#Abaqus

Explore tagged Tumblr posts

Text

Abaqus Assignments Made Easy: Unveiling the Top 5 Online Resources for Help

As a passionate mechanical engineering student, I have often found myself grappling with the complexities of Abaqus assignments. The world of finite element analysis can be both intriguing and overwhelming, demanding a deep understanding of the software and its applications. Thankfully, I've discovered a lifeline in the form of online Abaqus assignment help that have made my significantly more manageable. In this blog post, I'll share my top 5 online resources that have proven to be invaluable in navigating the challenges of Abaqus assignments.

Mechanical Engineering Assignment Help

The first resource on my list is a game-changer for anyone seeking Abaqus assistance. Mechanical Engineering Assignment Help provides specialized support for students tackling the intricacies of Abaqus assignments. The platform boasts a team of experienced professionals with a profound understanding of finite element analysis. What sets this resource apart is its commitment to delivering solutions tailored to individual assignment requirements. The experts at Mechanical Engineering Assignment Help have been instrumental in clarifying my doubts, providing step-by-step solutions, and enhancing my overall comprehension of Abaqus.

AssignmentPedia

AssignmentPedia is another gem in the realm of online resources for mechanical engineering students. The platform offers comprehensive assistance with Abaqus assignments, covering a wide array of topics within finite element analysis. What I appreciate most about AssignmentPedia is the accessibility of its services. The user-friendly interface makes it easy to submit assignments, receive timely responses, and track progress. The expert guidance I've received from AssignmentPedia has been instrumental in elevating the quality of my Abaqus submissions.

Visit: https://www.assignmentpedia.com/mechanical-engineering-assignment-help.html

TheAssignmentHelper

For those seeking personalized attention and tailored solutions, TheAssignmentHelper is a go-to resource. This platform takes a collaborative approach to Abaqus assignments, ensuring that students actively participate in the learning process. TheAssignmentHelper's team comprises experts who not only provide solutions but also explain the underlying principles, fostering a deeper understanding of Abaqus concepts. Through one-on-one interactions and a focus on conceptual clarity, TheAssignmentHelper has played a pivotal role in enhancing my proficiency in using Abaqus for mechanical engineering applications.

Visit: https://www.theassignmenthelper.com/mechanical-engineering-assignment-help/

EduAssignmentHelp

EduAssignmentHelp is a versatile resource catering to the diverse needs of mechanical engineering students. When it comes to Abaqus assignments, this platform stands out for its commitment to delivering accurate and well-documented solutions. The experts at EduAssignmentHelp possess a knack for simplifying complex concepts, making Abaqus more approachable for students at various skill levels. Additionally, the platform offers a range of resources, including tutorials and reference materials, making it a comprehensive hub for all things related to Abaqus in mechanical engineering.

Visit: https://www.eduassignmenthelp.com/mechanical-engineering-assignment-help

TakeMyClassCourse

For those juggling multiple responsibilities and finding it challenging to keep up with their mechanical engineering coursework, TakeMyClassCourse provides a unique solution. This platform allows students to delegate their Abaqus assignments to experts who handle the tasks on their behalf. While some may view this as a last resort, I've found it to be a practical option during particularly hectic periods. TakeMyClassCourse has a pool of experienced professionals who ensure that assignments are completed with precision and submitted on time, offering a much-needed reprieve for students with demanding schedules.

Visit: https://www.takemyclasscourse.com/take-my-mechanical-engineering-class/

In conclusion, navigating Abaqus assignments in mechanical engineering can be a daunting task, but with the right online resources, it becomes a manageable and even enjoyable journey. The platforms mentioned above have not only provided me with expert guidance but have also significantly contributed to my overall understanding of Abaqus and its applications in the field of mechanical engineering. Whether you prefer hands-on collaboration or a more streamlined assistance approach, these resources offer a spectrum of options to cater to your individual learning preferences. As you embark on your Abaqus assignments, remember that you're not alone—these online resources are here to make your journey smoother and more successful.

#Online abaqus assignment help#abaqus assignment help#Mechanical Engineering Assignment Help#Education#Online Help#study blog#Abaqus

7 notes

·

View notes

Text

Learn about 5 websites that offer Abaqus Online courses and Abaqus Online training to improve your simulation skills.

1 note

·

View note

Text

Efficient MESH technique for complex geometry in ABAQUS

Efficient mesh is important to produce better results given the limited resources. Abaqus has been a favourite finite element analysis software for researchers in top engineering and research institute like MIT, IITs, Caltech, etc. It is best suited for non-linear analysis and gives huge control on the procedure to users. This video explains a simple technique to mesh a part so that memory and…

View On WordPress

0 notes

Text

Little P.Eng. for Discrete Element Modeling (DEM) Services

In a world driven by technological advancements, the ability to understand granular systems at a particle level has never been more essential. This precise understanding has been made possible through a computational technique known as Discrete Element Modeling (DEM). While many entities offer DEM services, Little P.Eng. has carved a niche for itself as a front-runner in this specialized domain.

Understanding Discrete Element Modeling (DEM)

Before diving into the specifics of Little P.Eng.'s offerings, it's essential to demystify DEM:

DEM is Calculation-based Modeling: At the heart of DEM is mathematics. This method uses precise calculations to predict the behavior of individual particles within a system. By doing so, it can accurately predict the interactions and outcomes when these particles are subjected to various conditions.

DEM Allows for Visualizing Results: One of the standout features of DEM is its ability to provide visual results. Users can observe:

Particle Velocity: Understand the speed and direction of individual particles.

Forces: This includes shear (parallel to the surface) and normal (perpendicular to the surface) forces that the particles experience.

Moments: This refers to the bending and torsional (twisting) moments affecting the particles.

Acceleration and Material Scatter: Track how quickly particles move and the variations in their dispersion patterns.

DEM: More than just Flow Simulation: While DEM is instrumental in predicting the flow of bulk materials, its capabilities extend beyond this. It plays a crucial role in understanding:

Wear Patterns: Predict how equipment will fare over time by simulating particle interaction and the resultant wear.

Mixing: Understand how different particles mix, which is vital in industries like pharmaceuticals and food production.

Center Loading: This refers to the loading pattern where materials concentrate towards the center, crucial in industries like construction.

DEM Programs: The Power Behind the Predictions

Any tool is only as good as the software powering it. When it comes to DEM, numerous programs can be used to perform this intricate modeling:

EDEM: A market leader, renowned for its comprehensive modeling capabilities.

PFC (Particle Flow Code): Known for its versatility, offering both 2D and 3D simulations.

LIGGGHTS: An open-source powerhouse that's both versatile and widely accepted.

Rocky DEM: Its strength lies in simulating realistic particle shapes, crucial for specific industries.

Yade: An open-source tool prized for its extensibility.

Abaqus: A multi-faceted software that, beyond its renowned finite element analysis, offers DEM capabilities.

Ansys Rocky: Building on the Ansys platform's strengths, it focuses on granular flow simulations.

Barracuda Virtual Reactor: Ideal for energy sector applications, especially particle reactions.

Also there are some open sources:

Kratos Multiphysics is developed by CIMNE (International Center for Numerical Methods in Engineering) in Barcelona and covers all kinds of numerical simulations, including DEM/PEM and DEM/PEFM-FEM coupling.

YadeDEM is a DEM package that is specifically designed for geomechanics.

Woo is a fork of YadeDEM with a strong focus on parallel computing and portability.

LAMMPS is a general purpose DEM/PEM.

LIGGGHTS is a general purpose DEM software that includes heat transfer simulations and is based on LAMMPS.

ESyS Particle is developed at the University of Queensland, Australia, with a focus on geoscientic/geotechnical applications.

GranOO is a general purpose DEM.

MercuryDPM is a general purpose Discrete Particle Method (DPM) software.

Little P.Eng.: Setting the Gold Standard in DEM Services

In the expansive realm of DEM, Little P.Eng. shines brightly, and here's why:

Mastery Over Multiple Platforms: Their team is proficient in a diverse array of DEM programs, ensuring they always have the right tool for the job.

A Client-centric Approach: They tailor their solutions, ensuring that each client's unique needs and challenges are addressed.

In-depth Analysis: Beyond merely running simulations, they delve deep, integrating real-world measurements to enhance simulation accuracy.

Applications and Implications of DEM in Industries

The true power of DEM, as harnessed by Little P.Eng., lies in its diverse applications:

Equipment Design: Through DEM, companies can design equipment that's optimized for longevity and efficiency.

Optimizing Production Lines: By understanding how granular materials behave, industries can fine-tune their production lines for maximum efficiency.

Safety Protocols: Predicting particle behavior, especially in industries dealing with hazardous materials, can lead to enhanced safety protocols.

Challenges in DEM and How Little P.Eng. Overcomes Them

DEM, while powerful, isn't without its challenges. The accuracy of simulations is heavily reliant on input parameters. Additionally, the computational demands for large-scale simulations are immense.

Little P.Eng. rises above these challenges through a blend of rigorous experimental data collection and a deep understanding of the DEM software landscape. Their iterative approach ensures that simulations are continually refined for better accuracy.

Conclusion

Discrete Element Modeling (DEM) is transforming our understanding of granular systems. With its capability to provide in-depth insights at a particle level, its applications span a wide array of industries.

In this domain, Little P.Eng. emerges not just as a service provider, but as a trusted partner, guiding businesses towards better efficiency, safety, and innovation. As we venture further into an era where the micro informs the macro, the services of entities like Little P.Eng., underpinned by the power of DEM, will undoubtedly be invaluable.

Read more:

Little P.Eng. for Discrete Element Modeling (DEM) Services: Unveiling the Power of Simulation

The Importance of Discrete Element Modeling (DEM) Studies and What Problems It Can Solve

Tags:

Little P.Eng.

Discrete Element Modeling

Mixing

Granular systems

Particle behavior

EDEM

PFC (Particle Flow Code)

LIGGGHTS

Rocky DEM

Yade

Abaqus

Ansys Rocky

Barracuda Virtual Reactor

Calculation-based modeling

Particle velocity

Shear forces

Normal forces

Bending moments

Torsional moments

Acceleration

Material scatter

Flow simulation

Wear patterns

Center loading

Equipment design

Production line optimization

Safety protocols

Computational simulations

Input parameters

Simulation accuracy

Bulk Material Handling & Processing

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng.#Discrete Element Modeling#Mixing#Granular systems#Particle behavior#EDEM#PFC (Particle Flow Code)#LIGGGHTS#Rocky DEM#Yade#Abaqus#Ansys Rocky#Barracuda Virtual Reactor#Calculation-based modeling#Particle velocity#Shear forces#Normal forces#Bending moments#Torsional moments#Acceleration#Material scatter#Flow simulation#Wear patterns#Center loading#Equipment design#Production line optimization#Safety protocols#Computational simulations#Input parameters#Simulation accuracy

0 notes

Text

ABAQUS Software – Finite Element Analysis - PIGSO LEARNING

Abaqus is a complete Abaqus environment that provides an interface for creating, monitoring, and evaluating results from Abaqus/Standard and Abaqus/Explicit simulations. Abaqus/CAE is further divided into modules, where each module defines the aspect of the modelling process like defining the geometry, defining material properties, and generating a mesh.

ABAQUS - Simulation Analysis Software

CAE is a common graphical user interface that is used for modelling, solving, and post-processing a finite element problem.

The steps involved in the construction of a model are explained below-

ABAQUS Solver

ABAQUS Standard is an implicit solver used to solve nonlinear problems.

ABAQUS Explicit used for solving dynamics/wave propagation problems.

Part Module

Part Module Is the first step towards creating a model as parts are the building blocks of an Abaqus/CAE model. Part can be created in the following ways: Create the part using the tools available in the Part module. Import the part from a file stored in a third-party format. Import the part (mesh) from an output database. Import a meshed part from an input file.

You use the Part module to create, edit, and manage the parts in the current model. The Part module allows you to do the following:

Property Module

You can define the properties of a part or part region by creating a section and assigning it to the part. In most of the cases, sections refer to the materials that you have created. A material definition specifies all the property data relevant to a material. You can specify a material definition by including a set of material behaviours, and you supply the property data with each material behaviour you include. Each material that you create is assigned its name and it is independent of any particular section. Abaqus/CAE assigns the properties of a material to a region/section of a part when you assign a section referring to that material that you have created to the region.

Assembly

You can use the Assembly module to create and assemble the assembly. A model contains one main assembly, which is composed of instances of different parts from the model as well as instances of other models. An instance maintains its association with the original part/model. If the geometry of a part changes, Abaqus will automatically update all instances of the part and changes will be reflected in the model. You can’t edit the geometry of an instance directly. Your main model can contain many parts and model subassemblies, and a part or model can be instanced many times with the main model assembly; however, a model contains only one main assembly. Loads/boundary conditions are all applied to the complete assembly.

Even if your model consists of only a single part, you have to create an assembly that consists of just a single instance of that part. A part instance can be a representation of the original part. You can create either independent or dependent part instances. An independent instance is effectively a clone of the part. A dependent instance is only a pointer to the part or virtual topology. You cannot mesh a dependent instance.

Step

Within a model, you can define a sequence of one or more analysis steps. The step sequence provides a convenient way to capture changes in the loading and boundary conditions of the model, changes in the way parts of the model interact with each other and any other changes that may occur in the model during the analysis.

Interaction

Interactions are step-dependent objects, which means that when you define interactions, you must indicate in which steps of analysis they are active. The Set and Surface toolsets in the Interaction module allow you to define and name the model to which you would like interactions and constraints to be applied. Abaqus does not recognize the mechanical contact between different part instances of an assembly unless the contact is specified in the Interaction module.

Load

Load is an independent module as Abaqus cannot apply load automatically; you have to select the load type and position on which load is to be applied. You can apply load to any node/Surface. You can use the Load module to define and manage the following prescribed conditions:

Loads

Boundary conditions

You can apply different types of loading

Concentrated force

Moment

General and shear surface traction

General shell edge load

Inertia relief

Current density

Boundary Conditions

Boundary Conditions is also an important module to check the specific point interaction. As Abaqus cannot apply real-life constraints in the model. So you have to manually specify the predefined condition to be applied to a model to make analysis more effective and accurate

Mesh

The Mesh module allows you to generate meshes on parts and assemblies created within Abaqus. Various levels of automation and control are available so that you can create a mesh that meets the requirements of the analysis model. As with creating the parts and assemblies, the process of assigning mesh attributes to the model such as seeds, mesh techniques, and element types is feature-based.

The Mesh module provides the following features:

Tools for prescribing mesh density and global levels.

Model colouring indicates the meshing technique is successful and assigned to each region in the model.

A variety of mesh controls, such as:

Element shape

Meshing technique

Meshing algorithm

Adaptive remeshing rule

Optimization

Optimization Is a process that generates results and analysis. You must combine the optimization results into an individual output file to view the results of the optimization in the Visualisation module (Dassault).

Job

Job In the job module we create a job Check job from the job manager by “Data Check” If no error is reported Submit the job Check results in the Visualization Module

Visualisation

Abaqus Training

You find the best training platform to learn Abaqus Simulation Software Online by the PIGSO LEARNING company. You can get trained from the very basics to advanced levels of simulation analysis for different types of industrial categories like Structural, Mechanical, Geotech, Aerospace and Automobile engineering. Abaqus Training online course helps you to explore the software and get trained. Its help in your research work and career boost.

0 notes

Text

Laminated composite shells: buckling of a cylindrical panel with a circular hole with Abaqus

This example illustrates modeling a thin, laminated composite shell in the presence of buckling. Animation-1. Geometry and model The structure analyzed is shown in Figure 1 and was originally studied experimentally by Knight and Starnes (1984). The test specimen is a cylindrical panel with a 355.6 mm (14 in) square platform and a 381 mm (15 in) radius of curvature, so that the panel covers a…

View On WordPress

0 notes

Text

#Marcy...........................#what did they do to you......................#adventure time#adventure time art#this is art#yes it counts#adventure time fanart#adventure time marceline#marceline abadeer#marceline the vampire queen#Marceline#marceline adventure time#Marceline Abaqueer

16 notes

·

View notes

Text

my stomach is failing me miserably and i have apparently completely forgotten how to work both solidworks and abaqus and i cant go home and get something to eat for another 3 and a half hours. but more like 4. truly a sick and twisted world we live in

10 notes

·

View notes

Text

wow i would sure not be having any serious issues finding cracks for current versions of comsol, abaqus and ansys right now if all my eastern european male rat internet friends weren't all killing each other right now

12 notes

·

View notes

Text

CP, peintures extérieures des fenêtres manquantes et d'autres babioles

ça y est, le CP de plafond est placé et à une vitesse impressionnante - merci Fred !

Je peins à tout va dés que j'ai le temps les plaques de CP - mais aussi les parties extérieures des fenêtres qui n'avaient pas été faites. Et certaines déjà peintes ont eu leur petite retouche car les pigeons du hangar ne les avaient pas loupées, malgré les bâches qui les entouraient (grrrr)

Une belle surprise : j'ai découvert que le chassis fixe aluminium que j'avais acheté à une ressourcerie est en fait un ouvrant oscillant - ô joie ! Nous le poserons bientôt, comme les autres fenêtres, d'ailleurs :) J'ai hâte !

Un premier liteau a été posé contre le mur Olympe au sol. D'autres vont suivre à différentes hauteurs - pour accueillir les autres plaques de CP.

J'ai repris les gaines qui étaient tombées malgré les embases et les ai allouées pour certaines à des objectifs différents d'alimentation.

D'ailleurs, à propos de gaine, celle du ventilateur a été placée dans le plafond. Pour avoir dés que c'est possible de quoi travailler avec de l'air (la châleur de la Drôme cuit bien, depuis quelques jours !)

J'ai vissé un petit extincteur à l'entrée de la tiny - petit geste de sécurité mais après tout, c'est une maison en bois !

Je fais aujourd'hui la commande de métrage électrique en différentes sections. C'est du fil souple de grosseur différente en fonction des appareils alimentés. Une abaque pour le 12V permet de faire l'évaluation de la section en fonction de la distance avec le tableau électrique.

Sur ce, je reviens à ma commande et à mes mesures - à bientôt !

2 notes

·

View notes

Text

Servotech’s FEA CAD Expertise for Superior Engineering

In today’s fast-paced world of engineering, precision, accuracy, and efficiency are the keys to developing superior products. The integration of advanced simulation and design tools into the product development cycle is paramount to staying ahead of the competition. One such powerful tool is Finite Element Analysis (FEA), an essential part of Computer-Aided Design (CAD) that helps engineers predict how products will behave under various conditions. Servotech, a leader in the field of engineering solutions, stands out for its exceptional FEA CAD expertise, ensuring superior engineering outcomes. This article will explore how Servotech’s proficiency in FEA and CAD is revolutionizing the engineering industry, enhancing product design, and delivering innovative solutions.

What is FEA and CAD?

Before diving into Servotech’s FEA CAD expertise, it is important to understand what FEA and CAD are and how they contribute to superior engineering.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a computational technique used to predict how a product or material will react to forces, temperature changes, and other physical effects. It breaks down complex structures into smaller, simpler parts called "elements." These elements are analyzed for various physical attributes, such as stress, strain, and deformation, to understand how the entire structure will behave. FEA is widely used in industries such as aerospace, automotive, civil engineering, and more, to optimize designs and avoid costly failures.

Computer-Aided Design (CAD)

Computer-Aided Design (CAD) involves the use of software to create precise drawings and models of physical objects. CAD allows engineers to visualize and modify their designs digitally before manufacturing. CAD software enables engineers to simulate how products will interact with their environment, ensuring that the design meets all functional and aesthetic requirements. FEA is often integrated into CAD systems, allowing engineers to run simulations directly within their design environment, making the process more efficient and streamlined.

Servotech's Approach to FEA and CAD Integration

Servotech’s commitment to excellence is reflected in its seamless integration of FEA into CAD workflows. This fusion enhances design processes by providing a virtual testing ground for products, reducing the risk of errors and improving the overall design quality.

Advanced Simulation Tools

Servotech utilizes the latest FEA and CAD software tools to create highly accurate simulations. These tools enable the engineers to model complex geometries and perform simulations with a high degree of precision. The use of advanced tools like ANSYS, Abaqus, and Autodesk Inventor, coupled with Servotech’s expertise, allows for more detailed simulations of real-world conditions, which is critical for ensuring that designs meet all requirements for functionality and safety.

Multidisciplinary Expertise

Servotech’s team comprises multidisciplinary engineers with extensive experience across various industries. This broad expertise allows Servotech to approach engineering challenges from multiple perspectives. Whether the challenge lies in the automotive, aerospace, or industrial equipment sectors, Servotech’s engineers leverage FEA and CAD to ensure that designs are not only structurally sound but also optimized for performance, efficiency, and cost-effectiveness.

Customized Solutions

One of the key benefits of Servotech’s approach is its ability to provide tailored solutions for each client. Servotech understands that every project is unique, and therefore, they offer customized FEA and CAD simulations that cater to the specific needs of each client. By collaborating closely with clients, Servotech ensures that every detail is accounted for, delivering engineering solutions that meet the highest standards of quality and performance.

Benefits of Servotech’s FEA CAD Expertise

1. Enhanced Design Accuracy

The integration of FEA into the CAD workflow significantly improves design accuracy. Engineers can visualize how their products will behave under real-world conditions, allowing them to make adjustments before manufacturing. This reduces the likelihood of costly design errors and ensures that the final product meets or exceeds performance expectations.

2. Reduced Development Time

FEA and CAD integration accelerates the product development process by allowing engineers to test multiple design iterations in a virtual environment. Instead of building physical prototypes for every iteration, engineers can simulate the effects of different design choices and optimize the product based on the results. This leads to faster decision-making and reduced time-to-market.

3. Cost Savings

By utilizing FEA simulations, Servotech helps clients reduce development costs. Virtual testing allows for early identification of potential issues, which means that costly design modifications during later stages of production can be avoided. Additionally, optimizing designs through FEA can lead to more efficient use of materials, reducing manufacturing costs and waste.

4. Improved Product Performance

FEA helps engineers optimize product designs for maximum performance. By analyzing factors like stress, strain, vibration, and thermal effects, engineers can fine-tune their designs to ensure that products perform optimally under all expected conditions. Whether it is a high-performance automotive component or a critical aerospace part, FEA ensures that products meet the highest standards of reliability and durability.

5. Risk Mitigation

Through the use of FEA, Servotech can identify potential failure points early in the design process. This enables engineers to take corrective actions before the product reaches the manufacturing stage, significantly reducing the risk of product failures. Early detection of design flaws helps prevent costly recalls, reputational damage, and potential safety hazards.

6. Seamless Collaboration

FEA CAD integration facilitates better collaboration between design, engineering, and manufacturing teams. Engineers can share 3D models, simulations, and results with stakeholders in real-time, ensuring everyone is on the same page. This leads to smoother workflows, faster decision-making, and greater overall efficiency.

Servotech's FEA CAD Expertise in Practice

Servotech’s FEA CAD expertise has been proven across a wide range of industries, with notable examples of successful implementations.

Automotive Industry

In the automotive industry, Servotech’s FEA and CAD expertise plays a crucial role in designing high-performance components that must meet strict safety and durability standards. By utilizing FEA simulations, Servotech helps automotive manufacturers optimize parts like chassis, suspension systems, and body structures to withstand extreme conditions while ensuring minimal weight and maximum fuel efficiency.

Aerospace Sector

For the aerospace industry, where precision and safety are paramount, Servotech’s FEA CAD solutions are invaluable. The ability to simulate stress, fatigue, and thermal effects on critical aerospace components allows engineers to design parts that meet strict regulatory standards while also optimizing for weight and performance.

Industrial Equipment

Servotech also works with manufacturers of industrial equipment, helping them optimize designs for everything from pumps and turbines to heavy machinery. FEA simulations allow for detailed analysis of load distribution and material strength, ensuring that the final product is both robust and cost-effective.

Conclusion

Servotech’s FEA CAD expertise is a game-changer for engineers looking to optimize their product designs. By integrating FEA simulations into the CAD workflow, Servotech helps businesses reduce development time, minimize costs, and improve product performance. Their multidisciplinary expertise, advanced simulation tools, and customized solutions ensure that clients receive high-quality engineering outcomes that exceed expectations. As the demand for more advanced and reliable products grows, Servotech remains at the forefront of innovation, driving superior engineering solutions through the power of FEA and CAD integration.

0 notes

Text

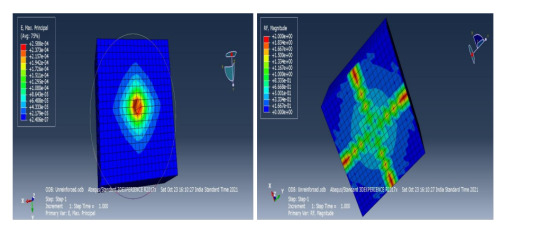

Advanced Finite Element Simulation of Pullout Test on Asphalt-Geotextile/geogrid-Asphalt Layer using Abaqus

What is Pullout Test? The pullout test is a common test used in civil engineering to determine the bond strength between two materials, typically between a soil or concrete substrate and a reinforcement material such as a geotextile or a reinforcing bar. In this test, a specimen is inserted into a hole in the substrate and a pulling force is applied to the reinforcement material until it fails…

View On WordPress

#abaqus#asphalt#civil engineering#geogrid#geotextile#materials testing#pavement#pullout test#viscoelasticity

0 notes

Text

Buy Autocad Online

ProConcept 3D is a premier software sales and support company committed to delivering excellence. Gold partner for Autodesk and authorized reseller and support provider for Primavera, Adobe, V-Ray, Sketchup, Rhino, Corel, Ansys and Abaqus.

Click here:- https://www.proconcept3d.com/

At ProConcept 3D, we empower creativity and innovation by providing industry-leading software solutions tailored to your needs. As an authorized reseller and support provider, we specialize in Autodesk, Adobe, Primavera, V-Ray, and Rhino 3D, catering to professionals and organizations across diverse industries.

ProConcept 3D is a premier software sales and support company committed to delivering excellence. As a Gold partner for Autodesk and an authorized reseller and support provider for Primavera, Adobe, V-Ray, SketchUp, Rhino, Corel, Ansys, and Abaqus with years of expertise, we assist architects, designers, engineers, and creative professionals in unlocking their full potential through cutting-edge tools and personalized guidance. Our team is dedicated to ensuring you get the most out of your software investment with seamless onboarding, troubleshooting, and ongoing support.

Autocad, Autodesk, Revit, Architecture and Engineering Collection, Civil 3D, 3Ds Max,��Robot Structure, Bim Collaborate Pro, Maya, Autodesk Plant 3D, Vault, Product design and Manufacture Collection, Primavera, Adobe, Acrobat, Photoshop, Illustrator, InDesign, AfterEffect, V-Ray, Sktechup, Rhino, Corel, Ansys, Abaqus

Expertise Training Center (ETC)

Established in February 2005 by Naji Sfeir, Expertise Training Center (ETC) is an authorized training center for Autodesk and Rhino, offering specialized courses in various fields, including Building Design, Project Management, and Coding. ETC provides comprehensive training in Autodesk software such as Revit, 3DS Max, AutoCAD, Civil 3D, and Navisworks, catering to architects, engineers, and designers seeking to enhance their skills in engineering and presentation software.

With a focus on engineering and presentation software from Autodesk, CSI, Adobe, Rhino, V-Ray, and Primavera, ETC serves a diverse clientele, including large corporations and university students. Their flexible schedule includes evening, morning, and weekend classes, offered live interactively online, face-to-face at clients' premises, or at their training center in Beirut, Lebanon.

0 notes

Text

Assessing Adherent Cell Mechanical Behavior by 6 and 12-Strut Tensegrity Model

Assessing Adherent Cell Mechanical Behavior by 6 and 12-Strut Tensegrity Model in Biomedical Journal of Scientific & Technical Research

The cytoskeleton is the main cellular component responsible for bearing mechanical loads and supporting the cell shape in the adherent cells. Number of structures have been proposed to investigate the behavior of the cytoskeleton which most of them were based on stretch elements which only stand against tension forces. actin filaments are rope-shaped filaments that only tolerate tensile forces. However, in biological systems, microtubules have a vital role in the behavior of living cells. Microtubules, which are tube-shaped filaments, have evolved to withstand compressive forces. In this way, the need to have a structure that has tensile and compression elements together for the better approximation of cell behavior is necessary. Hence, tensegrity structures were considered as a tool for modelling and understanding the cytoskeleton behavior. Multiple experiments have proven that the tensegrity model is an appropriate structure in approximating the cytoskeleton behavior of non-suspension cells. In this study, we suggested two different tensegrity structures to examine the effect of the complexities of these structures in response to mechanical stimulus. Both 6 and 12-strut structures were simulated and subjected to theoretical atomic force microscopy loading through the software ABAQUS. Next, the relation between structure reaction forces and the amount of deflection, and also cell response to the stiffness change of the substrate were investigated. After comparing behavior of these two structures, it was concluded that it is more appropriate to apply a tensegrity model with fewer struts in stiffer cells’ behavior. The structure behavior in response to changes in substrate stiffness revealed that six-strut tensegrity is more sensitive to higher substrates stiffness.

For more articles in Journals on Biomedical Sciences click here bjstr

Follow on Twitter : https://twitter.com/Biomedres01 Follow on Blogger : https://biomedres01.blogspot.com/ Like Our Pins On : https://www.pinterest.com/biomedres/

#journals on biomedical imaging#journals on biomedical engineering#biomedical open access journals#open access clinical and medical journal#medical and medicinal journal

0 notes

Text

Explore Abaqus Geotechnical Engineering Course | Join Now!!

Looking for the Geotechnical Engineering Training Course. Join our Abaqus Geotechnical Engineering program. You will learn about how you can analyze soil models in geotechnical software. Enroll Now!

1 note

·

View note

Text

🚀 Master Geotechnical Analysis with Abaqus – Enroll Now!

Enhance your geotechnical modeling skills with industry-focused Abaqus training. Learn to tackle real-world engineering challenges through hands-on simulations and expert guidance.

🔹 Key Highlights: ✔️ Fundamentals & Advanced Geotechnical Analysis ✔️ 30+ Hours of Video Lessons ✔️ 5 Practical Assignments ✔️ Live Q&A Sessions ✔️ 1-Year Access to Course Materials ✔️ Industry-Recognized Certification ✔️ Networking with Experts

📢 Want a Sneak Peek? Watch our FREE Demo Class on our website! 🔗 https://pigsolearning.com/abaqus-geotechnical-analysis/?utm_source=Facebook+&utm_campaign=Raja+Yadav

📅 Batch Starts: 11th February 🎯 Secure Your Spot Today!

0 notes