#StructuralEngineering

Explore tagged Tumblr posts

Text

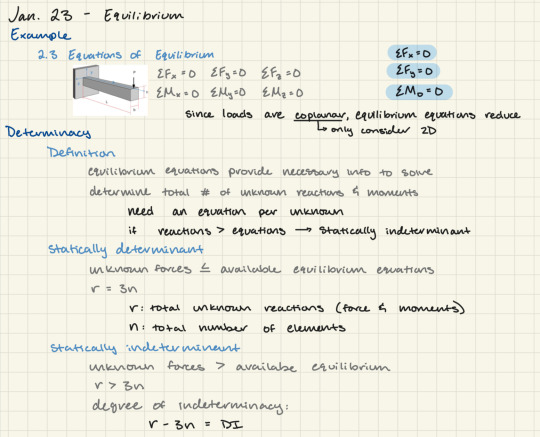

structural analysis notes *゚+.*.。

#ignore my handwriting#my prof talks too fast#study girl#girl blogging#girlblogging#light acadamia aesthetic#dark acadamia aesthetic#classic academia#study inspo#study blogging#studyblog#studyblr#study blogger#study movitation#structuralengineering#structural analysis#it girl#that girl#becoming an academic weapon#becoming that girl

20 notes

·

View notes

Text

Connect with leading Engineering Consultancy firms in UAE on TradersFind! Find experts for your projects, from structural to MEP engineering. Browse our extensive list of companies to find the perfect match for your needs.

Connect with us on WhatsApp at +971 56 977 3623 to discuss your Engineering Consultancy requirements.

Visit our website and find your perfect engineering partner! https://www.tradersfind.com/category/engineering-consultancy

Engineering Consultancy In UAE

#engineeringconsultancy#engineeringservices#consultancyworks#uae#b2b#tradersfind#engineeringexperts#structuralengineering#mepengineering#consultingfirms#engineeringsolutions#engineeringprojects#findyourexpert#engineeringconsultants#engineeringdesign#buyersguide#consultingservices#engineeringuae

2 notes

·

View notes

Text

Structural engineering Company in Coimbatore | Zhagaram

2 notes

·

View notes

Text

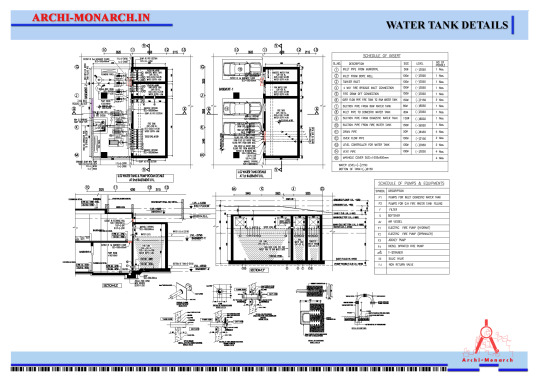

WATER TANK DETAILS

A water tank is a container that is used to store and hold water. Water tanks are often found on rooftops, in basements... https://archi-monarch.in/water-tank-details/

#architecture#architecturelovers#design#building#construction#structuralengineering#interiordesign#cityscape#skyscraper#architecturephotography#architecturedesign#landscapearchitecture#modernarchitecture#sustainablearchitecture#architecturestudent#architecturemodel#architectureporn#architecturehunters#urbanplanning#arquitectura#archilovers#architecture_hunter#architecture_greatshots#architecture_view

3 notes

·

View notes

Text

How BIM Revit is Transforming the Architecture, Engineering & Construction Industry

Introduction

The Architecture, Engineering, and Construction (AEC) industry has undergone significant advancements over the past few decades, thanks to technological innovations. One of the most transformative tools in this sector is Building Information Modeling (BIM), specifically Autodesk Revit. Revit bim Structure training in hyderabad has revolutionized how professionals design, plan, and manage construction projects, making processes more efficient, cost-effective, and sustainable. This article explores how BIM Revit is reshaping the AEC industry, highlighting its key features, benefits, and real-world applications.

Understanding BIM Revit

What is BIM?

Building Information Modeling (BIM) is an intelligent 3D model-based process that provides architects, engineers, and construction professionals with tools to design, visualize, and manage building projects efficiently. BIM integrates multiple aspects of a project into a single digital model, fostering collaboration and improving decision-making.

What is Revit?

Autodesk Revit is a leading BIM software that enables users to create detailed 3D models, coordinate data across disciplines, and streamline workflows. Unlike traditional CAD software, Revit allows for parametric modeling, meaning any changes made to one part of the model automatically update across the entire project.

Key Features of BIM Revit

Parametric Design

Revit allows users to make design modifications effortlessly. Any changes made to a component reflect throughout the entire model, ensuring consistency and reducing errors.

2.Collaborative Workflow

The software facilitates multi-disciplinary collaboration, enabling architects, structural engineers, and MEP (mechanical, electrical, and plumbing) professionals to work on the same model simultaneously.

3.3D Visualization & Rendering

Revit provides high-quality 3D renderings, allowing clients and stakeholders to visualize the project before construction begins.

4.Clash Detection

One of Revit’s standout features is its ability to detect design clashes between different systems (e.g., structural and MEP), reducing costly mistakes and rework during construction.

5.Cost Estimation & Material Takeoff

The software automates quantity takeoffs and cost estimations, helping project managers budget effectively.

6.Construction Documentation

Revit streamlines the creation of construction documents, ensuring accuracy and compliance with industry standards.

How BIM Revit is Transforming the AEC Industry

1. Enhanced Collaboration & Coordination

Traditionally, architects, engineers, and contractors worked in silos, leading to communication gaps and errors. BIM Revit fosters seamless collaboration by allowing all stakeholders to work on a centralized model, reducing misunderstandings and improving efficiency.

2. Improved Design Accuracy & Reduced Errors

With intelligent parametric modeling, Revit eliminates manual drafting errors. The software automatically updates all related elements when a change is made, ensuring accuracy and reducing costly revisions.

3. Better Visualization & Client Communication

Revit’s 3D visualization capabilities help clients understand design concepts better. Architects can create realistic walkthroughs, making it easier to convey ideas and receive feedback, leading to more informed decision-making.

4. Time & Cost Efficiency

BIM Revit minimizes project delays and cost overruns by automating repetitive tasks, improving material estimation, and reducing on-site modifications. Accurate data and real-time collaboration enable faster project completion.

5. Sustainable & Energy-Efficient Designs

Sustainability is a growing concern in the AEC industry. Revit integrates energy analysis tools that help designers optimize building performance, reduce energy consumption, and adhere to green building standards.

6. Streamlined Construction & Facility Management

Revit not only aids in the design and construction phases but also assists in facility management. The detailed BIM model serves as a digital twin of the building, providing valuable data for maintenance, renovations, and future modifications.

Real-World Applications of BIM Revit

1. High-Rise Buildings

Revit is extensively used in the design and construction of skyscrapers, ensuring precise structural planning and coordination between multiple disciplines.

2. Healthcare Facilities

Hospitals and medical centers require intricate MEP systems. Revit helps in designing these complex networks efficiently, reducing errors and ensuring regulatory compliance.

3. Infrastructure Projects

From bridges to highways, Revit supports large-scale infrastructure projects by improving coordination among different engineering teams.

4. Residential & Commercial Developments

BIM Revit streamlines the design process for residential complexes and commercial buildings, optimizing space utilization and enhancing design efficiency.

Challenges & Future of BIM Revit in the AEC Industry

Challenges

Initial Learning Curve: Revit has a steep learning curve, requiring proper training and expertise.

High Implementation Costs: The software and associated hardware upgrades can be expensive for small firms.

Data Management Complexity: Large BIM models require efficient data management strategies to ensure smooth operation.

Future Trends

Integration with AI & Machine Learning: Future versions of Revit will leverage AI for automated design optimizations and predictive analytics.

Cloud-Based Collaboration: Cloud computing will further enhance real-time collaboration, making BIM accessible from anywhere.

Virtual & Augmented Reality Integration: VR and AR will revolutionize design visualization and client presentations.

IoT & Smart Buildings: BIM models will integrate with IoT to create intelligent buildings that enhance operational efficiency.

Conclusion

BIM Revit is undeniably transforming the Architecture, Engineering, and Construction industry by enhancing collaboration, improving accuracy, reducing costs, and promoting sustainability. As technology continues to evolve, BIM Revit will become even more powerful, driving innovation and efficiency in the AEC sector. Embracing this tool is no longer an option but a necessity for firms looking to stay ahead in a competitive industry.

#Revit#BIM#RevitBIM#RevitStructure#StructuralDesign#BuildingInformationModeling#Architecture#CivilEngineering#StructuralEngineering#ConstructionTech#AutodeskRevit#RevitExperts#BIMModeling#AECIndustry#EngineeringDesign#RevitTraining#BIMforEngineers#3DModeling#RevitCourse#DhyanAcademy#RevitTutorials#DesignAutomation#RevitArchitecture#BuildingSmart

0 notes

Text

Best Structural Engineering Services Provider in Arizona

Silicon Outsourcing is a trusted name in the Structural Engineering Services, offering precise solutions to clients across Arizona. Our team of experienced CAD Engineers collaborates with architects, contractors, and developers to create robust and innovative structural designs. By utilizing advanced engineering techniques and the latest industry standards, we ensure that every structure is safe, durable, and optimized for long-term performance.

Visit our website:

#SiliconOutsourcing#StructuralEngineering#PrecisionInDesign#CADDraftingExperts#SafeDurableStructures#YourStructuralPartner

1 note

·

View note

Text

The Ultimate Waterproof Attachment Solution

The stronger, smarter attachment solution, that gives you the ability to completely waterproof any connection on your structure.

📍 Address: 67 Mariner Dr, Southampton, NY 11968, United States

🌐 Website: https://nillbuildingsolutions.com/

✅ Facebook: https://www.facebook.com/nillbuildingsolutions/

✅ YouTube: https://www.youtube.com/@NillBuildingSolutions/

✅ Pinterest: https://www.pinterest.com/nillbuildingsolutions/

✅ Instagram: https://www.instagram.com/nillbuildingsolutions/

#waterproof#waterproofing#roof#solar#solarmounts#construction#glassrail#innovate#changetheworld#nillway#nillbuildingsolutions#patented#patentpending#hardware#buildingmaterials#architecture#structuralengineering

0 notes

Text

🏗️ Expert Residential Structural Engineering in London – MF Contemporary Build 🏡

Planning a home renovation, extension, or new build? MF Contemporary Build provides expert residential structural engineering services across London, ensuring safety, stability, and precision in every project. Whether you're modifying existing structures or designing from scratch, our team offers tailored solutions to meet your needs.

🔹 Structural assessments & reports 🔹 Loft conversions & home extensions 🔹 Foundation & beam calculations 🔹 New build structural design

With years of experience, we ensure compliance with UK building regulations while delivering innovative and cost-effective solutions. Trust MF Contemporary Build to bring your vision to life with expert engineering and craftsmanship.

📞 Call us today: +44 7588232535 📩 Email: [email protected] 🌐 Learn more: mfcontemporarybuild.co.uk

🏡 Strong Foundations for Your Dream Home!

#residentialengineering#structuralengineering#londonconstruction#homebuilding#mfcontemporarybuild#engineeringexperts#london#uk

0 notes

Text

𝟏𝟏𝐭𝐡 𝐀𝐍𝐍𝐈𝐕𝐄𝐑𝐒𝐀𝐑𝐘 𝐎𝐅𝐅𝐄𝐑………. 📣 നിങ്ങൾ BIM (Building Information Modeling) മേഖലയിൽ കരിയർ ആഗ്രഹിക്കുന്നുണ്ടോ? എങ്കിൽ കരിയറിനെ കുറിച്ച് കൂടുതൽ ചിന്തിച്ച് ഇനി സമയം കളയണ്ട. നല്ലൊരു ജോലി ഉയർന്ന ശമ്പളം ഉറപ്പാക്കാം MASTERS IN BIM PROGRAM-ലൂടെ. ENGINEERING മേഖലയിൽ ഏറ്റവും മികച്ച അവസരങ്ങൾ നേടിയെടുക്കുവാൻ ഈ കോഴ്സിലൂടെ സാധ്യമാകുന്നു. ഒപ്പം ഈ കോഴ്സ് നിങ്ങളുടെ ഡിസൈൻ, മോഡലിംഗ്, പ്രോജക്ട് മാനേജ്മെന്റ് കഴിവുകൾ മെച്ചപ്പെടുത്തുകയും NEW BIM ടെക്നോളജി ഉപയോഗിച്ച് നിർമ്മാണ മേഖലയിൽ ഒരു പ്രൊഫഷണൽ ആയി മാറുവാൻ നിങ്ങളെ പ്രാപ്തരാക്കുന്നു. ഈ ഓഫർ മിസ്സ് ആക്കേണ്ട ഇപ്പോൾ JOIN ചെയ്യൂ!

✅ AUTOCAD ✅ REVIT ARCHITECTURE ✅ BIM METHODS ✅ RECAP ✅ LUMION ✅ REVIT STRUCTURE ✅ REVIT MEP (LOAD CALCULATION) ✅ NAVISWORKS ✅ PROJECT MANAGEMENT

⭐ Offer Closing 25th February 2025

For Details: 🌐 www.solidcad.org 📌 Kottayam, Changanacherry, Kochi ☎ +91 7560989347, +91 9562261281

#SolidCad#BIM#MastersInBIM#Engineering#CareerGrowth#AutoCAD#Revit#RevitArchitecture#RevitMEP#RevitStructure#BIMMethods#Navisworks#Lumion#ProjectManagement#ConstructionTechnology#JobOpportunities#HighSalary#MEPDesign#StructuralEngineering#3DModeling#BuildingDesign#FutureReady#CivilEngineering#ArchitecturalDesign#BIMTraining#CareerSuccess

0 notes

Text

Omg arcane reference in the structures homework??!

#arcane#studyblr#engineering#structuralengineering#aerospace#aerospace engineering#league of legends

2 notes

·

View notes

Text

The City That Almost Fell Apart: A Tale of Architecture, Resilience, and Reinvention

It started with a single crack. Not large, barely noticeable to the untrained eye, but to the engineers overseeing the structure, it was an ominous whisper of trouble. The building had stood for decades, a silent witness to the growth of the city around it. But time is a relentless force, and even the strongest of foundations can falter under its weight.

A routine inspection had turned into a nightmare. The walls, once proud and unyielding, now bore hairline fractures that traced delicate spiderwebs across their surface. The structural integrity of the entire block was in question. Tenants were evacuated, businesses shuttered, and a sense of unease settled over the neighborhood. What had gone wrong? More importantly, how could it be fixed?

The Forgotten Layers Beneath Our Feet

Every city has its hidden layers, buried beneath concrete and steel. Foundations rest on history, often quite literally, as old structures are built upon remnants of the past. In this case, the problem lay not in the building itself but in what lay beneath it. The ground had shifted, subtly but persistently, undermining the stability of everything above.

Experts traced the issue back to old, forgotten sewer lines that had weakened over time. Water had seeped into the soil, creating pockets of instability. It was a ticking time bomb that no one had noticed until the cracks had appeared.

This was more than just an isolated problem—it was a wake-up call. How many other structures across the city were vulnerable? Could a disaster be looming just beneath the surface, hidden in plain sight?

Engineering a Solution

The challenge wasn’t just about fixing the damaged structure; it was about preventing future failures. A team of architects, engineers, and urban planners gathered to strategize. The solution required a deep understanding of materials, stress points, and the interplay between natural forces and human-made structures.

Instead of merely patching the cracks, they opted for a comprehensive approach. Reinforcements were made to the foundation, accounting for shifts in the soil. The outdated sewer system was replaced, ensuring proper drainage and reducing the risk of further erosion. But beyond these physical repairs, the team also recognized the need for smarter urban planning—designs that accounted for the changing landscape beneath the city’s feet.

When Buildings Tell Stories

Cities are more than just collections of buildings; they are living narratives of human ambition, failure, and resilience. Every street has its own story, every structure a history of decisions made, risks taken, and challenges overcome.

In the aftermath of the repairs, something fascinating happened. People began to see their city differently. Where they once saw just sidewalks and facades, they now saw the hidden forces at play—the weight of history, the power of engineering, and the delicate balance that keeps a city standing. Architects and designers began incorporating new methods into their projects, ensuring that future constructions were not just beautiful but built to last.

The Future of Sustainable Architecture

This incident sparked a broader conversation about sustainable architecture and resilient city planning. Traditional construction methods, while effective for their time, often failed to account for long-term environmental changes. Now, new technologies were being integrated into urban development—smart materials that adapt to stress, self-healing concrete that repairs minor cracks, and AI-driven analysis tools that predict structural weaknesses before they become critical.

The question was no longer just about fixing what was broken; it was about designing structures that could withstand the tests of time, nature, and human expansion. The lesson learned from that one cracked building rippled outward, influencing future projects and shaping a city that was prepared for whatever lay ahead.

The Unseen Architects of Stability

Most people never think about the invisible work that keeps their world standing. The bridges they cross, the buildings they enter, the tunnels they travel through—all of these are the result of meticulous planning, constant monitoring, and a deep understanding of materials and mechanics.

Yet, for those who dedicate their lives to this field, every project is a puzzle, every structure a challenge to be solved. They work in the background, ensuring that what stands today does not crumble tomorrow. Their work is rarely noticed, except in moments of crisis. But without them, the very fabric of urban life would collapse.

This is the essence of great design—not just creating something that looks impressive, but ensuring that it endures. Behind every well-built structure is a team of minds who have considered every possibility, accounted for every variable, and planned for every contingency.

And as the repaired building once again became a thriving hub of activity, the city moved forward, stronger and wiser. Because in the end, architecture isn’t just about structures; it’s about the people who live within them and the stories they carry forward.

At the heart of these efforts, in the quiet but determined pursuit of excellence in architectural solutions, stands a name dedicated to the craft: ParamountBuilt.

#architecture#branding#commercial#architectural design#structuralengineering#structural integrity#structuraldesign

1 note

·

View note

Text

Structural Engineer — ANZSCO 233214 | Immigration Australia

Structural engineers must study and evaluate the architectural features of different structures, assess the condition or serviceability and life expectancy of the materials in use, as well as the form of buildings and their components and supervise their developments. In some geographic regions, registration and later licensure may be required for the legal practice of the profession.

The job of a Structural Engineer (ANZSCO 233214) is to design and assess the integrity of structures, including bridges, buildings, tunnels, and other vital structures. Engineers look at the safety and stability of these structures and their abilities to endure loads, natural elements, and even disasters. To achieve this, structural design and analysis are conducted through AutoCAD, ETABS, and STAAD.Pro while adhering to the Australian code of engineering, such as AS3600 and AS4100, which are for concrete and steel, respectively.

Their role also includes overseeing the cooperation with architects, contractors, and other stakeholders to deliver on time and within the budget. Engineers always include eco-friendly features with innovative materials in their designs, further encouraging their commitment to sustainability. Because of all this, the profession focuses on Australia’s MLTSSL, which grants qualified migrating engineers opportunities. Most of the time, engineers under ANZSCO 233214 have to provide a Skill Demonstration Report (CDR) to fit the requirements of Engineers Australia.

On the Occupation Lists

489 (S/T) Occupations List

482 TSS Visa Medium Term List

407 Training visa occupations List

482 TSS Visa Regional Occupation List

189 Skilled Independent and Family Sponsored 489 Occupations List and 485 Graduate Work Stream

190 State/Territory Sponsored

186 ENS Visa Occupations List

187 RSMS Visa Occupations List

491 — Skilled Work Regional (provisional) visa (subclass 491) Occupation List

494 — Skilled Employer-Sponsored Regional (provisional) (subclass 494) — Employer-sponsored stream

Task Included

The methods of construction, the materials to be used, their quality specifications, and other relevant standards are defined and developed in conjunction with the specifications, drawings, plans, methods of construction, and processes to be followed.

Supervising and organizing the site workers and providing construction materials, plant and equipment is done along with developing comprehensive activity coordination plans for the site.

Soil and rock samples are collected at various depth levels across the selected sites; these samples are then tested for strength and compressibility as well as other related characteristics that might affect the behaviour of soil and rock when the structure is placed; in addition, the safe loading for the soil is calculated.

Formulate full costs by examining the detailed architectural and structural sketches and the other accompanying documents. Formulate detailed cost plans and estimates that are useful in controlling the budget.

Modifying design and implementation of monitoring, considering cost impact and quantifying value, and negotiating design alternatives.

Structurally analyze systems for static and dynamic loading.

Ensure that structures are designed in such a manner as to avoid collapse or undesirable bending, twisting, or vibration of such kind that can be detrimental.

Evaluate the future and current travel flow patterns because of population growth and changing needs.

Develop the physical features of transport systems, including highways, railways, urban public transport, air transport, logistics logistic supply and terminal systems.

Unit Group 2332: Civil Engineering Professionals

Structural engineers and civil engineering professionals play a vital role in planning, designing, and overseeing the construction of critical infrastructure projects such as bridges, dams, pipelines, water supply schemes, roads, airports, sewerage systems, and other structures. They analyze the statistical properties of structures, assess soil and rock behavior under pressure, and design robust foundations to ensure safety and durability. Additionally, they test the materials used in construction, estimate costs, and monitor project progress. Their expertise extends to developing transportation systems and ensuring that all projects are efficient, sustainable, and compliant with engineering standards.

Why is CDR for Australia the best service out there?

We understand the customer’s needs and work diligently to satisfy them, accurately creating their application, CV, RPL reports, and CDR reports. CDR for Australia is the best option for CDR services since our group of specialist CDR writers is familiar with the unique needs of ANZSCO Codes, and we can assist engineers in preparing an outstanding report that adheres to Engineers Australia’s guidelines. We specialize in providing 100% unique MSA content that strictly adheres to MSA guidelines.

Our staff is highly qualified and experienced in the technical aspects of generating a CDR report, ensuring that it meets Engineers Australia’s stringent standard.

For more details

Call or WhatsApp : +61 482 081 740

Email: [email protected]

Visit our website: CDR for Australia

#cdr#skillassessment#engineeraustralia#structuralengineer#structuralengineering#structuraldesign#anzsco233214

0 notes

Text

How Bolts Improve Structural Integrity

In construction and heavy-duty applications, foundation bolts play a vital role in securing structures and preventing movement. These bolts enhance durability, ensuring buildings and industrial equipment remain stable under heavy loads. Choosing the right fasteners is essential, and a trusted anchor bolt manufacturer can provide high-quality solutions for various industrial needs.

For additional reinforcement, stud bolts offer superior strength, making them ideal for projects requiring high-load-bearing capacity. Whether you're working on large-scale infrastructure or machinery installations, using reliable foundation J bolts ensures long-term stability.

In industries like construction and automotive, stainless steel U bolt manufacturers and U bolts manufacturers supply durable fasteners for securing pipes, beams, and support structures. Additionally, a dependable U clamp manufacturer can provide the right clamps for various industrial applications.Investing in high-quality bolts is essential for maintaining structural integrity, reducing maintenance costs, and ensuring safety. Whether you need foundation J bolts, foundation bolts, or other industrial fasteners, working with top manufacturers guarantees durability and performance in demanding environments.

#StructuralIntegrity#BoltsInConstruction#BuildingStrength#StructuralEngineering#ConstructionMaterials#BoltsAndBraces#EngineeringEssentials#StrongStructures

0 notes

Text

KITCHEN DETAILS

A kitchen is a room or part of a room used for cooking and food preparation in a dwelling or in a commercial establishment... https://archi-monarch.in/kitchen-details/

#architecture#architecturelovers#design#building#construction#structuralengineering#interiordesign#cityscape#skyscraper#architecturephotography#architecturedesign#landscapearchitecture#modernarchitecture#sustainablearchitecture#architecturestudent#architecturemodel#architectureporn#architecturehunters#urbanplanning#arquitectura#archilovers#architecture_hunter#architecture_greatshots#architecture_view

2 notes

·

View notes

Text

The Impact of Smart Technologies on the Evolution of Structural Engineering

The journey of structural engineering has been nothing short of remarkable. From the ancient pyramids to modern skyscrapers, we've come a long way in how we design, build, and maintain structures. But perhaps the most significant transformation has occurred in the last few decades, thanks to the integration of smart technologies.

From Traditional Methods to Digital Solutions

Remember the days when structural engineers relied solely on hand calculations and physical models? Those times seem almost ancient now. The transition from paper-based designs to computer-aided solutions has revolutionized how we approach structural engineering challenges. If you live in Michigan, you'll appreciate how the latest technologies are being leveraged for better outcomes. Innovative solutions in structural engineering in Michigan for sustainable buildings are now shaping the future, with advanced tools and materials making projects more efficient and eco-friendly.

Smart Technologies Revolutionizing the Field

Key Smart Technologies in Modern Engineering

Sensor Technologies and Implementation : Smart sensors have become the eyes and ears of modern structures. These tiny but powerful devices continuously monitor everything from structural integrity to environmental conditions, providing real-time data that was impossible to gather just a few years ago.

Cloud Computing Solutions : The cloud has transformed how we store, process, and analyze structural data. Engineers can now access project information from anywhere, collaborate seamlessly, and utilize powerful computing resources on demand.

Integration of IoT in Structural Engineering

Real-time Monitoring Systems : The Internet of Things (IoT) has introduced unprecedented capabilities in structural monitoring. Imagine having thousands of sensors working together, creating a nervous system for buildings and bridges.

Machine Learning Applications : Machine learning algorithms can now predict structural behavior patterns, identify potential issues before they become problems, and optimize design solutions in ways that human engineers alone never could.

Data Analytics and Structural Health Monitoring

Predictive Maintenance Applications : Smart technologies have revolutionized maintenance strategies. Instead of reactive approaches, we can now predict and prevent structural issues before they occur.

Safety Improvements : The implementation of smart technologies has dramatically enhanced structural safety. Real-time monitoring and early warning systems have become invaluable tools in protecting both structures and their occupants.

Artificial Intelligence in Structural Analysis

AI has become an indispensable tool in structural analysis, offering capabilities that extend far beyond traditional computational methods.

Building Information Modeling (BIM) : BIM has transformed how we conceptualize, design, and manage structural projects, creating a digital twin that evolves with the structure throughout its lifecycle.

Sustainable Design Through Smart Tech

Environmental Impact: Smart technologies have enabled more sustainable structural engineering practices, reducing waste and optimizing resource usage through precise calculations and simulations.

Future Challenges and Opportunities

Cost-Benefit Analysis : While smart technologies require significant initial investment, their long-term benefits often outweigh the costs through improved efficiency and reduced maintenance needs.

Frequently Asked Questions

How have smart technologies improved structural safety?

Smart technologies enable real-time monitoring and early detection of potential structural issues, significantly enhancing safety through predictive maintenance and continuous assessment.

What is the role of AI in modern structural engineering?

AI helps in design optimization, predictive analysis, and decision-making processes, making structural engineering more efficient and accurate than ever before.

How cost-effective are smart technology implementations in structural engineering?

While initial costs can be high, smart technologies typically offer positive ROI through reduced maintenance costs, improved efficiency, and extended structural lifespan.

Can smart technologies help in making structures more sustainable?

Yes, smart technologies enable better resource optimization, energy efficiency, and waste reduction through precise calculations and real-time monitoring.

What future developments can we expect in smart structural engineering?

Future developments will likely include more advanced AI applications, improved sensor technologies, and better integration of various smart systems for more comprehensive structural management.

Conclusion

The integration of smart technologies in structural engineering represents a paradigm shift in how we approach the built environment. As we look to the future, the continued evolution of these technologies promises even more exciting developments in structural engineering.

0 notes