#MIG vs TIG welding

Explore tagged Tumblr posts

Text

A Study of Leading MIG Welding Machine Manufacturers in India

The Indian industry is booming and welding technology is playing a vital role in its growth. Among the various welding techniques, MIG (Metal Inert Gas) welding stands out for its efficiency and versatility. In this article, we explore the top mig welding machine manufacturers in India, explore the benefits of MIG welding and highlight how these manufacturers are shaping the industry. Additionally, we cover TIG welding equipment manufacturers and the wider landscape of welding product manufacturers in India.

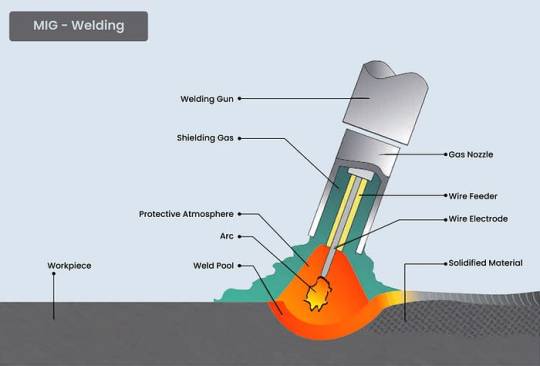

Understanding MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), uses a continuous wire electrode that is passed through a welding gun, creating an arc that melts the wire and joins the metals. The process is protected by an inert gas, usually argon or a mixture of argon and carbon dioxide, which protects the weld from impurities. This technology is popular due to its high productivity, ease of use and compatibility with different materials such as stainless steel, aluminium and carbon steel.

Best MIG Welding Equipment Manufacturers in India

1. weldarc India

Weldarc India is a leading welding products manufacturer in India, known for its advanced MIG welding equipment. Their products are designed to meet the diverse needs of industries from automotive to construction. Weldarc India MIG welding machines are known for their precision, durability and user-friendly features, making them the best choice for professionals.

2. Ador Welding Ltd.

Ador Welding Ltd. has been a major player in the Indian welding market for decades. Their MIG welding machines are known for their robust design and consistent performance. Ador Welding's commitment to innovation and quality has earned it a loyal customer base in various industries.

3. ESAB India

A subsidiary of global welding giant ESAB, ESAB India offers a wide range of MIG welding equipment. Known for cutting-edge technology and reliability, ESAB MIG welding equipment is preferred by industries that require high-quality welding solutions. Their machines are designed to produce excellent welds with minimal spatter and excellent arc stability.

4. Kemppi India

As part of Finnish welding equipment manufacturer Kemppi, Kemppi India supplies state-of-the-art MIG welders. Kemppi's focus on advanced technology and user-oriented design ensures that their MIG welding machines are efficient and easy to use. Their products are widely used in heavy engineering, shipbuilding and manufacturing.

5. Panasonic Welding Systems India

Panasonic Welding Systems India offers a wide range of MIG welding equipment known for its reliability and efficiency. Panasonic's commitment to research and development has led to the creation of innovative welding solutions that meet the changing needs of the industry. Their machines are popular for their energy efficiency and precision.

Advantages of MIG Welding

MIG welding has several advantages that make it the preferred choice in many industries:

Speed and Efficiency: MIG welding is faster than traditional welding methods, which increases productivity .

Versatility: Suitable for welding a variety of materials, including thin and thick metals.

Ease of Use: MIG welding is relatively easy to learn, making it accessible to novices.

Clean welds: Creates cleaner welds with minimal spatter, reducing post-welding.

TIG welding equipment manufacturers in the spotlight

While MIG welding is popular, TIG (Tungsten Inert Gas) welding also has an important position in the industry. TIG welding is known for its precision and quality welds, making it ideal for critical applications.

Top TIG welding machines in India:

Weldarc India: weldarc India not only excels in MIG welding machines but also offers state of the art TIG welders. Their TIG welding machines are designed for precision welding and to serve industries that require high-quality welds, such as aerospace and electronics.

Rilon Welding: Rilon Welding is known for its advanced TIG welding machines that combine technology and durability. Their machines are used in a variety of applications from light manufacturing to heavy industrial welding.

Hi Tech Welding: Hitech Welding offers a variety of TIG welding equipment known for its efficiency and reliability. Their products are designed to produce precise welds, making them a favourite among professionals.

Manufacturers of welding products in India

The Indian welding industry is supported by a strong network of welding manufacturers. These companies provide the consumables and accessories needed to ensure smooth welding.

Famous manufacturers of welding products:

Ador Welding Ltd.: In addition to welding machines, Ador Welding Ltd. manufactures a wide range of welding accessories including electrodes, wires and flux.

DandH Sécheron: DandH Sécheron is a leading manufacturer of welding accessories in India and offers a variety of products suitable for various welding processes.

Diffusion Engineers: Diffusion Engineers specialise in the supply of welding accessories and wear-resistant products, ensuring the longevity and efficiency of welding operations.

Conclusion

The Indian welding industry is growing and leading manufacturers such as weldarc India, Ador Welding Ltd., ESAB India, Kemppi India and Panasonic Welding Systems India are driving innovation and quality. MIG welding remains the cornerstone of this industry, offering many advantages for a variety of applications. Additionally, the presence of well-known TIG welding machine and welding product manufacturers provides the industry with the support and resources it needs to succeed.

By choosing the right MIG welding machine, the industry can improve its productivity and achieve quality welds. Committed to excellence and innovation, weldarc India continues to be a trusted partner to companies across the country. Be it MIG or TIG welding or a wide range of welding products, Indian manufacturers are well equipped to meet the demands of a dynamic and evolving industry.

#MIG welding machine manufacturers#TIG welding machine manufacturers#welding products manufacturer in India#MIG welding benefits#top welding machine manufacturers in India#Weldarc India#Ador Welding Ltd.#ESAB India#Kemppi India#Panasonic Welding Systems India#welding industry in India#MIG vs TIG welding#welding technology

0 notes

Text

Welding Blanket vs. Welding Screen: Key Tools for Welding Safety and Protection

Welding is a fundamental process in various industries, including construction, automotive, and manufacturing. While it plays a crucial role in creating strong, lasting bonds, welding also produces hazardous smoke and fumes that can pose serious health risks to workers. This is where welding smoke extractors come into play, serving as an essential safety solution for any welding operation.

Understanding Welding Fumes

Welding fumes are a byproduct of the welding process, consisting of a mixture of metals, gases, and other harmful substances. Common components include particles from metals like manganese, nickel, and lead, as well as gases such as ozone and nitrogen oxides. Prolonged exposure to these fumes can lead to various health issues, including respiratory problems, neurological disorders, and even long-term conditions like lung cancer.

To mitigate these risks, effective fume extraction is critical in maintaining a safe working environment for welders and other personnel.

What is a Welding Smoke Extractor?

A welding smoke extractor is a specialized device designed to capture and filter welding fumes at the source. These extractors can be portable or stationary, depending on the needs of the workspace. They work by employing various filtration technologies, including HEPA filters and activated carbon, to remove harmful particles and gases from the air.

Benefits of Welding Smoke Extractors

Health Protection: The primary function of a welding smoke extractor is to protect workers’ health. By removing toxic fumes from the air, these devices help reduce the risk of respiratory illnesses and other serious health issues.

Enhanced Visibility: Weldclass fumes can obscure visibility, making it challenging for welders to see their work clearly. By effectively filtering out smoke and particulates, smoke extractors improve visibility, allowing for greater precision and safety during welding operations.

Increased Productivity: When workers are protected from harmful fumes, they can focus better on their tasks. This leads to improved productivity, as welders are less distracted by discomfort and health concerns.

Regulatory Compliance: Many industries are subject to strict regulations regarding air quality and worker safety. Implementing a welding smoke extractor helps businesses comply with these regulations, ensuring a safer workplace and avoiding potential fines.

Versatility: Modern welding smoke extractors are designed to handle a variety of welding processes, including MIG, TIG, and stick welding. This versatility makes them suitable for diverse applications and environments, whether in a large factory or a small workshop.

Choosing the Right Welding Smoke Extractor

When selecting a welding smoke extractor, consider the following factors:

Type of Welding: Different welding methods produce varying types of fumes. Ensure the extractor is compatible with the specific welding processes you use.

Filtration Efficiency: Look for models with high-efficiency filters, such as HEPA filters, which are effective at capturing fine particles.

Portability: Depending on your workspace, you may need a portable unit for mobility or a stationary unit for fixed setups.

Noise Levels: Some extractors can be noisy, which may be a concern in certain environments. Check the decibel rating of the model you choose.

Conclusion

Welding smoke extractors are not just an accessory; they are a critical investment in workplace safety and health. By effectively capturing harmful fumes and improving air quality, these devices protect workers and enhance overall productivity.

In an industry where safety cannot be compromised, incorporating a reliable welding smoke extractor into your operations is essential. Prioritizing the health of your workforce today leads to a more efficient and sustainable workplace tomorrow. Make the smart choice for your business and ensure a safer environment for your welders with a high-quality smoke extractor.

0 notes

Text

How Does Aluminum Welding Differ from Steel Welding?

Welding is a critical process in industries from construction to automotive manufacturing, but welding aluminum and steel presents very different challenges. These differences are due to the unique properties of each metal, the types of welding methods used, and the specific precautions required to achieve durable and strong welds. Below, we explore these distinctions to help understand why welding aluminum differs so markedly from welding steel.

1. Properties of Aluminum vs. Steel

The foundational difference between aluminum and steel welding starts with their material properties.

Aluminum Properties: Aluminum is much lighter, with high thermal conductivity and a low melting point (660°C). It oxidizes quickly, forming a thin layer of aluminum oxide, which has a high melting point (over 2,000°C) and must be removed before welding. Aluminum is also softer, more ductile, and susceptible to distortion from heat.

Steel Properties: Steel, an alloy of iron and carbon, has a higher melting point (around 1,370°C for mild steel) and does not conduct heat as efficiently as aluminum. It is less prone to oxidation in the short term, is structurally strong, and holds up well under heat and pressure, making it easier to control during the welding process.

These physical differences are significant because they dictate specific welding approaches and techniques for each metal.

2. Challenges of Aluminum Welding

Welding aluminum involves a set of unique challenges due to its thermal characteristics and oxide formation.

Thermal Conductivity: Aluminum conducts heat rapidly, causing heat to dissipate from the weld area. This rapid heat conduction can make it difficult to maintain a consistent weld bead, especially when welding thinner aluminum materials.

Distortion and Warping: Due to its softness and high thermal expansion rate, aluminum is more prone to warping and distortion under the welding torch. Welders need to use lower heat input and faster travel speeds, and they often use fixturing techniques to hold parts in place.

Oxidation Issues: Aluminum’s surface oxidizes immediately when exposed to air, creating a layer that must be cleaned off before welding. Methods like wire brushing, chemical cleaners, or anodized coatings are used to remove this oxide layer, as it can cause inclusions in the weld.

3. Common Aluminum Welding Techniques

The techniques commonly used for welding aluminum are specially adapted for its properties:

Gas Tungsten Arc Welding (GTAW/TIG): This is a go-to method for welding aluminum, as it provides the precise control needed for this material. An alternating current (AC) is typically used in TIG welding to break down the oxide layer, making it easier to form a clean, strong weld.

Gas Metal Arc Welding (GMAW/MIG): For thicker aluminum sections, MIG welding is often preferred. A spool gun is commonly used to feed the aluminum wire because aluminum is too soft to pass through a standard MIG torch. Shielding gases like argon or a mix of argon and helium help protect the weld from oxidation and promote smoother welding.

4. Challenges of Steel Welding

Steel welding, though generally more straightforward, presents its own challenges.

Heat Management: Steel’s slower heat conduction allows welders to control the weld pool more easily, but higher heat input is needed. With high-strength or alloyed steels, welders must avoid overheating, which could change the metal's properties and lead to brittleness.

Distortion Control: Though less of a concern than with aluminum, distortion can still be an issue, particularly with thin steel sections or large assemblies. Preheating steel parts and post-weld heat treatments can help to manage these risks.

Corrosion and Rust: Steel is prone to rust when exposed to moisture and air. Applying rust-resistant coatings after welding helps preserve the integrity of the weld and surrounding metal.

5. Common Steel Welding Techniques

Several welding techniques are commonly used for steel, each with specific advantages:

Shielded Metal Arc Welding (SMAW): Also known as stick welding, this method is versatile and popular for welding steel. It’s especially useful for outdoor projects as it doesn’t require an external shielding gas.

Gas Metal Arc Welding (GMAW/MIG): MIG welding works well with mild steel and other common alloys, providing strong welds and high deposition rates for productivity. This method is favored in manufacturing and construction due to its speed.

Flux-Cored Arc Welding (FCAW): This method, similar to MIG, uses a tubular wire filled with flux, which shields the weld from contaminants. FCAW is suitable for high-strength steel and outdoor projects, where wind could disperse shielding gases.

6. Key Differences in Preparation and Technique

Both aluminum and steel welding require preparation, but aluminum is generally more demanding.

Surface Cleaning: Aluminum requires thorough cleaning to remove oxide layers. For steel, surface cleaning is often less intensive, though removing rust and oil is still necessary.

Preheating: Preheating steel, particularly for thicker sections, helps reduce distortion. Aluminum, however, generally requires minimal preheating because it can absorb heat quickly, making it easy to overheat.

Post-Weld Treatments: For steel, post-weld heat treatments help relieve stress and improve toughness. Aluminum rarely requires post-weld treatment, but anodizing or painting may be needed to prevent future oxidation.

7. Applications of Aluminum vs. Steel Welding

Aluminum Applications: Due to its light weight and resistance to corrosion, aluminum is commonly used in the aerospace, marine, and automotive industries.

Steel Applications: Steel’s strength and versatility make it suitable for structural applications, heavy equipment, automotive parts, and construction projects.

Conclusion

While aluminum and steel welding share the core goal of joining metal parts, the processes differ significantly. Aluminum’s thermal conductivity, low melting point, and oxidation layer require careful handling, specific techniques, and equipment, making it a more challenging material to weld. Steel, with its higher melting point and slower heat conduction, is more forgiving but still presents issues like distortion and rust. By understanding these differences, welders can better adapt their approach to meet the unique requirements of each metal, achieving high-quality and lasting welds. For More Visit Us:- https://www.ted.com/profiles/37914817

0 notes

Text

6061 aluminum vs 7075 aluminum

What Is 6061 Aluminum Grade?

Aluminum grade 6061 is one of the most commonly used aluminum alloys. it is the most famous member of the 6000 series of aluminum alloys. Due to the perfect balance of hardness and machinability, 6061 aluminum alloy is referred to as structural aluminum. it is Composed primarily of aluminum(97.9%) and magnesium, silicon, copper, chromium, and a tiny amount of other elements.

What Is 7075 Aluminum Grade?

Aluminum 7075 is a high-strength heat-treatable aluminum alloy used for highly stressed structural parts. it is a member of the 7000 series aluminum alloys. As a primarily zinc-based aluminum alloy, It contains 5.6% zinc, 2.1% magnesium, and 1.2% copper.

Differences Between Aluminum 6061 and 7075

6061 Vs. 7075 Aluminum: Chemical Composition Comparison

Below is a table to show the Chemical Composition of both materials and you will find how each Chemical affects the performance of the materials.

6061 vs. 7075 Aluminum: mechanical properties comparison

A comparison table is below for the mechanical properties of both materials.

Tensile Strength

This property measures a material’s resistance to a longitudinal pulling force. Aluminum 7075 is very good in this aspect, making it ideal for applications where high strength is critical, such as aerospace components.

Yield Strength

Yield strength indicates the point at which a material begins to deform plastically. Aluminum 7075 has a higher yield strength compared to 6061, which means its superior ability to withstand deformation.

Hardness

Hardness means a material’s resistance to surface indentation or abrasion. Aluminum 7075’s hardness is higher than that of aluminum 6061, making it more resistant to wear and damage.

Elongation

Elongation measures how far a material can stretch before breaking. Aluminum 6061 is more ductile in this aspect, meaning it can deform significantly before reaching its breaking point compared to 7075.

Young’s Modulus(Modulus of Elasticity)

This property defines a material’s stiffness and its ability to return to its original shape after deformation. Both alloys have similar values, but 6061 is slightly more elastic, making it better suited for applications requiring flexibility.

Thermal Conductivity

It means how efficiently a material conducts heat. Aluminum 6061 has higher thermal conductivity, making it suitable for heat dissipation applications like heat sinks.

Electrical Resistivity

This property quantifies a material’s opposition to electrical current flow. 7075 has slightly lower electrical resistivity, making it better for electrical conductivity applications.

Elasticity

Elasticity reflects a material’s ability to deform and regain its original shape under applied stress. Aluminum 6061 has higher elasticity, allowing it to flex more without permanent deformation.

Temperature Resistance

This property indicates how well a material can withstand elevated temperatures. Aluminum 7075 is better in high-temperature environments due to its higher melting point.

Corrosion Resistance

6061 vs. 7075 Aluminum: machinability comparison

CNC Machinability

Aluminum 6061 is easy to machine, and used for producing longer, continuous chips during CNC Aluminum machining. On the other hand, Aluminum 7075 is also machinable, but it generates shorter, segmented chips. so, for CNC machinability, 6061 aluminum will be better.

Weldability

In terms of weldability, Aluminum 6061 is better. It is adaptable to various welding techniques, including TIG and MIG welding with a good result. Although Aluminum 7075 is weldable, it demands more expertise and careful control of welding parameters.

Bending

For bending operations, Aluminum 6061 is highly formable and can be bent to various angles without the risk of cracking or distortion. In contrast, Aluminum 7075 is less ductile and possible to crack during bending.

Sawing

Both alloys can be cut effectively, but Aluminum 6061 is easier to cut. Standard sawing equipment can easily cut 6061, ensuring precise and clean cuts. Aluminum 7075 requires specialized sawing equipment for optimal cutting results.

EDM (Electrical Discharge Machining)

Wire EDM is not commonly used on Aluminum 6061 due to its excellent machinability using conventional methods. For Aluminum 7075, EDM is a viable option, especially in cases demanding high-precision components.

Tool Wear

Tool wear is a key consideration during machining. Aluminum 6061 shows low tool wear. Aluminum 7075, while still machinable has high tool wear due to its high hardness.

Surface Finish

Aluminum 6061 generally delivers a smooth surface finish, making it an excellent choice when aesthetics is important. Aluminum 7075 can also achieve a satisfactory surface finish, but it may require more effort due to its high hardness.

6061 VS 7075 Aluminum: How To Choose?

With the answer to the following three questions, you will know how to choose.

Which One is Stronger: 6061 or 7075 Aluminum?

7075 aluminum alloy has a higher yield strength compared to 6061 aluminum, So it can withstand impacts better than 6061.

Which One is Easier to Machine: 6061 or 7075 Aluminum?

6061 aluminum has lower tensile strength and hardness compared to 7075 aluminum. So, 6061 aluminum is easier to machined and shaped.

Which One is More Cost-Effective?

The raw material cost and machining expenses for 7075 are higher. So Aluminum 6061 is more cost-effective.

When to choose: 6061 or 7075 Aluminum

According to the comparison above, we summarize a when list to help you decide how to choose.

Aluminum 6061 can be considered for use in the following situations:

When parts require a lot of welding process.

When there’s a high demand for corrosion resistance.

When a lower cost is a priority.

7075 aluminum is more suitable for the following situation:

When achieving a high strength-to-weight ratio is needed.

When parts need to withstand high temperatures.

When parts will be subjected to high stress.

When the budget allows for higher material costs.

Conclusion

6061 and 7075 Aluminum alloys are both wonderful in the machining process. if you can not decide well, Contact a professional aluminum machining supplier. KUSLA is a manufacturer of precision aluminum machining in China. Feel free to get in touch with us for your aluminum machining projects.

You may also interested in other comparisons:

Titanium vs Aluminum

this actical was printed from

0 notes

Text

How Does the MIG Welder Compare to Other Welders?

When evaluating welding equipment, the MIG welder stands out for its versatility and ease of use. However, it's important to understand how it compares to other types of welders, including MIG stick welders, TIG welders, and flux-cored welders. Each welding method has its advantages and limitations, making it essential to choose the right tool for your specific needs. In this article, we will explore how MIG welders compare to other welding methods and what makes them unique.

MIG Welders vs. MIG Stick Welders

MIG stick welders and mig welders often need clarification, but they serve different purposes. A MIG welder uses a continuous wire feed system to provide a steady supply of filler material, which is shielded by MIG welder gas. This setup allows for smooth, consistent welds with minimal spatter, making it ideal for both beginners and professionals. MIG welding is particularly effective for thin materials and is known for its high-speed operation and ease of use.

In contrast, mig stick welder can operate using flux-coated electrodes, which do not require external gas. Instead, the flux creates a protective shield around the weld. This gasless approach makes stick welders versatile and suitable for outdoor or windy conditions where maintaining a gas shield might be challenging. However, compared to MIG welders, MIG stick welders often produce more spatter and require more clean-up. They are also generally more suitable for thicker materials and heavy-duty applications.

MIG Welders vs. TIG Welders

TIG welders offer a different approach compared to MIG welders. TIG welding uses a non-consumable tungsten electrode to produce the weld, which is then filled with a separate filler rod. This process allows for greater control over the weld pool and produces cleaner, more precise welds. Unlike MIG welding, which uses a continuous wire feed, TIG welding requires more skill and can be slower due to the manual feeding of the filler rod.

MIG welders, including high-performance models like the everlast mig welder, are generally faster and easier to use for larger projects or continuous welding tasks. They are preferred for tasks that require high productivity and consistent results. TIG welders, on the other hand, are often chosen for applications that require high precision and a high-quality finish, such as in the aerospace or automotive industries.

MIG Welders vs. Flux-Cored Welders

Flux-cored welders share some similarities with MIG welders but operate without the need for external shielding gas. Instead, they use flux-cored wire, which generates its protective gas shield when heated. This makes flux-cored welding a practical choice for outdoor or windy conditions where maintaining a gas shield can be problematic.

Due to the external gas shield provided by mig welder gas, MIG welders typically offer better control and cleaner welds. They are ideal for indoor applications where a clean and precise weld is required. However, flux-cored welders are often more portable and less expensive than MIG welders, making them a popular choice for budget-conscious users or those who need a more versatile tool.

Comparing MIG Welders on Sale

When looking for mig welders on sale, it's essential to consider what you need for your specific projects. The best mig welders will offer features such as adjustable settings for different materials, reliable wire feed systems, and compatibility with various types of gases. These features ensure that the welder can handle a range of tasks from light-duty to heavy-duty applications.

Everlast MIG welders are known for their robust performance and versatility, making them a good option for those who need high-quality equipment. However, the choice of MIG welder should align with your specific welding requirements, such as the type of materials you work with and the environment in which you will be welding. In summary, while best mig welders are known for their ease of use and efficiency, comparing them to MIG stick welders, TIG welders, and flux-cored welders highlights their unique advantages and limitations. Understanding these differences will help you select the right equipment for your needs, whether you're working on small DIY projects or larger professional tasks.

0 notes

Text

Traditional Welding vs. Laser Welding: Why Indian Manufacturers Are Making the Switch?

India’s manufacturing landscape is undergoing a significant transformation as industries embrace more advanced technologies to enhance productivity and quality. One of the most notable shifts is the transition from traditional welding methods, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas MIG) to laser welding. As laser welding technology gains traction globally, the demand for advanced laser welding machines in India is rapidly increasing, reflecting the country’s growing manufacturing capabilities. This change is driven by the numerous advantages that laser welding offers, including precision, speed, and cost efficiency. In this blog, we’ll explore why Indian manufacturers are increasingly adopting laser welding and how this technology is shaping the future of the industry.

Challenges of Traditional Welding

Traditional welding techniques, while proven and widely used, come with limitations that are becoming more apparent as manufacturing demands evolve. As the demand for electric vehicles and energy storage solutions grows, lithium-ion battery manufacturing equipment suppliers are adopting laser welding technology to enhance the safety and efficiency of battery production.

Higher Heat Input: Traditional methods often require more heat, leading to greater contamination and wastage of materials. This inefficiency can be costly, both in terms of material use and the quality of the final product.

Labor-Intensive: Traditional welding is labor-intensive and relies heavily on skilled workers. With a growing shortage of skilled labor, manufacturers face challenges in maintaining productivity. Automation, which is more feasible with laser welding, offers a solution to this problem.

Limited Precision: While traditional welding can achieve good results, it often falls short of the precision offered by laser welding. In applications that demand high accuracy, traditional methods may not meet the stringent requirements, leading to potential quality issues.

Advantages of Laser Welding

Laser welding has always been better than the traditional source. Even though the cost is not something we will keep an eye on this time as it is the same. There are a couple of things which we must notice. here are some of them.

1. Precision and Accuracy

Laser welding equipment stands out for its remarkable precision. Utilizing focused laser beams allows for highly accurate welds, making it ideal for industries that require intricate designs and minimal heat-affected zones (HAZ). Sectors such as aerospace and electronics, where even the slightest deviation can lead to significant issues, benefit greatly from this precision. The ability to achieve such fine detail with minimal impact on surrounding materials is a game-changer for manufacturers aiming to meet high standards. The introduction of laser fiber welding machines has brought a new level of precision and efficiency to industries requiring fine, detailed welds, such as electronics and automotive manufacturing.

2. Speed

One of the most compelling reasons for the shift to laser welding is its speed. The focused laser beam quickly melts and bonds materials, significantly reducing production times. This increased throughput is crucial for industries looking to scale up operations and meet growing demand. Faster welding processes mean manufacturers can produce more in less time, contributing to overall efficiency and competitiveness in the market.

3. Minimal Heat-Affected Zone (HAZ)

Traditional welding methods often result in a large heat-affected zone, which can compromise the structural integrity of the materials being welded. This can lead to thermal distortion and damage, especially in delicate or thin materials. Laser welding, however, produces a much smaller HAZ, minimizing the risk of these issues. This precision ensures that the structural properties of the materials are preserved, leading to higher-quality outcomes.

4. Cost Efficiency

While the initial investment in laser welding technology may be higher, the long-term savings make it a cost-effective choice for manufacturers. Reduced labor costs, faster processing times, and lower material waste contribute to significant cost savings over time. Additionally, the high precision of laser welding reduces the need for rework and repairs, further enhancing its cost-effectiveness.

5. Lower Maintenance Requirements

Compared to traditional welding equipment, laser welding systems generally require less maintenance. This reliability makes them easier to operate over time, reducing downtime and associated costs. For manufacturers, this means more consistent production schedules and fewer disruptions, contributing to overall operational efficiency.

6. Versatility

Laser welding is highly versatile and capable of handling a wide range of materials and applications. The versatility of laser welding machines in India allows manufacturers to tackle a wide range of applications, from thin metals to intricate components, with ease and precision. From thin metals to delicate components, laser welding can adapt to various requirements, which are often challenging for traditional welding methods. This flexibility is particularly valuable in industries where a diverse range of materials and designs must be accommodated.

Conclusion

The transition from traditional welding to laser welding among Indian manufacturers is not just a trend but a strategic move towards more advanced, efficient, and precise technologies. As industries strive to improve productivity, reduce costs, and maintain high-quality standards, laser welding presents a compelling alternative to conventional methods. This shift aligns with the broader demands of modern manufacturing environments, where innovation and efficiency are key to staying competitive.

Indian manufacturers who embrace laser welding are positioning themselves at the forefront of the industry, ready to meet the challenges and opportunities of the future. As this technology continues to evolve, it will undoubtedly play a critical role in shaping the next chapter of India’s manufacturing story. Battery manufacturing equipment suppliers in India are leading the charge in adopting laser welding technologies, ensuring that the country’s manufacturing sector remains at the forefront of innovation.

#laser welding#laser welding machine#laser welding machine in India#laser welding machines in india#laser welding equipment#fiber laser welding machine#laser fiber welding machine#battery manufacturing equipment#battery manufacturing equipment supplier#lithium ion battery manufacturing equipment supplier#lithium ion battery manufacturing equipment

0 notes

Text

Gas vs. Electric Welding Equipment: Which is Better?

Welding is a crucial process in many industries, from construction to automotive manufacturing. But when it comes to choosing the right equipment, the debate often centers around gas versus electric welding. Both have their merits, but which one is truly better? In this article, we will explore the differences, advantages, and disadvantages of gas and electric welding equipment to help you make an informed decision.

Introduction: Why the Choice Matters

Choosing between gas and electric welding equipment is not just a matter of preference; it can significantly impact your work's quality, efficiency, and cost. Have you ever wondered why some professionals swear by their TIG Welder machine while others prefer a MIG Welder machine? What factors should you consider when selecting your welding equipment? Let’s dive into the specifics.

Understanding gas welding equipment

How Does Gas Welding Work?

Gas welding, also known as oxy-fuel welding, uses a flame produced by burning a fuel gas (usually acetylene) with oxygen. This flame melts the base metal and allows the welder to join the materials.

Advantages of gas welding

Portability: Gas welding equipment is typically more portable than electric setups, making it ideal for fieldwork.

Versatility: It can be used for welding, cutting, and heating.

Cost: Initial costs are generally lower compared to electric welding machines.

Disadvantages of Gaswelding

Safety risks: handling flammable gases poses a safety risk.

Slower Process: Gas welding is often slower compared to electric methods.

Precision: Not as precise as some electric welding techniques.

Understanding Electric Welding Equipment

How does electric welding work?

Electric welding uses an electric arc to generate the heat needed to melt and join metals. Common types of electric welding include MIG (metal inert gas) and TIG (tungsten inert gas) welding.

Advantages of Electric Welding

Speed: Electric welding is generally faster than gas welding.

Precision: Techniques like TIG welding offer high precision, ideal for detailed work.

Safety: Generally safer as it does not involve flammable gases.

Disadvantages of Electric Welding

Cost: higher initial investment for the equipment.

Power Dependency: requires a stable power source, limiting portability.

Complexity: Can be more complex to set up and operate.

Comparing TIG and MIG Welder Machines

TIG Welder Machine

Precision: TIG welding is known for its precision and control, making it suitable for thin materials and detailed work.

Clean Welds: Produces clean, high-quality welds with minimal spatter.

Skill Level: requires a higher skill level to operate effectively.

MIG Welder Machine

Speed: MIG welding is faster, making it ideal for larger projects.

Ease of Use: Easier to learn and operate, suitable for beginners.

Versatility: Can be used on a variety of materials and thicknesses.

Factors to Consider When Choosing Welding Equipment

Project Requirements

Material: The type of material you are welding (e.g., aluminum, steel) can dictate the best equipment choice.

Thickness: Thicker materials may require the higher power output of electric welders.

Environment

Location: For fieldwork, portability may be more important, favoring gas welding.

Power Availability: If power supply is unreliable, gas welding might be the better option.

Budget

Initial Costs: Electric welding equipment usually has higher upfront costs.

Operating Costs: Consider the long-term operating costs, including maintenance and consumables.

Conclusion: Making the Right Choice

So, which is better: gas or electric welding equipment? The answer depends on your specific needs and circumstances. If portability and versatility are your top priorities, gas welding might be the way to go. However, if you value speed, precision, and safety, electric welding could be the better choice. Ultimately, understanding the differences and considering your project's unique requirements will help you make the best decision. Whether you’re in a welding supply store eyeing a new TIG Welder machine or debating the merits of a MIG Welder machine, having the right information can make all the difference.

What are your thoughts on gas versus electric welding? Do you have a preference or any experiences to share? Let’s continue the conversation and find the best solutions together.

0 notes

Text

Comparing Welding Cables: Finding the Perfect Fit for Your Needs

When it comes to welding, the choice of welding cables can significantly impact the quality, safety, and efficiency of your work. Welding cables are the lifelines that deliver power to your welding equipment, and selecting the right type can make all the difference. In this blog, we'll explore the key factors to consider when comparing welding cables and help you find the perfect fit for your needs.

Welding Cables ?

Welding cables are designed to carry high currents required for welding applications. These cables are typically made from finely stranded copper to maximize flexibility and are insulated with durable, heat-resistant materials such as rubber or neoprene. The primary function of welding cables is to ensure a reliable electrical connection between the power source and the welding electrode.

Key Factors to Consider

Cable Size and Amperage Capacity

Gauge Size: Welding cables come in various gauge sizes, typically ranging from 6 AWG to 4/0 AWG. The gauge size determines the cable’s current-carrying capacity. Thicker cables (lower gauge numbers) can carry higher currents, which is essential for heavy-duty welding tasks.

Amperage Requirements: Consider the amperage requirements of your welding equipment. For example, a 2 AWG cable might be suitable for applications up to 200 amps, while a 2/0 AWG cable could handle up to 400 amps. Matching the cable size to your equipment's needs ensures optimal performance and safety.

Cable Length

Voltage Drop: The length of the welding cable affects the voltage drop. Longer cables have higher resistance, leading to a potential drop in voltage and reduced efficiency. It's crucial to choose a cable length that minimizes voltage drop while providing sufficient reach for your work.

Flexibility Needs: In environments where mobility is essential, shorter, more flexible cables might be preferable. Conversely, longer cables may be necessary for projects that require extended reach.

Insulation Material

Durability: Welding environments can be harsh, with exposure to high temperatures, abrasion, and chemicals. Insulation materials like EPDM rubber or neoprene offer excellent durability and heat resistance, making them ideal for heavy-duty use.

Flexibility: The flexibility of the cable is crucial for maneuverability and ease of use. Finely stranded copper conductors combined with flexible insulation materials can provide the necessary flexibility without compromising durability.

Environment and Application

Indoor vs. Outdoor Use: If you are working in an outdoor environment, ensure the cable is resistant to UV radiation, moisture, and extreme temperatures. Indoor cables may not require such stringent protective features.

Specific Applications: Different welding processes (MIG, TIG, Stick) may have specific requirements for cable performance. Ensure that the welding cable you choose is compatible with your welding process and equipment.

Comparing Welding Cable Options

To illustrate the process of finding the perfect welding cable, let's compare a few options based on the factors mentioned above:

IMT Cables' Standard Welding Cable

Gauge Size: Available in 2 AWG, 1 AWG, and 1/0 AWG.

Insulation Material: High-quality EPDM rubber, known for its durability and flexibility.

Applications: Suitable for general-purpose welding, offering a balance of performance and cost-effectiveness.

Heavy-Duty Welding Cable

Gauge Size: Available in 2/0 AWG and 3/0 AWG for higher amperage requirements.

Insulation Material: Neoprene insulation, providing enhanced resistance to chemicals and extreme temperatures.

Applications: Ideal for industrial and construction environments where cables are subjected to heavy wear and tear.

Flexible Welding Cable

Gauge Size: Available in 4 AWG and 6 AWG for lower amperage requirements.

Insulation Material: Flexible rubber insulation for maximum maneuverability.

Applications: Best suited for light-duty welding tasks and applications requiring frequent cable movement.

Making the Right Choice

Choosing the right welding cable involves assessing your specific needs and matching them to the cable's features. Here are some steps to guide you through the selection process:

Determine the Amperage Requirements: Identify the maximum amperage your welding equipment will require and select a cable gauge that can handle this load.

Consider the Work Environment: Evaluate whether you need a cable that can withstand outdoor conditions, chemical exposure, or high temperatures.

Assess the Cable Length: Choose a cable length that provides adequate reach without causing significant voltage drop.

Prioritize Flexibility: If your work involves frequent movement or intricate welding tasks, prioritize cables with high flexibility.

Consult Experts: Don’t hesitate to consult with cable manufacturers or suppliers. At IMT Cables, we offer expert guidance to help you select the perfect welding cable for your needs.

Conclusion

Finding the perfect welding cable is essential for ensuring efficient, safe, and high-quality welding operations. By considering factors such as cable size, length, insulation material, and specific application needs, you can make an informed decision. At IMT Cables, we offer a wide range of welding cables designed to meet the diverse requirements of various industries. Explore our selection and find the ideal welding cable that delivers the performance and reliability you need.

For more information or to discuss your specific requirements, feel free to contact us. At IMT Cables, we’re committed to providing the best cable solutions for your projects.

0 notes

Text

0 notes

Text

Welding (PT8)

Next I'll Talk about SMAW or Stick welding. It stands for Shielded Metal Arc Welding. This is another form of Metal welding but can be done in all environments. When you stick weld it lays a bead down with a flux coating referred to as slag. Slag protects the weld from the outside environment once the weld is cooled you can break the slag off, that is the biggest difference between Stick vs MIG/TIG. You see a lot of stick welding on the pipelines where you have to be outside to weld the workpiece.

0 notes

Text

Exploring Precision and Power: A Comparative Study of Welders - Lincoln vs. ESAB Welding

Welding, an art and science that binds structures together, has seen remarkable advancements over the years. Two prominent names that resonate in the world of welding are Lincoln and ESAB. In this article, we delve into the intricacies of these welding giants, exploring their technologies, innovations, and the impact they've had on the welding landscape.

Introduction:

Welding, once a rudimentary process, has evolved into a sophisticated craft, thanks to companies like Lincoln and ESAB. These industry leaders have consistently pushed the boundaries of welding technology, providing welders with tools that offer precision, efficiency, and reliability.

Lincoln Welding:

Lincoln Electric, a name synonymous with welding excellence, has a rich history dating back to its founding in 1895. Known for its commitment to quality and innovation, Lincoln welders are revered for their precision and durability. From traditional stick welders to advanced TIG and MIG machines, Lincoln covers a wide spectrum, catering to the needs of both hobbyists and professional welders. For further details, please visit https://gruporogu.com.mx/categoria-producto/soldadoras-lincoln/

Key Features of Lincoln Welders:

Advanced Inverter Technology

Multi-Process Capabilities

User-Friendly Interfaces

Durability and Longevity

ESAB Welding:

On the other hand, ESAB, a global player in the welding industry, has been revolutionizing the field since 1904. ESAB's diverse range of welding equipment encompasses everything from cutting-edge welding machines to protective gear. ESAB is renowned for its focus on research and development, consistently introducing innovative solutions that redefine welding standards. For further details, please visit https://gruporogu.com.mx/soldadoras-esab/

Noteworthy Aspects of ESAB Welders:

Intelligent Welding Systems

Welding Automation Technologies

Environmental Sustainability Initiatives

Comprehensive Training and Support

Comparative Analysis:

When comparing Lincoln and ESAB welding systems, several factors come into play. The choice between the two often depends on the specific needs of the welder, the type of projects undertaken, and the desired level of technology integration.

Technology and Innovation: Both Lincoln and ESAB invest heavily in research and development, constantly introducing cutting-edge technologies. Lincoln's focus on inverter technology and ESAB's intelligent welding systems showcase their commitment to staying ahead in the technological curve.

Versatility: Lincoln's multi-process capabilities make it suitable for a wide range of applications. ESAB, with its emphasis on automation, offers solutions that cater to high-volume industrial demands. Understanding the nature of projects is crucial in choosing the more suitable option.

User-Friendly Interfaces: Lincoln welders are known for their user-friendly interfaces, making them accessible to welders of varying skill levels. ESAB, with its emphasis on comprehensive training and support, ensures that welders can maximize the potential of their equipment.

Conclusion:

In the realm of welding, the choice between Lincoln and ESAB is not just about the brand but about aligning the right technology with the specific requirements of the job. Both companies have contributed significantly to the welding industry, pushing the boundaries of what is possible.

1 note

·

View note

Text

Choosing the Right Technique for Sheet Metal Welding: MIG vs. TIG Welding

Welding is a crucial process in metal fabrication, and when it comes to sheet metal cutting, two popular techniques stand out — MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Each technique has its strengths and weaknesses, making the choice between them essential for achieving optimal results in sheet metal applications. In this blog, we will delve into the key differences between MIG and TIG welding, explore their suitability for sheet metal cutting, discuss the pros and cons of each method, highlight factors influencing the choice between them, and provide real-life examples of successful sheet metal cutting using both techniques.

What is MIG welding?

MIG welding involves a continuous wire feed that is fed through a welding gun and melted into the joint. A shielding gas, typically a mixture of argon and carbon dioxide, protects the weld pool from atmospheric contaminants. MIG welding is known for its efficiency and speed, making it a popular choice for various applications

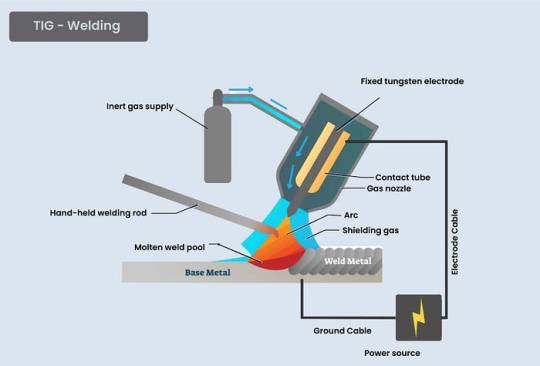

What is TIG welding?

TIG welding is done by using a non-consumable tungsten electrode. The welder manually feeds a filler rod into the weld pool, which is protected by an inert gas, usually argon. TIG welding is recognized for its precision, control, and ability to produce high-quality welds on thin materials.

Which Welding Technique Is More Suitable for Sheet Metal Welding?

The choice between MIG and TIG welding for sheet metal cutting depends on several factors, including the thickness of the metal, the required precision, and the desired finish.

– MIG Welding for Sheet Metal Welding:

MIG welding is well-suited for cutting thin sheet metals due to its high travel speed and efficiency. It is ideal for projects where speed is crucial, such as in mass-production environments. However, MIG welding may not provide the same level of precision as TIG welding, and the heat input can sometimes be a concern for thinner materials.

– TIG Welding for Sheet Metal Welding:

TIG welding is preferred for cutting thinner sheet metals when precision and a clean finish are essential. It offers excellent control over the heat input, reducing the risk of warping or distortion in the metal. TIG welding is commonly used for intricate designs and projects where aesthetics and precision are critical.

What are The Pros and cons of MIG and TIG welding in sheet metal applications?

Pros:

High welding speed, making it suitable for mass production.

Good for thicker sheet metals.

Minimal skill requirement compared to TIG welding.

Cons:

Limited precision, which may not be suitable for intricate designs.

More heat input increases the risk of warping with thin materials.

Pros:

Excellent precision and control, making it ideal for thin sheet metals.

Clean and aesthetically pleasing welds.

Low heat input, reducing the risk of distortion.

Cons:

Slower welding speed compared to MIG welding.

Requires a higher skill level.

What Factors Need to Be Consider When Selecting the Appropriate Welding Method?

Choosing the right welding method for sheet metal cutting involves considering various factors to ensure the desired outcome. Here are some key considerations:

– Material Thickness:

MIG welding is more suitable for thicker sheet metals, while TIG welding excels in precision work on thinner materials.

– Precision Requirements:

If the project demands high precision and intricate detailing, TIG welding is often the preferred choice.

– Speed and Efficiency:

MIG welding is faster and more efficient, making it suitable for projects with tight deadlines and large production volumes.

– Skill Level:

Consider the skill level of the welder, as TIG welding requires more expertise than MIG welding.

– Aesthetics:

If the appearance of the weld is crucial, such as in architectural or decorative applications, TIG welding is often preferred for its cleaner finish.

– Cost Considerations:

Evaluate the cost of equipment, consumables, and labour associated with each welding method to determine the most economical choice for the project.

Read More-https://www.lsw.co.in/choosing-the-right-technique-for-sheet-metal-welding-mig-vs-tig-welding/

#manufacturing#aviation#construction#sheet metal fabrication manufacturers#metalworking#welding services

0 notes

Text

MIG and TIG Welding: Unraveling the Secret Techniques of Commercial Metal Fabrication

Welding, an integral process in commercial metal fabrication, has come a long way since its inception. With many methods available today, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding stand out for their versatility and efficiency, making them popular in manufacturing industries.

In this blog post, we will look closer at MIG and TIG welding techniques used by commercial steel fabrication companies and why metal fabrication professionals in Orange County, CA, and beyond prefer these methods.

MIG vs. TIG: What's the Difference?

Let's first differentiate the two and understand why they're so popular in commercial metal fabrication.

MIG Welding

Also known as Gas Metal Arc Welding (GMAW)

Utilizes a consumable electrode wire and an inert shielding gas

The electrode wire is continuously fed through a welding gun

Suitable for a wide range of metal types and thicknesses

Metal fabrication companies near you commonly use MIG welding, and have earned a reputation for being a fast and efficient solution for joining metal pieces. Cresco Manufacturing's primary advantage is its adaptability to various metals, making it a top choice for custom metal cutting services.

TIG Welding

Also known as Gas Tungsten Arc Welding (GTAW)

Employs a non-consumable tungsten electrode and an inert shielding gas

It requires higher precision and more skill from the welder

Produces exceptionally clean and high-quality welds

TIG welding is favored in more specialized metal fabrication projects, such as welding thinner metals or more complex joints. The resultant welds often have better strength and durability, making TIG welding a preferred process in critical applications such as aerospace or automotive components.

Why Choose MIG and TIG Welding for Your Commercial Metal Fabrication Needs?

Now that we've listed the key characteristics of MIG and TIG welding let's explore some reasons why these methods find widespread usage in commercial steel fabrication:

Efficiency: MIG welding offers speed and efficiency that few other welding methods can match. Due to the constant wire feed, MIG welding minimizes downtime and increases productivity.

Versatility: As mentioned earlier, both MIG and TIG welding can accommodate a wide range of metals and projects, making them practical choices in diverse industries.

Quality: TIG welding, in particular, produces high-quality welds that are aesthetically pleasing, strong, and reliable. High quality is crucial in custom metal cutting and high-precision projects.

Cost-effectiveness: Thanks to the efficiency and versatility of these techniques, MIG and TIG welding can contribute to cost savings in the long run.

Finding the Right Metal Fabrication Company in California

When you need high-quality commercial metal fabrication solutions in California, look no further than Cresco Custom Metals. Servicing Orange County and beyond, we offer a range of services, including MIG and TIG welding and other state-of-the-art metal fabrication techniques.

#Commercial Steel Fabrication#Metal Fabrication Companies Near Me#Commercial Metal Fabrication#Welding Orange County Ca#Cresco Custom Metals

1 note

·

View note

Text

How to Choose Quality Welding Supplies: A Buyer's Guide

Welding is both an art and a science, requiring not just skill but also the right tools. Quality welding supplies can make a significant difference in the ease, safety, and quality of your welding projects. Whether you are a beginner or an experienced welder, understanding how to choose the right welding supplies is crucial. This guide will help you navigate the world of welding supplies, ensuring that you make informed decisions for your welding needs. Visit us at JGW Machine for better insights.

Understanding Your Welding Needs

Before diving into the plethora of welding supplies available, it's essential to understand your specific welding needs. Consider the type of welding you'll be doing (MIG, TIG, Stick, etc.), the materials you'll be working with (steel, aluminum, etc.), and the frequency of your welding projects. Your choices in supplies will vary significantly based on these factors.

Key Welding Supplies to Consider

1. Welding Machine

The heart of your welding supplies is the welding machine. Choose a machine that suits the type of welding you plan to do. For instance, MIG welders are versatile and suitable for beginners, while TIG welders offer more precision but require more skill. Look for a machine with adjustable settings to accommodate different materials and thicknesses.

2. Welding Helmet

Safety comes first, and a quality welding helmet is non-negotiable. Opt for an auto-darkening helmet, which adjusts the lens shade depending on the light intensity. Ensure it covers your face and neck entirely and is comfortable for long periods.

3. Welding Gloves

Your hands need protection from heat, sparks, and electric shock. Choose gloves that are heat-resistant, durable, yet flexible enough to allow easy movement of your fingers.

4. Welding Rods and Wire

Selecting the right welding rods and wire is crucial for the integrity of your weld. The material and diameter of the rods should match the material you are welding. Consult a professional or refer to manufacturer guidelines if you're unsure.

5. Safety Gear

Beyond the helmet and gloves, invest in a welding jacket, safety glasses, and ear protection. Ensure that your safety gear is of high quality and meets industry safety standards.

Quality and Brand Reputation

When choosing welding supplies, don't compromise on quality. Higher quality equipment may be more expensive upfront but can save you money in the long run due to its durability and efficiency. Research brands and read reviews from other welders to gauge the reputation and reliability of the products.

Price vs. Performance

While price is an important consideration, it should not be the only factor. Cheap supplies might not be durable and can compromise your safety and the quality of your welds. Balance the cost with the performance and longevity of the supplies.

Warranty and Support

Look for welding supplies that come with a warranty. A warranty is a sign of the manufacturer's confidence in their product. Also, consider the availability of customer support and ease of access to spare parts.

Compatibility and Ease of Use

Ensure that all your welding supplies are compatible with each other. For example, the welding wire should be suitable for your welding machine. Additionally, choose supplies that are user-friendly, especially if you are a beginner.

Maintenance and Durability

Invest in welding supplies that are known for their durability. Also, consider the ease of maintenance. A well-maintained welding machine and accessories can last many years.

Where to Buy

Purchase your welding supplies from reputable dealers or directly from the manufacturer. Trusted suppliers offer quality assurance and are more likely to provide after-sales support.

Final Thoughts

Choosing quality welding supplies is about balancing your needs with safety, durability, and budget. Whether you’re setting up a new workshop or upgrading your existing tools, the right supplies will ensure that you can tackle any welding project with confidence and skill. Remember, the quality of your welding supplies directly impacts the quality of your work. Happy welding! Contact us for more queries.

Read more:

Who is JGW Machine Limited?

What is metal fabrication?

0 notes

Text

What Are Some Misconceptions About Welding That You'd Like to Clarify?

Welding is a crucial skill in many industries, yet there are numerous misconceptions about it that can lead to misunderstandings about the craft and its tools. In this blog, we'll explore some common myths and clarify the facts, addressing topics from equipment choices to safety gear.

Is welding only for heavy-duty industrial projects?

What types of welding exist?

One common misconception is that welding is exclusively for large-scale industrial projects. In reality, welding is used in a variety of applications, from intricate jewelry making to car repairs. The three most common types of welding are MIG welding, stick welding, and TIG welding.

MIG Welder: Often used for its ease and speed, making it ideal for beginners and small to medium-sized projects.

Stick Welder: Known for its versatility and ability to weld in outdoor conditions, even on rusty or dirty metals.

TIG Welder Machine: preferred for its precision and clean welds, often used in automotive and aerospace industries.

Are all welding helmets the same?

What makes a good welding helmet?

Another misconception is that all welding helmets provide the same level of protection. However, the quality and features of welding helmets can vary significantly.

ESAB Welding Helmet: This brand is renowned for its high-quality helmets that offer superior protection and comfort. Features to look for include auto-darkening lenses, adjustable shade settings, and a comfortable fit.

Can Anyone Become a Skilled Welder Quickly?

How important are training and practice?

Many people believe that welding is a skill that can be quickly mastered. While basic welding techniques can be learned relatively quickly, becoming proficient requires extensive training and practice. Mastery involves understanding different materials, techniques, and safety protocols.

Is safety equipment overrated?

Why is safety crucial in welding?

A dangerous misconception is that safety equipment is often unnecessary. Welding involves high temperatures, bright light, and potentially hazardous fumes, making safety gear essential.

Everlast Welders: This brand offers equipment designed with safety in mind, ensuring reliable and secure operation. Essential safety gear includes welding helmets, gloves, protective clothing, and proper ventilation systems.

Are all welders the same?

How Do You Choose the Right Welder?

Not all welders are created equal, and choosing the right one depends on the specific needs of your project.

Everlast Welders: Known for their durability and advanced features, Everlast welders are a popular choice among professionals.

MIG Welder vs. Stick Welder vs. TIG Welder Machine: Each type of welder has its strengths. MIG welders are great for beginners, stick welders are versatile, and TIG welders offer precision for detailed work.

Does welding only involve joining metals?

What materials can be welded?

While welding is most commonly associated with metal, it is not limited to it. Welding techniques can also be used on various materials, including plastics and thermoplastics, expanding their applications in different industries.

Is welding just a manual labor job?

What career opportunities exist in welding?

Many people view welding as a simple manual labor job, but it offers a wide range of career opportunities. Welders can work in diverse fields, such as underwater welding, robotics, and industrial inspection. Advanced welders are highly skilled professionals who often work on complex and critical projects.

Does welding equipment have to be expensive?

Are there affordable options for quality welders?

A common belief is that quality welding equipment must be expensive. While high-end models are available, there are also affordable options that provide excellent performance.

Everlast Welders and ESAB Welding Helmet: Both brands offer a range of products to fit different budgets without compromising on quality and safety.

FAQ Section

Q: What is the best type of welder for a beginner?

A MIG welder is often recommended for beginners due to its ease of use and versatility.

Q: Can I use the same welding helmet for all types of welding?

Yes, but ensure it has adjustable shade settings and features like auto-darkening to accommodate different welding types.

Q: How important is brand choice in welding equipment?

Choosing reputable brands like Everlast welders and ESAB welding helmets can ensure reliability, safety, and quality.

Q: Is it necessary to wear a welding helmet even for small projects?

Absolutely. Welding helmets protect your eyes and face from harmful UV rays and flying debris, which can occur even in small projects.

Q: Can I weld materials other than metal?

Yes, certain welding techniques can be used on plastics and thermoplastics, among other materials.

In conclusion, welding is a versatile and complex skill that extends beyond misconceptions. Understanding the different types of welders, the importance of safety gear, and the career opportunities available can provide a clearer picture of what welding truly involves. Whether you are using an Everlast welder or an ESAB welding helmet, investing in quality equipment and proper training is crucial for success in this field.

1 note

·

View note