#Kaolin Market

Explore tagged Tumblr posts

Text

The global Kaolin market was valued at USD 4,396.9 Million in 2022 and is expected to grow a CAGR of 3.7% during the forecast period (2023-2030)

0 notes

Text

Kaolin Market Report: Key Trends, Analysis, and Forecasts | P&S Intelligence

The kaolin market was USD 4,734.3 million in 2023, which will increase to USD 6,557.9 million, growing at a 4.9% compound annual growth rate, by 2030. The growth of this industry is boosted by its surging utilization as a pharmaceutical ingredient as well as the rising need in sanitary and ceramic sectors. The paper category, on the basis of application, led the industry, and it will propel at a…

View On WordPress

#analysis#Competitive Analysis#emerging opportunities#Forecasts#Global Kaolin Market#Growth Factors#industry trends#Kaolin Demand#Kaolin Industry Insights#Kaolin Market#Kaolin Suppliers#Market dynamics#Market Landscape#Market Report#Market Research#market size#P&S Intelligence#regional analysis

0 notes

Text

“The war in Ukraine is also a battle for raw materials. The country has large deposits of iron, titanium and lithium, some of which are now controlled by Russia.” That’s what the federally owned German foreign trade agency Germany Trade and Invest (GTAI) reported on its website on January 16 under the title “Ukraine’s raw materials wealth at risk.”

There are trillions at stake. According to the GTAI, “raw material deposits worth $12.4 trillion” remain beyond the control of the Ukrainian army, “including 41 coal mines, 27 gas deposits, 9 oil fields and 6 iron ore deposits.” Ukraine has not only coal, gas, oil and wheat but also rare earths and metals—especially lithium, which has been called the “white gold” of the transition to new energy and transportation technologies. The country accounts for around one-third of Europe’s explored lithium deposits.

Only the ignorant could believe that this is irrelevant to NATO’s war aims. It would be the first major war in over 100 years that is not about mineral resources, markets and geostrategic interests. The World Socialist Web Site has pointed out in previous articles that deposits of critical raw materials in Russia and China, which are essential to the transition to electric mobility and renewable energy, are an important factor in the war calculus of NATO states.

Yet they go unmentioned in the media’s round-the-clock war propaganda. The media wish the public to believe that NATO is waging this war to defend “freedom” and “democracy”—and that after bombing Afghanistan, Iraq, Libya and Syria back into the Middle Ages under similar pretexts.

Relevant trade journals, industry magazines and think tanks, on the other hand, rave about Ukraine’s mineral wealth and discuss how best to capture it. It was to this end that German Economics Minister Robert Habeck (Green Party) even traveled to Ukraine at the beginning of April with a high-ranking business delegation.

According to the industry magazine Mining World, Ukraine has a total of around 20,000 raw material deposits, of which only 7,800 have been explored. Numerous other articles and strategy papers openly state that this is what the war is about.

On February 24, 2022, the day of the Russian invasion of Ukraine, the largest German business magazine, Capital, published an article stating that “Europe’s supply of raw materials” was “threatened” by the Russian occupation of eastern Ukraine. Ukraine was not only “the leading grain exporter” but also the largest EU supplier of iron ore pellets and “a linchpin for Europe’s energy security.” Among investors, the magazine said, there is “concern that the war will cut off exports of key raw materials.”

The GTAI article cited earlier reports that European steel mills were sourcing nearly one-fifth of their iron ore pellets from Ukraine in 2021. GTAI goes on to write that Ukraine is among the top ten producers of iron ore, manganese, zirconium, and graphite, and is “among the world leaders in titanium and kaolin.” In addition to “untapped oil and gas fields,” Ukraine’s lithium and titanium deposits, in particular, hold “enormous potential” for the European economy. In 2020, production volumes amounted to 1,681,000 tons of kaolin, 537,000 tons of titanium, 699,000 tons of manganese and 49,274,000 tons of iron ore.

Lithium for electromobility and energy storage

The price of lithium has increased more than eightfold in the last decade and is the subject of intense speculation. The metal is of strategic importance to the major imperialist powers because it is used in lithium-ion batteries installed in electric vehicles and off-grid renewable energy sources, and is also needed for lightweight aluminum alloys in the aerospace industry.

The largest lithium deposit in Europe is located in the Donetsk Oblast in the middle of the embattled Donbas region, only kilometers from the front lines. An article in the Tagesspiegel, published two months after the Russian invasion, points to untapped lithium reserves of 500,000 tons in Shevchenko near Potrovsk and at least two other Ukrainian deposits.

Western companies and Ukrainian oligarchs were already fighting bitterly for control of this “white gold” before the war. As the Tagesspiegel reports, “Ukrainian businessmen” (who stood close to the Ukrainian government of the time under the oligarch Petro Poroshenko) with connections to Western mining companies obtained mining licenses, without a tender process, for the lithium deposit in Shevchenko as early as 2018.

The company in question, Petro Consulting—which was renamed “European Lithium Ukraine” shortly before the war began—is expected to be bought out by the Australian-European mining company European Lithium once its access to Ukraine’s lithium reserves is secured.

In 2018, when the Ukrainian Geological Survey refused to issue a “special permit” for Ukraine’s second largest lithium deposit at Dobra, likewise bypassing the tender process, Petro Consulting went so far as to sue the agency. After the Ukrainian Procurator General’s Office eventually launched an investigation into the allegedly illegal special permits, Petro-Consulting had its Shevchenko mining license revoked by the courts in April 2020 until further notice.

However, a spokesman for European Lithium told Der Tagesspiegel that the company bears “no risk in connection with the Ukrainian deposits.” He expressed confidence that the projects would be “made production-ready” after the end of the war.

Titanium for the Western arms industry

In a September 2022 article titled “Ukraine’s Titanium Can Armor the West,” the transatlantic think tank Center for European Policy Analysis (CEPA) wrote: “Support for Ukraine has been driven by strategic concerns and moral-political values. But long-term Western help should also be based on solid material interests.”

“Ukraine’s substantial titanium deposits” are “a key resource critical to the West” because the metal is “integral to many defense systems,” such as aircraft components and missiles. Currently, the raw material for Airbus, Boeing and Co. is extracted “in an expensive and time-consuming six-step process” from titanium ore, which until then had been sourced to a considerable extent from Russia. This “dependence” on “strategic competitors and adversaries” is unacceptable from the West’s point of view and can be ended with the help of Ukrainian resources:

For example, Dnipro-based Velta, the largest private exporter of raw titanium in Europe, has developed a new production system that bypasses the intensive process of producing titanium sponge and could supply the US and European defense and aerospace industries with finished metal. Given there are only five countries in the world actively producing titanium sponge —China, Russia, Kazakhstan, Japan and Ukraine — Velta’s technology could be a game changer for the supply chain by cutting reliance on Russia and China.

CEPA is funded by US and European defense contractors and lists as members of its “scientific advisory board” Donald Trump’s National Security Advisor General H. R. McMaster, former German Defense Minister Annegret Kramp-Karrenbauer, former Swedish Prime Minister Carl Bildt and publicists Anne Applebaum, Francis Fukuyama, and Timothy Garton Ash among others.

The CEPA article continues, “Reorienting titanium contracts to Ukraine would stimulate the country’s economy, even during wartime, not to mention during postwar reconstruction, and simultaneously strike another blow at Russia’s war machine.” The goal, it states, should be “cementing Ukraine’s integration into Europe.”

A January 28, 2023 report in Newsweek reports, “there is a nascent effort underway in the U.S. and allied nations to identify, develop, and utilize Ukraine’s vast resources of a key metal crucial for the development of the West’s most advanced military technology which will form the backbone of future deterrence against Russia and China.” The report adds, “If Ukraine wins, the U.S. and its allies will be in sole position to cultivate a new conduit of titanium.”

“Strategic raw materials partnership” between EU and Ukraine

The US and EU efforts to plunder Ukraine’s lithium and titanium deposits are part of the broader goal of tying Ukraine to the West as a strategic raw materials supplier. In particular, the EU is seeking to free itself from dependence on China—currently its most important raw materials supplier—against which the imperialist powers, especially the United States, are preparing to wage war.

On July 13, 2021, Ukrainian Prime Minister Denys Shmyhal and Maroš Šefčovič, Vice President of the European Commission, signed a “Strategic Partnership on Raw Materials and Batteries” in Kiev to “integrate critical raw materials and battery value chains.” Ukraine’s inclusion in the European Raw Materials Alliance (ERMA) and the European Battery Alliance (EBA) serves to “bolster Europe’s resilience and open strategic autonomy in key technologies,” the EU Commission said.

Referring to the list of critical raw materials in the EU’s associated “action plan,” Šefčovič told the press, “21 of these critical raw materials are in Ukraine, which is also extracting 117 out of 120 globally used minerals.” He added: “We’re talking about lithium, cobalt, manganese, rare earths—all of them are in Ukraine.”

Following the signing, EU Internal Market Commissioner Thierry Breton, who is also responsible for the defense and space industries of EU countries, praised the “high potential of the critical raw material reserves in Ukraine” that could help in “addressing some of the strategic dependencies [of the EU].”

Speaking at Raw Materials Week in Brussels in November 2022, Prime Minister Shmyhal stressed that Ukraine is “among the top ten producers of titanium, iron ore, kaolin, manganese, zirconium and graphite” and renewed his pledge to make the country an “integral part of industrial supply chains in the EU.”

The EU’s “strategic dependencies” are by no means limited to Russia or China and certainly not to Ukraine. A global race for strategic sources of raw materials has long since begun, in the course of which the US and the leading EU powers are attempting to divide among themselves the mineral resources and other resources of the “weaker” states. Although they are jointly waging war against Russia in Ukraine, this inevitably exacerbates conflicts between themselves as well.

The escalation of the war in Ukraine shows that the ruling elites are willing to go to extremes to enforce their profit interests. Only the working class can put an end to permanent war and the prospect of devastating nuclear war by bringing the resources of the entire planet under its democratic control on the basis of a socialist program and holding war profiteers to account.

3 notes

·

View notes

Text

R&D Innovations in Kaolin Clay: How New Processing Methods Are Changing the Market

Kaolin clay, also known as china clay, is a naturally occurring material that has been utilized for centuries across various industries. From ceramics to cosmetics and pharmaceuticals, the versatility of china clay has made it an indispensable material globally. With ongoing advancements in research and development (R&D), the kaolin producer industry is witnessing groundbreaking innovations in the processing methods of china clay. These innovations are shaping the future of the market by improving efficiency, quality, and expanding the range of applications.

Understanding Kaolin Clay: A Brief Overview of China Clay Properties

To fully appreciate the significance of the recent innovations in kaolin clay, it is important to first understand its unique properties. China clay is primarily composed of kaolinite, a mineral that gives it its soft, white appearance and makes it an ideal material for various applications.

The china clay properties include:

High Purity: Kaolin is known for its low impurity content, making it ideal for uses where cleanliness and high standards are required.

Fine Particle Size: The fine particle size of kaolin contributes to its smooth texture, which is essential for use in industries like ceramics, paper, and cosmetics.

Plasticity and Molding Ability: Kaolin has an inherent ability to mold and shape, making it ideal for ceramic products and pottery.

High Chemical Stability: The material has strong chemical resistance, making it suitable for applications in pharmaceuticals, paints, and coatings.

These characteristics have made china clay a sought-after material in a wide range of industries. As demand increases, kaolin producers are constantly looking for ways to improve their production processes, maximize output, and meet the growing needs of the market.

The Role of Kaolin Producers in Advancing R&D

As the global demand for china clay increases, particularly in emerging markets, kaolin producers are stepping up their R&D efforts to innovate and stay competitive. Kaolin producers are focused on improving the quality of their products through better processing techniques. By refining these processes, producers can achieve a higher degree of purity, finer particle sizes, and greater versatility, all of which are critical to expanding kaolin's market share.

For example, the development of new methods of processing china clay is enabling producers to create more specialized forms of kaolin, such as ultrafine kaolin or calcined kaolin, which offer unique advantages in specific applications. These developments allow kaolin producers to better serve industries like pharmaceuticals, where product purity is paramount, or the paper industry, where improved brightness and opacity are highly valued.

Innovations in Processing Methods

R&D innovations are leading the way in the enhancement of kaolin processing methods. Historically, kaolin processing involved simple mechanical techniques, such as grinding and washing. However, new technologies are now revolutionizing the industry, providing china clay suppliers with the tools to offer even more advanced products.

1. Advanced Flotation Techniques

Flotation is a technique used to separate the valuable kaolin from impurities like feldspar and quartz. New flotation methods that utilize innovative chemicals and more precise control over operating parameters are making the process more efficient and cost-effective. These advancements are reducing the need for chemical additives, improving environmental sustainability while increasing the overall purity of china clay.

2. Ultrasonic and Microwave-Assisted Treatments

Ultrasonic and microwave technologies are gaining traction in the kaolin processing industry. These technologies allow for more uniform and efficient heating of the kaolin, which enhances the dewatering and calcination processes. As a result, china clay products are being produced with superior properties, such as increased whiteness, brightness, and reduced moisture content. For china clay suppliers, this translates into higher-quality products that can command better prices in competitive markets.

3. Nanotechnology in Kaolin Clay Processing

Nanotechnology has been making waves in many industries, and kaolin clay is no exception. By utilizing nanomaterials and nanostructures, researchers are developing kaolin products with enhanced properties. These include improved performance in applications such as coatings, packaging materials, and cosmetics. Nanotechnology allows for the manipulation of kaolin at the molecular level, creating products with unique characteristics such as greater flexibility, strength, and conductivity. As kaolin producers incorporate nanotechnology into their production processes, they can offer an entirely new range of high-performance kaolin products to meet the demands of industries pushing the boundaries of innovation.

4. Acid Leaching and Surface Modification

In addition to the traditional beneficiation methods, acid leaching and surface modification are gaining prominence in the kaolin industry. These processes involve treating kaolin with acid or other chemicals to remove iron oxide and other contaminants, resulting in higher-purity kaolin with improved properties such as whiteness and opacity. Furthermore, surface modifications, such as coating the kaolin particles with various functional groups, are enabling new applications, particularly in the cosmetics and pharmaceutical industries.

5. Calcination for High-Performance Products

Calcination is the process of heating kaolin to high temperatures to alter its structure and improve its properties. Innovations in calcination techniques are enabling kaolin producers to create kaolin products that offer higher thermal stability and mechanical strength. These high-performance products are essential in applications such as refractory materials and advanced ceramics, where durability and heat resistance are critical.

Impact of Innovations on the Market

As china clay suppliers continue to adopt these innovative processing methods, the kaolin market is experiencing significant changes. These advancements are not only improving product quality and consistency but are also opening up new markets and applications for kaolin.

1. Meeting Environmental Demands

One of the major challenges facing the kaolin industry is environmental sustainability. The increased focus on environmental impact has led to the development of more sustainable processing techniques. For example, new flotation and washing techniques are being designed to use fewer chemicals and reduce water consumption. These eco-friendly methods are helping kaolin producers meet stricter environmental regulations and appeal to environmentally conscious consumers.

2. Expanding Applications in Emerging Industries

The improvements in kaolin processing are allowing china clay suppliers to tap into new markets. In the electronics industry, for instance, kaolin is used as a filler in various materials, and its use in advanced ceramics is growing. Similarly, the development of ultra-pure kaolin is opening up new opportunities in the pharmaceutical and biomedical sectors, where purity and consistency are crucial.

3. Customization and Product Diversification

The ability to fine-tune the properties of kaolin through advanced processing methods is also enabling china clay suppliers to offer customized products to meet the specific needs of their clients. For instance, kaolin can now be processed to achieve particular properties, such as increased whiteness, lower particle size, or enhanced chemical resistance, making it a more versatile material across various industries. As a result, the market is witnessing the introduction of more diverse kaolin products, expanding the range of applications and increasing competition among kaolin producers.

Challenges and Future Outlook

Despite the numerous innovations in kaolin processing, the industry still faces several challenges. The development of advanced processing techniques requires significant investment in research, infrastructure, and skilled labor. Additionally, the increasing demand for china clay is placing pressure on raw material supply chains, leading to concerns about the long-term availability of high-quality kaolin resources.

However, the future of the kaolin industry looks promising. As R&D continues to drive innovation in processing methods, the quality, efficiency, and versatility of china clay are only expected to improve. This will help ensure that kaolin remains a valuable material in a wide range of industries, from ceramics to biotechnology.

Conclusion

Innovations in R&D are significantly transforming the kaolin industry. The new processing methods being developed by kaolin producers are improving the quality, efficiency, and sustainability of china clay production, while opening up new markets and applications. With continued advancements in processing technologies, china clay suppliers are poised to meet the ever-growing demand for kaolin products across industries. As the market evolves, these innovations will continue to shape the future of china clay, making it a key player in various sectors worldwide.

0 notes

Text

Pharmaceutical & Cosmetic Raw Material Manufacturer in India – Delivering Quality for Superior Formulations

The pharmaceutical and cosmetic industries require premium-quality raw materials to create safe, effective, and high-performance products. A trusted supplier ensures consistency, purity, and regulatory compliance, which are crucial for manufacturers. Among the leading names in India, Caltron Clays & Chemicals Pvt Ltd has earned a strong reputation for offering top-grade pharmaceutical and cosmetic raw materials.

From Algae Calcium Powder to Kaolin Powder, Caltron Clays supplies a wide range of ingredients that support the development of nutraceuticals, skincare products, and pharmaceutical formulations. This blog explores why sourcing high-quality raw materials matters and how Caltron Clays meets industry demands.

Why Choosing High-Quality Raw Materials is Essential?

In pharmaceuticals and cosmetics, the effectiveness, safety, and success of a product depend largely on the quality of raw materials used. Selecting a reliable supplier ensures:

Consistent Purity & Quality – Helps maintain formulation standards.

Regulatory Compliance – Adheres to industry certifications such as GMP, ISO, and FSSAI.

Enhanced Product Performance – Improves stability, absorption, and overall effectiveness.

Sustainable & Ethical Sourcing – Supports eco-friendly and responsible ingredient procurement.

By prioritizing purity, safety, and industry regulations, Caltron Clays ensures its raw materials meet the highest quality benchmarks.

Caltron Clays – Providing Reliable Raw Materials for Pharmaceuticals & Cosmetics

Caltron Clays specializes in manufacturing and supplying pharmaceutical and cosmetic ingredients that are widely used in nutraceuticals, personal care, and pharmaceutical formulations. The company’s expertise ensures safe, effective, and industry-approved materials for diverse applications.

Product Line at Caltron Clays

1. Algae Calcium Powder

A highly bioavailable calcium source, Algae Calcium Powder is rich in minerals and trace elements, making it ideal for bone health supplements and nutraceuticals.

🔗 Explore more: Algae Calcium Powder Manufacturer

2. Coral Calcium Powder

This marine-derived calcium is widely used in dietary supplements for its superior absorption and support for bone health.

🔗 More details: Coral Calcium Powder

3. Oyster Shell Calcium Carbonate

Known for its natural purity, this calcium source is used in pharmaceutical tablets, capsules, and fortified foods, ensuring optimal nutrient absorption.

🔗 Explore more: Oyster Shell Calcium Carbonate Supplier

4. MCHC Powder (Microcrystalline Hydroxyapatite Complex)

An excellent bone health supplement ingredient, MCHC Powder is a natural source of calcium, phosphorus, and collagen, promoting joint and skeletal health.

🔗 More details: MCHC Powder

Why Partner with Caltron Clays?

A dependable raw material manufacturer plays a crucial role in helping businesses create products that meet industry standards and customer expectations. Caltron Clays is a preferred choice for many brands due to its commitment to quality and sustainability.

What Makes Caltron Clays Stand Out?

Strict Quality Control Every batch undergoes thorough testing to maintain purity, consistency, and performance.

Sustainable & Ethical Sourcing Ingredients are sourced through eco-friendly and responsible procurement methods, ensuring minimal environmental impact.

Industry-Certified Manufacturing The company complies with GMP, ISO, and FSSAI standards, making its raw materials suitable for pharmaceutical and cosmetic applications.

Global Supply Network Caltron Clays is trusted by leading brands worldwide, providing high-quality ingredients for international markets.

Applications of Caltron Clays’ Raw Materials

Pharmaceutical Industry

Used in dietary supplements to support bone and joint health.

Essential for pharmaceutical tablets, capsules, and syrups.

Formulated in nutritional powders and oral suspensions.

Cosmetic Industry

Kaolin Powder helps control excess oil in face masks and cleansers.

Diatom Scrubbing Salt is used in natural exfoliators and body scrubs.

Plays a role in personal care products, including creams and lotions.

Emerging Trends in Pharmaceutical & Cosmetic Raw Materials

The demand for natural and sustainable ingredients is transforming both pharmaceutical and cosmetic industries.

Current Market Trends

Growing Preference for Plant-Based & Marine-Derived Ingredients More manufacturers are opting for Algae Calcium and Coral Calcium due to their bioavailability and sustainability.

Eco-Conscious Beauty & Skincare Brands are increasingly using natural exfoliants like Diatom Scrubbing Salt instead of synthetic microbeads.

Advancements in Nutraceuticals Ingredients like MCHC Powder provide high-absorption calcium, making them ideal for bone health supplements.

As Caltron Clays continues to innovate, it remains a leading supplier of natural and functional raw materials that meet evolving market demands.

Conclusion – Trusted Supplier for High-Quality Raw Materials

Manufacturers in the pharmaceutical, nutraceutical, and cosmetic industries require raw materials that are safe, effective, and sustainable. Caltron Clays & Chemicals Pvt Ltd delivers high-quality ingredients, ensuring businesses can create top-tier formulations.

0 notes

Text

HD Microns Limited: Leading Kaolin Exporters for Superior Industrial Solutions

Kaolin, a versatile clay mineral, plays a crucial role in a wide array of industries, from paper to paints, rubber, and cement. Among the top-tier kaolin exporters, HD Microns Limited stands out as a leader, delivering unparalleled quality and innovation since its establishment in 1997. With a legacy of excellence and a commitment to customer satisfaction, HD Microns has solidified its reputation as a trusted supplier of high-grade kaolin products.

The HD Microns Advantage

Comprehensive Product Range

HD Microns Limited offers an extensive range of kaolin products tailored to meet diverse industrial needs:

Levigated China Clay

Hydrous China Clay

Spray Dried China Clay

Calcined China Clay

Meta Kaolin

Each product undergoes rigorous quality checks to ensure it meets international standards, making them ideal for applications in paper, paint, adhesives, cables, and more.

State-of-the-Art Facilities

HD Microns Limited utilizes cutting-edge technology and advanced machinery to produce top-quality kaolin products. The company’s calcined kaolin plant exemplifies this commitment, enabling precise control over the calcination process to produce kaolin with exceptional pozzolanic properties.

Meta Kaolin: A Game-Changer

One of HD Microns’ standout products is Meta Kaolin, a dehydroxylated form of kaolinite created through a controlled calcination process. This high-performance material offers numerous benefits for the construction industry, particularly in cement and concrete applications:

Enhanced Strength: Meta Kaolin reacts with calcium hydroxide to form additional calcium silicate hydrates (C-S-H), increasing the strength of concrete.

Reduced Permeability: The pozzolanic reaction densifies the concrete matrix, reducing water and chloride penetration.

Improved Durability: Concrete mixed with Meta Kaolin exhibits superior resistance to reinforcement corrosion, sulfate attacks, and alkali-silica reactions.

Aesthetic Appeal: Its light color makes it ideal for architectural concrete and white cement applications.

Typical dosages of Meta Kaolin range from 8-20% replacement of Portland cement by weight, making it a cost-effective solution for enhancing concrete performance.

Commitment to Excellence

Under the visionary leadership of Mr. Hansraj D. Patel, HD Microns Limited has continually evolved to meet the dynamic needs of the market. The company’s team of experienced professionals ensures that every product delivers maximum value to customers worldwide.

Why Choose HD Microns Limited?

As a leading name among kaolin exporters, HD Microns Limited stands out for its:

High-quality products that meet international standards.

Advanced manufacturing processes and facilities.

Dedicated customer support and tailored solutions.

Competitive pricing and reliable delivery.

Contact HD Microns Limited Today

Ready to elevate your industrial processes with superior kaolin products? Get in touch with HD Microns Limited

0 notes

Text

How India Became a Global Leader in China Clay Powder Production

China clay, also known as kaolin, is a naturally occurring mineral that has been a cornerstone of numerous industries for centuries. China Clay Powder Manufacturers for its purity, smooth texture, and versatility, this white clay is extensively used in ceramics, paper, rubber, paint, and various other applications. India is one of the leading producers of high-quality china clay powder, making it a hub for industries seeking premium-grade raw materials.

What is China Clay Powder?

China clay is a soft, white mineral primarily composed of kaolinite. Its unique chemical properties, such as excellent whiteness, high brightness, low moisture content, and resistance to high temperatures, make it an indispensable material in various industries. The clay undergoes a meticulous refining process to produce fine-grade powder, ensuring it meets the stringent quality standards required for industrial applications.

Applications of China Clay Powder

Ceramics IndustryChina clay powder is a fundamental component in the ceramics industry. Its ability to enhance the strength, smoothness, and whiteness of ceramic products makes it highly desirable. From tiles and sanitary ware to pottery, kaolin is an essential raw material in crafting durable and aesthetically pleasing ceramic goods.

Paper IndustryIn the paper industry, china clay acts as a filler and coating material. It enhances the paper's brightness, opacity, and smoothness, making it ideal for high-quality printing and writing papers. The addition of kaolin improves printability and reduces production costs.

Paints and CoatingsAs an extender in paints, china clay powder improves the paint's opacity and durability. Its inclusion reduces the consumption of expensive pigments and enhances the overall finish and quality of the coatings.

Rubber IndustryIn the rubber industry, china clay is used as a filler to improve the mechanical properties of rubber products. It enhances elasticity, tensile strength, and resistance to wear, making it a valuable additive in the manufacturing of tires, hoses, and other rubber-based products.

Cosmetics and PharmaceuticalsDue to its non-toxic and absorbent properties, china clay powder is also used in cosmetics and pharmaceuticals. It serves as a base material in face powders, foundations, and ointments, ensuring a smooth texture and gentle application.

Why India is a Leading Producer of China Clay Powder

India has abundant reserves of high-quality kaolin, distributed across states like Gujarat, Rajasthan, Kerala, and West Bengal. These reserves, coupled with advanced mining and refining technologies, have positioned India as a global leader in the production of china clay powder. Indian manufacturers focus on delivering products that meet international standards, catering to the diverse needs of industries worldwide.

Characteristics of High-Quality China Clay Powder

To meet the rigorous demands of industries, china clay powder must possess specific characteristics:

High brightness and whiteness

Low moisture and impurity content

Consistent particle size distribution

Excellent plasticity and workability

Resistance to high temperatures

Choosing the Right Manufacturer

Selecting a reliable china clay powder manufacturer is critical to ensure the quality and performance of end products. Manufacturers that emphasize quality control, sustainability, and customer satisfaction often stand out in this competitive market. Additionally, the ability to customize products according to industry-specific requirements is a hallmark of a dependable supplier.

Leading China Clay Powder Manufacturers in India

The Indian market is home to numerous manufacturers specializing in high-quality china clay powder. Among them, Sudarshan Group is a name that stands out for its commitment to excellence and innovation. Known for its extensive experience, the company offers premium-grade china clay powder that meets the needs of various industries. Their dedication to quality, timely delivery, and customer satisfaction has earned them a stellar reputation in the market.

Conclusion

China clay powder plays a pivotal role in multiple industries, from ceramics and paper to paints and cosmetics. India, with its rich mineral resources and skilled manufacturers, has become a global hub for high-quality kaolin production. Whether you are looking for a reliable supplier for large-scale industrial applications or niche requirements, India offers a diverse range of options to suit your needs.

By choosing a trusted manufacturer like Sudarshan Group, businesses can ensure access to top-notch china clay powder that delivers superior performance and consistency in every application.

0 notes

Text

0 notes

Text

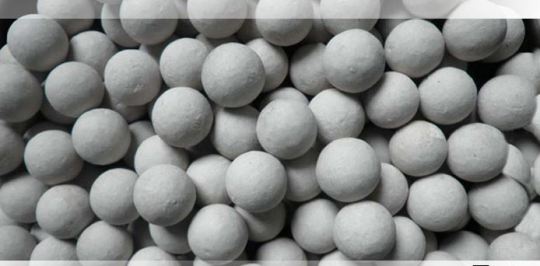

Ceramic Proppant Prices: Trend | Pricing | News | Price | Database

Ceramic Proppant are essential materials used in hydraulic fracturing, commonly known as fracking, to enhance the extraction of oil and gas from underground reservoirs. These proppants are made from high-strength ceramic materials that resist crushing under extreme pressure and are designed to keep fractures in the rock formation open, allowing oil or gas to flow freely. The ceramic proppant market has seen significant growth in recent years due to the increasing demand for oil and gas, particularly from shale plays. As a result, the prices of ceramic proppants have fluctuated in response to various factors, including raw material costs, technological advancements, and the supply and demand dynamics within the energy industry.

The price of ceramic proppants is influenced by several key factors, with raw materials being one of the primary determinants. Ceramic proppants are typically made from bauxite, kaolin, and other mineral-based materials. These raw materials have seen price fluctuations due to changes in global supply and demand, mining regulations, and geopolitical events. For instance, bauxite, the primary raw material for ceramic proppants, has been subject to price volatility due to changes in mining activity in countries like China, Australia, and Brazil. The cost of kaolin, another significant material, has also experienced fluctuations, driven by changes in demand from various industries, including ceramics and paper.

Get Real time Prices for Ceramic Proppant: https://www.chemanalyst.com/Pricing-data/ceramic-proppant-1576

In addition to raw material costs, the manufacturing process of ceramic proppants plays a crucial role in determining their price. Ceramic proppants are produced through a high-temperature sintering process, which involves heating the raw materials to a temperature where they melt and form small, spherical pellets. The energy-intensive nature of this process can impact the cost of production, particularly in regions where energy prices are high. Technological advancements in manufacturing processes have led to the development of more efficient methods for producing ceramic proppants, which could potentially reduce production costs and, in turn, impact the overall pricing of these materials.

The supply and demand dynamics of the oil and gas industry also significantly affect the price of ceramic proppants. When oil and gas prices are high, there is typically an increase in exploration and production activity, leading to a higher demand for proppants. Conversely, when oil and gas prices decline, exploration and production activities may slow down, leading to a decrease in demand for proppants. This cyclical nature of the oil and gas industry means that ceramic proppant prices are often highly sensitive to fluctuations in commodity prices. For example, during periods of high oil prices, the demand for hydraulic fracturing services increases, which in turn boosts the demand for ceramic proppants, driving up their prices. However, when oil prices drop, the demand for proppants may decrease, causing prices to soften.

Geopolitical factors can also influence ceramic proppant prices. Trade tensions, sanctions, and changes in government policies can impact the global supply chain for raw materials and finished proppants. For example, trade disputes between major ceramic proppant-producing countries like China and the United States can result in tariffs or restrictions on the import and export of these materials. Such disruptions in the supply chain can lead to shortages or price hikes for ceramic proppants in certain regions. Additionally, government regulations related to the oil and gas industry, such as stricter environmental standards or changes in hydraulic fracturing regulations, can affect the demand for ceramic proppants and, consequently, their prices.

The development of alternative proppant technologies is another factor that can influence ceramic proppant prices. While ceramic proppants are known for their high strength and durability, they are also more expensive than other types of proppants, such as sand. As a result, some oil and gas companies are exploring the use of alternative proppants that offer similar performance at a lower cost. If these alternative technologies gain traction in the market, they could put downward pressure on ceramic proppant prices. However, the high performance and reliability of ceramic proppants continue to make them a preferred choice for many operators, particularly in deep and ultra-deep wells where the risk of crushing is higher.

The competitive landscape of the ceramic proppant market also plays a role in determining pricing trends. Several large multinational companies dominate the market, and these companies typically have the resources and economies of scale to offer ceramic proppants at competitive prices. However, smaller, regional manufacturers may provide lower-cost alternatives, contributing to price fluctuations within the market. Additionally, the level of competition can affect the pricing strategies of manufacturers, as companies may adjust their prices based on market conditions and the actions of competitors.

In recent years, the global ceramic proppant market has seen increasing consolidation, with mergers and acquisitions taking place between major players in the industry. These strategic moves are aimed at expanding production capabilities, improving market reach, and achieving cost efficiencies. As a result, the consolidation trend may impact the competitive landscape and pricing dynamics in the future, as larger companies are able to leverage their resources to maintain competitive pricing.

In conclusion, the ceramic proppant market is influenced by a complex set of factors, including raw material costs, manufacturing processes, supply and demand dynamics in the oil and gas industry, geopolitical factors, and the competitive landscape. While ceramic proppants are a premium product in terms of strength and performance, their prices are subject to fluctuations based on the broader economic and energy market conditions. As the demand for hydraulic fracturing services continues to rise in response to growing global energy needs, the ceramic proppant market is expected to remain a key component of the oil and gas industry, with price trends being closely tied to the ebb and flow of global commodity prices and technological advancements.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Ceramic Proppant#Ceramic Proppant Prices#Ceramic Proppant Price Trend#Ceramic Proppant News#Ceramic Proppant Monitor#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research

0 notes

Text

Unveiling the Wonders of Kaolin: A Natural Marvel in the World of Minerals

Among earth’s minerals and treasures, kaolin stands out as a true marvel. Derived from the Chinese word “jailing”, meaning “high ridge”, kaolin is a soft white clay that has found its way into various industries, showcasing its versatility and unique properties Let’s embark on a journey to sleep kaolin miracles and let us examine their many applications. The global kaolin market size is…

View On WordPress

#Kaolin Market#Kaolin Market Outlook#Kaolin Market Research Report#Kaolin Market Share#Kaolin Market Size#Kaolin Market Trends

0 notes

Text

Why India is the Leading China Clay Exporter A Hub for High-Quality Kaolin

India has long been recognized as one of the world’s top suppliers of various minerals, and China clay, also known as kaolin, is no exception. As a China Clay Exporter in India, the country plays a vital role in the global supply chain, providing high-quality kaolin that meets the diverse needs of industries around the world. Kaolin’s versatility and wide range of applications have fueled its demand in sectors such as ceramics, paper, paints, rubber, pharmaceuticals, and cosmetics. This blog explores why India is the leading China Clay Exporter and how the country has become a hub for high-quality kaolin.

What is China Clay (Kaolin)?

China clay, or kaolin, is a naturally occurring white clay mineral, primarily composed of kaolinite. It forms from the weathering of rocks like feldspar and is rich in alumina and silica. Due to its high whiteness, low iron content, fine particle size, and excellent plasticity, China clay is used extensively across multiple industries. The mineral's non-toxic, absorbent, and non-abrasive nature makes it ideal for applications in ceramics, paper, rubber, paints, cosmetics, and pharmaceuticals.

China clay is an essential raw material for the manufacturing of porcelain, high-quality paper products, rubber compounds, and various beauty and personal care products. Given its wide-ranging utility, it is in high demand globally, and India’s significant reserves, along with advanced manufacturing capabilities, make the country a leading China Clay Exporter in the world.

India’s Position as a Leading China Clay Exporter

India’s dominance in the global kaolin market can be attributed to a combination of natural resources, technological advancements, cost-effective production methods, and a strong export infrastructure. Here are the key reasons why India is the leading China Clay Exporter:

1. Abundant Natural Reserves

India boasts extensive reserves of China clay, particularly in states like Rajasthan, Tamil Nadu, and Andhra Pradesh. These regions are rich in high-quality kaolin, making India a major global supplier of this mineral. The country has some of the purest and finest kaolin deposits, ensuring that the clay produced is of the highest quality, suitable for a wide range of industrial applications. India’s China clay is known for its low iron content and high whiteness, which are crucial properties for industries such as ceramics and paper production.

2. High-Quality Kaolin Production

One of the primary reasons India has become a leader in the global China clay market is its ability to produce high-quality kaolin that meets the stringent requirements of various industries. China Clay Exporters in India focus on maintaining high standards of quality, ensuring that their products are free from impurities that could affect performance.

Indian China Clay Exporters use advanced processing techniques to refine the kaolin, removing impurities such as iron, titanium, and other minerals that may impact the clay's characteristics. The refined kaolin is then tailored to meet the specific needs of different industries, whether for ceramics, paper coatings, or cosmetics. This consistency in quality has helped Indian kaolin gain global recognition.

3. Cost-Effectiveness and Competitive Pricing

India has a competitive advantage in terms of the cost of production. The relatively low cost of labor, combined with efficient mining and processing techniques, allows China Clay Exporters in India to offer kaolin at competitive prices without compromising on quality. This cost-effectiveness has made Indian kaolin a popular choice among international buyers, particularly those in the ceramics, rubber, and paper industries.

For businesses looking to source kaolin at a lower cost while maintaining high-quality standards, India provides an attractive solution. The combination of natural resources, efficient production methods, and favorable economic conditions contributes to India’s position as a cost-effective and reliable China Clay Exporter.

4. Technological Advancements in Processing

Indian China Clay Exporters have invested heavily in state-of-the-art processing technologies to meet the ever-growing global demand for kaolin. These advancements ensure that the kaolin produced is of consistent quality and meets the specific requirements of various applications. The use of modern beneficiation techniques, such as high-efficiency washing, refining, and drying processes, ensures that the clay is free from contaminants and meets international standards.

The processing plants in India are equipped to handle large volumes of kaolin while maintaining quality control, making the country one of the most efficient exporters of China clay in the world. This has enabled India to meet the needs of international markets consistently and reliably.

5. Well-Established Export Infrastructure

India’s export infrastructure plays a crucial role in facilitating the smooth and timely delivery of kaolin to global markets. Major ports like Mumbai, Chennai, and Kolkata serve as key gateways for the export of China clay, ensuring that shipments are efficiently handled and delivered to international destinations.

The country also has a strong network of logistics and transportation systems that ensure timely deliveries to global customers. As a China Clay Exporter in India, we have built strong relationships with shipping companies and freight forwarders, ensuring that our kaolin reaches our international clients on time and in excellent condition.

6. Global Demand for China Clay

The demand for China clay has been steadily rising due to its diverse applications across industries. For example, the ceramics industry uses kaolin to manufacture porcelain, tiles, and sanitary ware. The paper industry uses kaolin as a coating and filler material to improve the smoothness and brightness of paper. The paints industry relies on kaolin as a filler to enhance the texture and performance of paints.

With India’s high-quality kaolin and competitive pricing, it has become a preferred supplier for industries in Europe, the United States, Africa, and the Middle East. As a China Clay Exporter in India, we are equipped to meet the growing demand for this essential mineral and deliver it efficiently to international markets.

7. Sustainability and Environmental Responsibility

In today’s global marketplace, sustainability is a key factor for many businesses when choosing suppliers. China Clay Exporters in India are increasingly focusing on environmentally responsible mining and processing practices. The country has introduced regulations and guidelines to ensure that kaolin extraction is done sustainably, minimizing environmental impact.

Responsible mining practices, such as proper land reclamation and waste management, help mitigate the ecological footprint of kaolin production. By adopting these sustainable practices, Indian exporters contribute to environmentally-friendly business practices that align with global sustainability goals.

8. Diverse Applications Across Industries

India’s China Clay Exporters cater to a wide range of industries, ensuring that the kaolin produced can be customized to meet specific industry needs. Some of the key applications of kaolin include:

Ceramics: Kaolin is used in the production of porcelain, pottery, tiles, and sanitary ware due to its smooth texture, high whiteness, and durability.

Paper: Kaolin enhances the brightness, smoothness, and opacity of paper products, making it a crucial material in the production of high-quality printing and packaging papers.

Paints and Coatings: In the paint industry, kaolin is used as a filler and extender to improve coverage, texture, and durability.

Rubber: Kaolin is used as a reinforcing agent in rubber, improving its strength and durability, particularly in tires and footwear.

Cosmetics and Pharmaceuticals: Kaolin is utilized in personal care products such as face masks, body powders, and in pharmaceutical formulations due to its absorbent and non-toxic properties.

The versatility of kaolin has contributed to the growing demand for Indian kaolin, and China Clay Exporters in India have capitalized on this trend by offering customized products that meet the specific requirements of these industries.

Conclusion

India’s position as a China Clay Exporter is underpinned by several factors, including the country’s abundant natural reserves, competitive pricing, advanced processing technologies, and strong export infrastructure. As a hub for high-quality kaolin, India serves industries around the world with top-grade China clay that meets the exacting standards of industries such as ceramics, paper, rubber, cosmetics, and more.

By choosing a trusted China Clay Exporter in India, businesses around the world can benefit from a reliable, cost-effective, and high-quality source of kaolin. India’s commitment to sustainability, coupled with its expertise in kaolin production, ensures that the country will continue to play a pivotal role in the global supply of China clay for years to come. Whether you are in the ceramics, paper, rubber, or cosmetics industry, India remains a preferred supplier of kaolin, meeting the diverse needs of international markets with efficiency and excellence.

0 notes

Text

The Timeless Beauty of Hangzhou Porcelain: A Legacy of Art and Craftsmanship

The Timeless Beauty of Hangzhou Porcelain: A Legacy of Art and Craftsmanship

Hangzhou, a city renowned for its picturesque landscapes and rich cultural heritage, is also a hub for exquisite porcelain craftsmanship. Hangzhou porcelain, with its delicate designs and high-quality craftsmanship, has enchanted collectors and enthusiasts for centuries. Let's explore the fascinating history, unique features, and enduring allure of Hangzhou porcelain.To get more news about hangzhou porcelain, you can visit shine news official website.

A Glimpse into History: The Origins of Hangzhou Porcelain The history of porcelain production in Hangzhou dates back to the Tang Dynasty (618-907 AD). The region's abundant natural resources, including high-quality kaolin clay, provided the perfect materials for creating fine porcelain. During the Song Dynasty (960-1279 AD), Hangzhou emerged as a significant center for porcelain production, with artisans perfecting their techniques and creating pieces that were highly valued by the imperial court and elite.

Distinctive Features of Hangzhou Porcelain Hangzhou porcelain is celebrated for its unique characteristics, which set it apart from other porcelain styles. Key features include:

Exquisite Glazes: Hangzhou porcelain is known for its beautiful glazes, often featuring vibrant colors and intricate patterns. The use of celadon glaze, in particular, is a hallmark of Hangzhou's porcelain, creating a smooth and lustrous finish.

Delicate Designs: Artisans in Hangzhou excel in creating delicate and detailed designs. Traditional motifs often include nature-inspired elements such as lotus flowers, bamboo, and mythical creatures, reflecting the region's cultural and artistic influences.

High-Quality Craftsmanship: The meticulous craftsmanship involved in producing Hangzhou porcelain ensures that each piece is of the highest quality. From the careful selection of clay to the precise firing process, every step is executed with skill and dedication.

Cultural Significance and Collectibility Hangzhou porcelain holds immense cultural significance in China. It is not only appreciated for its aesthetic beauty but also for its historical and artistic value. Collectors around the world seek Hangzhou porcelain for its rarity and craftsmanship, making it a prized addition to any collection. Museums and galleries often feature Hangzhou porcelain as part of their exhibits, showcasing its enduring legacy.

Modern Innovations and Trends While traditional techniques continue to be revered, modern innovations in porcelain production have also emerged in Hangzhou. Contemporary artists and designers are experimenting with new forms, glazes, and designs, blending traditional craftsmanship with modern aesthetics. This fusion of old and new has resulted in innovative pieces that appeal to a broader audience while preserving the essence of Hangzhou porcelain.

Visiting Hangzhou: Exploring Porcelain Artistry For those visiting Hangzhou, exploring the city’s porcelain heritage is a must. Several workshops and studios offer insights into the intricate process of porcelain making. Visitors can witness artisans at work, learn about the history and techniques, and even try their hand at creating their own porcelain pieces. Additionally, local markets and galleries provide opportunities to purchase authentic Hangzhou porcelain as a souvenir or collectible.

Conclusion Hangzhou porcelain embodies the timeless beauty and meticulous craftsmanship that have defined Chinese porcelain for centuries. Its rich history, distinctive features, and cultural significance continue to captivate collectors and art enthusiasts worldwide. As Hangzhou porcelain evolves with modern innovations, it remains a testament to the enduring legacy of art and craftsmanship that this historic city proudly upholds.

0 notes

Text

Sustainable Practices in China Clay Manufacturing: What Indian Suppliers Are Doing Right

Industrial applications for kaolin, mineral mining company, and china clay manufacturers are at the forefront of transforming the industry through innovative and sustainable practices. By adopting methods that prioritize environmental preservation, Indian suppliers are leading the way in sustainable china clay manufacturing and setting benchmarks for the global market.

Introduction

The industrial sector is witnessing a paradigm shift towards sustainable operations, and the china clay manufacturing industry is no exception. India, known for its vast reserves of kaolin (commonly referred to as china clay), has emerged as a global hub for its extraction and processing. This surge in activity is fueled by the increasing industrial applications for kaolin in ceramics, paper, rubber, paints, and more.

At the heart of this transformation are Indian mineral mining companies and china clay manufacturers, who are adopting environmentally friendly practices while ensuring the efficient extraction and processing of this versatile mineral. This article delves into the sustainable strategies employed by Indian suppliers and how they are reshaping the industry landscape.

The Importance of Sustainability in China Clay Manufacturing

Sustainability is no longer a choice but a necessity in today’s industrial operations. The china clay manufacturing process involves several stages, from mining to refining, each of which has a significant environmental impact. Unsustainable practices can lead to deforestation, water pollution, and loss of biodiversity. Recognizing these challenges, Indian mineral mining companies have prioritized eco-friendly methods to minimize their environmental footprint.

Key Industrial Applications for Kaolin

Before exploring the sustainable practices, it’s essential to understand the diverse industrial applications for kaolin:

Ceramics Industry: Kaolin’s fine particle size and white color make it a preferred material for producing high-quality ceramics, including porcelain and tiles.

Paper Industry: In paper manufacturing, kaolin is used as a coating and filler to enhance brightness, smoothness, and printability.

Rubber Industry: Kaolin acts as a reinforcing agent in rubber, improving its strength and durability.

Paint Industry: It is a key ingredient in paint formulations, providing opacity and reducing costs.

Pharmaceuticals and Cosmetics: Its non-toxic nature makes it suitable for use in medicines and cosmetic products.

Indian china clay manufacturers have excelled in catering to these diverse applications, ensuring consistent quality while adhering to sustainable practices.

Sustainable Mining Practices by Indian Mineral Mining Companies

1. Land Reclamation

Indian mineral mining companies are focusing on land reclamation to restore ecosystems affected by mining. Post-mining landscapes are rehabilitated through tree planting, soil enrichment, and converting abandoned mines into water reservoirs or agricultural land.

2. Water Management

Water is crucial in the china clay manufacturing process, especially for washing and refining kaolin. To address water scarcity and pollution, Indian suppliers have adopted water recycling systems. Advanced filtration and sedimentation techniques are used to treat and reuse water, significantly reducing freshwater consumption.

3. Renewable Energy Integration

Many china clay manufacturers in India are transitioning to renewable energy sources such as solar and wind power to run their operations. This shift not only reduces carbon emissions but also lowers energy costs in the long run.

4. Minimizing Waste

The mining and refining of kaolin produce by-products such as quartz and mica. Indian mineral mining companies are exploring ways to utilize these by-products in other industries, such as construction, thus minimizing waste and maximizing resource utilization.

Technological Innovations in China Clay Manufacturing

Indian china clay manufacturers are leveraging cutting-edge technology to enhance sustainability:

Automation and AI: Automated systems and AI-driven analytics are improving precision in mining and reducing wastage.

Advanced Processing Equipment: Energy-efficient machinery and eco-friendly chemicals are being used to refine kaolin without compromising quality.

Emission Control Systems: Air filtration and emission control systems are being installed to reduce pollutants released during processing.

Collaboration and Compliance

Indian mineral mining companies are collaborating with government bodies, NGOs, and international organizations to establish sustainability standards. Compliance with regulations such as ISO 14001 (Environmental Management Systems) and adherence to local environmental laws reflect their commitment to responsible mining.

Benefits of Sustainable Practices

The adoption of sustainable practices in china clay manufacturing offers numerous benefits:

Environmental Preservation: Reduced carbon footprint, water conservation, and waste management contribute to ecosystem health.

Cost Efficiency: Energy savings and waste reduction lead to lower operational costs.

Market Competitiveness: Sustainable practices enhance brand reputation and open doors to global markets that prioritize environmentally friendly products.

Social Responsibility: By supporting local communities and protecting natural resources, Indian mineral mining companies foster goodwill and long-term sustainability.

Case Studies of Leading Indian China Clay Manufacturers

1. Company A

A leading mineral mining company, Company A has implemented a zero-discharge policy in its processing plants. By recycling 95% of the water used in operations, it has significantly reduced its environmental impact.

2. Company B

This china clay manufacturer has set up solar power plants to meet 50% of its energy requirements. Additionally, it has partnered with local communities to develop agroforestry projects on reclaimed mining land.

3. Company C

Focusing on innovation, Company C uses AI-driven technology to monitor and optimize mining operations, ensuring minimal wastage and efficient resource use.

Challenges and the Way Forward

While Indian china clay manufacturers have made commendable progress in sustainability, challenges remain:

High Initial Costs: Implementing eco-friendly technologies and renewable energy systems requires significant investment.

Regulatory Hurdles: Navigating complex environmental regulations can be time-consuming and costly.

Technological Barriers: Access to advanced technology and skilled labor remains a challenge for smaller companies.

To overcome these challenges, collaboration among industry stakeholders, increased government support, and continuous innovation are crucial. By addressing these issues, Indian mineral mining companies can further solidify their position as global leaders in sustainable china clay manufacturing.

Conclusion

The commitment of Indian china clay manufacturers and mineral mining companies to sustainable practices is setting a precedent for the global industry. By adopting eco-friendly methods, leveraging advanced technologies, and prioritizing environmental conservation, they are not only meeting the growing demand for kaolin but also contributing to a greener future.

The diverse industrial applications for kaolin highlight its importance across sectors, and India’s focus on sustainability ensures that this valuable resource is extracted and processed responsibly. As the world moves towards a more sustainable future, Indian suppliers are proving that economic growth and environmental stewardship can go hand in hand.

0 notes

Text

What is Noritake tableware, and what is so special about it?

Noritake stands as a beacon of porcelain excellence, offering more than just tableware—it represents a sophisticated cultural heritage that transforms ordinary meals into extraordinary experiences. Whether considering corporate gifts in Sri Lanka or selecting the best housewarming gifts, Noritake has long been a symbol of refined taste and meticulous craftsmanship that transcends mere functional utility.

Origins and Historical Significance

Noritake's journey began in 1904 when the Morimura Brothers established their first porcelain manufacturing venture in Nagoya, Japan. Their vision was ambitious: to create high-quality, Western-style porcelain that could compete on the global stage. This wasn't merely a business endeavour but a cultural bridge, introducing Japanese artistry to international markets through meticulously crafted tableware.

The company's early years were characterised by remarkable innovation. Unlike traditional Japanese ceramic production, Noritake focused on creating delicate, translucent porcelain that appealed to Western aesthetics. Their designs seamlessly blended Japanese precision with European elegance, quickly establishing a reputation for exceptional quality that would soon become legendary in the world of fine ceramics.

Craftsmanship and Production Techniques

What sets Noritake apart is an unwavering commitment to craftsmanship. Each piece undergoes a complex manufacturing process that involves multiple stages of design, moulding, painting, and firing. Skilled artisans meticulously hand-paint intricate patterns, ensuring that every plate, cup, and serving dish is a unique work of art.

The porcelain itself is a marvel of material science. Composed of fine kaolin clay, feldspar, and quartz, Noritake porcelain achieves a remarkable balance of durability and delicacy. The firing process occurs at extremely high temperatures, creating a smooth, non-porous surface that resists staining and maintains its lustrous appearance for decades. This scientific approach to ceramics ensures that each piece is not just beautiful, but also incredibly resilient.

Design Philosophy and Versatility

Noritake's design philosophy transcends mere functionality. Their collections range from classic, timeless patterns that evoke traditional elegance to contemporary designs that reflect modern aesthetic sensibilities. This versatility makes Noritake an ideal choice for various occasions—from intimate family dinners to grand wedding celebrations.

For those seeking employee gifts or gifts for a wedding couple in Sri Lanka, Noritake offers collections that communicate sophistication and thoughtfulness. Each piece tells a story, representing not just a dining implement but a cultural artifact that bridges traditions and celebrates human connection. The intricate designs often incorporate cultural motifs, historical references, and artistic expressions that make each collection unique.

Global Recognition and Prestige

Over the decades, Noritake has garnered international acclaim. Their tableware graces the tables of luxury hotels, fine dining restaurants, and royal households worldwide. The brand has become synonymous with quality, representing Japanese manufacturing excellence on the global stage.

What truly distinguishes Noritake is its ability to evolve while maintaining core principles of quality and artistry. Each generation of designers brings fresh perspectives, ensuring that the brand remains relevant and exciting without compromising its fundamental commitment to excellence. This continuous innovation has allowed Noritake to stay at the forefront of ceramic design and manufacturing.

Sustainability and Modern Innovations

In recent years, Noritake has embraced sustainability, implementing environmentally conscious manufacturing processes. They have invested in reducing carbon emissions, optimising resource usage, and developing more sustainable production techniques. This forward-thinking approach ensures that their commitment to quality extends beyond aesthetic and functional considerations.

Modern Noritake collections often incorporate advanced technologies, such as microwave-safe glazes and enhanced durability treatments. These innovations demonstrate the brand's commitment to meeting contemporary consumer needs while preserving traditional craftsmanship. The result is a perfect balance between technological advancement and artistic tradition.

Noritake tableware holds a special place in the hearts of enthusiasts and collectors, transcending its functional purpose to become an investment in art and history.

The Value of Noritake Collectibles

Certain vintage Noritake collections are highly sought after in the world of antiques, with rare patterns and limited-edition pieces commanding impressive prices at international auctions. These items are valued not only for their craftsmanship but also for their uniqueness and the story they tell. As a result, owning a piece of Noritake can feel like holding a tangible piece of design history.

Collectors often look for distinguishing factors such as:

Unique patterns and designs that showcase Noritake's artistic diversity.

Maker's marks and backstamps that identify the era and authenticity of a piece.

Historical significance, as certain collections reflect the cultural and artistic trends of their time.

Historical and Artistic Significance

Every Noritake piece is a reflection of the era in which it was created, making it a valuable artifact of design history. From the elegant Art Deco motifs of the early 20th century to the intricate hand-painted florals of the mid-century, Noritake's designs capture the changing tastes and cultural sensibilities of each period.

Some collectors specialise in specific time frames, such as the vibrant designs of the 1920s or the post-war minimalist aesthetics.

Others aim to build a collection that spans the breadth of Noritake's evolution, showcasing the brand’s progression over time.

Preservation Tips for Noritake Tableware

Preserving the beauty and value of Noritake tableware requires care and attention:

Gentle cleaning: Handwash pieces using a soft sponge, mild detergent, and lukewarm water to avoid abrasions or damage to delicate decorations. Avoid dishwashers, as their harsh cycles can chip or fade designs.

Safe storage: Store items in padded compartments or with separators to prevent chipping. Avoid stacking delicate pieces without protective layers.

Proper display: If showcasing items, keep them away from direct sunlight to prevent fading and ensure they are securely placed to avoid accidental tipping.

Noritake collectors cherish these pieces not just for their exquisite craftsmanship but also for their ability to evoke a sense of timeless elegance and cultural heritage. Whether as a personal passion or an investment, collecting Noritake tableware offers a unique opportunity to celebrate artistry and history.

Noritake represents more than a tableware brand; it embodies a philosophy of beauty, precision, and cultural exchange. From its humble beginnings in early 20th-century Japan to its current status as a global luxury brand, Noritake continues to transform dining experiences, one meticulously crafted piece at a time.

Whether you are seeking the perfect gift, looking to elevate your dining aesthetic, or simply appreciate exceptional craftsmanship, Noritake offers something truly extraordinary—a testament to the enduring power of artistic vision and technical mastery that continues to inspire and delight people around the world.

#corporate gifts sri lanka#Employee Gifts#best housewarming gifts#gift for wedding couple in sri lanka

0 notes

Text

Paper Pigments Market Analysis Report: Size, Share, and Trends Forecast for the Next Period

Global Paper Pigments Market Overview: Major Trends and Insights

The Paper Pigments Market research report offers an in-depth analysis of market dynamics, competitive landscapes, and regional growth patterns. This comprehensive report provides businesses with the strategic insights necessary to identify growth opportunities, manage risks, and develop effective competitive strategies in an ever-evolving market.

According to Straits Research, the global Paper Pigments Market market size was valued at USD 13.18 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 26.35 Billion by 2031, growing at a CAGR of 8% during the forecast period (2023–2031).

Request a Sample Report Today @ https://straitsresearch.com/report/paper-pigments-market/request-sample

Global Paper Pigments Market Segmental Analysis

As a result of the Paper Pigments market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Type

Calcium Carbonate

Kaolin

By Application

Coated

Satin-Coated

Gloss-Coated

Dull-Coated

Woven or Smooth Uncoated Paper

Laid Uncoated Paper

You can check In-depth Segmentation from here: https://straitsresearch.com/report/paper-pigments-market/toc

Why Invest in this Report?

Leverage Data for Strategic Decision-Making: Utilize detailed market data to make informed business decisions and uncover new opportunities for growth and innovation.

Craft Expansion Strategies for Diverse Markets: Develop effective expansion strategies tailored to various market segments, ensuring comprehensive coverage and targeted growth.

Conduct Comprehensive Competitor Analysis: Perform in-depth analyses of competitors to understand their market positioning, strategies, and operational strengths and weaknesses.

Gain Insight into Competitors' Financial Metrics: Acquire detailed insights into competitors' financial performance, including sales, revenue, and profitability metrics.

Benchmark Against Key Competitors: Use benchmarking to compare your business's performance against leading competitors, identifying areas for improvement and potential competitive advantages.

Formulate Region-Specific Growth Strategies: Develop geographically tailored strategies to capitalize on local market conditions and consumer preferences, driving targeted business growth in key regions.

List of Top Leading Players of the Paper Pigments Market -

Omya AG

Kemira Oyj

the Chemours Company

Imerys

Minerals Technologies

BASF SE

Ashapura Group

Huber Corporation

Thiele Kaolin Company

KaMin LLC. / CADAM.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

Regional Analysis Paper Pigments Market

The regional analysis sectio n of the report offers a thorough examination of the global Paper Pigments market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Paper Pigments market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

To Understand How Covid-19 Impact Is Covered in This Report - https://straitsresearch.com/report/paper-pigments-market/buy-now

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Paper Pigments Market#Paper Pigments Market Share#Paper Pigments Market Size#Paper Pigments Market Research#Paper Pigments Industry#What is Paper Pigments?

0 notes

Text

Porcelain Countertops 101: Answers to Your Questions

Porcelain surfaces have become popular among homeowners and interior designers for their spectacular aesthetic and unwavering strength. Among all engineered stones, porcelain offers the closest resemblance to natural stones. They are reliable for everyday wear and tear. Many high-end hotels and commercial spaces use porcelain tiles and slabs to give their interior settings a premium finish. In this blog, we are answering some of the common questions asked by clients regarding porcelain.

Are Porcelain Countertops Durable?

Porcelain surfaces are highly durable. They go through an intense manufacturing process to make them stronger and more durable. Made from Kaolin and other minerals, porcelain slabs undergo heat treatment to ensure they are dense and hardy. These surfaces are highly resistant to heat, scratching, staining, and etching, meaning they are suitable for high-traffic areas.