#Manufacturing Engineering Services

Explore tagged Tumblr posts

Text

0 notes

Text

Why Industrial Engineering Services Are Critical for Business Growth

Improve your business growth with the help of industrial engineering services. Unlock efficiency, streamline processes, and maximize operational potential through innovative strategies tailored to modern industrial challenges. Transform your operations to long-term success today!

#industrial engineer projects#Industrial manufacturing#manufacturing engineering services#industrial engineering services

1 note

·

View note

Text

Engineering DNA offers custom engineering solutions including 3D printing, reverse engineering, drafting, and simulations. Specializing in production engineering, product design, and CFD simulation, we deliver accuracy and excellence. Contact us today for innovative mechanical design and FEA Analysis services.

#3D Printing Design#Reverse Engineering Services#Drafting Services#3D Simulation#Interior design 3D Modeling#CFD Simulation#Product Design Engineering#3D Modeling for 3D Printing#Manufacturing Engineering#Finite Element Analysis Services#Design and Drafting Services#3D CAD Services#Manufacturing Engineering Services#3D Modeling Services#3D Design Services

0 notes

Text

How Manufacturing Engineering Services Streamline Your Operations

In the ever-evolving landscape of manufacturing, innovation and efficiency are paramount. One of the key drivers of these advancements is manufacturing engineering services. This blog explores the significance and benefits of these services, emphasizing the importance of product design optimization, manufacturing execution systems, and digital manufacturing.

What are Manufacturing Engineering Services?

Manufacturing engineering services encompass a wide range of activities aimed at improving the production process. These services include designing efficient manufacturing systems, optimizing product designs, implementing advanced technologies, and ensuring that products are manufactured to the highest standards of quality and efficiency.

Product Design Optimization Process

A critical component of manufacturing engineering services is the product design optimization process. This process involves refining a product's design to enhance its performance, reduce costs, and improve manufacturability. Key benefits include:

Cost Reduction: Minimizing material usage and production costs.

Improved Performance: Enhancing product functionality and reliability.

Manufacturability: Simplifying the manufacturing process to increase efficiency.

A product design optimization company provides specialized expertise in this area, helping businesses create products that are not only innovative but also economically viable.

Manufacturing Execution System (MES)

The manufacturing execution system (MES) is a pivotal tool in modern manufacturing engineering services. An MES provides real-time data and insights into the production process, enabling better decision-making and process optimization. Key features of MES include:

Real-Time Monitoring: Tracking production activities in real-time.

Quality Control: Ensuring products meet quality standards.

Production Efficiency: Streamlining operations to reduce waste and improve productivity.

Manufacturing execution system services help companies implement and maintain MES solutions, driving efficiency and competitiveness.

Advanced Manufacturing Engineering Services

Advanced manufacturing engineering services involve the application of cutting-edge technologies and methodologies to enhance manufacturing processes. These services include:

Automation: Implementing robotic and automated systems to increase efficiency and reduce human error.

Additive Manufacturing: Utilizing 3D printing and other advanced techniques to create complex components.

Sustainability: Adopting eco-friendly practices to minimize environmental impact.

By leveraging these advanced manufacturing engineering services, companies can stay at the forefront of technological innovation and operational excellence.

Digital Manufacturing Services

Digital manufacturing services represent the future of the manufacturing industry. These services involve the integration of digital technologies into the manufacturing process, creating a seamless and efficient production environment. Benefits include:

Enhanced Collaboration: Facilitating communication and collaboration across global teams.

Data-Driven Decisions: Utilizing big data and analytics to optimize processes.

Flexibility: Adapting quickly to changes in market demand and production requirements.

Digital manufacturing services are crucial for companies looking to thrive in the digital age, offering the tools and insights needed to stay competitive.

Conclusion

In conclusion, manufacturing engineering services are essential for businesses aiming to innovate and optimize their production processes. From the product design optimization process and manufacturing execution systems to advanced and digital manufacturing engineering services, these offerings provide comprehensive support to enhance efficiency, quality, and competitiveness. By embracing these services, companies can ensure they are well-positioned to meet market demands, drive growth, and achieve long-term success.

0 notes

Text

ozone

#had to fix this one before posting it#was supposed to be included in the last post - but didn’t exactly fit with the other images thematically#this building/sector is at the mouth of the entire park — I think it’s spot that manufactures/cans/pumps compressed natural gas?? not 100%#and it’s LOUD. not this building specifically but the 4 dozen other factories and assembly plants that operate on this block#similar noise level to working ground services at an intl airport; the passive noise level is somewhat-distant jet engine at best#hard to capture that aspect in the image — I should do a field recording tho#anyways yeah - it’s fun to drive through the heart of the park at night and listen to the whirrs and groans of machinery#I want to capture more but obv being oblique with a camera in this area or making frequent passes warrants a little more sensitivity#I do not want to deal with cops OR well-meaning-but-misguided working class folk who open carry to their shift at Dangerous Chemicals INC#my art#webcore#internetcore#glitchcore#artists on tumblr#night photography#distortion#noise#art#y2kcore#abstract art#glitch aesthetic#artwork#abstract#industry#infrastructure#machinery

236 notes

·

View notes

Text

BIM Careers: Building Your Future in the Digital AEC Arena

The construction industry is undergoing a digital revolution, and BIM (Building Information Modeling) is at the forefront. It's no longer just a fancy 3D modeling tool; BIM is a collaborative platform that integrates data-rich models with workflows across the entire building lifecycle. This translates to exciting career opportunities for those who can harness the power of BIM.

Are you ready to step into the octagon of the digital construction arena? (Yes, we're keeping the fighting metaphor alive!) Here's a breakdown of the in-demand skills, salary ranges, and future prospects for BIM professionals:

The In-Demand Skillset: Your BIM Arsenal

Think of your BIM skills as your tools in the digital construction toolbox. Here are the top weapons you'll need:

BIM Software Proficiency: Mastering software like Revit, ArchiCAD, or Navisworks is crucial. Understanding their functionalities allows you to create, manipulate, and analyze BIM models.

Building Science Fundamentals: A solid grasp of architectural, structural, and MEP (mechanical, electrical, and plumbing) principles is essential for creating BIM models that reflect real-world construction realities.

Collaboration & Communication: BIM thrives on teamwork. The ability to collaborate effectively with architects, engineers, and other stakeholders is paramount.

Data Management & Analysis: BIM models are data-rich. Being adept at data extraction, analysis, and interpretation unlocks the true potential of BIM for informed decision-making.

Problem-Solving & Critical Thinking: BIM projects are complex. The ability to identify and solve problems creatively, while thinking critically about the design and construction process, is invaluable.

Salary Showdown: The BIM Payday Punch

Now, let's talk about the real knock-out factor – salaries! According to Indeed, BIM professionals in the US can expect an average annual salary of around $85,000. This number can vary depending on experience, location, and specific BIM expertise. Entry-level BIM roles might start around $60,000, while BIM Managers and BIM Specialists with extensive experience can command salaries exceeding $100,000.

Future Forecast: A Bright BIM Horizon

The future of BIM is bright. The global BIM market is projected to reach a staggering $8.8 billion by 2025 (Grand View Research). This translates to a continuous rise in demand for skilled BIM professionals. Here are some exciting trends shaping the future of BIM careers:

BIM for Specialty Trades: BIM is no longer just for architects and engineers. We'll see increased adoption by specialty trades like HVAC technicians and fire protection specialists.

Integration with AI and Machine Learning: Imagine BIM models that can predict potential issues or suggest optimal design solutions. AI and machine learning will revolutionize BIM capabilities.

VR and AR for Enhanced Collaboration: Virtual Reality (VR) and Augmented Reality (AR) will allow for immersive BIM model walkthroughs, facilitating better collaboration and design communication.

Ready to Join the BIM Revolution?

The BIM landscape offers a dynamic and rewarding career path for those with the right skills. If you're passionate about technology, construction, and shaping the future of the built environment, then BIM might be your perfect career match. So, hone your skills, embrace the digital revolution, and step into the exciting world of BIM with Capstone Engineering!

#tumblr blogs#bim#careers#buildings#bim consulting services#bim consultants#construction#aec#architecture#3d modeling#bim coordination#consulting#3d model#bimclashdetectionservices#engineering#MEP engineers#building information modeling#oil and gas#manufacturing#virtual reality#collaboration#bim services#uaejobs

2 notes

·

View notes

Text

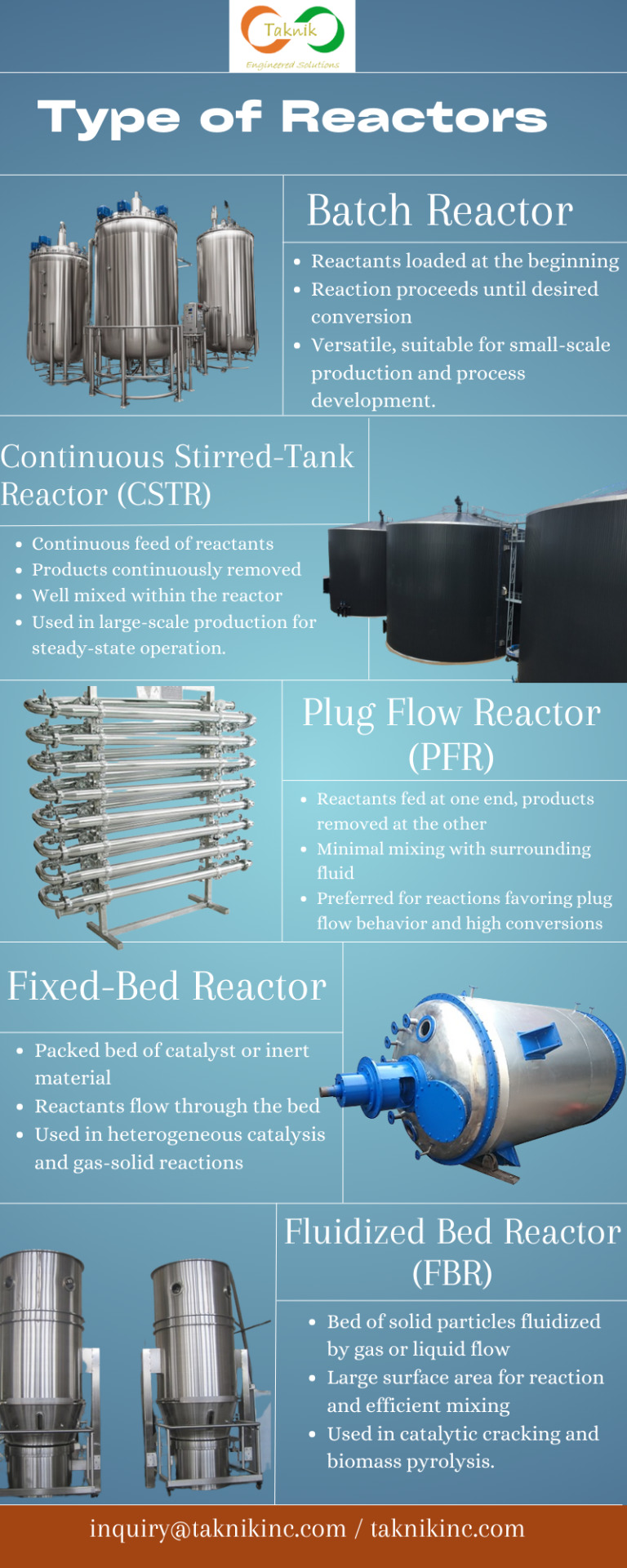

Taknik Inc is an Engineering Consultant it is a leading provider of Engineering design & Consultancy Services solution in India.

We Provide Process Equipment for the Manufacture Industries ,all kind of Matallic and non Metallic Equipment ,Reactor,HDPE Sprial Tank Blower Scrubber, Heat Exchanger, Storage Tank, Pressure Vessel etc .

for more details you can contact us

9510430147

or

email Id- [email protected]

#taknikinc#engineering#consultant#services#manufacturingindustry#manufacturer#metallic#Reactor#solutions#process#equipment#production#chemicals#tank#bharuch#gujarat

4 notes

·

View notes

Text

ERP Trends 2024: What Engineering and Manufacturing Industries Need to Know

As we navigate through 2024, the landscape of Enterprise Resource Planning (ERP) systems continues to evolve, presenting both opportunities and challenges for engineering and manufacturing industries. Companies in this sector, especially those in key industrial regions like Maharashtra, Mumbai, Pune, and Gujarat, must stay abreast of the latest ERP trends to maintain competitive advantage and operational efficiency. In this blog, we’ll delve into the significant ERP trends of 2024 and their implications for the engineering and manufacturing sectors.

1. Increased Adoption of Cloud-Based ERP Solutions

One of the most significant trends in ERP software for engineering companies in Maharashtra and across India is the shift towards cloud-based solutions. Cloud ERP offers several advantages over traditional on-premise systems, including lower upfront costs, greater scalability, and enhanced accessibility.

Benefits of Cloud-Based ERP:

Cost Efficiency: Eliminates the need for expensive hardware and reduces IT maintenance costs.

Scalability: Easily adjusts to the growing needs of a manufacturing company in Gujarat or an engineering firm in Mumbai.

Accessibility: Provides access to real-time data from anywhere, facilitating better decision-making.

Leading ERP software companies in Pune are increasingly offering cloud-based solutions tailored to the needs of local engineering and manufacturing businesses. These solutions support remote work and ensure business continuity in an increasingly digital world.

2. Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing ERP systems by providing intelligent insights and automating routine tasks. For ERP software for engineering companies in Mumbai, integrating AI can enhance predictive maintenance, optimize supply chain management, and improve production planning.

AI and ML Applications in ERP:

Predictive Analytics: Helps foresee equipment failures and reduce downtime.

Supply Chain Optimization: Enhances demand forecasting and inventory management.

Process Automation: Automates repetitive tasks, freeing up human resources for more strategic roles.

ERP solution providers in Pune are at the forefront of integrating AI and ML into their systems, enabling companies to leverage advanced analytics and improve overall operational efficiency.

3. Emphasis on Cybersecurity

With the increasing digitization of manufacturing processes, cybersecurity has become a critical concern. ERP systems, being the backbone of business operations, are prime targets for cyber-attacks. Engineering and manufacturing companies in regions like Gujarat and Maharashtra need robust cybersecurity measures to protect their sensitive data.

Key Cybersecurity Features:

Data Encryption: Protects data during transmission and storage.

Multi-Factor Authentication: Enhances user authentication processes.

Regular Security Audits: Ensures continuous monitoring and improvement of security protocols.

ERP software for engineering companies in Maharashtra must incorporate these advanced security features to safeguard against data breaches and cyber threats.

4. Enhanced User Experience (UX)

User experience has become a critical factor in ERP adoption and utilization. Modern ERP systems are focusing on intuitive interfaces and user-friendly designs to ensure that all employees, regardless of their technical expertise, can effectively use the system.

UX Improvements:

Intuitive Dashboards: Provide real-time insights and easy navigation.

Mobile Accessibility: Ensures that users can access ERP data on-the-go.

Customization Options: Allow users to tailor the system to their specific needs.

ERP software companies in Pune are prioritizing user experience in their solutions, making it easier for engineering and manufacturing firms to train their staff and increase productivity.

5. Internet of Things (IoT) Integration

The integration of IoT with ERP systems is another trend transforming the manufacturing industry. IoT devices collect vast amounts of data from production lines, equipment, and other operational areas, which can be analyzed by the ERP system to optimize performance.

IoT Benefits in ERP:

Real-Time Monitoring: Provides immediate insights into production processes.

Predictive Maintenance: Schedules maintenance activities based on equipment condition rather than time intervals.

Enhanced Quality Control: Monitors product quality throughout the manufacturing process.

For ERP for manufacturing companies in Gujarat, IoT integration offers a significant advantage by improving efficiency and reducing operational costs.

6. Sustainability and Green Manufacturing

Sustainability is becoming a critical focus for manufacturing companies worldwide. ERP systems are evolving to support green manufacturing practices by tracking and optimizing resource usage, reducing waste, and ensuring compliance with environmental regulations.

Sustainable ERP Features:

Resource Management: Tracks energy and material usage to minimize waste.

Regulatory Compliance: Ensures adherence to environmental laws and standards.

Sustainability Reporting: Provides detailed reports on sustainability metrics.

Engineering and manufacturing companies in regions like Mumbai and Maharashtra can benefit from ERP solutions that incorporate sustainability features, helping them achieve their environmental goals and enhance their corporate reputation.

7. Modular and Flexible ERP Solutions

In response to the diverse needs of engineering and manufacturing firms, ERP solution providers in Pune are developing more modular and flexible ERP systems. These systems allow companies to select and implement only the modules they need, which can be easily scaled and customized as their business grows.

Advantages of Modular ERP:

Cost-Effective: Pay only for the features you need.

Scalability: Easily add new modules as your business requirements evolve.

Customization: Tailor the system to fit specific operational needs.

This trend is particularly beneficial for small to medium-sized enterprises (SMEs) in the engineering and manufacturing sectors, enabling them to adopt ERP systems without the burden of high costs or complexity.

8. Focus on Customer-Centric Manufacturing

ERP systems are increasingly supporting customer-centric manufacturing practices, where production processes are aligned with customer needs and preferences. This approach enhances customer satisfaction and drives business growth.

Customer-Centric ERP Features:

Custom Order Management: Handles unique customer requirements and specifications.

Enhanced CRM Integration: Integrates with customer relationship management (CRM) systems for a holistic view of customer interactions.

Real-Time Order Tracking: Provides customers with real-time updates on their orders.

Manufacturing companies in Gujarat and engineering firms in Maharashtra are leveraging these customer-centric ERP features to improve their service levels and build stronger customer relationships.

9. Advanced Analytics and Business Intelligence (BI)

Advanced analytics and BI are becoming integral components of modern ERP systems. These tools provide deep insights into business operations, helping companies make data-driven decisions and improve performance.

Key BI Features:

Data Visualization: Converts complex data into easy-to-understand charts and graphs.

Dashboards: Offer a real-time overview of key performance indicators (KPIs).

Predictive Analytics: Forecasts future trends based on historical data.

ERP software companies in Pune are incorporating advanced analytics and BI capabilities into their systems, empowering engineering and manufacturing firms to gain a competitive edge through better insights and informed decision-making.

10. Globalization and Localization Support

As engineering and manufacturing companies expand their operations globally, ERP systems must support multiple languages, currencies, and regulatory requirements. Globalization and localization features are essential for companies operating in diverse markets.

Globalization Features:

Multi-Language Support: Accommodates users from different regions.

Multi-Currency Handling: Manages transactions in various currencies.

Compliance with Local Regulations: Ensures adherence to regional laws and standards.

ERP solution providers in Pune and other industrial hubs are enhancing their systems to support global operations, enabling companies to seamlessly manage their international business processes.

Conclusion

The ERP landscape for engineering and manufacturing industries is rapidly evolving, driven by advancements in technology and changing business needs. Companies in Maharashtra, Mumbai, Pune, and Gujarat must stay informed about these trends to leverage the full potential of ERP systems. By adopting cloud-based solutions, integrating AI and IoT, prioritizing cybersecurity, and focusing on sustainability, businesses can achieve greater efficiency, competitiveness, and growth in 2024 and beyond.

For engineering and manufacturing firms looking for the best ERP software for engineering companies in Maharashtra or ERP for manufacturing companies in Gujarat, it is crucial to partner with leading ERP solution providers in Pune who understand the unique challenges and opportunities in this sector. Embracing these trends will not only enhance operational efficiency but also drive innovation and sustainability in the engineering and manufacturing industries.

By staying ahead of these ERP trends, companies can position themselves for success in an increasingly digital and interconnected world. Whether you are an engineering firm in Mumbai or a manufacturing company in Gujarat, the right ERP system can transform your operations and pave the way for a prosperous future.

#ERP software in Vadodara#Manufacturing ERP software in Gujarat#ERP software companies in Vadodara#ERP software providers in Vadodara#ERP for manufacturing company in Gujarat#ERP software#ERP system#cloud ERP#ERP solutions#software development#engineering ERP#management software#engineering services#engineering industry

5 notes

·

View notes

Text

Smart Maintenance Tips for Pre-Engineered Metal Buildings: A Guide from Industry Experts

Want your metal structure to stand strong for decades? A well-maintained, pre-engineered metal building can stand the test of time, offering durability and efficiency. However, routine upkeep is key to preserving its structural integrity. Let's dive into some smart maintenance tips that'll keep your pre-engineered metal building in top shape, no matter what Mother Nature throws at it!

Beyond the Basics: Your Building's Health Check

Think of your building like a car where regular checkups make all the difference! If you've invested in commercial metal buildings, here's what needs your attention:

Fastener Focus: Keep those bolts and fasteners snug as a bug. Loose ones? They're like open doors for water damage, definitely not what we want!

Door & Vent Care: Show some love to your doors and vents with regular lubrication. A smooth-operating building is a happy building.

Annual Spa Treatment: Give your building a yearly wash with a gentle power wash. Trust us, it's like a refreshing shower for your structure!

Paint Protection: Spot some scratches? Don't let them turn into rusty headaches. A fresh coat of paint works wonders for protection.

Insulation Inspection: Keep an eye on your insulation – it is not just about comfort, it is about protecting your investment too.

Ready to build something amazing? Lacey Construction Inc is your local experts in pre-engineered metal buildings, offering free consultations and comprehensive design/build services in Nebraska. Let's turn your vision into reality. Reach out today at (402)-443-1112 for a no-obligation chat about your commercial metal building needs!

#metal building construction#construction services#custom steel buildings#pre engineered building manufacturers

0 notes

Text

The Growing Demand for Aluminium Hanger Tents in India: Market Trends and Insights

Aluminium hanger tents are rapidly gaining popularity across various industries in India. From large-scale events and exhibitions to industrial storage and disaster relief operations, these versatile structures offer numerous benefits that make them the preferred choice for many businesses and organizations. The demand for aluminium tents in India is growing due to their durability, flexibility, and cost-effectiveness. In this blog, we will explore the key market trends and insights driving the demand for aluminium hanger tents in India and what the future holds for this industry.

Why Aluminium Hanger Tents Are in High Demand

The increasing popularity of aluminium hanger tents in India can be attributed to several factors. Businesses and event organizers are shifting towards these structures due to their ability to provide efficient, temporary, and semi-permanent solutions for multiple applications. Below are some of the primary reasons why aluminium hanger tents are witnessing a surge in demand.

1. Durability and Strength

Aluminium hanger tents are designed to withstand harsh weather conditions, making them an ideal choice for both temporary and long-term use. The aluminium frame ensures strength and resistance to rust and corrosion, which is particularly beneficial for Indian climatic conditions, where heavy rains and high humidity can impact other types of structures.

2. Cost-Effectiveness

Compared to traditional buildings, aluminium hanger tents are significantly more affordable. They provide a practical solution for businesses looking for a temporary or mobile structure without the high costs associated with permanent buildings. Additionally, the relatively low aluminium tent hanger price in India makes them accessible for a wide range of industries.

3. Quick and Easy Installation

Time efficiency is a critical factor when setting up temporary structures, and aluminium hanger tents excel in this aspect. These tents can be installed and dismantled quickly, saving valuable time and labor costs. This makes them an ideal choice for exhibitions, corporate events, and industrial applications.

4. Versatility Across Industries

Aluminium hanger tents are not limited to a single industry. They are widely used in multiple sectors, including:

Events and Exhibitions: Providing spacious and well-structured venues for trade shows, corporate events, and social gatherings.

Warehousing and Storage: Acting as temporary warehouses for goods, machinery, and raw materials.

Aviation and Defense: Offering aircraft hangars and military shelters.

Disaster Relief and Emergency Shelters: Serving as quick and effective relief shelters during natural calamities.

Sports Facilities: Creating covered spaces for outdoor sports and training facilities.

Market Trends Driving the Growth of Aluminium Hanger Tents in India

With an increasing number of industries recognizing the benefits of aluminium hanger tents, the market is witnessing notable trends that indicate steady growth. Let’s look at some of the key trends shaping the aluminium tent industry in India.

1. Expansion of the Event Management Industry

India’s event management industry has been expanding rapidly, with more companies investing in large-scale corporate, entertainment, and public events. The demand for flexible and cost-effective venues has driven the need for aluminium tents in India, as they offer the perfect balance between affordability and functionality.

2. Growth in Warehousing and Logistics

With the boom in e-commerce and logistics, companies require temporary storage solutions to manage fluctuating inventory needs. Aluminium hanger tents provide an excellent alternative to permanent warehouses, especially for businesses that need flexible storage spaces in different locations.

3. Rising Construction and Infrastructure Projects

India’s growing infrastructure sector is another major driver for the aluminium hanger tent market. Construction sites often require temporary shelters for workers, equipment, and materials. These tents are increasingly being used to create safe and weather-resistant spaces at construction sites.

4. Increased Use in Military and Aviation Sectors

The defense and aviation sectors in India are adopting aluminium hanger tents for their flexibility and efficiency. Military bases require temporary structures for training, storage, and operational use, while the aviation industry uses them for aircraft hangars and maintenance areas.

5. Sustainable and Eco-Friendly Alternatives

As sustainability becomes a priority, aluminium tents are emerging as an environmentally friendly alternative to conventional structures. They require fewer raw materials and generate less construction waste, making them a preferred choice for organizations looking to reduce their carbon footprint.

Key Considerations When Choosing an Aluminium Hanger Tent

When investing in an aluminium hanger tent in India, there are several factors to consider to ensure you get the best value for your money. Here are some key aspects to keep in mind:

1. Quality of Materials

Ensure that the aluminium tent is made from high-quality materials that can withstand environmental conditions. Look for corrosion-resistant aluminium frames and durable fabric covers.

2. Size and Customization Options

Different applications require different tent sizes. Many aluminium tent manufacturers in India offer customizable solutions to meet specific needs, whether for a large-scale event or a small warehouse.

3. Installation and Maintenance

Choose a supplier that provides easy installation services and ensures minimal maintenance costs. Some aluminium tents require additional weatherproofing features, depending on the location of use.

4. Price Comparison and Budgeting

The aluminium tent hanger price in India varies based on size, material quality, and customization. It’s essential to compare prices from different manufacturers to get the best deal.

5. Vendor Reputation and Customer Support

Selecting a reliable aluminium tent manufacturer in India is crucial. Look for vendors with a strong reputation in the industry and excellent customer support services to ensure a smooth purchasing experience.

Future Outlook of the Aluminium Hanger Tent Market in India

The demand for aluminium hanger tents in India is expected to grow further as businesses and industries continue to explore innovative and cost-effective solutions for temporary structures. With advancements in materials and design, these tents are likely to become even more durable, adaptable, and eco-friendly.

Government initiatives supporting infrastructure growth, the rising need for disaster relief solutions, and the booming logistics sector will all contribute to the increasing adoption of aluminium hanger tents nationwide. Furthermore, as sustainability becomes a priority, the industry may witness greater demand for recyclable and energy-efficient tent materials.

Conclusion

The growing demand for aluminium hanger tents in India reflects their practicality, cost-effectiveness, and adaptability across multiple industries. Whether for events, warehousing, defense, or emergency relief, these structures provide a reliable and efficient solution. As the market continues to expand, aluminium tent manufacturers in India will play a crucial role in meeting the increasing demand by offering high-quality, customizable, and affordable solutions.

For businesses and organizations looking for temporary or semi-permanent shelter solutions, aluminium hanger tents offer an excellent investment, ensuring flexibility, durability, and economic viability in the long run.

#pre engineering building company in india#aluminium hangers tents infrastructure#services offered by a construction company#pre engineered building manufacturers in india#aluminium hanger tent in india#aluminium hangers tents manufacturers#modern a type canopy tents#pre engineered building manufacturers#steel building construction company#aluminium tent hanger price

0 notes

Text

#design and drafting services#standing seam roof manufacturers and suppliers#structural roof decking#roofing services and solution providers#metal building accessories and solutions in india#Maxroof#complete metal building solutions#pre-engineered buildings manufacturer in india

0 notes

Text

Maximize Efficiency & Minimize Costs with Industrial Engineering Services

Maximize efficiency while minimizing costs with industrial engineering services. Improve operations through workflow and productivity enhancement, thus leading to elevated success across industries based on innovative, cost-saving approaches.

#industrial engineer projects#Industrial manufacturing#manufacturing engineering services#industrial engineering services

1 note

·

View note

Text

Looking for a reliable hydraulic system manufacturer? We design and manufacture high-quality hydraulic systems, including jacks, cylinders, pumps, power packs, and valves. Engineered for durability and efficiency. Contact us today for expert solutions!

#hydraulic system manufacturer#hydraulic equipment#hydraulic cylinder#hydraulic engineering services#hydraulic cylinder suppliers#hydraulic jack manufacturer#hydraulic jack

0 notes

Text

Shape Your Cloud Business with Surfytech!

Manufacturers & Exporters – Maximize Your Product Visibility!

Struggling to get your products in front of the right buyers? Surfytech helps manufacturers, suppliers and Exporters:

- Showcase products with SEO-friendly listings

- Optimize search rankings to increase visibility

- Target the right customers via AI-driven social media marketing

- Boost engagement & conversions with data-backed strategies

Let’s take your business global! Contact us today.

#manufacturer#exporter#supplier#software development#website#web design#search engine optimization#seo services#social media

0 notes

Text

Comprehensive Contracting and Manufacturing Solutions by INECO

INECO offers a comprehensive range of services, including INECO Group was established as a contracting and manufacturing organization to be a single, as a contracting and manufacturing entity. INECO offers a comprehensive range of services, including INECO Group was established as a contracting and manufacturing organization to be a single, as a contracting and manufacturing entity.

Since its inception, INECO has built a reputation for delivering innovative solutions that align with the ever-evolving demands of the market. The company’s expertise spans multiple domains, including construction, engineering, fabrication, and project management. Whether it's a small-scale project or a large, complex undertaking, INECO leverages its advanced infrastructure and skilled workforce to deliver results that exceed expectations.

INECO’s contracting services are tailored to provide end-to-end solutions, from conceptualization and design to implementation and maintenance. This holistic approach allows clients to focus on their core objectives while INECO handles the operational complexities. On the manufacturing front, the company specializes in producing high-quality components and systems that adhere to stringent industry standards.

INECO Group’s core values of integrity, innovation, and excellence underpin its operations. By combining state-of-the-art technology with a customer-centric approach, the company remains committed to delivering value-driven solutions that contribute to sustainable growth for its clients and stakeholders.

INECO also places great emphasis on fostering long-term partnerships, ensuring that each engagement is marked by trust, transparency, and mutual growth. With a dedicated team of professionals and a proven track record, INECO continues to set benchmarks in the contracting and manufacturing sectors.

As a contracting and manufacturing organization, INECO is poised to play a pivotal role in shaping the future of the industries it serves, staying true to its mission of being a single-source provider of excellence and innovation.

#INECO#Contracting Services#Manufacturing Solutions#Single-Source Provider#Engineering and Fabrication#Project Management#Innovation in Contracting#High-Quality Manufacturing#End-to-End Solutions#Industry Excellence

1 note

·

View note