#Inkjet Printing Industry

Explore tagged Tumblr posts

Text

Inkjet Printing Market Report, Market Size, Share, Trends, Analysis By Forecast Period

The Inkjet Printing Market Report for 2024 provides a comprehensive overview of the Inkjet Printing market industry, presenting crucial data and insights into market dynamics, including growth drivers, challenges, and future potential. The report evaluates the Inkjet Printing Components, focusing on significant opportunities and trends that could shape the industry's trajectory. Key stakeholders such as CEOs, global managers, traders, and analysts will find value in the SWOT analysis, which assesses the competitive strengths, vulnerabilities, opportunities, and threats impacting market players.

According to Straits Research, the global Inkjet Printing Market size was valued at USD 101.23 billion in 2023. It is projected to reach from USD 109.73 billion in 2024 to USD 209.43 billion by 2032, growing at a CAGR of 8.4% during the forecast period (2024–2032).

Get a Sample PDF/Excel of report starting from USD 995: https://straitsresearch.com/report/inkjet-printing-market/request-sample

Top Key Players of Inkjet Printing Market:

HP Development Company LP

Jet Inks Private Limited, Brother Industries Ltd

Xerox Corporation

Canon Inc.

Hitachi Industrial Equipment Systems Co. Ltd

Lexmark International Inc.

Videojet Technologies Inc.

Inkjet Inc.

Fujifilm Holdings Corporation

Regional Analysis for Inkjet Printing Market:

The regional analysis section of the report offers a thorough examination of the global Inkjet Printing market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Inkjet Printing markets in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

Inkjet Printing Market Segmentations:

By Printer Type

Single functional Printers

Multi-functional Printers

Large Format Printers

Industrial Inkjet Printers

Textile Inkjet Printers

Inkjet Press

By Technology Type

Continuous Inkjet

Drop on Demand

By Substrate

Plastic

Metal

Paper

Fabric

Ceramic

Others

By Applications

Books/Publishing

Commercial Print

Advertising

Transaction

Labels

Packaging

Others

Get Detail Market Segmentation: https://straitsresearch.com/report/inkjet-printing-market/segmentation

Top Reasons to Choose This Report

Access to Comprehensive Insights: Gain access to extensive analysis, research, and data that are often challenging to gather independently. This report provides valuable information, saving you significant time and effort.

Support for Informed Decisions: Enhance your decision-making process with in-depth insights into market trends, consumer behavior, and key industry factors. This report is essential for strategic planning, including investments, product development, and marketing strategies.

Gain a Competitive Edge: Stay competitive by understanding market dynamics and competitor strategies. The report provides detailed insights into competitor performance and market trends, helping you craft effective business strategies.

Cost-Effective Research Solution: Save on research costs by investing in this report, which offers a detailed and comprehensive analysis of the market. This cost-effective option eliminates the need for extensive independent research.

COVID-19 Aftermath and Geopolitical Influences: Russia-Ukraine Conflict and Middle East Crisis

The report explores the multifaceted impact of COVID-19 on the Inkjet Printing market, covering both direct and indirect effects across global and local levels. It discusses market size, trends, and growth trajectories in the Inkjet Printing, classified by type, application, and customer sector. Additionally, it provides a detailed evaluation of market development components before and after the pandemic, supported by a PESTEL analysis to assess key influencers and barriers to market entry. We offer the flexibility to customize the report based on specific regions, applications, or any other statistical details. Our goal is to align our analysis with your specific needs, ensuring a more complete market study. The final report will also examine the impact of the Russia-Ukraine War on the Inkjet Printing market, assessing how these geopolitical events are influencing current market conditions and future opportunities.

This Report is available for purchase at: https://straitsresearch.com/buy-now/inkjet-printing-market

About Us:

Straits Research is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us:

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: +1 646 905 0080 (U.S.) +91 8087085354 (India) +44 203 695 0070 (U.K.)

#Inkjet Printing Market#Inkjet Printing Market Share#Inkjet Printing Market Size#Inkjet Printing Market Research#Inkjet Printing Industry

0 notes

Text

Ink To Screen: Exploring The Dynamic Landscape Of The Digital Printing Market

The world of Digital Printing Market is a vibrant and ever-evolving landscape that has revolutionized the way we bring ideas to life. From its humble beginnings to the cutting-edge technologies of today, this market has seen remarkable growth, impacting industries far and wide.

At its core, the Digital Printing Market is all about transforming virtual concepts into tangible reality. This dynamic process bridges the gap between imagination and execution, making it a crucial player across various sectors. The market's versatility is evident in its applications, ranging from textiles and signage to packaging and personalized merchandise. As technology advances, the precision and speed of digital printing continue to redefine what's possible, offering businesses new opportunities to stand out in competitive markets.

One of the most exciting aspects of the Digital Printing Market is its ability to cater to individuality on a massive scale. Traditional mass production often sacrifices uniqueness for efficiency, but digital printing flips that narrative. This market empowers businesses and consumers alike to embrace their creativity by allowing for customized designs, limited print runs, and even one-of-a-kind creations. This trend aligns perfectly with the modern consumer's desire for personalized products that resonate with their identities, creating a win-win scenario for both sellers and buyers.

As technology and creativity intersect in the Digital Printing Market, innovation becomes the driving force. New printing techniques, materials, and inks are constantly being developed to enhance the quality and aesthetics of printed output. From UV-curable inks that offer unmatched durability to 3D printing capabilities that bring depth and texture to designs, the market's capacity to surprise and delight is boundless. This continuous innovation not only fuels market growth but also ensures that businesses can keep up with ever-changing consumer preferences and demands.

In conclusion, the Digital Printing Market is a dynamic realm where imagination meets innovation. Its impact on industries, personalization trends, and the very way we perceive printed materials is undeniable. As businesses and consumers continue to recognize its value, the market is poised for further expansion and transformation. In an increasingly visual and fast-paced world, the market stands as a testament to the power of technology in turning ink into screen and ideas into reality.

#Inkjet Printing#Printing Technology#Print Innovation#Color Printing#Digital Printing Solutions#Commercial Printing#Print Industry Trends#coherent market insights

1 note

·

View note

Text

High-Quality Industrial Inkjet Printing For All Your Needs

https://kelcodesolutions.com/ - If you are looking for Industrial Inkjet Printing Services, contact Kelco Code Solutions. With their cutting-edge inkjet printing technology, they can generate high-quality, long-lasting prints that fit your exact specifications. For more information, please visit kelcodesolutions.com.

1 note

·

View note

Text

I now have a Folksy shop where I sell my prints! It’s essentially like Etsy used to be 🤍 and it is based here in the U.K.

Cottage industry businesses like mine are fighting for oxygen in a space now clogged with mass manufactured goods that drown out our work with mass marketing and spam.so please consider supporting small creative businesses! :)

I’ll be adding lots more of my illustrations in coming weeks, too. Please take a look & share/ like 🍀 every interaction helps so much for a small creative business like mine! Thank you!

(I now print my own fine art prints of my illustrations, since I purchased a beautiful pro inkjet printer for top notch giclée printing. I use fine art, heavyweight museum etching paper of archival quality 👌✨)

#art#illustration#sketchbook#concept art#painting#tolkien#jrr tolkien#silmarillion#lotr#middle earth#shinee#fanart#art prints#poster art#print shop#prints for sale#small art business#art business#whimsical illustration#fantasy landscape#fantasy illustration#support small artists#support small business#visual arts#creativebusiness#creativelife

22 notes

·

View notes

Text

youtube

One of the primary issues with traditional dyeing methods is their water consumption. The fashion industry uses roughly five trillion liters of water annually just for dyeing, as reported by the World Resources Institute. This enormous volume translates to a staggering 20% of the world's industrial water pollution, impairing ecosystems and draining precious underground water supplies.

Environmental activists and tech innovators are now rallying to address these pressing concerns, focusing particularly on more sustainable dyeing practices. A promising example is the UK-based start-up, Alchemie Technology, which recently unveiled its revolutionary digital dyeing process aimed at drastically reducing water usage and waste generation.

Dr. Alan Hudd, the founder of Alchemie, explained how traditional dyeing methods, which involve bathing fabrics in hot water with dyes for several hours, generate massive volumes of toxic wastewater—30 tons for just one ton of dyed polyester. The outmoded practices, originating from the cotton mills of 175 years ago, are ripe for disruption.

Alchemie's solution, named Endeavour, employs state-of-the-art technology to redefine the dyeing process. By mimicking the principles of inkjet printing, this machine applies dye with incredible precision and speed, emitting around 1.2 billion droplets of dye per linear meter of fabric. It can compress the traditional dyeing, drying, and fixing phases significantly, thereby reducing water consumption by about 95% and energy usage by up to 85%.

This innovative approach is not only faster but also allows for more vibrant colors with less environmental impact. "What we're effectively doing is placing very small drops of dye precisely onto the fabric, and we can switch these drops on and off, just like flipping a light switch," Dr. Hudd elaborated.

12 notes

·

View notes

Text

Custom Prints: How to Choose Printers That Align with Your Architectural Needs

In the architecture industry, the quality of printed materials significantly impacts the presentation and execution of projects. Various printing technologies are available to meet these needs. How can architects ensure they choose the right printer that aligns perfectly with their requirements? This challenge is crucial for maintaining high standards in architectural work.

This guide will help you steer the options available, highlighting the critical factors to consider. Selecting the ideal printer for architectural uses involves understanding the different types of plotters and their capabilities. Each type offers distinctive benefits depending on the specific needs of your projects.

Understanding Plotter Printers

They are indispensable in architecture because they can handle large-format prints essential for detailed architectural drawings and blueprints. These produce crisp, high-resolution images on large paper sizes, crucial for detailed work. When choosing a plotter, it’s essential to consider the types available:

Pen plotters use pens to draw on paper. They are great for high precision but generally slower than their modern counterparts.

The Inkjet plotter’s spray ink allows for a broader range of colours and faster output. They are suited for both high-quality presentations and standard drafts.

Laser Printers for Fast Outputs

Laser printers might be the way to go for architects needing quicker print jobs for client meetings or internal reviews. These are not typically used for large format prints but are excellent for smaller, high-volume tasks where speed is critical. They deliver fast and reliable outputs, although with a slight compromise on the fine detail that plotters can achieve.

Key Features to Consider

Resolution and Quality

The resolution of a printer dictates the clarity and detail of the printed document. High-resolution printers are essential in architecture because they ensure that every line and detail of the sketches and plans is visible and clear. Generally, a higher DPI (dots per inch) rating indicates better resolution.

Speed and Efficiency

Time is often a constraint in project deliveries, making a printer’s speed another vital consideration. However, the choice should carefully balance speed and quality, as some fast printers may sacrifice detail for quicker output. Evaluate its speed in the context of typical project sizes and deadlines.

Media Handling

Architectural printing often requires different media types, ranging from thick card stocks to glossy-finish papers for high-quality presentations. Ensure the printer can handle the diversity of media you use in your practice. Check for the maximum and minimum paper sizes and whether the printer supports roll-fed or sheet-fed options.

Cost Considerations

Initial Investment vs. Long-Term Costs

Printers come with varying price tags; often, higher-priced models offer greater versatility and quality. However, the ongoing operating costs, such as ink or toner, maintenance, and paper, must be considered. A cheaper one can lead to higher long-term expenses due to inefficient ink usage or frequent maintenance needs.

Ink or Toner Expenses

Depending on the type, the ink or toner cost can significantly affect the overall cost of ownership. Plotters typically use ink, which can be pricey, especially if it is inefficient. On the other hand, toner used in laser printers might be less expensive per page, especially for high-volume printing.

Connectivity and Software Integration

Ease of Use and Compatibility

A printer’s compatibility with existing architectural software is crucial in today’s digital-focused workflow. Seamlessly integrating with software like AutoCAD, Revit, or other design tools can streamline the printing process, reducing errors and saving time.

Network Connectivity

Consider printers with built-in network capabilities that allow multiple users to access it across the office network. Wireless printing and cloud capabilities are additional features that enhance flexibility, enabling you to print from various devices or even remotely.

Environmental Impact

Energy Efficiency and Sustainability

With an improving focus on sustainability in architecture, the environmental impact of your office equipment should be noticed. Look for printers with energy-saving features and those that meet environmental standards like ENERGY STAR. Additionally, consider the ones that offer features like automatic duplex printing to save on paper.

Making the Right Choice

Choosing the right printer involves weighing various factors, from print quality and speed to cost and environmental impact. By understanding the specific demands of your architectural projects and how different printers meet those needs, you can select a printer that fits your budget and enhances your firm’s productivity and output quality. The right one becomes invaluable in bringing architectural visions to life, ensuring every print reflects the precision and detail your projects deserve.

By considering the detailed needs of your practice—including the different types of plotters available—you can choose a printer that not only meets but enhances your professional output. A well-chosen one will serve as a reliable tool that supports your creative process, ensures high standards are maintained, and ultimately contributes to the satisfaction of your clients. Invest wisely, and your chosen printer will prove integral to the precision and efficiency of your architectural endeavours.

10 notes

·

View notes

Text

New solvent-free 3D printing material could enable biodegradable implants

Additive manufacturing (AM) has revolutionized many industries and holds the promise to affect many more in the not too distant future. While people are most familiar with the 3D printers that function much like inkjet printers, another type of AM offers advantages using a different approach: building objects with light one layer at a time. One such technology is digital light processing (DLP). Widely used in both industrial and dental applications, DLP works by converting a liquid resin into a solid part using light, essentially pulling solid objects out of a shallow pool of resin one layer at a time. A major challenge to using this 3D printing method, however, is that the resins need to have a low viscosity, almost like water, to function properly at high resolution. Plenty of polymers that would otherwise be useful in DLP printing are solids or too viscous, requiring solvents to dilute them to an appropriate consistency.

Read more.

8 notes

·

View notes

Text

I posted this on Twitter but I should probably share this here too:

Quick tiny bit of knowledge for anyone planning any print media (using CMYK printing instead of like...pure monochrome grayscale) but grey, especially toned greys like cool or warm greys, are REALLY HARD to print cleanly over large areas. Just for your info so you can plan.

I ran an industrial inkjet printer for 8 years at the job I had before COVID, making signage and stickers and posters and banners and all sorts of things like that. My bosses never listened when we had a grey order and I told them we needed to send the customer a physical proof instead of our usual digital one so they could actually see the striping/static that shows up almost NO MATTER WHAT on printed grey. Without fail the customers always had to be given a caveat because even the best of the run (usually 20+ more than required to get even remotely clean looking ones) had visible static, even after multiple cleanings of the print-heads and every anti-static trick we could think of.

5 notes

·

View notes

Photo

Akram Zaatari, Archeology, 2017. Pigment inkjet print on gelatin treated glass and mixed media. Courtesy of the artist.

Akram Zaatari has produced more than forty videos, a dozen books, and countless installations of photographic material.

All pursuing a range of interconnected themes, subjects, and practices related to excavation, political resistance, the lives of former militants, the legacy of an exhausted left, intimacies among men, the circulation of images in times of war, and the play of tenses inherent to various letters that have been lost, found, buried, discovered, or otherwise delayed in reaching their destinations.

Zaatari has played a critical role in developing the formal, intellectual, and institutional infrastructure of Beirut’s contemporary art scene.

He was one of a handful of young artists who emerged from the delirious but short-lived era of experimentation in Lebanon’s television industry, which was radically reorganized after the country’s civil war. As a co-founder of the Arab Image Foundation, a ground-breaking, artist driven organization devoted to the research and study of photography in the region, he has made invaluable and uncompromising contributions to the wider discourse on preservation and archival practice.

Akram Zaatari was part of Documenta 13 in 2012, and represented Lebanon at the Venice Biennale in 2013.

[Moderna Museet]

57 notes

·

View notes

Text

"Eco-solvent inks in 2024: sustainability and high quality change the printing industry"

In an era where environmental concerns are at the forefront, the emergence of eco-solvent ink represents a significant milestone in the printing industry.

Unlike its counterparts, UV and water-based inks, eco-solvent ink is a composition of non-toxic solvents and natural pigments.

Please take note: a remarkable 50% of its components derive from renewable resources. With a minimal volatile organic compound (VOC) content, this ink is virtually odorless.

The Birth of Eco-Solvent Ink:

Since the advent of inkjet printers in the 1990s, the ink industry has grappled with toxicity, irritation, and high pollution.

However, through three generations of technological evolution and the relentless efforts of scientists, the printing world has been introduced to a game-changer – the non-toxic, non-irritating, and odorless eco-solvent ink. It signifies the industry's definitive break from the stigma of high pollution associated with traditional printing practices.

Cost Control and Print Quality of Eco-Solvent Ink:

The high cost of traditional inks has long been a bone of contention in the printing industry. Eco-solvent ink has opened a window of opportunity, epitomized by the phrase “a long slope with thick snow.” The substantial investment required yields a steady and stable return. Boasting excellent adhesion and vibrant color, eco-solvent ink has solidified its position in an era where print quality is a critical differentiator.

Applications of Eco-Solvent Ink:

A chasm exists between traditional inks and eco-solvent inks in the industry. The market for eco-solvent inks spans a wide range, from outdoor billboards to textile banners and car stickers, showcasing its boundless adaptability. It also defines the contours of modern printing practices:

Indoor and outdoor advertising and signage printing Automobile body stickers and wraps Industrial labeling and packaging printing Textile and eco-friendly fabric printing

Amidst the daunting challenges, from increasingly stringent regulations to technological iterations, our company, Panjet(https://www.pan-jet.com/), remains committed to the path of green and sustainable development. We stand as your provider of high-quality printing ink solutions.

3 notes

·

View notes

Text

Choosing the Right Printing Technology for Your Business Needs.

In today's dynamic business landscape, selecting the appropriate printing technology is crucial for ensuring efficiency, quality, and cost-effectiveness. With various printing options available, making an informed decision requires careful consideration of several factors.

Understanding Your Printing Requirements

Begin by comprehensively evaluating your business's printing needs. Consider the volume of printing required, the type of materials to be printed on, and the desired quality and speed. For instance, a small office with minimal printing needs might find a basic laser printer sufficient, while a printing company specializing in high-quality graphics will likely require advanced digital or offset printing solutions.

Types of Printing Technologies

Laser Printing: Ideal for high-speed printing of text documents and basic graphics. It's cost-effective for office settings with moderate printing demands.

Inkjet Printing: Versatile and capable of producing high-resolution images, making it suitable for small-scale graphic printing and photo printing.

Digital Printing: Offers flexibility for short print runs, variable data printing, and on-demand printing. Well-suited for businesses requiring quick turnaround times and customization.

Offset Printing: Known for its superior quality in large-volume printing. It involves a more complex setup but delivers high-quality prints for brochures, magazines, and marketing materials.

Considerations for Selection

Print Volume: Assess the quantity of printing your business regularly requires. If it's high, offset printing might be more cost-effective despite the setup costs.

Quality Requirements: Determine the level of print quality needed for your materials. Inkjet and digital printing usually offer better color accuracy and resolution compared to laser printing.

Turnaround Time: If your business frequently needs quick prints, digital printing provides faster results as it doesn’t require the setup time that offset printing does.

Budgetary Constraints: Evaluate the initial investment cost, maintenance expenses, and overall operational costs of different printing technologies. Sometimes, a higher initial investment may result in long-term savings.

Consulting with Printing Experts

Engage with printing industry professionals or vendors to gain insights into the latest printing technologies and their suitability for your specific business needs. They can provide valuable guidance based on their expertise and experience.

Conclusion

Choosing the right printing technology involves a thoughtful analysis of your business requirements, considering factors such as print volume, quality, speed, and budget. By understanding these parameters and consulting with experts, businesses can make informed decisions that optimize their printing processes and enhance overall efficiency.

In Dubai , Your Online print shop - That provide you all printing solutions!

PRINTENCY.COM

#printing services#printing shop#printing company#printing industry#printing press#book printing#offset printing#digital printing#brochure#keychain#tshirt#business card#flyers printing

2 notes

·

View notes

Text

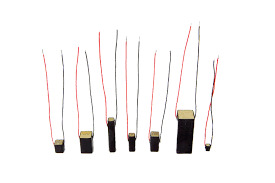

Powerhouse of Precision: Exploring the Key Features of Piezo Stacks

Piezo stacks are innovative devices that utilize the piezoelectric effect to achieve precise and controlled movements. These stacks consist of multiple layers of piezoelectric ceramic materials stacked together, enabling them to generate high forces and displacements with nanoscale precision. In this infographic, we explore the key features, working principle, and applications of piezo stacks.

For More Information Please visit, pzt stacks

Key Features of Piezo Stacks:

Nanoscale Precision: Piezo stacks offer exceptional precision, allowing for nanometer-level movements and control. This precision is crucial in applications such as microscopy, semiconductor manufacturing, and optical alignment.

High Force Output: Despite their compact size, piezo stacks can generate significant amounts of force. The stacked design allows for the amplification of force, enabling precise control even in applications that require high force requirements.

Rapid Response: Piezo stacks can respond to electrical signals in microseconds, enabling fast and dynamic adjustments. Their rapid response is vital in applications that require quick positioning or movement changes.

Direct Drive and Non-Magnetic Operation: Piezo stacks operate without the need for mechanical gears or magnetic components. This direct drive mechanism eliminates backlash and allows for precise control, even in non-magnetic environments.

Working Principle of Piezo Stacks:

Piezoelectric Effect: Piezo stacks utilize the piezoelectric effect, which refers to the ability of certain materials to generate an electric charge when subjected to mechanical stress. This effect allows the stack to convert electrical signals into precise mechanical movements.

Layered Structure: Piezo stacks consist of multiple thin layers of piezoelectric ceramics. Each layer is carefully engineered to maximize the piezoelectric effect.

Voltage Application: When a voltage is applied to the stack, an electric field is created within the piezoelectric layers. This field causes the layers to expand or contract, resulting in precise mechanical displacements.

Applications of Piezo Stacks:

Precision Positioning: Piezo stacks are extensively used in positioning systems for microscopy, atomic force microscopy (AFM), lithography, and optical alignment. Their precise control allows for accurate positioning and scanning.

Micro-dispensing and Jetting: Piezo stacks find application in micro-dispensing and jetting systems, enabling precise control of fluid flow. They are utilized in industries such as inkjet printing, pharmaceuticals, and biotechnology.

Active Damping and Vibration Control: Piezo stacks are employed in active damping and vibration control systems to minimize unwanted vibrations. They find use in precision manufacturing equipment, semiconductor fabrication, and optical instruments.

Adaptive Optics: In astronomy and laser applications, piezo stacks are used in adaptive optics systems to compensate for atmospheric distortions. They allow for real-time adjustments of deformable mirrors, improving image quality and resolution.

Conclusion:

Piezo stacks provide an effective solution for achieving precision and control in various industries. Their nanoscale precision, high force output, rapid response, and direct drive operation make them invaluable in applications requiring accurate positioning, micro-dispensing, vibration control, and adaptive optics. With ongoing advancements in technology, piezo stacks are poised to continue empowering innovation and driving progress in precision engineering and control systems.

2 notes

·

View notes

Photo

FILM POSITIVES 👉 http://ow.ly/UK1v308KbeU 👈👀❤️😍😉 #Inkjet & #LaserJet A4 & A3 100per box & 30m Rolls 432 & 610mm wide #Screenprinting #Tshirts #Posters Micro-porous aqueous coated translucent #Inkjet film, specially developed for producing high quality positives, negatives and colour separations. Instant dry with good water resistance. Our film offers excellent dimensional stability and high HV density. ALSO Double matt translucent polyester #Laserjet film. Antistatic treated, excellent for reproduction. High contrast visuals can be easily produced and further work added using drafting pens or pencils. Available in 0.100mm Both in A4 and A3 100 sheets per box And Micro-porous aqueous coated translucent inkjet film, specially developed for producing high quality positives, negatives and colour separations. Instant dry with good water resistance. Our film offers excellent dimensional stability and high HV density. Roll: 432 mm wide x 30mtr Roll: 610 mm wide x 30mtr Price Online http://www.screenstretch.co.uk/inkjet-laserjet-films/ Ideal for all types of #Silkscreen #Textiles #Handmade #Illustration #Graphics #Merchandise #Merch #BandMerch #Apparel #FineArt #Printmaking #Signs #HandPulled #TShirtPrinting Screen Print Industry #ScreenprintingUK (at Screenstretch Ltd) https://www.instagram.com/p/Cr1hssmo773/?igshid=NGJjMDIxMWI=

#inkjet#laserjet#screenprinting#tshirts#posters#silkscreen#textiles#handmade#illustration#graphics#merchandise#merch#bandmerch#apparel#fineart#printmaking#signs#handpulled#tshirtprinting#screenprintinguk

2 notes

·

View notes

Text

CV > Skills > Photoshop, Illustrator, In Design

Since 2 month, I’ve been searching internship opportunities. I must say that I am concerned because they aren’t in search of a student intern but a five legged sheep. I mean they hope to find a complete designer who master as many softwares as possible. But, this week end, I’ve read a chapter in the new publication of Graphisme en France (2022) written by Joost Grootens, a graphic designer based in Amsterdam. The article helped me to relax and questioned the usefulness of skills that we mentioned in our CV.

First, Grootens studied a sample of resumes that French students have sent to his studio for an internship. He realized a table to compare and divide students according to their schools. All of them mentioned the most used softwares as Adobe Photoshop, Adobe Illustrator and Adobe Indesign. This observation shows the monopoly of this company. Yes, the use of these softwares proves their quality. However, Grootens warned us about their limits. He thinks that pre-configurations impact our designs. We unconsciously restrict our creativity and singular expression because we use to follow the instructions (or « councils ») given by the software.

Moreover, I wonder if we really master it as we can said in our CV. Is this mention helpful to know our practice of Photoshop or Illustrator ? I think our projects can best express the quality of our work but we can’t measure our level of control of software. Plus, I have to entrust that it’s not interesting because the repetition of this mention shows our lack of originality.

(I will add, in the skill’s category of my CV, my mastery of a pencil or the inkjet printer EPSON ET 85-50)

After this study of the skills/ tools mentioned in CVs, Grootens tried to classify them in three different moment of the Design History. He calls the first moment « mechanization » (from 1900 to 1970) and define it as all the industrial production of informations. The tools that took part of this movement were scanner, phototypesetting or inkjet printing. The second moment called « digitization » (from 1970 to 1990) is the use of tools that stay inside a computer or a software like digital fonts, Adobe In Design or Blender. The final and third moment called « dissemination » (from 90’s to today) is the use of tools that allowed the speed of distribution, interaction and sharing of the information with others like Tumblr, TikTok or Figma. Thanks to this period, and all inventions, Grootens defended that we can’t divide the designer/creator and the reader/user. This opening of the design practice to a more large public is rich to study the use of these new tools by unprofessional users.

In the final part of his article, Grootens tried to demonstrate how the practice of unconventional tools by amateur can teach us how to create more freely than what we do due to Adobe’s software. By the help of four examples, Grootens showed first the poor technique of the designs but highlighted the strength of the shapes and their inventiveness. For example, Taylor Pierce created a short video on TikTok where she’s dancing an a Hip hop song of Ice Cube. The accessibility of the software and his poor technical level let her invent movement to simulate camera movement without any post production or editing.

Finally, Grootens invited schools of design to teach us the use of softwares but also help us to question about the company’s intentions and develop a critical point of view. After that we could be more open to discover new tools and practices.

I’m now very curious to experiment new things. The lack of rules or knowledge needed for the use of some tools can be an open door to complete my own practice. This article written by Grootens doesn’t mean that we don’t need conventional software. It’s an invitation to fall outside of the framework and have fun. I can now invent the new intern student I desire to be.

2023/03/06 3200 types

4 notes

·

View notes

Text

The issue with microfluidics is they deliberately don't include a cleaning cycle so they clog when you don't use them for a few weeks -- which is exactly what printing companies want, because it means your memory of their usefulness is far back enough.

If only there were some sort of self-cleaning microfluidic printer.

Oh wait, that's every printer, you just don't get told this!

The companies bet on you not being smart enough or invested enough and they make their official gear really unreliable on purpose and don't tell you the procedures to fix it.

Most of the headache is up front and short lived and once the ball is rolling its very mindless "clean the cartridge, then put the cartridge in the doohicky after filling it then put it in the printer and its fine for like a month".

30 minutes once a month is all it takes.

Something manufacturers don't tell you is that you're meant to do is self-clean them over and over and over again (10-20+ times)

youtube

Alternatively, you can use 10/20 drops of isopropyl alcohol and let the print head sit in it, and then let it air dry and repeat this that number of times to clean without using any ink.

Same as a 3D printer, there is a proper print-cycle for 2D printers, and that cycle includes upkeep (same as you'd clean the bed or calibrate or remaster the motors in a 3D).

There are kits which are literally for this very thing.

No I don't get any kickback from this, and you can do this just as well with improvised materials around your home.

Epson and other sellers deliberately don't tell you any of this stuff, because they want you to get mad and throw out your device. Its an anticonsumer practice and some basic knowledge can save you this headache.

Likewise, you can buy generic refillable cartridges.

Behold, the forbidden cartridge:

Sometimes, you have to take the chip and ribbon from a used cartridge and use a chip resetter which looks like this: the forbidden "you're fine actually shut up and print" unit.

ebay and inkjetmail and many other retailers are phenomenal sources for these devices and new replacement ink.

Non-genuine dye inks perform far better than pigment ones. Dye inks are like tea and pigments are like coffee. Try to go for a printer which uses a dye based ink, rather than a pigment based ink for best results.

What the world really needs is a printer which can do this automatically from an iso resevoir, or ask for iso when its needed and then self-drain and dry it safely.

You know. The way industrial printers do?

Ask /r/printers if you want something specific. As crappy as Reddit can be, they are a genuinely great community with a lot of knowledge.

You can completely bypass the ink racket and buy generic which will completely crash the cost of your printer ink so you can spend it on something nicer like glossy photo paper for your prints, or sticker paper.

All it takes is a little bit of specialist knowledge, and if you're printing on a large scale with an inkjet some equipment on standby that's a big cost-saving and a procedure-list.

Source:

I have a TBI and covering my walls in prints to prompt me with things massively helps. The day AR is good enough I'll switch but until then, paper it is!

i feel like it says something about us as a species that somebody worked real hard to invent 3D printing when i think anyone who has ever used a printer would agree with me that we have not really gotten our arms around 2D printing yet. we’re getting ahead of ourselves.

44K notes

·

View notes