#Labourers are unsung heroes

Explore tagged Tumblr posts

Text

The Underground War (1998).

The British tunnellers of the Western Front in the First World War.

Note: This is a shortened transcript I created of a video discussing clay kickers and tunneling operations in World War I—the dangerous and often overlooked work done by men (like those in the 179th Tunnelling Company, which Tommy Shelby was part of in Peaky Blinders). I’ve trimmed some sections for brevity and clarity. The full video is linked at the bottom if you’d like to watch it in its entirety.

Simon Jones (Curator, Kings Liverpool Regiment Museum): The nature and scale of trench warfare during the First World War was shocking at the time and continues to shock historians. What is less well known about, but is equally remarkable, is the scale of the labour and endeavour that occurred underground beneath the front line in an entirely secret and hidden warfare. Today, if you visit the Western Front, you will see peaceful and tranquil fields that betray little of what occurred during the First World War. In those fields, there remain many thousands of miles of dugouts, subways and tunnels.

Voice Over: —A 3,000 mile network of tunnels dug by both sides in a highly secret war within it’s walls. By late autumn 1914, the Allies had halted the German offensive. Within three months, all movements had stalled. The great armies of the First World War were in position and the Western Front was born. Dreadful losses and the grip of winter forced both sides to dig in and wait for spring. Three years of stalemate had begun. The deadlock inevitably raised the thought of a traditional military tactic in taking the war underground, tunnelling beneath enemy lines. But British commanders were reticent.

Jones: There certainly was a belief that tunnelling could be avoided, that if the British didn't start it, then the Germans wouldn't. However, it was simply German tactical doctrine that if trenches were 100 yards or less apart, then they would automatically start tunnelling.

VO: And so, in secret, they started an underground war for the next three years that would increase in scale and ferocity. The full truth about the British response remained an official secret until 1962. Even now, its history is still being uncovered in the archives of the Royal Engineers at Chatham. Peter Barden has been researching the Underground War for more than 20 years. It's his ambition to locate and explore one of the most important Allied tunnel systems of the war, the Underground Complex at Mount Sorrel, near the Belgian city of Ypres

Peter Barden: The Royal Engineers kept such detailed maps and plans that by overlaying the originals onto today's map and taking measurements and bearings, we know we can pinpoint the tunnels to within a yard or two. In the Flanders area, all underground systems were built in solid timber, often English oak. And these workings have been full of water since 1918, which is a great preservative. So, with a bit of luck, we expect to be able to explore both the tunnels and the dugouts. The biggest dugouts house 5,000 men and more. They're amazing structures.

VO: Here, too [archives of the Royal Engineers at Chatham], are filed the stories of the clay kickers, the miners who went to war.

Barden: It would be nice to find some tunnelers [to speak to]. It won't be very easy, though, because they would all be at least 100 years old now. But it's possible.

VO: There were men like Lieutenant John Westcott, who fought a hand-to-hand battle in the dark under Mount Sorrel. And there were unsung heroes. Sapper William Hackett, who won a posthumous VC for refusing to leave an injured comrade. And the Tunnelling War's extrovert and dynamic architect, John Norton Griffiths.

Anne Morgan (Granddaughter & Biographer of Sir John Norton-Griffiths): He [Griffiths] was action itself. And he saw the war coming in 1914, early on. And he saw the generals dithering. And the politicians dithering.

VO: In civilian life, Norton Griffiths was a contractor. His company was building sewers in the clay beneath Manchester, similar ground to Flanders. He was convinced that clay kicking, a process devised for digging small tunnels swiftly, would be ideal for military meaning.

Jones: So what Norton Griffiths wanted the army to do was simply to take his clay kickers to the front line trenches and let them really get on with digging towards the Germans.

VO: In a letter to the War Office in December 1914, he suggested the formation of the “Moles” civilian tunnelling units under his charge, coal miners for the Somme Chalk and clay kickers for the Flanders Clay. The idea was shelved.

Morgan: So the letters were filed under ”M” for Moles and forgotten.

VO: December 20th, the Germans stole the initiative. They tunnelled beneath Allied trenches at Festubert near the French- Belgian border and exploded ten mines.

Jones: The effects of the first blow, the first German mine blows against the British line was one of quite considerable shock and surprise. If you consider that in trench warfare, the only safe place was to dig underground and that a trench and a dugout could give considerable security to the infantrymen from both rifle machine gun bullets but also shell fire. Once the earth beneath him [soldiers] was actually being undermined, this really robbed him of that security.

VO: Now the British had to retaliate. [Herbert] Kitchener [Britain's Secretary of State for War] summoned Norton Griffiths.

Morgan: He stormed into Kitchener's dressed in a mixture of hunting kit and uniform and took a tool from the fire, got down on the floor on his back and started to demonstrate what he meant by clay kicking.

VO: Kitchener instantly demanded 10,000 clay kickers, but there were barely 1,000 in the country. Coal miners were also in short supply, as in wartime mining was a reserved occupation. And besides, to the War Office, the notion of recruiting an army of untrained, free-thinking men was as unsettling as the methods of Norton Griffiths himself. The generals feared an undisciplined mob.

Jones: I think what GHQ [general headquarters— main center from which a military operation is controlled] were fearful of was that war itself is a terrifying business and unless men are well- trained, well-drilled and well-disciplined, you simply cannot fight a war.

Fred Francis (174 Tunnelling company): They said to me, would you volunteer to dig a mine under the German trench? I said, you must be barmy asking me to do that. But I say, I was always a silly bugger like that, volunteering.

VO: With Norton Griffiths in charge, recruitment began. Specialist tunnelling companies were formed under the auspices of the Royal Engineers. He wanted older, more experienced, steady men and ignored War Office objections by offering them six shillings a day— six times an infantryman's pay.

Bert Fearns (170 Tunneling company): Most of the tunnellers were from the north-east, Northumberland way, or South Wales. And most of them were small, they were very physically broad, fit men.

Colonel Norman Dillon Mc (178 Tunnelling Company): Just odds and ends. They were picked for their particular skill at that particular job. You couldn't take a platoon of a Guards and say: “You will get on mining”, It doesn't work that way.

Fred Francis: That's one thing that the First War did for me. It got me out of the damp pits and never been back since. AndI won't be going back either.

VO: On February 19th, 1915, almost two months after the Festubert mines and many subsequent attacks, Norton Griffiths finally took his first draft of clay kickers to the front.

Jones: In a matter of days, they were taken from the sewers of Manchester to the trenches of Belgium and were immediately set to work. They were really bringing civilians into war as bad as it would get. In the winter of 1914, the conditions at the front were quite appalling.

VO: By March 1915, the first tunneling company was installed on the Western Front. Eventually there would be 25,000 men working underground, with twice as many infantry in support.

Bert Fearns (tunneler): They [infantry] were the experts, we [miners] were the labourers. And- uh- we were treated as such. No pain to be polite if I don’t put it that way. We were an unnecessary bloody nuisance.

Donald Hodge (178 Tunneling Company): We were there to do a job, and that was our be- all and end- all, really. Had to justify it, you're going here, you're going to do this, and that was that.

George Louth (178 Tunneling Company): All of a sudden they said, anybody here can use a shovel? I said—volunteered—which you shouldn't do, but I did, because I thought it was something different. One or two other chaps done the same. So we were all sent to this pit, which was 80 feet down. Then we had to walk along probably about a mile.

Jones: I think the infantry initially perhaps may not have welcomed tunnellers arriving in their sector, unless the Germans were already active. Once, however, the Germans began to blow mines, then the infantry would become quite desperatefor tunnellers to go and counteract the effects of them.

VO: The German mining threat was growing rapidly.

Albert ‘Smiler’ Marshall (172 Tunneling Company): They were tunnelling one way, we were tunnelling the other, bothfor the same purpose. That's for them to blow up our front line, and for us to blow up their front line.

VO: John Norton Griffiths was now recruiting furiously, both in Britain and on the Western Front itself, where many miners were already in uniform, having volunteered for infantry regiments at the outbreak of war. He poached them, with his offer of six shillings a-day

Jones: Norton Griffiths' working methods were really completely at odds with traditional army methods that deferred to rank, hierarchy, chain of command…driving around in his Rolls Royce and getting things done with a mixture of cajoling, threats, bluster and charm.

VO: At all costs, tunnelling had to be kept going around the clock.

Jones: The Tunneling War has been likened to the largest civil engineering contract ever carried out under conditions of most extreme danger.

George Louth (tunneler): We went down there every night and worked eight hours. And we had to walk back, I suppose, a couple of miles to a rest each day. then go back again the next night. We had to walk the two miles every night, eight on our own,under gunfire. We never found out what the problem of the mine was. They don't tell you that, that's all secret. That's all secret, that was.

VO: Very few were told what they were doing. be captured with such knowledge could lead to the waste of months, evenyears of toil. Secrecy was paramount, and so was silence.

Albert ‘Smiler’ Marshall (tunneler): If you stopped, you could hear the Germans, other side, tunneling, you could hear them,tunneling next to you. And I was buying that man, standing there ready in case they broke, that broke through, so that Icould shoot and, well, you kill them as quick as you can, or else one of the two, either you or them.

VO: Lieutenant John Westacott's account details several underground breakthroughs. In June 1916, he led four of his meninto enemy tunnels, their purpose, to explore and destroy. Almost discovered, they hid as four German miners passed by.

Lieutenant John Westacott [written account]: The Germans came past us, torches flashing, heavy footwear clumping on the wood floor. Stealthily, we crept around a corner, following their footsteps, gaining on them. The Germans paused— one seeing the torches of a second party of our men. They challenged them and, not getting a reply, fired a shot. Our second party fired back. They were trapped. The Germans turned and came face to face with us.

VO: On that occasion, they won the day, but they were not always so lucky. Later the same year, Westacott and his sergeant emerged from the shaft into their front line trench. It was full of Germans. Unbeknownst to the tunnelers, the enemy had captured the line during the night. Diving back down the shaft, they sounded the alarms.

Lieutenant John Westacott [written account cont’]: All hell broke loose, the Germans kept dropping more and more men down after us, piling on top of their own dead and wounded. We had a terrible scrap down there, using candles and torches. We were often fighting in the dark. Groping for epaulets on German shoulders was the only way to tell friend from foe. We used knuckle knives, very handy. When the infantry recaptured the trench, some of us had been fighting for over 20 hours. We were so sick and weary from the gas and the smell of blood. We had lost 60 out of 80 men. We couldn't have taken much more.

VO: Some 2,000 Allied tunnellers died in the war. The biggest killer was invisible. Every underground explosion trappedcarbon monoxide gas in the was odourless and lethal. The tunnellers used canaries to warn of its presence. They clippedthe claws so the bird would topple over when affected, rather than grip its perch in rigor mortis. A tunneller's life depended on the length of a canary's claws. Entombment, hand-to-hand fighting and gas. All the time digging, where there was no night and no day beneath the wasteland.

Colonel Norman Dillon (tunneler): I think the worst part is finding a way. It is so easy to get completely lost. The (?) was so deep in mud it took 12 hours to get a wounded man from the trench line to an ambulance. I was many times on the track, and nothingbut dead mules, dead men, dead horses, nothing.

VO: The enemy wanted Mount Sorrel [1.9 miles east of Ypres, Belgium] badly. It would complete their domination of the high ground overlooking Ypres.

Barden: The Germans took this position twice and were driven out twice, a huge loss of And each attack was preceded by a gigantic barrage. And the trenches were completely destroyed. And they were retaken quite quickly. But when they came back, there was nothing left. The shafts were full of water, they were full of corpses. And they found it difficult to even find the trenches

VO: At Mount Sorrel, the opposing lines were barely 50 yards apart. They ran through woods and fields, along the crest of a low hill. Deep beneath was the labyrinth. There were several entrances in the Allied front line. Some were shafts, some staircases. These led to shallow defensive workings with many listening posts, tunnellers quarters and rescue stations, each separate area protected by a special gas door. Further shafts led to deeper workings. In these cramped tunnels, directly beneath no man's land, were more listening posts. Beyond, probing far beneath the enemy lines, the fighting tunnels. The sharp end. At the end of these, a chamber packed with high explosives.

Ted Rimmer (Kings Liverpool Regiment): We were six of us on patrol, and this damn big shell dropped right by us. Can you imagine that? I was terrified. We all crouched down, you know, waiting for it to go off. It was a dud. I was thinking— I’ll never see home again, you know. And I thought this was the end, you know? You know, I was terrified. We were all terrified. I only breathed a sigh of relief when it didn't go off. We soon scrambled away from there. Don't you worry.

Donald Hodge (tunneler): We were down there, head to tail, on our hands and knees. And when we came out, we couldn't stand up because we'd been in that hands and knees position for We just couldn't stand. It was the most horrible job that I had on the Western Front, I believe. I faced many a shell and sniper, but I never liked(?) my knees.

George Louth (tunneler): The air got weaker as you went, the further you went, the weaker it got because of the poor bloke that was using the pump. He had to keep going all day, all the eight hours. Keep pumping, because if he had stopped, I would have been finished.

Colonel Norman Dillon (tunneler): Tick, tick, tick. somebody’s picking away. It's rather an eerie feeling. You know, this chap with the pick is out to kill you.

Barden: The infantry only got a tablespoonful [of Rum], But these guys [tunnelers], because of the pressure—every four hours, they could drink as much rum as they wanted. And in Westcott's diary, he says that the pressure was so intense that he wouldn't get out of bed in the morning before his servant had brought him a mug of rum. Before he got out of bed! One of the biggest problems was that, in the silence, their imagination would start playing tricks on them. And they'd be able to hear their own heart beating. And think that was the sound of possibly the Germans closeby.

Colonel Norman Dillon (tunneler): Part of one's job, as an officer, was to sit with these listening things on your ears. And you could hear the Germans getting a bit nearer…a bit nearer…a bit nearer..then your mind was racing. Should I get out? Should I stay here and tell them what's going on? Or what? If you stay there too long, you might be there forever.

John Laister (171 Tunneling Company): He (?) spoke in a whisper. He said, ‘We're going to blow it up.” I said, “What?” He said, “We're going to blow it up.” So I said, “Are you still picking?” He said, “Bloody good luck, John.”

Donald Hodge: It was really a case of who blew first, whether it was us who were going to be buried or the Germans

Jones: Only one Victoria Cross was awarded to the tunnellers, to Sapper Hackett, who was awarded his medal posthumously for refusing to leave a buried comrade on the grounds that he was a tunneller and couldn't do so, and was later buried by the tunnel collapse. The tunnellers often lost out because of the secrecy of their operations, especially so during the preparation for the deep and long tunnels for the Messines[—west Flanders] operation, when a dozen tunnellers were buried alive at Petit Bois. And after about five and a half days, they managed to break back into the and they found 11 men dead and one man, Sapper Bedsen, still alive. Sapper Bedsen certainly never got a Medal. The tunnellers who carried out the rescue under extremely hazardous conditions never got recognised either, even though their commanding officer put in recommendations. And he was told that it was because the Messines operation was so secret that no awards could bemade.

VO: The Messines operation was conceived to relieve pressure on the Belgian city of Ypres which lay within a salient, a bulge in the line, which the Allies sought to straighten. In April 1915, Norton Griffiths arrived to propose an ambitious plan. His tunnellers would help break the stranglehold on the beleaguered city. To the southeast of Ypres lay the German-held Messines Ridge. Norton Griffith's proposal was to create the biggest explosion in a man-made earthquake, and shake them off it. Over two years, 11 tunnels would be secretly dug, several of half-a-mile long and up to 120 feet deep. Then 22 giant charges would be triggered,followed by a huge ground and artillery attack….To reach these depths, shafts have to be sunk deep into the blue Flanders clay.

Jones: Offices, brigade headquarters with telephone exchanges, dressing stations could be installed underground. And by 1917, dugouts were being specially prepared for infantry attacks that would accommodate whole battalions of a thousand men. Even whole brigades of 5,000 or more men could be accommodated underground so that they could be brought up safe and unobserved, ready for an attack.

Ted Rimmer (Kings Liverpool Regiment): All the dugouts there were damp and cold. Cold is my dugout, wet are my feet, waiting for whizzbangs to send me to sleep. (laughs)

Donald Hodge (tunneller): Somehow there was a resignation about things, it was as though we knew it had to happen, there was no escape, and you just did it. You accepted anything. Very often, if it was cold, you'd have your grey coat with you, and get under that, and you could light a cigarette, and you were at peace with the world then.

Fred Francis (tunneler): On one occasion we had a very deep dugout, and we'd got an old blazer from somewhere, and we had a bit of fire on to keep us warm, and it was my turn to go up on the top, and as soon as I got in the fresh air, I became unconscious. I dropped flat on my face, and I was mud from head to foot, and I thought— Oh hell, miles from home…how the hell am I going to get clean?

(?) :Some chaps would sleep, we just chatted. You won't be surprised to find that women were part of it[conversation]. Food was a very big subject, about what we were going to have when we'd come out of the army. They all had their own mother's favorite dishes. Nobody made Lancaster hot pots like my mum. And we just went into dreamland

VO: Here [underground] men lived and died, wrote…letters to families and lovers, tended the wounded. At night they climbed the stairs to bury their comrades, and all the time the tunnellers were digging ever further beneath the enemy. And by June 1917, all roads led to Messines.

Morgan: There was a little drawing of how to build a tunnel and where to place an explosive. There was an arrow from that going up and it said, to heaven. (laughs)

VO: At dawn on June the 7th, 1917, 19 charges totalling almost a million pounds of explosive were detonated.

Bert Fearns (tunneler): All of a sudden it was as though somebody had left a torch. It started at one end and just shot along.

Albert ‘Smiler’ Marshall (tunneler): And the dirt goes up in the air, oh, 50 yards.

John Laister (tunneler): Yes. It was like a mountain of bodies going up and coming down. It was like a mountain standing in the sky—I'll never forget it as long as I live. I thought, how many people could have gone up with that lot?

VO: So John Norton Griffiths finally got his earthquake. The effect was monstrous. An estimated 10,000 German soldierslost their lives in a moment. The blast was heard by Lloyd George in Downing Street and by Norton Griffiths at homewith his family in Brighton.

Jones: The mines had the effect of completely neutralising any defences that the Germans had For example, the concretepillboxes were simply hurled physically into the air. Germans were obviously completely disorientated and there areaccounts of men being found wandering around in no man's land or in the remains of their front line trenches, weepingand bewildered. This must have had considerable impact on German morale, knowing that their miners underground could not prevent the British tunnellers from blowing them up. Mining therefore contributed to the attrition—the attritional warfare that gradually wore down the Germans and ultimately paid off.

Morgan: Deep inside him [Griffiths], he must have known that the whole war was completely unjust and unnecessary— and he wanted it over as quickly as possible. And if it meant blowing up Germans, well, too bad.

VO: The great mines had been instrumental in achieving a model victory, the Allies' first true success of the war. But now the front lines were becoming mobile, making the work of the tunnellers obsolete. There was no longer a place for their very special brand of warfare. Messines had been their finest and final hour. Within months, the ridge was back in enemy hands. The underground war was over and destined to be forgotten.

original video:

youtube

21 notes

·

View notes

Text

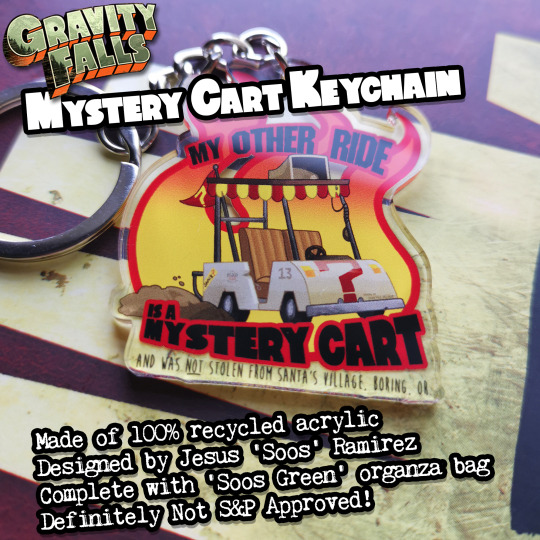

New to Not S&P Approved!

My Other Ride is a Mystery Cart (and was not stolen from Santa's Village, Boring, OR) Acrylic Keychain!

100% recycled acrylic

Complete with 'Soos Green' organza bag

Definitely Not S&P Approved!

A 5.11cm x 4.4cm recycled acrylic keyring, with silver keychain - designed by none other than the Shack's golf-cart-loving handyman, Soos Ramirez!

"Hey, dudes. It's me, Soos! Mister Pines told me to put something together for his gift shop so he could use me for free labour. What an honour! I decided to go to that unsung hero of the Mystery Shack: the ever-reliable Golf Cart, bro! If you know anything about these babies, you'll know the absolute twin-stroke fury you can get from these un-governed 8hp masters of the woodland clearing. It's only right that if you own one, you celebrate it - with this super dope keychain! These keychains are manufactured using 100% recycled and recyclable acrylics, that have reached the end of their life-cycle and are destined for landfill or incineration. It's just as good as new plastic, whilst being completely VOC and HFC free and way better for the fish and stuff. Any offcuts are recycled too! It's like, eco-to-the-extreme, and 3mm thick - so it won't just break like my heart did when they stopped making Dinkies snack cakes for a few months back in 2012. This is the coolest, cartiest keychain out there. You should totally buy it, dawg!"

#gravity falls#not s&p approved#gravity falls fandom#gravity falls merch#gravity falls keychain#etsy

34 notes

·

View notes

Note

💌

this might not sound like a compliment but one of my favourite things about you is your willingness to disagree with me and others and your willingness to be disagreed with, publicly in both cases, if you really disagree with something. i thought i knew a lot about who is allowed to dissent and who isn't without being branded as "mean" , but i've learned a lot from you on that and subsequently on how to have thick skin. i don't think those were lessons you intended to impart upon anyone but i think about this often.

also appreciate your tangible contributions to the wider MASH fandom through curation, compilation and dissemination of resources for everyone to use. sharing and access i think were at the heart of the old days of fandom that people like to reminisce upon, but even back then the unsung heroes were the people doing the labour of maintaining archives and sharing information.

#💌#no matter how cringe i also have to shout out the MLM-WLW Committee of Two for Trapper > BJ Propaganda#the mlmwlwCoTfT>BP#hand in unlovable hand

9 notes

·

View notes

Text

Some things I picked up growing up:

"I would (simply)..." is a marker-phrase

It is usually how you know someone...

Doesn't understand the problem

Doesn't understand their own human limits (and thus is inexperienced)

Has unrealistic expectations of human outcome produced by group-action

Thinks they can (usually) personal-choices their way out of problems

Thinks they wouldn't panic during a catastrophie

Thinks they would be capable of forming plans during a catastrophie

Thinks they would even have useful information to form a plan with

Can't theory-of-mind that they wouldn't know in the situation what they know now

Are usually the first person to panic during a catastrophie

With this in mind:

They are the one who comes up with unhelpful paranoid theories

They inflict their lack of experience upon others by asking them to do unrealistic things

They will not take ownership when things do not meet their expectations and will insist its a fluke (and ask you all to do it again)

Will be outraged and thus disrupt everybody else experiencing a motivational lapse as a required time/energy conservation/planning technique in order to regroup, and thus will prevent useful outcomes from emerging

Will require a lot of emotional labour to keep calm

Will distort and disrupt plans made by others, to satisfy their own egotism often at the cost of others or by making good plans take longer to make

Will result in an atmosphere of mistrust created by their own panic and misinformation based on their unuseful information

Will disrupt the theory-of-mind others require to understand the group's mentality to maintain cohesion or an oppositional force who must be comprehended in order to safely negotiate the threat

Will be the first to die, often loudly, often revealing the rest of the group to a potential threat

Source:

Repeated unpleasant childhood development experiences (do not ask about them, I will not talk about them, I will automatically block you if you do so) which were then later validated with Crisis Prevention training in college, and extended research into outcomes of disaster workers documented by the US National Transportation Safety Board's incredibly well done investigations. If you take anything from this, its the person who says they know exactly what they'd do who has done no drilling, no prior preperation and no group-training is the exact person who is most likely to make a situation worse. Also that the NTSB are unsung heroes and do the best forensic investigations in the world because they do so with a framework of causality for preventative measures rather than attempting to assign accountability (which is culturally biased investigation). A lot of the regulation you will hear is "written in blood" is specifically written in rules formed by the NTSB.

Sorry for the rant, this stuff just gets under my skin even if its meant in good humour.

Unrelated: "Pyroclastic flow" is a borderline erotic phrase. Someone name a song about mother-nature's drippy-bits after this, please.

why didn't they just leave pompeii when the volcano erupted? were they stupid?

84K notes

·

View notes

Text

Maximising Construction Efficiency with Site Dumpers

In the dynamic world of construction, every piece of equipment plays a crucial role in ensuring projects are completed on time and within budget. One often-underestimated hero in this realm is the site dumper. These versatile machines are the unsung workhorses that keep construction sites humming along smoothly. Let’s delve into why site dumpers are indispensable and how they can transform your construction operations.

Understanding the Role of Site Dumpers

Site dumpers are specialised vehicles designed to move bulk materials around construction sites, mining operations, agricultural properties, and more. They consist of a large open skip mounted on wheels, capable of tilting to unload contents effortlessly. These machines are equipped with powerful engines, allowing them to navigate uneven terrain while carrying substantial loads. Safety is also a priority, with features like Rollover Protective Structures (ROPS) and ergonomic seating in an enclosed cabin.

Key Uses of Site Dumpers

Site dumpers are incredibly versatile, making them suitable for a wide range of applications:

Material Transport: Ideal for carrying soil, gravel, sand, rocks, debris, and construction waste across rugged terrains.

Construction: Essential for moving materials to and from various locations, aiding in the development of roads, buildings, and infrastructure.

Mining: Used to transport extracted minerals and ore from excavation sites to processing areas or transportation vehicles.

Agriculture: Useful for tasks like transporting harvested crops, compost, or other agricultural materials.

Waste Management: Employed to collect and transport waste and recyclable materials within waste management facilities.

The Benefits of Site Dumpers

Increased Efficiency

One of the most significant advantages of using a site dumper is the boost in efficiency. These robust machines can transport up to 6-9 tonnes of material quickly and effortlessly, reducing the reliance on manual labour. This time-saving feature is particularly beneficial for large-scale projects where time is money.

Versatile Applications

Site dumpers are incredibly adaptable, making them suitable for various industries. Whether you’re working in construction, mining, agriculture, or waste management, a site dumper can be a valuable addition to your fleet. Their heavy-duty skips and compact design allow them to handle a wide range of tasks, from hauling construction debris to transporting agricultural produce.

Enhanced Safety

Safety is a top priority on any construction site, and site dumpers are equipped with features like seatbelts and Rollover Protection Systems (ROPS) to ensure a secure working environment. These safety measures reduce the risk of workplace accidents and protect both the operator and other workers on site.

Cost Savings

Reducing project costs is always a priority, and site dumpers help achieve this by minimising the need for manual labour and speeding up material transportation. By investing in a site dumper, you can control expenses and maximise profitability.

Agility and Site Access

Compact dimensions and excellent manoeuvrability make site dumpers ideal for accessing areas that larger machinery might struggle with. This is particularly useful on sites with limited space or challenging terrain. The Wacker Neuson Dual View site dumper, for example, allows operators to maintain a complete view by rotating the console 180°, making it perfect for tight-access jobs like narrow roads or railway applications.

Durability

Site dumpers are built to withstand the rigours of worksite conditions. Assembled with robust materials and components, they are extremely durable, even in harsh Australian conditions. This longevity ensures that site dumpers are a worthwhile investment for ongoing projects.

Reduced Environmental Impact

Modern site dumpers are equipped with advanced engine technology that reduces emissions. This minimises their carbon footprint and helps limit pollution on site, contributing to a lower environmental impact compared to other heavy-duty machinery.

Operator Comfort

Operator comfort is a priority in the design of site dumpers. Features like comfortable seating, easy-to-use controls, excellent visibility, and air conditioning in an enclosed cabin enhance comfort, reduce fatigue, and contribute to overall safer operation.

Material Handling

Site dumpers offer excellent flexibility in terms of terrain and material handling. They can adapt to a range of onsite needs, making them indispensable for various construction projects. The Wacker Neuson Dual View dumper, for example, excels in handling various types of materials, including loose soil, gravel, sand, concrete, and debris.

Choosing the Right Site Dumper

When selecting a site dumper, consider the following key factors:

Load Capacity

Determine the maximum weight of materials you need to transport regularly. Choose a site dumper with a payload capacity that comfortably accommodates your requirements.

Terrain Compatibility

Assess the worksite terrain. If you have rugged or uneven terrain, opt for a site dumper with excellent off-road capabilities, such as the Wacker Neuson Dual-View site dumper. The dual-view operation eliminates the need to drive over tricky terrain in reverse.

Safety Features

Always prioritise safety. Ensure that the site dumper is equipped with safety features like ROPS, seatbelts, and effective braking systems to protect operators and workers on site.

Why Hire a Site Dumper for Your Next Project?

Site dumpers offer a multitude of benefits that enhance efficiency, safety, and productivity on worksites. Hiring a site dumper can significantly improve operational effectiveness, offering a practical solution for diverse project requirements. Whether you’re working on a small-scale home building project or a large-scale commercial construction site, a site dumper can make a substantial difference.

As a trusted construction equipment provider, Conplant Pty Ltd offers a range of site dumpers designed to meet various project needs. Our team is here to assist you with equipment hire and ensure you have the right tools for your next project. Contact us today to learn more about how site dumpers can transform your construction operations.

Reference: https://conplant.com.au/news/the-benefits-of-a-site-dumper-for-construction-projects/

0 notes

Text

Meet Your Warehouse’s Best Friend: The Agile AMR Robot

These days, warehouses are vibrant, dynamic spaces that require more accuracy and speed than ever before. And in the middle of this change? The Autonomous Mobile Robot, or AMR robot, is a surprisingly useful, clever, and nimble piece of warehouse handling equipment.

With the aid of sensors and intelligent mapping software, an AMR robot navigates aisles with ease rather than on fixed tracks. It can deliver parts, move totes, and pick up pallets without human supervision. This translates into a smoother flow of commodities, fewer bottlenecks, and less manual labour. Additionally, your staff may concentrate on strategy, quality assurance, or customer service areas where human brains still outperform machines when they are not burdened with tedious carrying duties.

Warehouses are falling in love with autonomous mobile robots for the following reasons:

Powerful plug-and-play: Do you need a robot or a different route? AMRs adapt without infrastructure changes, therefore there is no issue.

Team-centric design: AMRs, as opposed to conventional forklifts or conveyor spools, are made to collaborate with people, which improves morale and safety.

As your business expands, you can start with one and grow it to a fleet while maintaining central software coordination.

Data-first execution: You gain a data-driven advantage with every run, which produces real-time insights from journey times to path optimisation.

Cost-efficient outcomes: Reduced damage, fewer stoppages, and steady speed help companies achieve more dependable throughput and a quicker return on investment.

Additionally, manufacturers, clinics, and airports are all seeing the same benefits from AMR systems, so it's not just warehouses. AMR robots are the unsung heroes who carry out the heavy lifting (literally) because they are intelligent, flexible, and infinitely expandable.

To put it briefly, the AMR robot is the intelligent, amiable, and always available warehouse handling equipment of the future. Is your operation prepared to welcome this robotic teammate? Efficiency never seemed so practical.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

1 note

·

View note

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability. These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches. One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework. Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows. As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

The Role of Automatic Winding Machines in Industry 4.0

When it comes to manufacturing, every second counts and every detail matters. Imagine a production floor where machines work tirelessly, winding coils and components without fatigue and variation, achieving perfect repetition. This isn’t a glimpse into the distant future; it’s the reality made possible by automatic winding machines. These advanced systems have quietly changed how industries approach coil and component production, shifting the focus from manual skill to programmable precision. As businesses strive to meet rising demand for quality and speed, automatic winding machines have emerged as the unsung heroes. They ensure that every product rolling off the line meets the highest standards of consistency and reliability.

These machines are designed to wind materials such as wires, threads, or films onto spools, bobbins, or cores with remarkable accuracy. In industries like electronics, automotive, and power equipment, automatic winding machines are crucial for producing coils for motors, transformers, and inductors. By automating the winding process, manufacturers can achieve higher production rates, reduce labour costs, and maintain consistent quality across large batches.

One of the key advantages of automatic winding machines is their adaptability. Modern systems can be programmed for different winding patterns, wire gauges, and coil sizes, making them suitable for a wide range of applications. Features such as digital displays, programmable turn counts, and automatic tension control makes sure that each coil meets exact specifications, minimizing material waste and rework.

Safety and scalability are also major benefits. Automated machines reduce the risk of workplace injuries by handling repetitive or potentially hazardous tasks. Additionally, their modular design allows manufacturers to scale up production as demand grows.

As technology continues to advance, automatic winding machines are expected to become even more versatile and intelligent, integrating IoT and AI capabilities for real-time monitoring and predictive maintenance. For manufacturers seeking to stay competitive, investing in automatic winding technology is a smart move toward greater productivity and product quality.

0 notes

Text

Discover the Best Deals on Pine Bark for Sale: Boost Your Landscaping & Soil Health Today

🌿 What is Pine Bark and Why It Matters for Your Landscaping?

When processed, it becomes an incredibly effective mulch and soil amendment, providing both aesthetic appeal and practical benefits. Whether you are an industrial business owner looking to cover large outdoor spaces or a homeowner refining your garden beds, pine bark is a go-to solution.

Available in various sizes, including large nuggets, small chips, and the fine-textured pine fines soil conditioner, pine bark caters to diverse landscaping needs. Its ability to retain moisture, suppress weeds, and regulate soil temperature makes it a favourite among U.S. landscaping professionals and commercial property managers.

🧱 Pine Bark Available for Purchase: Reasonably priced, Adaptable, and Shipped

If you are searching for pine bark for sale, you are probably balancing cost with quality. Good news reliable U.S. suppliers offer bulk quantities of pine bark at competitive prices. This natural material not only enhances curb appeal but also helps cut long-term maintenance costs, a major win for commercial clients and industrial-scale projects.

Key benefits of sourcing bulk pine bark:

Budget-friendly for large-scale landscaping

Wide availability across the USA

Improves drainage and supports healthy plant growth

Perfect for residential, commercial, and industrial use

Top quality mulch suppliers often include delivery, ensuring you can access premium pine bark mulch wherever you are in the country whether you are outfitting a public park, a corporate campus, or a residential development.

🌱 How Pine Bark Mulch Transforms Outdoor Spaces

Here is the deal:mulch is not just about aesthetics it is a strategic tool in sustainable landscaping. When you apply pine bark mulch, it does more than sit there looking good.

Let us break down its real benefits:

Water retention: Pine bark mulch reduces water evaporation from soil, keeping roots moist longer.

Weed control: By blocking sunlight, it helps prevent weed germination.

Industrial businesses love pine bark mulch because it saves on irrigation costs and cuts labour required for weeding.

🌾 Pine Fines Soil Conditioner: The Secret to Healthy

If you are aiming to boost plant performance, the pine fines soil conditioner should be your secret weapon. This ultra-fine version of pine bark improves soil tilth and nutrient absorption. It is ideal for potting mixes, flower beds, and vegetable gardens—especially in compacted or clay-heavy soils.

Why businesses choose pine fines:

Breaks up heavy clay soils

Enhances aeration and root penetration

Improves organic matter and long-term soil health

Its benefits extend to commercial agriculture, large-scale greenhouses, and urban landscaping firms. Integrating pine fines soil conditioner into your soil management plan could be the game-changer your business needs.

📦 Where to Buy High-Quality Pine Bark in the USA

Finding the right supplier is half the battle. Look for companies that specialize in bulk pine bark products and offer tailored service for businesses. Leading U.S. distributors provide:

Competitive pricing for pine bark for sale

Custom sizing and mixes (including pine bark mulch and pine fines)

Nationwide delivery with flexible scheduling

By partnering with reputable suppliers, industrial companies and commercial landscapers ensure long-term value and superior product performance.

🚛 Call to Action: Bulk Order Pine Bark for Sale – Delivered Fast Across the USA!

Do not wait until your landscaping project is behind schedule. Whether you need pine bark mulch, raw bark, or pine fines soil conditioner, act now to secure high-quality products at unbeatable prices. Reach out to a trusted U.S. supplier today and elevate your landscaping game.

✅ Conclusion: Pine Bark—The Smart Investment for Businesses & Landscapers

From its practical benefits to aesthetic charm, pine bark is the unsung hero of commercial landscaping. It supports soil health, saves water, suppresses weeds, and looks amazing while

doing it. With pine bark for sale now more accessible than ever, U.S. businesses and industrial property owners have no reason to delay.

If you are serious about creating sustainable, low-maintenance, and professional-looking green spaces, make pine bark your next landscaping purchase.

❓ Frequently Asked Questions

Q: Is pine bark mulch safe for all plants?

A: Yes, it is safe and beneficial for most landscaping plants and trees. It is especially good for acid-loving species.

Q: How often should I replace pine bark mulch?

A: Typically, every 1–2 years, depending on weather conditions and how fast it decomposes.

Q: Does soil conditioner made of pine particles work well in raised beds?

A: Absolutely. It is perfect for improving soil structure and root development in confined growing areas.

Q: How much pine bark mulch do I need per square foot?

A: For best results, apply 2–3 inches thick. That is about 2 cubic feet per 12 square feet of space.

Q: Where can I get bulk pricing on pine bark for sale in the U.S.?A: Many U.S.-based suppliers offer bulk discounts online.

#pine bark for sale#pine bark#pine bark mulch#pine fines soil conditioner#pine soil conditioner#composted pine bark fines#composted pine bark

0 notes

Text

The Unsung Heroes of Modern Warehousing

Efficiency is crucial in the hectic fields of logistics and production. Whether it's handling goods across countries or completing online purchases, companies depend on backend systems that silently handle the laborious tasks. Conveyor systems stand out among them; they are crucial but frequently disregarded.

What Exactly Are Conveyor Systems?

Conveyor systems are essentially mechanical devices that move goods from one location to another. Sounds easy? Not exactly. In factories, warehouses, and distribution centres, these systems are made to maximise speed, minimise manual handling, and establish smooth operation. They can be roller conveyors, belt-driven lines, or overhead conveyors, among other types.

The Significance of Roller Conveyors

One of the most widely used kinds, roller conveyors provide a useful and affordable means of moving things, particularly in settings involving manufacturing or packing. Consider them to be highways for pallets, crates, or boxes. Because the rollers lessen friction, moving big objects requires less effort and personnel. Additionally, because they are modular, companies can add, delete, or reroute pieces in response to changing needs.

While gravity roller conveyors rely on incline and basic physics, powered roller conveyors use motors to transport objects automatically. Both kinds provide safety, speed, and consistency, things that physical labour can't always provide.

Smart Conveyor Systems' Ascent

Conveyor systems change with the industry. Smarter than ever, today's setups frequently incorporate robotics, automation software, and sensors. These intelligent technologies notify operators of maintenance requirements prior to a breakdown, track goods in real-time, and modify speeds based on load.

Conveyor systems are now the foundation of dependable, scalable operations in the cold chain, pharmaceutical, and e-commerce industries. They guarantee that goods travel from point A to point B without interruption, harm, or misunderstanding.

Choosing Trustworthy Conveyor Belt Suppliers

If you plan to set up or change your system, working with experienced conveyor belt suppliers is crucial. When choosing a conveyor, the type of material, needed speed, load weight, and available space are all crucial factors to take into account. Whether it's belt conveyors for fragile goods or roller systems for bulk movement, effective design and component selection can have a big impact on long-term performance.

0 notes