#Logistics Warehouse

Explore tagged Tumblr posts

Text

The Essence Of Logistics Warehouse And The Vital Role Of Logistics Specialists In Warehouse Logistics

In the intricate dance of global commerce, the logistics warehouse stands as a silent sentinel, a nexus where goods transition from production to distribution. But behind the scenes, orchestrating this symphony of movement, are the logistics specialists—the unsung heroes of warehouse logistics.

Understanding the Logistics Warehouse

A logistics warehouse is not merely a repository for goods; it is a dynamic ecosystem where efficiency reigns supreme. Within its walls, inventory ebbs and flows, each movement meticulously orchestrated to minimize waste and maximize throughput. From the moment a shipment arrives at the loading dock to its final dispatch, every step is carefully choreographed to ensure seamless operation.

The Role of a Logistics Specialist

Enter the logistics specialist, a maestro of efficiency, armed with a keen understanding of supply chain dynamics and a repertoire of tools to optimize warehouse logistics. Their domain encompasses a wide array of responsibilities, from inventory management and order fulfillment to transportation coordination and process optimization.

Navigating the Complexities of Warehouse Logistics

In the realm of warehouse logistics, every decision carries weight. Logistics specialists must navigate a labyrinth of variables—demand forecasts, inventory turnover rates, transportation constraints—to chart the most efficient course forward. Leveraging advanced analytics and modeling techniques, they unravel the complexities of supply chain dynamics, identifying bottlenecks and opportunities for improvement.

Harnessing Technology for Efficiency

In an era defined by technological innovation, logistics specialists wield an array of tools to enhance warehouse logistics. RFID tags track the movement of goods with pinpoint accuracy, while automated storage and retrieval systems optimize space utilization. Meanwhile, predictive analytics algorithms forecast demand patterns,

allowing for proactive inventory management and resource allocation.

The Human Element

Yet, amidst the sea of data and automation, the human touch remains indispensable. Logistics specialists serve as liaisons between suppliers, carriers, and internal stakeholders, forging partnerships that grease the wheels of commerce. Their ability to communicate effectively and resolve conflicts ensures that the gears of warehouse logistics continue to turn smoothly.

Embracing Continuous Improvement

In the fast-paced world of warehouse logistics, stagnation is not an option. Logistics specialists are perpetually on the lookout for ways to refine processes and drive incremental gains in efficiency. Whether through the adoption of lean principles or the implementation of cutting-edge technologies, they remain steadfast in their pursuit of excellence.

In conclusion, the logistics warehouse is more than just a physical space—it is the beating heart of the global supply chain. And at its helm are the logistics specialists, dedicated stewards of efficiency and architects of success. Through their tireless efforts, they ensure that the wheels of commerce continue to turn, driving progress and prosperity in an ever-changing world.

0 notes

Text

5 Essential Strategies for Streamlining Your Logistics Warehouse

In the fast-paced world of logistics, a well-organized and streamlined warehouse is the heart of a successful supply chain. As businesses strive to meet customer demands and stay ahead of the competition, optimizing the logistics warehouse becomes a top priority. To achieve peak efficiency and productivity, innovative strategies must be employed. In this comprehensive guide, we will explore five essential strategies that will revolutionize your logistics warehouse and elevate your operations to new heights.

1. Embrace Cutting-Edge Technology:

The future of logistics lies in advanced technology, and integrating it into your warehouse operations is the key to success. Embrace automation, IoT devices, and AI-powered systems to revolutionize the way you handle inventory and processes.

Automated Storage and Retrieval Systems (AS/RS): Employing AS/RS allows for seamless storage and retrieval of products, minimizing manual labor and reducing human errors. Utilize robotic systems to handle repetitive tasks, freeing up your skilled workforce for more complex challenges.

Internet of Things (IoT) Devices: Outfit your warehouse with IoT sensors to monitor real-time inventory levels, temperature, and humidity. This data-driven approach enables proactive decision-making, ensuring optimal stock management and minimizing the risk of stockouts.

Artificial Intelligence (AI) for Predictive Analytics: Leverage the power of AI to analyze historical data, predict demand patterns, and optimize inventory levels. AI-driven algorithms can anticipate fluctuations in demand, enabling you to stay ahead of market trends.

2. Optimize Warehouse Layout for Efficiency:

A well-organized warehouse layout is the cornerstone of smooth operations. By maximizing space utilization and optimizing the flow of goods, you can minimize handling time and improve overall productivity.

ABC Analysis for Inventory Segmentation: Apply the ABC analysis technique to classify inventory based on its importance and value. Store high-demand items closer to the packing stations for quicker access, while lower-demand items can be placed further away.

Cross-Docking and Zone Picking: Implement cross-docking and zone picking strategies to reduce unnecessary handling and expedite order fulfillment. These strategies promote efficient movement of goods from the receiving area to shipping docks, bypassing the need for lengthy storage.

Dynamic Slotting: Continuously reevaluate the arrangement of products in the warehouse based on real-time demand data. Dynamic slotting ensures that popular items are always within easy reach, cutting down on travel time for pickers.

3. Implement a Robust Warehouse Management System (WMS):

A modern Warehouse Management System is the backbone of a streamlined logistics warehouse. This comprehensive software solution brings automation and optimization to every aspect of warehouse operations.

Real-Time Inventory Tracking: A WMS provides real-time visibility of inventory levels, enabling accurate stock management and reducing the risk of stockouts or overstocking.

Order Fulfillment Automation: Automate the order fulfillment process, from order receipt to shipping, to eliminate manual errors and reduce lead times.

Optimized Picking Routes: A WMS can optimize picking routes to ensure the most efficient movement of pickers, minimizing travel time and maximizing productivity.

4. Foster Collaboration and Communication:

A well-coordinated logistics warehouse relies on effective collaboration and communication between all stakeholders. Break down silos and establish clear channels for information flow to enhance efficiency.

Cross-Functional Teams: Create cross-functional teams involving various departments to address warehouse challenges collectively. This approach fosters a culture of collaboration and problem-solving.

Regular Performance Review Meetings: Schedule regular meetings to review warehouse performance metrics. Analyze data and identify areas for improvement to continuously enhance warehouse efficiency.

Employee Empowerment: Encourage employees to contribute ideas and suggestions for process improvement. Empowered employees feel valued and motivated to actively participate in streamlining operations.

5. Invest in Workforce Training and Development:

Your warehouse staff are the backbone of daily operations. Investing in their training and development enhances their skills and boosts overall warehouse productivity.

Continuous Training Programs: Conduct regular training sessions to keep your workforce up-to-date with the latest industry trends, safety protocols, and technological advancements.

Upskilling and Cross-Training: Encourage employees to diversify their skill sets by cross-training them in various warehouse functions. A versatile workforce can seamlessly adapt to changing demands.

Employee Recognition and Incentives: Recognize and reward exceptional performance to boost employee morale and foster a positive work environment. Incentives can inspire employees to exceed expectations and drive warehouse efficiency.

By embracing these five essential strategies, you will transform your logistics warehouse into a well-oiled machine, capable of meeting customer demands with unmatched efficiency. Utilize cutting-edge technology, optimize warehouse layout, implement a robust WMS, foster collaboration, and invest in workforce development to streamline your logistics warehouse and secure a competitive edge in the dynamic world of logistics.

Remember, the logistics industry is constantly evolving, and continuous improvement is the key to staying ahead. Embrace innovation and stay proactive to achieve sustained success in the ever-changing logistics landscape.

0 notes

Text

Which Warehouse Does Your Business Need?

You need a warehouse.

You have pinpointed the most optimal location and finalised on all the high-tech equipment and machinery to function with ease, but how do you decide which warehouse building is best suited for your operations and functions? Let’s find out.

The Standard Warehouse

For operations that only need basic walls, a roof and some clear space, the standard warehouse is the way. These warehouses can be made in any size required and are extremely versatile.

It is possible to fit them with skylights and windows as well as with multiple gates, ramps and docks. They are a popular solution for almost every industry, providing storage for machines, raw materials and equipment, and products in production; serving as transshipment points in logistics; storing goods for retailers and wholesalers; acting as distribution centres for e-commerce; and even housing donations and relief supplies for non-profit organisations.

A standard warehouse can be easily adapted to specific equipment and spatial requirements by the warehouse developer and are extremely cost effective for businesses that require minimal retrofits to get going.

The Container Warehouse

This is a specific kind of storage warehouse is a stopover for goods coming or going from freight transport. These warehouses are used to consolidate or deconsolidate freight goods to prepare them for the next legs of their journey. Or in other words, it is a temporary storage for the goods to wait a little for other goods to come and fill a container up, before they can be shipped off. The challenge here is to have a system that allows storing, tracking and retrieving the goods easily and efficiently.

Container warehouses need to be located close to ports, airports, or major railway hubs. These warehouses can be designed for efficient cross-docking and provision can be made for ample parking space for holding trucks even in case of demand surges. These warehouses are also equipped with stacking racks, crane systems, container frames, floor anchors, proper lighting, and robust security systems.

The Open-Air Warehouse

For large and heavy items that are difficult to move in and out of warehouse dock doors, open-air warehouses provide an efficient storage solution. Custom-designed racks for open yard storage can offer protection from atmospheric elements and play a key role in keeping the goods safe. Typically, the warehouse is an open area with space demarked and fenced in with walls with a high level of security to safeguard the assets.

Depending on the sensitivity of the goods and the extremities of the climate, storage can be covered or partially roofed. Goods are also protected by covering them in plastic wraps or tarps. These warehouses are commonly used to store vehicles, spare parts, machines, and raw materials for construction, metalworks, or timber sectors. The design of open-air warehouses focuses on shielding goods from harsher natural elements like direct sun or snow but may not address milder elements like humidity, wind, dust, and temperature fluctuations.

The Industrial Warehouse

This is the modern-day factory which may span across multiple halls and floors and can be tailored to integrate advanced technology and equipment. The industrial warehouse can be designed to have spacious loading and unloading areas; ample space for machinery, equipment, goods, and workplaces; high ceilings and large doors for the transporting of goods and large machines, even indoors; bright administrative and office areas; parking spaces for delivery and staff vehicles; pleasant social and relaxation areas for the workers; strong load-bearing floors; a reliable energy supply and ventilation; independent lighting systems for each work area and fire protection measures like fire alarms, smoke detectors, and fire extinguishers.

These warehouses are especially popular for manufacturing companies, energy and utility companies and businesses in the food and beverage industry.

The Custom-Made Warehouse

When your business needs are too complex to be housed in a pre-made standard warehouse, you need a warehouse designed around your requirements. These are called built-to-suit warehouses. They provide a high degree of customisation and can be made to create the ideal environment needed for your operations and goods.

Need a cold storage with consistent temperature and humidity, immaculate hygiene and protected electrical circuits? It is possible. Need a chemical warehouse with good ventilation systems, fire containment measures and specialised storage? Also, possible. Retail warehouses with space for smart racking and processing machines, auto warehouses with complex assembly lines or heavy industry that need tall lifting equipment and sturdy densified floors, a custom-made warehouse lacks for nothing.

The Automated Warehouse

If you are a business that uses machines to do it all, then an automated warehouse is what you are looking at. These are computer-controlled environments with automated racking and shelving, conveyor and retrieval systems. While the investment cost is definitely high, the efficiency is unmatched. These warehouses are sought by large trading companies, global e-commerce giants, logistics parks in India and manufacturing behemoths.

At the end of the day, you know your business needs better than anybody. It is crucial thus, to find a warehouse developer who is proactive in understanding your functional requirements and who works with you to overcome any infrastructural challenges in a collaborative way. At Horizon Industrial Parks, our teams specialise in delivering custom-made warehouses as well as providing swift plug-and-play solutions that can get your operations running in no time. To learn about what our customers like about us, click here, and visit our website to connect with us for exploring collaboration opportunities.

#warehouse#business#ecommerce#supply chain management#manufacturing#automobile#last mile delivery#logistics#real estate

2 notes

·

View notes

Text

RHYME ANIMA PLEASE!!!!!!!! MERCY!!!!!!!!!! I AM BEGGING FOR MERCY PLEASE!!!!!!!!!!!

#this is vee speaking#KUUKOU HAS A MOPED SO PLS IMAGINE HIM DELIVERING PACKAGES WITH HIS MOPED#GRRRRRRRRRRRRRRAAAAAHHHHH#i think it’s equally fun to have kuukou on logistics lol and have him guiding jyushi and hitoya on their routes lol#kuukou receives the packages at the warehouse he and jyushi load up vans and jyushi and hitoya deliver them#after hitoya and kuukou plan routes lol and hitoya’s the one with the license so he’ll take the delivery trucks#and jyushi sometimes goes by bicycle lol bat’s postal service if they were stationed in a small town lol

8 notes

·

View notes

Text

easyTRACK Warehouse Management System

An intelligent solution to control movement and storage of materials within a Warehouse.

A well-structured Warehouse Management system is important for the smooth and efficient operation of any warehouse, irrespective of the size or volume of material it handles. Most of the small and medium warehouses do not require an expensive WMS with redundant features. easyTRACK WMS is a perfect solution on the enterprise mobility for the warehouse management of small and medium enterprises which helps them manage all the essential warehouse functions. easyTRACK warehouse automation software allows the users in warehouse to manage the following operations at their palm.

Goods receiving

Put away

Picking & Palletizing

Dispatch

Stock count, etc.

easyTRACK WMS Lite Benefits

Solves the challenges faced in the conventional system.

Goods Receiving-

Priority Issue Multiple Shipments received at a time

Delayed Data entry Stock may be available but not available for Sale Dead /Damage/Short supply on arrival not instantly notified.

SOLUTION: GRN on PDT “goods receiving made easy with GRN on PDT”

Welcome to Technowave Group, your trusted provider of advanced technology solutions in Dubai. Our RFID Warehouse Inventory Management Systems can help businesses improve their inventory management and provide complete visibility into their warehouse operations.

What is RFID Warehouse Inventory Management System?

RFID Warehouse Inventory Management System uses RFID technology to automate the process of inventory tracking and management. It involves tagging inventory items with that contain unique identification numbers. The RFID tags are read by RFID readers, which transmit the data to a computer system that stores the information and provides real-time updates on the inventory’s location, movement, and status.

Key Features of our RFID Warehouse Inventory Management System

Our RFID Warehouse Inventory Management System comes with the following key features:

Real-time inventory tracking:

Our RFID system provides accurate and up-to-date information on inventory levels, locations, and movements in real-time. This means that businesses can quickly identify any discrepancies, such as missing or misplaced items, and take corrective action before they become bigger problems.

Inventory management:

Our RFID system automates the inventory management process, including item counting, reordering, and tracking. This means that businesses can easily monitor inventory levels and reorder products when they are running low. This helps prevent stockouts and ensures that products are always available for customers.

Asset tracking:

It can track and manage assets, including equipment, tools, and vehicles, helping businesses keep track of their assets’ location, status, and maintenance schedules. This allows businesses to optimize asset utilization and minimize downtime, which can result in significant cost savings.

Reporting and analytics:

The RFID system generates detailed reports on inventory and asset tracking, providing businesses with valuable insights into their warehouse operations. Businesses can use this information to identify areas for improvement and make informed decisions about inventory levels, order fulfillment, and asset management.

Improved accuracy and efficiency:

Our RFID system eliminates the need for manual inventory tracking, reducing the risk of errors and improving accuracy. This saves time and resources by automating inventory management and asset tracking, allowing businesses to focus on other critical tasks.

Improved visibility and control:

It provides real-time updates on inventory and asset movement, giving businesses complete visibility into their warehouse operations. This helps businesses make informed decisions and take corrective action quickly, leading to increased efficiency and productivity.

Improved customer satisfaction:

Our RFID system helps businesses improve their order fulfillment process, reducing stockouts and improving delivery times. This leads to increased customer satisfaction and repeat business, which can be a significant competitive advantage in today’s market.

Compliance with regulations:

Last but not least, our RFID system helps businesses comply with regulations related to inventory tracking and management. For example, our system can provide traceability requirements for food and pharmaceutical products, ensuring that businesses meet regulatory requirements and avoid costly penalties.

Overall, our RFID Warehouse Inventory Management System offers businesses a range of benefits, from increased efficiency and productivity to improved customer satisfaction and regulatory compliance.

Get in Touch With Us!

At Technowave Group, we have a team of experienced professionals who are dedicated to providing high-quality service and support to our clients. We work closely with our clients to understand their unique business needs and provide tailored solutions that help them achieve their goals.

Whether you are a small business or a large enterprise, we can help you leverage technology to improve your warehouse operations and achieve your goals. Contact us today to learn more about our RFID Warehouse Inventory Management System and other technology solutions.

3 notes

·

View notes

Photo

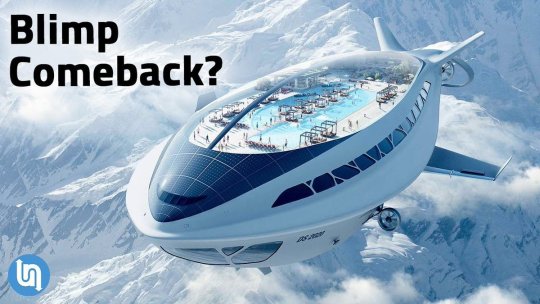

#this is what i believe in#sorta related i was reading an article a few weeks ago#where they discussed the idea of using dirigible drones to load and unload cargo ships off the coast#instead of waiting for them to enter port#at least partly#i just love airships and i'm hoping they make a comeback#also on a related note i'm just really excited to see how automation/robotics changes logistics#things are about to get really efficient#logistics have largely been the same for like a century#we're about to witness a supply chain revolution#and at all levels of the supply chain#just imagine#autonomous cargo ships unloading at autonomous ports#ships waiting in line are unloaded by drones#then fleets of autonomous trucks#and revitalized trains#then smaller drones to directly deliver packages from stores/warehouses to consumers

6 notes

·

View notes

Text

Finally got to sit down with my friends and do the session 0 bookkeeping for Beam Saber and I'm so pumped. Going into sessions I'm GMing and being genuinely surprised by something we collectively find/create is The Juice for me.

#The PC base is an underground metro. They have a warehouse-train on the tracks they're getting operational again.#One of the PCs is half scene kid half Thracian Auxiliary#The term Rogue Logisticians could be used to describe about half of what this game is shaping up to be#And you'd think Rogue Logistician would mean smuggler but nay. It just so happens that people in logistics are crafty and treasonous

5 notes

·

View notes

Text

Embrace the Future of Warehousing with IT! Say goodbye to manual processes and hello to efficiency. Imagine real-time tracking, lightning-fast order processing, and easy inventory management. We're at the forefront of a tech revolution in warehouse operations, where innovation leads to smarter, faster, and more effective workflows. Join us in this exciting journey! 📈💡

2 notes

·

View notes

Text

I never thought that applying for different schools (or well two schools, five educations) could be this exhausting. 😓 It’s like a job application, just a lot more questions.

But at least this time, for the first time in my life, I actually felt like I had something to give. And actually had some solid work/training/volunteering experience to list here as well, which feels pretty freaking nice let me tell ya. 🙃🤣 My work history/experience is quite varied and colorful after all, and there are some fairly large gaps there and there, too, so. It felt nice - for once - to actually just think about those questions - why they should pick me for their education/school and what are my qualifications/hobbies yadda yadda - and you know, just. Feel the flow. How my fingers just started magically typing, and I ended up writing a whole goddamn essay about it. 😅 (of course then I had to copypaste all that 2-3 times because it was all under the same occupation, just different career fields so---)

But anyway, it’s all good now. I’ve applied for two different schools, filled four different applications. I still have one more to go but that’s for an entirely different occupation, so. I’m gonna do it tomorrow. 🤣

I just hope at least one school would accept me because I really need this.

#personal#i don't know what the education is called in english. they've got all kinds of fancy names here#but it would basically allow me to work either with children or teens. either by guiding them and their activities#or helping with their school and stuff as a personal assistant#the other one i'm thinking about is working at the logistics. mainly warehouse or airport terminals etc.#i've got a little bit of experience from that kind of stuff too#i just don't know if my bad back/hips could take that kind of work for a long time so#it's my second option

9 notes

·

View notes

Text

Let's unite, shoulder to shoulder, as one nation, one army, standing strong and resolute. We Abhi Group of companies Wishing you a day full of energy, strength, and pride !

#supply chain#sea freight forwarder#logistics solutions#warehouse#logistics company#storage containers#warehousing#import export business#logistics#India#independence day#happy independence day#15 august

2 notes

·

View notes

Text

#warehousity#4pl#fulfillment#warehouse#ecommerce#india#controltower#logistics#warehousing#supplychain

2 notes

·

View notes

Text

Logistics Warehouse

Logistics Warehouse - From sourcing the finest products to connecting businesses worldwide, we're your gateway to global trade. Let's unlock opportunities together! 🚀🌐

0 notes

Text

Flostream’s 45,000 sq ft Warehouse is the home for our vast range of professional warehousing services, including e-commerce fulfilment, pick and pack, and more.

Get in touch with us today for e-commerce warehousing solution!

#Warehouse Storage#E-Commerce Fulfillment Services#Warehousing Storage Solutions#Logistics#FloStream

2 notes

·

View notes

Text

Varuna logistics companies in mumbai, India. With a strong presence in the bustling city, the company specializes in providing comprehensive logistics solutions to businesses across various industries. Known for its efficient and reliable services, Varuna Logistics offers a wide range of services including transportation, warehousing, supply chain management, and customs clearance. With a dedicated team of professionals and a commitment to customer satisfaction, Varuna Logistics is a trusted partner for companies seeking seamless and cost-effective logistics solutions in Mumbai.

#logistics companies in mumbai#Third Party Logistics#warehouse services in bangalore#warehouses in bangalore#third party logistics companies in india

2 notes

·

View notes

Photo

Sustainability in freight forwarding: challenges and opportunities Sustainability has become a major concern in the freight forwarding industry as customers increasingly demand environmentally responsible practices. Here are some challenges and opportunities related to sustainability in freight forwarding:

Challenges:

Limited visibility: The complex nature of supply chains and the lack of transparency in transportation networks make it difficult for freight forwarders to track the environmental impact of their operations.

Regulatory compliance: Freight forwarders must comply with a range of environmental regulations, such as emissions standards, fuel efficiency requirements, and waste disposal regulations, which can be complex and costly to implement.

Cost implications: Sustainable practices often require significant investment in new technology, equipment, and processes, which can be expensive for freight forwarders, particularly small and medium-sized enterprises.

Limited awareness: Some freight forwarders may not fully understand the benefits of sustainable practices, or may not be aware of the latest technologies and techniques available to reduce their environmental footprint.

Opportunities:

Green technologies: Freight forwarders can adopt new technologies such as electric vehicles, alternative fuels, and energy-efficient equipment to reduce their environmental impact.

Collaboration: Freight forwarders can work with their customers, carriers, and other stakeholders in the supply chain to develop sustainable practices and share knowledge and resources.

Innovation: Freight forwarders can explore new business models and innovative approaches to reduce their environmental footprint, such as circular supply chains, low-carbon logistics, and sustainable packaging.

Competitive advantage: Adopting sustainable practices can provide a competitive advantage for freight forwarders, attracting environmentally conscious customers and enhancing their reputation as responsible corporate citizens.

In summary, sustainability poses significant challenges for the freight forwarding industry, but also presents opportunities for innovation, collaboration, and competitive advantage. Freight forwarders that embrace sustainable practices can position themselves for long-term success in a rapidly evolving business landscape.

Do follow us: 𝐋𝐢𝐧𝐤𝐞𝐝𝐢𝐧:- https://lnkd.in/dDPayNqD 𝐅𝐚𝐜𝐞𝐛𝐨𝐨𝐤:- https://lnkd.in/dhepw6qM 𝐈𝐧𝐬𝐭𝐚𝐠𝐫𝐚𝐦:- https://lnkd.in/dW8UHay9 𝐘𝐨𝐮𝐭𝐮𝐛𝐞:- @spiderworldglobal 𝐓𝐰𝐢𝐭𝐭𝐞𝐫:- https://lnkd.in/dGUjQKGs Do Visit:- 🌏 https://spiderworld.net/

#entrepreneurship#freight forwarding#shippingworldwide#shipping#internationaltrade#sustainability#custom#innovation#logisticsandsupplychain#supplychain#supplychainsolutions#ecommerce#globalization#warehouse#trendin#TrendingPost#trending new#LogisticsManagement#logistics news#photooftheday#challenger

2 notes

·

View notes