#fea analysis services

Explore tagged Tumblr posts

Text

0 notes

Text

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

0 notes

Text

Do you want to know how structures and components behave in different physical conditions? Try FEA Analysis UAE! We, Renewtherm Engineering, are one of the leading companies that offer excellent FEA & CFD services. For more information, you can visit our website https://www.renewtherm.com/ or call us at +971-506180620 / +91-9884791650

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Text

fea dynamics analysis in india

fea dynamics analysis in india finite element analysis services in india FEA for aerospace in india structural analysis services in india vibration analysis services in india stress analysis services in india FEA for failure analysis in india best FEA services in india

3d-labs is an engineering consulting firm that provides full analysis using state-of-the-art FEA , CFD, and CAD/CAE tools. We help our clients reduce product development costs, decrease time-to-market , and improve product quality.9843511204 We, offer not only reliable analysis results but also insight solutions to clients' projects….. We are from all sectors of the industry and have excellent analytical skills and knowledge. We have co-operation with universities, national laboratories, and other engineering firms, which enable us to address and solve clients' questions and problems simply and quickly. We solve a broad range of engineering analysis problems based on FEA techniques including stress analysis, fluid dynamics, kinematics, heat transfer, dynamics and vibration (seismic, harmonic), structural dynamics and electromagnetics. etc.

0 notes

Text

How Engineers Use FEA Analysis To Improve Project’s Quality?

FEA analysis services conducted by engineers in Brisbane or anywhere else help to improve the quality of the project.

0 notes

Text

Best Product Design Services | 3D CAD Modeling and Prototyping Solutions

Are you looking for the best product design services that bring your ideas to life? At Shalin Designs, we specialize in product innovation, CAD modeling, and engineering design, helping businesses create market-ready products with precision and efficiency.

Why Choose Our Product Design Services?

✔ Concept-to-Prototype Development – Transform ideas into functional prototypes with 3D CAD modeling and engineering analysis.✔ Custom Product Design Solutions – Whether it's industrial design, mechanical components, or consumer goods, we tailor designs to your unique requirements.✔ High-Quality CAD Drafting – Using SolidWorks, AutoCAD, and Fusion 360, we deliver highly detailed 3D models and technical drawings.✔ Cost-Effective & Scalable Design – Optimize material selection, manufacturability, and cost-efficiency to reduce production expenses.✔ Reverse Engineering & Design Improvements – Enhance existing products with modernized designs and performance upgrades.

Industries We Serve

🔹 Automotive & Aerospace🔹 Consumer Electronics & Home Appliances🔹 Medical Device Design🔹 Industrial Machinery & Equipment🔹 Furniture & Interior Design

Our Expertise in CAD Product Design

🔹 3D Product Modeling & Rendering – Realistic visualizations for prototyping.🔹 DFM (Design for Manufacturing) Analysis – Ensuring manufacturability and material efficiency.🔹 Sheet Metal & Plastic Design – Specialized in lightweight, durable product designs.🔹 Finite Element Analysis (FEA) – Structural analysis for product performance.

Why Product Design Matters?

Having a well-designed product can significantly impact market success. With our CAD product design and 3D modeling services, you can enhance usability, aesthetics, and functionality, ensuring a seamless manufacturing process.

🚀 Get in Touch Today! Whether you're a startup or an established brand, Shalin Designs is your trusted partner for innovative product design solutions.

📩 Contact us now! Visit Shalin Designs – Product Design Services for a free consultation.

#Product design services#3D CAD modeling services'#Prototype development '#Industrial product design#Custom product design solutions#Mechanical product design#Engineering design service

0 notes

Text

ESPL: Leading Engineering Consultancy & Automotive Solutions Provider in India

Equilibrium Solutions Pvt. Ltd. (ESPL) are a trusted engineering consultancy in Pune, India. We offers expert CAE services, CFD simulation, FEA analysis, thermal management, and product design solutions for various industries. To know more about ESPL Visit https://www.eqmsol.com/

0 notes

Text

Co-Engineered EMI and Non-EMI Metallic - Techni3

Laird also offers a vast array of co-engineered EMI and non-EMI METALLIC, precision thin-gauge metal stamping capabilities. Laird’s team of engineers and scientists will collaborate directly with the customer to design a solution for the application and provide predictive modeling services such as finite element analysis (FEA), EMI modeling, and deep draw simulations when needed to ensure the design is right the first time. Once a part design is finalized, Laird has prototyping centers in each region for rapid delivery of prototypes prior to launching into mass production.

0 notes

Text

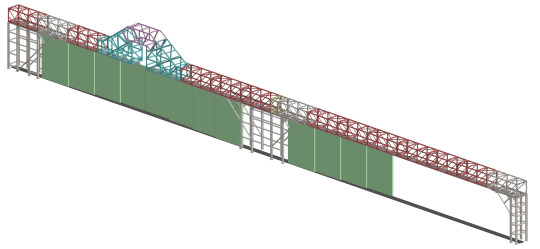

Structural Design and FEA Simulation of Aircraft Hangar Outrigger Door Structure

The structural design and simulation of an aircraft hangar outrigger door are pivotal in ensuring the reliability and safety of this essential part of the hangar infrastructure. In this blog, we explore the technical aspects of the design and finite element analysis (FEA) simulation of such structures, with a focus on optimizing performance, ensuring durability, and meeting stringent safety standards.

Overview of Aircraft Hangar Outrigger Door Structure

An outrigger door is typically designed as part of large hangar facilities, providing additional clearance for the aircraft. Its design must withstand the operational loads and environmental conditions, ensuring longevity and minimal maintenance.

Key Structural Components:

Trusses: Large trusses (e.g., TRUSS-1 to TRUSS-5 as indicated in design layouts) form the backbone of the structure, distributing loads efficiently.

Vertical Columns: These columns, often consisting of robust materials, support the trusses and provide vertical stability.

Rails and Supports: The top and bottom rails, supported by various beams such as NPB (narrow parallel flange beams) and ISMB (Indian Standard Medium Beams), guide the door’s movement and secure the structure.

These components, made of high-strength steel, are interconnected with bracing and rib structures to provide both rigidity and flexibility under load.

Structural Design Considerations

The design of the outrigger door must account for several factors, including:

Load Distribution: The door structure should evenly distribute loads, including the weight of the door itself and dynamic forces from wind or operational activities.

Material Selection: High-strength steel, such as ISMB beams, is often used for its ability to handle the high loads and dynamic stresses encountered during the door’s operation.

Space Optimization: As seen in the design, dimensions and spacing of the trusses, vertical columns, and rails are meticulously calculated to ensure space efficiency without compromising structural integrity.

Thermal and Environmental Stresses: The door must withstand environmental factors such as temperature variations, wind loads, and possible seismic activity.

Finite Element Analysis (FEA) for Structural Integrity

FEA is a crucial step in validating the design of the outrigger door structure. By simulating real-world conditions, engineers can predict how the structure will perform under various loads and stresses.

FEA Simulation Process:

Model Creation: A 3D model of the door structure is created based on the design drawings, including all trusses, columns, and rails.

Material Properties: The material properties (elastic modulus, yield strength, etc.) are input into the simulation software to ensure accurate behavior during loading.

Meshing: The structure is divided into small elements for analysis. A finer mesh may be applied to critical areas like the junctions of trusses and vertical columns, where stress concentrations are expected.

Boundary Conditions: Realistic boundary conditions, such as fixed supports at the base of the columns and loading from the door’s operation or environmental forces, are applied.

Load Cases: Various load cases, including dead load (structure’s weight), live load (operational forces), and environmental forces (wind, seismic), are simulated to analyze the stress and deformation of the structure.

Results and Optimization

The FEA simulation results are used to assess:

Stress Distribution: The software highlights regions with high stress concentrations. If the stress exceeds material limits, design modifications are made to redistribute the load.

Deformation: Excessive deformation, especially in the rails or trusses, can affect the door’s function. The simulation helps ensure that deformations remain within acceptable limits.

Factor of Safety: A critical outcome of the analysis is ensuring that the design meets the required factor of safety, accounting for uncertainties in loading conditions and material properties.

Conclusion

The structural design and FEA simulation of an aircraft hangar outrigger door structure are essential processes in ensuring the reliability and safety of the door system. By combining robust design principles with advanced simulation techniques, engineers can create a structure that withstands operational and environmental challenges while maintaining optimal performance throughout its lifecycle.

This detailed approach not only ensures compliance with safety standards but also reduces the risk of future structural failures, ensuring smooth operations for the aircraft hangar facility. Graphler Technology Solution provides CFD Analysis services, Engineering Animation services, stress analysis services and structural design services They have well expertise team with 10 yrs of industrial knowledge. Partnering up with the best structural analysis services provider or top product design companies will help you to discover new ideas.

0 notes

Text

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

fea engineering services

FEA (Finite Element Analysis) engineering services provide advanced simulation and analysis solutions for structural, thermal, and fluid dynamics challenges. These services help engineers optimize product designs, improve durability, and reduce prototyping costs.

visit at: https://www.servotechinc.com/cadfea-design-and-analysis

0 notes

Text

Ensure your product's overall performance with Data Center CFD Analysis! At Renewtherm Engineering, we have vast knowledge about top-level mechanical systems. For any queries, contact us now! For any details, contact us! For more information, you can visit our website https://www.renewtherm.com/ or call us at +971-506180620/+91-9884791650

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Text

fea fatigue analysis in hyderabad

thermal analysis services in hyderabad fatigue analysis services in hyderabad nonlinear analysis services in hyderabad fea for product development in hyderabad top fea consultants in hyderabad https://3d-labs.com/fea-services/ Comprehensive FEA Services for Enhanced Engineering Design and Analysis 3d-labs is an engineering consulting firm that provides full analysis using state-of-the-art FEA , CFD, and CAD/CAE tools. We help our clients reduce product development costs, decrease time-to-market , and improve product quality. We, offer not only reliable analysis results but also insight solutions to clients' projects….. We are from all sectors of the industry and have excellent analytical skills and knowledge. We have co-operation with universities, national laboratories, and other engineering firms, which enable us to address and solve clients' questions and problems simply and quickly. We solve a broad range of engineering analysis problems based on FEA techniques including stress analysis, fluid dynamics, kinematics, heat transfer, dynamics and vibration (seismic, harmonic), structural dynamics and electromagnetics. etc. Introduction Why Should we do Analysis Elastic Stress Analysis Method static Structural Analysis Engineering Data Geometry Model Setup Solution Results Fatigue Analysis Fatigue Tool Solution Results

https://3d-labs.com/

#thermal stress fea analysis services in hyderabad#fea consulting service provider in hyderabad#fea for civil engineering in hyderabad

0 notes

Text

Experience top-notch Mechanical Engineering services with Ideametrics Global Engineering. We deliver advanced design, precise 3D modeling, detailed engineering drawings, and expert FEA analysis for pressure vessels, heat exchangers, and reactors. Trusted in the United States, United Kingdom, France, Italy, and Germany, our innovative solutions empower industries with reliability and safety.

1 note

·

View note