#Lockout Tagout Procedure

Explore tagged Tumblr posts

Text

Enhancing Safety and Productivity: The Essential Role of Lockout Tagout

Maintenance of a machine is done to increase productivity and efficiency, but a careless servicing process leads to deterioration and accidents. While servicing a machine, workers face the danger of exposure to hazardous energy. This hazardous energy can be present in any form and cause the machine to start moving again. Workers can fall off moving belts, get crushed under automated machines and even get electrocuted by faulty panels. All these incidents happen when a machine either retains stored energy or is unintentionally started by an unaware employee. Operating belts, sharp cutters, grinding/mixing machines, toxic material carrying pipelines and other such machines pose a serious threat to workers. Craft workers, electricians, machine operators and labourers are a few among many workers who are prone to accidents. Machinery-related fatalities form a significant part of accidents and result from failure to control hazardous energy.

The evolution of energy has been a steady progression from simple to more powerful and dangerous sources. Hazard associated with all forms of energy and force includes unexpected movement, direct contact with an unshielded energy source, and being caught in a mechanism driven by a form of energy or source. Safety measures like Lockout Tagout are more crucial today than ever before.

Just informing the facility personnel or assuming the machine will remain inoperative is not enough to ensure safety. Workplace accidents are a critical issue that needs to be addressed by every health and safety official regardless of the company's size. Specific steps must be taken to guarantee safe working conditions for all workers. It is the duty and responsibility of employers and employees to protect their own lives and those around them. Lockout Tagout not only helps you avoid OSHA violations but also protects workers' lives. According to OSHA, LOTO saves workers from approximately 120 fatalities and 50,000 injuries yearly.

OSHA or Occupational Safety and Health Administration enforced Lockout Tagout for control of hazardous energy guidelines in 1990. The Lockout Tagout procedure is a safety policy that protects workers from unexpected machine start-up. Lockout/Tagout is the practice of shutting down and disconnecting power from machinery or equipment and placing locks and warning tags on energy-isolating devices to prevent the machine or equipment activation during maintenance or servicing by bringing it to a zero-energy state. It renders the machine inoperative and harmless. This safety procedure ensures that hazardous energy is controlled and any worker present in the area can't be harmed.

Control of hazardous energy can be achieved through Lockout Tagout devices. The employee puts the Lockout Tagout devices on the machine's energy control points, isolating and securing its movement. The authorised employee adds a padlock and a tag to the lockout device so no other person can accidentally energise the machine. These devices should be durable, substantial, standardised, and identifiable. Although there are thousands of available LOTO products in the market, you can identify the best ones for your facility or take advice from an expert. Every control point must be locked and tagged for a successful safety program using effective devices. In addition, a maintenance worker needs to know how to use energy-isolating products effectively.

The worker servicing the machine should have in-depth knowledge about the Lockout Tagout process. Whether it is a third-party servicing team or the company's employees, they need suitable training in the application of Lockout Tagout. They should know, understand and follow documented Lockout Tagout procedures. OSHA mandates that every authorised employee possess the necessary skills and knowledge about the LOTO process. Affected employees or other employees should be aware of the ongoing maintenance process and receive basic training. Safety administrations like OSHA have imposed such directives to create an effective safety program with workers’ participation.

OSHA addresses standards for the protection of employees during maintenance from unexpected start-up of machines. Companies must develop, implement and enforce machine-specific procedures to control hazardous energy. It outlines specific actions, training and devices to create your safety policy. It gives guidelines for general industry as well as particular industries for an efficient LOTO program. Workers need not use Lockout Tagout during regular servicing operations, which are essential for the machine's normal functioning and don’t put workers in harm's way.

The Lockout Tagout Standard requires employers in certain industries to establish an energy control program for locking out equipment, employee training, and periodic inspections. Different industries call for different protective measures. Workers who service industrial machinery and equipment face unique hazards due to their close contact with equipment. They frequently work in dangerous zones beyond machine guards that protect workers during normal production operations. Consequently, special procedures are necessary to protect workers during maintenance and servicing.

OSHA estimates that failure to adequately control hazardous energy accounts for 7% of all occupational fatalities and nearly 10% of severe accidents in many industries. There is a prevailing presumption that if an employer develops a Lockout Tagout program meeting the requirements of the OSHA 29 CFR 1910.147 standard, compliance will be achieved and energy release incidents will be more or less eliminated. It is important to remember that attaining legal compliance represents only the minimum safety criteria and employers need to go beyond minimalism. With an effective Lockout Tagout program in place, injuries and losses arising from failure to control hazardous energy are entirely preventable.

# Case Study 1 - In an automotive manufacturing industry, greasing operations are performed by an automatic machine enclosed in a cage. A worker wanted to unjam the greaser’s stuck arm; he entered the cage without de-energizing the machine and locking it out. When he tried to unjam the arm, the machine short-circuited and started unexpectedly. The operator’s arm was caught in the machine and was injected with grease. Such a situation could have been avoided by draining and isolating the energy sources of the machine.

# Case Study 2 - A scrap metal shredder took a worker’s life due to a lack of LOTO devices. The employee tried to unjam a metal piece stuck in the shredder. As soon as he unclogged the shredder, it started working and took the employee down.

All these incidents occurred due to improper implementation of LOTO devices. LOTO implementation has been saving numerous lives by -

· Lockout Tagout Safety devices prevent accidental clicking of switches. It prevents another employee from unknowingly operating the machine.

· They warn and inform employees about the ongoing service. New employees or shift changes can create confusion without proper warnings.

· It holds the employee accountable for his own safety and that of others around him. Having a mandatory LOTO procedure saves workers from accidents.

· It creates awareness among employees and makes them attentive towards incidents occurring in the workplace.

Year after year, Lockout Tagout violations continue to be amongst the top ranks of OSHA’s top ten violation list of most frequently cited standards and serious violations. Despite the alarming number of machine-related accidents and OSHA’s enforcement efforts, Lockout Tagout is still viewed by many as burdensome and production slowing-task. But companies which have employed effective Lockout Tagout programs have seen a boost in employee morale, and productivity resulting in souring profits.

#Lockout Tagout#Lockout Tagout Procedure#LOTO Safety#Lockout Tagout Safety Devices#LOTO Products#Lockout Tagout Procedures#Role of Lockout Tagout#OSHA#Lockout Tagout Case Study#E-Square Alliance

0 notes

Text

#Laws of Motion/Fight Club#Laws of Thermodynamics/self care affirmations#Pool rules/Arnold Schwarzenegger's rules of success#Lockout tagout procedures/prison tamale recipe#Road safety tips/bear survival tips#Rules for gun safety/genie rules from that one meme#is this anything#what? anda... no.

7 notes

·

View notes

Text

hey girl are you in violation of Title 29 Code of Federal Regulations Part 1910.147, because i'd hot tap that ass, and the exception listed in 1910.147(a)(2)(iii)(A), uh... actually, wait, shit is that even the right one? [flipping through a gigantic book] uh... shit where is it... shit. fuck. okay no it was 1910.147(a)(2)(iii)(B). uhhh. anyway I'd hot tap that ass... without...... proper lockout/tagout procedures... and your ass does not qualify as [tracing my finger along the page as I read] a transmission or distribution system for substances such as gas, steam, water or petroleum products where, uhhh, where the employer has—wow okay this is a lot more than i remembered—where the employer has... demonstrated that continuity of service is essential, shutdown of the system is impractical, and documented procedures are followed, and special equipment is used which will provide proven effective protection for employees. yeah. oh, 1910.147(a)(2)(iii)(A) is an exception too of course, but that one doesn't reference hot tapping so it doesn't work as a double entendre. but that one doesn't apply to your ass either, just trust me. oh, nor does the other set of exceptions in 1910.147(a)(1)(ii). so. um. uhh. I forget where I was going with this. sorry to bother you.

929 notes

·

View notes

Text

why does so much robotfucking hornyposting on this site revolve around opening up a computer/robot/android and rooting around in its internal wiring WHILE IT'S ON? do yall not value your fingers? at least integrate proper lockout/tagout procedure into your fantasies. and then there's the issue where letting someone literally open you up and stick their hands in your organs carries a pretty high risk of straight up dying, especially if that person's only medical/technical qualification is being horny about it. that's like letting a grindr hookup with a surgery fetish but no medical education whatsoever perform an appendectomy on you

#being an android and seeing the person doing maintenance on you checking the manual mid-repair#would be like seeing your dentist google “how to fill cavity” while he has a drill in your mouth

108 notes

·

View notes

Text

i work in the factory that makes those little boxes of 'juice that makes you cum super hard' you see twitter nsfw artists draw. yeah it's actually pretty high-safety because the raw ingredients are a lot more concentrated. we need full PPE on the shop floor because the full concentrate can work on skin contact. we keep the mixture in two separate components until the last moment possible, but someone still got hit by some spray from the reactor vessel last year when working on it, and orgasmed into cardiac arrest. we have a really good bystander chest-compressions procedure, and on-site AEDs, after the union established the new first aid training policy, so they made it to hospital and survived, but we have a new lockout-tagout policy for that entire part of the production line now

204 notes

·

View notes

Text

[It is January of 2022. I’m entering a wing of the DC Office site that looks older than the others. The carpets are a strange brown, vintage looking, and the lighting casts an almost yellow pallor over the wood paneled walls. I can practically smell the cigarettes. I pass by an empty room labeled “social media office” - boxes piled up by the door. Maybe they’re going to be using it soon. They’ll need it.

I approach a door labeled Necrocommunications, knock lightly twice, then enter.

I am greeted with the sound of a voice drifting softly across the room. A few chairs and tables sit around me, the same vintage style as the hallway before, the same browns and yellows. A high desk is across the room, and a woman is seated at a control panel. She has black curly hair, done up in an old fashioned style, a polka dotted blouse, and though she’s facing away from me, I can see the edges of cats-eye glasses.

The panel she’s working at is huge, and resembles the type of switchboards they used to use in the ‘50s, dozens of physical wire connections crisscrossing the device and attaching via plugs. The woman has a headset, one ear covered in a bulky speaker, with a microphone near her mouth. She speaks casually, with an incredibly heavy New Jersey accent.]

I] Oh, him? He’s circled, babe. Taken as hell. Mhmm. And he still asked you? Ain't that a bite. So now you know he’s out of the question and yarding on. Dodged a bullet, hun.

M] Irene?

I] Oh, god, hold on. My appointment is here. Yeah. I’ll call you later, beautiful. Caio.

[She hung up the call, taking her headset off and turning to me. She looked like she was straight out of my grandfather’s high school photo album, including the color. Her skin was almost grey, it was so pale, but she didn’t seem like she was sick. She looked me over with a smirk and a raised eyebrow, leaning forward on her desk.]

I] Well, hello Miss Meghan Hendricks. What can I do for you, sugar?

M] I’m here to interview you for my audit, Ms Donofrio.

I] All business, aincha?

M] This is my job.

I] ….yeah, you’re right. Sorry. I don’t get cute visitors much.

M] Right.

I] Pull up a chair, hun.

M] I’ll just stand. This won’t be long. I came here because of your Occult Communication Tools poster.

[She sits back with a dramatic sigh.]

I] Yeah, took me forever to convince them to let me do that. We had agents using spirit boards, pendulums, casting runes, tarot cards, ghost boxes, all kinds of shit they brought from home. Bought from Walmart, or worse, a thrift store. I was always telling them, honey, baby, you gotta use our stuff, we maintain it, we disinfect it of ectoplasmic residue, lockout-tagout procedures, the works. It’s so, so unsafe to use anything but our tools. Sure, you gotta do paperwork when you check it out, but it’s better than somethin’ following you home…

M] Right into it, I guess. That’s what Necrocommunications does, right? Talk to the dead?

I] You bet, sugar. The dead, demons, angels sometimes when they ain’t on our plane or in realspace. Other little spiritual twerps and bugaboos.

M] I’ve been asking this a lot in the last few months, but…you can do that? Consistently?

I] Consistent enough to make it worthwhile. S’not perfect. Fails most of the time, depending on who you’re calling.

M] How so?

I] Well, some people don’t wanna be called. Some people are chatterboxes. We got a list of likely contacts who we suggest people contact, but…we do other people sometimes, too. Always worth a shot, I say.

M] How does it work?

[At that, Irene winced slightly and wagged her head from side to side.]

I] We got theories, but more importantly we got procedures. We know different things work for different people. Sometimes it’s cultural. The method that contacts Mr Smith may not work for Mr Chan, y’know?

M] It’s mostly for information gathering, then. Like the Board of Infernal Affairs.

I] Information gathering’s a big part of it. Someone died with a secret? See if they got loose lips now. Also, y’know, helps with hauntings or gettin’ rid of little jerk spirits.

M] You mentioned disinfection….

I] Yeah, yeah, there’s….risks, y’know. Sometimes the person you contact ain’t a fink, you know, and they start a whole new haunting. Sometimes one spirit’ll lie and say they’re another. Then they follow you home, start leeching your energy. Happens less when we cleanse the tools. Which is why there’s procedures for this, and every Office staff member in the building is trained on at least the basics.

M] Is it….is it only for Office personnel? Is it something I could…

[Irene’s face grows into a playful smirk as she hears the hesitation in my voice, leaning her face in her hand.]

I] You got fifty cents?

[She leads me into a back area of the office. Lining the walls in storage containers are row upon row of spirit boards, each box with a paper listing the dates each was used and then cleaned, along with the name of the person who did it. There are other items, too - pendulums, bags of runes, spirit boxes like you see on ghost hunting shows, and other devices and artifacts I don’t recognize. Irene’s attention, however, is on a phone booth at the end of the room. It’s clean but battered, clearly old and used. It has no door, but an open front, and above the phone itself is a depiction of a figure on a boat, with one word beside it: “Charon.”]

I] We confiscated these in the 80’s. It’s easier to use this one than have to sign out spirit board, y’know.

M] Weren’t you just complaining about that?

I] I complain about a lot of things, sugar.

[I approach, standing before the phone in disbelief. Irene senses my hesitation.]

I] Put in the money, then use the keypad to type out the person’s name. It’ll take it from there. Who you gonna call? Grandma? Mom?

M] My brother.

I] Ah. Shit, honey.

M] He died in California. Two summers ago.

[As I reach for the receiver, I see Irene’s face freeze in some sort of concern.]

I] H-honey, that…was he in—

M] Yes.

[I put my hand on the receiver, and I feel her hand on mine. She’s cold. She’s so cold and clammy that I jump slightly and look her in the eyes. Her face is sorrowful and scared, searching me.]

I] Honey…you won’t be able to—

M] You said—

I] If he was in…there’s no one there, sugar. He’s gone.

M] I know he’s gone, but you said I could—

I] No, no, he’s…if he was…he’s gone, gone. There’s nothing left of him. You can pump quarters into that thing all night long and you won’t get anyone.

M] H…how? I was…I was on the phone with him when it—

[As I watch, her eyes go wide, and she covers her mouth.]

I] Th-that’s how you remember, isn’t it? Thought you were just…in the Office but you hadn’t known about…that’s how you remember.

[I let go of the receiver. I can’t feel my fingers. I’m shivering, but not from the cold.]

M] I know how I remember. What I want to know is why everyone else forgot.

#office for the preservation of normalcy#interview#necrocommications#necromancy#microfiction#sci fi#horror#writers on tumblr

153 notes

·

View notes

Text

OSHA has cited AJLS Enterprises Inc.—which operates as Schoep’s Ice Cream in Madison, Wisconsin—for multiple safety violations and proposed penalties totaling $145,097. According to a release dated Jan. 29, the agency’s investigation was spurred by a report that workers were being exposed to anhydrous ammonia, a hazardous chemical used in refrigeration that can cause severe respiratory injuries and burns. OSHA ultimately issued 12 serious citations, including failure to institute processes for controlled release of hazardous chemicals. Other violations include the absence of lockout/tagout procedures, inadequate machine guarding, failure to train workers in lockout/tagout procedures, the absence of a written hazard communication plan, failure to update the emergency action plan and unprotected ladder openings posing fall hazards.

#news#labor news#osha#ajls enterprises inc#schoep's ice cream#madison wisconsin#wisconsin#wisconsin news#us news#osha violations

37 notes

·

View notes

Text

The thing about the woman who died in the walmart walk-in oven is that you'd have an easier time convincing me the earth was flat than you would trying to convince me that this wasn't first degree murder.

Why? First degree murder has to be proven to be intentional and premeditated. It can't be something that happens as an act of passion (example: killing your partner who you had just discovered cheating on you or road rage). And it has to be intentional.

There are too many fucking steps to just leap over in order for this to be an accident.

1): There's emergency buttons in these ovens just like the ones they put in walk-in freezers/coolers. Suggests that the button was blocked (or the door was) or she was unable to use it for some reason. Otherwise she would've just opened it up.

2): How the absolute fuck do you let it go this far? CUSTOMERS heard her screaming. CUSTOMERS. If a customer can hear her, how the fuck can YOU not hear her??? I understand people will go into walk-in freezers in order to scream because that's a common thing to do at my work at least but that is because freezers have thick walls to keep shit frozen long after the power goes out. That's not really the same for a walk-in oven. If she was trapped in there by accident, there were two opportunities to call for help. A): when she first got trapped in and, if nobody was back there at the time, B): WHEN A CUSTOMER TELLS YOU THEY HEAR FUCKING SCREAMING.

3): If this WAS a crime of passion, then the perpetrator would have most likely realized what they did and tried to undo their fuck up.

So, either a shit ton of ignorance and neglect has plagued this walmart which, considering how often retail stores especially a chain as big as Walmart does inspections, these OSHA violations would have been caught at least once or there at least would have been warning to members about it posted or the lockout-tagout procedure would've taken place in order to prevent anyone from using the oven at all.

So, uh, no. I don't believe this woman died accidentally. Someone in that fucking store murdered that poor girl and there's either a lot of ignorant people in that store or that murderer has accomplices.

Also wanted to clear something out since I've seen a lot of people online get this wrong: She was a Sikh woman as determined by a member of her community. A lot of people are claiming that she's Muslim but she's Sikh. The outrage should be the same whether she's Sikh or Muslim but the distinction is important considering a lot of racism, xenophobia, and Islamophobia overlaps with people in the Sikh community especially with people confusing the two groups.

2 notes

·

View notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Explore One Stop Shop for all Types of LOTO Solutions in Australia

Maintaining a safe working environment is paramount in Australia's diverse industries. Lockout Tagout procedures are essential for preventing workplace accidents during maintenance and repair. Finding all the necessary LOTO equipment can be time-consuming. Luckily, there are suppliers in Australia that offer a comprehensive range of LOTO solutions under one roof, simplifying the procurement process and ensuring you have everything you need for effective safety protocols.

These one-stop shops provide a wide range of LOTO devices, from padlocks and tags to lockout boxes and hasps etc. They also stock specialized equipment for various energy sources, including electrical, mechanical, hydraulic, and pneumatic systems. This comprehensive offering ensures you can find the right tools for any LOTO application in Australia.

Wide range of LOTO devices: Padlocks, tags, hasps, valves, lockout boxes, stations, and more.

Solutions for all energy sources: Control all types of energies - electrical, mechanical, hydraulic, and pneumatic.

Expert advice and support: Get guidance on selecting the right LOTO devices and also avail the Lockout Tagout services under one roof.

Compliance with Australian safety standards: Ensuring your LOTO procedures meet regulations.

Don't compromise on safety. Streamline your LOTO procurement process and ensure you have the right tools for the job. Contact a leading LOTO solutions provider in Australia today to explore extensive product range and receive expert advice on implementing effective LOTO procedures.

Explore all types of available LOTO solutions - https://www.safetylock.net

#Lockout Tagout#LOTO Solutions#Lockout Tagout Products#LOTO Devices#Lockout Tagout Services#Lockout Tagout Devices#Lockout Tagout Manufacturer#Lockout Tagout Supplier#LOTO Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

Who is responsible for Lockout Tagout?

Following the initiation of the lockout/tagout program, designated employee groups take on specific responsibilities. These encompass delivering and receiving training, supplying appropriate devices for lockout/tagout procedures, and performing regular assessments. Each member of the organization plays a vital role in ensuring the success of the lockout program through their assigned tasks.

#Lockout Tagout#Lockout Tagout Procedure#LOTO Safety#Lockout Tagout Devices#Lockout Tagout Program#Lockout Tagout Responsibilities#Lockout Tagout Accidents#LOTO Training#Occupational Halth and Safety#E-Square Alliance

0 notes

Text

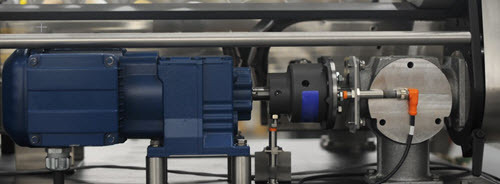

Essential Guide to Industrial Geared Motor Care & Repair

Industrial geared motors are critical components in various applications, from manufacturing to heavy machinery operations. Ensuring their proper maintenance and timely repairs can significantly improve performance, extend lifespan, and prevent costly downtime. This guide covers essential maintenance practices, troubleshooting techniques, and safety measures to keep your geared motors operating efficiently.

Why Geared Motor Maintenance Matters

Increased Lifespan and Performance

Regular maintenance of geared motors enhances their longevity and efficiency. Proper lubrication, routine inspections, and timely part replacements help avoid premature wear and failure, ensuring optimal operation.

Cost Efficiency and Reduced Downtime

Proactive maintenance minimizes unexpected breakdowns, reducing the need for costly emergency repairs. Scheduled upkeep helps businesses save on repair expenses and maximize production efficiency.

Routine Maintenance Checklist

Daily:

Check for unusual noises, vibrations, or overheating.

Inspect for any visible oil leaks or damages.

Ensure electrical connections are secure and operational.

Weekly:

Monitor motor temperature and lubrication levels.

Inspect mounting bolts for tightness.

Check for signs of wear on gear teeth and bearings.

Monthly:

Conduct a thorough inspection of gears, shafts, and seals.

Clean accumulated dust or debris around the motor.

Test motor efficiency and alignment.

Lubrication Best Practices for Optimal Performance

Proper lubrication is essential to minimize friction and wear. Use manufacturer-recommended lubricants and adhere to the following guidelines:

Check lubricant levels regularly.

Replace lubricants as per manufacturer’s specifications.

Avoid over-lubrication, as it can cause overheating.

Inspect and Replace Worn Parts

Timely replacement of worn-out parts prevents secondary damage to the motor. Inspect gears, seals, bearings, and belts frequently, replacing them as necessary to maintain performance.

Troubleshooting Guide

Identifying the Root Cause of Issues

When a geared motor malfunctions, pinpointing the exact problem is crucial. Common signs of issues include excessive noise, reduced efficiency, overheating, or failure to start.

Step-by-Step Diagnostic Procedures

Check for electrical supply issues.

Inspect mechanical components for damage.

Verify lubrication levels and contamination.

Assess motor alignment and mounting stability.

Tools and Techniques for Effective Troubleshooting

Multimeters for electrical diagnostics

Vibration analyzers for detecting imbalances

Thermal imaging cameras for identifying overheating components

Bearing pullers and alignment tools for mechanical adjustments

Preventive Maintenance Tips for Different Gear Head Types

Inline Helical Gear Heads:

Regularly check gear alignment.

Maintain proper oil viscosity to reduce wear.

Parallel Helical Geared Heads:

Monitor load distribution to prevent uneven wear.

Ensure correct tension in coupling mechanisms.

Bevel Helical Gear Heads:

Inspect bevel gear mesh engagement.

Use recommended lubricants to prevent excessive friction.

Safety Precautions and Best Practices

Essential Safety Gear and Procedures

Always wear personal protective equipment (PPE) such as gloves, goggles, and ear protection.

Ensure the motor is disconnected from the power supply before maintenance.

Follow lockout/tagout (LOTO) procedures to prevent accidental startups.

Common Mistakes to Avoid During Repairs

Ignoring minor issues that can escalate over time.

Using incorrect lubricants or failing to follow manufacturer specifications.

Overlooking alignment checks, leading to premature component failure.

When to Call a Professional

While regular maintenance can prevent most issues, certain situations require expert intervention. Call a certified maintenance and repair service when:

The motor exhibits persistent failures despite routine troubleshooting.

Internal components, such as gears and bearings, need complex repairs or replacements.

Specialized diagnostic tools are needed to assess performance and efficiency.

Get Reliable & High-Performance Geared Motors – Contact Us for Expert Solutions

Maintaining industrial geared motors is key to ensuring smooth operations and minimizing downtime. If you need expert maintenance services or high-quality replacement parts, reach out to our team today.

Read More: Santram Engineers - Industrial Geared Motor Maintenance & Troubleshooting

0 notes

Text

Key Topics Covered in an Electrical Safety Courses

Electrical Hazard Identification

Safe Work Practices & PPE Usage

Lockout/Tagout (LOTO) Procedures

Emergency Response & First Aid for Electrical Injuries

Fire Prevention & Electrical Fire Safety

Working with High Voltage Equipment

Grounding & Insulation Techniques

Conclusion

An electrical safety course is vital for preventing workplace accidents, protecting lives, and ensuring compliance with safety regulations. By educating employees on safe practices, businesses can create a safer, more efficient, and legally compliant work environment.

safety course in chennai

safety institute in chennai

safety training institute

nebosh course in chennai

nebosh course in madurai

#nebosh course in chennai#safety course in chennai#safety institute in chennai#fire and safety course in chennai#industrial safety course in chennai

0 notes

Text

T-Shirt that says “I ❤️ Lockout/Tagout Work Safety Procedure”

1 note

·

View note

Text

Remember, A proper Lockout/Tagout procedure insures that the machinery cannot be tampered with while in maintenance. If you need to shut down and unplug all electronically devices associated with the tagout, you should! An OSHA workplace is a SAFE workplace.

getting a lot of questions about my shirt that says “I WANT TO HAVE SEX WITH INDUSTRIAL MACHINERY” that are already answered by the shirt

24K notes

·

View notes

Text

Core Topic Covered

Introduction to Electrical Safety:

Importance of electrical safety in engineering and industry.

Statistics and case studies on electrical incidents.

Electrical Hazards:

Shock and electrocution risks.

Arc flash and arc blast hazards.

Fire and explosion risks from electrical faults.

Risk Assessment and Hazard Control:

Identifying electrical hazards in the workplace.

Conducting risk assessments and implementing control measures.

Safety Standards and Regulations:

Overview of key standards, such as:

NFPA 70E (Standard for Electrical Safety in the Workplace).

OSHA Electrical Safety Standards.

IEC and ISO standards for global compliance.

Importance of grounding and bonding.

Electrical System Design Safety:

Designing systems to minimize hazards (e.g., safe circuit design, use of protective devices).

Proper selection of cables, circuit breakers, and insulation materials.

Personal Protective Equipment (PPE):

Importance of PPE in electrical work (e.g., arc-rated clothing, gloves, face shields).

Selection and maintenance of PPE.

Safe Work Practices:

Lockout/Tagout (LOTO) procedures.

Working safely on live circuits and de-energizing equipment.

Proper handling of tools and equipment.

Arc Flash Safety:

Understanding arc flash hazards.

Calculating incident energy and determining safe approach distances.

Emergency Preparedness and First Aid:

Responding to electrical accidents, such as shocks and burns.

Administering CPR and using AEDs (Automated External Defibrillators).

Inspection and Maintenance:

Periodic inspection of electrical systems to prevent faults.

Maintenance best practices to ensure safety and system longevity.

safety course in chennai

safety institute in chennai

safety training institute

nebosh course in chennai

nebosh course in madurai

#safety institute in chennai#nebosh course in madurai#eosh course in chennai#safety course in ambattur#safety institute in madurai#education

0 notes