#Finite Element Analysis Services

Explore tagged Tumblr posts

Text

Unlock the power of premium 3D product rendering and animation services for exceptional visual detail and dynamic motion. Perfect for enhancing presentations, our high-quality animations breathe life into your designs, ensuring they stand out in any setting. From intricate product details to immersive environmental context, our 3D visuals create a compelling narrative around your product. Whether you're showcasing a prototype or a final product, our services deliver precision and impact. Elevate your presentations with visuals that captivate your audience.

#3DProductAnimationServices#3dProductRenderingServices#finite element analysis services#3d prototype in mumbai#3d cad services#3d modeling for 3d printing#3d modeling services

0 notes

Text

Unveiling the Strength: A Comprehensive Finite Element Analysis of the Strap U-Frame

In the realm of engineering, structural integrity and performance are paramount. At Graphler Technology Solutions, our commitment to delivering cutting-edge analyses ensures that every project achieves its full potential. Recently, we undertook an extensive finite element analysis (FEA) of a Strap U-Frame. This blog delves into the highlights and insights from the study.

Objective of the Study:

The primary goal of the FEA was to evaluate the structural behavior of the Strap U-Frame under a variety of operational loads and conditions. This included assessing how the U-Frame responded to forces induced by tension in the strap, moments generated during operation, and reaction forces from components like the crank and pawl. By simulating these real-world conditions, the analysis aimed to:

Identify Critical Stress Points: Determine locations within the U-Frame where stress exceeded safe operational thresholds, particularly areas prone to potential cracking or fatigue failure.

Examine Deformation Patterns: Evaluate how the structure deforms under load to ensure that any displacements remain within acceptable limits to maintain functionality.

Validate Material Performance: Analyze whether the materials selected for the U-Frame and its components could withstand the applied loads without permanent damage or failure.

Guide Design Improvements: Provide actionable insights for optimizing the design and material usage to enhance durability, safety, and cost-effectiveness.

This holistic approach ensured that the U-Frame design met stringent performance standards while aligning with the operational demands and longevity expectations of the client.

Analysis Setup

The analysis focused on multiple load cases, including:

Belt Tension: Simulated at 26688 N, generating a significant moment of 1334400 N-mm.

Force Transmission: Evaluated through the crank lever requiring a force of 3587.10 N for operation.

Boundary conditions, material properties, and operational loads were meticulously configured to replicate real-world scenarios.

Key Findings

1. Deformation Analysis

Maximum deformation observed: 2.93 mm.

Despite localized deformation, the overall structure maintained functional integrity.

2. Stress Distribution

U-Frame: Maximum principal stress reached 1032 MPa, exceeding the material’s ultimate tensile strength. However, the stress concentration was confined to the surface peel layer, indicating potential for localized cracking without immediate failure.

Pawl: Maximum stress of 858.23 MPa surpassed yield strength at contact points. The compressive nature of stress ensured no catastrophic failure.

Shaft: Surface stress exceeded yield strength but remained within acceptable limits at the core, highlighting resilience against major deformation or breakage.

3. Reaction Forces

4. Engineering Inferences

Localized Cracking: Stress concentrations in the U-Frame and Pawl necessitate enhanced surface treatments or reinforcements to mitigate fatigue risks.

Material Performance: While the materials demonstrated high resilience, exceeding yield thresholds in localized regions requires design refinements.

Optimized Design: Potential adjustments in geometry or material distribution can enhance load-bearing capacity without significant weight increases.

Graphler Technology is one of the leading product design companies in India. We have experts in FEA services and also we are specialized in CFD consulting services, structural design services, 2D to 3D Conversion services, stress analysis services etc.

0 notes

Text

Transforming Industries with Engineering Manufacturing Services and Finite Element Analysis Consultants

Engineering and manufacturing have always been at the forefront of technological advancement, driving progress in countless industries. Imagine a world where precise and innovative solutions to complex engineering challenges are readily available. This is where the synergy of engineering manufacturing services and finite element analysis consultants comes into play, revolutionizing the way products are designed, tested, and brought to market.

The Backbone of Modern Industry: Engineering Manufacturing Services

Engineering manufacturing services are essential in today's fast-paced industrial landscape. These services encompass a wide range of activities, from product design and development to prototyping, testing, and full-scale production. The role of engineering manufacturing services is pivotal in ensuring that products meet high standards of quality, reliability, and performance. The integration of advanced technologies and methodologies has elevated these services to new heights, enabling businesses to bring innovative products to market faster and more efficiently.

The Power of Finite Element Analysis in Engineering

Finite element analysis (FEA) is a powerful computational tool used by engineers to predict how a product will react to real-world forces, such as heat, vibration, and stress. By breaking down a complex structure into smaller, manageable elements, FEA allows for detailed analysis and optimization. Finite element analysis consultants play a crucial role in this process, offering their expertise to ensure accurate simulations and interpretations. This helps in identifying potential issues early in the design phase, thus reducing the need for costly revisions and enhancing product performance.

Enhancing Collaboration for Optimal Results

One of the key advantages of integrating engineering manufacturing services with finite element analysis consultants is the enhanced collaboration it fosters. This integration ensures that the transition from design to production is seamless, with potential issues being addressed at every stage. Engineers and consultants work closely to refine designs, conduct simulations, and validate results, leading to a more efficient and effective development process. Such collaboration is particularly beneficial in sectors that require high precision and reliability, resulting in superior products and reduced time to market.

The Future of Engineering and Manufacturing

The future of engineering and manufacturing is undoubtedly exciting, with continuous advancements in technology driving innovation. The integration of finite element analysis consultants with engineering manufacturing services is set to play a crucial role in this evolution. As industries become increasingly complex, the need for precise and reliable solutions will only grow. Companies that leverage these services will be better equipped to meet the challenges of tomorrow, delivering products that are not only innovative but also safe and reliable.

Conclusion

The synergy between engineering manufacturing services and finite element analysis consultants is transforming industries by providing comprehensive solutions to complex engineering challenges. This integration enhances product quality, reduces development time, and fosters innovation. For more information and to explore how these services can benefit your business, visit feamax.com. Embracing these advanced methodologies is the key to staying ahead in a rapidly evolving industrial landscape, ensuring continued success and growth.

Blog Source Url:-

0 notes

Text

fea dynamics analysis in hyderabad

structural analysis services in hyderabad vibration analysis services in hyderabad stress analysis services in hyderabad feafor failure analysis in hyderabad best feaservices in hyderabad https://3d-labs.com/fea-services/ Comprehensive FEA Services for Enhanced Engineering Design and Analysis Welcome to 3D Labs FEA Services! Unlock the full potential of your engineering designs and simulations with our comprehensive Finite Element Analysis (FEA) services. At 3D Labs, we specialize in providing accurate and efficient FEA solutions to help you optimize your product development process and achieve superior performance. Expertise and Experience: Our team of skilled engineers and analysts have extensive experience in FEA and are well-versed in the latest industry practices. With a deep understanding of engineering principles and advanced simulation techniques, we can deliver reliable and insightful results.

https://3d-labs.com/

#fea linear/nonlinear analysis in hyderabad#finite element analysis services in hyderabad#fea for aerospace in hyderabad

0 notes

Text

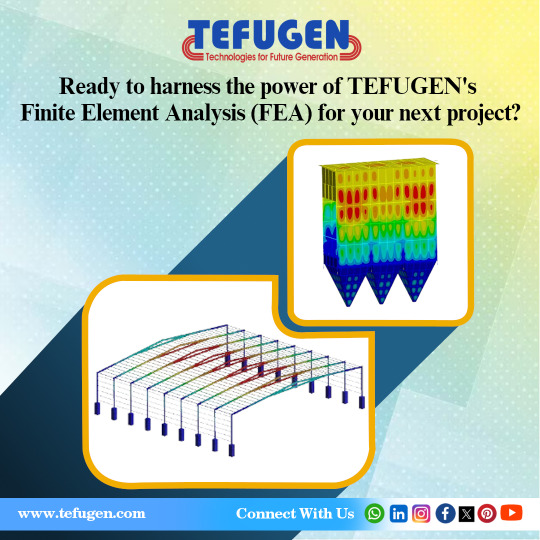

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

0 notes

Text

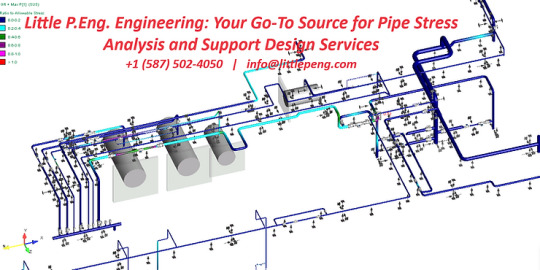

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

Importance of Correctly Evaluating FEA Results in Post Processing

FEA is useful for engineers, but it must be applied & evaluated correctly. Learn about Finite Element Analysis and post-processing.

https://trevillaengineering.com.au/post-processing-importance-of-accurately-evaluating-fea-results/

#Finite Element Analysis#Finite Element Analysis and post-processing#3d scanning reverse engineering services#solidworks drafting services#3d scanner commercial#engineering companies in australia

0 notes

Text

Modern Academic AU pt3

All this because I couldn't stop thinking about what kinds of classes Professor Raphael would teach... He's laughing up at me from hell, I just know it.

part 1 and part 2

------------------------------

Kagha (by request!) - Environmental Science. Will only teach courses about political lobbying and activism. She's also a militant vegan and active member of PETA, and won't shut up about it.

Dammon - College of Engineering. Teaches "Advanced Manufacturing Processes" and "Finite Element Analysis", and runs the machining shop. Also teaches a metal sculpture class when there's room in the Art School's budget. He's one of the faculty liaisons for several LGBTQA+ orgs on campus as well, and is completely oblivious to the fact he has a fan club (which is for the best, really)

Zevlor - Campus Security. A retired Green Beret who refuses to talk about his time in the service, he's well liked by most faculty and known to be a bit of an old school charmer. LOTS of rumors and speculation about what kind of injury got him discharged, and how he got it.

Barcus - College of Engineering. He teaches classes on Thermodynamics and Process Design & Safety. Has no idea how popular and well-liked he is by both students and staff.

Wulbren - Chemical Engineering Dep't Chair. He's brilliant, but also an asshole, and is constantly trying to weasel more grant money for his research into ethically questionable chemical compound modifications. Also makes his TAs teach all his classes for him.

Lorroakan - English Dep't Chair. Thinks he's hot shit for it but really no one else wanted the job. He makes his TAs teach all his classes AND do all his admin work, so he can spend all his time (and the department's money) on schmoozing with alumni and donors.

Blurg - Environmental Science. Isn't that great of a teacher but it's required for keeping the research grants coming in. Thankfully his passion and enthusiasm for topics like Sustainability in Agriculture make up for his shortcomings.

Omeluum - They're actually Bluurg's research partner and not technically a member of faculty, though they also act as his unofficial TA because otherwise Bluurg's course work interferes with their research timelines.

Nine-Fingers Keene (by request) - School of Business. Her classes are all advanced level and titled things like "Gaining The Competitive Edge". She also runs an entrepreneurial outreach program for young women seeking to start their own businesses.

Dame Aylin - VP of Diversity and Inclusion. She's very passionate about her job and a VERY vocal advocate for social justice issues like inclusivity, diversity, and accessibility. Completely incapable of keeping her personal life separate from her professional one, as she's a devout believer in leading by example.

Isobel - School RN. Is fiercely protective of students right to medical privacy and access to judgment free care, but is much better known on campus for being Dame Aylin's wife.

The Emperor - Board of Trustees. Outwardly just an ordinary Trustee, generally pleasant to interact with and actually rather good at rubbing elbows with students, faculty, and admin alike. There's just something off about them, enough that they've had multiple audits and inquests over the years despite nobody ever being able to find any actual signs of misconduct.

------------------------------

Sorry this set took a bit longer to figure out. A bunch of these characters were a real challenge to fit into roles that actually exist in reality, and I had to do a bit of research to find out wtf kinds of classes or departments certain fields of study even have. Ah, the things we do for the blorbos, amirite?

#bg3#baldurs gate 3#baldur's gate 3#bg3 the emperor#bg3 isobel#dame aylin#nine fingers keene#omeluum#bg3 blurg#lorroakan#wulbren bongle#barcus wroot#zevlor#dammon#kagha

28 notes

·

View notes

Text

Abaqus Assignments Made Easy: Unveiling the Top 5 Online Resources for Help

As a passionate mechanical engineering student, I have often found myself grappling with the complexities of Abaqus assignments. The world of finite element analysis can be both intriguing and overwhelming, demanding a deep understanding of the software and its applications. Thankfully, I've discovered a lifeline in the form of online Abaqus assignment help that have made my significantly more manageable. In this blog post, I'll share my top 5 online resources that have proven to be invaluable in navigating the challenges of Abaqus assignments.

Mechanical Engineering Assignment Help

The first resource on my list is a game-changer for anyone seeking Abaqus assistance. Mechanical Engineering Assignment Help provides specialized support for students tackling the intricacies of Abaqus assignments. The platform boasts a team of experienced professionals with a profound understanding of finite element analysis. What sets this resource apart is its commitment to delivering solutions tailored to individual assignment requirements. The experts at Mechanical Engineering Assignment Help have been instrumental in clarifying my doubts, providing step-by-step solutions, and enhancing my overall comprehension of Abaqus.

AssignmentPedia

AssignmentPedia is another gem in the realm of online resources for mechanical engineering students. The platform offers comprehensive assistance with Abaqus assignments, covering a wide array of topics within finite element analysis. What I appreciate most about AssignmentPedia is the accessibility of its services. The user-friendly interface makes it easy to submit assignments, receive timely responses, and track progress. The expert guidance I've received from AssignmentPedia has been instrumental in elevating the quality of my Abaqus submissions.

Visit: https://www.assignmentpedia.com/mechanical-engineering-assignment-help.html

TheAssignmentHelper

For those seeking personalized attention and tailored solutions, TheAssignmentHelper is a go-to resource. This platform takes a collaborative approach to Abaqus assignments, ensuring that students actively participate in the learning process. TheAssignmentHelper's team comprises experts who not only provide solutions but also explain the underlying principles, fostering a deeper understanding of Abaqus concepts. Through one-on-one interactions and a focus on conceptual clarity, TheAssignmentHelper has played a pivotal role in enhancing my proficiency in using Abaqus for mechanical engineering applications.

Visit: https://www.theassignmenthelper.com/mechanical-engineering-assignment-help/

EduAssignmentHelp

EduAssignmentHelp is a versatile resource catering to the diverse needs of mechanical engineering students. When it comes to Abaqus assignments, this platform stands out for its commitment to delivering accurate and well-documented solutions. The experts at EduAssignmentHelp possess a knack for simplifying complex concepts, making Abaqus more approachable for students at various skill levels. Additionally, the platform offers a range of resources, including tutorials and reference materials, making it a comprehensive hub for all things related to Abaqus in mechanical engineering.

Visit: https://www.eduassignmenthelp.com/mechanical-engineering-assignment-help

TakeMyClassCourse

For those juggling multiple responsibilities and finding it challenging to keep up with their mechanical engineering coursework, TakeMyClassCourse provides a unique solution. This platform allows students to delegate their Abaqus assignments to experts who handle the tasks on their behalf. While some may view this as a last resort, I've found it to be a practical option during particularly hectic periods. TakeMyClassCourse has a pool of experienced professionals who ensure that assignments are completed with precision and submitted on time, offering a much-needed reprieve for students with demanding schedules.

Visit: https://www.takemyclasscourse.com/take-my-mechanical-engineering-class/

In conclusion, navigating Abaqus assignments in mechanical engineering can be a daunting task, but with the right online resources, it becomes a manageable and even enjoyable journey. The platforms mentioned above have not only provided me with expert guidance but have also significantly contributed to my overall understanding of Abaqus and its applications in the field of mechanical engineering. Whether you prefer hands-on collaboration or a more streamlined assistance approach, these resources offer a spectrum of options to cater to your individual learning preferences. As you embark on your Abaqus assignments, remember that you're not alone—these online resources are here to make your journey smoother and more successful.

#Online abaqus assignment help#abaqus assignment help#Mechanical Engineering Assignment Help#Education#Online Help#study blog#Abaqus

7 notes

·

View notes

Text

EnggDNA provides expert reverse engineering services, delivering precise 3D models and detailed analyses to support design and development.

#reverse engineering services#finite element analysis services#3d prototype in mumbai#3d modeling services#3d modeling for 3d printing#finite element analysis

0 notes

Text

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Text

fea dynamics analysis in india

structural analysis services in india vibration analysis services in india stress analysis services in india FEA for failure analysis in india best FEA services in india

https://3d-labs.com/fea-services/ Comprehensive FEA Services for Enhanced Engineering Design and Analysis Welcome to 3D Labs FEA Services! Unlock the full potential of your engineering designs and simulations with our comprehensive Finite Element Analysis (FEA) services. At 3D Labs, we specialize in providing accurate and efficient FEA solutions to help you optimize your product development process and achieve superior performance. Expertise and Experience: Our team of skilled engineers and analysts have extensive experience in FEA and are well-versed in the latest industry practices. With a deep understanding of engineering principles and advanced simulation techniques, we can deliver reliable and insightful results.

#fea linear/nonlinear analysis in india#finite element analysis services in india#FEA for aerospace in india

0 notes

Text

Dynemech Anti Vibration Solutions: Pioneering vibration control solutions for a stable industrial future.

Advancing Industrial Precision: Dynemech's Revolutionary DXO Series Reshapes Manufacturing Stability

In an era where manufacturing precision determines market leadership, Dynemech Anti Vibration Solutions celebrates its 23rd year of engineering excellence by introducing the groundbreaking DXO Series. This innovative vibration control system represents a quantum leap in industrial stability management, particularly for high-precision manufacturing environments and industrial machinery.

Engineering Innovation Meets Industrial Demands

Advanced Load Management System

The DXO Series introduces a revolutionary approach to load distribution through its proprietary multi-layer DHS1 insulation technology.

This system of rubber anti vibration mounts achieves:

Dynamic load handling capacity DXO1-SP1 7,000kg to DXO4-SP1 21,000 kg

Exceptional performance as heavy duty anti vibration pads for industrial applications

Precision-Engineered Stability Features

The system's architecture incorporates:

Reinforced composite damping elements

Multi-directional stability control mechanisms

Advanced elastic response management

Integrated thermal stability components

Vibration isolators for optimal performance

Revolutionary Applications in Heavy Manufacturing

Forging Press Implementation

The DXO Series transforms forging press operations through:

Active compensation for eccentric loading conditions

Reduced foundation stress by up to 85%

Optimal performance in confined spaces with limited footprint availability

Enhanced stability for power presses and forging hammers

VMC Machine Enhancement

For Vertical Machining Centres and CNC machines, the system delivers:

Precision stability during high-speed operations (up to 15,000 RPM)

Vibration reduction achieving 95% efficiency at critical resonant frequencies

Enhanced accuracy in micro-machining operations

Sustained precision during rapid axis movements

Effective Anti-Vibration Pad for machine tools and rotating machines

Technical Specifications and Performance Metrics

Core Technology Components

Multi-Layer DHS1 Insulation System

Proprietary composite materials

Variable density layering

Engineered stress distribution patterns

Incorporation of viscous damping and spring isolators

Lateral Stability Enhancement

Multi-directional restraint system

Progressive resistance characteristics

Self-aligning capabilities

Enhanced seismic protection and shock isolation

Performance Parameters

Isolation Efficiency: Up to 99% at frequencies > 7x natural frequency

Temperature Stability: Maintained performance across industrial temperature ranges

Chemical Resistance: Compatible with common industrial fluids and environments

Load Capacity: Optimized for a wide range of industrial machinery, including generators and motors

Industry-Specific Solutions

Heavy Engineering Sector

Custom anti vibration rubber mounts for press shops and foundries

Specialized configurations for metal forming equipment and textile machines

Adaptive systems for varying load conditions

Enhanced stability for high-impact operations like hammers and compressors

Precision Manufacturing

Ultra-stable platforms for measuring equipment

High-frequency isolation for precision machine tools

Custom solutions for clean room environments

Integrated monitoring capabilities for lathe machines and other precision equipment

Research and Development Excellence

Dynemech's commitment to innovation is evidenced by:

Continuous material research programs

Advanced finite element analysis implementation

Real-time performance monitoring systems

Custom solution development capabilities for specific antivibration needs

Installation and Support Services

Professional installation teams

Comprehensive site analysis

Custom foundation design support considering structural safety

Ongoing performance monitoring

Preventive maintenance programs

Emergency support services

Expert advice on foundation requirements for optimal performance of anti vibration mounts for machines

Quality Assurance and Certification

ISO 9001:2015 certified manufacturing processes

Individual load testing of all units

Comprehensive performance documentation

International compliance standards

Extended warranty programs

Experience With Dynemech Team in Imtex 2025

Live Demonstrations

Visit us at IMTEX 2025 in Bangalore to experience:

Real-time performance monitoring displays

Interactive load testing demonstrations

Comparative analysis presentations

Technical consultation sessions on anti vibration mounting pads

Location Details

Hall: 3A

Stall: A128

One-on-one consultation opportunities

Future-Ready Solutions

Dynemech's DXO Series represents more than just current technological excellence; it embodies our vision for the future of industrial stability. Our ongoing development programs focus on:

Industry 4.0 integration capabilities

Smart monitoring systems

Predictive maintenance features

Sustainable manufacturing practices

Vibration-reducing attachments for extended tool life and reduced machine operator fatigue

The DXO Series stands as a testament to Dynemech's 23 years of engineering excellence and unwavering commitment to manufacturing precision.

As we showcase this revolutionary vibration control system at IMTEX 2025, we invite industry professionals to experience firsthand how our advanced vibration damping solutions can transform their manufacturing operations.

For detailed technical specifications or to schedule a consultation on our anti vibration rubber pads for heavy machinery, visit our stall at IMTEX 2025 or contact our engineering team.

#IMTEX2025 #DynemechSolutions #VibrationControl #IndustrialAutomation #ManufacturingExcellence #MadeInIndia #IndustryInnovation #IMTEX2025 #DynemechSolutions #VibrationControl #IndustrialAutomation #ManufacturingExcellence #MadeInIndia #IndustryInnovation #HeavyMachinery #IndustrialEquipment #ManufacturingTechnology #FactoryAutomation #SmartManufacturing #IndustryTech #dynemech #antivibrationmount.

To learn more about our products: https://www.vibrationmountsindia.com/products/

Dynemech Systems Pvt. Ltd.

Contact Us: +91-9810760131; +91-9911145131

Email: [email protected]

vibrationmountsindia.com

1 note

·

View note

Text

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

fea engineering services

Finite Element Analysis (FEA) engineering services involve advanced computational techniques to simulate, analyze, and optimize product designs under various conditions. These services help identify structural, thermal, and mechanical performance issues, ensuring reliability and safety.

visit at: https://www.servotechinc.com/cadfea-design-and-a0lysis

0 notes