#CFD Consulting Services

Explore tagged Tumblr posts

Text

As technology advances, the role of CFD in tunnel safety will continue to grow, ensuring that these critical infrastructures can withstand the challenges posed by fire emergencies.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

#CFD Consulting Services#Structural Analysis Services#Stress Analysis Services#Structural Design Services#Product Design Companies

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Link

Imaginationeering is a leading CFD analysis company, Texas. We offer CFD consulting services that will help solve product design challenges. Enquire Now

0 notes

Text

Understanding CFD in Heat Exchanger Design: A Case Study

In modern engineering, Computational Fluid Dynamics (CFD) is vital for optimizing thermal systems. This blog explores a recent CFD thermal analysis performed by Graphler Technology Solutions to evaluate a heat exchanger’s efficiency in transferring heat from a hot fluid (MSW slurry) to a cold fluid (DM water). Here’s what the study uncovered:

The Study Setup

The analysis simulated the heat transfer dynamics between two fluids using steady-state Conjugate Heat Transfer (CHT) analysis. Key parameters included:

Hot fluid (MSW Slurry): Initial temperature of 400°C, flow rate of 0.5 LPM, and inlet pressure of 300 Bar.

Cold fluid (DM Water): Initial temperature of 10°C, flow rate of 38.61 LPM, and inlet pressure of 2 Bar.

The system comprised four heat exchange passes, designed to ensure progressive heat transfer and achieve target temperature levels.

Key Findings

Temperature Distribution

In Pass 1, the hot fluid’s temperature dropped significantly from 400°C to 29.86°C.

Subsequent passes refined the output temperature, with Pass 4 reaching equilibrium at ~10°C.

Heat Transfer Efficiency

The cold fluid flow rate was 77 times higher than the hot fluid’s, driving an aggressive temperature drop.

The heat exchanger required approximately 9–10 meters to align the hot fluid’s temperature with that of the cold fluid.

Material Effectiveness

Stainless steel (Grade 304) and rockwool insulation ensured thermal integrity, with average heat transfer coefficients of:

Cold fluid side: 1027 W/m²-K

Outer insulation: 454 W/m²-K

Energy Implications

The design successfully minimized thermal losses while maintaining the structural and thermal stability of the exchanger.

Material Selection: The use of rockwool insulation and stainless steel proved effective. For future designs, these materials should remain standard, especially for similar operational conditions.

Flow Rate Optimization: High cold fluid flow rates were critical to achieving rapid heat exchange. Depending on energy costs, optimization between flow rates and exchanger length can be explored.

Length Considerations: A total pipe length of 18 meters, with four sequential passes, was adequate for the temperature targets. This insight aids in reducing unnecessary material and space usage in similar designs.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

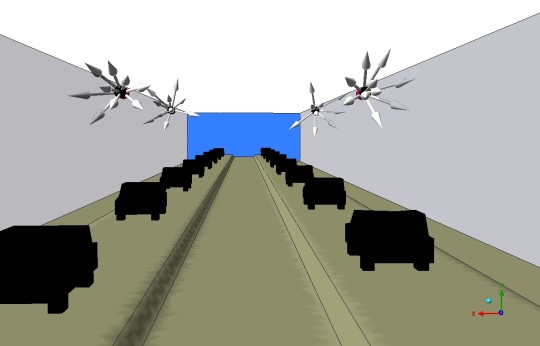

Fire and Smoke CFD Analysis in Road Tunnels: Ensuring Safety and Preparedness

Introduction

Understanding CFD Analysis

CFD is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems involving fluid flows. In the context of road tunnels, CFD is used to simulate the behavior of fire and smoke, helping engineers predict their spread and impact under various scenarios.

Key Components of Fire and Smoke CFD Analysis

Fire Dynamics Simulation:

Heat Release Rate (HRR): This is a measure of the energy released by the fire. It is a critical input for CFD simulations as it influences the temperature and smoke production.

Fuel Characteristics: The type of materials involved in the fire affects the combustion process, influencing smoke production and toxicity.

Smoke Behavior and Dispersion:

Smoke Movement: CFD models predict how smoke travels through the tunnel, considering factors such as ventilation systems, tunnel geometry, and traffic conditions.

Visibility and Toxicity: The simulation assesses how smoke affects visibility and air quality, crucial for evacuation and rescue operations.

Ventilation Systems:

Natural Ventilation: Utilizes the tunnel’s design and natural airflow to manage smoke.

Mechanical Ventilation: Involves fans and other mechanical systems to control smoke spread and ensure clear escape routes.

Emergency Response:

Evacuation Modeling: CFD helps in planning and optimizing evacuation routes and procedures, ensuring that people can exit the tunnel safely and quickly.

Firefighting Strategies: Simulations can evaluate the effectiveness of different firefighting tactics and equipment placement.

Applications and Benefits of CFD Analysis

Design Optimization: Engineers use CFD to optimize tunnel design, ensuring that ventilation systems and safety measures are effective in controlling fire and smoke.

Risk Assessment: By simulating various fire scenarios, CFD helps in identifying potential risks and weak points in the tunnel design.

Regulatory Compliance: CFD analysis supports compliance with safety standards and regulations, providing evidence of the tunnel’s ability to handle fire emergencies.

Training and Preparedness: Emergency response teams can use CFD simulations for training, improving their readiness and effectiveness in real-world scenarios.

Challenges and Future Directions

While CFD analysis offers significant benefits, it also presents challenges. Accurate simulations require detailed input data and considerable computational resources. Additionally, real-world conditions can be complex and variable, making it difficult to account for all possible scenarios.

Conclusion

Fire and smoke CFD analysis is an indispensable tool in the design and management of road tunnels. By providing detailed insights into fire dynamics and smoke behavior, it helps engineers create safer environments and develop effective emergency strategies. As technology advances, the role of CFD in tunnel safety will continue to grow, ensuring that these critical infrastructures can withstand the challenges posed by fire emergencies.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

Elevating Precision and Innovation: The Impact of CAD Design Services

Imagine a world where every intricate detail of a new skyscraper or a cutting-edge smartphone is designed and tested virtually before any physical creation begins. This is the realm of CAD Design Services, where technology meets creativity to revolutionize how conceive, design, and ultimately create new products. Computer-Aided Design (CAD) has transformed the engineering, architectural, and manufacturing landscapes, making it possible to visualize complex objects with precision that was unimaginable just a few decades ago.

The Essential Role of CAD in Modern Design

The CAD Design Services have become indispensable in today’s fast-paced industrial environment. By allowing designers and engineers to create detailed 3D models, CAD systems enable a level of precision and efficiency that accelerates the development process and reduces costs. From automotive to aerospace, every sector benefits from the enhanced capability of CAD to manipulate and modify designs effortlessly and accurately.

Enhancing Productivity and Accuracy with CAD

The deployment of CAD Design Services in any project means significantly less time spent on drawing and reworking designs. CAD software not only speeds up the drafting process but also improves the accuracy of the designs by eliminating manual errors. The ability to simulate how a product will look and function in the real world allows for corrections and enhancements to be made quickly, vastly improving the final product.

Advanced Capabilities of Computer Aided Design Services

The real power of Computer Aided Design Services lies in their versatility and depth. These services encompass everything from drafting and part assembly to parametric modelling and photorealistic rendering. Engineers can test different materials and configurations, assess stress points, and simulate environmental impacts without ever leaving their desks, ensuring that the final product is both practical and cost-effective.

Transforming Industries with Computer Aided Design

The Computer Aided Design Services are not just about creating more efficient workflows. They are transforming industries by enabling the creation of more complex and sophisticated designs. The architecture industry, for example, uses CAD to create safer, more sustainable buildings by simulating various stress scenarios and environmental impacts. In manufacturing, CAD facilitates the design of tools and systems that are highly optimized for performance and sustainability.

Global Impact and Future Trends in CAD

As technology advances, the scope of CAD Design Services continues to expand. With the integration of AI and machine learning, CAD systems are beginning to predict user preferences and automate parts of the design process, further increasing productivity. The future of CAD is also moving towards more collaborative environments where teams around the world can work simultaneously on the same project, sharing insights and updates in real-time.

Conclusion

In conclusion, CAD Design Services is a cornerstone of modern design and engineering, providing the tools necessary to drive innovation and efficiency across multiple industries. They allow for more precise control over the design process, foster innovation, and deliver products that meet the high standards of functionality and sustainability demanded by today’s market. For those looking to leverage this powerful tool, feamax.com offers expert Computer Aided Design Services that can help transform visions into tangible solutions.

0 notes

Text

1 note

·

View note

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

CFD Consulting Services

0 notes

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

CFD Consulting Services

0 notes

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

CFD Consulting Services

0 notes

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

CFD Consulting Services

0 notes

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

CFD Consulting Services

0 notes

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

CFD Consulting Services

0 notes

Text

Bridging Design and Production: The Power of FEA Simulation Services in Manufacturing

In the intricate dance of product development, the spotlight often falls on the tools that ensure designs not only look good on paper but perform flawlessly in real life. FEA Simulation Services play a crucial role in this process, acting as the bridge between innovative design and efficient manufacturing. This service uses advanced computational models to predict how new designs will behave under various conditions, ensuring that every product is robust, reliable, and ready for the market.

Understanding FEA Simulation Services

The FEA Simulation Services utilize the Finite Element Analysis (FEA) method to provide detailed insights into the physical behaviours of products under different stressors, such as force, heat, and vibration. This critical evaluation helps engineers identify potential design flaws and make necessary adjustments long before a prototype is built, saving significant time and resources.

The Impact of FEA on Product Development

The application of FEA Simulation Services in product development is transformative, enabling engineers to accelerate innovation and enhance the integrity of their designs. By predicting how products will respond to real-world forces, FEA helps in refining product structures, choosing appropriate materials, and ensuring that the products are safe, effective, and manufacturable.

Introduction to Engineering Manufacturing Services

As the engineering world evolves, so does the complexity of production processes. Engineering Manufacturing Services are at the forefront of this evolution, offering comprehensive solutions that cover everything from product design to assembly line setup. These services ensure that every aspect of manufacturing is optimized for efficiency and quality.

The Role of Engineering Manufacturing Services in Streamlining Production

Engineering Manufacturing Services provide the backbone for modern manufacturing operations. To guarantee that goods are produced to the best of standards, they combine cutting-edge technology and techniques. This integration includes everything from the initial design reviews to the final steps of production, ensuring that each product meets the rigorous demands of today’s markets.

Synergizing FEA Simulation with Manufacturing

Combining engineering manufacturing services with FEA simulation tools produces a strong synergy that can greatly improve the design and manufacturing stages of product development. By means of this integration, designs are not only possible but also optimized for cost-effective manufacturing, therefore facilitating a seamless transition from the creative stage to the manufacturing floor.

Conclusion

The collaboration between FEA Simulation Services and Engineering Manufacturing Services is reshaping the landscape of product development and manufacturing. By employing sophisticated simulation tools and comprehensive manufacturing solutions, companies can achieve higher standards of quality and efficiency. For businesses looking to embrace these advanced capabilities, feamax.com offers expert services that ensure success from the drawing board to the marketplace, delivering products that are not just made but engineered to perfection.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services

0 notes

Text

Cfd Consulting Services | Feamax.com

Utilise Feamax.com CFD consulting services to optimise your business potential. Our team of professionals provides customised solutions to ensure your success.

0 notes