#Industrial fire water containment tanks

Explore tagged Tumblr posts

Text

#Industrial fire fighting tanks in Perth#Industrial fire fighting tanks#Industrial fire fighting tanks Australia#Industrial fire safety tanks Perth#Industrial fire tank suppliers Perth#Fire water storage tanks Australia#Industrial fire water containment tanks#Fire fighting water storage systems#Perth industrial fire protection solutions

0 notes

Text

And firebenders can tweak the electric signals in someone's body-

But this made me think. Waterbenders can control water molecules and can bend anything the water will bring along. That is why they can bend blood. But waterbenders are also capable of NOT picking up objects that the water is carrying. So they can also dehydrate people, flood their lungs, flood their bladder, flood their digestive track, in turn giving someone diarrhoea, they can give someone a cough and a cold by increasing the volume of their mucus.

This means waterbenders would make great medics, btw. Any water is potable water. Everything is a water container. The most powerful water bender should be able to turn water into ice or steam, access groundwater in the deserts, and be able to make canals and streams.

The earth bender can bend a select range of minerals, but if they work really hard on it, they can bend any of them. Like toph did.

Strong earthbenders should be able to manipulate the very structure of molecules of the minerals so that they can sit on top of one another in a way that makes them pliable, malleable, strong, springy, etc to form the right shape and the right type of earth.

Like the water benders, they have the ability to add pressure and also control the movement of the rocks. Boomi and Toph already demonstrated what crazy fighters earthbenders can make. But i also think about how easily they can poison someone, oversalt them (dehydration 2.0), and calcify organs while the person is alive. They can cause bone cancer, they can break teeth, crush bones to powder, and puncture the internal organs. Manipulate bones did not even cover it.

They could manipulate armour to move to fight wars for the country. They could set flintstone fires without being there. They could weave metal into fabric. So many possibilities. I'm not even mentioning the industrial use, i believe LoK covered that?

Air benders and fire benders are different. Fire bending is easier to cover on an atomic level.

So they can bend heat, basically, right? But also, for some reason, they can channel electricity. The conclusion i am coming to is that they have command over the kinetic energy of individual electrons. That is why it is hard to master.

But this opens possibiliti3s. So i joked that they could modify the electric signals in the brain, but they literally could. But they can do so much more. Because this isn't atomic, it is subatomic. Yes, they can heat (and cool) things. Yes, they can use electricity. But if they can move electrons? So much more. They can change the properties of things. I can't even begin to list them. They can cut things, they can mend things seamlessly, and they can perform alchemy, changing the very structure of the atom. But that means it is an extremely volatile ability. Even the strongest bender would have to work these things one at a time or risk radiation.

Lastly, we have airbenders. There's two things that could be manipulating just air. One, they can move only free atoms. Which actually fits in with the heirarchy of molecular bonds of earth bender, molecules of water benders, airbenders with free atoms, and firebenders with subatomic electrons.

The other one would be the ability to create vacuums in space, and the air follows the small vacuums. Seeing how rigorously airbenders train, that seems the likely option despite the harmony from the other one. And then, the air bicycle is not possible. Which means. The airbenders just were into aesthetics and acting like a cult. Oh well, that's ok.

Aang has proven that airbenders can lift things with air. Heavy, dense things. They can probably aerosolise any atoms. Basically, they could pick atoms to put next to each other and let them form molecules. Airbending air out of lungs is probably the easiest thing. They can literally travel to space and make their own space suit. Out of air. Their scuba diving gas tank can be made out of literal air.

#i can't type at the speed of my thought#hit F to pay respect#atla#avatar the last airbender#katara#toph beifong#atla zuko#aang#atla boomi#legend of korra#waterbending#airbending#firebending#earthbending#i should learn physics before i open my mouth but that comes with the territory of being a writer#atla headcanons#if you read even the tags#here's a potato#i wonder if there exist other types of benders that don't realise they are benders

250 notes

·

View notes

Note

so like, they make these ionic membranes for dehumidifying 3d printer filament boxes... basically by turning water into hydrogen. they're really expensive tho.

we've been thinking if it's possible to make something significantly cheaper, and we think we have come up with something. it uses the same principle of electrolysis, but instead of a solid membrane, it uses a liquid. specifically, sulfuric acid is really good at pulling moisture out of the air, down to very low relative humidity, and it's also really good as an electrolyte for electrolysis of water, enabling you to do both processes simultaneously. and unlike the very expensive membranes, which fill the filament box with oxygen gas, you can pipe out both the oxygen and the hydrogen, reducing the risk of explosions and fire.

only problem it might react with the filament. someone would have to try it and find out. what do you think?

Most of the industrial sulphuric-acid based tank dryers are whole external systems that pipe air through the acid side in a separate container pretty far from the tank contents to reduce the opportunity for interaction between the tank contents and acid, so unless you do that it would probably be hard to get the concentration high enough without having loose acid vapour eat your filament.

If you're trying to avoid heat-based drying, I'm not sure this helps, I think the limiting factor on drying at room temperature is a migration rate for moisture out of the filament, not the dryness of the air being used for drying.

There's those solid-state dehumidifier elements which seem like a better idea if you are looking for a very reliable long-term dry holding system and you're willing to go through the equivalent rigamarole of a sulphuric acid dryer.

4 notes

·

View notes

Text

For two decades, researchers worked to solve a mystery in West Coast streams. Why, when it rained, were large numbers of spawning coho salmon dying? As part of an effort to find out, scientists placed fish in water that contained particles of new and old tires. The salmon died, and the researchers then began testing the hundreds of chemicals that had leached into the water.

A 2020 paper revealed the cause of mortality: a chemical called 6PPD that is added to tires to prevent their cracking and degradation. When 6PPD, which occurs in tire dust, is exposed to ground-level ozone, it’s transformed into multiple other chemicals, including 6PPD-quinone, or 6PPD-q. The compound is acutely toxic to four of 11 tested fish species, including coho salmon.

Mystery solved, but not the problem, for the chemical continues to be used by all major tire manufacturers and is found on roads and in waterways around the world. Though no one has studied the impact of 6PPD-q on human health, it’s also been detected in the urine of children, adults, and pregnant women in South China. The pathways and significance of that contamination are, so far, unknown.

Still, there are now calls for regulatory action. Last month, the legal nonprofit Earthjustice, on behalf of the fishing industry, filed a notice of intent to sue tire manufacturers for violating the Endangered Species Act by using 6PPD. And a coalition of Indian tribes recently called on the EPA to ban use of the chemical. “We have witnessed firsthand the devastation to the salmon species we have always relied upon to nourish our people,” the Puyallup Tribal Council said in a statement. “We have watched as the species have declined to the point of almost certain extinction if nothing is done to protect them.”

The painstaking parsing of 6PPD and 6PPD-q was just the beginning of a global campaign to understand the toxic cocktail of organic chemicals, tiny particles, and heavy metals hiding in tires and, to a lesser extent, brakes. While the acute toxicity of 6PPD-q and its source have strong scientific consensus, tire rubber contains more than 400 chemicals and compounds, many of them carcinogenic, and research is only beginning to show how widespread the problems from tire dust may be.

While the rubber rings beneath your car may seem benign — one advertising campaign used to feature babies cradled in tires — they are, experts say, a significant source of air, soil, and water pollution that may affect humans as well as fish, wildlife, and other organisms. That’s a problem because some 2 billion tires globally are sold each year — enough to reach the moon if stacked on their sides — with the market expected to reach 3.4 billion a year by 2030.

(Researchers weigh a salmon that died after four hours in a tank filled with road runoff.)

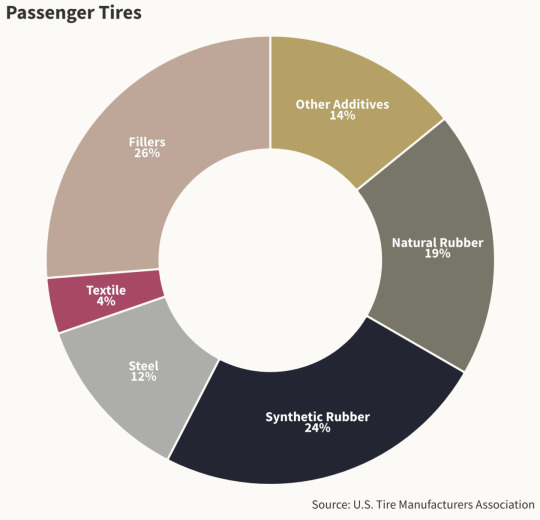

Tires are made from about 20 percent natural rubber and 24 percent synthetic rubber, which requires five gallons of petroleum per tire. Hundreds of other ingredients, including steel, fillers, and heavy metals — including copper, cadmium, lead, and zinc — make up the rest, many of them added to enhance performance, improve durability, and reduce the possibility of fires.

Both natural and synthetic rubber break down in the environment, but synthetic fragments last a lot longer. Seventy-eight percent of ocean microplastics are synthetic tire rubber, according to a report by the Pew Charitable Trust. These fragments are ingested by marine animals — particles have been found in gills and stomachs — and can cause a range of effects, from neurotoxicity to growth retardation and behavioral abnormalities.

“We found extremely high levels of microplastics in our stormwater,” said Rebecca Sutton, an environmental scientist with the San Francisco Estuary Institute who studied runoff. “Our estimated annual discharge of microplastics into San Francisco Bay from stormwater was 7 trillion particles, and half of that was suspected tire particles.”

Tire wear particles, or TWP as they are sometimes known, are emitted continually as vehicles travel. They range in size from visible pieces of rubber or plastic to microparticles, and they comprise one of the products’ most significant environmental impacts, according to the British firm Emissions Analytics, which has spent three years studying tire emissions. The company found that a car’s four tires collectively emit 1 trillion ultrafine particles — of less than 100 nanometers — per kilometer driven. These particles, a growing number of experts say, pose a unique health risk: They are so small they can pass through lung tissue into the bloodstream and cross the blood-brain barrier or be breathed in and travel directly to the brain, causing a range of problems.

According to a recent report issued by researchers at Imperial College London, “There is emerging evidence that tyre wear particles and other particulate matter may contribute to a range of negative health impacts including heart, lung, developmental, reproductive, and cancer outcomes.”

The report says that tires generate 6 million tons of particles a year, globally, of which 200,000 tons end up in oceans. According to Emissions Analytics, cars in the U.S. emit, on average, 5 pounds of tire particles a year, while cars in Europe, where fewer miles are driven, shed 2.5 pounds per year. Moreover, tire emissions from electric vehicles are 20 percent higher than those from fossil-fuel vehicles. EVs weigh more and have greater torque, which wears out tires faster.

Unlike tailpipe exhaust, which has long been studied and regulated, emissions from tires and brakes — which emit significant amounts of metallic particles in addition to organic chemicals — are far harder to measure and control and have therefore escaped regulation. It’s only in the last several years, with the development of new technologies capable of measuring tire emissions and the alarming discovery of 6PPD-q, that the subject is receiving much needed scrutiny.

Recent studies show that the mass of PM 2.5 and PM 10 emissions — which are, along with ozone and ultrafine particles, the world’s primary air pollutants — from tires and brakes far exceeds the mass of emissions from tailpipes, at least in places that have significantly reduced those emissions.

The problem isn’t just rubber in its synthetic and natural form. Government and academic researchers are investigating the transformations produced by tires’ many other ingredients, which could — like 6PPD — form substances more toxic than their parent chemicals as they break down with exposure to sunlight and rain.

“You’ve got a chemical cocktail in these tires that no one really understands and is kept highly confidential by the tire manufacturers,” said Nick Molden, the CEO of Emissions Analytics. “We struggle to think of another consumer product that is so prevalent in the world, and used by virtually everyone, where there is so little known of what is in them.”

“We have known that tires contribute significantly to environmental pollution, but only recently have we begun to uncover the extent of that,” said Cassandra Johannessen, a researcher at Montreal’s Concordia University who is quantifying levels of tire chemicals in urban watersheds and studying how they transform in the environment. The discovery of 6PPD-q has surprised a lot of researchers, she said, because they have learned that “it’s one of the most toxic substances known, and it seems to be everywhere in the world.”

Regulators are playing catch up. In Europe, a standard to be implemented in 2025, known as Euro 7, will regulate not only tailpipe emissions but also emissions from tires and brakes. The California Environmental Protection Agency has passed a rule requiring tire makers to declare an alternative to 6PPD-q by 2024.

(A worker takes apart a tire at a recycling shop in Mit al-Harun, Egypt.)

Tire companies are conducting their own studies of 6PPD, which they have long considered critical for tire safety, and seeking alternatives. In response to new regulations and the emerging research on tire emissions, 10 of the world’s large tire manufacturers have formed the Tire Industry Project to “develop a holistic approach to better understand and promote action on the mitigation” of tire pollution, according to a statement by the project. The group has committed to search for ways to redesign tires to reduce or eliminate emissions.

One critical area of research is how long tire waste, and its breakdown products, persist in the environment. “A five-micron piece of rubber shears off the tire and settles on the soil and sits there a while,” said Molden. “What, over time, is the release of those chemicals, how quickly do they make their way into the water, and are they diluted? At the system level, how big of a problem is this? It is the single biggest knowledge gap.”

Another area of research centers on the impacts of aromatic hydrocarbons — including benzene and naphthalene — off-gassed by synthetic rubber or emitted when discarded tires are burned in incinerators for energy recovery. Even at low concentrations, these compounds are toxic to humans. They also react with sunlight to form ozone, or ground-level smog, which causes respiratory harm. “We have shown that the amount of off-gassing volatile organic compounds is 100 times greater than that coming out of a modern tailpipe,” said Molden. “This is from the tire just sitting there.”

When tires reach their end of life, they’re either sent to landfills, incinerated, burned in an energy-intensive process called pyrolysis, or shredded and repurposed for use in artificial turf or in playgrounds or for other surfaces. But as concern about tire pollutants grows, so do concerns about these recycled products and the hydrocarbons they may off-gas. There is ongoing debate over whether crumb rubber, made from tire scraps, poses a health threat when used to fill gaps in artificial turf. Based on several peer-reviewed studies, the European Union is instituting stricter limits on the use of this material. Other studies, however, have shown no health impact.

Besides California’s requirement to study alternatives to 6PPD, there are a number of efforts worldwide to redesign tires to counter the problems they pose. More than a decade ago, tire makers hoped that dandelions, which produce a form of rubber, and soy oil could provide a steady and sustainable supply of rubber. But tires made from those alternatives didn’t live up to expectations: they still required additives. The Continental Tire Company, based in Hanover, Germany, markets a bicycle tire made of dandelion roots. Tested by Emission Analytics, it emitted 25 percent fewer carcinogenic aromatics than conventionally made bike tires, but the plant-powered tire still contained ingredients of concern.

(Rubber made from dandelions.)

Other companies are searching for ways to address the problem of tire emissions. The Tyre Collective, a clean-tech startup based in the U.K., has developed an electrostatic plate that affixes to each of a car’s tires: The plates remove up to 60 percent of particles emitted by both tires and brakes, storing them in a cartridge attached to the device. The particles can be reused in numerous other applications, including in new tires.

In San Francisco, scientists studying the pollutants in storm runoff found a potential solution: Rain gardens, installed in yards to capture stormwater, were also trapping 96 percent of street litter and 100 percent of black rubbery fragments. In Vancouver, B.C. researchers found that rain gardens could prevent more than 90 percent of 6PPD-q from running off roads and entering salmon-bearing streams.

Tire waste particles, says Molden, of Emissions Analytics, are finally getting the attention they deserve, thanks in part to California’s rule requiring a search for alternatives to 6PPD. The legislation “is groundbreaking,” he says, “because it puts the chemical composition [of tires] on the regulatory agenda.” For the first time, he adds, “Tire manufacturers are being exposed to the same regulatory scrutiny that car manufacturers have been for 50 years.”

8 notes

·

View notes

Text

Genuine questions about the Apocalyptic Genre

So, what is the shelf life of a bullet? Assuming that it was left in a box in a relatively dry, temperate room?

What would happen if it got humid / wet?

What about guns? Let's assume they're in a safe, how long can they go unoiled and ignored before they're useless?

A lot of the things Survivors in apocalypse and zombie movies find to save them just, don't seem practical to find and be able to use without any ongoing maintainence or care

And some things break down naturally (eg petrol has about 6mths of use if stored perfectly).

Fabric frays and can wear thin over time, but heat, rain, huidity and substances can increase the decay

Food is impermanent

Seeds do not last forever, unless stored Very Specifically, and your average shopping centre isn't going to.

Plastic gets brittle over time, and breaks.

A lot of stuff we use is straight up designed to fail after a certain period of time.

Medications? Forget it, you're already dead. Mobility aids? Anything that needs electricity?

Generators that aren't solar powered are likely going to be impacted after a period of time, esp fuel based.

Cars? There's a lot of little parts that can go tits up. Sure, maybe you luck out and you bunk down next to a nearby car superstore, still not going to have Everything for Every Model and Year. Headlights, wipers, etc. may sound small... but when you need them, you need them.

Tyres? Rubber wears down rapidly.

Clothes - do you know how to manufacture fabric? Sure you might run into a lincraft or spotlight in the early days and have fabric to spare in your panic hut but, at some point, someone's going buck wild. Fabric wears out.

Camping stuff? Assuming you have a tent and basic stuff? Not many are made to last forever (except some super expensive models, etc)

--------------

So, what could you reasonably expect to find say...

a) Day 1 of the apocalypse, zombie or otherwise? Probably most things.

b) Month 1 of the apocalypse? A lot of food and medications would have spoiled, industry went down even if only in certain fields, cars would be blocking the way, maybe some places have electricity and water. Depends on the area.

c) Two months? 6 months? A lot of things people assume they will find or have access to in an apocalyptic setting are gone, or not in useable condition.

d) 12 months to 2 years, even a lot of the canned stuff isn't safe. The main thing you need is common sense and a knowledge of dangerous food signs (botulism) like buldging cans.

------------

What could we possibly think to have access to, scavenger wise?

Let's assume that that apocalypse was a devastation that did not involve aliens or zombies or being hunted. The rules would be different. Not a lot of humanity left.

+First things would be checking house to house in a radius out from your own to find people and animals that have been left. Free who you can. Livestock might need to have gates opened so they can move to somewhere with more grass or food... if you are not used to livestock, use your brain but also try to find someone who might have more of a clue how to move them safely.

+Take inventory of what you have on you and have access to, food, water, clothes, etc.

+One good zombie apocalypse podcast mentioned that day one they had everyone fill up all containers and bathtubs and buckets with water in case the power went out. Sounds good. If you have tanks, make sure you have a ladder somewhere, to do the old 'how much' test.

+Some way to make fire. The flick lighter you have now will work, until it runs dry... start thinking of other options from day 1, because that day will come. The wood sticks and friction works, but is slow, flint/steel not everyone has options, two stones can take ages to spark, etc.

+Probably cutlery and some cooking items. Worth collecting, esp if its more than just you and you lost your own home / were a brand new uni person with nothing in the apartment.

+If you have a cooler, but no access to ice, it might not be ideal. In the first days, though, you might have a chance to use it with ice for meat and other items. Ice boxes are brilliant and last DAYS if used right, without a change to ice. But not a forever option.

The question is if you then need to move somewhere cooler.

+If you raided a school you could get one of those big plastic drink containers to store water in. Or most bunnings type places have the 20L water containers, some with spouts. Bonus of getting a trolley thing to pull it about in. Its about a lot of water that can be ported as needed. They are uncomfy to lug hand-wise over distance, because of the way it dangles of your arm, but if you got creative with ties, you could backpack it.

+Bags. Different shapes and types, especially backpacks.

+Water bottles, or containers like thermos that would hold stuff for long treks, etc. Most camping stores could have the little pouches and the long straw but like... you get a bit of mildew in there and the whole thing is a pain to clean etc.

+Assuming you can settle somewhere, and are not 100% mobile the whole time, you'd be focused on being somewhere with access to wood for fire (food, heat, light) depending on the type of apocalypse.

+Cheap stores could be plundered in the early times for shitty items that might work a few times, and basic hygiene items. You don't need brand name if you're desperate to be clean. Soap, toothbrushes, toothpaste, a towel or two, etc. They won't last foreever, but when a towel starts to die out, it becomes other things like rags,, something to patch up a hole in the wall, fire starter material (most are polycotton)

Stuff that you need in the moment but can replace as life goes on.

+A basic toolkit, might last a while (live in a Bunnings, you might have a chance to rebuild society lmao, garden section, tools, even dog and cat foods there too if you manage to get out with your furry fam)

+In any school or ofice there should be at least one orange over full first aid kit. Grab it. The things in it will need a bit of updating over time, and discarded after a time.

+Pharmacy - you're gonna need meds and a local medicine wizard who can find solutions for the meds that run out and aren't replaced, if any.

+Paper and pens, something to help you leave notes for others to let them know where you are, or where to get help. Even just keep diary and inventory. You could try carving on rock but who has the time?

+Seeds and fertiliser. This'd need to happen earlier o, and if water is scarce you might need to get creative - is there a dam nearby or a creek they could plant near? Can you get soe of those Easy Planters that have a little wate tray under that kind of manages itself.

At least one shovel. If the rich try to raise prices on things... remember, a lot of fertiliser can be improved through the addition of blood and bone.

+I'd raid the library for things like a Big Book of First Aid, any book that told of native foods and poisonous plants, any How To Guides, and also some novels of different kinds to make sure no one was going to lose their minds. Maybe steal a whiteboard and some markers, so you can teach others these things, because hopefully there'd be a community starting up to replace what was lost.

Hopefully, the librarians wouldnt kill you.

+Cloth, pillows, bedding (possibly from stores or from abandoned homes of the gone), even scraps from the op shops and general clothes. Thread - try to find the cotton stuff, the plastic 2 dollar stuff from cheap stores tends to snap easy, esp with too much tension. fine for little stuff tho.

Coathangers too, you want this stuff up off the ground and not in a Pile. that's snake heaven and also a quick way for it to molder. Where possible, for a community, you'd want to find a way to get and store clothes of all ages and sizes because there'll be kids, and they grow so goddamn fast. Shoes... are negotiable.

+Lots of those Put 'em together Yourself furniture items will die if too old, wet or simply the stars are aligned wrong. Plan further out whn possible.

+Fuel - we know it doesn't last forever. Also a lot of chemicals will likely either be inert or super dangerous after a period of time, be careful handling bottles you find, etc.

+Food - finding in the initial, no wokkas. OVer time? Flour doesn't last forever. You can get eggs if you have food for chickens and the shelter for them. Maybe if you have a butcher you would be able to manage the acquisition of meat... or make do.

I have thought about Farming in the Apocalypse. The problem with the idea of a protagonist just Finding a farm and mangically getting food is that, that's not how it works.

Any farming family can tell you that there's so many different parts to a farm, turning crops, caring for cows and cattle, even just milking must be done regularly or the cows can have severe problems or die. Sheep need regular care and shearing, and also you have to manage them so they don't get flyblown, etc.

You can't turn the tractors on after a certain time, the harvesters, etc. You'd need to think about possible acres of fields needing to be managed by hand. Some crops get burned to stubble, how can that be safely managed? What do you, random possible city protagonist, know about rotating crops?

Do yuo understand what to do for animal husbandry? Hopefully someone from one of the families around would be there, and able to guide and manage it overall, train the survivors, but that never works out in movies.

You might have eggs, milk, meat, and some forms of food in this situation (depending on the farm, some are specifically one or two things), not much fruit

You would need to find a fruit solution, even if you have to raid a shopping centre for rotting fruit to see if you can salvage the seeds. IT would take time to cultivate, even if it did.

Could reach out to any horticulturists who survived, I guess.

+If you can learn to cure the skins, you'd have leather. It needs some human intervention, and piss, so someone would find joy in that...

You can use leather for clothes, shoes, bags, waterskeins (find yourself a medieval reenactor, most can do it themselves), tents, even (if done right) a makeshift pot on the fire. Absolutely fascinating what can be done with it, and it lasts.

----------

There's so much I think about when it comes to the apocalypse.

Maybe it wouldn't be the most exciting to read/listen to someone eeking out each day in the world left behind, but imagine the story.

Even several stories of people all over hte globe finding new ways to keep going. Some countries would barely be affected, given they alreay live between modern and traditional, and that duality is passed down to the following generations.

But in the industrialised world, where everything is from somewhere so removed from us that the public couldn't work out how to cook a roast on a fire without etting it aflame... like, ometimes I wonder.

The possibilities are endless.

The loss of what is known and the distress of realising that the loss isnt finished. It's going to keep going... again and again, as food runs out, clothes wear away, cars stop working, fuel goes inert, what was known corrodes and either you adapt, or let it drive you inwards.

It could be more fun if the only worry in the apocalyptic wastelands isn't 'need guns, and gun food (bullets)' - also sex.

Sure, that's a human desire but like, we can swing by the adult toy store and see if there's someone inflatable for you to chill with until we get basic needs going, because a baby would be the Worst Thing right now. Actually, what is the expiry date on most contraceptives?

I mean, you'd need weapons. Esp in a farming situation... sometimes births go wrong or an animal breaks their leg, or they're poisoned and suffering. Like, you have to manage that. Especially in a time without vets at the snap of a finger.

There's some practicalities, apart from just This Is Our Town Stranger as part of the dramatic climax, where they then have an Intense Head Nod during an ensuing fight, and now Stranger is One of Us.

I have no idea where this was going lmao, I have been thinking about how silly some of the Survival nonsense is in movies and books and podcasts.

And everything again changes if you are contending with being hunted by aliens, the infected/zombies, animals, etc...

But you can't eat bullets... except in one way. You can't quench thirst with a well oiled gun. Also, guns are loud, I know that gets brought up a lot but what is the fastest way to alert someone to your location? Firework boom boom. Get a damn axe. And a GRINDSTONE. Blunt ones won't split skulls or carapaces or whatevs.

#random thoughts about the apocalypse genre#also what if you need glasses?#ya fucked#hearing aids? again the batteries are hard to come by

5 notes

·

View notes

Text

Water Storage Tanks and Their Types

Water storage tanks are large containers used to store water for a variety of purposes, such as irrigation, drinking, fire protection, and industrial processes. They can be made of various materials, including plastic, steel, and concrete, and can be overhead or underground. The size and capacity of the tank will depend on the intended use and the amount of water that needs to be stored.

Water storage tanks are essential for a variety of uses, from irrigation to fire protection to household use. These tanks come in a variety of types, each with its own set of advantages and disadvantages.

TYPES OF WATER STORAGE TANKS

Overhead Tank

One of the most common types of water storage tanks is the overhead tank. These tanks are typically made of plastic or steel and are placed on a concrete foundation. They are easy to install and can be used for a variety of purposes, including irrigation, fire protection, and household use. One of the main benefits of overhead tanks is that they are relatively inexpensive and can be easily replaced if they become damaged. However, they are also vulnerable to leaks and can be easily damaged by natural disasters such as floods or earthquakes.

Underground Tank

Another popular type of water storage tank is the underground tank. These tanks are buried below ground level and are typically made of plastic or steel. They are more expensive than overhead tanks but offer a number of benefits, including greater stability and protection from natural disasters. Underground tanks are also less visible and can be used in areas where overhead tanks are not allowed. However, they are more difficult to install and can be expensive to repair if they become damaged.

Bladder Tank

A third type of water storage tank is the bladder tank. These tanks are typically made of a flexible material such as plastic or rubber and are filled with air. They are often used in areas where space is limited and can be easily deflated and stored when not in use. Bladder tanks are also relatively inexpensive and easy to install. However, they are not as durable as other types of tanks and can be easily punctured or damaged.

Loft Tank

A fourth type of water storage tank is the loft tank. These tanks are placed in the attic or other high spaces in a building and are typically made of plastic or metal. They are a good solution for homes or buildings with limited space. Loft tanks are also relatively inexpensive and easy to install. However, they are not as durable as other types of tanks and can be easily damaged by leaks or high temperatures.

Cistern Tank

Finally, a fifth type of water storage tank is the cistern tank. These tanks are typically made of concrete or other durable materials and are buried underground. Cistern tanks are often used for rainwater harvesting and can be used to store large amounts of water. They are also very durable and can withstand natural disasters such as floods or earthquakes. However, cistern tanks are also expensive and difficult to install.

Conclusion

water storage tanks are essential for a variety of uses and come in a variety of types. Each type has its own set of advantages and disadvantages and the best choice will depend on the specific needs of the user. overhead tanks are easy to install and inexpensive, while underground tanks offer greater stability and protection. Bladder tanks are a good solution for limited space, while loft tanks are a good solution for homes or buildings with limited space. Cistern tanks are often used for rainwater harvesting and can store large amounts of water. It is important to consider the specific needs and budget before choosing a water storage tank.

2 notes

·

View notes

Text

Glass Fused Steel Tanks Supplier in India | Durable & Corrosion-Resistant Storage Solutions

Glass Fused Steel Tanks: The Ultimate Storage Solution for Durability & Reliability

Glass fused steel (GFS) tanks are among the most durable and long-lasting storage solutions for water, chemicals, and other liquids. These tanks are created by fusing molten glass to steel at high temperatures, resulting in a non-porous, smooth, and highly resistant surface. Whether for industrial, municipal, or agricultural applications, glass fused steel tanks provide superior performance with minimal maintenance.

As a leading glass fused steel tanks supplier in India, we provide high-quality GFS tanks tailored to meet various industry requirements. Our tanks are widely used for water storage, wastewater treatment, and fire protection, offering a cost-effective and reliable alternative to conventional storage solutions.

Why Choose Glass Fused Steel Tanks?

Corrosion Resistance: GFS tanks are resistant to corrosion, rust, and harsh environmental conditions, making them ideal for long-term liquid storage.

Durability & Longevity: The fusion of glass and steel ensures a robust, high-strength structure that can last for decades.

Low Maintenance: Unlike traditional tanks, GFS tanks require minimal upkeep due to their non-corrosive surface.

Easy Installation & Scalability: Prefabricated panels allow for quick on-site assembly, making them ideal for projects with tight deadlines.

Customizable for Various Applications: Available in different sizes and capacities, GFS tanks are suitable for industries such as water treatment, fire protection, and agriculture.

Applications of Glass Fused Steel Tanks in India

Water Storage Tanks: Ideal for potable and industrial water storage, ensuring hygiene and safety.

Wastewater Treatment Tanks: Used in sewage and effluent treatment plants due to their chemical-resistant nature.

Fire Protection Water Tanks: FM-approved tanks ensure sufficient water supply for fire emergencies.

Chemical & Industrial Liquid Storage: Resistant to aggressive chemicals, ensuring safe containment.

Why Choose Us as Your Glass Fused Steel Tank Supplier in India?

As a trusted glass fused steel tank supplier in India, we provide high-quality prefab storage tanks designed for superior performance and longevity. Our GFS tanks comply with international quality standards, ensuring reliability for industrial and municipal applications.

Looking for a durable and cost-effective storage solution? Contact us today to explore our GFS tanks in India and find the best solution for your storage needs!

#Glass fused steel tanks#Glass fused steel tanks supplier#Glass fused steel tanks supplier in india#Glass fused steel tanks in India#Prefab tanks storage tank#Gfs Tank in India#GFS tank#glass water tank#glass fused steel tank#glass water tank supplier#glass fused steel tank supplier#glass fused steel tank supplier in india

0 notes

Text

Mizutanks: Your Trusted Water Tank Suppliers for All Storage Needs

Mizutanks is a leading name in providing high-quality and reliable water tank solutions for diverse industries and applications. As expert water tank suppliers, we offer a wide range of storage solutions, including demineralized water tanks, glass water tanks, steel water tanks, and more, designed to meet the specific requirements of our clients.

Our Product Range

Demineralized Water Tanks: Our demineralized water tanks are designed for industrial and commercial applications where pure water storage is critical. These tanks ensure the safe and efficient containment of demineralized water, maintaining its quality over time.

Glass Water Tanks: Mizutanks provides durable and long-lasting glass water tanks that are ideal for storing potable and non-potable water. Their corrosion-resistant design ensures longevity, even in the most demanding conditions.

Steel Water Tanks: Our steel water tanks offer robust and secure storage for a variety of needs, from industrial processes to agricultural applications. These tanks are engineered for durability and strength, making them a dependable choice for long-term use.

Agricultural Water Storage Tanks: Designed specifically for farming needs, our agricultural water storage tanks provide efficient water storage solutions for irrigation, livestock watering, and more.

Fire Water Storage Tanks: Meeting critical fire water storage tank requirements, Mizutanks delivers FM-approved tanks that ensure compliance with safety regulations and provide reliable water storage for fire protection systems.

Industrial Storage Tanks: Our range of industrial storage tanks is designed to cater to industries such as manufacturing, power generation, and wastewater treatment. These tanks ensure efficient and safe storage for water and other industrial fluids.

Why Choose Mizutanks?

FM-Approved Solutions: We offer FM-approved tanks for applications requiring adherence to stringent safety and quality standards.

Customized Designs: Our tanks are tailored to meet the unique needs of our clients, ensuring optimal performance and durability.

Premium Quality Materials: All Mizutanks products are crafted using high-quality materials, guaranteeing long-lasting and reliable storage solutions.

Comprehensive Services: From design and manufacturing to installation and maintenance, we provide end-to-end services for all our storage tanks.

Applications We Serve

Mizutanks caters to a variety of industries, including:

Agriculture: Reliable agricultural water storage tanks for irrigation and livestock needs.

Fire Protection: Compliant solutions for fire water storage tank requirements.

Industrial Storage: Efficient tanks for demineralized water and other industrial applications.

Contact Mizutanks for Your Storage Needs

Mizutanks is committed to delivering high-quality water tank solutions that combine functionality, durability, and innovation. Whether you need demineralized water tanks, glass water tanks, or steel water tanks, we are here to provide the perfect solution for your needs.

Visit Mizutanks today to explore our wide range of industrial storage tanks and discover why we are the preferred water tank suppliers in India.

#water tank suppliers#demineralized water tanks#glass water tanks#fire water storage tank requirements#agricultural water storage tanks#steel water tanks#industrial storage tanks#Mizutanks#FM approved

0 notes

Text

Glass-Fused-to-Steel Tanks: Ideal for Sewage Treatment Applications with High Resistance to Corrosion and Abrasion

Glass-Fused-to-Steel Tanks: Ideal for Sewage Treatment Applications with High Resistance to Corrosion and Abrasion

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we understand that sewage treatment requires robust and reliable infrastructure to ensure the long-term success of the system. One of the most critical elements in sewage treatment is choosing the right storage solution that can withstand the harsh, corrosive, and abrasive environments that are prevalent in these applications. That’s where Glass-Fused-to-Steel (GFS) tanks come in.

With over 30 years of expertise in the design, manufacture, and installation of bolted storage tanks, Center Enamel has become the leader in the Glass-Fused-to-Steel tank industry, offering superior solutions for various industrial and municipal applications, including sewage treatment.

Our GFS tanks have high resistance to corrosive attack and abrasion, making them the ideal choice for sewage treatment facilities, where they are exposed to aggressive chemicals, sewage solids, and microbial activity. Let's explore why Glass-Fused-to-Steel tanks are the perfect solution for sewage treatment applications.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Glass-Fused-to-Steel Tanks for Sewage Treatment?

The treatment of sewage and wastewater often involves challenging environmental conditions. Whether it's dealing with acids, alkalines, sulfides, or other corrosive elements, sewage storage and treatment systems need tanks that can withstand these harsh environments for decades.

Glass-Fused-to-Steel tanks provide the ultimate solution for these extreme conditions, offering a number of benefits that ensure long-term reliability, reduced maintenance costs, and excellent corrosion resistance. Below are the key reasons why Glass-Fused-to-Steel tanks are the ideal choice for sewage treatment applications.

1. Superior Resistance to Corrosive Attacks

One of the most significant challenges in sewage treatment is corrosion. The highly corrosive nature of sewage, which often contains organic acids, sulfides, and other harsh chemicals, can cause traditional tank materials such as concrete and steel to deteriorate over time. This not only compromises the structural integrity of the tank but also increases the need for frequent repairs and replacements.

Our Glass-Fused-to-Steel tanks are manufactured by fusing glass at high temperatures onto the surface of steel, creating a smooth, non-porous, and highly resistant barrier. This barrier offers exceptional protection against the corrosive agents found in sewage and wastewater. The glass coating prevents the steel from coming into direct contact with the aggressive substances in sewage, ensuring the tank's longevity and reliability.

Whether you're storing municipal sewage, industrial effluents, or wastewater, our GFS tanks maintain their performance even in highly corrosive environments, offering a long lifespan with minimal maintenance.

2. Unmatched Resistance to Abrasion

In addition to corrosion, sewage treatment often involves the movement of solids and sludge that can cause significant wear and tear on storage tanks. The abrasive action of suspended solids and grit in sewage can wear down conventional tank surfaces, leading to erosion, leaks, and potential failure.

Our Glass-Fused-to-Steel tanks are not only highly resistant to corrosion but also to abrasion. The glass enamel coating provides a hard, durable surface that can withstand the mechanical stress caused by abrasive materials. This makes GFS tanks an ideal choice for sludge storage, where the tank walls need to endure constant wear from solid waste particles. The superior abrasion resistance ensures the tank's structural integrity over time, reducing the need for costly repairs and downtime.

3. Low Maintenance and Long Lifespan

The inherent durability of Glass-Fused-to-Steel tanks means that they require very little maintenance. The glass enamel coating is designed to last for decades, even in harsh environments. Unlike concrete tanks, which may crack or deteriorate over time, or steel tanks, which are susceptible to rust and corrosion, GFS tanks maintain their performance for the long term with minimal maintenance.

In addition, Glass-Fused-to-Steel tanks do not require the frequent resurfacing or recoating that is common with other materials. Once the glass enamel coating is applied, it forms a permanent bond with the steel, creating a seamless, corrosion-resistant surface that is easy to clean and maintain.

4. Hygienic and Safe for Sewage Storage

The non-porous surface of Glass-Fused-to-Steel tanks helps prevent the growth of bacteria, algae, and other harmful microorganisms, which can be problematic in sewage treatment systems. This makes them a more hygienic option compared to other materials, reducing the risk of contamination.

Additionally, the smooth surface makes it easier to clean the interior of the tank, ensuring that sewage or wastewater remains safely stored without risk of contamination or microbial growth. This helps maintain the integrity and quality of the stored sewage, which is crucial for compliance with environmental and public health standards.

5. Designed for Harsh Conditions

Sewage treatment tanks are often located in areas with extreme weather or operational conditions. Whether subjected to high temperatures, freezing conditions, or intense UV exposure, the durability of the tank material is critical.

Glass-Fused-to-Steel tanks are designed to perform in a wide range of environmental conditions, making them perfect for both industrial and municipal sewage treatment facilities. The high temperature and chemical resistance of the glass enamel coating ensures that the tanks will not degrade over time, even in the harshest of environments. Furthermore, our GFS tanks can be custom designed to fit any location, ensuring a perfect fit for your specific sewage storage needs.

6. Cost-Effective Solution for Sewage Treatment

While Glass-Fused-to-Steel tanks may have a higher initial cost compared to concrete or GRP (Glass Reinforced Plastic) tanks, their long-term value is unmatched. The durability and low maintenance of GFS tanks result in significant cost savings over time. With no need for frequent repairs or replacements, GFS tanks offer an economically viable option for sewage treatment facilities looking for a reliable, cost-effective solution for wastewater storage.

7. International Standards and Certifications

At Center Enamel, we are committed to producing tanks that meet the highest industry standards. Our Glass-Fused-to-Steel tanks are certified to international standards such as AWWA D103-09, NSF/ANSI 61, ISO 28765, ISO 9001, CE/EN 1090, and NFPA, ensuring that every tank we produce meets the stringent requirements for safety, quality, and performance.

With successful projects in over 100 countries worldwide, including the USA, Canada, Australia, South Africa, and Brazil, our GFS tanks have proven their effectiveness in sewage treatment applications across the globe.

The Best Choice for Sewage Treatment

Glass-Fused-to-Steel tanks from Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) provide a superior solution for sewage treatment systems, offering high resistance to corrosion, abrasion, and harsh chemicals. Designed for long-term performance with low maintenance, these tanks are the ideal choice for municipal sewage, industrial wastewater, and sludge storage.

With customizable designs, modular expansion capabilities, and global project success, our GFS tanks are the most reliable, cost-effective, and environmentally friendly solution for your sewage treatment needs. Choose Center Enamel for your wastewater storage needs and enjoy a secure, durable, and high-performance solution for years to come.

For more information on our Glass-Fused-to-Steel tanks, contact us today to discuss your specific requirements and get a tailored solution for your sewage treatment facility.

0 notes

Text

water tank

water supply layout container drawing irrigation drawing reservoir drawing https://3d-labs.com/product/water-tank/ A water tank is a container used to store water for various purposes, including drinking, irrigation, fire suppression, and industrial use.

0 notes

Text

Top Diesel Testing Services Offered by Labs in Ajman | +971 554747210

Diesel fuel plays a vital role in powering industries, transportation fleets, and backup systems across Ajman. Ensuring its quality is critical for maintaining engine performance, meeting environmental standards, and safeguarding equipment. Diesel testing labs in Ajman offer a variety of specialized services to address these needs. These labs help businesses identify impurities, comply with regulatory standards, and optimize fuel efficiency.

In this blog, we’ll explore the top diesel testing services provided by labs in Ajman and how they contribute to operational excellence and sustainability.

Why Diesel Testing is Essential

Diesel quality directly impacts the performance and longevity of diesel-powered engines and machinery. Low-quality diesel or contaminated fuel can result in:

Increased Maintenance Costs: Impurities in diesel can clog filters, damage injectors, and cause engine wear, leading to frequent repairs.

Regulatory Non-Compliance: Failing to meet UAE fuel quality and emissions standards can result in fines or penalties.

Reduced Efficiency: Poor-quality diesel results in incomplete combustion, leading to higher fuel consumption and operational costs.

Environmental Damage: Contaminated diesel contributes to higher emissions of harmful pollutants.

By leveraging diesel testing services, businesses can mitigate these risks and maintain the highest standards of fuel quality.

Top Diesel Testing Services Offered by Labs in Ajman

1. Sulfur Content Testing

Sulfur is a significant component in diesel that can harm engines and increase emissions. Testing labs analyze sulfur levels to ensure compliance with Ultra-Low Sulfur Diesel (ULSD) standards, which are critical for reducing air pollution and adhering to environmental regulations.

2. Cetane Number Testing

The cetane number indicates the combustion quality of diesel fuel. A higher cetane number ensures smoother ignition and efficient engine operation. Diesel testing lab assess this parameter to help businesses optimize engine performance and reduce wear and tear.

3. Density and Viscosity Analysis

Density and viscosity affect how diesel flows and combusts within an engine. Labs measure these properties to ensure that the fuel meets the specifications required for optimal engine performance.

4. Water and Sediment Testing

Water and sediment contamination in diesel can lead to severe engine damage and reduced efficiency. Testing labs in Ajman use advanced techniques to detect and quantify these impurities, helping businesses avoid costly repairs.

5. Flash Point Testing

Flash point is the lowest temperature at which diesel vapors ignite. Ensuring an appropriate flash point is essential for safe storage and transportation. Testing labs evaluate this parameter to minimize fire risks.

6. Oxidation Stability Testing

Diesel fuel can degrade over time due to oxidation, leading to sludge formation and reduced fuel quality. Labs test for oxidation stability to determine the shelf life of diesel and recommend storage solutions for long-term use.

7. Cold Flow Properties Testing

In colder conditions, diesel can form wax crystals, leading to fuel filter blockages and engine failure. Cold flow testing evaluates properties like cloud point and pour point to ensure diesel performs efficiently in low-temperature environments.

8. Lubricity Testing

Diesel fuel must provide adequate lubrication to prevent wear on engine components such as fuel pumps and injectors. Testing labs analyze the lubricity of diesel to ensure it meets the required standards for engine protection.

9. Microbial Contamination Testing

Diesel storage tanks are susceptible to microbial growth, which can cause corrosion and clogging. Labs in Ajman offer microbial testing to detect bacteria and fungi, enabling businesses to take preventive measures.

10. Additive Analysis

Diesel often contains additives to improve performance and stability. Testing labs evaluate these additives to ensure they are present in the right proportions and delivering the intended benefits.

Industries That Benefit from Diesel Testing Services in Ajman

1. Transportation and Logistics

Diesel testing labs support fleet operators by ensuring high-quality fuel for vehicles, which translates to lower maintenance costs and compliance with emission standards.

2. Construction and Infrastructure

Heavy machinery and equipment used in construction projects rely on diesel fuel. Testing ensures optimal performance, minimizing downtime and enhancing project efficiency.

3. Marine Industry

Diesel-powered vessels need to meet strict maritime fuel standards. Testing labs ensure compliance while helping maintain engine reliability and fuel efficiency.

4. Manufacturing and Power Generation

Industries that use diesel for backup generators and machinery benefit from testing services by ensuring a consistent fuel supply that supports uninterrupted operations.

Advantages of Using Diesel Testing Services in Ajman

1. Regulatory Compliance

Ajman, like the rest of the UAE, enforces strict fuel quality and environmental standards. Testing labs help businesses stay compliant with regulations, avoiding fines and reputational damage.

2. Operational Efficiency

High-quality diesel verified by testing labs reduces engine wear, improves fuel efficiency, and minimizes downtime, ensuring smooth operations.

3. Cost Savings

Preventing engine damage and optimizing fuel efficiency translates to significant cost savings for businesses. Testing services help identify and eliminate potential issues before they escalate.

4. Environmental Responsibility

Testing labs help businesses reduce emissions by ensuring fuel meets ULSD standards and other environmental benchmarks. This supports sustainability initiatives and enhances corporate social responsibility.

5. Enhanced Safety

By testing critical parameters such as flash point and microbial contamination, labs help businesses minimize risks associated with fuel storage and transportation.

Key Features of Diesel Testing Labs in Ajman

1. ISO Accreditation

Most reputable diesel testing labs in Ajman are ISO/IEC 17025 accredited, ensuring they meet international standards for testing accuracy and reliability.

2. State-of-the-Art Equipment

These labs use advanced equipment and methodologies to deliver precise results, enabling businesses to make informed decisions about fuel quality.

3. Experienced Professionals

Certified chemists and engineers in these labs ensure thorough analysis and accurate reporting.

4. Comprehensive Reporting

Labs provide detailed reports on diesel quality, helping businesses identify issues and implement corrective actions.

5. Customized Solutions

Diesel testing labs in Ajman offer tailored services to meet the specific needs of different industries, ensuring businesses receive the most relevant insights.

How to Choose the Right Diesel Testing Lab in Ajman

When selecting a diesel testing lab, consider the following:

ISO Accreditation: Ensure the lab meets ISO standards for quality and reliability.

Range of Services: Opt for a lab that offers comprehensive testing solutions.

Reputation: Choose a lab with a proven track record and positive client reviews.

Timely Reporting: Look for labs that provide fast and detailed results.

Customer Support: Select a lab that offers excellent customer service and guidance.

Conclusion

Diesel testing labs in Ajman play a crucial role in maintaining fuel quality, ensuring regulatory compliance, and supporting operational efficiency across various industries. With services like sulfur content analysis, microbial contamination testing, and cold flow properties evaluation, these labs provide businesses with the insights needed to optimize diesel performance and minimize risks.

By partnering with a reputable diesel testing lab, businesses in Ajman can achieve significant cost savings, enhance environmental responsibility, and ensure the longevity of their equipment. As fuel quality standards evolve, the role of diesel testing labs will remain indispensable in promoting sustainability and operational excellence.

0 notes

Text

Top-Quality Commercial Water Storage Tanks in India – COEP Prefab Water Tanks 💦🏗️

COEP Prefab Water Tanks is a leading provider of commercial water storage tanks in India, delivering durable and efficient storage solutions for various industries. Whether you need industrial water storage tanks in Pune or custom water storage tanks in India, our expertise ensures high-performance water containment systems tailored to your needs. ✅🌍

Why Choose COEP Prefab Water Storage Tanks? 🔩💧

✔️ Premium Quality & Durability – Our GFS tanks, GFL tanks, and steel bolted tanks are made from corrosion-resistant materials, ensuring long-lasting performance. ✔️ Custom Solutions Available – We specialize in custom water storage tanks in India, offering flexible designs and sizes to meet specific industrial requirements. ✔️ Ideal for Industrial & Commercial Use – Our industrial GFS water tanks in India are perfect for factories, manufacturing plants, commercial buildings, and municipal projects. ✔️ Reliable & Certified – As a trusted name in commercial water storage tanks in Pune, we adhere to global safety and quality standards.

Best Commercial Water Storage Tanks in Pune & India 🌎💦

Our coepprefabwatertanks storage tanks in India are widely used across various industries, including agriculture, food processing, pharmaceuticals, and fire protection systems. Whether you need a GFS tank in India for bulk water storage or a GFL tank for industrial use, we offer high-quality solutions designed for efficiency and sustainability.

Leading Industrial Water Storage Tanks Supplier in Pune 🔥🏭

As a recognized provider of industrial water storage tanks in Pune, COEP Prefab Water Tanks ensures optimal water management solutions for industries requiring large-scale and reliable water storage. Our GFS tanks, GFL tanks, and custom-built storage solutions meet diverse commercial and industrial demands.

💡 Discover More: 👉 COEP Prefab Water Tanks

🔹 Hashtags: #CommercialWaterStorageTanks #IndustrialWaterStorage #COEPPrefabWaterTanks #GFS #GFLTanks #StorageSolutions #WaterStorageIndia 🚀💧

#Commercial water storage tanks#Commercial water storage tanks in Pune#Commercial water storage tanks in India#coepprefabwatertanks storage tanks in India#GFS tank in India#GFL tank#Gfs tank#Industrial GFS water tanks India#Custom water storage tanks India#Industrial water storage tanks Pune

0 notes

Text

HDPE Plastic and FR4 Composite: Essential Materials for Modern Industry

GRM Custom Products is dedicated to delivering innovative, high-quality materials that meet the evolving needs of various industries. Among our product offerings, HDPE plastic and FR4 composite stand out as essential materials used across many applications. In this blog, we explore the unique properties, benefits, and common uses of these two versatile materials, helping you better understand why they are indispensable in modern manufacturing and design.

Understanding HDPE Plastic

High-Density Polyethylene (HDPE) is a widely-used thermoplastic known for its durability, strength, and resistance to impact and moisture. Here’s why HDPE is a material of choice in many sectors:

Key Properties of HDPE Plastic

High Strength-to-Weight Ratio: HDPE is lightweight yet extremely durable, which makes it easy to transport and ideal for applications that require high tensile strength.

Chemical and Moisture Resistance: This material is highly resistant to chemicals and water, allowing it to endure harsh environmental conditions without degrading.

Impact Resistance: HDPE can absorb impact without cracking or breaking, making it ideal for demanding applications such as protective equipment or industrial components.

Ease of Fabrication: HDPE is easy to machine and shape, providing flexibility for custom designs and complex manufacturing needs.

Common Applications of HDPE Plastic

At GRM Custom Products, we often recommend HDPE plastic for applications where durability and adaptability are paramount. Common uses include:

Industrial Containers: HDPE’s resistance to chemicals makes it ideal for manufacturing chemical containers and storage tanks.

Pipe Systems: Its durability and moisture resistance make HDPE an excellent choice for piping and water transportation systems.

Construction Components: HDPE plastic is often used in geomembranes, flooring, and other construction materials due to its high impact resistance and weather resilience.

Packaging: Lightweight yet durable, HDPE is a popular choice for packaging, especially for food and beverage containers.

Exploring FR4 Composite

FR4 composite is a versatile, flame-resistant material predominantly used in the electronics industry. Made from a fiberglass-reinforced epoxy laminate, FR4 is known for its strength, lightweight properties, and excellent electrical insulation capabilities.

Key Properties of FR4 Composite

High Dielectric Strength: FR4 offers excellent electrical insulation, making it ideal for applications requiring high voltage resistance.

Flame Resistance: The flame-retardant properties of FR4 composite help ensure safety, especially in high-temperature environments.

Mechanical Strength: FR4 is rigid, durable, and resistant to bending, allowing it to maintain structural integrity under various conditions.

Low Moisture Absorption: This material resists moisture absorption, which helps maintain its properties even in humid or wet conditions.

Common Applications of FR4 Composite

FR4 is a critical component in the electronics and electrical industries. At GRM Custom Products, we see strong demand for FR4 composite in:

Printed Circuit Boards (PCBs): FR4 is the primary material for PCBs due to its excellent insulation and mechanical properties.

Insulation Panels: The flame resistance and dielectric properties of FR4 make it a safe choice for insulation in high-voltage electrical panels.

Aerospace Components: FR4 composite is used in aerospace applications where lightweight, high-strength, and fire-resistant materials are necessary.

Test Fixtures and Jigs: The stability and resilience of FR4 make it ideal for custom manufacturing jigs, where reliable performance is essential.

HDPE Plastic vs. FR4 Composite: Which is Right for Your Application?

While both HDPE plastic and FR4 composite offer outstanding durability and resistance to environmental factors, they serve distinct purposes based on industry needs. HDPE plastic is often preferred for projects requiring chemical resistance, impact strength, and cost-effectiveness. Its versatility makes it suitable for industrial containers, piping, and construction. FR4 composite, on the other hand, is designed for high-performance applications, especially in the electronics and electrical sectors. Its flame resistance, electrical insulation, and rigidity make it the material of choice for circuit boards, insulation, and aerospace components.

Why Choose GRM Custom Products?

At GRM Custom Products, we pride ourselves on providing top-quality materials tailored to your specific industry needs. We offer custom solutions in HDPE plastic and FR4 composite, ensuring that you receive products that meet rigorous standards for safety, durability, and performance. Our team of experts works closely with clients to recommend the best material for each application, delivering solutions that help drive innovation and efficiency in your operations.

Conclusion

If you’re looking for reliable, high-performance materials like HDPE plastic or FR4 composite, GRM Custom Products is here to help. Our extensive inventory, customized solutions, and commitment to quality make us the ideal partner for all your material needs. Contact us today to discuss your project

1 note

·

View note

Text

Newberry Tanks and Equipment, LLC

BUSINESS ADDRESS:

205 North Walker Street

West Memphis, Arkansas

72301

BUSINESS PHONE NO:

870-735-4473

BUSINESS WEBSITE:

KEYWORDS:

bulk fuel storage tanks, aboveground fuel storage tanks, underground fuel storage tanks, lube oil tanks

WORKING HOURS:

Monday - Friday, 7 am–5 pm

Saturday & Sunday, Closed

SOCIAL LINKS:

https://www.linkedin.com/company/newberry-tanks-and-equipment-llc

DESCRIPTIONS:

Newberry Tanks is a leading manufacturer and distributor of above-ground and underground storage tank systems. With over 90 years of experience, the company has established itself as a trusted provider of high-quality, custom-engineered solutions for various industries, including petroleum, chemical, and water treatment sectors.

Specializing in steel tank fabrication, Newberry Tanks offers a comprehensive range of products, from small portable tanks to large-capacity storage systems. Their lineup includes fuel storage tanks, chemical storage tanks, fire protection tanks, and water storage solutions. The company's commitment to innovation is evident in their advanced tank designs, which incorporate cutting-edge materials and technologies to ensure optimal performance, safety, and environmental compliance.

Newberry Tanks' services extend beyond manufacturing, encompassing tank installation, maintenance, and regulatory compliance assistance. Their team of expert engineers and technicians provides tailored solutions to meet each client's unique requirements, ensuring seamless integration and long-term reliability.

Key strengths of Newberry Tanks include their state-of-the-art manufacturing facilities, rigorous quality control processes, and dedication to customer satisfaction. The company's adherence to industry standards and certifications, coupled with their extensive knowledge of regulatory requirements, positions them as a go-to partner for businesses seeking dependable storage solutions across diverse applications.

1 note

·

View note

Text

The Importance of a Water Reservoir Tank for Efficient Water Management

Efficient water storage is essential for industries, agriculture, and residential areas alike. A water reservoir tank plays a crucial role in ensuring consistent water availability. Whether for drinking water, irrigation, or emergency purposes, the right storage solution can significantly impact water management systems.

What is a Water Reservoir Tank?

A water reservoir tank is a large container designed to store water for various uses. These tanks come in different sizes and materials, including steel, concrete, and fiberglass. They can hold thousands of gallons of water and are essential in regions where water supply is inconsistent. The purpose of these tanks is to provide a continuous water source, regardless of fluctuating demand or supply issues.

Types of Water Reservoir Tanks

There are several types of water reservoir tanks, each offering unique benefits depending on the need.

1. Steel Water Tanks

Steel tanks are known for their durability and strength. They can withstand harsh environmental conditions and are commonly used in industrial and commercial settings. Galvanized steel tanks offer resistance to corrosion, making them a preferred choice for storing potable water.

2. Concrete Water Tanks

Concrete tanks are popular in large-scale applications due to their robust structure. These tanks are ideal for long-term water storage and are commonly found in municipal water systems. However, they require regular maintenance to prevent cracking and deterioration.

3. Fiberglass Reinforced Plastic (FRP) Tanks

FRP tanks are lightweight yet durable, making them ideal for both residential and industrial water storage. They are resistant to rust, corrosion, and UV radiation, which extends their lifespan and reduces maintenance costs. These tanks are also customizable and can be adapted to specific storage requirements.

Advantages of Using a Water Reservoir Tank

1. Ensures a Consistent Water Supply

A major advantage of having a water reservoir tank is its ability to ensure a consistent water supply. In areas with unreliable or seasonal water sources, these tanks act as a buffer. They store excess water during times of abundance and provide it when demand is higher or supply is limited.

2. Reduces Water Waste

Water reservoir tanks help reduce water waste by storing rainwater or other natural sources that would otherwise go unused. This captured water can be utilized for agricultural irrigation, firefighting, or emergency situations, reducing the reliance on treated water for these applications.

3. Lowers Operational Costs

Water management systems with adequate storage can help lower operational costs. With a water reservoir tank, facilities can take advantage of off-peak water rates and reduce the need for continuous water treatment. Additionally, fewer water deliveries and reduced pumping demands lower energy consumption, making the system more sustainable.

4. Adaptable to Various Environments

The versatility of a water reservoir tank makes it suitable for different environments. Whether installed in rural areas, urban settings, or remote industrial sites, these tanks can be tailored to the specific needs of the location. Above-ground and underground options are available, depending on space and aesthetic preferences.

Applications of Water Reservoir Tanks

Water reservoir tanks serve multiple industries and applications. Here are some key uses:

1. Agricultural Irrigation

Farms rely on consistent water supplies to maintain crops. A water reservoir tank provides a reliable source for irrigation, ensuring crops get the water they need during dry periods. This reduces dependency on external water sources and improves crop yields.

2. Fire Protection Systems

A water reservoir tank is an integral part of fire protection systems in residential, commercial, and industrial environments. In case of a fire, these tanks ensure that water is readily available for firefighting efforts, especially in remote areas without easy access to hydrants or municipal water systems.

3. Municipal Water Storage

Municipalities use water reservoir tanks to store treated water for distribution to homes and businesses. These tanks help manage demand during peak usage times, ensuring that there is always enough water available for residents.

Environmental Benefits of Water Reservoir Tanks

Using a water reservoir tank can have several environmental benefits. By storing rainwater, they help reduce the strain on municipal water systems. This practice, known as rainwater harvesting, promotes water conservation and minimizes the risk of flooding in urban areas. Additionally, storing untreated water for purposes like irrigation or firefighting conserves treated water, which can be reserved for human consumption.

Conclusion

A water reservoir tank is a vital component in modern water management systems. Its ability to store large quantities of water for various applications, combined with its durability and adaptability, makes it a practical solution for ensuring consistent water availability. Whether for irrigation, emergency storage, or municipal use, a well-chosen water reservoir tank can significantly improve efficiency and reduce operational costs.

1 note

·

View note

Text

Modern Firefighting Systems: Essential Components and Innovations

Introduction

Firefighting systems are integral to protecting both lives and property from the devastating effects of fires. In residential, commercial, and industrial settings, the risk of fire is always present, and the consequences can be catastrophic without proper preventive measures. Firefighting systems are not just a collection of equipment but a well-coordinated set of components that work together to detect, suppress, and control fires before they cause significant harm.

Each component within these systems is meticulously designed to fulfill a specific role, from storing and delivering water to ensuring that the right amount of pressure reaches the most critical points during a fire emergency. Whether it’s the storage reservoir that holds water, the pumps that move it, or the network of pipes that delivers it to essential locations, every piece of the system must function flawlessly in order to mitigate the risks associated with fires.

Beyond the traditional systems, recent advancements in fire protection technology are enhancing how fires are managed and contained. Modern innovations, such as smart fire detection systems, automated sprinklers, and advanced materials for water storage tanks, are reshaping the future of firefighting. These advancements not only improve response times but also increase the efficiency and effectiveness of fire suppression efforts, ultimately saving more lives and minimizing property damage.

This article delves into the essential components of firefighting systems, explains their roles in fire prevention and suppression, and highlights the cutting-edge innovations that are driving the next generation of fire protection technology.

The Role of Fire Storage Reservoirs

At the heart of every firefighting system lies the fire storage reservoir, more commonly referred to as the fire storage tank. This crucial component serves as the backbone of the system, ensuring that a substantial supply of water is readily available to tackle fires at a moment’s notice. Firefighting requires large volumes of water to suppress and control the spread of flames, and without a reliable water source, even the most advanced firefighting technology would fall short.