#Miniature Model Makers

Explore tagged Tumblr posts

Text

How is technology transforming the field of miniature model making?

In the ever-evolving world of engineering and design, miniature model making has long been a specialized craft where precision, artistry, and technical skill converge. From architectural models depicting future skyscrapers to intricate miniatures for tabletop games, miniature model making has always been a blend of art and science. However, as we move into the 21st century, technology is transforming this traditional craft in unprecedented ways. In this blog post, we will explore how modern innovations are reshaping the field of miniature model making, with a special focus on the impact of these changes on the role of Miniature Model Makers.

The Traditional Craft of Miniature Model Making

Before we delve into the technological advancements, let’s take a moment to appreciate the traditional techniques that have defined miniature model making for decades. Historically, miniature model makers used handcrafting techniques, including sculpting, painting, and assembling intricate parts to create detailed and accurate representations of real-world objects.

Miniature Model Makers were often skilled artisans who utilized manual tools such as X-Acto knives, precision pliers, and hand drills. These tools allowed them to cut, shape, and assemble plastic, wood, and metal materials. Each model was painstakingly crafted with attention to detail, resulting in stunning creations that could convey complex ideas and visions in a compact form.

Scale model makers

The Rise of Digital Tools in Miniature Model Making

3D Modeling Software One of the most significant technological advancements in miniature model making is the advent of 3D modelling software. Programs like Autodesk Fusion 360, SketchUp, and Blender have opened up new possibilities for Miniature Model Makers. These tools allow creators to design intricate models with precision and efficiency.

With 3D modelling software, Miniature Model Makers can:

Visualize Designs: Create detailed 3D representations of their ideas before starting the physical construction process.

Experiment with Variations: Easily modify designs, explore different configurations, and see real-time outcomes.

Generate Technical Drawings: Produce accurate blueprints and schematics that can be used for further development or manufacturing.

3D Printing 3D printing technology has been a game-changer in miniature model making. Also known as additive manufacturing, 3D printing allows Miniature Model Makers to produce complex geometries that were previously impossible or too labour-intensive to create by hand.

Key advantages of 3D printing include:

Rapid Prototyping: Quickly turn digital designs into physical models, allowing faster iterations and refinements.

Customization: Produce bespoke models tailored to specific requirements or preferences.

Complex Structures: Advanced printing techniques like SLA (stereolithography) and FDM (fused deposition modeling) allow you to create intricate details and structures with high precision.

Laser Cutting and Engraving Laser cutting and engraving technology offer another significant advancement for Miniature Model Makers. Laser cutters use high-powered lasers to precisely cut and etch acrylic, wood, and cardboard.

Benefits of laser cutting and engraving include:

Precision: Achieve intricate designs with exact measurements and clean edges.

Versatility: Work with a wide range of materials and thicknesses.

Efficiency: Produce high-quality cuts and engravings quickly, ideal for creating complex models or multiple copies of a design.

The Impact of Technology on Miniature Model Making

Increased Efficiency One of the most noticeable impacts of technology on miniature model making is the increase in efficiency. Digital tools streamline the design and production processes, allowing Miniature Model Makers to complete projects faster and more precisely. The ability to quickly prototype designs and make adjustments has revolutionized how models are developed and refined.

Enhanced Creativity Technology also opens up new avenues for creativity. Miniature Model Makers can explore more innovative design concepts with advanced software and tools. Digital simulations and virtual reality offer new ways to visualize and interact with models before they are built, leading to more creative and ambitious projects.

Broader Accessibility Modern technology has made miniature models more accessible to a wider audience. Where traditional methods required specialized skills and equipment, today’s tools lower the barrier to entry. Online resources, tutorials, and affordable software enable hobbyists and aspiring model makers to experiment with new techniques and develop their skills.

Collaborative Opportunities Technology has also facilitated collaboration among Miniature Model Makers. Digital platforms and online communities allow creators from around the world to share ideas, offer feedback, and work together on projects. This global knowledge exchange and expertise enriches the field and fosters a vibrant community of miniature model enthusiasts.

Conclusion Technology has undeniably transformed the field of miniature model making, offering Miniature Model Makers a wealth of new tools and techniques to explore. From 3D modeling and printing to laser cutting and digital collaboration, these advancements have made the craft more efficient, creative, and accessible.

As we look to the future, it’s exciting to imagine how new technologies will continue to shape the world of miniature model making. Whether you are a seasoned professional or a hobbyist just starting, embracing these technological advancements can open up new opportunities and elevate your craft to new heights.

The future of miniature model making is bright, and technology is at the heart of this transformation. So, if you’re passionate about creating intricate models and exploring new possibilities, there has never been a better time to dive into this fascinating field.

Stay tuned to the Engg Model website for more insights, updates, and tips on the latest in miniature model making technology!

0 notes

Text

The Growing Demand for Engineering Model Makers & The Benefits of Using Scale-Down Model Makers in India

Global advancement in technology and the industrial revolution opened a gate for innovation that has brought demand for engineering model makers in India for various sectors. With a combination of technical advancements, knowledge in engineering, craftsmanship, and innovative thinking turning it into a newer business model.

What is the use of Engineering models?

Prototype design plays a vital role in transforming conceptual engineering into a tangible simulation model. Model making is the art of creating a scaled or miniature model of a product or a structure, that guides the engineers to visibly analyze the functionality and aesthetics of the outcome, before moving into the production or construction phase. The detailed model is the combination of both manual and digital techniques that helps the designers to visualize the product outcome after validation, testing, and evolution. A perfect model simulation completes 10% work of the overall project.

Engineering model makers are greatly needed in industries like manufacturing, architecture, automobile, robotics, Aerospace, real estate, and product designing and they may vary depending on a specific product or industry.

Model makers work along with project developers and engineers looking into project drawings, blueprints, and development platforms that help them in creating a better model by using appropriate materials like plastic, wood or metal, PVC, and acrylic boards, to meet requirements.

How are the scale down models are developed?

Scale-down models are the smaller replicas of a product or a structure. These model makers are professionally skilled in creating accurate miniature models, maintaining their actual prepositions without missing their essential features. Scale-down models are widely used for demonstration, education, and display purpose.

Benefits of using scale-down model makers

India is the fastest-growing economy in the sector of engineering, manufacturing, industries, architecture, design, and real estate that needs scale-down model makers to serve them. They design scale-down prototypes for visualization, validation, and testing of the product or a structure which helps the company to better understand the product before production.

Using scale-down model makers across various industrial sectors benefits the product or business through various aspects:

Cost effectiveness: Indian scale-down model makers offer better services when compared to international prototype-making through available resources within the country, which adds an advantage for small-scale companies with budget limitations.

Accessibility and time saving: These scale-down prototype makers are easily accessible by the clients for collaboration and communication for a better understanding of the project and its requirements. They also deliver project models on time with required modifications and changes.

Skilled workforce: India has a large scale of skilled craftsmen and artists who can create excellent models through their expertise in working with a variety of materials like wood, metal, plastics, PVC, acrylic boards, and other forms of resources in making high-quality prototype competing with international standards.

Cultural Diversity: Our rich cultural heritage and spiritual beliefs that strictly reflects in our architectural design which adds more cultural value to the structures. Scale-down model makers in India are highly qualified in making traditional and holistic design models to meet requirements.

Conclusion:

Having skilled engineering model makers in India offers numerous advantages in terms of design evaluation, cost constraints, and project visualization which will help the client for selecting a better one for their kind of business.

0 notes

Text

8/29, Film

youtube

View On WordPress

#aGIANTmonster#Model maker#Movie Miniatures#Movies explained#prop maker#Simon Weisse#Vox#Wes Anderson#Youtube

2 notes

·

View notes

Text

Miniature Scale Model in Malaysia | Scalemodel3dprinting

Miniature scale models are more than just a gift. They reflect the recipient’s ability to inspire teams, overcome challenges, and achieve remarkable feats. For example, gifting a miniature model of an upcoming headquarters or a cutting-edge facility serves as an acknowledgment of the recipient’s forward-thinking approach. Such gifts resonate particularly well with top executives, project leaders, and industry pioneers, who often value attention to detail and craftsmanship. Moreover, scale models serve as conversation starters and centerpieces. Displayed in an office or boardroom, they become an extension of the company’s story, showcasing its accomplishments to clients, partners, and stakeholders. To Know More Visit Here:

#Miniature Maker Malaysia#Miniature Scale Model#Miniature Model Malaysia#Miniature Malaysia#Miniature House Model

0 notes

Text

AR Scale Model Making Company | Architectural Model Makers in india

AR Model Makers is the best scale model making company in Mumbai & Delhi, India. At AR Model Makers, we turn your concepts into reality with precision-crafted scale models. We are based in Delhi and Mumbai and specialize in building architectural model making, 3d scale model maker, engineering model making, industrial model making and marine model making among other types of miniature models. Our staff is committed to realizing your idea with unparalleled workmanship and attention to detail, whether it be through intricate product miniatures, state-of-the-art 3D models, or building models.

More Info : Contact Number : +918263862853 Mail us: [email protected] Website : https://armodelmakers.com/

#art#craft#scale model#miniature model#model makers#3d models#architectural model#engineering model#industrial model#marine model#master plan model

0 notes

Text

Miniature Scale Model Maker in Mumbai

In the world of architecture, design, and planning, precision and detail are everything. When it comes to bringing intricate ideas to life, a Miniature Scale Model Maker in Mumbai is an invaluable asset. These experts in miniature modeling transform concepts into tangible, scaled-down versions, offering a visual and tactile experience that digital renderings often can’t match.

More Information

Click Here :-

0 notes

Text

miniature model makers in India

engineering and design, miniature models play a crucial role. Whether you are an architect looking to present your building design, an engineer testing a prototype, or a business owner planning an exhibition, finding the right miniature model maker is essential. There are numerous options in India, a country rich in craftsmanship and talent. In this article, we will guide you through selecting the perfect miniature model maker for your project while highlighting the key factors to consider when searching for miniature model makers in India.

Define Your Project Requirements

Before you search for miniature model makers in India, it's crucial to understand your project requirements clearly. Ask yourself the following questions:

Having a well-defined project scope will help you communicate your needs effectively and also assist you in narrowing down your options when choosing a miniature model maker.

Research Miniature Model Makers in India

Now that you have a clear idea of your project's requirements, it's time to start your research. You can also ask for recommendations from colleagues, peers, or industry associations.

Create a list of potential model makers and explore their websites and portfolios. Look for previous projects that align with your requirements, and pay close attention to their work's quality, detail, and precision. A model maker's portfolio can provide valuable insights into their expertise and capabilities.

Check for Experience and Expertise

Experience matters significantly when it comes to choosing a miniature model maker. Look for model makers with a proven track record of delivering high-quality models in your industry or niche. Experienced model makers are more likely to understand the intricacies of your project and can provide valuable insights and suggestions to enhance it.

Feel free to ask for references or case studies from their previous clients. This will give you a better understanding of their expertise and the satisfaction of their past customers.

Visit Their Workshop

If possible, arrange a visit to the workshop of the miniature model maker you are considering. This will give you a firsthand look at their working environment, equipment quality, and team's skill level. A well-equipped and organized workshop is a positive sign, as it indicates professionalism and commitment to quality.

During your visit, you can also discuss your project, ask questions, and gauge their enthusiasm and willingness to take on it.

Discuss Materials and Techniques

Different projects may require different materials and techniques for creating miniature models. Ensure that the model maker you choose has experience working with the materials and techniques that align with your project's needs. Whether laser cutting, 3D printing, handcrafting, or combining these methods, the model maker should proficiently use the required tools and materials.

Budget Considerations

While quality is paramount, it's essential to consider your budget when choosing a miniature model maker. Discuss your budget openly with potential model makers and request detailed quotations. On the other hand, excessively high prices may not guarantee the best results. Look for a model maker who can balance quality and affordability.

Timeline and Communication

Timeliness is often critical when it comes to engineering and design projects. Ensure that the miniature model maker can meet your project's deadline. Discuss the timeline and milestones in detail to ensure clarity. Effective communication is also key. Choose a model maker who is responsive to your inquiries and keeps you updated on the progress of your project.

Reviews and Testimonials

Reading reviews and testimonials from previous clients can provide valuable insights into the reliability and reputation of the miniature model maker. Look for online reviews on platforms like Google, Yelp, or their website. Positive reviews and testimonials indicate customer satisfaction and the model maker's commitment to quality.

Request a Prototype or Sample

If you need more clarification on a model maker's capabilities, consider requesting a small prototype or sample model before committing to a larger project. This can help you assess their attention to detail, craftsmanship, and ability to meet your requirements.

Conclusion

Choosing the right miniature model maker in India is a crucial decision that can significantly impact the success of your engineering or design project. You can make an informed choice by defining your project requirements, conducting thorough research, considering experience and expertise, visiting workshops, discussing materials and techniques, budget considerations, timelines, communication, and reviewing testimonials.

Remember that finding the perfect miniature model maker may take time, but the effort is well worth it when you see your project come to life with precision and accuracy. Make your decision wisely, and your miniature model will not only serve its functional purpose but also become a work of art that showcases your vision and expertise.

So, start your search for miniature model makers in India today, and bring your engineering and design projects to life with the help of skilled and talented professionals.

0 notes

Text

Introduction to Building Model Making

In this chapter, we introduce the art of building model making and its various applications. We delve into the history of scale model making and its evolution over time. From architectural and engineering models to film and gaming industry models, discover the diverse range of fields where models are utilized.

Also Read : Miniature Model Making Company in India

Tools and Materials

To build exceptional models, it is essential to understand the tools and materials required. This chapter provides an in-depth exploration of the different types of tools, from basic essentials to specialized instruments. Learn about the properties of materials such as plastic, wood, foam, and metal, and gain insights into selecting the right materials for specific projects.

Planning and Design

Also Read : Engineering Model Makers in Mumbai

Construction Techniques

The heart of model making lies in the construction process. In this chapter, we explore various techniques such as cutting, shaping, joining, and detailing. From basic construction methods to advanced techniques like 3D printing and laser cutting, discover the tools and techniques that will elevate your models to the next level.

Painting and Finishing

A beautifully painted and finished model brings it to life. This chapter covers the art of model painting, including color theory, airbrushing, brush techniques, and weathering effects. Learn how to add realistic textures, apply decals, and achieve professional-quality finishes to enhance the visual impact of your models.

Also Read : Industrial Model Making Company

Dioramas and Scene Creation

Dioramas provide an opportunity to create immersive and captivating scenes. This chapter explores the artistry behind diorama design, storytelling, and creating dynamic compositions. Discover how to select appropriate materials, incorporate lighting effects, and convey a narrative through carefully crafted scenes.

Advanced Techniques and Specialized Models

For those seeking to expand their skills further, this chapter delves into advanced techniques and specialized models. Explore topics such as figure modeling, vehicle detailing, architectural lighting, and creating realistic landscapes. Gain insights from experienced scale model makers and learn from their expertise.

Also Read : Marine Model Making Company

Showcasing and Presentation

A well-presented model can leave a lasting impression. In this chapter, we explore techniques for photographing and showcasing your models effectively. Learn how to create visually appealing display bases, design exhibition layouts, and leverage digital media platforms to share your work with a wider audience.

Challenges and Tips from Experts

Building models can present challenges along the way. This chapter addresses common hurdles faced by model makers and provides practical solutions. Benefit from the tips and advice of seasoned experts who share their insights and wisdom gained through years of experience.

Also Read : Architectural Model Makers in Mumbai

Inspiring Model Making Projects

To inspire your creativity, this chapter showcases a selection of captivating model making projects. Explore a variety of themes, styles, and scales, and discover the endless possibilities of model making. Each project includes detailed descriptions, step-by-step instructions, and accompanying images to guide and motivate you.

Conclusion:

#art#model makers#3d model maker#industrial model#architectural model#craft#3d scale model maker#engineering model#3d model#a one model making#building model#miniature model

0 notes

Text

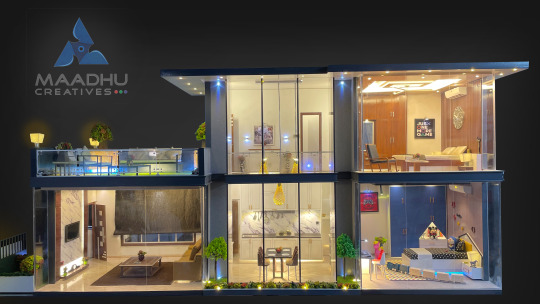

Architectural Scale Model Making by Maadhu Creatives

Architectural scale model making is an essential process in the field of architecture. It involves creating physical models that represent buildings or spaces in miniature form. These models are used to visualize designs, demonstrate concepts to clients, and communicate ideas to the building team.

The process of creating an architectural scale model starts with the design. Architects use computer-aided design (CAD) software to create detailed 3D models of the building or space. Once the design is finalized, the model-making process begins.

The first step in creating an architectural scale model is to select the appropriate scale. The scale is the ratio of the size of the model to the size of the actual building. Common scales used in architectural model making include 1:50, 1:100, and 1:200. The scale chosen depends on the size of the building and the level of detail required in the model.

Once the scale is determined, the model maker will create a base for the model. This is usually made of a sturdy material such as foam board or plywood. The base is cut to the size of the model and then covered with a layer of modeling clay or plaster. This provides a smooth surface for the model to be built on.

Next, the model maker will use various materials to construct the model. These materials may include balsa wood, plastic, metal, or even paper. The model maker will use these materials to create the walls, floors, and other features of the building.

As the model is being built, the model maker will often use a variety of tools to create intricate details. These may include knives, saws, and sandpaper. The model maker will also use paints and other materials to add color and texture to the model.

Once the model is complete, it is time to add the final touches. This may include adding landscaping, furniture, and other details that bring the model to life. The finished model is then used by the architect to demonstrate the design to clients, and by the building team to ensure that the design is properly executed.

Exterior Model Making

Exterior model making is the process of creating a physical representation of an exterior design, such as a building, vehicle, or product, using various materials and techniques. This can be done for a variety of reasons, including prototyping, design visualization, and presentation purposes.

The process of exterior model making typically involves several steps, including:

Conceptualization: This is the initial stage where the designer sketches out the rough idea of the design they want to create.

Scale modeling: After the design has been conceptualized, the designer creates a small-scale model of the design using materials such as clay, foam, or 3D printing.

Refinement: Once the scale model is created, the designer can refine the design, making changes to the shape, proportions, and details.

Final model: After the design has been refined, the designer creates the final model using materials such as wood, plastic, or metal.

Finishing: Finally, the designer applies finishing touches to the model, such as paint, decals, and other decorative elements, to make it more realistic.

Exterior model making requires a wide range of skills, including drafting, sculpting, painting, and 3D modeling. It is often used by architects, product designers, and engineers to create physical representations of their designs, which can be used for presentations, marketing, or testing purposes.

Interior Model Making

Interior model making is the process of creating physical scale models of interior spaces, such as buildings, rooms, or furniture, in order to visualize and communicate design concepts. Interior model making can be done using a variety of materials, such as wood, plastic, cardboard, and foam.

The process of creating an interior model typically involves several steps. First, the designer will create a 3D computer model of the space or object they want to represent. This model can be created using software such as SketchUp or AutoCAD. Next, the designer will use the computer model to create plans for the physical model, including the materials that will be used, the scale of the model, and any details or features that need to be included.

Once the plans are complete, the designer will begin building the physical model. This may involve cutting and shaping materials using a variety of tools, such as saws, knives, and sanders. The designer will also add details such as furniture, fixtures, and decorations to the model, using materials such as paint, fabric, and glue.

Interior models can be used for a variety of purposes, such as presenting design concepts to clients, testing the feasibility of a design, or simply as a visual aid for the designer. Interior models can also be used in film and television production, where they are often used to create sets and props.

Overall, interior model making is an important tool for interior designers and architects, allowing them to communicate their ideas in a tangible and easily understood way.

Maadhu Creatives’ skilled, professional and technologically advanced team works diligently towards realizing this vision and develops world-class creatives architecture interior models. We are a trusted name and specialize in developing all types of high quality and creatives architecture interior models. You share the details and we deliver creatives and stunning architecture interior model based on your requirement.

0 notes

Text

My very first 3D printer, which I bought in 2020, has recently suffered a malfunction of it's motherboard that would be too expensive for me to reasonably fix. As a result, I've decided to say goodbye to the old machine.

Never let it be said that I am not a sentimental person, though, because I felt compelled to memorialize it in the form of it's very own miniature 3D printed replica.

Thought it would also be fitting to have my first Pure Vessel, who was nearly all printed on that machine, pay homage to it as well.

Please join me in saying goodbye to my old X-Maker. You got me into this hobby. Printed so many Hollow Knight parts in your time, made so many of my customers happy. You will be missed.

I also wanted this post to be a sort of update for those of you who have been watching my Etsy. I'm going to be out of town for the remainder of June, and possibly the beginning part of July too, so I won't be selling any physical figures during at least that amount of time. I realize that I have been releasing new figures extremely slowly, and I've wanted to rectify that for a while now.

That is why I likely won't be selling any printed figures until I have a new one, or multiple, to include in my lineup. The death of my first printer has luckily spurred some motivation in me to 3D model once again, and I've been working on some personal projects aside from this tiny one. But after that, I'm going to do my damnedest to make some more Hollow Knight figures. Might branch off into Rain World territory as well, but I'm not totally sure yet.

Rest assured, I'll be working on it. Thank you all for your patience.

#my art#digital art#blender#3d print#3d model#3d printing#3d modeling#hollow knight#pure vessel#art#miniature#tiny#prop#figure#pippa talks

45 notes

·

View notes

Text

CW;; bottom surgery talk and fears, intersex struggles vent

Bottom surgery is already daunting for anyone. Surgery cost is a significant concern, with the simplest form being just as expensive as my top surgery.

As an intersex individual, the journey towards bottom surgery is riddled with complexities and uncertainties. Many insurance companies will refuse to cover GAC, often citing how it's not the "proper care" for us, or saying they paid years ago when we were mutilated, leaving us to shoulder the financial burden alone. To compound the issue, many surgeons will outright refuse to operate on intersex bodies. It leaves me between a rock and a hard place

Even if I do manage to scrounge up the tens of thousands of dollars for the surgery that fits me best, I'm confronted with the reality that most surgeons are not accustomed to operating on bodies that look like mine. It's like asking a micro model maker to make a miniature model instead. While the basic principles may be similar, the nuances of working on a larger scale can pose significant challenges. As an artist, I'm familiar with the challenge of adjusting to different scales and proportions. I fear surgeons may struggle to adapt their techniques to accommodate the intricacies of my anatomy, possibly increasing the risk of complications during and after surgery.

That's if they're even willing to work with me. I know many surgeons who won't. Knowing how far away bottom surgery is for me, if I can even access it, rips my lungs out. It's like watching all my friends stroll through the process with such ease, while I'm stuck in a perpetual cycle of trying to find a surgeon who will even consider operating on me. Even with a willing surgeon, I'd face the additional challenge of securing multiple documents to validate my mental health, bottom surgery oftentimes requiring more paperwork, most especially for insurances, despite the fact I will most likely be paying OOP.

I think to myself, it's going to be years before the technique is more available. It's going to be years before I have the money. Is it worth it when I'm 30? To put my body through such trauma? To then relearn my anatomy? Will it be too late?

#trans vent#metoidioplasty#bottom surgery#transmasc issues#trans intersex#intersex transmasc#intersex issues#purrspectives

21 notes

·

View notes

Text

High-end engineering firms called Miniature Model Makers in India create tiny prototype versions of the original, crucial engineering and process equipment while taking into account all of the originals' crucial and significant parameters. This industry has developed into a high order precision engineering industry that serves several manufacturing industries and educational institutions after being restricted to being merely display objects in board rooms for the ideal of the common people.

0 notes

Text

I read Outer Wilds fanfic sometimes and ponder over like, how long some of the Hatchlings in the stories spend in the cycle of loops. Not every story has a loop between exactly 22 minutes, but a lot of them do and then discuss how the Hatchling has been looping for months or years and I just wonder what they were doing in all that time. I consider myself a truly average gamer and in under 200 loops- less than 48 hours of playtime- I've nearly completed the game.

Given that even if you 100% the log it still takes less than 100 hours of play, what can you do in the hundreds of thousands of hours contained in a year or three of looping? Are you taking samples of Nomai pottery back for chemical analysis? Trying to perfectly hop around the black hole such that you can jump off from the Tower and get to Riebeck without dying?

From a *player* perspective, it's fun to match story time to player type to Hatchling personality too.

Perhaps on a meta level, this reckless Hatchling who spent years in the Ash Twin Project is a speed runner. They spent ages practicing to be able to take part A to location B in under twelve minutes. Perhaps this nervous wreck of a Hatchling is controlled by someone who has never touched a video game before and thus barely even knows that the A and B buttons do. Their months of loop time is spent learning how to use a jetpack without killing themself. Perhaps this Hatchling who loves the Nomai so much spent *their* loops examining every inch of Brittle Hollow because their player is a miniature maker who wants to make a Brittle Hollow scale model.

Food for thought, you know?

99 notes

·

View notes

Text

3D Model Builder Maker Malaysia | 3D Modelling Services

Model Builder is the ultimate tool for anyone passionate about scale model building, providing a virtual space to explore, learn, and create without limitations. Whether you’re an experienced scale model builder or someone curious about building scale models in Malaysia, Model Builder makes it easy to turn your ideas into reality.

Visit Here:

#3D Scale Model Maker#3D Physical Model#Large Scale Modeler#Scale Model Maker Malaysia#Miniature Maker Malaysia

0 notes

Text

How to Participate in This Event

Character Appreciation Weeks like this one are all about creativity!

If you think you're not a writer or an artist but you still want to participate, consider the following list of ideas!

Writing

Fanfiction (it does not have to be long to count as fanfiction!)

Headcanons

Theories

Essays

AU (Alternate Universe) ideas

Poetry

Song Lyrics

Quotes (especially when paired with a fan edit; see below)

Audio/Visual

Fan edits (aka digital photo collages aka moodboards)

Fan trailers (using existing clips of movies and music to make a "movie trailer")

Fancasts (photos of actors you'd like to see in the role)

Playlists (YouTube, Spotify, etc.)

Art/Photography

Fanart (both 2-D and 3-D; Digital and Traditional)

Pencil/Colored Pencil

Pen and Ink/Marker

Paint (Watercolor, Acrylic, Oil, etc.)

Canva (with photo resources like Pixabay, Unsplash, etc.)

Cosplay (costumes, hair, makeup, nails)

Model-Making

Miniatures (clay, 3-D printed, etc.)

Customized Dolls (e.g. Funko pops, poseable dolls)

3-D Models (Hero Forge, etc.)

RPG Character Makers (Dragon Age, Baldur's Gate, World of Warcraft etc.)

2-D Models (Azalea's Dolls, Doll Divine, Picrew, etc.)

Crafts

Book Nooks

Bookmarks/Book Binding/Altered Books

Pins

Cross-stitch/Embroidery

Knitting/Crochet (e.g. Amigurumi)

Candles

Stained Glass

and many, many more!

There are so many options that don't rely on the use of AI art (which we will not accept as submissions), so please consider making something yourself! And if you can't or don't have time, consider commissioning an artist to make something for you!

We look forward to seeing everyone's creativity!

#tamlin week#what to make#ideas#tamlin#pro tamlin#tamlinweek#tamlinweek2024#tamlin week 2024#acotar#a court of thorns and roses

39 notes

·

View notes

Text

Saturday Movie Night: Railscale 1

Here's an idea I've been sitting on for ages, which I hope will become a semi-regular feature on this here blog. It's a pretty basic idea - every week (if I remember), I share a video on here which I think you guys would be interested in seeing. Naturally, that means a lot of the videos will be to do with Thomas, or real-life railways (real and model), or anything else I decide is worth sharing.

I don't know if anyone here has heard of Phil Parker, but yes, I am basically ripping off the Saturday Film Club feature he does on his blog.

youtube

You may well remember me talking about Railscale a couple of years back. Well, since then, someone's gone and uploaded all three issues to YouTube (see that earlier post for why there were no more). So I thought, what better way to kick off this semi-regular feature?

See above to watch the programme, and see below for more details about the contents.

THE BROMFORD & HIGH PEAK RAILWAY (7mm/O)

This huge, spectacular O gauge layout was deliberately shrouded in mystery by its creator, Ferrari importer Ronnie Hoare. For security and insurance reasons, he rarely allowed visitors to the layout - the Railscale team were thus privileged to be allowed to film it for this feature. The layout itself featured over a scale mile of track, and included models from some of the country's leading model makers.

INSIDE A SAWMILL (7mm/O)

We next look around Les Tindal's scale model of an American sawmill of the interwar period. The sequence shows how Les adds details and develops scenery, and finishes with a look at huge he achieves the authentic weathering of timbers and metals.

PECORAMA (Various)

Pecorama is a permanent model railway exhibition in sunny south Devon, own and operated by the PECO company. They believe that any house or flat can accommodate a model railway, and the layouts on display have been made with this philosophy in mind.

WINCHESTER CHESIL (4mm/P4)

The Scalefour Society was one of the leading pioneers in the great push towards greater realism for model railways. This exact scale model of the GWR's Winchester station was made by society members from the Southampton area, and they take up the story of how the model came into being.

BOYTON CROSSING - PART 1 (4mm/OO)

The first in a series of segments demonstrating the construction of a model building - based on the crossing keeper's cottage at Boyton, on the Salisbury-Warminster line. Railscale's resident model maker, Mike Jolly, talks us through the process of researching and measuring the prototype, before building up the basic structure with card and embossed sheets.

LIVE STEAM ON THE ISLE OF MULL (Live Steam/10.25")

In 1984, a miniature railway opened on the Scottish island of Mull, linking Torosay Castle to the ferry pier at Craignure. The line has since developed into a tourist attraction in its own right. Nick Dodson of Railfilms shows us around, and talks with founder Graham Ellis.

PROJECT N - PART 1 (2mm/N)

Mike Jolly returns to commence the construction of an N gauge layout. After deciding on the plan, he chooses and cuts the timber, and makes a start on assembling the baseboard.

COACH CONVERSION (2mm/N)

Railscale 1 concludes with this short segment, demonstrating how to convert a Graham Farish BR Mk2 coach, to represent types not available in the ready-to-run market.

12 notes

·

View notes