintain traction and fuel efficiency by activating AWD only when necessary.

Versatility: AWD vehicles can handle a wide range of terrains and weather conditions thanks to better motor control methods.

Real-world Applications:

Let’s take a closer look at how various motor control strategies manifest in practical situations:

Off-roading: Torque vectoring and adjustable AWD modes are essential in off-road vehicles such as trucks and SUVs. When traveling rough terrain, steep inclines, or uneven ground, they can distribute power to certain wheels as needed.

Torque vectoring improves handling and traction in high-speed cornering in sports cars equipped with AWD systems. These systems can divide power between the left and right wheels, supporting the vehicle in maintaining its intended path.

Routine Commuting: AWD systems with advanced motor control strategies improve performance and safety even under routine driving circumstances. These devices can prevent wheel spin and loss of control on slick roads, reducing the likelihood of an accident.

Challenges and considerations:

Although motor control techniques have altered AWD systems, there are still certain challenges and factors to consider.

Cost: The high manufacturing and maintenance expenses associated with AWD systems, including complex motor control techniques, may have an impact on the vehicle’s overall cost.

Weight: The additional elements required for AWD systems can make a vehicle heavier, reducing handling and fuel efficiency. Manufacturers are attempting to reduce this by using lightweight materials and effective designs.

Maintenance: Because they have more components that can wear out or need repair than 2WD vehicles, AWD systems may require more maintenance.

Conclusion:

The performance and versatility of all-wheel drive systems in modern automobiles are largely due to motor control techniques. These strategies are at the heart of what makes AWD systems so valuable for drivers, whether it’s improving traction in slick conditions, increasing stability during hard driving, or permitting off-road adventures. As technology advances, we should expect ever more complex motor control algorithms to improve the capabilities of AWD systems, guaranteeing that cars can confidently negotiate a wide range of terrains and weather situations while providing improved handling and safety.

#ADAS#Autonomousdriving#AWD#Motorcontrolstrategies#emobilitycontrols#Dorleco#VCUProducts#Sensorfusion#Programablevcu

0 notes

Text

Motor Control Strategies For All-wheel Drive Systems

Introduction

In the field of automotive engineering, all-wheel drive (AWD) systems have become a crucial part of many cars since they increase performance, stability, and grip. Motor Control Strategies that maximize power distribution to improve vehicle dynamics and safety are at the core of these systems. The motor control techniques used in AWD systems, their benefits, and how they improve driving dynamics in a variety of situations will all be covered in this blog.

All-Wheel Drive (AWD) System Fundamentals

Appreciating motor control schemes requires an understanding of the fundamentals of AWD systems. AWD systems transfer power to all four wheels, in contrast to conventional two-wheel drive (2WD) systems that only supply power to two wheels. Traction and stability are greatly enhanced by this arrangement. AWD systems can adjust to changing road conditions and driving demands thanks to motor control strategies that decide how power is distributed among the wheels.

AWD System Types

AWD systems are divided into groups according to how they distribute power and operate. The primary kinds are as follows:

1. AWD Full-Time

Power is continually distributed to all four wheels using full-time AWD systems. These systems, which provide reliable stability and traction in a range of situations, such as rain, snow, and off-road terrain, are frequently seen in crossovers and SUVs.

2. AWD Part-Time

The driver can switch between 2WD and AWD modes as needed with part-time AWD systems. These systems are common in pickup trucks and off-road vehicles. They are especially helpful when navigating difficult terrain or slick areas.

3. AWD on-demand

To save gasoline, on-demand AWD systems mostly run in 2WD mode. They immediately engage the other two wheels to improve traction when they detect wheel slides. This mechanism is frequently found in contemporary sedans and small automobiles.

Motor Control Strategies in AWD Systems

In an AWD system, motor control strategies determine how power is allocated to each wheel. These tactics are essential for maximizing performance, stability, and traction. The main motor control strategies employed in AWD systems are examined below:

1. The Open Differential

The most basic kind of differential seen in cars is the open differential. It evenly divides power between the front and rear wheels in AWD systems. Although it works well in typical driving circumstances, it has trouble when one tire loses traction because the wheel with less grip gets most of the power, which makes it spin.

2. The LSD, or limited-slip differential

By supplying power to the wheel with improved traction and permitting some wheel speed variation, limited-slip differentials compensate for the drawbacks of open differentials. Both mechanical and electronic LSDs are possible. Electronic LSDs, which dynamically modify power distribution based on inputs including wheel speed, steering angle, and throttle position, are frequently used in advanced AWD systems.

3. Torque vectoring

Beyond dividing power between the front and back wheels, torque vectoring is a sophisticated motor control strategy. It improves handling, cornering, and stability by accurately regulating the power applied to each wheel. High-performance cars and challenging driving situations benefit most from this tactic.

4. Active AWD Systems

Road conditions and driver inputs are continuously monitored by active AWD systems using sensors and control units. These systems dynamically modify power distribution between wheels based on variables including wheel slip, steering angle, and acceleration. They can also convert between 2WD and AWD modes with ease.

Benefits of Sophisticated Motor Control Techniques

AWD systems benefit greatly from modern motor control strategies, which improve performance and safety. Among the main benefits are:

1. Improved Traction

By focusing power on the wheels with the greatest grip, advanced motor control systems maximize traction. This is particularly helpful in inclement weather, such as rain, snow, or mud.

2. Improved Stability

Vehicle stability is enhanced by torque-vectoring AWD systems when making abrupt turns and tight turns. They reduce the possibility of oversteering or understeer by regulating the power sent to each wheel.

3. Enhanced Fuel Economy

To conserve gasoline, many contemporary AWD systems are built to run mostly in 2WD mode. Performance and efficiency are balanced because AWD mode is only engaged when required.

4. Adaptability

AWD cars can easily navigate a variety of terrains and weather situations thanks to advanced motor control strategies, giving drivers more control and confidence.

Applications of Motor Control Strategies in the Real World

1. Off-Roading

Adjustable AWD modes and torque vectoring are crucial for off-road vehicles such as trucks and SUVs. These techniques stabilize uneven terrain and steep inclines by directing power to particular wheels as needed.

2. Sports Performance

Sports cars with torque-vectoring AWD systems provide better handling and high-speed cornering. They assist in preserving the vehicle’s desired trajectory by evenly allocating power between the left and right wheels.

3. Everyday Commuting

Modern AWD systems enhance performance and safety when driving daily. They lessen the chance of accidents on slick roads by preventing wheel spin and loss of control.

Challenges and Considerations

Although motor control strategies greatly improve AWD systems, there are drawbacks as well:

1. Cost

AWD systems’ intricate motor control schemes and complexity can raise production and maintenance expenses, which will affect the final cost of the vehicle.

2. Weight

AWD systems increase a car’s weight, which can impact handling and fuel economy. Manufacturers are employing creative designs and lightweight materials to overcome this difficulty.

3. Maintenance

Because AWD systems have more parts than 2WD systems, they frequently need more maintenance. Additionally, sophisticated sensors and electronics may make diagnostics and repairs more difficult.

Conclusion

The performance and adaptability of contemporary AWD systems are fueled by motor control techniques. These techniques are essential for today’s drivers because they increase stability during high-speed maneuvers and improve grip in slick conditions. We should expect increasingly complex motor control algorithms to advance the capabilities of AWD systems as automotive technology develops. By doing this, automobiles will continue to be able to react to a variety of weather patterns and terrains, guaranteeing better handling and safety for drivers everywhere.

By providing AWD systems with accurate Motor Control Strategies, Dorleco’s cutting-edge VCU products, CAN Keypads, CAN Display, and EV software services, maximize performance, stability, and traction. By incorporating state-of-the-art technology, Dorleco guarantees adaptable, dependable, and effective solutions for contemporary automobiles, facilitating smooth adaptation across various driving situations and terrains for improved safety and driving dynamics.

#**MotorControlStrategies**#**AllwheelDriveSystems **#EVInfrastructure#Dorleco#CANKeypads#CANDisplays#VCUs#Vehiclecontrolunit#EVSoftwareServices

0 notes