#Magnesium Metal price

Explore tagged Tumblr posts

Text

#Magnesium Metal market size#Magnesium Metal market share#Magnesium Metal market price#Magnesium Metal market trends

0 notes

Text

Acid dissolution of mining waste—a new eco-friendly method for extracting metals

New research shows that magnesium and other metals in mine waste can be solubilized and recovered thanks to acid-producing bacteria. Researcher Nathan van Wyk believes that the method has great potential for reducing environmental pollution, extending the life of mines and providing raw materials for industry. Each year, more than three billion tons of metal are produced for use in various products. However, the metal content of ores has decreased with exploitation, which has made it more difficult to access the metals. This has resulted in increased metal prices and more harmful wastes. In addition, there is an increased demand for so-called rare earth elements, which are often found in very low concentrations, which can also generate a lot of mine waste. The mine waste is often disposed of in large, open piles at the mine. It is an environmental hazard, because metals in the waste can leach into groundwater, fine windblown waste can spread contaminants, and some chemicals used in metals extraction can also cause pollution. But these wastes also presents an opportunity.

Read more.

15 notes

·

View notes

Text

#op how do you make the custom metal logo plate @xactodreams

i don't make them myself, i prep the art from digital files and get the magnesium plates from evergreen engravers! been buying from them for years and years, totally consistent & they're close by to me. I hear good things about beaver engraving in oregon as well, but i don't know much about specific engravers outside the pnw. the engraving is a pretty cool process, there's a photoexposure step that fixes a protective film to the surface of the plate, and then some kind of. acid mist part that removes the negative space with a sloping edge.

idk how much context you have for commercial letterpress backend so ignore me if i'm repeating things you know! letterpress classes might do at least one project where you make plates directly from a digital file like these, but they'll usually use photopolymer rather than magnesium. It's a way cheaper material (NOT worse to print from, seriously, there's just a lot of other factors that make magnesium worth the price for some things), but the file preparation is basically the same. vector art is vastly preferable, use if at all possible, but raster is workable as long as it's at least 600 ppi. 1200 is ideal.

i also use photopolymer for some things, & the differences between polymer & magnesium plates are……complicated. also there's a bunch of options within each category about thickness & engraving depth & mounting & other file prep finessing etc etc, anyway! happy to answer any specific questions about it if you have them but that's the short version.

10 notes

·

View notes

Text

Do Alkaline Water Pitchers Really Work?

Alkaline water has gained popularity for its potential health benefits, including improved hydration, better digestion, and pH balance in the body. Many people turn to alkaline water pitchers as a convenient and affordable way to enjoy alkaline water at home. But do they really work? Let’s explore how they function and whether they’re a reliable alternative to high-quality alkaline drinking water solutions like Aquaplus.

How Do Alkaline Water Pitchers Work?

Alkaline water pitchers use a filtration system that typically contains activated carbon, ion-exchange resins, and mineral-enhancing materials. These filters: ✅ Remove chlorine, heavy metals, and other impurities. ✅ Add minerals like calcium, magnesium, and potassium. ✅ Increase the pH level of water, making it more alkaline.

While they do enhance water quality, they may not be as effective as naturally sourced alkaline water in BPA-free water bottles from trusted Dubai water suppliers like Aquaplus.

Do They Really Work? Pros & Cons

✅ Pros of Alkaline Water Pitchers:

✔ Affordable and convenient for home use. ✔ Can improve taste by reducing contaminants. ✔ Slightly increases water pH and adds minerals.

❌ Cons of Alkaline Water Pitchers:

✖ Limited filtration compared to RO systems or mineral water suppliers. ✖ pH increase is temporary and may not be as stable. ✖ Filters require frequent replacement.

A Better Alternative: Aquaplus Alkaline Water

For consistent pH levels and high-quality mineral-rich hydration, Aquaplus offers: ✔ Alkaline drinking water solutions that maintain pH stability. ✔ BPA-free water bottles for safe and eco-friendly hydration. ✔ Affordable alkaline water prices in UAE for premium-quality water. ✔ Mineral water supplier in Dubai, delivering pure, health-enhancing hydration.

Final Verdict: Should You Use Alkaline Water Pitchers?

Alkaline water pitchers are a decent temporary solution, but if you want long-term health benefits, opt for professionally purified and mineral-enriched alkaline water from Aquaplus.

For the best alkaline water in Dubai, visit Aquaplus today and enjoy the benefits of alkaline water with superior hydration! 🚰✨

#bpa free water bottle#alkaline water in bpa free water bottle#pure lilac drinking water#alkaline water benefits#dubai water supplier#alkaline#alkaline water#bpa free bottle

2 notes

·

View notes

Text

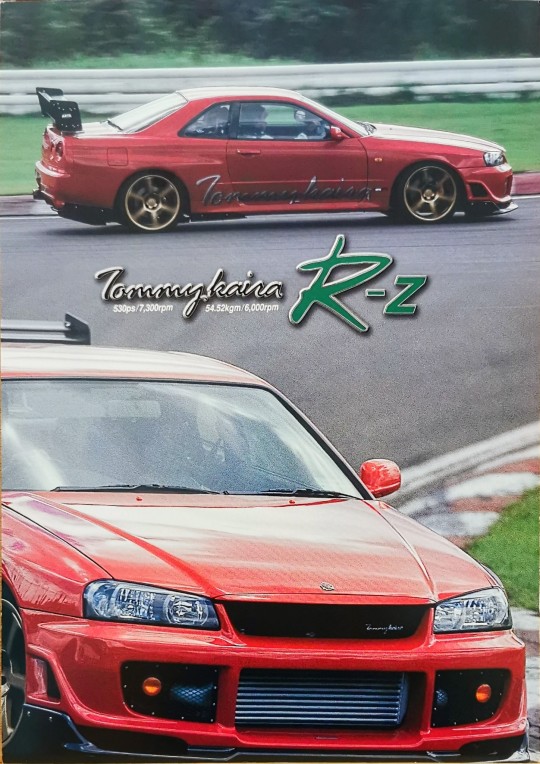

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Foods and Fuel Sources of Windbreak

Hello!!! I wanted to make a comprehensive list of popular foods ranked by class, from lowest to highest, just to have it here for future reference. This is specifically talking about foods that keep the energy-source alive and active, which includes fire, steam engines, nuclear reactors, and electricity. This does not cover metal-based foods used for growth. That will be covered and explained later.

Low-Class (Hearthfire robots)

Tar Dirt Tar dirt is a mixture of tar and other materials, like metal shavings, dirt or sand. The mixture is made to make consuming it easier, as tar is extremely sticky and hard to swallow on its own. It is rather effective, but it burns extremely dirty. It's the lowest of the low when it comes to poverty foods, and those who eat it for long periods of time often get their smoke vents so black and caked in soot and tar residue it can eventually clog vents if left to fester long enough. When vents are clogged, the internal fire (sometimes called a "hearth") of a robot will suffocate itself with its own smoke. This can be lethal without proper medical help, which the impoverished often don't receive.

Pitch Pitch is another extremely dirty-burning fuel source, but it's slightly less degrading to one's health than tar dirt. Most of these materials like tar, pitch, and crude oil are byproducts of coal processing, like in the making of coke or coal gas. These are extremely labor-intensive and low-paying, so in order to stay alive, historically, coal processors would take the flammable waste products of their trade and use it as food.

Sulphur (powdered) Sulphur is a very flammable material in powdered form, and burns a unique blue flame, but it comes at the price of dreaded rotten-egg breath. The stench it carries is bound to make the consumer unpopular, but it isn't always inherently dangerous in its pure form*. Some robots even use sulphur almost exclusively for fuel, though it is to be noted that they are specialized in hyperthermic fuels. However, Sulphur its pure form is rarely being consumed by the average robot. The dangers of Sulphur come mainly from what it's cut with. Pure Sulphur is hard to come by and rather expensive for those not specialized. But mixing it with other materials, such as stone dust, magnesium powder, etc. cheapens the manufacturing process, and can cause a litany of hazards. In general, it is ill-advised to consume anything non-metallic and non-flammable, as when nonflammable material is burned by hearthfire robots it tends to either stick to the bottom of the Hearth-chamber or clog up the vents. In extreme cases, both of these occurrences can kill by smothering one's hearth or reacting badly to the fire. * Sulphur, even pure Sulphur, is extremely dangerous to robots not suited to handle extreme heat. Burning it creates an extreme exothermic reaction that can gravely damage naturally lower-temperature robots, so if your hearth is low-burning or you have a hearth-related thermoregulation disorder, it is very dangerous to use this fuel. Sulphur shares many dangers with White Phosphorus, which burns at extremely high temperatures and is very combustible when in contact with oxygen or certain metals. If a robot is not specialized to process unstable materials like Sulphur and Phosphorus, it is strongly advised to avoid them.

Coal Gas Coal gas is another byproduct of coking and other coal processes. This one is a bit different, as it isn't as actively damaging to the vents of a robot as pitch or tar, so it isn't as unhealthy. But using coal gas as a fuel source is oftentimes not very filling, and doesn't really give the impression of having eaten a good meal. for this reason, it isn't very popular outside of necessity.

Coal Coal is still considered a "poor" food by most outside of the lower districts, but this isn't just for those that are most desperate. Coal is a major fuel source in the iron district, and sometimes in lower parts of the stone district, too. In those lower circles, it's considered a rather normal food, and only has connotations of poverty in higher levels. Most super poverty-stricken robots, like those who work in coal processing mentioned above, or even coal miners for that matter, rarely if ever get to eat coal. The coal that they are employed to handle is a product that does not belong to the workers who gather it, so personal use of it is considered stealing, and is a punishable offense.

Moonshine (homemade ethanol products) Ethanol itself is a very sought-after fuel, normally popular in the middle and higher classes, like the upper stone district and lower ember district. It's very clean-burning, easy to consume, fizzy and pleasant, though overconsumption of highly concentrated alcohols are considered mind-altering and are banned in many places. Alcohols with a concentration more than 60-70% are illegal and dangerous, and can even be addictive. The creation of any type of alcohol is banned in the Iron district, because it's basically copyrighted by the companies that do create and sell it. Nonprofessional creation of booze can also be dangerous in some cases, for instance, if there is too much water it can douse your hearth and kill you. If the concentration of alcohol is too high, it can cause your fire to burn itself out or cause other permanent damage to your hearth/body. non-authorized creation of booze for personal use/distribution anywhere is banned, because the government of Windbreak cannot tax it like it can commercial trade. But brand-name alcohol, being an efficient, clean-burning and desirable fuel, is expensive to get compared to something like coal, so oftentimes illegal manufacturing is practiced anyways. It's better than tar, at least. This bootlegging is often done in basements, cellars, or anywhere large enough for several booze-filled barrels to fit into. Moonshine is a common alcohol to make, but often the materials used in fermenting doesn't matter much. Any organic material will do, which often consists of any kind of plant that manages to grow in the iron district. This has caused major problems for the already struggling flora there. Sometimes, in high-profile cases, criminal organizations with ways of moving between levels will purchase, steal or poach sugar and plant material from upper districts and supply it to illegal ironclad distilleries for a cut of the profits.

Gasoline/Petrol The most common fuel source for Ironclads. This is cheap to get, legal, and commonplace. It is a fossil fuel, and does not burn the cleanest, but it does not cause many issues if regular maintenance to the vents and general body is practiced. This is a low-risk fuel, so is unlikely to cause problems for the average Hearthfire robot. (part 2 coming soon)

4 notes

·

View notes

Text

MAGNESIUM METAL BLOCK

YiRui Metal supplies all kinds of pure magnesium metal block and magnesium alloy scrap for magnesium alloy factory to lower the cost.

15 notes

·

View notes

Text

Nirvasa Shilajit Liquid – Natural & Pure Shilajit for Improved Immunity and Strength

Natural & Pure Shilajit

Nirvasa Shilajit Liquid is made from the finest sourced Shilajit from the Himalayan mountains. A natural immunity booster that has been in use to amplify human health, it got lost somewhere in the world of modern medicines. Now, as the world is recognizing the ability of this natural immunity booster, Nirvasa Shilajit Liquid is the perfect form to experience the change for good in your body. • Helps boost energy levels in the body • Helps improve your immunity • Promotes a balanced metabolism

1,799.00549.00 (You Save 69%)Delivery:Check

Enter pincode for exact delivery dates/charges

ADD TO CARTBUY IT NOW

Free Shipping

Cash on Delivery

14 days Return

Authenticity Guaranteed

Available Offers

physical Wellness

Immunity Booster

Fights Anemia

Boosts Energy

Frequently Bought Together

Nirvasa Shilajit Liquid – Natural & Pure Shilajit for Improved Immunity and Strength1,799.00 549.00

Nirvasa Electrify Vitamin C and Zinc Effervescent Vitamin C 1000mg, Zinc 10mg – 20 Tablets699.00 246.00Rated 4.35 out of 5 based on 62customer ratings(1062 Reviews)

Nirvasa Maca Root Extract to Boost Testosterone Levels – 60 Capsules1,099.00 659.00Rated 4.80 out of 5 based on 5customer ratings(1005 Reviews)

Total price:

Rs. 3597 Rs. 1454ADD TO CART

Purified

No Heavy Metals

Ayurvedic

ISO Certified

How to Consume

Put 2-3 drops

In a glass of water or milk

30 minutes after meals

Twice a day or as directed by a healthcare expert

Nature’s Drop of Power

Nirvasa Shilajit in Liquid Form is a treasure trove of essential nutrients and antioxidants that help keep the body energetic and active. It helps overcoming nutritional inadequacy and specifically work on body cells to improve your physical wellness.

Good for Women

Shilajit helps regulating women’s menstrual cycle and solving infertility issues. Shilajit is known to improve oxygen & nutrient flow to reproductive organs, repair hormonal imbalances, and ease the process of conceiving.

Improves Bone Mineral Density

Age-related factors, estrogen deficiency during menopause, diet, etc. reduce calcium absorption, leading to low bone mineral density. Shilajit boosts the supply of minerals like calcium, magnesium, and phosphate into bones, improves their absorption, and makes bones stronger.

2 notes

·

View notes

Text

North America Electric Vehicle Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the North America Electric Vehicle Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, North America Electric Vehicle Market scenario, and feasibility study are the important aspects analyzed in this report.

The North America Electric Vehicle Market is experiencing robust growth driven by the expanding globally. The North America Electric Vehicle Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. North America Electric Vehicle Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

North America is the third largest region in the global electric vehicle market. It is projected to record a CAGR of 16.1% during the forecast period. The North American electric vehicle market size is projected to grow from USD 62.73 billion in 2022 to USD 228.47billion by 2030.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/107688

Key Strategies

Key strategies in the North America Electric Vehicle Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of North America Electric Vehicle Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the North America Electric Vehicle Market.

Major North America Electric Vehicle Market Manufacturers covered in the market report include:

Tesla Inc. (U.S.)

General Motors (U.S.)

Nissan Motor Co., Ltd (Japan)

Mercedes-Benz USA, LLC (U.S.)

Volkswagen AG (Germany)

BYD Company Ltd. (China)

Ford Motor Company (U.S.)

Honda Motor Co., Ltd. (Japan)

Hyundai Motor Company (South Korea)

Mitsubishi Motors Corporation (Japan)

Canada is in the top five countries producing cobalt, copper, graphite, precious metals, nickel, and uranium and has the potential to expand in lithium, magnesium, and rare earth production; The above material is used in EV components, and this development augments the North America electric vehicle market share during the forecast period.

Trends Analysis

The North America Electric Vehicle Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable North America Electric Vehicle Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly North America Electric Vehicle Market Solutions.

Regions Included in this North America Electric Vehicle Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the North America Electric Vehicle Market.

- Changing the North America Electric Vehicle Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected North America Electric Vehicle Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the North America Electric Vehicle Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global North America Electric Vehicle Market?

► Who are the prominent players in the Global North America Electric Vehicle Market?

► What is the consumer perspective in the Global North America Electric Vehicle Market?

► What are the key demand-side and supply-side trends in the Global North America Electric Vehicle Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global North America Electric Vehicle Market?

Table Of Contents:

1 Market Overview

1.1 North America Electric Vehicle Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] R for Rabbit is introducing Tiny Toes Magna, made from high-quality magnesium material for lightweight and durable strength. This kids’ bicycle has UV-free PP-coated paint to ensure children’s safety from harmful emissions. Also, this paint is wear, tear, and rust resistant. The smooth finish of the paint and the magnesium material also makes it easier to clean and withstand even extreme weather conditions. Seeking a long-term investment? R for Rabbit’s Tiny Toes Magna is your best option! This lightweight children’s bike also has 90% Plug n Play installation with wide training wheels and a soft cushioned and adjustable seat for balanced riding. The phthalates-free handles make R for Rabbit’s Tiny Toes Magna child-friendly as they provide a comfortable grip and are designed exclusively for little munchkins. Also, you have many vibrant colors to choose from! Amazing, Right! Safety First: Its high-quality magnesium material and UV-free PP-coated paint ensure children's safety due to its lightweight, wear, tear, and rust resistance. 90% Plug N Play Installation: This R for Rabbit's Tiny Toes Magna's feature makes it easy to assemble, portable, safe, and the best option for your little one's personal ride. Disc Brake: R for Rabbit's Tiny Toes Magna comes equipped with a child-friendly disc brake system that offers enhanced safety and control for little riders on any terrain Lightweight Magnesium Frame: Magnesium is lighter compared to other metals, making it easier to handle by kids for their smooth and safe ride. Wide training wheels: This R for Rabbit's Tiny Toes Magna's feature makes this children's bike stable, safe, and supportive. It also increases kids' confidence to pedal and steer smoothly, without the fear of tipping over. [ad_2]

0 notes

Text

Automotive Metals Market Economic Impact and Global Trade Dynamics to 2033

The automotive industry is one of the largest consumers of metals, with materials such as steel, aluminum, magnesium, and others playing a crucial role in vehicle manufacturing. As the industry continues to evolve with trends like electrification, lightweight vehicles, and sustainability initiatives, the demand for specific metals is expected to change. This article explores the trends, growth factors, and forecast for the global automotive metals market up to 2032.

Market Overview

The automotive metals market encompasses the production, supply, and utilization of metals used in manufacturing vehicles. These metals contribute to the structural integrity, safety, performance, and efficiency of automobiles. Key metals used in the automotive sector include:

Steel: The most commonly used metal, known for its durability, strength, and cost-effectiveness.

Aluminum: Valued for its lightweight properties and increasing adoption in electric vehicles (EVs) and fuel-efficient cars.

Magnesium: Lightweight and often used in high-performance vehicles.

Titanium: Used in specialized automotive applications, particularly in luxury and sports cars.

Download a Free Sample Report:- https://tinyurl.com/4skt5rw6

Key Industry Trends

1. Lightweight Materials for Fuel Efficiency

One of the most prominent trends in the automotive industry is the push for lightweight materials to improve fuel efficiency and reduce emissions. Automakers are increasingly incorporating aluminum and magnesium in vehicle frames, engine components, and body panels to achieve weight reduction without compromising strength.

2. Electrification and Battery Materials

The rise of electric vehicles (EVs) has significantly impacted the demand for automotive metals. While steel and aluminum remain essential, EVs also require materials like lithium, nickel, and cobalt for battery production. Additionally, the increased use of lightweight metals in EVs enhances battery efficiency and driving range.

3. Sustainability and Recycling Initiatives

Environmental concerns are driving the adoption of sustainable practices in the automotive metals market. Manufacturers are focusing on recycling metals and reducing carbon footprints in the production process. Aluminum, in particular, is highly recyclable and is being repurposed extensively to reduce waste.

4. Advanced Manufacturing Technologies

Technological advancements such as additive manufacturing (3D printing), high-strength steel alloys, and nanotechnology-based materials are shaping the future of automotive metals. These innovations enable the production of lighter, stronger, and more durable vehicle components.

5. Regulatory Influence and Emission Standards

Governments worldwide are imposing stringent regulations on vehicle emissions and fuel efficiency. Automakers are responding by incorporating lightweight materials and advanced metal composites to meet regulatory requirements. This has increased demand for high-strength aluminum alloys and hybrid metal compositions.

Market Drivers

The growth of the automotive metals market is influenced by several key factors:

Rising Automotive Production: The increasing global demand for vehicles, especially in emerging economies, fuels the need for automotive metals.

Shift Towards Electric Vehicles: The global transition to EVs is altering the demand for specific metals, particularly aluminum and lithium-based components.

Consumer Preference for Fuel-Efficient Vehicles: Growing awareness of fuel economy and sustainability drives the adoption of lightweight materials.

Technological Innovations: Advances in metallurgy, material science, and manufacturing processes enhance the efficiency and performance of automotive metals.

Challenges Facing the Automotive Metals Market

Despite its growth potential, the automotive metals market faces several challenges:

Fluctuating Raw Material Prices: The volatility in metal prices, driven by geopolitical issues and supply chain disruptions, can impact production costs.

High Production Costs for Advanced Materials: While lightweight metals like titanium and magnesium offer advantages, their high cost remains a barrier to widespread adoption.

Supply Chain Disruptions: The COVID-19 pandemic and other geopolitical events have highlighted vulnerabilities in global metal supply chains.

Regional Insights

North America

The North American automotive metals market is driven by the presence of major automakers, stringent fuel efficiency regulations, and a strong focus on electric vehicle production. The U.S. and Canada are investing heavily in lightweight materials and metal recycling initiatives.

Europe

Europe is a leader in sustainable automotive practices, with strict emission norms driving the adoption of lightweight and recyclable metals. Countries like Germany, the UK, and France are spearheading advancements in EV manufacturing and metal innovations.

Asia-Pacific

Asia-Pacific dominates the automotive metals market due to high vehicle production in countries like China, Japan, and India. China, in particular, is a major consumer and producer of automotive metals, with a strong push towards electric mobility and metal recycling initiatives.

Latin America & Middle East

These regions are witnessing moderate growth in the automotive metals market, driven by increasing vehicle demand and investments in automotive manufacturing. However, economic instability and raw material supply constraints remain challenges.

Market Forecast to 2032

The global automotive metals market is expected to grow steadily over the next decade, driven by:

Increased Adoption of Lightweight Vehicles: Automakers will continue to integrate aluminum, magnesium, and other lightweight metals to meet fuel efficiency and emission standards.

Expansion of Electric Vehicles: The rising demand for EVs will reshape the demand for specific metals, particularly those used in battery technology and lightweight vehicle construction.

Technological Advancements: Continued research and development in high-strength and sustainable materials will enhance market growth.

Growth in Emerging Markets: Rising disposable incomes and urbanization in developing economies will boost vehicle sales, increasing demand for automotive metals.

Conclusion

The automotive metals market is undergoing significant transformation, influenced by technological advancements, sustainability goals, and regulatory requirements. While challenges like raw material price fluctuations and supply chain disruptions persist, the industry's focus on lightweight materials, electrification, and recycling initiatives presents numerous growth opportunities. As automakers innovate and adapt to evolving market dynamics, the demand for automotive metals will continue to rise, making it a crucial component of the automotive industry's future. By 2032, the industry is expected to be more sustainable, efficient, and technologically advanced, ensuring long-term growth and competitiveness in the global market.

Read Full Report:-https://www.uniprismmarketresearch.com/verticals/automotive-transportation/automotive-metals

0 notes

Text

Best Shilajit in India – Organic, Natural, and Fulvic Acid-Rich

Choosing the best Shilajit in India is crucial to ensure authenticity and effectiveness. With various brands offering different forms—resin, powder, and capsules—it can be challenging to find the right one. This article provides a comprehensive guide on Shilajit, its benefits, how to choose the best one, and top brands available in India.

1. What is Shilajit?

Shilajit is a sticky, tar-like substance formed over centuries by the decomposition of plant matter and minerals in high-altitude regions like the Himalayas. It is packed with Fulvic Acid, Humic Acid, and essential minerals, making it a powerful natural supplement.

Key Nutrients and Active Compounds

Fulvic Acid – Enhances nutrient absorption and detoxifies the body.

Minerals – Contains over 80 trace minerals, including iron, zinc, and magnesium.

Antioxidants – Helps fight oxidative stress and supports anti-aging.

Traditional Ayurvedic Uses & Modern Scientific Validation

In Ayurveda, Shilajit is classified as a “Rasayana” (rejuvenator) that enhances vitality, stamina, and immunity. Modern research also supports its role in boosting testosterone levels, improving energy, and cognitive function.

2. Benefits of Using Pure Shilajit

Shilajit offers numerous health benefits, making it a valuable addition to one’s daily routine.

1. Boosts Energy and Stamina

Ideal for athletes, fitness enthusiasts, and those with a sedentary lifestyle.

Enhances mitochondrial function, improving energy production.

2. Enhances Cognitive Function

Supports mental clarity, memory, and focus.

May help reduce brain fog and stress-related fatigue.

3. Improves Testosterone and Fertility

Known to enhance testosterone levels naturally.

Promotes sperm health and reproductive wellness in men.

4. Supports Immunity and Detoxification

Rich in Fulvic Acid, which helps remove toxins from the body.

Strengthens the immune system, reducing the risk of infections.

5. Anti-Aging and Longevity

Promotes cellular regeneration and reduces oxidative stress.

Helps maintain youthful skin, hair, and overall vitality.

3. How to Choose the Best Shilajit in India?

To get maximum benefits, selecting the right Shilajit is essential. Here are key factors to consider:

1. Purity and Authenticity

Choose brands that offer lab-tested and certified Shilajit.

Ensure the product is free from additives, heavy metals, or synthetic ingredients.

2. Resin vs. Powder vs. Capsules – Which is Better?

Resin: Most potent and purest form.

Powder: Easy to mix but may lose some potency.

Capsules: Convenient but often contain fillers.

3. Sourcing Location

Himalayan Shilajit is considered the best due to its high nutrient content.

Avoid products sourced from low-altitude regions, as they may lack essential minerals.

4. Brand Reputation and Customer Reviews

Look for trusted brands with positive reviews and transparent sourcing information.

5. Price vs. Quality

High-quality Shilajit may be expensive, but it ensures better potency and effectiveness.

4. Top Shilajit Brands in India (2025 Edition)

1. Simply Herbal Divya Himalayan Raw Shilajit

100% Pure Himalayan Shilajit Resin.

High Fulvic Acid content for maximum benefits.

Lab-tested and free from contaminants.

2. Dabur Shilajit Gold

Popular brand with added herbs for extra benefits.

Comes in capsule form for convenience.

3. Upakarma Ayurveda Pure Shilajit Resin

Premium quality resin-based Shilajit.

Rich in minerals and fulvic acid.

5. How to Use Shilajit for Maximum Benefits

To get the best results, follow these guidelines:

1. Recommended Dosage

Beginners: Start with a pea-sized amount (250-500mg) per day.

Experienced Users: Up to 1g daily, based on body needs.

2. Best Time to Consume Shilajit

Morning: For an energy boost.

Night: For recovery and relaxation.

3. How to Take Shilajit?

Dissolve in warm water, milk, or honey for better absorption.

Avoid mixing with carbonated or caffeinated beverages.

4. Precautions and Who Should Avoid It

Pregnant or breastfeeding women should consult a doctor.

Avoid if you have low blood pressure or kidney disorders.

6. Side Effects and Precautions

Though Shilajit is natural, some people may experience mild side effects.

1. Possible Detox Effects

Initial symptoms may include headaches or digestive changes.

2. Avoiding Fake and Adulterated Shilajit

Check for lab certification and purity tests.

Real Shilajit dissolves in water but not in alcohol.

3. When to Consult a Doctor

If you have underlying health conditions like heart disease, diabetes, or low blood pressure.

Choosing the best Shilajit in India ensures you receive its full health benefits. Simply Herbal Divya Himalayan Raw Shilajit stands out due to its purity, high Fulvic Acid content, and authentic Himalayan sourcing.

For those looking for a natural energy booster, testosterone enhancer, or overall wellness supplement, Shilajit is an excellent choice. Ensure you buy from reputed brands with lab-tested certifications for the best results.

Where to Buy Authentic Shilajit Online?

Simply Herbal Divya Himalayan Raw Shilajit – Buy Here

Amazon, Flipkart, and official brand websites.

#best shilajit brand#best shilajit#natural shilajit#Gummies for hair#Best hair vitamins for growth#best biotin supplement for hair growth#best skin brightening cream#skin lightening cream

0 notes

Text

Skyrocketing Aluminum Alloy Ingot Prices- What You Need to Know and How It Impacts You!

Aluminum alloy ingots are used in many different industries like construction, car manufacturing, and electronics. These ingots are blocks of aluminum that have been mixed with other metals to make them stronger and more useful. Since aluminum alloy ingots are in so many everyday products, their price changes can affect both businesses and people who buy those products. This article looks at what might happen to the Aluminum alloy ingots pricesin 2025 and what causes them to change.

What Are Aluminum Alloy Ingots?

An aluminum alloy ingot is a chunk of aluminum mixed with other metals like copper, magnesium, or zinc. These mixtures make the aluminum stronger and better for different uses. These ingots are used as raw materials to make things like car parts, airplane components, and building materials.

Aluminum alloy ingots are important because they are used in many products. For example, in cars and airplanes, lighter materials are needed for better fuel efficiency and performance. Aluminum alloys are a perfect choice because they are strong but also lightweight.

What Affects Aluminum Alloy Ingot Prices?

Several things can affect the price of aluminum alloy ingots. Most of the time, it depends on the supply and demand of the raw materials used to make the alloys.

The cost to mine bauxite, the raw material for aluminum, can impact on prices. If mining costs go up or if energy prices increase, the cost to produce aluminum goes up too, which affects alloy prices.

The demand for aluminum alloys is also a big factor. As countries grow and more cars, airplanes, and buildings are being made, there’s a higher need for aluminum. More demand can lead to higher prices.

Energy prices matter because aluminum production uses a lot of energy. If the cost of energy goes up, manufacturers may increase the price of aluminum alloys to cover the higher costs.

Lastly, supply chain problems can affect prices. If there are disruptions in key regions where aluminum is produced, like in parts of Africa or Asia, shortages can cause prices to go up.

>> 𝐁𝐨𝐨𝐤 𝐚 𝐝𝐞𝐦𝐨 𝐭𝐨 𝐠𝐞𝐭 𝐫𝐞𝐚𝐥-𝐭𝐢𝐦𝐞 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬: https://www.price-watch.ai/book-a-demo/

What to Expect for Aluminum Alloy Ingot Prices in 2025?

Looking into the future, we expect aluminum alloy prices in 2025 to go up in some areas because of higher demand, especially from countries like China and India. As these countries continue to grow, their need for aluminum alloys will rise, which could push prices higher.

Energy prices will continue to play a big role. If energy costs rise, it will become more expensive to produce aluminum alloys, which will lead to higher prices. However, new methods to make aluminum production more efficient could help keep prices stable.

Finally, supply chain problems can affect the availability of aluminum. If there are disruptions in key aluminum-producing regions, the price of aluminum alloys may increase.

In 2025, it’s likely that the price of aluminum alloy ingots will rise in some areas. The growing demand for aluminum in industries like automotive and construction will probably lead to higher prices. At the same time, if energy costs go up or if there are disruptions in supply, prices may increase even more. However, efforts to recycle aluminum or make production more energy-efficient may help keep prices from rising too quickly.

While it’s hard to predict the exact prices, businesses and consumers should expect some changes in the cost of aluminum alloy ingots. It’s always a good idea to stay aware of these trends, especially if your business relies on aluminum products.

Aluminum alloy ingots are essential for many industries, and their prices are affected by things like the cost of raw materials, energy prices, and supply chain issues. In 2025, prices are expected to fluctuate depending on demand and global events. Get real time commodity price update with pricewatch. If the demand for aluminum continues to rise and energy costs increase, we may see higher prices. However, efforts to make aluminum production more sustainable and efficient could help balance things out. Whether you're running a business or just a consumer, understanding these price changes can help you plan for the future.

0 notes

Text

The Absorbable Heart Stent Market: A Promising Frontier in Cardiovascular Care

Globally cardiovascular diseases stand as the leading cause of mortality with coronary artery disease serving as its significant component. As a minimally invasive procedure, Percutaneous Coronary Intervention (PCI) stands as a fundamental treatment method for coronary artery disease (CAD). A stent is positioned into a constricted artery during PCI to reopen blood circulation. Traditional metal stents deliver beneficial results yet they face restrictions such as late stent thrombosis and challenges during subsequent medical procedures. The limitations of traditional metal stents have led to the development of absorbable heart stents which are also known as bioresorbable scaffolds (BRS). This blog post examines both the present condition and future outlook of the absorbable heart stent market.

The absorbable heart stent market anticipates a steady CAGR of 10.0% between 2024 and 2031 which will cause market size to grow from US$ XX million in 2024 to US$ XX Million by 2031.

What are Absorbable Heart Stents?

Absorbable heart stents function by temporarily supporting arteries during healing before completely dissolving. The primary materials used to construct these stents include biocompatible polymers and magnesium alloys. BRS provides the primary benefit of avoiding permanent metallic structural remnants within the artery which diminishes the danger of late stent thrombosis while allowing natural vessel function to recover.

Market Dynamics

The absorbable heart stent market demonstrates consistent expansion due to several driving factors.

• Increasing prevalence of CAD: Global CAD incidence rates are rising which increases the demand for effective treatment solutions such as BRS. • Technological advancements: Current research developments continuously enhance the reliability and efficiency of BRS technology. • Growing patient preference for minimally invasive procedures: BRS serves as a minimally invasive surgical option that attracts numerous patients. • Favorable reimbursement policies: The market for BRS is expanding in some areas because of advantageous reimbursement rules.

Despite its progress, the market encounters several obstacles.

• Higher cost: BRS commands higher prices than traditional metal stents which creates an obstacle to their widespread adoption. • Clinical evidence: Although clinical research indicates potential benefits of BRS, additional long-term studies are required to confirm their advantages compared to conventional stents. • Technical complexity: Specialized training and expertise requirements for implanting BRS limit their adoption.

Market Segmentation

By Material

• Metals • Polymer

By End User

• Hospitals • Cardiac Centers • Research institutions

By Region

• North America • Europe • Asia-Pacific • South and Central America • Middle East and Africa

Key Players

Abbott Laboratories • Biotronik • Arterial Remodeling Technologies SA • Amaranth Medical Inc • Kyoto Medical Planning Co. Ltd • Elixir Medical Corporation • Reva Medical Inc • OrbusNeich • Synterra

Future Outlook

The absorbable heart stent market shows great potential for future growth. Advancements in technology combined with rising clinical evidence indicating benefits for BRS will lead to increased acceptance in future years. More competitors entering the market will intensify competition within the space.

Conclusion

Absorbable heart stents provide major progress in treating coronary artery disease. Despite current obstacles, the market shows strong potential for future expansion. The progression of technology combined with growing clinical evidence makes it possible for BRS to transform into the favored treatment choice for CAD patients by providing better long-term results and enhanced quality of life.

About Us-

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Magnesium Powder Prices, News, Trend, Graph, Chart, Monitor and Forecast

The magnesium powder market has witnessed significant fluctuations in pricing due to various influencing factors such as raw material costs, supply chain disruptions, and demand from key end-use industries. Magnesium powder is widely used across multiple sectors, including automotive, aerospace, pharmaceuticals, pyrotechnics, and metallurgy, making it a crucial industrial material. Over the past few years, magnesium prices have been volatile, primarily due to supply chain constraints and fluctuating production levels in major producing countries such as China, the United States, and Russia. The demand for magnesium powder has remained strong in industries focused on lightweight metal production and high-performance applications. The growing adoption of magnesium-based alloys in the automotive and aerospace industries has significantly impacted price trends, with manufacturers seeking lightweight and durable materials to improve fuel efficiency and performance. Additionally, magnesium powder plays a critical role in pyrotechnics and fireworks, where its high-energy combustion properties are essential for bright, intense explosions.

The pricing dynamics of magnesium powder are largely dictated by the cost of raw materials and the availability of magnesium metal. The production of magnesium powder involves extracting magnesium from ores such as dolomite and magnesite, followed by refining and powdering processes. The extraction and refining processes are energy-intensive, which means that fluctuations in energy prices directly impact magnesium powder costs. Moreover, regulatory policies on mining activities and environmental restrictions in key producing regions have further influenced supply and pricing. For instance, China, the largest producer of magnesium, has implemented strict environmental regulations to reduce carbon emissions, leading to temporary production halts and price surges. These supply-side constraints have created volatility in the global market, with buyers facing higher costs due to reduced availability.

Get Real time Prices for Magnesium Powder: https://www.chemanalyst.com/Pricing-data/magnesium-powder-1513

The demand for magnesium powder has been increasing across industries due to its unique properties such as high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. In the automotive industry, magnesium-based alloys have gained popularity due to the shift towards lightweight materials that enhance fuel efficiency and reduce overall vehicle weight. Many car manufacturers have started integrating magnesium components into their designs to meet stringent emission regulations and improve vehicle performance. Similarly, the aerospace industry has seen a surge in magnesium alloy adoption for manufacturing structural components, engine parts, and other critical aerospace applications. The ability of magnesium to withstand high temperatures while remaining lightweight makes it a preferred material in aerospace engineering.

In the pharmaceutical sector, magnesium powder is used as an excipient in various drug formulations, enhancing the stability and effectiveness of medications. The food and beverage industry also utilizes magnesium powder as a dietary supplement, given its essential role in maintaining bone health, nerve function, and muscle contraction. The increasing consumer awareness regarding health and wellness has led to a surge in demand for magnesium-based supplements, which has influenced market dynamics and pricing trends. Furthermore, the use of magnesium powder in steel manufacturing and metallurgy has remained steady, with the material playing a crucial role in desulfurization processes to enhance steel quality.

Geopolitical factors have played a crucial role in shaping the magnesium powder market, particularly concerning trade policies and international relations among key producing and consuming countries. The imposition of tariffs, trade restrictions, and geopolitical tensions have led to supply disruptions, influencing global price trends. For instance, trade disputes between China and the United States have affected magnesium exports, leading to increased prices in North America. Additionally, the COVID-19 pandemic severely impacted supply chains, causing delays in production and distribution, further contributing to price volatility. The magnesium powder market is highly sensitive to these external factors, making it imperative for buyers and manufacturers to closely monitor global trade developments.

Sustainability concerns and advancements in recycling technologies have also influenced the magnesium powder market. The industry has been exploring ways to enhance recycling efficiency and reduce reliance on primary magnesium extraction. Recycled magnesium powder has gained traction as an alternative, particularly in regions where environmental regulations have tightened. The development of eco-friendly production methods and improvements in recycling processes are expected to shape future pricing trends and supply chain dynamics. Companies investing in sustainable production technologies may benefit from cost advantages and increased market competitiveness.

Looking at regional market trends, Asia-Pacific remains the dominant producer and consumer of magnesium powder, with China being the largest supplier. The region’s strong industrial base and high demand from automotive and electronics manufacturing have driven magnesium powder consumption. Europe and North America are also significant markets, with growing investments in lightweight materials and aerospace applications contributing to demand growth. The Middle East and Africa have shown potential for expansion, particularly in steel manufacturing and construction applications. Latin America has experienced steady growth in magnesium powder consumption, driven by developments in metallurgy and automotive manufacturing.

Price forecasts for magnesium powder indicate potential fluctuations due to ongoing supply chain disruptions, geopolitical uncertainties, and economic conditions. While demand remains strong across multiple industries, supply constraints and regulatory policies may lead to price volatility in the short term. Analysts predict that the increasing adoption of magnesium-based materials in next-generation technologies will drive market growth, with steady price adjustments expected in response to production capacity expansions and technological advancements. The role of alternative sources, such as magnesium recycling and sustainable mining practices, will likely play a crucial role in stabilizing market prices in the long run.

The magnesium powder market presents a complex landscape influenced by multiple factors, including raw material costs, industrial demand, geopolitical developments, and sustainability trends. As industries continue to innovate and integrate magnesium-based materials into their applications, the demand for high-quality magnesium powder is expected to rise. Companies operating in this sector must stay informed about market trends, regulatory changes, and technological advancements to navigate price fluctuations effectively. By leveraging sustainable production practices and investing in efficient supply chain management, stakeholders can mitigate risks and capitalize on growth opportunities in the evolving magnesium powder market.

Get Real time Prices for Magnesium Powder: https://www.chemanalyst.com/Pricing-data/magnesium-powder-1513

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Magnesium Powder#Magnesium Powder Price#Magnesium Powder Prices#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

How to Identify High-Quality Slaked Lime Powder

Slaked lime, also known as calcium hydroxide, is widely used in construction, agriculture, and various industrial applications. However, not all slaked lime powder is of the same quality. Here’s a step-by-step guide to help you identify high-quality slaked lime powder for your needs.

1. Check the Purity

The first indicator of high-quality slaked lime powder is its purity. The best slaked lime has a high percentage of calcium hydroxide, typically above 90%. Impurities such as magnesium, silica, and iron should be minimal. Checking the chemical composition on the packaging or requesting a laboratory test can help determine purity.

2. Examine the Color and Texture

High-quality slaked lime should be white and finely powdered. A dull or greyish color may indicate impurities. The texture should be smooth and soft, without visible lumps, which ensures proper reactivity and performance in applications.

3. Perform the Water Reactivity Test

To test reactivity, mix a small amount of slaked lime with water. High-quality slaked lime will dissolve quickly, forming a smooth paste without residues. If you notice excessive grittiness or undissolved particles, the lime may be of inferior quality.

4. Verify the Source and Manufacturer

Reputable slaked lime manufacturers follow stringent quality control processes. Always purchase from certified and well-known brands. Check for ISO certifications and other quality standards that ensure the product meets industrial requirements.

5. Assess the Packaging

Proper packaging prevents contamination and moisture absorption. High-quality slaked lime suppliers provide lime in moisture-resistant, airtight bags to maintain its chemical integrity. Avoid products with damaged or loosely sealed packaging, as exposure to air can degrade the lime’s effectiveness.

6. Check the pH Level

Slaked lime should have a pH level of around 12.4. You can test this using a pH meter or pH strips. If the pH is significantly lower, it might be contaminated or not well-processed.

7. Look for Certifications and Lab Reports

Quality lime is often accompanied by certifications and lab reports. These documents provide insights into its composition, purity, and performance standards. Always ask the supplier for these reports before purchasing.

8. Consider the End Use Application

Different applications require varying grades of slaked lime. For example:

Construction: Must have high purity and fineness.

Water treatment: Should be free from heavy metals.

Agriculture: Requires a balanced composition for soil conditioning. Ensure the lime you choose is suitable for your specific needs.

9. Compare Prices and Reviews

While price is a factor, extremely cheap slaked lime might be of subpar quality. Check customer reviews and testimonials to gauge the reliability of a supplier. Trusted manufacturers maintain consistent quality, ensuring the product performs as expected.

10. Conduct a Small-Scale Trial

Before making bulk purchases, conduct a small-scale trial to observe the lime’s performance. This step helps verify its effectiveness in your application and ensures you get the best quality. By following these steps, you can easily identify and purchase high-quality slaked lime powder that meets your specific needs. Always rely on trusted slaked lime suppliers and manufacturers to ensure you receive the best product for your application. Also Read:- How Calcium Hydroxide Can Help Balance pH Levels in Water

0 notes