#MechanicalSystems

Explore tagged Tumblr posts

Text

DI (Ductile Iron) Butterfly Valves are essential in fluid control systems, known for their strength, durability, and efficient flow regulation across industrial and commercial applications.

#dibutterflyvalves #butterflyvalves #valvesupplier #industrialvalves #flowcontrol #valvetechnology #fluidcontrolsystems #ductileironvalves #bangalorevalvesupplier #industrialsolutions

#dibutterflyvalves#butterflyvalves#valvesupplier#industrialvalves#flowcontrol#valvetechnology#fluidcontrolsystems#ductileironvalves#bangalorevalvesupplier#industrialsolutions#valveengineers#pipingandvalves#mechanicalsystems#qualityvalves#processcontrol#bangaloreindustry#engineeringproducts#valvedistributors#trustedvalvesupplier#efficientflowcontrol

0 notes

Text

The SBRSL-300 / 400 / 500 Ampoules and Vials Sticker Labeler are designed for high-speed, accurate labeling of round objects like ampoules and vials. With the ability to label up to 500 products per minute, this sturdy, user-friendly machine features a SERVO-controlled dispensing system and label-sensing technology. Its unique mechanical and electronic system allows for transparent label application at high speeds, while the preset label length detection system minimizes downtime and ensures smooth operation. For more details, visit - https://www.bhagwatilabeling.com/products/ampoules-and-vials-sticker-labeler/

#bhagwatilabelling#ampoulelabellingmachine#viallabellingmachine#servocontrol#labelsensingtechnology#MechanicalSystems#electronicsystems

0 notes

Text

Finding the Best Program to Become a Certified RV Technician

If you’ve ever dreamed of working on the road, fixing up RVs for fellow travelers, and helping people hit the open road with confidence, becoming a certified RV technician could be the perfect fit for you. Not only does it offer a great career with plenty of hands-on work, but it also gives you a chance to be part of the booming RV industry. RV technicians do a little bit of everything—from…

#AdvancedElectricalSystems#AdvancedRVRepair#ApplianceRepair#campingrecipes#CampingTips#CertifiedRVTechnician#coopershortcut#CooperShortcutCampingJourney#ElectricalSystems#HandsOnTraining#HVAC#JobPlacement#MechanicalSystems#NationalRVTrainingAcademy#NRVTA#OnlineRVTraining#PlacesToVisitWhileCamping#RecreationalVehicleServiceAcademy#RVCareer#RVCertification#RVDiagnostics#RVEducation#RVIndustry#RVJobs#RVMaintenance#RVPlumbing#RVRepair#RVRepairCareer#RVRepairPrograms#RVRepairs

0 notes

Text

Annulus ring Gear

The Annulus Ring Gear is a circular gear component with teeth along its inner circumference, crucial for power transmission in mechanical systems. Crafted with precision from durable materials like steel or alloy, it meshes with pinions or smaller gears to change motion direction, adjust speed, and transfer power efficiently.

https://ringandgears.com

#AnnulusRingGear#GearMechanism#PowerTransmission#PrecisionEngineering#MechanicalSystems#GearComponents#EngineeringDesign#IndustrialEngineering#MechanicalEngineering#GearTechnology

0 notes

Text

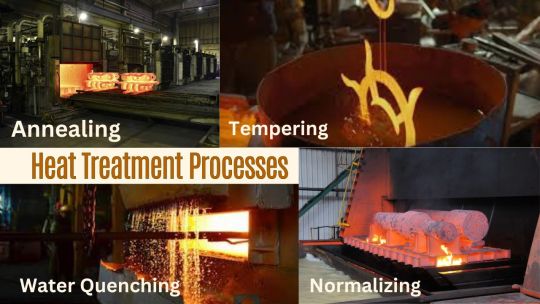

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

All moving mechanical systems will eventually fail and require the repair or replacement of different components. Even the best quality turning machines may suffer a spindle failure, especially when you consider that spindles can rotate as fast as 65,000 RPM or more for high-speed spindles. Spindles may fail due to:

Lack of maintenance

Air contamination

Machine mishandling

Incorrect Preload

Poor lubrication

Machine overload

Spindle imbalance

Drawbar Failures

- Bearing Failures

🌐 https://unitedaxleofnm.com . . . . .

mechanicalfailures #spindleissues #machinemaintenance #highspeedspindles #mechanicalrepair #componentreplacement #machinereliability #industrialmaintenance #spindlefailureanalysis #lubricationmatters #machinehealth #bearings #machinerytroubleshooting #precisionmachining #engineeringchallenges #mechanicalsystems #machinefailuremodes #manufacturingissues #industrialengineering #preventivemaintenance #machinerycare #rotationalfailures #operationalreliability

0 notes

Text

𝗘𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴 𝗳𝗼𝗿 𝘁𝗵𝗲 𝗗𝗶𝗴𝗶𝘁𝗮𝗹 𝗔𝗴𝗲: 𝗠𝗮𝘀𝘁𝗲𝗿𝗶𝗻𝗴 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗖𝗔𝗗 𝗳𝗼𝗿 𝘁𝗵𝗲 𝗠𝗼𝗱𝗲𝗿𝗻 𝗪𝗼𝗿𝗹𝗱 This Master's program in Mechanical CAD offers advanced studies in computer-aided design for mechanical engineering professionals seeking to enhance their skills and knowledge in this critical field. Our program combines theoretical and practical training in advanced CAD techniques and tools, with an emphasis on precision and creativity in design.

#MasteringMechanicalCAD#DesigningTheFuture#PrecisionEngineering#InnovativeDesign#AdvancedCADTechniques#EngineeringExcellence#MechanicalMastery#CADforManufacturing#CreativeSolutions#DigitalDesign#MechanicalEngineering#ProductDesign#CADSoftware#MechanicalSystems#SimulationAndAnalysis#DataManagement#Collaboration#ManufacturingIndustry#ResearchAndDevelopment#CuttingEdgeTechnology#Kalyan#Ulhasnagar#dombivali#ambarnath#thane#mulund#badlapur#karjat#kasara#titwala

1 note

·

View note

Photo

Combining a digital touch-screen on the front with interchangeable mechanical dials on the back, the Rotary Mechanical Smartphone is a concept designed by Richard Clarkson to merge digital technologies with physical mechanical systems, in order to elicit more value in our everyday objects.

Via Dezeen.

https://www.iainclaridge.co.uk/blog/3562

https://www.dezeen.com/2011/06/16/rotary-mechanical-smartphone-by-richard-clarkson/

0 notes

Photo

Boilers as far as the eye can see... #11hoyt #11hoytbk #tishmanspeyer #downtownbrooklyn #mep #mechanicalsystems (at 11 Hoyt) https://www.instagram.com/p/B5II305g7zg12lPaJG9XmP9FhlwS-9wOZ7-hQ40/?igshid=6rxindyryxbo

0 notes

Video

vimeo

Zimoun : Compilation Video 3.7 (2017) by Zimoun A video compilation of Zimoun’s work, all playing with the same idea of repetition and also possibly his love for using motors and basic materials. Every installation seems to be a masterpiece on its own, and Zimoun himself (or maybe the motors) can be compared to that of a musical composer. Aside from the soothing sounds that his work produces, noticing the subtle movements also adds on to the user’s experience, possibly similar or mimicking a similar experience to that of watching the waves crash on beaches, or the trees rustling in the wind.

#Vimeo#zimoun#installation#soundart#soundsculptures#physicalsound#mechanicalsystems#organicsound#art#simplicity#reduction#preparedmotors#physicalcomputing#bitformsgallerynyc#leerraum[]#vibrationmotor#artificialorganicsystems#mechanic#untitledsoundobjects#kineticsculpture

0 notes

Text

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes

Photo

Wrapping up the goods for our trip down to San Diego 🚙🚙🚙🚙 See you soon @kaaboodelmar 😃🌴🌞 . . . #kaabooartwork #tapedmetalcanvas #kaaboodelmar #tapeart #contemporaryart #sandiego #kaaboo #metalcanvas #artresin #art #hittheroad #mechanicalsystems #zerowaste

#mechanicalsystems#zerowaste#art#artresin#sandiego#contemporaryart#kaaboo#kaaboodelmar#hittheroad#tapeart#kaabooartwork#metalcanvas#tapedmetalcanvas

2 notes

·

View notes

Video

vimeo

Zimoun : Compilation Video 3.1

#installation#soundart#soundsculptures#physicalsound#mechanicalsystems#organicsound#art#simplicity#preparedmotors#physicalcomputing#vibrationmotor#kineticsculpture#contemporary art#architec#cardboard

1 note

·

View note

Text

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes

Text

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes